Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

JJP-10 BTO S 10" Joint er- P laner

WALTER MEIER (Manuf acturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M- 707410

Ph.: 800-274-6848 Revision A1 12/09

www.walt er meier.c om Copyright © 2009 Walt er Meier (M anufacturi ng) Inc.

Page 2

W arranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of these

Walter Meier Authorized Service Centers can authori ze warranty repair, assist you in obtaining parts, or perfor m routine

®

maintenance and major repair on your JET

1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product infor mation, check with

your local Walter Meier distributor, or visit waltermeier.com.

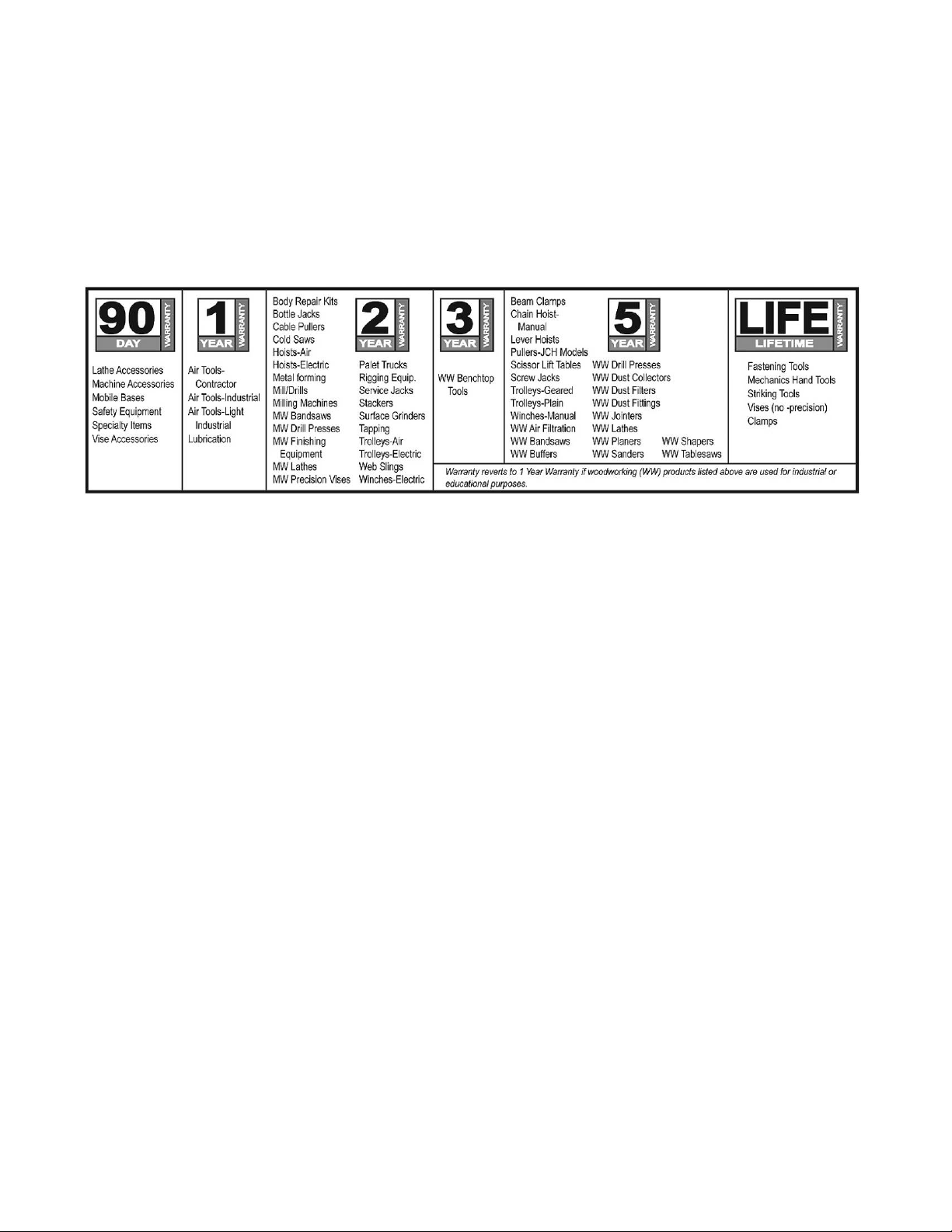

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW stands for Metalworking, WW

stands for Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Three Year, Five Year and Lifetime Warranties do not cover products used for industrial or educational purposes.

Products with Three Year, Five Year or Lifetime Warranties that are used for industrial or education purposes revert to a

One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse, abuse, negligence or

accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for e xamination, postage prepaid, to a location designated by us. For the na me of

the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must acco mpany the merchandise. If

our inspection discloses a defect, we will repair or replace the product, or refund the purchase price, at our option. We will

return the repaired product or replacement at our expense unless it is determined by us that there is no defect, or that the

defect resulted from causes not within the scope of our warranty in which case we will, at your direction, dispose of or

return the product. In the event you choose to have the product returned, you will be responsible for the shipping and

handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED

WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERT Y, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general infor mation

and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice, those alterations

to parts, fittings, and accessory equipment which they may dee m necessary for any reason whatsoever. JET

products are not sold in Canada by Walter Meier.

tools. For the name of an Authorized Service Center in your area call

®

branded

2

Page 3

Table of Contents

Warranty and Service................................................................................................................................2

Table of Contents .....................................................................................................................................3

Warnings..................................................................................................................................................4

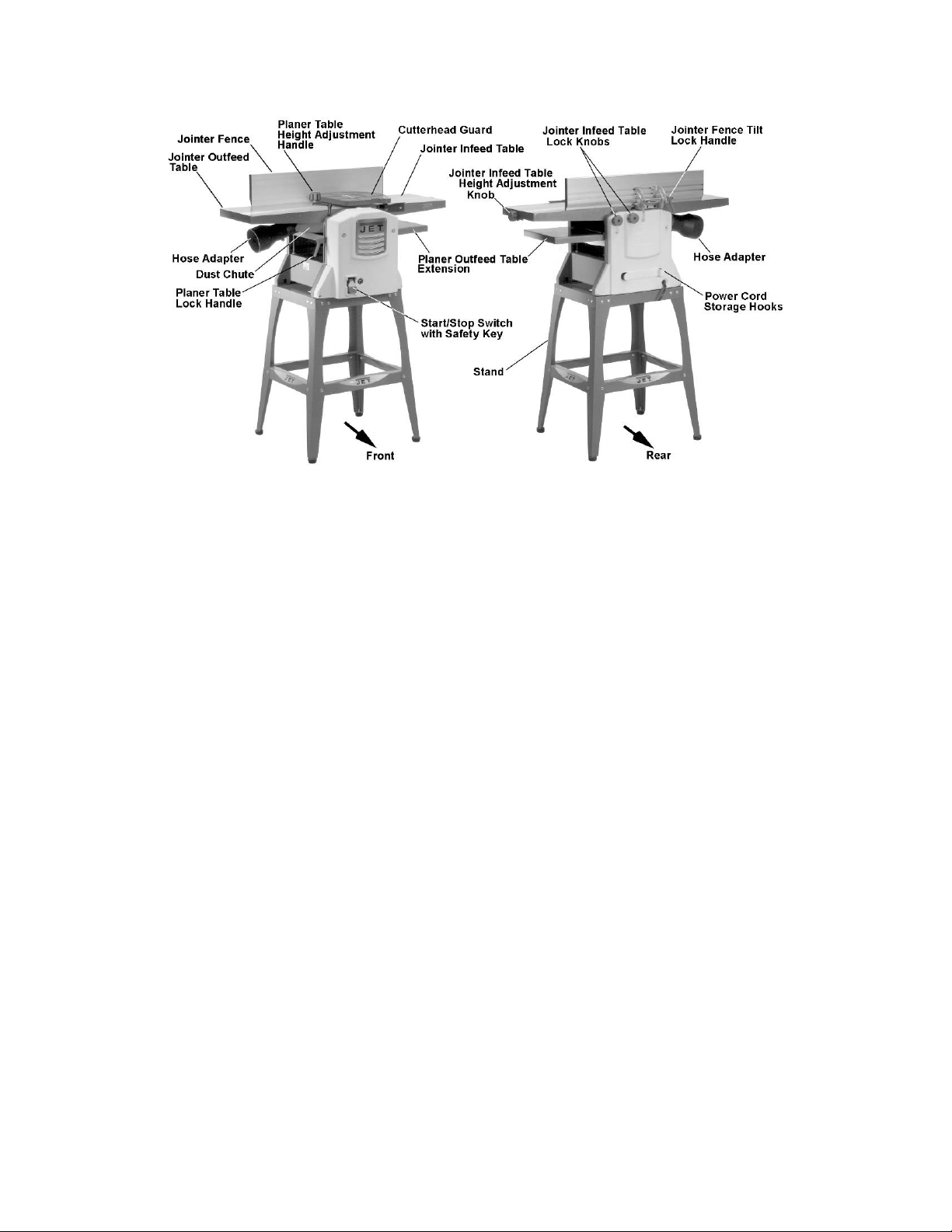

Fea ture s ..................................................................................................................................................7

Spe cifi cation s ...........................................................................................................................................7

Optional Accessories ................................................................................................................................7

Shipping Contents ....................................................................................................................................8

Ass embly ............................................................................................................................................... 10

Jointer Setup .......................................................................................................................................... 12

Planer Setup .......................................................................................................................................... 12

Operating Controls.................................................................................................................................. 13

Adju s tmen ts ........................................................................................................................................... 15

Basic Operations .................................................................................................................................... 18

Mai nten ance .......................................................................................................................................... 22

Lu bri cati on ............................................................................................................................................. 22

Troubleshooting ...................................................................................................................................... 23

Parts ...................................................................................................................................................... 26

Electrical Connect io n .............................................................................................................................. 39

The specifications in this manual are given as general information and are not binding. Walter Meier

(Manufacturing), Inc. reserves the right to effect, at any time and without prior notice, changes or alterations to

parts, fitt ings, and accessory equipme nt deemed necessary f or any reason whats oever .

3

Page 4

Warnings

1. Read and understand t he entire owner's ma nual before at t empting assemb ly or oper ation.

2. Read and understand the war nings post ed on the machine and in this manual. Fa ilure t o comply with

all of these warnings may cause serio us injury.

3. Replace the warning labels if they become obscured or removed.

4. This Woodworking Jointer-planer is designed and intended for use by properly trained and

experienced personnel only. If you are not familiar with the proper and safe operation of a

woodw or king jointer or planer, do not use until proper tr aining and knowledge have been obtained.

