Page 1

OWNER'S MANUAL

JDS-12B Benchtop 12” Disc Sander

(708432K shown with optional stand 708438 and Canister Filter 708434)

JET P.O. BOX 1349 Phone: 253-351-6000

WMH Tool Gr oup Auburn, W A 98071- 1349 Fax: 1-800-274-6840

www.wmhtoolgroup.com e-mail jet@wmhtoolgroup.com M-708433 05/02

Page 2

This manual has been prepared for t he owner and operators of a JDS-12B Sander . Its purpose, aside

from machine operation, is to promote safety through the use of accepted correct operating and

maint enance procedures. Completely r ead the safety and m aintenance i nstructions bef ore operati ng or

servi cing the mac hine. To obtai n maxi mum life and effic iency from your JET Sander, and to aid in using

the machine safely, r ead this manual thoroughly and f ollow instructions carefully.

Warranty & Service

The WMH Tool Gr oup warrant s every product it sells. If one of our tools needs servic e or r epair, one of

our Authorized Repair Stations located throughout the United St ates can give y ou quick serv ice.

In most cases, any one of these W M H Tool Group Repai r S tations can authorize warranty repair, assist

you in obtai ning parts, or perform rout ine maint enanc e and major repair on your JET, P erform ax, Wilt on,

or Powermatic tools.

For the nam e of an Authorized Repair Stat ion in your area, please call 1-800-274- 6848, or visit

www.wmhtoolgroup.com

More Information

Remember , the WMH Tool Group is consistently adding new products to the li ne. For complete, up-todate product i nformation, check with your local WMH T ool Group distributor, or visit

www.wmhtoolgroup.com

WMH Tool Group Warranty

The WMH Tool Gr oup ( including P er formax, Wilton and P owermatic brands) makes every effort to

assure that its product s meet high quality and durability standards and war r ants to the origi nal retail

consumer/purc haser of our products that each product be fr ee from defects in materials and

workmanship as follow: 1 YEAR LIMI T E D WARRANTY O N ALL PRO DUCTS UNLESS SPECIFIED

OTHERWISE. This War r anty does not apply to defects due direct ly or indi r ec tly to m isuse, abuse,

negligence or accidents, normal wear-and-tear, r epair or alter ations outside our f ac ilities, or to a lack of

maintenance.

THE WMH TO O L GROUP LIMIT S ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN,

ANY IMPLIED WARRANTIES OR MERCHANTIBILITY AND FITNESS ARE EXCLUDED. SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO

THE ABOVE LIMITATION MAY NOT APPLY TO YOU. T HE WMH TOOL GROUP SHALL IN NO

EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. S OME STATES DO NOT ALLOW THE EXLUSION OR LIMITA TION OF I NCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the produc t or part must be returned for examinat ion, postage

prepaid, to an A uthorized Repair S tation designated by our office. Proof of purchase date and an

explanat ion of the c omplaint must accompany the merchandise. If our i nspect ion discloses a defect, we

will either repair or replace the product, or refund the purchase pric e if we cannot readily and quickly

provide a repair or replacement, if you ar e willing to accept a refund. We will return repai r ed product or

replacement at JET’S expense, but if it i s deter mined there is no defect, or that the defec t resulted f r om

causes not within the scope of JET’S warranty, then the user must bear t he c ost of storing and ret ur ning

the product. This warranty gives you specif ic legal rights; you may also have other rights which vary

from state to state.

The WMH Tool Gr oup sel ls through distri butors only. Mem ber s of the WMH Tool Gr oup r eserve the

right to effec t at any time, without prior notice, those alterati ons to par ts, fittings, and accessory

equipment whi c h they may deem nec essary for any reason whatsoever.

2

Page 3

WARNING

Wear eye protection.

Always keep guards in place an d in prop er operating condition. Do not operate the machine

without the guards for any reason.

This disc sander is intended to be used with wood and wood products only. Use of this disc

sander and a dust collector with metal products is a potential fire hazard.

Support the workpiece adequately at all times during operati on; maintai n control of the work at

all times.

This disc sander is designed and intended for use by properly trained and experienced

personnel only. If you are not familiar with the proper and safe operation of a disc sander, do

not use until proper training and knowledge has been obtained.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form a habi t of checking to see that keys and

adjusting wrenches are removed from the machine before turning it on.

• KEEP THE WORK AREA CLEAN. Cluttered areas and benches invite accidents.

• DON’T US E IN A DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locati ons,

or expose them to rain. Keep work area well light ed.

• KEEP CHILDREN AWAY. Al l visitors should be kept a saf e distance from the work area.

• MAKE THE WORKSHO P KIDPROOF with padlocks, master swatches, or by r emoving starter keys.

• DON’T FORCE THE M ACHINE. It will do the job better and safer at the rate for which i t was

designed.

