Page 1

JET JOVS-10 Oscillating Spindle Sander

Oscillating spindle sanders have a unique set of capabilities that

make sanding odd-shaped work pieces easy and accurate. The JET

JOVS-10 Oscillating Spindle Sander packs those capabilities and

more into one tough machine with the capacity, power and

reliability you expect from the JET brand.

Solid Base and Power

The all steel base cabinet gives the JET JOVS-10 Oscillating Spindle

Sander a solid footing and puts the table surface at a comfortable 39”

above the floor. It also encloses the heavy-duty 1HP, 1Ph, 115V TEFC

(totally enclosed, fan cooled) motor. The motor is mounted directly to

the worm and heavy gear mechanism that generates the 75 oscillations

per minute while turning the spindle at a consistent 1725-RPM. The

gear and worm drive run in an oil bath that insures many years of

smooth, quiet and dependable operation.

The JET 1HP motor

and the oil bath case

make the work and

gear mechanism

strong, smooth and

reliable.

An industrial-style pushbutton switch set is mounted on the front of the

cabinet to be within easy reach. The guarded On switch helps prevent

accidental starts. Storage racks on either side of the base cabinet keep

the spindle assemblies and inserts organized and close at hand. A large

door on the rear of the cabinet provides ample access to the motor and

drive housings.