5. Do not use this for other than its intended use. I f used for other purposes, Walter M eier disclaims any

real or implied warr anty and holds itself harmless f r om any injury that may result from that use.

6. Always wear approved safety glasses/face shields while using this woodworking jointer-planer.

Everyday eyeglasses o nly have impact r esist ant lenses; t hey are not safet y glasses.

7. Before operat ing this woodw orking joi nter-pla ner, r emove tie, ri ngs, wat ches and other jewelry, and

roll sleeves up past the elbows. Remove all loose clot hing and confine long hair. Non-slip footwear or

anti-skid floor str ips are r ecommended. Do not w ear gloves.

8. Wear ear pr otect or s (plugs or muffs) duri ng exte nded periods of oper at io n.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemicals k nown to cause cancer, birt h defects or ot her reproductive harm. Some e xamples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium fr om chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make cer t ain the switch is in the OFF position before connecti ng the machine t o t he power s ource.

12. Make cer t ain the machine is properly grounded.

13. Make all machine adjustme nts or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the mac hine before tur ning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme cautio n and replace t he guards immed iately.

16. Make sure the woodw or king jointer- planer is firmly secured to t he floor or benc h before use.

17. Check damaged parts. Before further use of the machine, a guard or ot her part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignme nt of moving part s, binding of moving part s, break age of part s, mounting

and any other condit ions t hat may affect its oper ation. A guard or other part that is damaged s hould

be properly repaired or r eplaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighti ng.

19. Keep the floor around t he machine clean and free of sc r ap material, oil and grease.

4

Page 5

20. Keep visitors a saf e dist ance from the wor k ar ea. Keep children away.

21. Make your workshop child proof with padlocks, master switches or by removing start er keys.

22. Give your work undivided att ention. Looking aro und, carrying on a conversat ion and “horse-play” are

careless acts that can result i n serious injury.

23. Maintain a balanced stance at all t imes so that you do not fall or lean against the cutterhead or other

moving parts. Do not overreac h or use excessive for c e t o perfor m any machine operation.

24. Use the right tool at t he correc t speed and feed rate. Do not force a tool or at t achment to do a jo b f or

which it was not designed. The r ight t o ol will do t he job b e tter a nd sa fer.

25. Use recommended accessor ies; improper acc essor ies may be hazardous.

26. Maintain too ls with care. Keep knives sharp and clean for t he best a nd safest performance. Follow

instructions for lubricat ing and changi ng accessori es.

27. Turn off t he mac hine bef or e cleaning. Us e a br ush or co mpress ed air t o r emo ve c hips or debr is — do

not use your hand s.

28. Do not stand on the machine. Serio us injury co uld occur if the machine tips over.

29. Never lea ve the machine r unni ng unattended. Turn the power off and do not leave the machine until it

comes to a complete stop.

30. Befor e turni ng on machine, remove all extra equipme nt such as keys , wrenches, scrap, stock, and

cleaning rags aw ay from the machine.

31. Always use a hold-dow n or p ush block when s urfacing stock less t han 12" inches lo ng, or 3 i nches

wide, or 3 inc hes thick.

32. Do not perform joi nting oper ations on material shorter than 8", narrow er than 3/4" or less than 1/4"

thick.

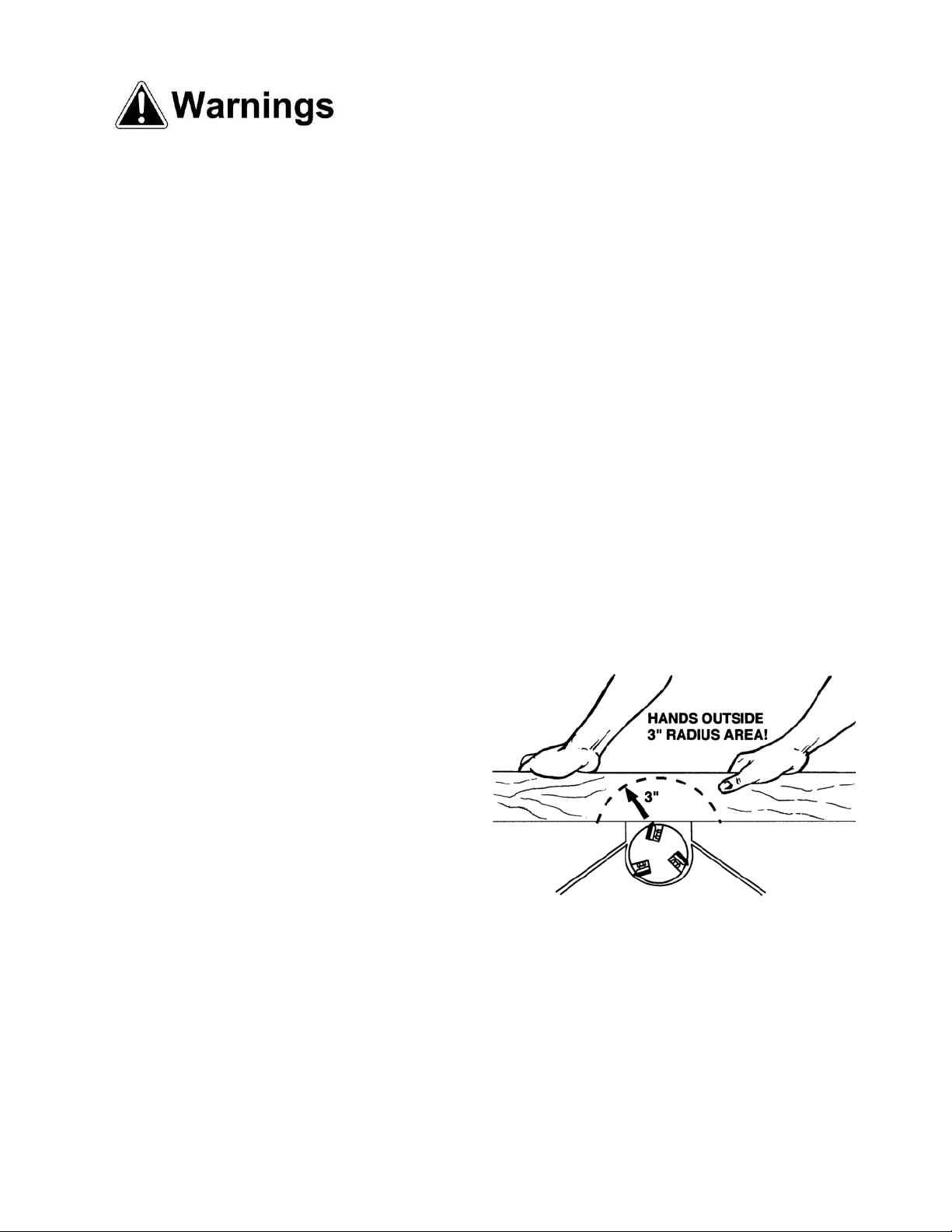

33. The hands must never be closer t han 3 inches t o

the cutter head (see Figure).

34. Never apply pressure to stock directly over the

cutterhead. This may res ult in the stock tipp ing

into the cutterhead along with the operator's

fingers. Position hands away f r om extreme ends

of stoc k, and push thro ugh with a s moot h, even

motion. Never back workpiece t ow ar d the infeed

table.

35. To avoid kickback, the grain must run in the

same direction you are cutting. Before

attempting to joint, or plane, each work piece

must be caref ully examined for stock co ndition

and grain orientation.

5

Page 6

36. When w or king w ith a swirl grai n wood or burls, making it necessary t o plane against the grai n, use a

lesser depth of cut and a slow rate of feed.

37. Move the hands in an alternate motion from back to front as the work continues through the cut. Never

pass the hands direct ly over the cutter knife. As one hand approaches the knives remove it f rom the

stock in an arc motion and place it back on the stock in a position beyond the cutter knife (Fig. 18).

38. At all times hold the stock f irmly.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if pr ecautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE I NSTRUCTI ONS - -

Read and understand the entire contents of this manual before attempting

assembly or operation! Failure to comply may cause serious injury!

6

Page 7

Features

Features

Specifications

Model number .................................................................................................................. J JP-10B TOS

Stock number ........................................................................................................................... 707410

Cutterhead speed ................................................................................................................... 9000rpm

Number of knives................................................................................................................................ 2

Cutter knife length...................................................................................................................... 10-1/4"

Cutter knife thickness .................................................................................................................. 0.060"

Dust port diameter ............................................................................................................... 2-1/2" or 4”

Jointer table ....................................................................................................................... 36" x10-1 /4 ”

Max stock removal .......................................................................................................................... 1/8”

Max cutting width ............................................................................................................................. 10"

Fen ce ................................................................................................................................ 4-7/8" x 25”

Fence tilt .............................................................................................................................. 90°- 45° R

Fence positive stop ................................................................................................................ 90° , 45° R

Planer table ................................................................................................................. 10-3/ 4" x 10-1/2"

Planer capacity

Maximum cutting thickness ........................................................................................................ 4-1/2"

Max depth of cut ........................................................................................................................... 5/64”

Min length of work piece.....................................................................................................................6"

Feed rate ................................................................................................................................19. 5 f pm

Motor

Voltage ................................................................................................................... 120V, 60Hz, 13A

Switch ...................................................................................... Toggle switch with overload prot ec t ion

Overall Dimensions (LxWxH) ............................................................................... 37-1/2" x 18-1/2" x 44"

Net weight ................................................................................................................................... 74 lbs

