Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

10" Job Site Table Saw

Benchtop Series – Model No. JBTS-10MJS

R

CUS

174315

WALTER MEIER (Manufacturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-707000

Ph.: 800-274-6848 Revision A3 10/2010

www.walt er meier.c om Copyright © 2010 Walt er Meier (M anufacturi ng) Inc.

Page 2

Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, o ne of our

Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of these

Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine

®

maintenance and major repair on your JET

6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with your

local Walter Meier distributor, or visit waltermeier.com.

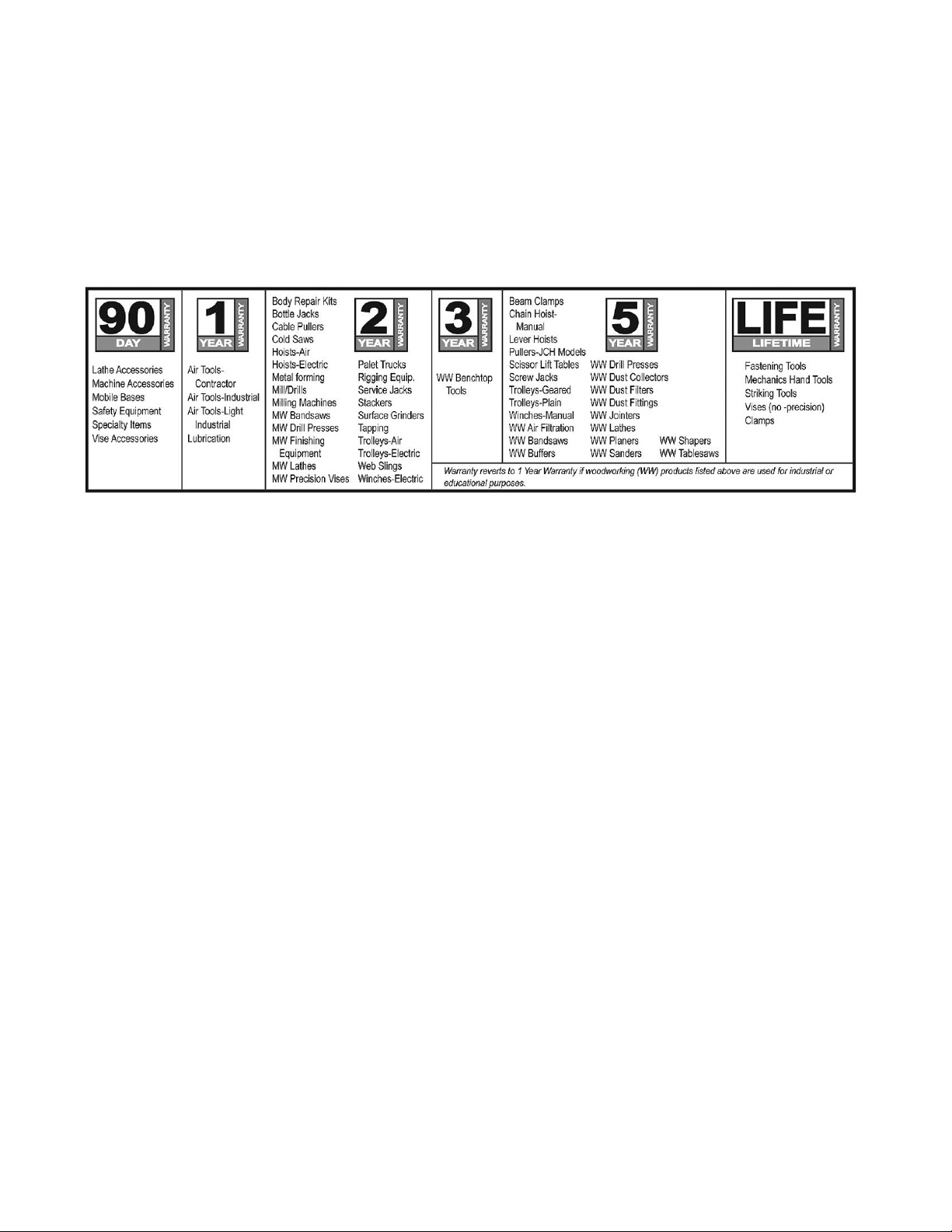

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW stands for Metalworking, WW

stands for Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools, abrasives

and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Three Year, Five Year and Lifetime Warranties do not cover products used for industrial or educational purposes. Products

with Three Year, Five Year or Lifetime Warranties that are used for industrial or education purposes revert to a One Year

Warranty. This warranty does not cover defects due directly or indirectly to misuse, abuse, negligence or accidents, normal

wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for e xamination, postage prepaid, to a location designated by us. For the na me of the

location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the merchandise. If our

inspection discloses a defect, we will repair or replace the product, or refund the purchase price, at our option. We will return

the repaired product or replacement at our expense unless it is determined by us that there is no defect, or that the defect

resulted from causes not within the scope of our warranty in which case we will, at your direction, dispose of or return the

product. In the event you choose to have the product returned, you will be responsible for the shipping and handling costs of

the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED

WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG

THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO E VENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general infor mation and

are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice, those alterations to parts,

fittings, and accessory equipment which they may deem necessary for any reason whatsoever. JET

sold in Canada by Walter Meier.

tools. For the name of an Authorized Service Center in your area call 1-800-274-

®

branded products are not

2

Page 3

Table of Contents

Warranty and Service................................................................................................................................2

Table of Contents .....................................................................................................................................3

Warnings..................................................................................................................................................4

Table Saw Safety .....................................................................................................................................6

Spe cifi cation s ...........................................................................................................................................7

Definitions and Terminology ......................................................................................................................7

El ectric al ..................................................................................................................................................8

Grounding Instructions ...........................................................................................................................8

115 Volt Operat ion Only .........................................................................................................................8

Extension Cords ....................................................................................................................................8

Fea tures ..................................................................................................................................................9

Shipping Contents .................................................................................................................................. 10

Ass embly ............................................................................................................................................... 12

Stand.................................................................................................................................................. 12

Attaching Saw to Stand ........................................................................................................................ 12

Mounting the Saw to Work Surface ....................................................................................................... 13

Rear Table Extension .......................................................................................................................... 13

Handwheel Handle .............................................................................................................................. 14

Installing the Blade .............................................................................................................................. 14

Removing the Blade ............................................................................................................................ 14

Blade Guard Assembly ........................................................................................................................ 15

Installing the Pus h-stick Storage........................................................................................................... 16

Storage............................................................................................................................................... 16

Adju s tmen ts ........................................................................................................................................... 17

Setting up the Stand ............................................................................................................................ 17

Folding the Stand ................................................................................................................................ 17

Adjusting t he Table Insert .................................................................................................................... 17

Aligning the Blade Guard Splitter .......................................................................................................... 18

90° and 45° Positive Stop Adjustment ................................................................................................... 19

Blade Tilt Pointer ................................................................................................................................. 19

Blade Parallel to the Miter Slot ............................................................................................................. 20

Adjusting t he Miter Gauge .................................................................................................................... 21

Rip Fence Adjustment ......................................................................................................................... 21

Rip Fence Indicator ............................................................................................................................. 22

Table Exte nsio n Sca le Pointer.............................................................................................................. 22

Rear Table Extension Adjustment......................................................................................................... 22

Adjusting t he Locking Lever ................................................................................................................. 22

Additional Blade Adjustments ............................................................................................................... 20

Operation ............................................................................................................................................... 23

Basic Saw Operations ......................................................................................................................... 23

Cutting Operatio ns .............................................................................................................................. 24

Mai ntenance .......................................................................................................................................... 28

Push Stick Construction .......................................................................................................................... 29

Troubleshooting ...................................................................................................................................... 30

Parts ...................................................................................................................................................... 31

Ordering Replacement Parts ................................................................................................................ 31

Table Saw........................................................................................................................................... 31

Mobile Sta nd ....................................................................................................................................... 38

Wiring Diagram....................................................................................................................................... 40

The specifications in this manual are given as general information and are not binding. Walter Meier

(Manufacturing) Inc. reserves the right to effect, at any time and w ithout prior notice, chang es or alterations to

parts, fitt ings, and accessory equipme nt deemed necessary f or any reason whats oever .

3

Page 4

Warnings

1. Read and understand t he entire owners' ma nual before at t empting assemb ly or oper ation.

2. Read and understand the war nings post ed on the machine and in this manual. Fa ilure t o comply with

all of these warnings may cause serio us injury.

3. Replace the warning labels if they become obscured or removed.

4. This saw is designed and intended for use by properly t r ai ned and experienced personnel only. If you

are not familiar w it h t he proper and safe operation of a table saw, do not use until proper tr aining and

knowledge have bee n obtai ned.

5. Do not use this saw for other than its intended use. If used for other purposes, Walter Meier

(Manufacturing) Inc., disclaims any real or implied w arranty and holds itself harmless f rom any injury

that may result from that use.

6. Always wear approved safety glasses/f ace shields while using this table saw . Everyday eyeglasses

only have impact resistant lenses; they are not saf et y glasses.

7. Bef ore operat ing this saw, remove tie, rings, w atches and other jewelry, and roll slee ves up past the

elbows. Remove all loos e clothing and confine long hair. Non-slip footwear or anti-skid floor st r ips ar e

recommended. Do not wear gloves.

8. Wear ear pr otect or s (plugs or muf f s ) during exte nded periods of oper at ion.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemicals k nown to cause cancer, birt h defects or ot her reproductive harm. Some e xamples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonr y pr oducts.

• Arsenic and chromium fr om chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any m edication.

11. Make cer t ain the switch is in the OFF position before co nnecti ng the machine to the power supply.

12. Make cer t ain the machine is properly grounded.

13. Make all machine adjustme nts or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the mac hine before tur ning it on.

15. Keep safety guards in place at all times when the machine is in us e. If removed for maintena nce

purposes, use extreme cautio n and replace t he guards immed iately.

16. Make sure this machine is firmly secured to t he floor or bench before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignme nt of moving part s, binding of moving part s, break age of part s, mounting

and any other condit ions t hat may affect its oper ation. A guard or other part that is damaged s hould

be properly repaired or r eplaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighti ng.

