Page 1

Operating Instructions and Parts Manual

15-Inch Vari-Speed Drill Press

Models: J-A3816, J-A5816, J- A5818

Model J-A3816 Model J-A5816

WMH TOOL GROUP, Inc.

427 New Sanford Road

LaVergne, Tennessee 30786 Part No. M-354500

Ph.: 800-274-6848 Revision A2 03/09

www.wmhtoolgroup.com Copyright © 2009 WMH Tool Group

Page 2

YEAR

DAY

WARRANTY

90

WARRANTY

YEAR

WARRANTY

LIFETIME

WARRANTY

LIFE

YEAR

WARRANTY

YEAR

WARRANTY

Warranty and Service

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our Authorized

Service Centers located throughout the United States can give you quick service. In most cases, any of these WMH Tool

Group Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance

and major repair on your JET® tools. For the name of an Authorized Service Center in your area call 1-800-274-6848.

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check with

your local WMH Tool Group distributor, or visit jettools.com.

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product. (MW =

Woodworking)

Beam Clamps

Chain Hoist Manual

Lever Hoists

WARRANTY

Pullers-JCH Models

Scissor Lift Tables

Screw Jacks

Trolleys-Geared

Trolleys-Plain

Winches-Manual

WW Air Filtration

WW Bandsaws

WW Buffers

5

WARRANTY

YEAR

WW Drill Presses

WW Dust Collectors

WW Dust Filters

WW Dust Fittings

WW Jointers

WW Lathes

WW Planers

WW Sanders

WW Shapers

WW Tablesaws

90

DAY

Lathe Accessories

Machine Accessories

Mobile Bases

Safety Equipment

Specialty Items

Vise Accessories

1

WARRANTY

YEAR

Air Tools Contractor

Air Tools-Industrial

Air Tools-Light

Industrial

Lubrication

Body Repair Kits

Bottle Jacks

Cable Pullers

Cold Saws

WARRANTY

Hoists-Air

Hoists-Electric

Metal forming

Mill/Drills

Milling Machines

MW Bandsaws

MW Drill Presses

MW Finishing

Equipment

MW Lathes

MW Precision Vises

2

WARRANTY

YEAR

Palet Trucks

Rigging Equip.

Service Jacks

Stackers

Surface Grinders

Tapping

Trolleys-Air

Trolleys-Electric

Web Slings

Winches-Electric

3

YEAR

WW Benchtop

Tools

Warranty reverts to 1 Year Warranty if woodworking (WW) products listed above are used for industrial or

educational purposes.

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools, abrasives

and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational purposes.

Woodworking products with Five Year Warranties that are used for commercial, industrial or education purposes revert to a

One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse, abuse, negligence or accidents,

normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name of the

location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the merchandise. If our

inspection discloses a defect, we will repair or replace the product, or refund the purchase price, at our option.

We will return the repaired product or replacement at our expense unless it is determined by us that there is no defect, or that

the defect resulted from causes not within the scope of our warranty in which case we will, at your direction, dispose of or

return the product. In the event you choose to have the product returned, you will be responsible for the shipping and handling

costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE

EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information and are

not binding. Members of WMH Tool Group reserve the right to effect at any time, without prior notice, those alterations to

parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever. JET® branded products

are not sold in Canada by WMH Tool Group.

Metalworking, WW =

LIFE

LIFETIME

Fastening Tools

Mechanics Hand Tools

Striking Tools

Vises (no -precision)

Clamps

WARRANTY

2

Page 3

Table of Contents

Warranty and Service ................................................................................................................................................ 2

Table of Contents ...................................................................................................................................................... 3

Warnings.................................................................................................................................................................... 4

Safety Instructions for Drill Presses....................................................................................................................... 6

ON/OFF Switch Padlock ........................................................................................................................................ 6

Specifications............................................................................................................................................................. 7

Introduction ................................................................................................................................................................ 8

Set-up ........................................................................................................................................................................ 8

Securing the Base.................................................................................................................................................. 8

Cleaning ................................................................................................................................................................. 8

Electrical Connection ................................................................................................................................................. 8

Operating Controls..................................................................................................................................................... 8

ON/OFF Switch...................................................................................................................................................... 8

Speed Control Handwheel ..................................................................................................................................... 8

Depth Stop ............................................................................................................................................................. 9

Operating Precautions ........................................................................................................................................... 9

Drilling Recommendations......................................................................................................................................... 9

Maintenance ............................................................................................................................................................ 10

Replacement of Drive Belt ................................................................................................................................... 10

Replacement of Motor.......................................................................................................................................... 10

Lubrication ............................................................................................................................................................... 10

Adjustments ............................................................................................................................................................. 11

Table Adjustment ................................................................................................................................................. 11

Wiring Diagrams ...................................................................................................................................................... 11

Electrical .................................................................................................................................................................. 12

115 Volt Operation ............................................................................................................................................... 12

230 Volt Operation ............................................................................................................................................... 12

Permanently Connected Tools............................................................................................................................. 12

Grounding Instructions......................................................................................................................................... 13

Extension Cords................................................................................................................................................... 13

Troubleshooting ....................................................................................................................................................... 14

Parts ........................................................................................................................................................................ 14

Parts List - Head Models J-A5816 and J-A5818.................................................................................................. 15

Exploded View — Head Models J-A5816 and J-A5818 ...................................................................................... 17

Parts List - Head Model J-A3816......................................................................................................................... 18

Exploded View — Head Model J-A3816.............................................................................................................. 20

Parts List – Base Floor Models J-A3816, J-A5816 and J-A5818 ........................................................................ 21

Exploded View – Base Floor Models J-A3816, J-A5816 and J-A5818................................................................ 22

The specifications in this manual are given as general information and are not binding. WMH Tool Group

reserves the right to effect, at any time and without prior notice, changes or alterations to parts, fittings, and

accessory equipment deemed necessary for any reason whatsoever.