Optional Accessories

Stock No. Description

707411 10" Jointer / Planer Blades

709207 13" Roller Support Stand

7

Page 8

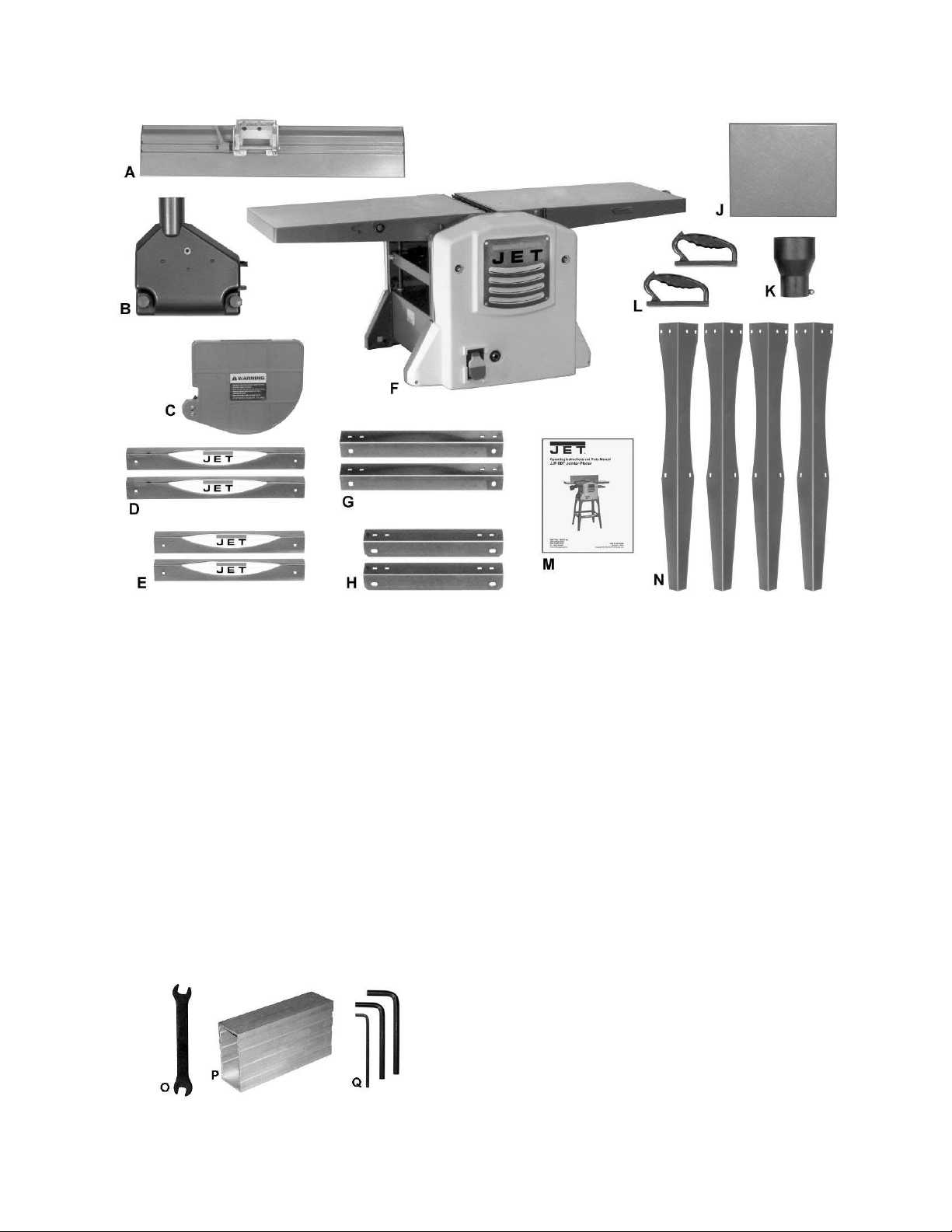

Shippi ng Cont ents

Figure 1 – Contents of the Mai n Carton

Unpacking

Remove all contents from the shipping carton.

Do not discard the carton or packing material

until your Model JJP-10BT Jointer-Planer is

assembled a nd is running satisfact or ily.

Compare the conte nts of the cart on against the

list of parts in Contents of Shipping Container

(below). The letter identification in the list

corresponds to t he items s hown at rig ht. This is

your key for identifying the parts used

throughout the Assembly section for easy

reference.

Remove the prot ective coating t hat is app lied to

the table with a house hold grease and spot

remover.

Contents of t he M ain Cart on

01 Jointer Fence (A)0

01 Dust Chute (B)

01 Cutter head Guard (C)

02 Long Support Plate( D)

02 Short Support Plate ( E)

01 Jointer-Planer (F)

02 Long Stand Top Support ( G)

02 Short St and Top Support ( H)

01 Planer Outfeed Table E xtension (J)

01 2-1/2" to 4" Hose Adapter (K)

02 Push Block (L)

01 Owner's Ma nual (M)

04 Stand Leg (N)

Tools Included

Figure 2 – Tools Included

01 8/10mm Ope n-e nd Wrench (O)

01 Knife Sett ing Gauge (P)

01 3, 5, 6mm hex wrenches (set of 3) (Q)

8

Page 9

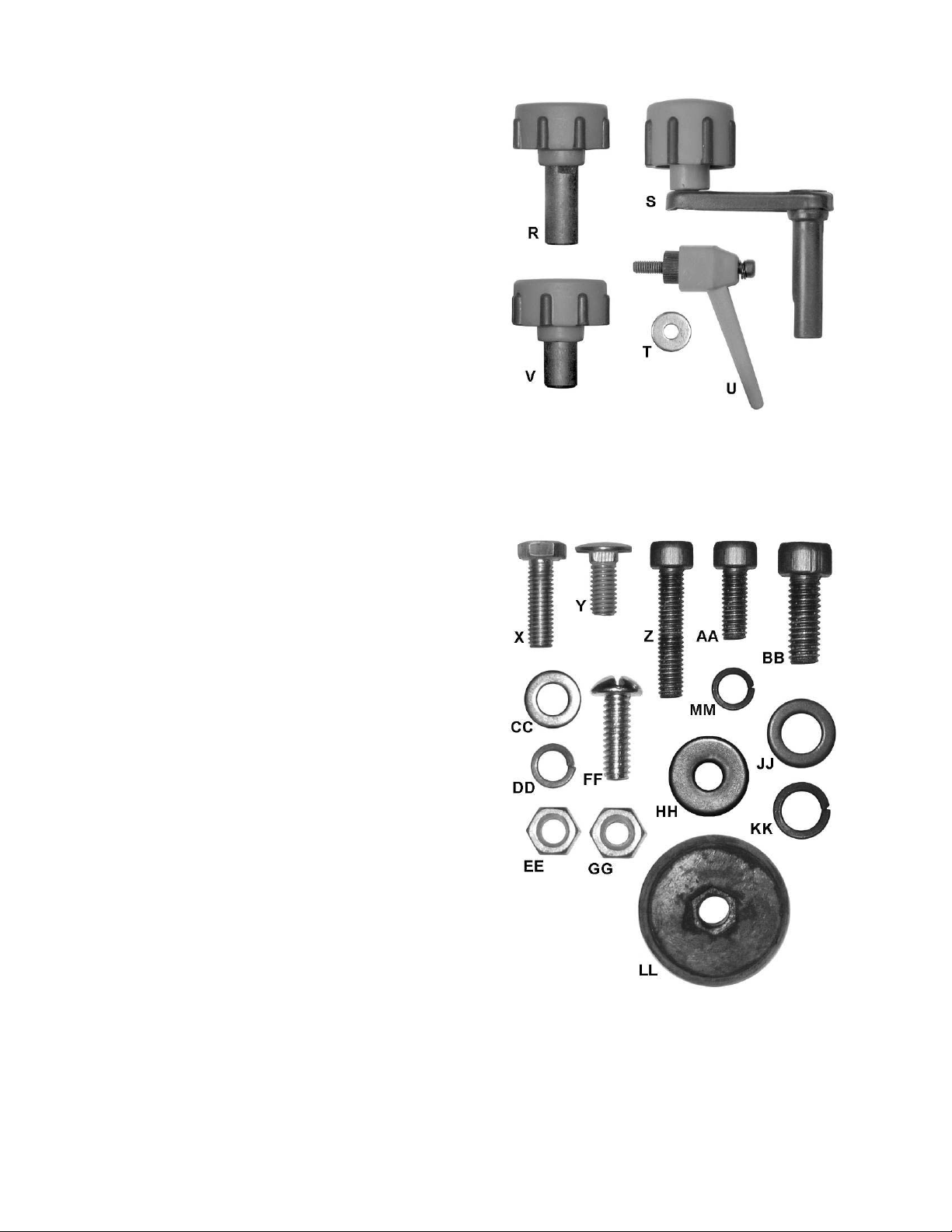

Knobs and Handles

01 Lock Knob (R)

01 He i ght Adj ust Handle (S)

01 Lock Handle ( U)

01 Flat Washer (T)

01 Lock Knob (V)

Figure 3 – Knobs and Handl es

Hardware

04 Hex Cap Screw( X)

24 Carriage Bolt (Y)

02 Socket Head Cap Screw ( Z)

03 Sock et Head Cap Screw ( AA)

04 Sock et Head Cap Screw ( BB)

28 Flat Washer (CC)

24 Lock Washer (DD)

28 Hex Nut (EE)

02 Pan Head Machi ne Screw ( FF)

02 Hex Nut (GG)

03 Flat Washer (HH)

04 Flat Washer (JJ )

04 Lock Washer (KK)

04 Rubber Foot ( LL)

02 Lock Washer (M M )

Figure 4 – Har dware ( actual siz e)

9

Page 10

Assembly

For assembly convenience, the item letter

designators used t hrougho ut the Assembly section

are the same as those used to identify shipping

content and hardware components on pages 8–9.