19. Keep the floor around t he machine clean and free of sc r ap material, oil and grease.

4

Page 5

20. Don't use i n dangero us e nvironment. Don't use power t ools i n damp or w et locations, or expose t hem

to rain. Keep work ar ea well lighted.

21. Keep visitors a saf e dist ance from the wor k ar ea. Keep children away.

22. Make your workshop child proof with padlocks, master switches or by removing st ar t er keys.

23. Give your work undivided att ention. Looking aro und, carrying on a conversatio n and “horse-play” ar e

careless acts that can result in serious injury.

24. Maintain a balanced stance at all times so that you do not fall or lean against the blade or other

moving parts. Do not overreac h or use excessive for c e t o perfor m any machine operation.

25. Use the right tool at t he correc t speed and feed rate. Do not force a tool or at t achment to do a jo b f or

which it was not designed. The r ight t o ol will do t he job b e tter a nd sa fer.

26. Use recommended accessor ies; improper acc essor ies may be hazardous.

27. Maintain tools wit h care. Keep saw blades sharp and clean for the best and safest performance.

Follow instructions f or lubricating and c hangi ng accessories.

28. Disconnect tools bef or e ser vicing and w hen changing access or ies such as blades.

29. Make sure the work piece is securely attached or clamped t o t he table.

30. Turn off t he mac hine bef or e cleaning. Use a brush or co mpres sed air t o r emove chips or debris — do

not use your hand s.

31. Do not stand on the machine. Serio us injury co uld occur if the machine tips over.

32. Never lea ve the machine r unni ng unattended. Turn the power off and do not leave the machine until it

comes to a complete st op.

33. Remove loose items a nd unnecessary w or k pieces f r om the area befor e starting the machine.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if pr ecautions are not heeded, it may result in serious injury or possibly

even death.

5

Page 6

Table Saw Safety

1. Always use a saw blade g uard, splitt er and anti-kickb ack pawls for every t hrough–sawing operatio n.

Through–sawing operations are those in which the blade cuts completely through the workpiece

when ripping or crosscutting. Always be sure the blade guard is tightened securely.

2. Always hold work firmly against the miter gauge or rip fence.

3. Always use a p ush stick (pr ovided with t his saw), especially w hen ripping narrow stock. Refer to the

ripping i nstructions in t his Operator’s M anual w here the push st ick is cover ed in det ail. A patt ern for

making your own push stick is included o n page 29.

4. Never perfor m any operatio n by freehand, w hich means using only your hands to support or guide the

workpiece. Alway s use either the fence or the miter gauge to position and guide the work .

Warning: Freehand cutting is the major cause of kickback and finger/hand amputations. Never

use the miter gauge and fence simultaneously.

5. Never stand or have any part of y our body in line wit h the path of the saw blade. Keep your hands out

of the saw blade path.

6. Never reach behind or over the cutting tool for any reason.

7. Remove the rip fence when crosscutt i ng.

8. Do not use a molding head with this saw.

9. Feed work into the blade against t he directio n of rotation o nly.

10. Never use the rip fence as a cut-off gauge when crosscutting.

11. Never att empt to f ree a stalled saw blade w ithout first turning t he saw OFF. Tur n power switc h OFF

immediately to pr event motor damage.

12. Provide adeq uate support to the r ear and the sides of the saw table for long or wide work pieces.

13. Avoid kickbacks (w or k t hrown back t owards you) by keep i ng t he blade sharp, the rip fence par al lel to

the saw blade and by keeping the splitter, anti-kickback pawls and guards in place, aligned and

functioning. Do not rel ease w or k bef or e passing it completely bey ond the saw bla de. Do not rip work

that is twist ed, warped or does not have a str aig ht edge to guide it along the fence. Do not attempt t o

reverse out of a cut with the blade running.

14. Avoid awkwar d operatio ns and hand positio ns where a s udde n slip could c ause your hand to move

into the saw blade.

15. Never use solve nts to clean plastic par ts. Solvents could possib ly dissol ve or otherwise da mage the

material. Only a soft damp cloth should be used to clean plastic parts.

16. Mount your table saw on a bench or st and before per f or ming any cut ting operations.

17. Never cut metals or materials that may make hazardous dust.

18. Always use i n a well- ventilat ed ar ea. Remove sawdust fr equently. Clean out sawdust from the interior

of the saw to prevent a potential fire hazard. Att ach a vacuum to t he dust port f or additional sawdust

removal.

19. Never leave t he saw running unattended. Do not leave t he saw until t he blade comes to a co mplete

stop.

20. For pr oper oper at ion follow the ins t ructions in this Operat or ’s M anual.

Note: O n machi nes with no st and or if a st and is not being used, a hole approxi mately 11 i n. square must

be cut under the saw to allow sa wdust to f all throug h. Fail ure to cut this hole will ca us e sa wd ust t o build

up in t he motor area, r esulting in a fire hazard and potential motor damage.

6

Page 7

Specifications

Stock Number .......................................................................................................................... 707000

Motor ................................................................................................. 120VAC, 1P H, 60 Hz, 15A, 4.4HP

Blade Speed - no load (RPM) ........................................................................................................ 4000

Saw Blade Diameter (in.)................................................................................................................... 10

Arbor Diameter (in.) ......................................................................................................................... 5/8

Blade Tilt (deg. ) ...........................................................................................................................45 left

Rip Capacity (in.) .............................................................................................................................. 25

Maximum Cutting Depth at 90º (in.)................................................................................................ 3-1/8

Maximum Cutting Depth at 45° (in.) ............................................................................................... 2-1/2

Dado Capacity (in.) ................................................................................................................. 13/16 x 6

Table Heig ht, with Stand (in.)............................................................................................................. 35

Main Table Size (in.) .......................................................................................................... 24 W x 21 D

Table Size with Side a nd Rear Exte nsio n Wings (in.) ..................................................... 30-1/4 W x 21 D

Table Size with Both Wings Fully Exte nded (i n.) ....................................................... 42-3/8 W x 35-3/4 D

Dust Port Diameter (in.)................................................................................................................. 2-1/2

Gross Weight (lbs.) ......................................................................................................................... 105

Net Weight (lbs.) ............................................................................................................................... 91

Definitions and Terminology

Arbor: Metal shaft that connects the drive

mechanism to the blade.

Bevel Edge Cut: Tilt of the saw arbor and blade

between 0° and 45° to perform an angled cutting

operation.

Blade Guard: Mechanis m mo unte d ove r the s aw

blade to prevent accidental contact with the cutting

edge.

Crosscut: Sawing operation in which the miter

gauge is used to cut across the grain of the

workpiece.

Dado Blade: Bl ade(s) used for cutti ng grooves and

rabbets.

Dado Cut: Flat bottomed groove in the face of the

workpiece made with a dado blade.

Feathe rboard: Device used to keep a board

against the rip fence or table that allows the

operator to keep hands away from the saw blade.

Kerf: The resulting cut or gap made by a saw

blade.

Kickback: An event in which the workpiece is lifted

up and thrown back toward an operator, caused

when a work piece binds on the saw blade or

between the saw blade and ri p fence (or ot her fix ed

object). To minimize or prevent injury from

kickbacks, see the Operating Instruction s section.

Miter Gauge: A component that controls the

workpiece movement while performing a crosscut

of variou s angles.

Non-Through Cut: A sawing operation that

requires the lowering of the splitter and removal of

the blade guard and kick-back pawls, resulting in a

cut that does not protrude through the top of the

workpiece (includes Dado and rabbet cuts).

The blade guard and kick-back pawls must be reins talle d and spl it te r r aised af te r p e r f ormi ng a nonthrough cut to avoid accidental contact with the

saw blade during oper ation.

Parallel: Position of the rip fence equal in distance

at every poi nt to th e side face of t he saw blade.

Perpendicular: 90° (right angle) intersection or

po sitio n of the vertic al and ho rizon tal pl anes s uch

as the position of the saw blade (vertical) to the

table sur face (horizontal).

Push Board/Push Stick: An instrument used to

safely push the workpiece through the cutting

operation.

Rabbet: A cutting operation that creates an

L-shaped channel al o ng the edge o f t he board.

Rip Cut: A cut made along the grain of the

workpiece.

Splitter: Metal plate to which the blade guard is

attached that maintains the kerf opening in the

workpiece when perfor m ing a cuttin g operation.

Standard Kerf: 1/8" gap made with a standard

blade.

Straightedge: A tool us e d to c hec k that a s urf ac e

is flat or parallel.

Through Sawing: A sawing operation in which the

workpiece thickness is completely sawn through.

Proper blade height usuall y allows a 1/8" of the top

of th e blade to extend above the wood stock.