• USE THE RIGHT TOOL. Don’t force a machine or attachment to do a job for which it was not

designed.

• USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good condition.

When usi ng an extension cord, be sure t o use one heavy enough to carr y the current your machine

will draw. An under sized cord will cause a drop in the line voltage resulting in power loss and

overheating. The t able following shows the correct size to use depending on the cord length and

nameplat e ampere rati ng. If i n doubt, use the next heavier gauge. Remember , the small er the

gauge number, t he heavier the cord.

Volts Total Length of Cord in Feet

120V 25 50 100 150

16 16 14 12

• WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught i n mov ing parts. Nonslip footwear is recom mended. Wear protective

hair covering to c ontain long hair .

• ALWAYS USE SAFETY GLASSES. Also use face or dust masks if the c utting operation is dusty.

Ever y day eyeglasses only have impact r esi stant lenses; they are not safety glasses.

• DON’T OVERREACH. Keep proper f ooting and balance at all ti mes.

• MAINTAIN T OOLS WITH CARE. Keep tools sharp and clean for best and safest performance.

Follow i nstr uc tions for l ubricating and c hanging accessories.

AWG

3

Page 4

• ALWAYS DISCONNECT THE MACHINE FROM THE POWER SOURCE BE FORE SERVICI NG.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure the switch is i n the off position

before pl ugging in.

• USE RECOMMENDED ACCESSORIES. The use of acc essories and attachments not

recommended by JET m ay c ause hazards or r isk of injury to persons.

• NEVER STAND ON A MACHINE. Serious injury could occur if the machine is tipped.

• CHECK DAMAGED PARTS. Before furt her use of the machine, a guard or other part that is

damaged should be carefully c hec k ed to determine that it will operate properly and perf or m its

intended function - chec k for ali gnment of moving parts, binding of moving parts, breakage of parts,

mounti ng, and any other conditions that may affec t its operation. A guard or other part that is

damaged should be properly repaired or replaced.

• NEVER LEAVE THE MACHINE RUNNING UNATTENDED. TURN PO WER O F F. Don’t leave the

machine until i t comes to a com plete stop.

• SOME DUST CREATED by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to cause cancer, birth defec ts or other reproductive harm. Some

examples of these chem icals are:

• Lead from lead based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

• Your risk from those ex posures varies, dependi ng on how often you do this ty pe of work. To reduce

your exposure to these chemical s: work in a well ventilated area, and work with approved safety

equipment , such as those dust masks that are specifically designed to filter out microscopi c par ticles

• DO NOT oper ate tool while under the influence of drugs, alcohol or any m edication.

• AVOID kickback by sanding in accor danc e with directional arrows. Sand on downward side of disc.

Sanding on the upward side could cause the workpiece to fly up causing i njury.

• SAND with the grain of the wood.

• DO NOT sand pi ec es of material that are too small to be safely supported.

• WHEN sanding a lar ge workpiece, provide additional support at t able height.

• ADDITIONAL INFORMATION regarding the safe and proper oper ation of t his product is available

from the National Safety Counc il, 1121 Spring Lake Drive, Itasca, IL 60143-3201, in the Accident

Prev ention Manual for Industrial Operati ons and al so i n the safety Data Sheets provi ded by the NSC.

Please also refer to the Am er ican National Standards Institute ANSI 01.1 Safety Requirements for

Woodworking Machinery and t he U.S. Departm ent of Labor OS HA 1910.213 Regulations.

• SAVE THESE INSTRUCTIONS refer to them often and use them to instruct others.

4

Page 5

Grounding Instructions

Caution: This tool must be grounded while in use to protect the operator from electric shock.

In the event of a malf unc tion or breakdown, groundi ng pr ovides a path of least resistance for electric

current to r educ e the risk of electric shock. This tool is equipped with an elect r ic cord having an

equipment -grounding conductor and a gr ounding plug. The plug must be plugged into a matc hing outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modi fy the pl ug pr ovided. If it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conduct or c an r esul t in a risk of electric shock. The

conductor, with insulation having an out er surface that is green with or without yellow stripes, is the

equipment -grounding conductor. If repair or replacement of t he electric c or d or plug is necessary, do not

connect the equi pment-groundi ng c onduc tor to a li ve terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not c ompletel y

understood, or if in doubt as to whether t he tool is properl y gr ounded. Use only three wire extension

cords that have three-prong grounding plugs and three-pole r ec eptacles that accept the tool’s plug.

Repair or replace a damaged or worn cord immedi ately.