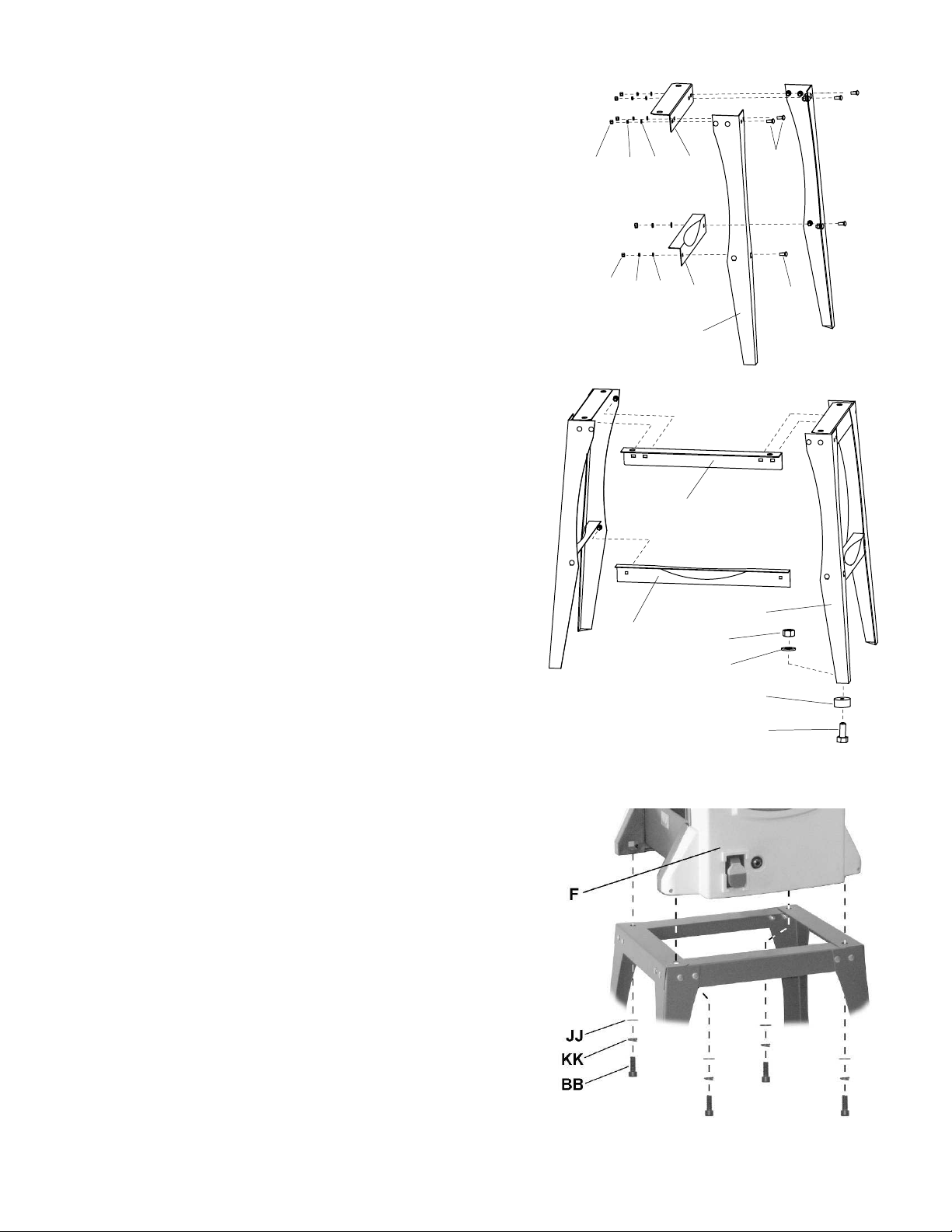

Stan d Assembly

Referring to Figure 5:

1. Select two legs (N),one shor t stand top s upport

(H) and one short support plate (E).

2. Attach one end of the stand top support (H) to the

top of the first leg with two carriage bolts (Y), flat

washers (CC), lock washers (DD) and hex nuts

(EE). Attach the other end of the stand top

support (H) to the second leg in the same

manner. Hand-tighten only at this time.

3. Attach a support plate (E) to each leg (N) in the

same manner with two carriage bolts (Y), flat

washers (CC), lock washers (DD) and hex nuts

(EE). Hand-tighten only at this time.

4. Repeat steps 1–3 using the remaining legs,

short stand top support and support plat e.

EE

EE

DD

DD

CC

CC

H

E

N

G

Y

Y

5. Complete the stand construction by attaching

long stand top supports (G) and long support

plates (D) to the leg assemblies co nstructed in

steps 1–4. Hand-tighten all hardware only at t his

time.

6. Place a r ubber foot (LL) on a hex cap screw (X),

then insert t he threaded end of the screw through

the opening on the bottom of the leg.

7. Secure with fla t wa s h er (CC) and hex nut (EE).

8. Attach r ubber feet t o r emai ni ng legs i n t he sa me

manner.

9. Place sta nd upright. E nsure that the stand is on

a level s urface a nd all f our legs are contact ing

the surface.

10. Tighte n all hex nuts w ith t he 10mm wrench (O )

provided.

M ou nting Joi nter-Planer to St and

Referring to Figure 6:

1. Place the Jointer-Planer (F) onto the assembled

stand and secure with 4 each socket head cap

screws (BB), l ock washers (KK), and fl a t wa s h er s

(JJ).

2. Tighten all socket head cap screws (BB) with

the 5mm hex wrench (Q) provided.

B

D

EE

CC

LL

X

Figure 5

Figure 6

10

Page 11

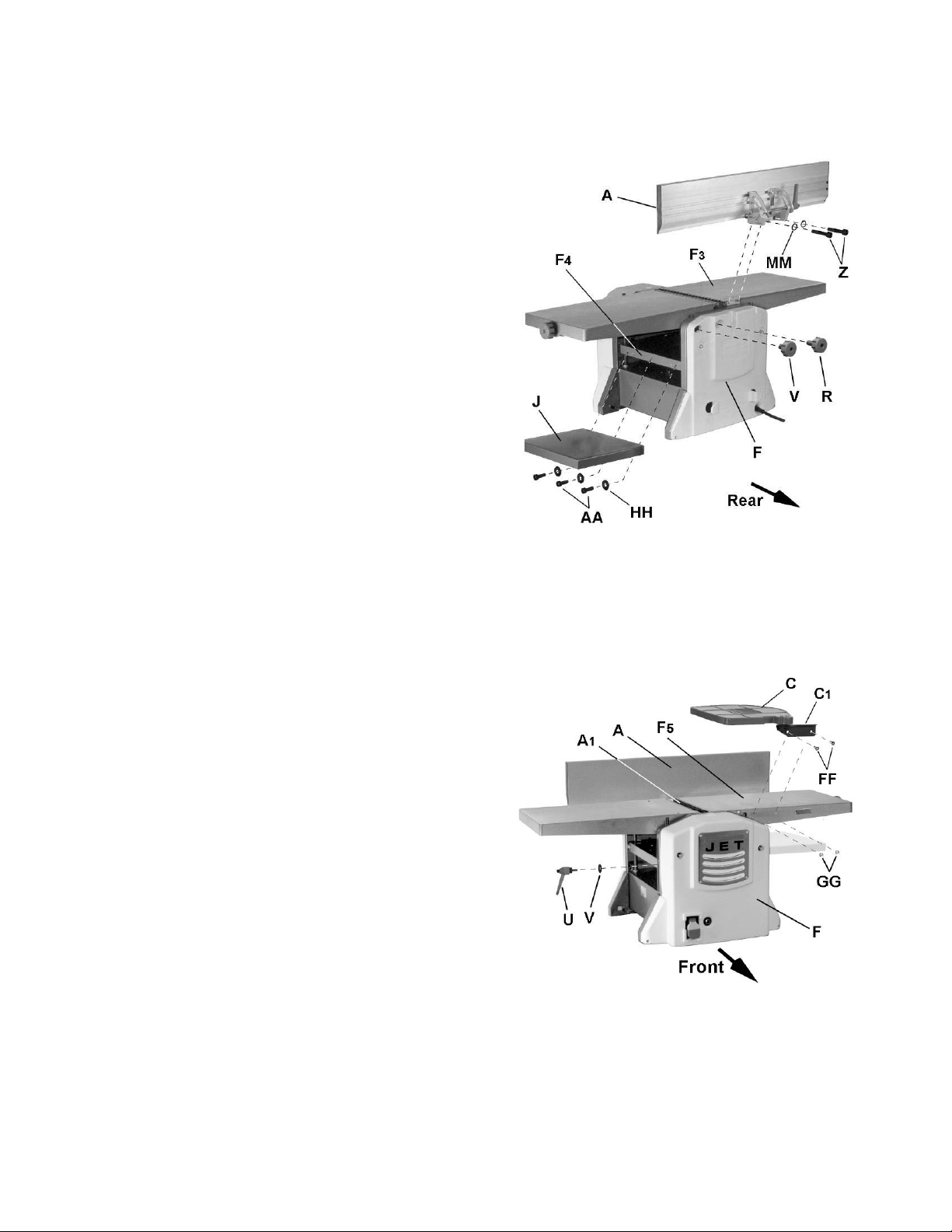

Joi nter-Planer Assemb ly

Referring to Figure 7:

Fence

1. Attach jointer fence (A) to back of jointer outfeed

table (F3) wit h two each socket head cap screws

(Z) and lock washers (MM). Tighten screws with

5mm hex wrench (provided).

Lock Knobs

The JJP-10BT Jointer-Planer comes equipped with

two lock knobs to secure the positi on of the joi nter

infeed table.

2. Install jointer infeed table lock k nobs (V, R).

Note: The shaft length of each lock knob (refer

to Figure 3) are diff er ent. Be sure to install eac h

in the correct location.

Exten sion Table

3. Attach the planer o utfeed extensi on table (J) to

the main planer table (F4) with three each

socket head cap screws (AA) and flat washer s

(HH). Tighten screws with 5mm hex wrench.

Exten sion Tabl e A dj ustment

Two setscrews located underneath the extension

table (J ) ar e used t o adjust the heig ht positio n of the

outer (protruding) edge, which must be slightly

higher than the main planer table (F4) in order to

minimize snipe (see Avoidi ng Sni pe on page 21).

4. Using a 4mm hex wrench (provided), turn

setscr ews slightly clockwise to raise t he table or

counterclockwise to low er t he table.

Lock Handle

Figure 7

Referring to Figure 8:

Attach pla ner ta ble lock handle (U) and flat washer (T).

Cutterhead G uar d

5. Install cutterhead guard (C) by securing the

bracket (C1) to the side of the jointer infeed

table (F5) with two each pan head machine

screws (FF) and hex nuts (GG).

Important: It is extremely important that spring

action causes the cutterguard ( C) to retrac t against

the fence (A), concealing the cutterhead (A1). If

spring return tension is not enough, adjust the spring

located on the cutterhead pivot shaft acc or di ngly.

Figure 8

11

Page 12

Jointer Setup

Disconnect mach ine from power

source before making any adjustments. Failure

to comply may cause serious injury.