7

Page 8

Electrical

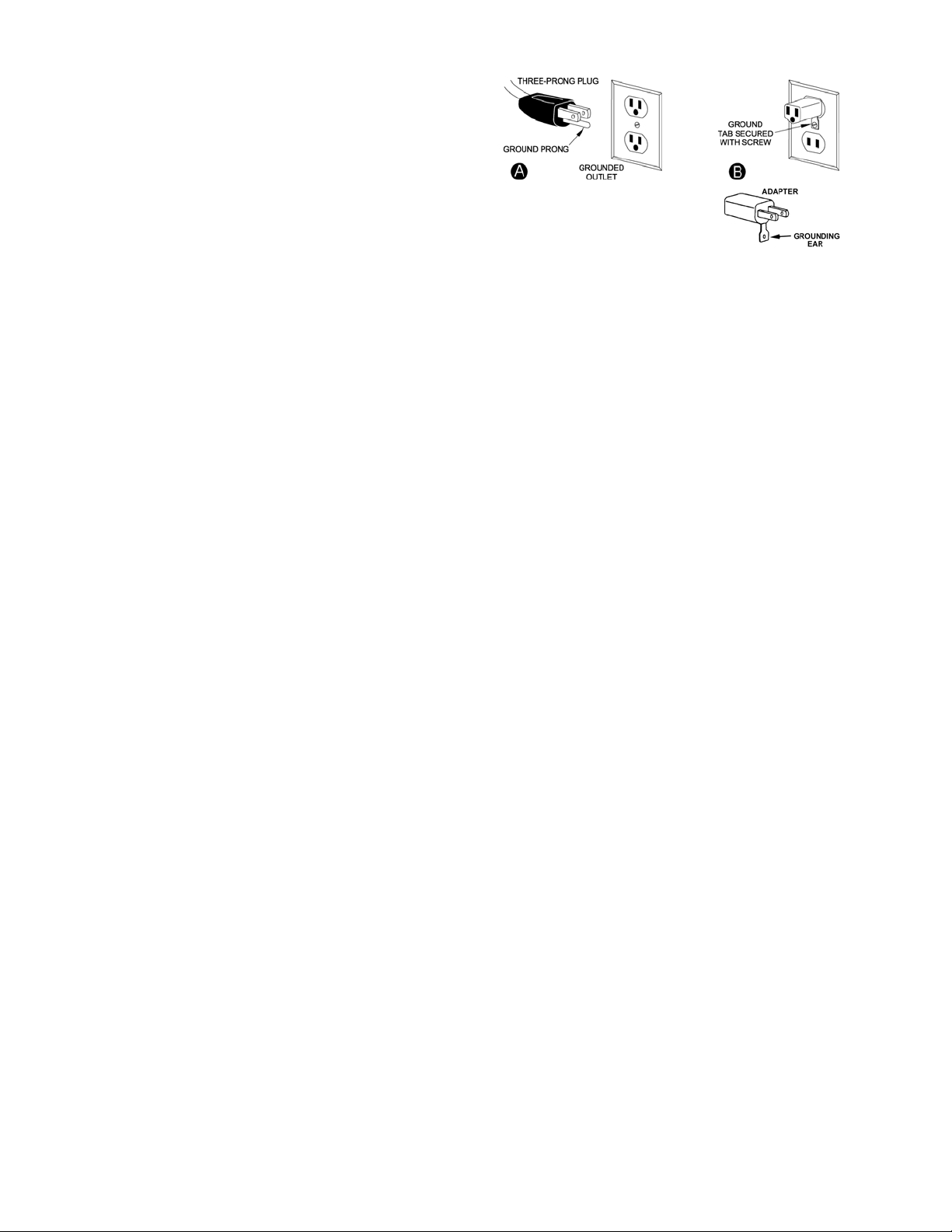

Grounding Instructions

In the event of a malfunction or breakdown,

grounding pro vides a path of least r esist ance for

electric current to reduce the risk of electric

shock. This tool is eq uipped w ith an electric cor d

having an equipment-grounding conductor and a

grounding plug.

The plug must be plugged into a matching outlet

that is properly installed and grounded in

accordance wit h all local codes and ordi nances.

Do not modify the plug pro vided – if it will not f it

the outlet, ha ve the proper outlet installed by a

qualified ele c trician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes is the equipmentgrounding conduc tor. If r epair or replaceme nt of

the electric cord or plug is necessary, do not

connect t he equipment-gr ounding conductor t o a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly gr ounded.

Use only 3-wire extension cords that have 3prong grounding plugs and 3-pole receptacles

that accept t he tool’s plug.

Repair or replace damaged or worn cord

immediately.

Figure A

Extension Cords

Make sure your extension cord is in good

condition. When using an extension cord, be

sure to use one heavy enough to carry the

current yo ur mac hine will draw . An undersized

cord will cause a drop in the line voltage

resulting in power loss and overheating. The

table below shows the correct size to use

depending on the cord length and nameplate

ampere rati ng. If in doubt, use the next heavier

gauge. Remember, the smaller the gauge

number, the heavier the cord.

Cord Length AWG

00 – 25ft 016

225 – 50ft 014

Important: Make certain the receptacle in

question is properly grounded. If you are not

sure, have a registered electrician check the

receptacle.

115 Volt Operation Only

Referring to Figure A:

As received f rom the factor y, your table saw is

ready to run at 115-volt operation. This table

saw, w hen wired for 115 volt, is inte nded for use

on a circuit that has an outlet and a plug that

looks like t he one ill ustrated i n (A). A tempor ary

adapter, which looks like the adapter show n in

(B), may be used to connect this pl ug t o a twopole receptacle if a properly grounded outlet is

not available. The temporary adapter should

only be used until a properly grounded outlet

can be installed by a qualified electrician. This

adapter is not applicab le in Canada. The green

colored rigid ear , lug, or t ab, extending from t he

adapter, must be connected to a permanent

ground such as a properly grounded outlet bo x.

8

Page 9

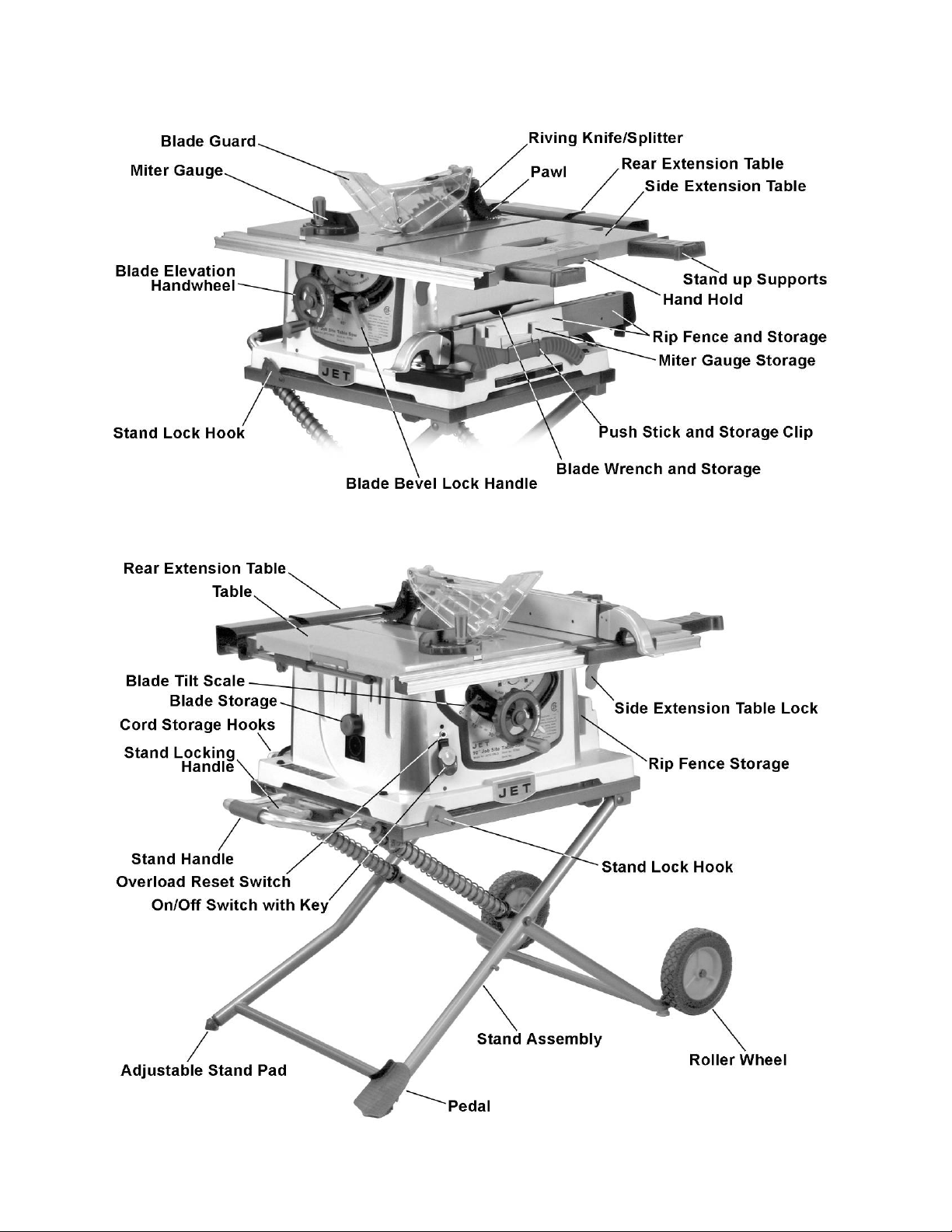

Features

Figure 1 – Features

9

Page 10

Shipping Contents

Unpacking

1. Remove the contents from the shipping

container.

2. Compare the contents of the shipping

container and hardware bags with the lists

found below. Make cert ain that all items are

accounted f or bef or e discar di ng any packing

material. Report any shortages or damage

to your JET dist r ibutor.