3

Page 4

Warnings

1. Read and understand the entire owner's manual before attempting assembly or operation.

2. Read and understand warnings posted on the machine and in this manual. Failure to comply with all of these

warnings may cause serious injury.

3. Replace warning labels if they become obscured or removed.

4. This band saw is designed and intended for use by properly trained and experienced personnel only. If you

are not familiar with the proper and safe operation of a band saw, do not use until proper training and

knowledge have been obtained.

5. Do not use this band saw for other than its intended use. If used for other purposes, WMH Tool Group

disclaims any real or implied warranty and holds itself harmless from any injury that may result from that use.

6. Keep guards in place and in working order when the machine is in use. If removed for maintenance purposes,

use extreme caution and replace the guards immediately.

7. Remove adjusting keys and wrenches. Form habit of checking to see that keys and adjusting wrenches are

removed from tool before turning it on.

8. Keep work area clean. Cluttered areas and benches invite accidents.

9. Do not use in dangerous environment. Don't use power tools in damp or wet locations, or expose them to

rain. Keep work area well lighted.

10. Keep children away. All visitors should be kept safe distance from work area.

11. Make workshop kid proof with padlocks, master switches, or by removing starter keys.

12. Don't force tool. It will do the job better and safer at the rate for which it was designed.

13. Use the right tool. Don’t force a tool or attachment to do a job for which it was not designed. The right tool will

do the job better and safer at the rate for which it was designed.

14. Use proper extension cord. Make sure your extension cord is in good condition. When using an extension

cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating. Table 1 shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller

the gage number, the heavier the cord.

15. Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry which

may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain

long hair.

16. Always use safety glasses. Also use face or dust mask if cutting operation is dusty. Everyday eyeglasses only

have impact resistant lenses, they are NOT safety glasses.

17. Secure work. Make sure the work piece is securely attached or clamped to the table. Never use your hand to

hold the work piece.

18. Don't overreach. Keep proper footing and balance at all times.

19. Maintain tools with care. Keep tools sharp and clean for best and safest performance. Follow instructions for

lubricating and changing accessories.

20. Disconnect tools before servicing; when changing accessories, such as blades, bits, cutters, and the like.

21. Reduce the risk of unintentional starting. Make sure switch is in off position before plugging in.

22. Use recommended accessories. Consult the owner's manual for recommended accessories. The use of

improper accessories may cause risk of injury to persons.

23. Never stand on tool. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally

contacted.

4

Page 5

24. Check for damaged parts. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function - check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions

that may affect its operation.

25. A guard or other part that is damaged should be properly repaired or replaced.

26. Direction of feed – Feed work into a blade or cutter against the direction of rotation of the blade or cutter only.

27. Do not leave tool running unattended. Turn power off. Don't leave tool until it comes to a complete stop.

28. Do not use this band saw for other than its intended use. If used for other purposes, WMH Tool Group

disclaims any real or implied warranty and holds itself harmless from any injury that may result from that use.

29. This drill press is designed and intended for use by properly trained and experienced personnel only. If you

are not familiar with the proper and safe operation of a drill press, do not use until proper training and

knowledge have been obtained.

30. Some dust created by power sanding, sawing, grinding, drilling and other construction activities contain

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well-ventilated area and work with approved safety equipment, such as face or

dust masks that are specifically designed to filter out microscopic particles.

31. Make certain the switch is in the OFF position before connecting the machine to the power supply.

32. Make certain the machine is properly grounded.

33. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are careless

acts that can result in serious injury.

34. The operator should not wear gloves when operating the machine.

35. All doors should be closed, all panels replaced and other safety guards should be in place prior to the

machine being started or operated.

36. Be sure the drill bit is not in contact with the work piece when the motor is started. The motor should be

started and up to full speed before bringing the drill bit into contact with the work piece.

37. Keep your hands away from the drilling area.

38. The drill press must be stopped and the electrical supply must be cut off before any drill bit replacement or

machine adjustment is done, or before any attempt is made to change the drive belts or before any periodic

service or maintenance is performed on the drill press.

39. Remove loose items and unnecessary work pieces from the area before starting the machine.

40. The work piece must be securely clamped before the drill bit comes in contact with the work piece.

41. The drill press must be stopped and the electrical supply cut off or machine unplugged before reaching into

the drilling area.

42. Wear eye protection.

43. Do not remove jammed pieces until motor has stopped.

44. Hold workpiece firmly against table.

5

Page 6

Safety Instructions for Drill Presses

1. All work shall be secured using either clamps or

a vise to the drill press table. It is unsafe to use

your hands to hold any workpiece being drilled.

2. Drill press head and table shall be securely

locked to the column before operating the drill

press. This must always be checked prior to

starting the machine.

3. Always use the correct tooling. Tooling shall

always be maintained and properly sharpened.

All tooling must be run at the proper speeds and

feeds as they apply to the job. Use only

recommended accessories and follow those

manufacturers instructions pertaining to them.

Tooling shall be not be forced in to any

workpiece but fed according to the proper

specifications. Failure to follow these

instructions will not only ruin the tooling as well

as the machine, but can cause serious injury.

4. Never brush away any chips while the machine

is in operation. All clean up should be done

when the machine is stopped.

5. Keep hands in sight. Do not put hands or

fingers around, on, or below any rotating cutting

tools. Leather safety gloves should be used

when handling any sharp objects or cutting

tools. See Figure A.