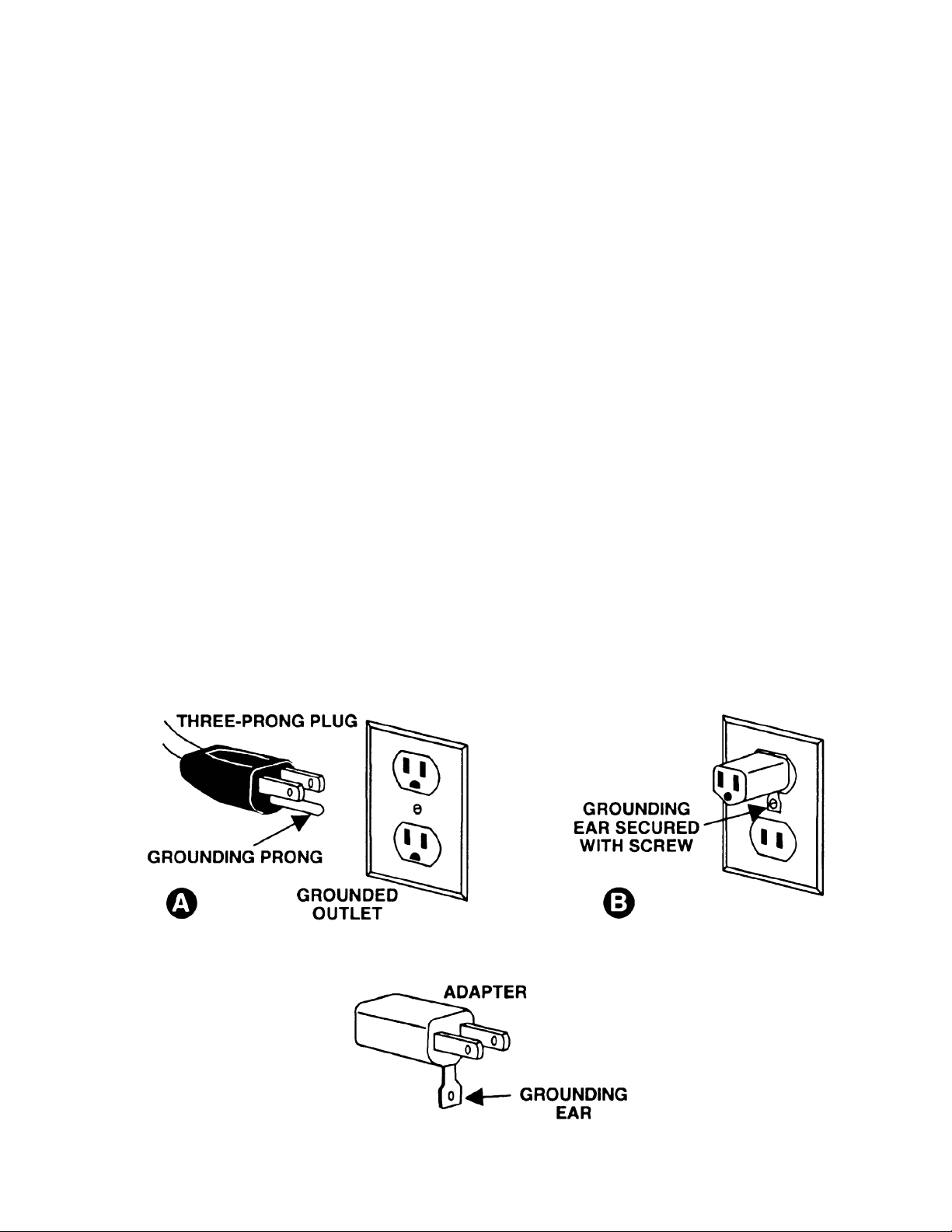

115 Volt Operation

As received from the factory, your sander is ready to run at 115 volt operation. This sander, when wired

for 115 volt, is intended for use on a circuit that has an outlet and a plug that look s l ike the one illustrated

in (A). A temporary adapter, which looks l ike the adapter as illustrated in (B), may be used to connect

this plug to a two-pole receptacl e, as shown in (B) if a proper ly grounded outlet is not av ailable. The

temporary adapter should only be used until a properly gr ounded outlet can be inst alled by a qualified

electrician. T his adapter is not applicable in Canada. The green colored rigid ear, lug, or tab,

extendi ng from the adapter, must be c onnec ted to a permanent gr ound such as a properly grounded

outlet box, as shown in (B).