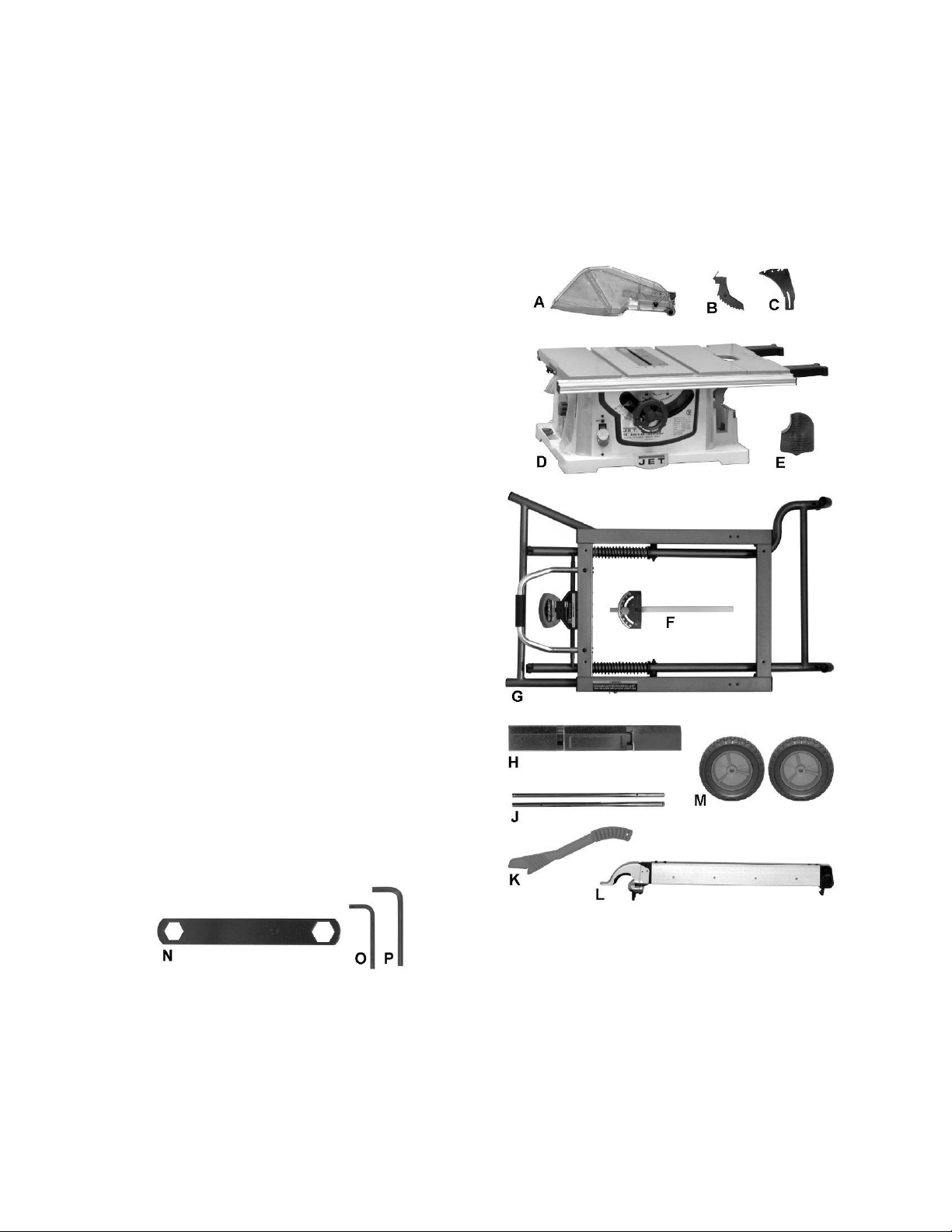

Contents of the Shipping Container

(These items s hown in Figur e 3)

A Blade Guard (1)

B Kickbac k Pawl (1)

C Riving Knife (1)

D Table Saw (1)

E Pedal (1)

F Miter Gauge (1)

G St and Assemb ly (1)

H Rear Table Exte nsion (1)

J Rear Table Extension Tube (2)

K Push Stick (1)

L Rip Fence (1)

M Roller Wheel (2)

-- Hardware Bags

see contents on next page

-- Owner’s Manual (1)

-- Warranty Registration Card

Tools Supplied for Assembly

(These items s hown in Figur e 2)

N Blade Wrench

O 4mm Hex Wrench

P 5mm Hex Wrench

Figure 2 – Supplied Tools

Tools not included

00Adjustable Wr ench

006mm Hex Wrench

00Crosspoint Screw dr iver

00Comb inatio n Wrench

Figure 3 – Contents of Shipping Container

10

Page 11

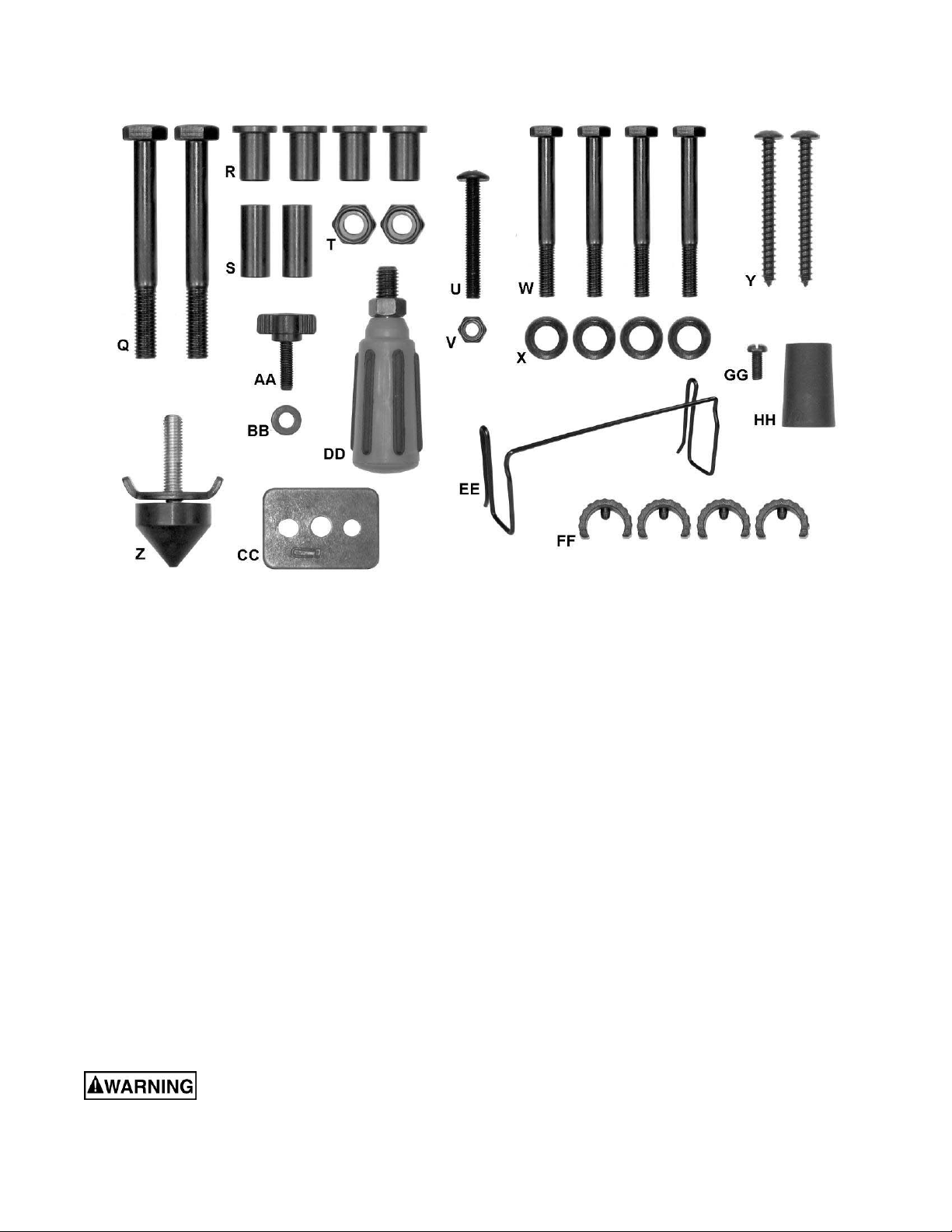

Hardware

The followi ng items are shown in Figure 4.

Q Screw (2)

R Collar (4)

S Shaft Sleeve (2)

T Nut (2)

U Screw (1)

V Nut (1)

W Screw (4)

X Plastic Flat Washer ( 4)

Y Screw (2)

Figure 4 – Har dware

aZ oStand Pad (1)

AA oSplitter/ Riving Knif e Loc k Knob (1)

BB oFlat Washer (1)

CC oSplitter / Ri ving K nife Plate (1)

DD oHa ndwheel Handle (1)

EE oPush Stick Storage Clip (1)

FF oPlastic Stop (4)

GG oScrew (1)

HH oRear Extens io n Pad (1)

Read and understand all assembly instructions before attempting assembly! Failure to

comply may cause serious injury!

11

Page 12

Assembly

Note: The letter designators used in the assembly

section are the same as those used in the shipping

contents a nd hardwar e section (page 10-11) for the

purpose of simplifying part ide ntificat io n.