6. Always wear protective eye wear when

operating, servicing or adjusting machinery.

Eyewear shall be impact resistant, protective

safety glasses with side shields complying with

ANSI Z87.1 specifications. Use of the eye wear

which does not comply with ANSI Z87.1

specifications could result in severe injury from

breakage of eye protection. See Figure B.

7. When drilling in material which causes dust, a

dust mask shall be worn. See Figure C.

8. Avoid contact with coolant, especially guarding

the eyes.

9. Non-slip footwear and safety shoes are

recommended. See Figure D.

10. Wear ear protectors (plugs or muffs) during

extended periods of operation. See Figure E.

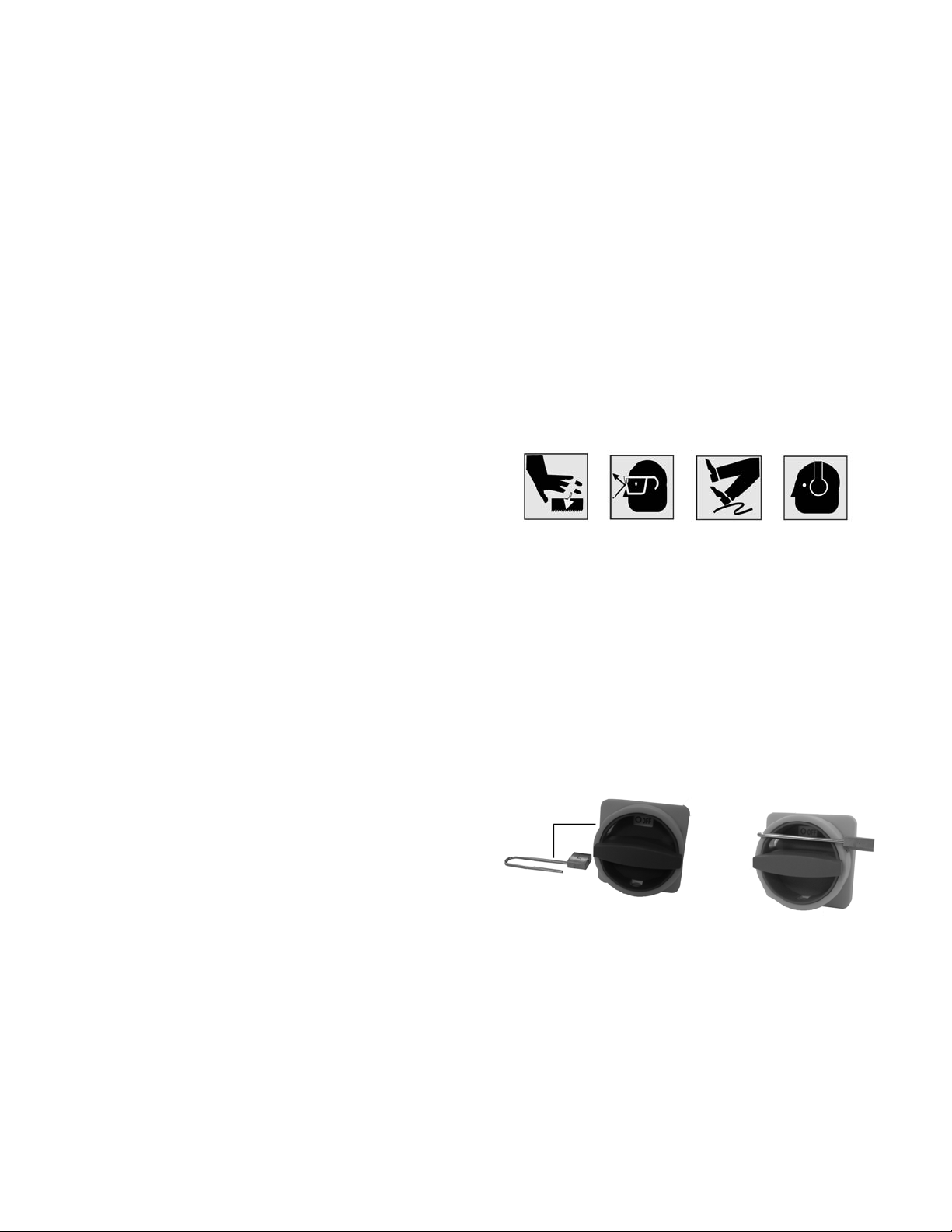

A B C D

ON/OFF Switch Padlock

For Model Numbers A5816 and A5818

To avoid accidental starting by young children or

others childrennot qualified to use the tool, the use

of a padlock is required.

1. Open the padlock (Fig E).

2. Insert the through hole in the switch cover.

3. Close the padlock (Fig F).

4. Place the key in a safe place.

Figure E Figure F

6

Page 7

Specifications

The JET 15-Inch Vari-Speed Drill Presses, Models

J-A3816, J-A5816, and J-A5818 provide drilling

speeds from 400 to 5,000 rpm. Simple handwheel

adjustment sets the speeds with an LED speed

display on the faceplate of the machine.

JET's 15-inch vari-speed drill press provides a solid

base for drilling and offers a wide range of spindle

speeds. The large quill provides greater accuracy.

The large worktable provides the operator with room

to work and ample support for the workpiece. The

drill press has a 3-inch diameter column for head

and table support. The 15-Inch Vari-Speed Drill

Press is equipped with a standard table raiser.