5

Page 6

230 Volt Operation

If 230V, single phase operation is desired, the following instr uc tions must be followed:

1. Disconnect the machine from the pow er source.

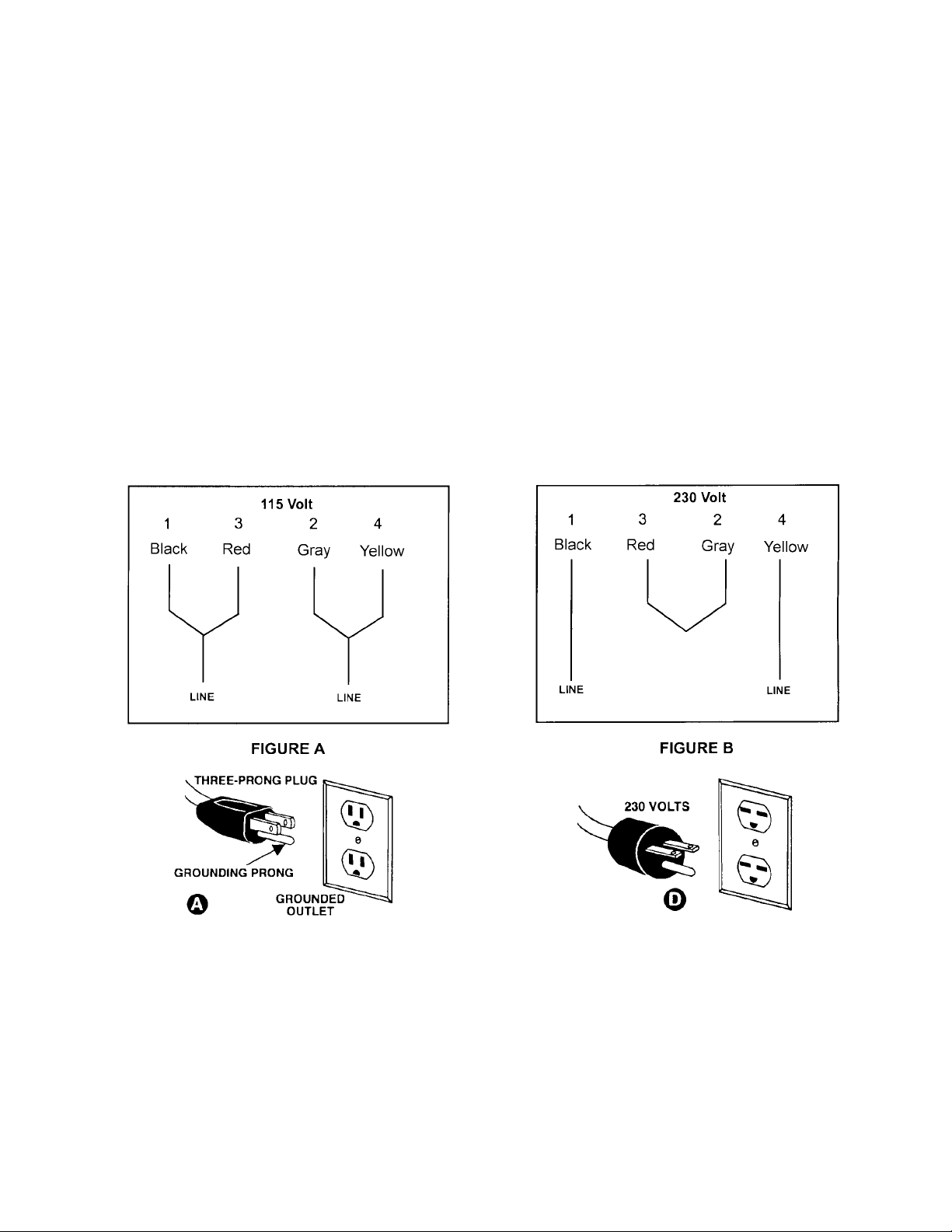

2. This JET sander is supplied with four motor leads that ar e c onnec ted for 115V operation, as shown in

Figure A. Reconnect these four motor leads for 230V operation, as shown in Figure B.

3. The 115V attachment plug (A), supplied with the sander, must be replaced wit h a UL/CSA listed plug

suitable for 230V operati on ( D) . Contact your local Authorized JET Service Cent er or qualified

electrician f or pr oper pr oc edures to install the plug. The sander must comply with all l oc al and

national c odes after the 230 volt plug is installed.

4. The sander with a 230 v olt plug should onl y be c onnected to an outlet havi ng the same configuration

(D). No adapter is available or should be used with the 230 volt plug.

Important: In all c ases (115 or 230 volts), make certain the receptacl e in question is properly grounded.

If you ar e not sure, have a r egistered electr ician check t he r eceptacle.

6

Page 7

Specifications JDS-12B

Stock Number................................................................................................................................708433

Disc Diameter.......................................................................................................................................12”

Table Tilt......................................................................................................................15° Up - 45° Down

Dust Chute Diameter..............................................................................................................................4”

Disc Tabl e .................................................................................................................16-3/8" W x 9-3/4” D

Motor..............................................................................................................1 HP, 115/230V, 60Hz, 1P h

Impeller.................................................................................................................................9” x 1-13/16”

Overall Dimensions...........................................................................................21” W x 25-5/8" D x 21” H

Net Weight (approx.) ....................................................................................................................100 Lbs.