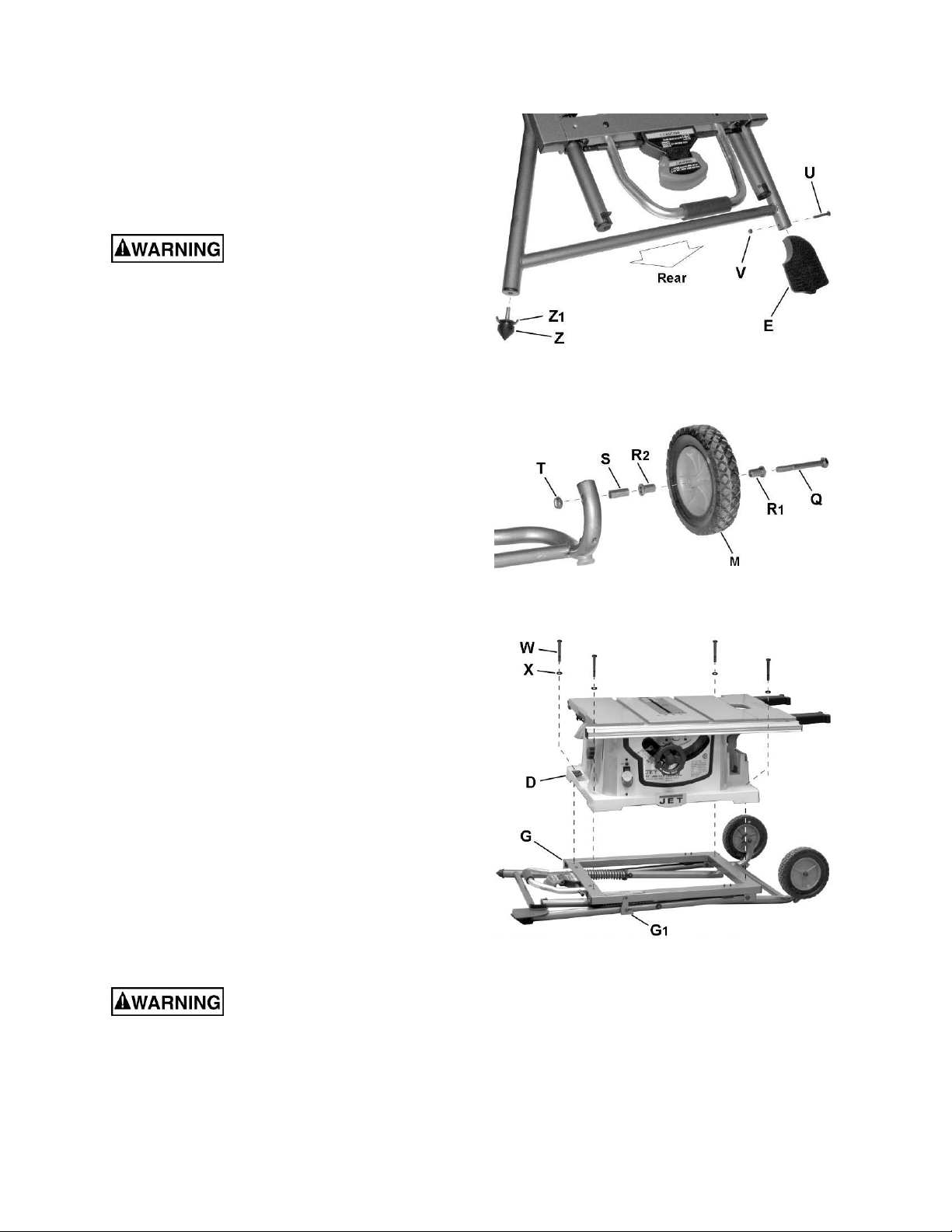

Stand

Stand may pop up unexpectedly

without weight of saw on stand. In order to

avoid injury, verify that the lock hook (G1, Fig.

7) located at the front of the stand is locked

onto the stop screw before mounting the table

saw.

Stand Pad and Pedal

Referring to figure 5:

1. Thread the sta nd pad (Z) throug h the wing nu t

(Z1) to the bottom of the left rear leg.

Adjustment is described in Setting up the Stand

on page 17.

2. Attach the pedal (E) to the left front leg using

the screw (U) and hex nut (V). Secure with

10mm socket and crosspoi nt screwdriver.

Wheel

Referring to Figure 6:

3. Attach two collars (R1, R2) to each roll er wheel

(M).

Figure 5

Figure 6

4. Attach one roller wheel assembly to the right

front leg using the bolt (Q), the shaf t sl eeve (S),

and the hex nut (T) as show n.

Note: Verify that the side of the wheel that has

more ribs is facing toward the inside of the

stand.

5. Attach the other roller wheel to the right rear

leg using the same manner.

6. Tighten screw (Q) and hex nut (T) with two

17mm wrenches.

Note: Do not o vertighten, bec ause doing so will

not allow the wheels to turn.

Attaching Saw to Stand

Referring to Figure 7:

Do not cut the bands and

release the stand hook (G1) until the table saw

is properly attached to the stand.

1. Place table saw (D) on the top of stand (G)

aligning t he holes in the base w ith the holes in

the stand.

Figure 7

2. Insert four hex bolts (W) through the pl astic f l at

washers (X) and holes in base and stand.

3. Tig hte n all four bolts (W) with a 13 mm socket,

but do not overtighten.

Note: To set up the stand or fold dow n t he stand,

see Setting Up The Stand and F olding The Stand

on page 17.

12

Page 13

Mounting the Saw to Work Surface

A hole to allow sawdust to fall

through must be provided when the saw is

mounted to a work surface (stand not used).

Failure to do so will cause sawdust to build up

in the motor area, which can result in fire or

damage to the motor.

Referring to Figure 8:

A

A

If the stand is not used, the saw must be pr operly

secured to a sturdy workbench through the four

mounting holes that are locat ed at the base of the

saw.

The surface of the table where the saw is to be

mounted must have a hole ( B) that is large eno ugh

to facilit a te sawdust fall-t hr ough and removal.

1. Square the saw on the mounti ng s ur face, a nd

mark the location of the four 3/8 in. mounting

holes (A).

2. Dr ill pilot holes in tw o d ia g onal corners (marke d

(A) in the mounting s urface.

3. Mark an 11x11 in. square (B), centered bet-

ween the fo ur mo unting holes (A).

4. Cut out and remove the square.

5. This openi ng w ill allow sawdust to f all through

the saw base.

6. Place the saw on the work surface, and align

the mounting holes of the saw with the two

holes drilled in step 2.

7. Fasten the saw to the work surface using

screws (Y, Fig. 4) provided.

B

A

A

Figure 8

Do not operate this saw on the

floor. Doing so is very dangerous. Failure to

comply may cause serious injury!

Rear Table Extension

Referring to Figure 9:

1. Attach the r ubber pad (HH) t o the inside of the

rear table extension (H). Thread the screw (GG)

thru the rubber pad wit h the screwdriver . Tight en

the screw (GG).

2. I nser t the two rear table extension tubes (J) into

the rear table extension (H). Follow arrows J1, J2.

Note: The t ubes (J) must be inserted into the

back of t he ext ensio n with the bent end last so

that the bar will hold the extension in place.

(J4).

3. Snap plastic stops (FF1) over the extension

tubes (J). This will ‘lock’ t he tube (J) into the

extension (H). Make sure the pin in the stops fit

Figure 9

into the matc hing holes in the extension tubes.

4. Following arrows J1, J3, insert the rear table

extension into t he two e xtension t ube brackets

(J3) under t he table.

5. Snap two black pl asti c stops (FF2) over the end

of the rear table ex tension tubes (J). Make sure

the pin in the stops fit into the matching holes in

the extension tubes.

13

Page 14

Handwheel Handle

Thread the handwheel handle (DD, Fig. 10) i nto t he

handwheel hole (A. Fig. 10), and then tighten t he

nut against the handwheel w ith a 10 mm wrench.

Installing the Blade

To avoid in jury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected from

the power source outlet.

Referring to Figure 11:

1. Remove the table insert (A).

2. Place the blade onto the arbor with the blade

teeth pointing forw ar d to t he front of the saw.

3. M ake sure the blade fits flush against the inner

flange.

4. Clean the outer blade flange (H) and install it

onto the arbor and against the blade.

5. Thread the arbor nut onto the arbor, making

sure the flat side of the nut is against the blade,

t he n ha nd - t i g ht e n.

6. Pull the arbor l ocki ng l ever (G) toward the front

of the machine while spinning the blade by

hand until the latch locks into place and the

blade will no longer turn.

7. Place the wrench (E) on the arbor nut a nd turn

clockwise (t ow ar d the rear of the saw table).

Figure 10

8. Low er the blade t o the dow n positio n. Replace

the table i nser t (A) and the blade guard.

Important: Do not operate t his saw unti l the blade

and blade guard splitt er are aligned a nd in working

order.

Removing the Blade

To avoid in jury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected from

the power source outlet.

Referring To Figure 11:

1. Remove the table inser t (A) and raise the blade

to the maximum height by turning the blade

elevation handwheel clockw ise.

2. Remove blade guard.

3. Adjust the blade to t he 90° vertical pos ition by

unlocking the blade t ilti ng lock knob and turning

the bevel tilting handwheel counterclockwise,

and then lock into position.

4. Pull the arbor l ock i ng lever (G) toward the front

Figure 11

of the tool while spinning the blade by hand

until the latch locks into place and t he blade will

no longer t urn.

5. Place the bl ade wrench ( E) on the arbor nut (J).

6. Loosen and remove the arbor nut and the

flange by p ulling t he wrench towar ds the front

of the machine.

7. Then remove the blade (F). Clean but do not

remove the inner blade flange before

reassembli ng the blade.

14

Page 15

Blade Guard Assembly

To avoid in jury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected from

the power source outlet.

● When installing the blade guard, cover the

blade teeth with a piece of folded cardboard to

protect yourself from possible injury.

Splitter (riving knife) installation (Figure 12)

1. Remove the table insert.

2. Raise the blade arbor to the maximum height

and set the bevel angle to 0°.

3. Install the splitter (C) o nto t he spli tter br acket,

fitting the curved slot on the splitter over the

bracket pins.

4. Install the splitter plate (CC), followed by the

flat washer (BB) a nd lock knob (AA). Tighten

the lock knob, leaving enough slack to

manually adjust the splitter (C).

5. Raise the splitter (C) as high as it will go, then

tighten the lock knob (AA) to sec ure the sp litter

in this position.

Kickback pawl installation (Figur e 12a)

Figure 12

6. Place the lock lever (B1) on the kickback pawl

assembly (B) in the unlock po s ition.

7. Install the kickback pawl (B) onto the splitter.

The flat sides of the mounting pin on the

kickback pawls should pass though the

mounting sl ot (C1) on the splitter (C).

Note: Make sure the “anti-kick back pawls do

not get caught between the insert and the

guard, but rest on top of the insert.

8. Press firmly down on the kickback pawl to

ensure that it is properly s eat ed on the splitter ,

then place the lock lever (B1) in the lock

position.

Blade guard i nstal l ati on (Figur e 12a)

9. Slide the lock lever ( A1) o n the bla de gu ard (A) up

and hol d. .

10. Place the blade guard (A) on the splitter (C),

mes hing t he pin (A2) on the blade guard with the

slot (C2) on the spl i tter.

11. Push the blade guard assembly down firmly on the

splitter; then release the lock lever (A1).

12. Lift up on the bl ade gu ard assem bl y (A) to confirm

that it is firmly secured to the splitter (C ).

Figure 12a

15

Page 16

Installing the Push-stick Storage

Attach the meta l push-s ti ck storage br acket (Fig ur e 13)

into the provided slot (D, Fig. 14) on the right side of the

body shell. The brack et will snap i nt o place.

Storage

Rip fence and miter gauge

Storage brac kets for the r ip fenc e (B, Fig. 14) and

miter gauge (C, Fig. 14) are located on the right

side of the saw housing.

Note: Adjust the miter gauge to 45º-60º before

putting away in storage.

Blade wrench

Insert the ha ndle of the bl ade wrench (A, Fig. 14)

into the slot located to the right side of the saw

housing.