Model J-A3816 J-A5816 J-A5818

Stock Number ..................354500 .................... 354550 ...................... 354551

Type................................. Floor Model ............. Floor Model ............... Floor Model

Motor:

Motor Speed (rpm)......1,725 rpm ................ 1,725 rpm .................. 1,725 rpm

HP............................... 1 HP ........................ 1 HP .......................... 1 HP

Power Rating ..............1 Ph, 115/220V ....... 1 Ph, 115/220V.......... 3 Ph, 220/440V

Spindle speed (rpm) ........400 to 5,000rpm ..... 400 to 5,000 rpm ....... 400 to 5,000 rpm

Capacity:

Cast iron .....................up to 5/8-in. ............ up to 5/8-in. ............... up to 5/8-in

Steel............................ up to 1/2-in. ............. up to 1/2-in. ............... up to 1/2-in.

Drills to center..................15 in. ....................... 15 in........................... 15 in.

Quill diameter...................2-1/4 in. ................... 2-1/4 in. ..................... 2-1/4 in

Quill travel........................6 in. ......................... 6 in............................. 6 in.

Spindle taper....................#2 Morse Taper....... #2 Morse Taper......... #2 Morse Taper

Dimensions:

Table (overall) ............ 15-1/4 x 17-3/4 in. ... 15-1/4 x 17-3/4 in. ..... 15-1/4 x 17-3/4 in.

Table (working area)... 12-1/2 x 14-1/2 in.... 12-1/2 x 14-1/2 in. ..... 12-1/2 x 14-1/2 in.

T-slot...........................1/2-in. ...................... 1/2-in. ........................ 1/2-in.

Spindle to table ........... 41 in. ....................... 41 in........................... 41 in.

Spindle to base ........... 47-1/2 in. ................ 47-1/2 in. ................... 47-1/2 in.

Overall height...................67-1/2 in. ................ 67-1/2 in.

7

Page 8

Introduction

Set-up

This manual includes operating and maintenance

instructions for the JET 15-Inch Vari-Speed Drill

Presses, Models J-A3816, J-A5816, and J-A5818.

This manual also includes parts listings and

illustrations of replaceable parts.

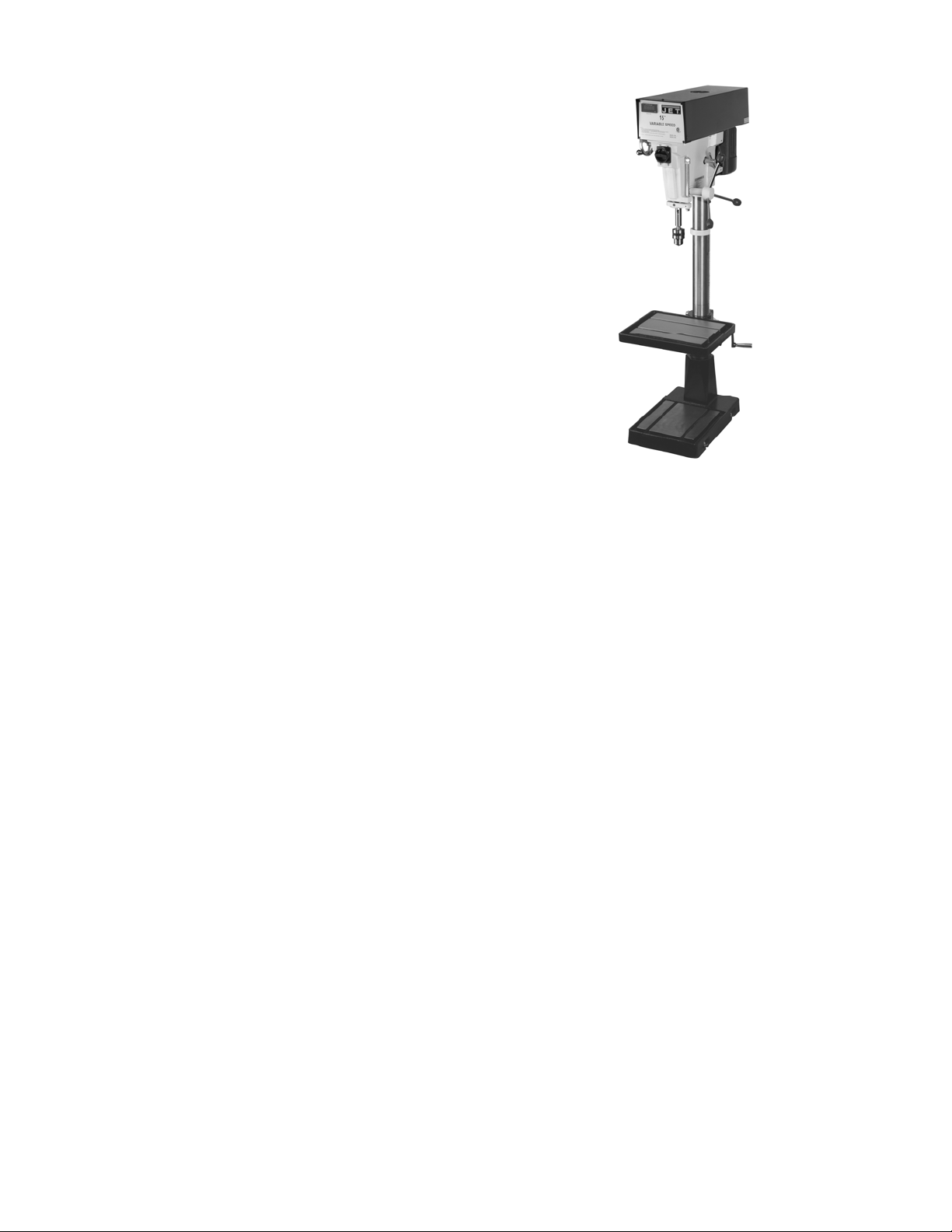

Refer to Figure 1 for key features of the drill press.