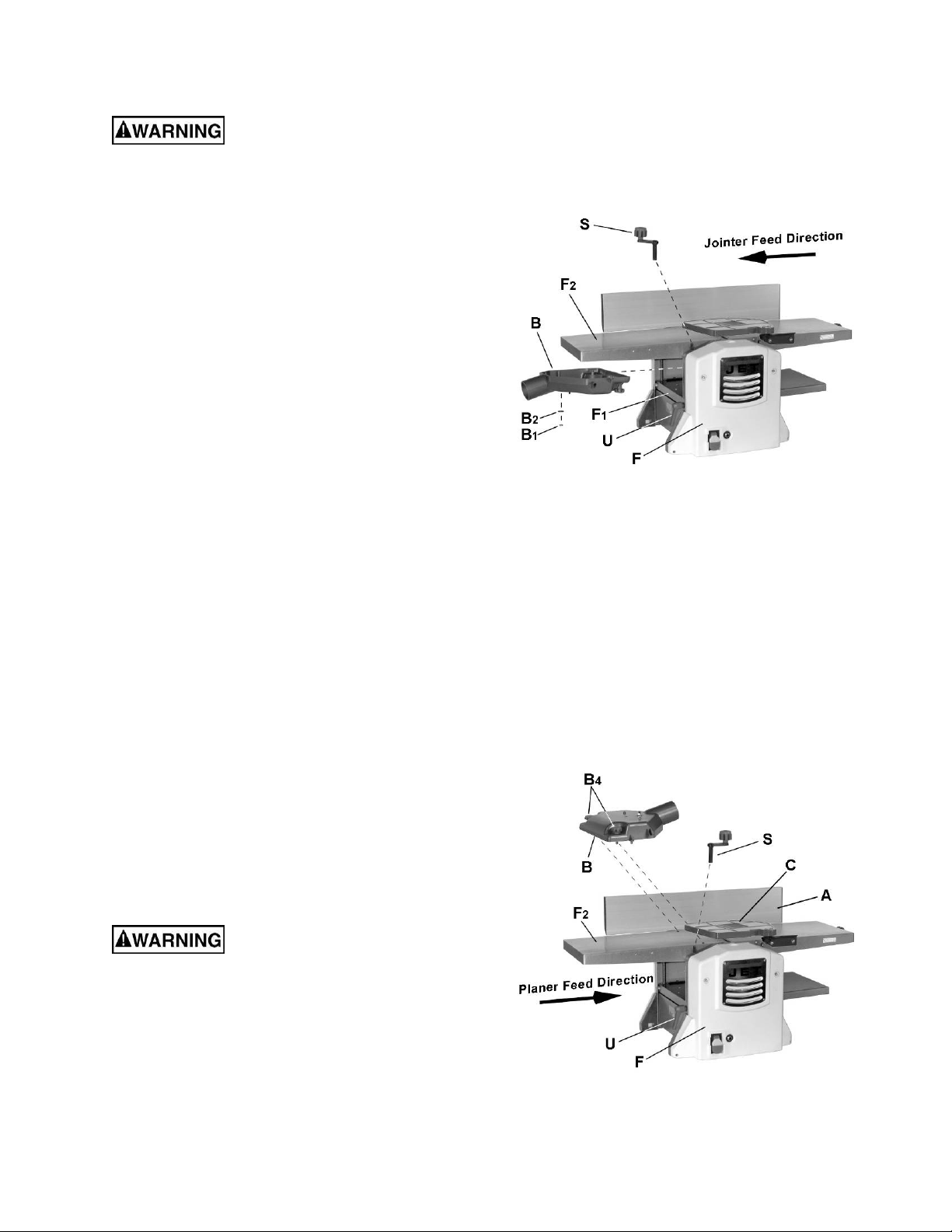

Referring to Figure 9:

1. Loosen lock handle (U).

2. In st all planer tabl e height adj ustment handle (S) .

3. Turn handle (S) counterclockwise and lower

planer table (F1) all the w a y .

4. Remove hex nu t (B1) and flat washer (B2) fro m

dust chute (B).

5. Orient the dust chute (B) as shown and install

into the infeed opening.

Position the chute (B) such that the two

positioning keys and one threaded positioning

screw underneat h the c hute mes hes with three

positioning holes o n the table (F1).

6. Raise the table (turn handle S clockwise) until

the dust chute (B) is held firmly in place

between t he planer inf eed table (F1) and jointer

outfeet table (F2). Do not overtighten.

7. Tighten lock handle (U).

Step 8 is optional.

8. Furt her secure the d ust chute by reinstalling the

hex nut (B1) and flat washer (B2) from

underneath the planer infeed table (F1).

9. Remove handle (S).

Figure 9

Important: Dust chute (B) must be proper ly i nstalled in

both Jointer setup and Planer setup. If improper

installation fails to activate a micro-switch, the machine

will n ot st art.

Planer Setup

If the machine is currently set up for jointer

operation, re move the dust chute (B, Fig. 9). Refer

to the Join te r Setup sect ion above.

Referring to Figure 10:

1. Swing cutterguard (C) away from fence (A),

which will e xpose t he cutte rhead.

Cutterhead knives are

dangerously sharp. Use extreme caution when

working around them. Failure to comply may

cause serious injury .

2. Orient the dust chu te (B) as show n. Install o nto

the jointer outfeed table (F2) and secure by

tightening l oc k knobs (B4).

Figure 10

12

Page 13

Operating Controls

Disconnect mach ine from power

source before making any adjustments. Failure

to comply may cause serious injury.

Power

Plug power cord into outlet.

Referring to Figure 11:

Start/Stop

Pull the red switch (A) out to start. Push in to stop.

Safety Key

Removing the safety key (B) will render the

start/stop switch inoperable. The machine can

continue to operate without the key, but upon

stopping cannot be r est arted until it is reinstalled.

Rese t Swit ch

If t he machine sho uld come to a n unexpect ed stop

during operation due to overload or jammed workpiece, etc. :

1. Set the start/stop switch (A) set to stop (pushed

in).

2. Momentarily press, t hen release the reset switch

(C).

3. Restart machine.

Planer Controls and Adjustments

Referring to Figure 12:

Table Lock

Turn the lock handle (A) counter clockw ise t o r elease

and permit table adjustment. Turn the lock ha ndle

(A) clockwise to secure the planer table (D) in its

selected positio n.

Table Height Adjustment

The planer table height is set as f ollows:

1. Unlock the table lock (A).

Figure 11

2. Install the removeable adjustment handle (C)

onto the shaft (B).

3. Rotate the adjustment handle (C) clockwise to

raise the planer table (D), counterclockwise to

lower.

Each revolution of the adjustment handle (C) results

in a 3/32" up or down movement of the table (D). A

scale indicates t he amount of table travel. The pointer

(E) indicates the table position on the scale relative to

the cutterhead.

Figure 12

13

Page 14

Joi nter Cont rols and Ad justmen t s

Refer to Figure 13.

Infeed Tabl e Hei ght Adj ustment

Two lock knobs (F) and a height adjustment knob

(E) control t he height adj ustment of t he infeed tabl e

(D).

To adjust:

1. Loosen lock knobs (F).

2. Turn the height adjustment knob (E) clockwise

to raise the i nf eed table (D) or counter-clockwise

to lower the table.

The amount of table adj ustment can be read o n

the scale (C).

3. Tighten the l ock knobs (F).

Note: A depth of cut of 1/16" or less is recom-

mended.

Cutterhead G uar d

Properly positio ned, t he cu tterhead guard (A) should

rest against the fence (B1).

Fence Bevel Adjustment

The fence (B2) can be tilted backward (G) up to 45°

(that is, f or a total included angle of 135° f rom table

surface) as f ollows:

1. Loosen lock handle (J).

2. Tilt the fence (B2) back to the desired angle up

to 135 degrees (G). Or you can place your

beveled reference piece on the table and

against the fence, adjusting the fence until the

angle of the fence matches the bevel of your

gauge piece.

3. Tighten the l ock handle (J).

Figure 13

14

Page 15

Adjustments

Cutt erhead Kni f e Adjust ment

Cutterhead knives are

dangerously sharp! Use extreme caution when

inspecting, removing, sharpening or replacing

knives into the cutterhead. Failure to comply

may cause serious injury!

Determining if adjustment is necessary:

1. Disconnect machi ne from the power s ource.

2. Remove the cutterhead guard.

Referring to Figures 14 and 15:

Note: To rotat e t he c utterhead the cutter head pulley

must be turned. T his req uires r emo ving t he panel o n

the front of the cabinet for access.

3. Rotate the cutterhead (E) until one knife is i n t he

12 o'clock positio n. The 12 o'clock position is the

highest point a b lade w il l reach in the cutting ar c

(C, Fig. 15) .

4. Place the knife setting gauge (J) on the outfeed

table (F). One end of the gauge should be

positioned over the cutting knife (C) towards the

near the end of the blade (G).

Use care when handling the knife

setting gauge near the blades to prevent damage.

Note the position of the knife blade wit h respect

to the gauge, the n move the ga uge to the other

side of the table towards the fence (H) and

again note the position of the knife blade with

respect to the gauge.

The blade must be at the same heig ht at each

end and m ust also be at the same heig ht as the

outfeed table (bot t om of gauge). If t his is not t he

case, adjustment is required as follows:

Adj ustment procedure

Figure 14

C

B

A

D

E

5. Slightly loosen seven gib lock screws (A) by

turning into the lock bar (B), clockwise as

viewed fr om the infeed tabl e (K).

6. Adjust the blade height by turning jack screws

(D) upon which the blade rests. To lower the

blade, turn the screw clockwise. To raise, turn

the screw counter- clockwise.

7. When the blade is at the proper height, alternately

tighten the seven gib lock screws (A).

Repeat steps 3 – 7 to adjust the remaining blade.

Note: The most common cause for unsatisfactory

cutting perfor mance is improperly set k nives. Many

aftermarket devices are avaialable to further assist

in the accurate setting of knives.

Figure 15

15

Page 16

Repl aci ng Cut t er Knives

Disconne ct machine fro m power

source before making any adjustments. Failure

to comply may cause serious injury.

1. Disconnect machi ne from the power s ource.

2. Remove the cutterhead guard.

Cutterhead knives are

dangerously sharp. Use extreme caution when

inspecting, removing, sharpening, or replacing

knives into the cutterhead. Failure to comply

may cause serious injury.

Referring to Figures 14 and 15 (page 15):

3. Turn all seve n gib lock screws (A) into the lock

bar (B) by turning in a clockwise direction as

viewed fr om the infeed tabl e (K).

4. Carefully remove the cutter knife (C) and lock

bar (B).

5. Repeat for the remaining knife.

6. Thoro ughly clea n all surfaces of the cutter head,

knife slots and lock bars of any dust or debris.

7. Insert the first replacement knife (C) into the

knife slot, making sure it faces the proper

direction.

8. Insert lock bar (B) and tighten just enough to

hold in place.

9. Repeat for other the remaining blade.

Following installation, the knives must be adjusted

as described in Cutterhead Knive Adjustment on

page 15.

Joi nter Fence Adjust ment

Referring to Figure 16:

The jointer fence (A) ca n be adj usted f r om a full forw ar d

position (90º to t able, cor responding to a scale readi ng

of 0º) t o a f ull back-t ilted position of 13 5 º (s cal e r eading

of 45 º).

If sett ing to ma ximum pos itions do not st op the fence at

0º or 90º, make adjustments as follows:

Fence 90º Adjustment

1. Loosen lock handle (H) and bring fence fully

forward. Using a square, determine if t he fence is

90º to the table.

If adjustment is required:

2. Loosen jam nut (E) a nd adjust stop screw (D) in or

out until a fenc e postion of 90º with respect to the

table is achieved.

3. Secure the jam nut (E).

Check the scale i ndication. If t he indicator ( C) does not

point to zero:

4. Loosen screw (B), adjust accordingly, then retighten

screw.

Fence 45º Adjustment

Verify that the fence and scale indication is accurate at

90º as outlined in Fence 90º Adjustment abo ve.

1. Loosen lock handle (H) and set the fence all the

way back. Using a sq uare, det ermine if the fence is

135º to the table.

If adjustment is required:

2. Loosen jam nut (G) and adj ust stop screw (F) in or

out until a fe nce post ion of 135º w it h respect to the

table is achieved. Note: The screw head stops

against the fence mounting bracket .