Blade

Figure 13

D

Figure 14

1. Loosen and remove the knob (A, Fig. 15) on

the left side of the saw housing.

2. Place extra blades (B, Fig. 15) onto the

bushing. Replace t he knob and tighten.

Figure 15

16

Page 17

Adjustments

Setting up the Stand

Referring to Figure 16:

1. Release the stand lock hook (D) by sliding it

away from the stop screw.

2. Raise the handle cover (A) first, then pull the

locki ng handle (B) out and hold.

3. Step on the pedal (C) and pull the stand

upward until it is fully unfolded.

4. Release the locking handle (B) to lock the

stand into position. Lower t he cover (A).

Note: M ake sure the stand is locked securely.

5. Place the stand on a level surface and adjust

the left stand p ad ( Z, Fig. 5) so that all legs ar e

contacting the floor and are at a s imilar angle to

the floor.

Note: Make sure the table saw is locked

securely in position. Adjust the stand pad to

make sure the table saw is tot ally st able.

Folding the Stand

1. Raise the handle cover (A, Fig. 16) first and

pull the locking handle ( B, Fig. 16) out.

Figure 16

2. Push slowly down ward on the stand (A, B, Fig. 17).

3. Release the locking handle (B, Fig. 16).

4. Rotate the stand hook (D, Fig. 16) onto the

stop screw to secure the stand legs into the

collapsed positio n.

5. Sec ure the side e xtensio n table (H, Fig. 16) by

pushing the cam locking lever (F, Fig. 16)

downward.

Note: For convenient storage, there are two

stand up supports (G, Fig. 16) on the right side

of the table saw for s upporting the table saw

when not in use (C, Fig. 17).

Adjusting the Table Insert

The table insert (A, Fig. 18) is already installed on

your table saw. Verify that the table insert is flush with

the table top surface on all four corners of the insert.

To avoid s erious injury, the

table insert must be level with the table.

If the table insert is not flush with the table, adjust

the four hex screws (B, F ig. 18) with a 4 mm hex

wrench until it is flush with the table.

To raise the insert, turn the hex screws (B) counter-

Figure 17

Figure 18

clockwise. To lower the insert, turn the hex screws

clockwise.

17

Page 18

Aligning the Blade Guard Splitter

To avoid in jury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected.

● When installing the blade guard, cover the

blade teeth with a piece of folded cardboard to

protect yourself from possible injury.

● Never operate this tool without the safety

guard in place for all through sawing operations.

Important: The splitter must always be correctly

aligned with the blade so the cut workpiece will

pass on either side without bindi ng or tw ist ing.

The splitter/riving knife is adjusted at the factory

and should not require adj ustment. I n the event that

adjustment becomes necessary, follow the

procedure below.

Referring to Figure 19:

1. Remove t he table insert and r aise the blade t o

the maximum height by turning the blade

elevation handwheel clockw ise.

2. Remove the blade guard and pawl assembly

(see Blade Guard Assembly o n page 15)

3. Adjust the blade to t he 90° vertical pos ition by

unlocking the blade t ilti ng lock knob and turning

the bevel tilting handwheel counterclockwise,

and then lock into position.

4. To see if the blade (A) and splitter (B) are

correctly aligned, lay a straightedge along the

side of the blade and against the splitter

(making sure the square is between t he teeth

of the blade).

The blade a nd splitter should be perfect ly in-li ne. If

the blade and splitter are not cor rectly aligned:

5. Loosen two screws (C) just enough to permit

adjustment of the splitter m ounti ng br acket (D).

6. Adjust the splitter ( B) unt il it is al ig ned with t he

saw blade (A), using the straightedge as

reference.

7. Tighten screw s ( C) and recheck alignment.

8. Replace table inser t, paw l assembly a nd blade

guard assembly.

Figure 19

18

Page 19

90° and 45° Positive Stop Adjustment

Adjusting the Positive Stop

Your saw has positive stops that will quickly

position t he saw blade at 9 0° a nd 45° to t he table.

Make adjust m ents only if necessary.

90° Stop

1. Disconnect the saw fr om the power source.

2. Raise the blade to the maximum elevation.

3. Loose n the blade bevel lock handle. Adjust the

blade (A) to the maximum vert ical positio n and

retighten the bevel lock handle.

4. Place a combination s quare (C) on the table (B)

and against the blade (A) to determine if the

blade is 90° to the t able.

5. If the blade is not 90° to t he table, loosen or

tighten the hex screw (G) with a 5 mm hex

wrench until 90° is achieved.

6. Loosen the bevel lock handle and reset the

blade at the maximum vertical position, then

tighten the bevel lock handle.

7. Check again to see if the b lade is 90° to the

table. I f not, repeat step 5.

8. Check the bevel angle scale. If t he pointer does

not read 0°, loose n the screw t hat secures t he

pointer, adjust to r ead 0°, retight en the pointer

screw.

45° Stop

1. Disconnect the saw fr om the power source.

2. Raise the blade to the maximum elevation.

Figure 20

3. Loose n the blade bevel lock handle. Adjust the

blade (D) t o t he ma xi mum bevel position (45°)

and retighten the bevel lock handle.

4. Place a com bination square (F) on the table (E)

and against the blade (D) to determine if the

blade is 45° to the table.

5. If the blade is not 45° to t he table, loosen or

tighten the hex screw (H) with a 5 mm hex

wrench until 45° is achieved.

6. Loosen the bevel lock handle and reset the

blade at the maximum bevel position (45°),

the n tighten the bevel lock hand le.

7. Check again to see if the b lade is 45° to the

table. I f not, repeat step 5.

Blade Tilt Pointer

When the blade is positioned at 90°, loosen the

holding screw , adjust t he b lade tilt po inter to read

0° on the scale, then retighten the screw .

Figure 21

19

Page 20

Blade Parallel to the Miter Slot

To avoid in jury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected from

the power source outlet.

This adjustment was made at the factory, but it

should be rechecked and adjusted if necessary.

This adjustment must be correct to assure acc urate

cuts and to prevent the possibility of kickback,

which can result in serious inj ury.

Referring to Figure 22:

1. Remove the yellow switch key and unplug th e saw.

2. Remove the blade guard.

3. Raise the blade to the maximum heig ht a nd set

the bevel angle at 0°

4. Select and mark with a felt tip marker, one

blade toot h with a “rig ht set ” angle and pos it io n

this toot h at the front of t he saw appr oximately

1/2 in. above the table (D) .

Additional Blade Adjustments

Refer to Figure 23.

If the front and rear measurements are not the

same:

1. Remove the combination square (C) and

loosen the four adjusti ng screws (A) on the top

of the table about a half tur n.

2. Cover the blade with a folded piece of

cardboard to protect your hands. Move the

blade and motor mounting rod car efully to t he

left or right as much as needed to align the

blade correct ly.

3. Tighten t he four screws (A) and r emeas ure, as

described in st eps 4 to 9 in the previous section.

Figure 22

5. Place the combi nat io n sq uare b ase ( G ) into the

right side miter ga uge slot (F) f lush against the

inside of the miter gauge slot.

6. Adjust the ruler (E) so it touches the front

marked toot h (D) and lock ruler so it holds its

position in the square assembly.

7. Next rot at e t he blade, mo vi ng the marked tooth

(D) to its new position (A) at the rear of the

saw.

8. Carefully move the combination square from

position (G) to (C).

9. If the ruler touches the marked tooth at the

front and rear position (E at D, B at A), no

adjustment is needed. If not, perform the

adjustment procedure described in the next

section.

Figure 23

4. If suff icient adjustment cannot be made by the

four adj usting scr ews (A), then also loosen the

two adjusting screws (B) and repeat all

previous steps. Loos en these screws (B) only if

necessary as they are set f or accurate 90° and

45° settings.

5. Rec heck the blade c leara nce maki ng sure that

the blade does not hit the table i nser t or other

parts when at the 90° and 45° settings.

6. Retighten all four adjusting screws (A) and

reset the 90° and 45° setting as described in

the 90° and 45° Positive Stop Adjustment

section (page 19).

20

Page 21

Adjusting the Miter Gauge

Referring to Figure 24:

1. Loosen the lock handle (B) to allow the miter

body (C) to rotate freely. Position the miter

body at 90° so the positive detent secures its

position. Tig hte n the lock handle (B) to hold the

miter body in position.

2. If the pointer (A) requires adjustment, loosen

the screw under the poi nter with a screw driver.

Adjust the pointer to 90° on the scale, then

firmly tig hten t he adjustment screw.

To change angles on the miter gauge:

3. Loosen the lock handle (B) and rotate the miter

body to the desired angle as indicated by the

scale. Sec ure in posit ion by tighte ning the lock

handle.

Rip Fence Adjustment

Referring to Figure 25:

1. For adjustments, posit ion the fe nce to t he right

of the blade, parallel with the miter ga uge slot.

2. Place the rear clamp (A) of the fence o n the

back rail of the table, and lower the front end

over the front rail (E). Push the handle (F)

down to lock.

Figure 24

3. To change t he pos ition of the fenc e, lift up on

the ha ndle to unlock, a nd s l ide the fence t o the

desired position, t hen push the handle down to

lock.

4. To check the rip fence adjustment, place the

fence along one edge of the miter gauge

groove, and lock the handle. It should be

parallel to t he miter groove to pro vide accurate

cuts.

If an adjustment is needed to make it parall el:

1. Loose n the tw o hex bolts ( C) o n the top of t he

rip fence, and lift up on the handle (F).

2. Adjust the fence (B) s o it is par allel t o the miter

gauge slot and lock the handle (F ) into pos ition.

3. Make sure t he fence (B) is paralle l to the s lot

and tighten the two hex bolts (C) secur ely.

4. Unlock the fence handle (F) and s lide the fence

left and right, t hen repositio n it against the miter

gauge slot again and lock into position to

double check its alignment.

Failure to properly align the fence can cause

“kickback” and serious injury could occur.

Figure 25

If the fence is loose when the handle is in the

locked posi ti on:

1. Move the handle upward to the unlocked

position.

2. Turn the adjusting sc r ew (D) clockwise unt il t he

rear clamp is snug.