LED Speed Display

Speed

setting

Handwheel

On/Off Switch

Depth Stop

Spindle

Motor

Feed Handle

Head locking

Handle

Column

Securing the Base

The base of the drill press has four mounting holes.

The drill press should be level and rest solidly on the

floor. Place shims under the four mounting holes in

the base as required to level the drill press.

Cleaning

Clean off any protective grease with solvent. After

cleaning, lubricate the base, table, and column with

a light coating of medium weight machine oil.

Repeat at six months intervals.

Internal parts of the drill press are lubricated at the

factory. No further lubrication is required at the time

of installation.

Electrical Connection

Refer to the Wiring Diagram section for wiring

information. Connection to electrical power should

be made by a qualified electrician. Observe local

electrical codes when connecting the machine.

The motor should be protected with a time delay

fuse or circuit breaker with a amperage rating slightly

higher than the full load current of the motor.

Operating Controls

(Refer to Figure 2)

Work Table

Base

Figure 1 – Drill Press Features

Table

height

adjustment

Rack

ON/OFF Switch

The ON/OFF switch is located at the front of the drill

head.

Speed Control Handwheel

To avoid damage to the speed

adjustment mechanism, the motor must be operating before attempting to adjust the speed rate.

The speed control handwheel is located on the left

side of the drill head. An LED speed indicator is

provided on the face plate on the drill head.

Page 9

LED Speed

××=

Display

1. The head assembly must be locked to the

column so the thrust produced by drilling will not

force the head assembly up the column.

2. The work table must be locked to the column so

it will not be forced down the column.

3. Be sure the belt is tightened to the proper

tension.

4. DO NOT start to drill the workpiece until making

certain the workpiece is held down securely.

Depth

Stop

Speed control

Handwheel

Figure 2 – Operating Controls

On/Off Switch

Depth Stop

A drilling depth stop (refer to Figure 3) is provided on

the right side of the drill head. The depth stop

consists of a threaded rod with depth setting jam

nuts. The front side of the threaded rod has a depth

scale. The jam nuts are loosened and moved to the

desired depth on the scale. The upper jam nut is

then tightened against the lower nut.

5. BEFORE

in either direction.

6. Point of operation protection is required for

maximum safety. This remains the responsibility

of the user/purchaser since conditions differ

between jobs.

7. Make sure the drill is secured in the spindle or

check before attempting to use the drill press.

8. Make sure the spindle taper is clean and free of

burrs, scoring, and galling to assure maximum

gripping.

turning the speed control handwheel

Drilling Recommendations

Speeds for Drilling

The speed of a drill is usually measured in terms of

the rate at which the outer periphery of the tool

moves in relation to the work being drilled. The

common term for this is Surface Feet per Minute

(SFM). The relationship of SFM is expressed in the

following formulas:

)(26.0 InchesinDiameterDrillRPMSFM

RPM ×=

In general, the higher the speed the shorter the drill

life. Operating at the low end of the speed range for

Figure 3 – Depth Stop

Operating Precautions

The following operating and safety precautions must

be observed in order to avoid harm to the operator

or damage to the drill press.

a particular material will result in longer life. The

most efficient speed for operating a drill depends on

many variables:

1. Composition and hardness of material.

2. Depth of the hole.

3. Efficiency of the cutting fluid.

4. Type and condition of the drilling machine.

5. Desired quality of the hole.

6. Difficulty of set-up.

9

8.3

SFM

InchesinDiameterDrill

)(

Page 10

Indication of Extreme Speeds and Feeds

A drill that splits up the web is evidence of too much

feed or insufficient tip clearance at the center as a

result of improper grinding. The rapid wearing away

of the extreme outer corners of the cutting edges

indicates that the speed is too high. A drill chipping

or braking out at the cutting edges indicates that

either the feed is too heavy or the drill has been

ground with too much tip clearance.

Speeds for High Speed Steel Drills

Material Speed In SFM

Alloy Steel — 300 to 400 Brinell ......................20 - 30

Stainless Steel .................................................30 - 40

Automotive Steel Forgings ..............................40 - 50

Tool Steel, 1.2C ...............................................50 - 60

Steel, .4C to .5C ..............................................70 - 80

Mild Machinery Steel, .2C to .3C ...................80 - 110

Hard Chilled Cast Iron .....................................30 - 40

Medium Hard Cast Iron..................................70 - 100

Soft Cast Iron..............................................100 – 150

Malleable Iron .................................................80 – 90

High Nickel Steel or Monel .............................40 – 50

High Tensile Bronze .......................................70 -150

Ordinary Brass and Bronze .........................200 - 300

Aluminum and its Alloys ..............................200 - 300

Magnesium and its Alloys............................250 - 400

Slate, Marble, and Stone ..................................15 -25

Plastics and similar material (Bakelite)........100 - 150

Wood ............................................................300 -400

Titanium Alloys ................................................10 - 25

Titanium Alloy Sheet........................................50 - 60

General Applications

5mm hole .....................................................550 - 600

10mm hole ...................................................250 - 300

15mm hole ...................................................100 - 110

In cases where carbon steel drills are applicable, the

drill should be run at speeds of from 40 to 50

percent of those given above.

Maintenance

Replacement of Drive Belt

Make sure to disconnect electrical power to the drill press to avoid the

possibility of inadvertent operation and exposure to potentially lethal voltage levels.

1. Start drill press. Set speed control to highest

speed. Stop drill press.

3. Remove head cover.

4. Remove belt. (With speed control setting at the

highest speed, the belt should be loose enough

to remove.)

5. Install the replacement belt. Install the head

cover.

6. Connect electrical power to the drill press.

7. Operate the drill press to verify correct

operation.