Table of Contents

Warranty .................................................................................................................................................2

Warnings ....................................................................................................................... .......................3-4

Grounding Instructions.............................................................................................................................5

115V Operati on .......................................................................................................................................5

230V Operati on .......................................................................................................................................6

Specifications..........................................................................................................................................7

Table of Contents....................................................................................................................................7

Contents of the Shipping Carton..............................................................................................................8

Tools Required for Assembly & A djustment .............................................................................................8

Unpacking ...............................................................................................................................................8

Stand Assembly ( optional accessory).......................................................................................................9

Sander Assembly.....................................................................................................................................9

Table Adjustment...................................................................................................................................10

Sanding Disc Replacement....................................................................................................................10

Center Point ..........................................................................................................................................11

Brake.....................................................................................................................................................11

On/Off Switch........................................................................................................................................11

Lubrication.............................................................................................................................................11

Motor.....................................................................................................................................................11

Dust Collection ......................................................................................................................................11

Canister Filter (optional accessory)........................................................................................................12

Cleaning the fil ter............................................................................................................................12

Optional Accessories.............................................................................................................................12

Troubleshooting.....................................................................................................................................13

Parts Breakdowns & Parts List..........................................................................................................14-17

Wiring Diagram .....................................................................................................................................18

The specif icat ions in thi s manual are giv en as general inf ormat ion and are not bindi ng. T he W MH Tool

Group reserves the right to ef fect, at any tim e and without prior notice, changes or alt erations to parts,

fittings, and accessory equipment deemed nec essary for any reason whatsoever.

7

Page 8

Contents of the Shipping Carton

JDS-12B Benchtop Sander

1. Sander

1. Sanding Disc

1. Table

1. Miter Gauge

1. Inlet

1. Inlet Gasket

1. Owner's Manual

1. Warranty Card

Hardware Kit

4. Hex Head Bolt M 10x40

8. Flat Washer M10

4. Lock Washers M10

4. Hex Nut M10

4. Hex Head Bolt M 6x16

1. Center Point

1. Right Angle Hex W r enc h 3mm

1. Filler Bar

1. Socket Head Cap Screw M5x 8

OS-12DS Stan d (optional accessory)

4. Stand Legs

4. Stand Supports

Hardware Kit

16. Carr iage Bolt M8x16

16. Hex Nut M8

CF-12DS Canist er Filter (optional accessory)

1. Canister Filter

1. Plastic Elbow

1. Grounding Wire

Tools Required for Assembly &

Adjustments

1. 13mm Wrench or socket

1. Combination Square

(708432K shown with optional stand 708438 and

Canister Filter 708434)

WARNING

Read and understand the entire contents of

this manu al before attemp t ing assembly or

operation of the disc sander!

Failure t o comply may cause serious inj ury!

Unpacking

1. Remove all contents from the shipping

carton(s).

2. Report any damage to your distri butor.

3. Do not discard any shipping material until

the sander has been assembled and is

running properly.

8

Page 9

Stand Assembly (optional accessory)

1. Match the hole patterns in the stand legs

with the hole patterns in the stand supports.

Mount the legs to the outside of the supports

using sixteen M8x16 carriage bolts and

sixteen M8 flange lock nuts, figure 1. Do

not tighten until the stand has been

assembled and is sitting level on the floor.

2. Bolt the sander to the stand with four

M10x40 hex cap bolts, eight M10 flat

washers, four M10 lock washers and four

M10 hex nuts

Sander Assembly

1. Mount the sander to JET’s open stand with

four M10x40 hex head bolts, eight M10 flat

washers, four lock washers, and four hex

nuts. Tight en the nuts t o secure the sander

to the stand.

Note: If you are going to use the sander as

a benchtop unit mount the sander to the

workbench with the suppli ed bolts.

2. Unscrew the knob (A, Fig. 2), remove the

washer (B, Fig. 2) and the trunnion holder

(C, Fi g. 2). Repeat f or opposi te side.

3. Lift the t able ( D, F i g. 2) i nt o positi on and set

on top of t he spl it pins and threaded shaft.

4. Reinstall the trunnion holder, washer and

knob. Repeat for opposite side.

5. Make sure the trunni on and trunnion holder

engage and tighten t he k nob.

6. Place the gasket (E, Fig. 3) against the

sander base and mount the i nlet port (F, Fi g.

3) to the sander with four M6x16 hex cap

bolts (G, Fig. 3).

Warning

Avoid kickback by sanding in accordance

with directional arrow. Sand on downward

side of disc. Sanding on the upward side

could cause the workp iece to fly up causing

injury! Failure to comply may cause serio us

injury!