3. Do not turn t he adj ust ing screw more t han 1/4

turn at a time.

4. Over-tightening the screw will cause the rip

fence to come out of alignment.

21

Page 22

Rip Fence Indicator

The rip fence indicator points to t he scale on the

front of t he table saw. The meas ure ment shown by

the i ndica tor w ill p rov ide t he user wit h ac c uracy up

to 1/16 of an inch. T he measureme nt shown is t he

distance from the blade to the side of the fence

closest to t he blade.

To check t he accuracy:

1. Measure the actual dista nce to the side of the

rip fence.

If there is a difference between the measurement

and the indicator, adjust the indicator as f ollows :

2. Loosen the indicator screw (A, Fig. 26).

3. Slide the indicator t o the correct measurement

position o n the scale, the n retig hten the screw.

Table Extension Scale Pointer

The table extension scale pointer (A, Fig. 27)

should be at 13 inches on the scale when the

extension is i n the clos ed pos ition. If adjustment is

required, loosen the holding screw (B, Fig. 27),

position t he poi nter over the 13 inch marker and retighten the screw.

Rear Table Extension Adjustment

The rear table extension (A, Fig. 28) should be

positioned as close as possible to the rear of the

table when ripping short material.

Figure 26

Figure 27

The rear table extension should be fully extended

when ripping longer materials that require extra

support.

Adjusting the Locking Lever

If the extension table moves when it is open and

locked in place, t he cam locking lever (A, Fig. 29)

may be loose and require adjustment.

To adjust the locking lever tension:

1. Hold the st ud (B) st at ionary , and loosen the nut

(C) wit h a 10 mm wrench.

2. Rotate the rod using a wrench on one of t he

flats (D). Do not overtension!

3. Re-tighten t he nut (C).

Figure 28

Figure 29

22

Page 23

Operation

Basic Saw Operations

Raising the Blade

To raise or lower the blade, t urn the blade elevati on

handwheel (A, Fig. 30) to the desired b lade height,

and then tighte n t he bevel l ock handle (B, Fig. 30) to

maintain the desired blade angle.

Figure 30

Tilting the Blade

Two methods are available for t ilting the saw blade.

Rapid blade tilting:

Loosen the bevel lock handle (B, Fig. 30) , move the

handwheel (A, Fig. 30) to the desired angle, then

tighten the bevel lock handle.

Fine adjustment blade til ti ng:

Loosen the bevel lock ha ndle (B, Fig. 30), push in

the handwheel (A, Fig. 30) and at the same time tur n

the handwheel (A, Fig. 30) to tilt the saw blade.

When the saw b lade is at t he desired a ngle, tig hten

the bevel lock handle (B, Fig. 30) .

5. If the remo vable safety key is remo ved while the

saw is running, it can be t urned OFF but cannot

be restarted without inserting the removable

safety key (A).

Figure 31

Overload Protection

This saw has an overl oad reset button ( C, Fig. 31)

that resets the motor after it shuts off due to

overloading or low voltage. If the motor stops during

operation, turn the ON / OFF switch to the OFF

position. Wait about five minutes for the motor to

cool, the push t he reset button (C, F ig. 31) and t urn

the switch to the ON position.

Dust Chute

To prevent fire hazard, clean and remove

sawdust from under the saw frequently.

To prevent sawd ust build up inside the saw housing,

attach a vacuum hose (A, Fig. 32) to the dust chute

(B, Fig. 32) at the rear of the table saw. DO NOT

operate the saw with the hose in place unless the

vacuum is turned on.

On/Off Switch

The O N / OFF switch has a removable saf ety key.

With the key removed fr om the switch, unauthorized

and hazardous use by children and others is

minimized.

Referring to Figure 31:

1. To turn the saw ON, insert the safety switch key

(A) into the slot in the switch (B). Move the

switch upward to the ON position.

2. To turn the saw OFF, move the switch

downward.

3. To lock t he switc h i n t he OFF position, grasp t he

end (or yellow part) of the safety switch key (A),

and pull it out.

4. With the removable safety key removed, the

sw itch will not operate.

Figure 32

Using the Table Extension

Us e the scale on the front rail for rip cuts up to 13 in.

For rip cuts great er than 13 i n., set and t he lock the

fence on the 13 in. mark. Unlock t he exte nsion table,

and slide the table with the fence to the desired

dimension using the scale on the rear rail.

Referring to Figure 33:

1. Release the cam locking lever (A).

2. Slide the table extension to the desired

measurement and then tighten the cam locking

lever.

23

Page 24

Figure 33

Cutting Operations

There are two basic types of cuts: ripping and

crosscutting. Ripping is cutting along the length and

the grain of the workpiece. Crosscutting is cutting

either across the width or across the grain of the

workpiece. (It is not safe to rip or crosscut by

freehand). Ripp ing requires t he use of the rip fence,

and crosscutting requires t he miter gauge. NEVER

USE THE TWO AT THE SAME TIME.

1. Remove the miter gauge and store it in the

“stor age” compart ment in the base of the saw.

2. Secure the rip fence to the table.

3. Raise the blade so it is about 1/8 in. higher than

the top of the wor kpiece.

4. Place the work piece flat on the table and against

the fence. Keep the workpiece away from the

blade.

5. Turn the saw ON and wait f or the blade to come

to full speed.

6. Slowly feed the workpiece into the blade by

pushing forward only on the workpiece section

(A, Fig. 34) t hat w ill pass betwee n the blade and

the fence.

AVOID KICKBACK by push ing

forward on the section of the workpiece that

passes between the blade and the fence. Never

perform any freehand operations.

Before using the saw each time,

check the following:

• The blade is tightened to the arbor.

• The bevel angle lock knob is tightened.

• If ripping, make sure the fence is locked into

position and is parallel to the miter gauge

slot.

• The blade guard is in place and working

properly.

• Safety glasses are worn.

• The failure to adhere to these common safety

rules, and those printed in the front of this

manual, can greatly increase the likelihood

of injury.

Ripping

To prevent serious injury:

• Never use a miter gauge when ripping.

• Never use more than one rip fence during a

single cut.

• Do not allow familiarity or frequent use of

your table saw to cause careless mistakes.

Remember that even a careless fraction of a

second is enough to cause a severe injury.

• Keep both hands away from the blade and

clear from the path of the blade.

• The workpiece must have a straight edge

against the fence and must not be warped,

twisted, or bowed when ripping.

Figure 34

Referring to Figure 35:

7. Keep your thumbs off the table top. When both of

your thumbs touch the f r ont edge of the table (C),

finish the cut with a push stick. To make an

additional pus h stick, use t he pattern on page 29.

8. The push stick (D) should always be used for

any ripping operatio n.

9. Continue pushing the workpiece with the push

stick (D) until it passes t hro ugh the blad e guard

and clears the rear of the table.

10. Never pull the piece back when the blade is

turning. Turn the switch OFF. When the blade

completely stops, you can then remove the

workpiece.

Never attempt to pull the

workpiece backwards during a cutting operation.

This will cause kickback and serious injury to

the user can occur. When the blade completely

24

Page 25

stops, raise the anti-kickback pawls (A) on each

side of the splitter and slide the workpiece out.

Figure 35

4. Start the saw and wait for the blade (C) to come

up to full speed. Never stand directly in line of

the saw b lade pat h, always st and t o t he side of

the blade that you are cutting on.

5. Keep t he w orkpiece (B) agai nst the face of t he

miter gauge ( A) a nd flat agai nst the tabl e. T hen

slowly push the workpiece t hroug h the blade.

6. Do not try to pull the workpiece back wit h t he

blade turning. Turn the switch OFF, and

carefully slide the wor kpiece out when the blade

has completely stopped.

Always position the larger surface

of the work-piece on the table when crosscutting

and/or bevel crosscutting to avoid instability.

Bevel Ripping

This cut is the same as ripping except the blade

bevel angle is set to an angle other than “0º.

Ripping Small Pieces

To avoid injury fr om blade contact, never make cuts

narrower t han 1/2 in. wide.

1. It is unsafe to rip small pieces. Instead, rip a

larger piece to obtain the size of the desired

piece.

2. When a small width is to be ripped and your

hand cannot saf ely pass between the blade a nd

the rip fence, use one or more push sticks to

move the workpiece. Always use a push stick

during ripping operatio ns.

Crosscutting

Do not allow familiarity or

frequent use of your table saw to cause careless

mistakes. Remember that even a careless fraction

of a second is enough to cause a severe injury.

Keep both hands away from the

blade and the path of the blade.

Figure 36

Using Wood Facing on the Miter Gauge

Slots are provided in the miter gauge for attaching

an auxiliary facing (A) to make it easier to cut very

long or short pieces. Select a suitable piece of

straight wood, drill t wo holes t hro ugh it a nd at ta ch it

to the miter gauge with screws. Make sure the facing

does not interfere with the proper operation of the

sawblade guard. When cutting long workpieces, you

can make a simple outfeed support by clamping a

piece of plywood t o a sawhorse.

Never attempt to pull the

workpiece backwards during a cutting operation.

This will cause kickback and serious injury to the

user can occur.

Referring to Figure 36:

1. Remove the rip f ence and place t he m iter gauge

in the miter gauge slot on the table.

2. Adjust the bla de height so that it is 1/ 8 in. higher

than the top of the workpiece.

3. Hold the workpiece firmly against the miter

gauge with the blade path in line with the

desired cut location.

Figure 37

Bevel Crosscutting 0°~45° Blade Level & 90° Miter

Ang le

This cutting operation is the same as crosscutting

except the blade is at a bevel angle other than 0°.

Always work to the right side of

the blade during this type of cut. The miter

gauge must be in the right side slot because the

bevel angle may cause the blade guard to

25

Page 26

interfere with the cut if used on the left side

groove.

1. Set the blade (B) t o 0° bevel angle a nd t ighten

the blade bevel lock knob.

Referring to Figure 38:

1. Adjust the blade (A) to the desired angle, and

tighten the blade bevel lock knob.

2. Tighten the m i ter lock handle (C) at 90°.

3. Hold workpiece (B) firmly agai nst the face of the

miter gauge throughout the c utti ng operation.