Replacement of Motor

Make sure to disconnect electrical power to the drill press to avoid the

possibility of inadvertent operation and exposure to potentially lethal voltage levels.

1. Disconnect electrical power to drill press.

2. Remove drive belt (see Replacement of Drive Belt).

3. Disconnect electrical wiring from motor junction box.

4. Remove nuts and washers from bolts securing

motor to drill head. Remove motor.

5. Remove pulleys and related components from

motor shaft.

6. Install pulleys and related components on

replacement motor shaft.

7. Install motor on mounting bolts and secure with

nuts and washers.

8. Connect electrical wiring (refer to Wiring

Diagram section for wiring details).

9. Install drive belt (see Replacement of Drive Belt).

10. Operate drill press to verify proper operation.

Lubrication

Following are lubrication recommendations for drill

press components.

Spindle pulley drive: Lubricate spindle splines

occasionally with light grease.

Quill, Table, and Column: Lubricate with light

film of oil.

Table lift rack: Lubricate regularly with SAE20 oil

(clean rack with solvent before applying oil.)

Variable speed drive fork: Lubricate contact

points occasionally with grease.

2. Disconnect electrical power to drill press.

10

Page 11

Adjustments

Table Adjustment

The table can be raised or lowered to accommodate

the height of the component being drilled (refer to

Figure 4). To raise or lower the table, loosen the

lock handle. Then use the hand crank to move the

table to the desired height. Then retighten the lock

handle.

Figure 4 – Table Adjustment

Head Adjustment

Change the radial position of the

drill head only if the drill press base is secured

to the floor. Swinging the drill head without the

base being secured to the floor will cause the

drill press to become unstable and tip over

resulting in injury and/or damage to the machine.

The radial position of the drill head can be changed

to accommodate the drilling of a hole that may be

offset from the center of the table. Reposition the

drill head by loosening the locking handles and

swinging the drill head to the desired position. Then

retighten the locking handles.

Wiring Diagrams

Refer to Figure 5 for wiring information. The drive

motor is115/230 volt single phase or 220/440 volt

three phase. Notice: When converting machine

voltage, it is necessarry to re-wire the LED display

connection accordingly. Refer to figure 5.

11

Figure 5

Page 12

Electrical

115 Volt Operation

Referring to Figure 6:

As received from the factory, your drill press is ready

to run at 115-volt operation. This drill press, when

wired for 115 volt, is intended for use on a circuit

that has an outlet and a plug that looks like the one

illustrated in (A). A temporary adapter, which looks

like the adapter shown in (B), may be used to

connect this plug to a two-pole receptacle if a

properly grounded outlet is not available. The

temporary adapter should only be used until a

properly grounded outlet can be installed by a

qualified electrician. The green colored rigid ear, lug,

or tab, extending from the adapter, must be

connected to a permanent ground such as a

properly grounded outlet box.

230 Volt Operation

Referring to Figure 7:

If 230V, single-phase operation is desired, the

following instructions must be followed:

1. Disconnect the machine from the power source.

2. The JET drill press motor has four numbered

leads that are factory connected for 115V

operation, as shown in (A). For 230V operation

reconnect the leads as shown in (B).

3. The 115V attachment plug (C), supplied with the

drill press, must be replaced with a UL listed

plug suitable for 230V operation (D). Contact

your local Authorized JET Service Center or

qualified electrician for proper procedures to

install the plug. The drill press must comply with

all local and national codes after the 230-volt

plug is installed.

4. The drill press with a 230-volt plug should only

be connected to an outlet having the same

configuration as shown in (D). No adapter is

available nor should be used with the 230-volt

plug.

A

B

Figure 7

Permanently Connected Tools

Models J-A3816, J-A5816 and J-A5818 drill presses

Figure 6

that are intended for permanent connection should

be connected to a grounded metal permanent wiring

system or to a system having an equipmentgrounding conductor.

12

Page 13

Grounding Instructions

This tool must be grounded

while in use to protect the operator from electric

shock.

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric shock.

This tool is equipped with an electric cord having an

equipment-grounding conductor and a grounding

plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor, with insulation having an outer surface

that is green with or without yellow stripes, is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conductor

to a live terminal.

The drill press with a 230-volt plug should only be

connected to an outlet having the same

configuration (D, Fig. 7). No adapter is available or

should be used with the 230-volt plug.

Important: In all cases (115 or 230 volts), make

certain the receptacle in question is properly

grounded. If you are not sure, have a registered

electrician check the receptacle.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to whether

the tool is properly grounded. Use only three wire

extension cords that have three-prong grounding

plugs and three-pole receptacles that accept the

tool’s plug.

Repair or replace a damaged or worn cord

immediately.

Extension Cords

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one

heavy enough to carry the current your machine will

draw. An undersized cord will cause a drop in the

line voltage resulting in power loss and overheating.

The table following shows the correct size to use

depending on the cord length and name plate

ampere rating. If in doubt, use the next heavier

gauge. Remember, the smaller the gauge number,

the heavier the cord.