3. Secure the jam nut (G).

16

Figure 16

Page 17

Belt Replacement

Refer to Figure 17 when installing or replacing the

the feed-roller (A) or cutterhead drive (D) belts.

Disconne ct machine fro m power

source before making any adjustments. Failure

to comply may cause serious injury.

Feed-rol l er Bel t Replacement

Cutterhead knives are

dangerously sharp. Use extreme caution when

replacing any belt. Contact with cutterhead

knives will cause serious in jury.

1. Remove the f r ont pa nel. This is the panel where

the Start/Stop switch is located.

2. Remove feed-roller belt (A) from pulley (B) while

manually rotating pulley (C).

When this is accomplished, belt will fall away

from pulley (C).

3. Loop the new belt around pulley (C), then

around pulley (B) while ma nually rot ating pulley

(C).

4. When installed, continue to manually rotate

pulley (C) and verify that be lt is properly seat ed

on both pulleys.

5. Replace front cover.

Cutterhead D r i ve Belt Repl acement

Cutterhead knives are

dangerously sharp. Use extreme caution when

replacing any belt. Contact with cutterhead

knives will cause serious in jury.

The cutterhead drive belt should seldom if ever,

require replace ment. Fo llow t he proce dure be low if,

however, t he belt should require replacement.

1. Remove the feed-roller belt as described in

Feed-rol ler Belt Replacement above.

2. Remove the bottom portion of the cutterhead

drive belt (D) from pulley (E) while manually

rotating pulley (F).

Figure 17

4. Install new belt by first feeding the lower loop

downward behi nd the gear ( H) and pulley (C). This

will properly position the lower loop of the belt in

close proximity t o pulley (E).

5. Slide t he top loop of the belt aro und and past pulley

(B), sliding it underneath and past chain (G); then

loop around pulley (F).

6. Loop belt around pulley (E) while ma nually r otat ing

pulley (F).

Use extreme caution to avoid

contact with cutt er head knives whi le perf orm ing t his

step. Contact with cutterhead knives will cause

ser io u s injur y .

Use extreme caution to avoid

contact with cutt erhead k nives whi le perform ing

this step. Contact with cutterhead knives will

cause serious injury .

3. Remove top portion of belt (D) from pulley F,

then work it under the chain and past pulley B to

remove completely.

7. M anually rotate p ulley (F) t o ver ify that t he grooves

in the belt are properly meshed with t he grooves on

both pulleys.

This completes t he cutter head drive belt i nstallation.

8. Replace the feed-roller belt (Feed-roller Belt

Replacement section steps 3–5).

17

Page 18

Basic Operations

Hand pla cement

Dust Collection

Before initial operation, the machine must be

connected to a dust collector.

Important: If a dust collection system is not

used, t he qualit y o f your cut will s uffer s e ver e ly .

Initial Startup

After the assembly and adjustments are

complete t he pla ner is ready to be t ested. Plug

in and start the machine. Keep your finger on

the Stop button in case of a problem. The

machine should run smoothly with little or no

vibration or rubbing noises. Investigate and

correct the source of any problems before

further operatio n.

DO NOT attempt to inves-

tigate or adjust the pl aner while it is running.

Wait until the machine is turned off,

unplugged a nd all work ing parts have co me

to a complete standstill.

Always wear ANSI-approved

safety glasses or goggles when operating

equipment.

Never pass hands directly

over the cutt er head.

Referring to Figure 18:

At the start of the cut, the left hand holds the

workpiece firmly against the infeed table and

fence w hile the right ha nd pushes the workpiece

in a smooth, even motion towar d t he cutter head.

After t he cut is under way, the new surface r es t s

firmly on the outfeed table. The left hand is

transferred to the outfeed side (Figure 18) and

presses down on this part of the workpiece, at

the same time maintaining flat contact with the

fence. The right hand presses the workpiece

forward and before the right hand reaches the

cutterhead it should be moved to the work on

the outfeed table.

Surfac ing

The purpose of surfacing on a jointer is to

produce one flat surface (Figure 19). The ot her

side can then be milled to precise, final

dimensions on a t hickness planer res ulting i n a

board that is smoot h and flat on bot h sides a nd

each side parallel to t he other.

!

If the wood to be jointed is cupped or

bowed, place the concave side down, and

take light cuts until the surface is flat.

Changing Mode of Operation

When changing the operating mode (planer to

jointer and back) t he machine must be turned off,

unplugged, and come to a complete stand-still.

To change the mode of operation, see sections

Jointer Se tu p and Planer Setup on page 12.

Joi nter Operations

Correct operat i ng position

The operator must be positioned offset to the

infeed table (Fig ure 18).

Figure 18

!

Never s urface pieces shorter t han 12 inches

or thinner tha n 3/8 inch wit hout the use of a

special work holding fi xture.

!

Never s urface pieces thinner t han 3 inches

without the use of a push block.

!

Cuts of appr oximately 1/ 16" or less at a t ime

are recom me nded, which pro vides f or bet t er

control over the material being surfaced.

More passes c an t hen be made to reac h t he

desired depth.

Figure 19

18

Page 19

Di re ction of Grain

Avoid feeding work into the jointer against the

grain (Figure 20).

Figure 20

This may result in chipped and splintered edges.

Feed with the gra in to obt ain a sm ooth s urface,

as shown in Figure 21.

Edge Jointi ng

Jointing (or edging) is t he process of cr eating a

finished, flat edge surface that is suitable for

joinery or finishing (Figure 22). It is also a

necessary step prior t o ripping stock t o width on

a table saw.

!

Never edge a board that is less than 3

inches wide, l ess than 1/4 inch t hick, or 12

inches long, without usi ng a push block.

!

When edging wood wider than 3 inches lap

the fingers over the top of the wood,

extending them back over the fence such

that they will act as a s top for the hands in

the event of a kickback.

When workpiece is twice the

length of the jointer inf eed or out f eed t able

use an infeed or outf eed suppor t .

To edge:

1. Make sure the fence is set to 90°. Double

check it with a square.

2. Inspect stock for soundness and grain

direction (refer to Direction of Grain on

previous page).

Figure 21

Figure 22

3. If the board is bowed (curved), place the

concave edge down on the infeed table.

4. Set the infeed table for a cut of approximately 1/16 inch.

5. Hold the st ock firmly against t he fence a nd

table, f eed the stock slowly a nd evenly over

the cutterhead.

19

Page 20

Beveling

Beveling an edge is the same operatio n as edge

jointing, except that the fence is tilted to a

specified angle.

!

Make cert ain material be ing beveled is over

12 inches lo ng, mor e t han 1/4 inch thick and

1 inc h wide.

To bevel:

1. Use a bevel ga uge to determine t he desired

angle. Then set the fence to the same angle.

2. Inspect stock for soundness and grain

direction (refer to Direction of Grain on

previous page).

3. Set the infeed table for a cut of

approximately 1/ 16.

4. If the board is bowed (curved), place the

concave edge down on the infeed table.

5. Feed the stock through the cutterhead,

making sure the face of the stock is

completely flat against the fence and the

edge is making solid contact on the infeed

and outfeed tables (Fig ure 23).

For wood wider than 3 inches – hold with

fingers close together near the top of the

stock, lapping over the board and exte nding

over the fence.

For wood less than 3 inches wide – use

beveled push blocks and apply pressure

toward the fence. Keep fingers near top of

push block.

Several passes may be req uired to achieve f ull

bevel.

lowering the planer table (D, Fig. 12) using the

adjustable handle (C, Fig. 12).

!

The quality of thickness p laning depe nds on

the operator's judgment about the depth of

cut.

!

The depth of cut depends on the width,

hardness, dampness, grain direction and

grain structure of t he wood.

!

The maximum thickness of wood that can be

removed in one pass is 5/64" for planing

operations on workpieces up to 5-1/2” wide.

The workpiece must be positioned away from

the center tab on the rollercase to cut 1/8”.

!

The maximum thickness of wood that can be

removed in one pass is 1/16” for planing

operations o n work pieces fr om 5-1/2” up to

10" wide.

!

For optimum planing performance, the dept h

of cut should be less than 1/16”.

!

The board should be planed with shallow

cuts until t he work has a level si de. Once a

level surface has been created, flip the

lumber and create parallel sides.

!

Plane alternate s ides unti l the desired t hickness is obtained. W he n half of the tot al cut

has been taken from each side, the board

will have a uniform, moisture content and

additional drying will not c ause it to warp.

!

The depth of c ut should be shallow er when

the workpiece is wider.

!

When planing hardwood, take light cuts or

plane the wood in thin widths.

!

Make a test cut wit h a test piece and verify

the thickness produced.

Figure 23

Planer Operatio ns

Dept h of Cut

Thickness planing refers to the sizing of lumber to

a desired thickness while creating a level surface

parallel to the opposite side of the board. Board

thickness that the pla ner will pr oduce is indicate d

by the scale (see Table Height Adjustment on

page 13). Preset the planer to the desired

thickness of the finished workpiece using the

gauge. The depth-of- cut is adjusted by raising or

!

Check the accuracy of the test cut before

working on the finished product.

Precautions

!

A thickness planer is a precision woodworking machine and should be used on

quality lumber only.

!

Do not plane dirty boards; dirt and small

stones are abrasive and will wear out the

blade.

!

Remove nails a nd stapl es. Use the planer t o

cut wood only.

!

Avoid knots. Heavily cross-grained wood

makes knots hard. Knots can come lose a nd

jam the blade. Any article that encounters

planer blades may be forcibly ejected from

the planer creati ng a risk of injury.

20

Page 21

Preparing t he W ork

!

A thickness planer works best when the

lumber has at least one flat s urf ace. Use a

jointer to cr eat e a flat surface.

!

Twisted or severely w arped boards ca n ja m

the planer. Rip the lumber i n half t o reduce

the magnitude of t he warp.

!

The work should be fed i nto the planer in t he

same direction as the grain of the wood.

Sometimes t he wood w ill change direct ions

in the midd le of t he board. I n such cases, if

possible, cut t he board in the middle so t he

grain direct io n is correct.

4. Slide t he workpiece into the infeed side of

the planer until the infeed roller begins to

advance the workpiece.

5. Let go of the workpiece and allow the

automatic feed t o advance the workpiece.

6. Do not push or p ull on the workpiece. Move

to the rear and rece ive the planed lumber by

grasping it in the same manner that it was

fed.

To avoid the risk of injury

due to kickbacks, do not stand directly in

line with the front or r ear of the planer.

Do not p lane a board that is

less than 6" long. It is recommended that

when planing short boards you butt them

end to end to avoid kickback and reduce

snipe.