Figure 38

Compound Miter Crosscutting 0°~45° Blade Bevel

& 0°~45 Miter Angle

This sawing operat io n comb ines a miter angle wit h a

bevel angle.

Always work to the right side of

the blade during this type of cut. The miter

gauge must be in the right side groove because

the bevel angle may cause the blade guard to

interfere with the cut if used on the left side

groove.

1. Set the mi ter gauge ( C) to the desired angle.

2. Place the m it er gauge in the r ig ht side gr oove of

the table.

3. Set the blade (B) bevel to the desired bevel

angle and tighten the blade bevel lock knob.

4. Hold workpiece (A) firmly agai nst the face of the

miter gauge throughout the c utti ng operation.

2. Set the miter gauge (A) at the desired miter

angle and lock in positio n by tightening the miter

gauge l ocki ng handl e.

3. Hold the w or kpiece ( C) f ir m ly ag ainst the face of

the miter gauge throughout the cutting

operation.

Figure 40

Using the Wood Facing on the Rip Fence

When performing some special cutting operations,

you can add a wood f acing to either side of t he r ip

fence (C, Fig. 41).

1. Use a smoot h s traight 3/4 i n. t hick wood board

(A, Fig. 41) that is as long as the rip fence.

2. Attach the wood facing to the fence with wood

screws (B, Fig. 41) (not included) through the

holes in the fence. A wood fence s hould be used

when ripping material such as thin paneling to

prevent the materia l from catc hi ng between the

bottom of the fence and the table.

Figure 39

Mitering 0°~45° Miter Angle

This sawing operation is t he same as crossc utting

except t he miter ga uge is locked at an angle other

tha n 90°.

Figure 41

Dado Cuts

The maximum dado cut width is 13/16 in.

Only Stackable dado blades can

be used on this saw.

DO NOT use Adjustable or Wobble

type dadoes.

Referring to Figure 42:

26

Page 27

1. Remove the saw blade and the blade guard for

dado cuts ONLY. Reinstall and realign blade

guard for a ll t hrough- sawi ng operations. I nst all

a dado not e xceedi ng 6 in. diameter a nd 13/ 16

in. width.

2. Install a da do table inser t making sure t hat t he

rear of the insert is flush with the table.

Note: A dado table i nsert is not included but ca n

be ordered (SN 707001) by calling the number

on the cover of this manual.

3. Instructions for operating the dado is packed

with the separately p urchased dado set.

4. The arbor (B) o n this saw r est ricts t he maximum

width of the cut to 13/16 in.

5. It is not necessary to install the outside flange (A)

before threading on the arbor nut (C) for the

maximum 13/16 in. dado cuts. Make sure that t he

arbor nut (C) is t ight, and that at least one thread

of the arbor sticks out past the nut.

6. Use only the correct number of round outside

blades and inside c hippers as s hown in the dado

set’s instruction manual. Blade/chippers must

not exceed 13/16 in. tot al in width.

7. Check the saw t o ens ure that t he dado w ill not

strike the housing, insert, or motor when in

operation.

For your own safety, always

replace the blade, blade guard assembly, and

table insert when you are finished with the dado

operation.

Figure 42

27

Page 28

Maintenance

General Maintenance

For your own safety, turn the

switch OFF and remove the switch key. Remove

the plug from the power source outlet before

maintaining or lubricating your saw.

1. Clean out all sawdust that has accumulated

inside the saw cabinet and the motor.

2. Polish the saw table w ith a n auto mot ive wax to

keep it clean a nd to make it easier t o slide t he

workpiece.

3. Clean cutting blades with pitch and gum

remover.

4. A worn, cut, or damaged pow er cord should be

replaced immediately.

All electrical or mechanical

repairs should be attempted only by a trained

repair technician. Contact customer service for

assistance. Use only identical replacement parts.

Any other parts may create a hazard.

5. Use liquid dishwashing detergent and water to

clean all plastic parts .

Note: Certain cleaning chemicals can damage

plastic parts.

6. Avoid use of cleaning chemicals or solvents,

ammonia and household detergents containing

ammonia.

Blade Raising and Tilting Mechanism

After every five hours of oper at ion, t he blade raising

mechanism and tilting mechanism should be checked

for looseness, binding, or any other abnormalities.

Referring Fig ure 43:

1. With the saw disconnected from the power

source, turn the saw ups ide d own and pull up

and push down on the motor unit.

2. Observe any movement of the motor mounting

mechanism. Looseness or play in the blade raising

screw r od (A ) should be li m i t ed to 1/8” or less.

3. If excessive looseness is obser ved i n a ny other

parts of the blade raising mechanism or tilting

mec ha nis m, t a ke the c o mpl et e u nit t o a Se r vic e

Center.

Place a s mall amount of dry lubricant on t he bevel

gear (B). The screw rod ( A) must be kept clean and

free of sawdust, gum, pitc h, and other conta minants

for smooth operations.

Figure 43

If excessive loose ness is observed in any par t of the

blade raisi ng m echanism or tilting mec ha nism, take

the complete unit to a Service Center.

Lubrication

All motor beari ngs are permanently l ubricated at the

factor y and require no additional lubrication.

On all mec hanical parts of yo ur table saw where a

pivot or threaded rod is present, lubricate using

graphite or silicone. These dry lubricants will not

hold sawdust as would oil or grease.

Replacing the Carbon Brushes

Always disconnect the plug from

the power source before inspecting the brushes.

The carbon brushes included with the unit will last

appr oximat ely 5 0 hours of running tim e, or 10,000 ON/

OFF cycles. Replace both carbon brushes when either

has less than 1/4 in. length of carbon remaining, or if

the s pring or wire is damaged or burned.

1. Remove t he blade guard, blad e, rip f ence, miter

gauge and stand assembly from the table saw.

2. Place cardboard or an old blanket on the floor t o

protect the saw table surface.

3. Place the saw upside down on the protective

material.

4. Tilt the b l ade elevat i on/tilti ng handwhee l ( A, Fig. 44)

to the 4 5 ° posi tion.

28

Page 29

Figure 44

5. Referring to Figure 45:

6. Remove the black plastic cap ( B) from the side

of the motor (C).

7. Carefully remove the spring-loaded cap, and

then pull out the brush and replace.

8. Replace the other side.

9. The ears o n the metal e nd of t he asse mbly go i n

the same hole the carbon part fits into. Do not

overtighte n the plastic cap.

Push Stick Construction

Use solid wood or good quality plywood t o construct

a push stick using the template below. The push

stick must be thi nner than the width of t he material

being cut.

10. Carefully set the saw in an upright positio n o n a

clean level surface.

11. Replace the blade g uard, blade, rip fe nce, miter

gauge and stand assembly to the table saw .

Note: To reinstall the same brushes, first make sure

the brushes go back in the way they came out. This

will avoid a break-in period that reduces motor

performance and increases wear.

Figure 45

Lubrication

All motor beari ngs are permanently l ubricated at the

factor y and require no additional lubrication.

On all mecha nical parts of your table saw where a

pivot or threaded rod is present, lubricate using

gra phite or s ilicone. These dr y lubricants will not hold

sawdust as would oil or gr ease.

Figure 46

29

Page 30

Troubleshooting

Adj

A

Trouble Probable Cause Remedy

Saw will not start .

Does not make

accurate 45° and

90° rip cuts.

Mater ial pinched

blade when ripping.

Mater ial binds on

splitter.

Saw makes

unsatisfactory cuts.

Mater ial kicked

back

from blade.

Blade does not

raise or tilt freely.

Blade does not

come up to speed.

Reset trips too

easily.

Machine vibrates

excessively.

Does not make

accurate 45° and

90° crosscuts.

nti-kickback pawls

catch on the table

insert opening.

1. Saw is not plugged in.

2. Fuse blown or circuit breaker

tr ipped.

3. Cord is damaged.

4. Debris in on/off switch

1. Positive stop not adjusted

correctly.

2. Tilt angle pointer not set

accurately.

1. Rip fence not aligned with blade.

2. Warped wood, edge against fence

is not straight.

1. Splitter not aligned correctly with

blade.

1. Dull blade.

2. Blade mounted backwar ds.

3. Gum or pitch on blade.

4. Incorrect blade for work being

done.

5. Gum or pitch on blade causing

erratic feed.

1. Rip fence out of adjustment.

2. Splitter not aligned with blade.

3. Feeding stock without r ip fence.

4. Splitter not in place.

5. Dull blade.

6. The operator letting go of material

before it is past saw blade.

7. Miter angle lock knob is not tight.

1. Sawdust and dirt in elevation/tilti ng

mechan i s ms .

1. Extension cord too light or too

long.

2. Low house voltage.

1. Saw not mounted securely to

workbench.

2. Bench on uneven floor.

3. Damaged saw blade.

1. Miter gauge out of adjustment. 1.

1. Splitter/riving knife not set in full

raised position.

1. Plug in saw.

2. Replace fuse or reset c ircuit breaker .

3. Replace power cor d.

4. Remove switch from saw and

separate in half. Clean any debris

accumulated within.

1. Check blade with square and adjust

positive st op.

2. Check blade with square and adjust

to zero.

1. Check and adjust rip fence.

2. Select another piece of w ood.

1. Check and align split ter with blade.

1. Replace blade.

2. Turn the blade around.

3. Remove blade and clean with

tur penti ne and coarse st eel w ool.

4. Change the blade.

5. Clean or change blade.

1. Align rip fence with miter gauge slot.

2. Align splitter w ith blade.

3. Install and use rip fence.

4. Install and use splitter. (with guard)

5. Replace blade.

6. Push materia l all the way past saw

blade before r eleasing work.

7. Tighten knob.

1. Brush or blow out loose dust and dirt.

1. Replace with adequate size cord.

2. Contact your electric company.

1. Tighten all mounting hardware.

2. Reposition on flat level surface.

3. Replace blade.

ust miter gauge.

1. Set splitter/riving k nife to full ra is e d

position using t he blade ele vatio n

handw heel.

30

Page 31

Parts

Ordering Replacement Parts