Length of Cord AWG

0–25 16

25-50 14

51-100 12

13

Page 14

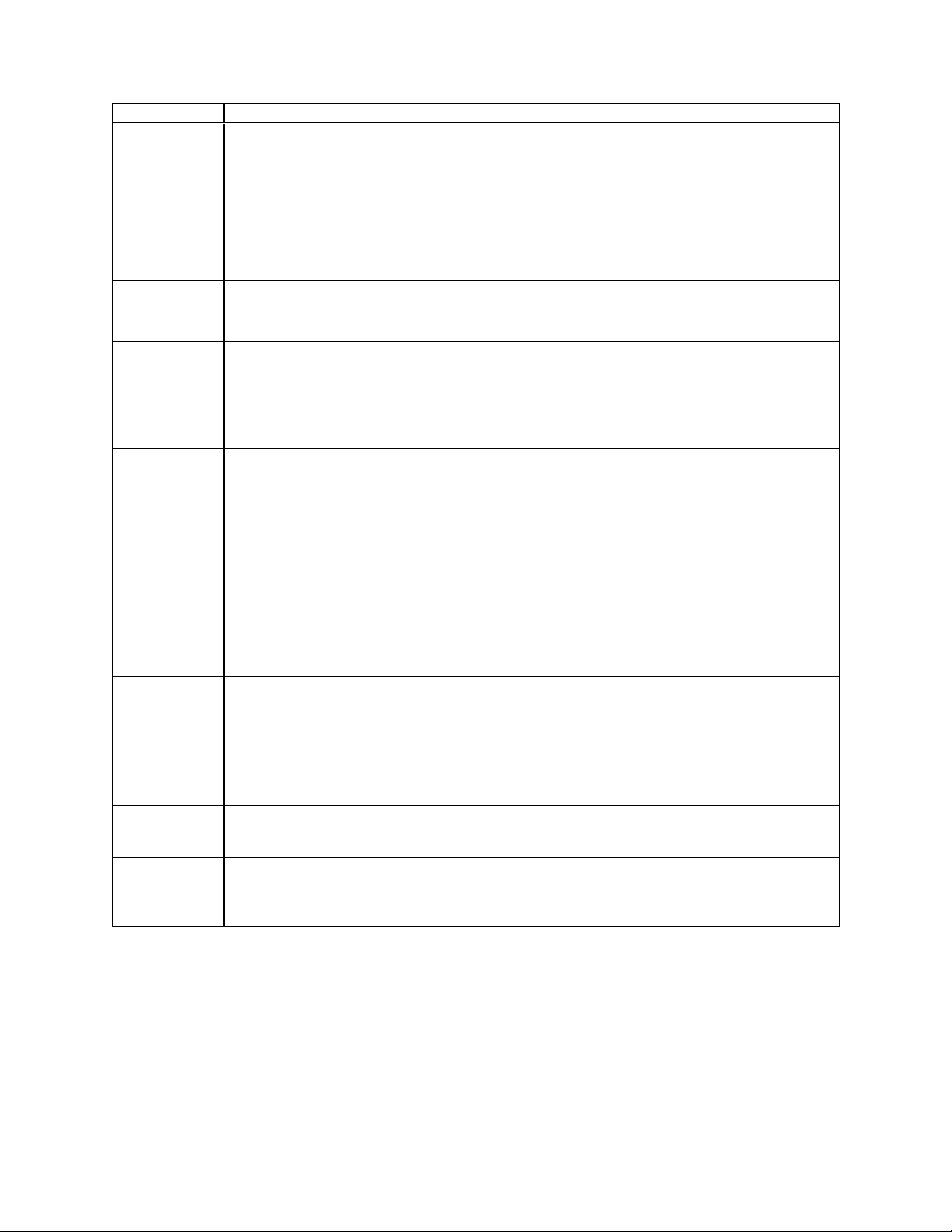

Troubleshooting

Problem Probable Cause Suggested Remedy

Spindle does

not turn.

Spindle noisy. Damaged spindle bearings.

Drill stalls. Worn drive belt.

Poorly drilled

holes.

Circuit breaker tripped.

Branch circuit breaker tripped or fuse

blown.

Open wire in switch circuit.

Defective switch.

Broken drive

Worn spline.

Excessive feed rate for size of drill and

material being drilled.

No cutting fluid or improper cutting fluid.

Drill dull

Lack of rigidity in hold-down method.

Speed too fast for material and drill size.

Feed too fast for material and drill size.

No or improper cutting fluid or coolant

being used.

Improperly ground drill bit.

belt.

Reset circuit breaker.

Reset branch circuit breaker/replace fuse.

Repair open circuit.

Repair switch.

Replace drive belt.

Replace bearings.

Replace spline.

Check condition of belt. Replace if glazed or

slipping on pulleys

Reduce feed pressure or use cutting fluid

Use correct cutting fluid.

Sharpen drill.

Check that all T-slot hold-downs are tight and that

table-lock and drill head bolts are tight.

Check spindle speed recom mendations. Reduce

speed if necessary.

Reduce feed rate.

Use cutting fluid, or change to proper fluid or

coolant for material being drilled.

Check for proper angles and reliefs. Regrind to

proper geometry.

Motor

overheating

Table can not

be raised.

No speed

readout.

Electrical circuit fault.

Oversize drill.

Excessive feed.

No cutting fluid, or wrong fluid

Lack of lubrication Lubricate.

Speed pickup out of adjustment or failed. Adjust gap between speed pickup and post spindle

Check current draw in circuit. Make sure current

draw is the same as rating on motor plate.

Reduce drill size.

Reduce feed rate.

Use correct cutting fluid for the material and drill.

pulley. If there is no readout on the speed

indicator, replace the speed pickup.

Parts

Ordering Replacement Parts

To order parts or reach our service department, call 1-800-274-6848 between 7:30 a.m. and 5:30 p.m. (CST),

Monday through Friday. Having the Model Number and Serial Number of your machine available when you call

will allow us to serve you quickly and accurately.

14

Page 15

Parts List - Head Models J-A5816 and J-A5818

Item Part No. Description Size Qty.