Feeding the W ork

The planer is supplied with planer blades

mounted in the c utterhead. Feed direc tion is left

to right (see Figure 10). The planer feed is

automatic; it will vary slightly depending on the

type of wood.

Preparation:

!

Feed rate refers to the rate at which the

lumber travels thro ugh the planer.

!

The operator is respo nsible for aligning t he

wo r k s o it will feed properly.

!

Raise or lower the table to get the depth of

cut desired.

!

The s urfac e t hat t he pla ner pro duce s w ill be

smoother if a shallower depth of cut is used.

!

Stand on the front side of the machine.

7. Do not grasp any portion of the board that

has not gone past the infeed r ol ler.

8. Repeat this operation on all of the boards

that need to be the same thickness.

Avoiding Sni pe

Snipe refers t o a depression at either end of the

board caused by an uneven force on the

cutterhead w hen t he work is e ntering or leavi ng

the planer.

Snipe will occur when the boards are not

supported prop erly or w hen o nly o ne feed roller

is in contact with the work at the beginning or

end of the cut.

Precautions for avoiding snipe:

!

Push the board up while feeding the work

until the outfeed roller st ar t s advancing it.

!

Move to the rear and receive the planed

board by pushi ng it up when the i nfeed roller

looses contact with the board.

!

When planing more t han one board of t he

same thickness, butt t he boards toget her to

avoid snipe.

!

Boards longer than 24” should have

additional support from free standing

material stands. These can be purchased

from JET – Stock # 709207. See Optional

Accessories on page 7.

Planing:

1. Position the workpiece with the face to be

planed on top.

Note: Feed direction is left to right (see

Figure 10).

2. Turn the planer on.

3. Rest the boar d end on t he i nfeed side of t he

table and direct the board into the planer.

!

Make shallow c uts. Snipe is more app arent

when deeper cuts are taken.

!

Feed t he work i n the directio n of the grain.

Work fed against the grain will have

chipped, splintered edges.

21

Page 22

Maintenance

the stone's surface is flush with the knife

bevel.

Blad e Care

Blades are extr emely sharp!

Use caution when cleaning

or changing. Failure to comply may cause

ser io u s injur y !

!

The condition of the blades will affect the

precision of the cut. Observe the quality of

the cut that the machine prod uces to check

the condition of the blades.

!

Dull blades will tear, rather than cut the

wood fibers and produce a fuzzy

appearance.

!

Raised grain will occur when dull blades

pound on wood that has varying de nsity. A

raised edge will also be pr oduced where the

blades have been nicked.

When gum and pitch collect on the blades,

carefully remove wit h a strong solvent. Failure to

remove gum and pitch build up may result in

excessive frict ion, blade wear and overheating.

When blades become d ull, t ouch up blades. See

Sharpening the Knives.

6. Keep the cutterhead from rotating by

grasping t he cutt erhead p ulley w hile s lidi ng

the stone back and forth across t he table.

7. Take t he same amount of passes f or all two

blades.

When the blades have been sharpe ned and still

are not cutting efficiently, trying to touch up the

blades f urther will o nly ca use the formatio n of a

second beveled edge. When this starts to

happen, it is time to replace blades w ith another

set. It is recommended t o keep a second set of

blades on hand so that they may be installed

while the first set is being professionally

sharpened.

Figure 24

Sharpenin g the Knives

Blades are extremely sharp! Use caution

when handling. Failure to

comply may cause serious

injury!

1. Disconnect the machine from the power

source.

2. Remove the blade guard and belt cover.

3. To protect the infeed table from scratches,

partially cover the sharpening stone with

paper (Figure 24).

4. Lay the stone on the infeed t able.

5. Lower the infeed table and turn the

cutterhead by t urning t he cutter head pulley.

The infeed table height is set proper ly when

Lubrication

!

Use a good grade of light grease on the

steel adjust ing screws located i n t he raisi ng

and lowering mechanisms of the work

tables.

The cutterhead ball bearings are lifetime

lubricated a nd need no further care.

22

Page 23

Troubleshooting

Alig

Performance Troubleshooting – Jointer

Trouble Probable Cause Remedy

Finished st ock is

concave on back

end.

Finished st ock is

concave on front end.

Chip out. Cutting against t he grain. Cut with the grain whenever possible.

Fuzzy grain.

Cutterhead slows

while operating.

Knife is higher than outfeed table.

Outfeed table is higher t han knife.

Dull knives. Sharpen or replace knives.

Feeding workpiece too fast. Use slower rate of feed.

Cutting too deeply. Make shallower cuts.

Knots, imperfections in wood.

Wood has high moist ure content.

Dull knives. Sharpen or replace knives/inser ts.

Feeding workpiece t oo quickly, or

applying too much pressure to

workpiece.

Align cutterhead kni ves with outf eed

table. See Cutterhead Knife

Adjustment o n page 15.

Align cutterhead kni ves with outf eed

table. See Cutterhead Knife

Adjustment o n page 15.

Inspect wood closely for

imperfections; use different stock if

necessary.

Allow wood to dr y or use different

stock.

Feed more slowly, or apply less

pressure to w or kpiece.

“Chatter” marks on

workpiece.

Uneven knife marks

on workpiece.

Set knives properly as described in

Knives incorrectly set.

Feeding workpiece t oo f ast .

Cutting too deeply. Make shallower cuts.

Knives are nicked, or out of

alignment.

the Cutterhead Knife Adjus tment on

page 15. Check that knife slots are

clean and free of dust or debris.

Feed workpiece slow ly and

consistently.

n knives per the Cutterhead Knife

Adjustment o n page 15. Replace

nicked knives.

23

Page 24

Performance Troubleshooting – Planer

Adj

Trouble Probable Cause Remedy

Snipe

Note: Snipe can be

minimized but not

eliminated

Fuzzy Grai n

Torn Grain

Rough/Raised Grain

Rounded, glossy

surface

Inadequate support of long boards. Support long boards with exte nsion

rollers.

Dull knives. Sharpen knives.

Lumber not butted proper ly. Butt end to end each piece of stock

as they pass through.

Planing wood w ith high moisture

content.

Dull knives. Sharpen or replace.

Too heavy a cut. Adjust proper dept h of cut

Knives cutting against gr ai n. Cut along the grain.

Dull knives. Sharpen knives.

Dull knives. Sharpen knives.

Too heavy a cut. Adjust proper dept h.

Moisture content too high. Remove high moisture content from

Dull knives. Sharpen or replace knives.

Feed speed too slow. Increase speed.

Remove high moisture content from

wood by dry ing.

wood by dry ing.

Uneven dept h of cut

side to side.

Board thickness does

not match depth of

cut scale.

“Chatter” marks on

workpiece.

Cutting depth too shallow. Increase depth.

Planer bed rough or dirty. Clean pitch and resid ue, and wax

planer table.

Surface of feed r ollers clogged. Clear residue chips off of rollers.

Knife incorrectly set. Adjust knives.

Depth of cut scale incorrect .

Knives incorrectly set.

Cutting too deeply. Make shallower cuts.

ust depth of cut scale.

Set knives properly as described in

the Cutterhead Knife Adjus tment on

page 15. Check that knife slots are

clean and free of dust or debris.

24

Page 25

M echanical Troubl eshooting – P laner/Jointer

Adj

Trouble Probable Cause Remedy

Mac hi n e will

not start/

restar t or

repeatedly

trips circuit

breaker or

blows fuses.

No inco m ing

power.

Planer frequently

trips.

Building cir cuit

breaker t r ips or

fuse blows.

Motor failure. If electric motor is suspect, have a qualified electrician test the

Dust chute not

seated proper ly

on either Jointer

Infeed or Planer

Table

1. Verify unit is connected t o pow er and Start / St op switch is in the

Start position (see Power on page 13) .

2. Verify unit is co nnected to power. Set the St art/ Stop sw itch to

the Stop positio n, depress a nd release t he reset switch, t hen

reset the Start/Stop switch to the Start positio n (see Power on

page 13).

One cause of overloading trips, which are not electrical in nature,

is too heavy a cut. The solution is to take a lighter cut.

Verify that planer is on a circuit of cor r ect size. If circuit size is

correct , t here is probably a loose electrical lead.

motor for function or take the machine to a service center and

have it tested.

ust the dust chute, making sure that the key on the dust chute

depresses t he micro-switch on machi ne.

25

Page 26

Parts

Ordering Repl acement P art s

To order par t s or reach our service depar t me nt, call 1-800-274- 6848 between 7:30am a nd 5:30pm (CST) ,

Monday through Friday. Having t he Model Number and Serial Number of your machi ne availabl e when

you call

Joi nter/Pl aner – Parts List

Note: Parts without part numbers are for refer ence only and cannot be purchased individually.

Index No. Part No. Descript ion Size Qty

1 .............. JJP8BT-1 ................C hain Support Bracket ........................................................................ 1

2 .............. JJP8B T -2 ................S p rocke t ............................................................................ ................ 1

3 .............. JJP 8BT-3 ................E -Cli p...............................................................Ø6 ............................. 1

4 .............. TS-2361051 ............Lock Wash er ....................................................M5 ........................... 42

5 .............. TS-1540031 ............Hex Nut............................................................M5 ............................. 9

6 .............. TS-1550031 ............Flat Wash er......................................................M5 ........................... 22

7 .............. JJP8BT-7 ................Corner Sprocket ................................................................................. 4

8 .............. JJP10BT-8 ..............Chain ................................................................................................. 1

9 .............. JJP10BT-9 ..............Base .................................................................................................. 1

10 ............ JJP8BT-10 ..............Infeed Pointer Label ............................................................................ 1

11 ............ TS-1502031 ............Socket Head Cap Screw ...................................M5x12........................ 3

12 ............ JJP8BT-12 ..............Driven Lead Screw ............................................................................. 3

13 ............ JJP8BT-13 ..............Drive Lead Screw ............................................................................... 1

14 ............ JJP 1 0 B T-14 ............Extension Tab le .................................................................................. 1

15 ............ TS-1503021 ............Socket Head Cap Screw ...................................M6x10........................ 3

16 ............ JJP8BT-16 ..............Crank Arm Bushing ............................................................................. 1

18 ............ JJP 1 0 B T-18 ............Mai n Tabl e ......................................................................................... 1

19 ............ JJP8BT-19 ..............Crank Arm.......................................................................................... 1

20 ............ JJP8BT-20 ..............Guide Rail .......................................................................................... 2

21 ............ TS-1503041 ............Socket Head Cap Screw ...................................M6x16........................ 4

23 ............ JJP8BT-23 ..............Knob Screw ........................................................................................ 1

24 ............ JJP8BT-24 ..............Knob .................................................................................................. 1