9

Page 10

Table Adjustment

The table stops have been set-up at the f ac tory .

However, if you run into a problem, or want to

check the table follow the below listed steps.

1. Loosen lock knobs (B, Fig. 4) and mov e t he

table to the 90 degree position. Tighten

knobs and place a square (A, Fig. 4) agai nst

the table and di sc. The square should rest

flat against the table and disc.

2. If adjustment is needed move the table so

that it rests 90 degrees from the table, and

loosen the hex nut (D, Fig. 5) and tighten

the set screw (C, Fig. 5) unti l it cont acts t he

table surface. Tighten hex nuts. This will

properly adjust the 90-degree stop.

3. Loosen t he l ock knobs (F , F ig. 5) and t i lt the

table up just enough to pivot the stop (E, Fig.

5) out of the way.

4. Ti lt the table down until it hi ts the 45 degree

stop (G, Fig. 5). Tighten lock knobs, and

check the table with a combination square.

5. If adjustm ent is needed, loosen the hex nut

(H, Fig. 5) and adjust the socket head cap

screw (G, Fig. 5) unt il it contac ts the table.

Tighten hex nuts.

6. Always maintain a gap of approximately

1/16” between the table edge, and disc. If

adjustment is necessary loosen hex cap

bolts (I, Fig. 5) and move the table into

position. Tighten hex c ap bolts.

7. The table tilts between 15° up - 45° down by

loosening the lock knobs and tilting the table

to the desired angle. Tighten the knobs.

8. If you want to tilt the table up you need to

pivot the stop (E, Fig. 5) out of the way.

Sanding Disc Replacement

1. Disconnect machine from the power

source.

2. Remov e the knobs (J, Fig. 6), washers (K,

Fig. 6), and trunnion holders (L, Fig. 6)

followed by the table assembl y ( M , Fig. 6).

3. Remove old sanding disc by striping from

wheel. Use a cleaner and putty knife to

remove the residue. Make sure the disc

plate is clean and dry.

4. Press the new disc firmly int o place.

10

Page 11

Center Point

The center point (A, Fig. 7) provided with the

sander can be used for sanding circles. Slide

the center point into the miter slot that is

perpendicular to the sanding disc. The radi us of

the desired circle should be the distance from

the center point to the sanding disc. Lock the

center point in position by tightening the set

screws. Cut the wood to the approximate

diameter and press on to the center point.

Rotate the wood until the desired results are

achieved.

Filler Bar

The f iller bar (H, Fig. 7) should be added when

sanding small workpieces. Secur e in pl ace with

the socket head cap screw (I, Fi g. 7) . When not

using the filler bar thread the socket head cap

screw (I, Fig. 7) in the tapped hole as a stop.

Brake

After you have t urned t he sander “OF F” y ou can

press the brake (B, Fi g. 7) to slow, or stop the

sanding disc.

On/Off Switch

The machi ne can be t urned “O N” by m oving t he

switch (D, Fig. 8) to the “UP” posi tion. The k ey

(E, Fig. 8) can be r em ov ed when the m achi ne i s

in the “OFF” position. With the key removed

the switch will not operate.

Lubrication

You may need to lubricate the trunnion, and

trunnion hol der (G, Fig. 8) if the table does not

tilt smoothly.

Motor

Make frequent i nspecti ons of the m ot or f an c over,

and blow out (with low pressure air hose) or

vacuum any accumulation of foreign material in

order to maintain normal mot or ventilation.

WARNING

All electrical connections must be done by

a qualif ied electrici an. All adjust ments or

repairs must be done with the sander

disconnected from th e power source,

unplugged. Failure to comply may result in

serious injury!

The JDS-12B disc sander is rated 115V/230V,

Prewired 115V.

If you want t o run the JDS- 12B on 230V refer to

the wiring diagram found on the inside of the

switch box cover (F, Fig. 8).

Before hooking up to the power source, make

sure that the switch is in the off position.

Dust Collection

The disc sander has a built in f an designed to

suck the saw dust away from the sanding disc

and exhaust through the inlet (C, Fig. 7). For

best results hook the sander to JET’s optional

accessory canister filter (#708434).

The sander can also be attached to a dust

collector using a 4” diameter hose and clamp.

JET of fers a wide v ar iety of hoses, adapters and

dust collec tors.

11

Page 12

Canister Filter (optional accessory)

1. Remove the inlet port that came with the

sander.

2. Mount the plastic elbow (A, Fig. 9) to the

sander using the same hardware (B, F ig. 9)

from the inlet port.

3. Connect the filter (C, Fig. 9) to the elbow

and turn counter-cl ockwise so that i t loc ks in

place.

WARNING

Static electricity will build up in the filter

during operation. The filter ground must be

attached to the machine ground, and to the

filter. Failure to comply may result in

fire/loss of property, or personal injury!