Spindles and Support

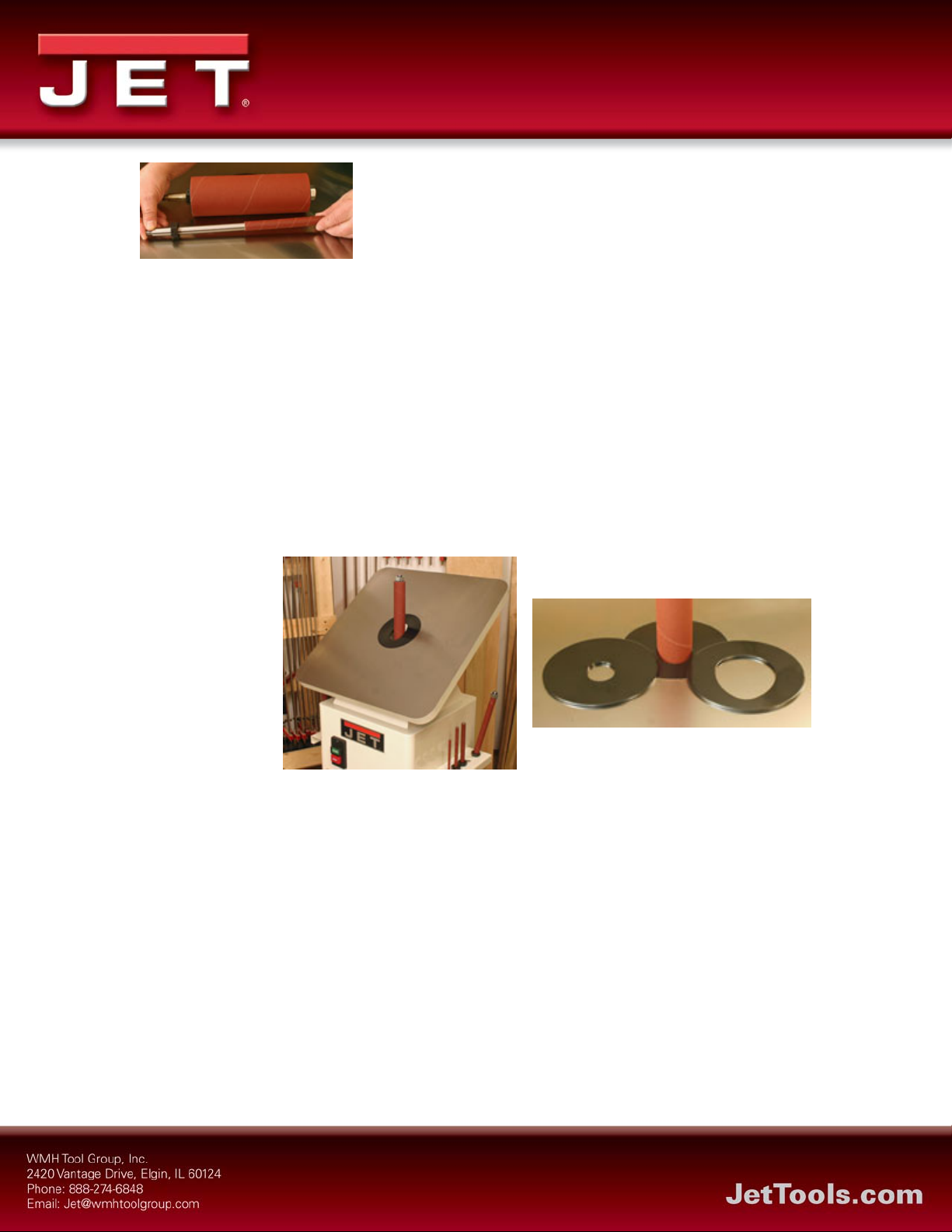

The JET JOVS-10 Oscillating Spindle Sander comes with a

complete set of 10 spindles and abrasive sleeves so you have the

tooling you need to get to work right out of the box! Spindle sizes

included are ¼” X 5” (steel), 3/8” X 6” (steel), ½” X 6” (steel),

5/8” X 6” (steel), ¾” X 9” (steel), 1” X 9” (rubber), 1 ½” X 9”

(rubber), 2” X 9” (rubber), 3” X 9” (rubber), 4” X9” (rubber).

Each spindle comes with one abrasive sleeve.

We include a full set of

10 spindles to handle all

of your sanding jobs!

Because nearly all of our sanding spindles and sleeves remain above the table, it is

possible to sand thick material without having to flip the piece over during sanding. That

makes sanding faster and far more accurate. That above table length also allows sanding

multiple pieces at the same time, making that once tedious process fast and accurate.

Page 2

Due to the oversized length of the sanding spindles users

are capable of removing the sanding sleeves and flipping

them end for end, utilizing the whole sanding sleeve

before finding a need to replace them.

The length of our spindles and

abrasive sleeves means you can often

turn the sleeves end for end to double

their life!

Just below the table is the main spindle drive and support

mechanism. The 1-1/2" oscillating action produced by

this mechanism reduces the buildup of friction-based heat

to protect the wood and prolong the abrasive sleeve life.

The main spindle support runs on precision ball bearings for smooth, trouble-free

operation.

We also made installing or changing the spindles fast and easy while insuring proper

alignment and secure mounting. Each spindle has a tapered arbor with a threaded end that

draws it into the precision-machined arbor housing. Wrenches are included for installing

or removing spindles.

Tilting Table

To further

extend the

capabilities of

the JET JOVS10 Oscillating

Spindle Sander

we gave it a

generous 24”

by 24” cast iron

table that

makes working

with large work

pieces easy and

The large cast iron table tilts to 45-degrees (left) and the specially shaped insert openings

(right) help keep the gap between them and the spindle to a minimum at any angle.

safe. That table

also tilts

(forward) up to 45 degrees and can be locked at any point to handle virtually any bevel

sanding operation. An adjustable stop makes returning the table to the horizontal position

fast and accurate.

The center hole of the JET JOVS-10 Oscillating Spindle Sander table has a large 6 1/8”diameter opening for using the larger sanding sleeves even with the table tilted. We

include three snap-in inserts with 3 ¼”, 2 1/8” and 1 ½” openings (at the narrowest point)

that help stabilize the work piece close to the sanding drum. The specially shaped insert

Page 3

openings help to minimize the table to abrasive gap when

tilting the table with various sized spindles installed.

Below the table is a full dust shroud with a 4"-diameter port

that makes connecting your dust collector easy. Using a dust

The dust shroud below the table

opening has a 4”-diameter port to

connecting to your dust collector

without adapters.

collector such as the JET DC1100 helps keep the work area

and the air clean.

Accessories

Mobile Base

If moving the JET JOVS-10 Oscillating Spindle Sander around

the shop is necessary, we offer the JET mobile base kit

(#708118) that makes that an easy and safe task. Two fixed

wheels on one end and a pair of full-swivel casters on the other –

all locking – make getting the JET JOVS-10 Oscillating Spindle

Sander where you need it easy and safe.

If moving the Oscillating

Spindle Sander is important

in your shop, our JET

mobile base makes that easy

and safe.

Sanding Sleeves

JET carries a full line of replacement sanding sleeves in 5”, 6” and 9” lengths and ¼” –

4” diameters available in 60, 80, 100 and 120 Grit. Please consult your manual or nearest

dealer for reorder stock numbers.

Loading...

Loading...