25 ............ JJP8BT-25 ..............Lockin g Handle................................................................................... 2

27 ............ TS-1532032 ............Pan Head M achi ne Screw .................................M4x10........................ 3

28 ............ TS-2361041 ............Lock Washer ....................................................M4 ............................. 3

29 ............ JJP8BT-29 ..............Pointer ............................................................................................... 1

31 ............ TS-1540021 ............Hex Nut............................................................M4 ............................. 2

32 ............ JJP8BT-32 ..............Cord Clamp ........................................................................................ 1

33 ............ TS-1532052 ............Pan Head M achi ne Screw .................................M4x16........................ 2

34 ............ JJP8BT-34 ..............Cover ................................................................................................. 2

35 ............ JJP8BT-35 ..............Rear Support ...................................................................................... 1

36 ............ JJP8BT-36 ..............Self-Tapping Screw ..........................................ST4 .2x 10 ................. 10

37 ............ JJP 8B T-37 ..............S cal e ................................................................................................. 1

38 ............ TS-1502011 ............Socket Head Cap Screw ...................................M5x8 ....................... 13

39 ............ JJP8BT-39 ..............Power Cord Protector.......................................................................... 1

40 ............ JJP8BT-40 ..............Rear Sup port Cover ............................................................................ 1

41 ............ JJP8BT-41 ..............Pin ..................................................................................................... 2

42 ............ JJP8BT-42 ..............Self-Tapping Screw ..........................................ST4 .2x 20 ................... 4

43 ............ JJP8BT-43 ..............Power Cord ........................................................................................ 1

44 ............ JJP 8B T-44 ..............S crew ................................................................................. ............... 2

45 ............ JJP8BT-45 ..............Spring ................................................................................................ 2

46 ............ TS-1550031 ............Flat Washer......................................................M5 ............................. 4

47 ............ TS-2331051 ............Cap Nut ...........................................................M5 ............................. 4

48 ............ JJP8BT-48 ..............Th read Lock B ushing .......................................................................... 4

49 ............ TS-1540031 ............Hex Nut............................................................M5 ............................. 2

26

Page 27

Joi nter/Pl aner – Parts List

Index No. Part No. Descript ion Size Qty

50 ............ JJP8BT-50 ..............Outfeed Table Spacer ......................................................................... 4

51 ............ JJP8BT-51 ..............Infeed Table Spacer............................................................................ 4

52 ............ JJP8BT-52 ..............Bearin g .............................................................................................. 1

53 ............ JJP8BT-53 ..............Spring ................................................................................................ 2

54 ............ JJP 8 B T-54 ..............B ushing Bloc k .................................................................................... 5

55 ............ JJP8BT-55 ..............Spring ................................................................................................ 1

56 ............ JJP 1 0 B T-56 ............Ro ller ................................................................................................. 2

57 ............ 707411....................Knife .................................................................................................. 2

59 ............ JJP8BT-59 ..............Pin ..................................................................................................... 4

60 ............ JJP 1 0 B T-60 ............Kn ife Gib ............................................................................................ 2

61 ............ JJP 8B T-61 ..............S crew ................................................................................. ............. 14

62 ............ JJP 1 0 B T-62 ............Cu tte r hea d ............................................................................. ............ 1

63 ............ TS-1540041 ............Hex Nut............................................................M6 ............................. 6

64 ............ JJP 1 0 B T-64 ............Outfeed Table .................................................................................... 1

65 ............ TS-1550021 ............Flat Washer......................................................M4 ............................. 3

66 ............ TS-1501041 ............Socket Head Cap Screw ...................................M4x12........................ 2

67 ............ JJP8BT-67 ..............Fence Support .................................................................................... 1

68 ............ TS-1550041 ............Flat Washer......................................................M6 ............................. 8

69 ............ TS-2361061 ............Lock Washer ....................................................M6 ............................. 9

70 ............ TS-1482021 ............Hex Cap Screw ................................................M6x12........................ 2

71 ............ JJP8BT-71 ..............Fence Bracket .................................................................................... 1

72 ............ JJP 8B T-72 ..............S crew ................................................................................. ............... 2

73 ............ TS-1503061 ............Socket Head Cap Screw ...................................M6x25........................ 2

74 ............ JJP8BT-74 ..............Washer .............................................................................................. 6

75 ............ JJP8BT-75 ..............Lockin g Nu t ........................................................................................ 2

76 ............ JJP8BT-76 ..............Angle Pointer...................................................................................... 1

77 ............ JJP8BT-77 ..............Pin ..................................................................................................... 1

78 ............ JJP8BT-78 ..............Shaft .................................................................................................. 1

79 ............ JWBS10OS-110 ......Carriage Bolt ....................................................M6x16........................ 1

80 ............ JJP8BT-80 ..............Hex Cap Screw ................................................M4x15........................ 2

81 ............ JJP8BT-81 ..............Angle Marked Fence Support .............................................................. 1

82 ............ JJP 1 0 B T-82 ............Fe nce ................................................................................................ 1

83 ............ JJP 1 0 B T-83 ............Ho s e Adapter ..................................................................................... 1

84 ............ JJP 1 0 B T-84 ............Kn o b .................................................................................................. 2

85 ............ JJP 1 0 B T-85 ............Du s t Ch ute ......................................................................................... 1

86 ............ JJP8 BT-3 ................E-C li p...............................................................Ø6 .............. ............... 2

87 ............ JJP8BT-87 ..............Pointer ............................................................................................... 1

88 ............ JJP8BT-88 ..............Infeed Direction Label ......................................................................... 1

89 ............ TS-1533042 ............Pan Head M achi ne Screw .................................M5x12........................ 3

90 ............ JJP8BT-90 ..............Knob .................................................................................................. 1

91 ............ JJP 1 0 B T-91 ............Ad justing Rod ..................................................................................... 1

92 ............ TS-1541031 ............Nylon Insert Lock Nut .......................................................................... 2

93 ............ JJP 1 0 B T-93 ............Sh a ft .................................................................................................. 1

94 ............ JJP 8B T-94 ..............B rack et .............................................................................................. 1

95 ............ JJP 8B T-95 ..............Cu sh ion Bl ock .................................................................................... 1

96 ............ JJP 1 0 B T-96 ............Cu tte r head Guard ............................................................................... 1

97 ............ TS-2245081 ............Flat Head Screw ...............................................M5x8 ......................... 2

98 ............ JJP8BT-98 ..............Post ................................................................................................... 1

99 ............ JJP8BT-99 ..............Spring ................................................................................................ 1

100 .......... JJ P 8 BT-1 0 0 ............S upport Bracket .................................................................................. 1

101 .......... TS-1534052 ............Pan Head Machine Screw .................................M6x16........................ 2

102 .......... JJ P 8 BT-1 0 2 ............R e ta ining Ring .................................................................................... 1

103 .......... TS-2361081 ............Lock Washer ....................................................M8 ............................. 2

104 .......... TS-1504051 ............Socket Head Cap Screw ...................................M8x25........................ 2

107 .......... JJ P 1 0 BT-1 0 7...........Sh ield ....................................................................................... ......... 1

108 .......... JJ P 1 0 BT-1 0 8...........Sh aft .................................................................................................. 1

27

Page 28

Joi nter/Pl aner – Parts List

Index No. Part No. Descript ion Size Qty

109 .......... JJ P 8 BT-1 0 9 ............Wa she r ............................................................................................ 29

110 .......... JJ P 8 BT-1 1 0 ............Anti-Kic kb a c k Finger ......................................................................... 56

111 .......... JJ P 8 BT-1 1 1 ............Be a r ing Cover .................................................................................... 1

112 .......... JJ P 8 BT-1 1 2 ............Be a r ing .............................................................................................. 1

113 .......... JJ P 8 BT-1 1 3 ............Fro nt Su pport ..................................................................................... 1

114 .......... JJ P 8 BT-1 1 4 ............Cut Depth Scal e Label ........................................................................ 1

115 .......... JJ P 8 BT-1 1 5 ............Sp r ing ................................................................................................ 1

116 .......... TS-1502021 ............Socket Head Cap Screw ...................................M5x10........................ 6

117 .......... JJ P 8 BT-1 1 7 ............Switch Mount...................................................................................... 1

118 .......... JJ P 8 BT-1 1 8 ............Switch ................................................................................................ 1

119 .......... JJ P 8 BT-1 1 9 ............Pu lle y................................................................................................. 1

120 .......... JJ P 8 BT-1 2 0 ............Be lt .................................................................................................... 1

121 .......... JJ P 8 BT-1 2 1 ............Sp a c e r ............................................................................................... 1

122 .......... JJ P 8 BT-1 2 2 ............Sp r o ck e t .................................................................................... ........ 2

123 .......... JJP8BT-123 ............Socket Head Cap Screw ...................................M6x15........................ 2

124 .......... JJ P 8 BT-1 2 4 ............D rive Ch a in ................................................................................. ....... 1

125 .......... JJ P 8 BT-1 2 5 ............Gea r .................................................................................................. 1

126 .......... JJ P 8 BT-1 2 6 ............Pu lle y................................................................................................. 1

127 .......... TS-1533062 ............Pan Head Machine Screw .................................M5x20........................ 3

128 .......... JJ P 8 BT-1 2 8 ............Ke y .................................................................................................... 1

129 .......... JJ P 8 BT-1 2 9 ............Be lt .................................................................................................... 1

130 .......... JJ P 8 BT-1 3 0 ............Sh a ft .................................................................................................. 2

131 .......... JJ P 8 BT-1 3 1 ............Fro nt Su pport Cover ........................................................................... 1

132 .......... JJ P 8 BT-1 3 2 ............JE T Na mepl a te................................................................................... 1

133 .......... JJ P 8 BT-1 3 3 ............Ke y .................................................................................................... 1

134 .......... JJ P 8 BT-1 3 4 ............Wa she r .............................................................................................. 1

135 .......... JJ P 8 BT-1 3 5 ............Sp r o ck e t .................................................................................... ........ 1

136 .......... JJ P 8 BT-1 3 6 ............Square Sp a c e r ............................................................................... .... 1

137 .......... JJ P 8 BT-1 3 7 ............Gea r .................................................................................................. 1

138 .......... JJ P 8 BT-1 3 8 ............Gea r Bra c k e t ...................................................................................... 1

139 .......... JJ P 8 BT-1 3 9 ............Sp r ing ................................................................................................ 1

140 .......... JJ P 8 BT-1 4 0 ............Ke y .................................................................................................... 1

141 .......... JJ P 8 BT-1 4 1 ............Pan Head Machine Screw .................................M3x18........................ 2

142 .......... TS-2361031 ............Lock Washer ....................................................M3 ............................. 2