4. Remove the screw (D, Fig. 9) from the

sander base. Attach the end of the

grounding wire to the screw and thread back

in to the base.

5. Attach the grounding clip (E, Fig. 9) to the

metal part of the filter. This will prevent

static electricity from building up in the filter .

Cleaning the Filter

CAUTION

Wearing a part icle mask/respirator for

protection against fine dust particles during

cleaning is highly recommended.

Clean the canister filter frequently to keep the

sander’s perform anc e at its optimum. T o c lean:

1. Disconnect the machine from th e power

source.

2. Take of f the gr ounding cli p and remov e t he

filter (C, F ig. 9) by turning clockwise.

3. Empty the contents into an appropriate

container.

4. The filter can be cleaned with a low

pressure air hose. Blow f rom t he outside of

the filter to clean the dust particles. For

best results check and empty the filter

frequently.

5. Install the filter and reattach the grounding

clip.

Optional Accessories

708438: Open Stand

708434: Canister Filter

57620025: JET St ik Abrasive Belt and Disc

Cleaner.

Dust Coll ect ors and Accessories see a JET

Distributor.

JDS-12B Sanding Disc PSA Aluminum Oxide

“J” Weight Cl oth Back.

12” 36 Grit 50 Grit 60 Grit

Stock

Number

Master

Carton

12” 80 Grit 100 Grit 120 Grit

Stock

Number

Master

Carton

57698525 57698650 57698750

25 50 50

57698850 57698950 57699050

50 50 50

12

Page 13

Troubleshooting

Trouble Possible Cause Solution

Sander will not start

Sanding disc does not come

up to speed

Machine vi brates excessively

1. Sander unplugged fr om wall

or motor

2. Fuse blown or circui t breaker

tripped

3. Cord damaged

1. Extension cor d too light or

too long

2. Low current

1. Stand or base on uneven

surface

1. Check all plug connections

2. Replace fuse or reset c ircuit

breaker

3. Replace cord

1. Replace with adequate siz e

and length cord

2. Contact a quali fied

electrician

1. Adjust stand or base so that

it rests evenly on the floor

2. Bolt down

Sanded edge not square

Sanding marks on wood

1. Table not square to sanding

disc

1. Work held still

2. Wrong grit sanding disc

3. Feed pressure too great

4. Sanding against the gr ain

1. Use a square to adjust table

to sanding disc

1. Keep workpiece moving

2. Use coarser grit f or stoc k

removal and fine grit for

finish sanding.

3. Never force workpiece

4. Sand with the grain

13

Page 14

Disc Sander Breakdown

14

Page 15

Parts List For The JDS-12B Benchtop Disc Sander

Disc Sander

Index Part

No. No. Description Size Qty

1..........612131......................... Guard Base........................................... ...............................................1

2..........MH612001 ...................Motor.....................................................1 HP, 1Ph 110V/220V............. 1

............ JDS12B-MFC............... Motor Fan Cover (not shown)................ ............................................... 1

............ JDS12B-MF.................Motor Fan (not shown)........................... ...............................................1

............ JDS12B-CS..................Centrifugal Switch (not shown)............... ............................................... 1

............ JDS12B-CC.................Capacitor Cover (not shown) ................. ...............................................1

............ JDS12B-JBC................ Junction Box Cover (not shown) ............ ...............................................1

............ JDS12B-SC..................Starting Capacitor (not shown)............... 200M FD, 125VAC.....................

............ JDS12B-RC.................Running Capacit or (not shown)..............10uF, 250V ...............................

3..........KS050565 .................... Key........................................................5x5x65....................................1

4..........994534......................... On/Off Switch........................................ ...............................................1

5..........998621......................... Strai n Relief........................................... ...............................................1

6..........IC100001 .....................Power Cord............................................ ...............................................1

7..........TS-1551071 ................. Spring Washer.......................................M8 ..........................................4

8..........SJ080400..................... Pan Head Socket Bolt............................ M8x20.....................................4

9..........612132......................... Fan Blade..............................................9”............................................1

10........ 612133......................... Parti tion................................................. ...............................................1

11........ SF069200 ....................Pan Head Bolt w/Flange........................M6x8.......................................5

12........ 612134......................... Sanding Disc......................................... ...............................................1

13........ SS060200 .................... Set Screw..............................................M6x8.......................................1

14........ 612113......................... Washer.................................................. ...............................................1

15........ SM089400.................... Countersunk Head Bolt..........................M8x16.....................................1

16........ 57698525.....................12” Disc Sandi ng P aper 36 Grit ............. .............................................25

............ 57698650.....................12” Disc Sandi ng P aper 50 Grit ............. .............................................50

............ 57698750.....................12” Disc Sandi ng P aper 60 Grit ............. .............................................50

............ 57698850.....................12” Disc Sandi ng P aper 80 Grit ............. .............................................50

............ 57698950.....................12” Disc Sandi ng P aper 100 Grit............ .............................................50

............ 57699050.....................12” Disc Sandi ng P aper 120 Grit............ .............................................50

17........ 612136......................... Front Cover ........................................... ...............................................1

18........ SF069200 ....................Pan Head Bolt w/Flange........................M6x8.......................................5

19........ TS-1504071 ................. Socket Head Cap Screw........................M8x35.....................................1

20........ TS-1540061 ................. Hex Nut.................................................M8 ..........................................1

21........ TS-1550061 ................. Fl at Washer...........................................M8x18.....................................1

22........ 612038......................... Trunnion Holder (A)............................... ...............................................1

23........ PS062600 .................... Spring Pin..............................................6x26........................................4

24........ SS081200 .................... Set Screw..............................................M8x60 .....................................2

25........ TS-1550061 ................. Fl at Washer...........................................M8x18.....................................2

26........ 612098......................... Knob...................................................... M8 ..........................................2

27........ 612052......................... Trunnion Holder (B)............................... ...............................................1

28........ 612135......................... Tabl e..................................................... ...............................................1

29........ 612046......................... Trunnion................................................ ...............................................2

30........ TS-1551061 ................. Lock Washer .........................................M8 ..........................................4

31........ TS-1490021 ................. Hex Head Bolt .......................................M8x16 .....................................4

32........ 612010......................... Locating Block....................................... ...............................................1

33........ PS053600 .................... Spring Pin..............................................5x36........................................1

34........ TS-1540041 ................. Hex Nut.................................................M6 ..........................................1

35........ TS-1523071 ................. Set Screw..............................................M6x25.....................................1

36........ 612116......................... Brake..................................................... ...............................................1

37........ 612118......................... Brake Fixed Base.................................. ...............................................1

38........ PS042600 .................... Spring Pin..............................................4x26........................................1

39........ SP040200 .................... Pan Head Bolt .......................................M4x10.....................................3

15

Page 16

Index Part

No. No. Description Size Qty

40........ 612140......................... Spri ng.................................................... ...............................................1

41........ WF051210...................Flat Washer...........................................M5x12.....................................1

42........ 612115......................... Stop Handle........................................... ...............................................1

43........ TS-1491061 ................. Hex Head Bolt .......................................M10x40...................................4

44........ TS-1550071 ................. Fl at Washer...........................................M10x20 ...................................8

45........ TS-1551071 ................. Lock Washer .........................................M10.........................................4

46........ TS-1540072 ................. Hex Nut.................................................M10.........................................4

47........ 612137......................... Packing ................................................. ...............................................1

48........ 612145......................... Inlet.......................................................4”............................................ 1

49........ TS-1482031 ................. Hex Head Bolt .......................................M6x16 .....................................4

50........ 612099......................... Sponge.................................................. ...............................................1

51........ TS-1551021 ................. Lock Washer .........................................M4 ..........................................2

52........ AB198101 .................... Miter Gauge Assembly .......................... ...............................................1

53........ AB612143 .................... Circle Gauge Assembly (A S M ) .............. ...............................................1

57........ 612117......................... Sponge Gasket ...................................... ...............................................1

58........ SP059200 .................... Pan Head Bolt .......................................M5x8.......................................1

59........ WE050000................... Star Washer..........................................M5 ..........................................1

60........ 612171......................... Filler Bar................................................ ...............................................1

61........ TS-1502011 ................. Socket Head Cap Screw........................M5x8.......................................1

* ..........JDS12B-HK.................. Hardware Kit (not shown)....................... .................................................

............ JDS12B-WL................. Warning Label (not shown).................... .................................................

............ JDS12B-ID................... I.D. Label (not shown)............................ .................................................

............ JDS12B-JL................... JET Label (not shown)........................... .................................................

Optio nal Accessory

54........ 612147......................... Elbow .................................................... ...............................................1

55........ 331022......................... Filter...................................................... ...............................................1

56........ 331033......................... Grounding Clip ...................................... ...............................................1

16

Page 17

Open Stand Breakdown (optional accessory)

JDS-12B Stand Assembly (optional accessory)

Index Part

No. No. Description Size Qty.

1..........612141............................. Stand Leg ...................................................... ...................................4

2..........612142............................. Stand Support ............................................... ...................................4

3..........SC089400........................ Carriage Bolt ................................................. M8x16 ......................16

4..........NF081300 ........................ Flange Lock Nut............................................ M8............................16

* ..........OS12DS-HK.....................Hardware Kit (not shown)............................... .....................................

17

Page 18

Wiring Diagram

18

Loading...

Loading...