1 ...............5507580 ...................Chuck (with Key) .................................................. ....................................1

2A ............. 5507495 ................... Arbor .................................................................... #2 MT x JT3................ 1

3A ............. 5507496A.................Spindle ................................................................. .................................... 1

4 ...............J-5053070 ................Quill Band............................................................. .................................... 1

5 ...............9010541 ...................O-Ring.................................................................. .................................... 1

6 ...............9054511 ...................Set Screw............................................................. 5/16-18 x 3/8............... 2

6-1 ............9054511A................. Flat Head Screw .................................................M6x16 ......................... 1

7 ...............5032611 ...................Bearing Retainer ................................................. .................................... 1

8 ...............9100331 ...................Bearing................................................................. 6203ZZ........................ 1

8-1 ............9100331A................. Bearing................................................................. 6204ZZ........................ 1

9 ...............5041010 ...................Quill ..................................................................... .................................... 1

10 .............9058561 ...................Wavy Spring Washer ........................................... ....................................1

11 .............9074081 ...................Truarc Retainer ................................................... .................................... 1

13 .............9056981 ...................Hex Jam Nut ........................................................1/4-20.......................... 3

16 .............5518170 ...................Sloted self taping Screw ...................................... 3/16-24 x 3/8 ............... 4

17 .............5518157 ...................Power Cord (1-Phase) ......................................... ....................................1

17A ........... 5517463 ................... Power Cord (3-Phase) ......................................... .................................... 1

18A ........... 5507500 ................... Switch (Single Phase) .......................................... .................................... 1

.................5507497 ...................Switch (3-Phase).................................................. .................................... 1

19A ........... 5507501 ................... Slotted Machine Screw ........................................1/4-20 x 1 .................... 4

21 .............5518158 ...................Wiring Harness (1-Phase).................................... .................................... 1

.................5517457 ...................Wiring Harness (3-Phase).................................... .................................... 1

24A ........... 5507502 ................... Socket Head Cap Screw ...................................... .................................... 3

25A ........... 5507503 ................... Return Spring Assemlby ...................................... .................................... 1

26A ........... 5507504 ................... Nylon Nut ............................................................. .................................... 1

27 .............9135311 ...................Lock Screw........................................................... 1/4-20 x 1.................... 2

28 .............J-5041050 ................Speed Change Housing....................................... .................................... 1

29 .............9127731 ...................Socket Set Screw................................................. 5/16-18 x 5/16............. 1

30 .............5024541 ...................Head Lock (Plain Side) ........................................ .................................... 1

31 .............1000771 ...................Lock Nut Assembly .............................................. ....................................1

32 .............5041071 ...................Speed Change Shaft............................................ .................................... 1

33 .............9053661 ...................Retainer................................................................ .................................... 1

34 .............5041201 ...................Bearing Spacer .................................................... .................................... 1

35 .............9100321 ...................Bearing................................................................. .................................... 2

36 .............9070291 ...................Knob..................................................................... .................................... 3

37 .............5053000 ...................Spoke ................................................................... .................................... 3

38 .............J-5507827 ................Feed Shaft Assembly........................................... .................................... 1

39 .............5513378 ...................Hi/Lo Speed Direction Plate................................. .................................... 1

40 .............5053100A.................Rod, Graduated ................................................... .................................... 1

41 .............9056381 ...................Jam Nut................................................................ 5/8-11.......................... 3

41-1 ..........9056381A................. Nut M10xP1.5/Spring Washer M10 ..................... .................................... 1

42 .............9128611 ...................Hex Head Cap Screw .......................................... 1/2-12 x 4.................... 1

44 .............TS-0270031 .............Set Screw ............................................................. 5/16-18 x 3/8............... 4

45 .............5032781 ...................Motor Plate Bar .................................................... .................................... 4

46 .............9057111 ...................Whiz Flange Locknut ........................................... .................................... 4

47 .............TS-0152051 .............Carriage Bolt ....................................................... 5/16-18 x 2.................. 2

48 .............9056171 ...................Carriage Bolt ........................................................ 5/16-18 x 1-1/2............ 4

49 .............9058051 ...................Split Lock Washer ............................................... 1/2 ID .......................... 2

50 .............9056841 ...................Hex Nut ............................................................... 1/2-12.......................... 2

51A ........... A5816-51A............... Lower Pulley......................................................... .................................... 1

51B ........... A5816-51B............... Upper Pulley......................................................... .................................... 1

51C...........A5816-51C ............... Spring ................................................................... .................................... 1

51D...........A5816-51D............... Spring Support Cover .......................................... .................................... 1

52 .............9054621 ...................Socket Set Screw ................................................ 1/4-20 x 1/2................. 2

53 .............5042011 ...................Key (Motor) .......................................................... .................................... 1

54 .............9077101 ...................Variable Speed Belt ............................................. .................................... 1

15

Page 16

Parts List - Head Models J-A5816 and J-A5818

Item Part No. Description Size Qty.

55 .............5041140 ...................Vaiable Speed Pulley (Spindle) ........................... .................................... 1

55A ........... 5513510 ................... Hex Nut ............................................................... ....................................1

55B ........... 5513511 ................... SHCS .................................................................. .................................... 1

56 .............9100421 ...................Bearing................................................................. .................................... 1

57 .............9058571 ...................Spring Washer .................................................... .................................... 1

58 .............5041761 ...................Speed Change Nut .............................................. .................................... 1

59 .............5041040 ...................Speed Change Lever ........................................... .................................... 1

60 .............9127951 ...................Socket Set Screw................................................. 1/4-20 x 1/2................ 1

61 .............9057461 ...................Washer................................................................. 1/4.............................. 3

62 .............9052101 ...................Hex Head Cap Screw ......................................... 1/4-20 x 1.................... 4

63 .............J-5041271 ................Right Mounting Plate............................................ .................................... 1

64 .............5518170 ...................Self Tapping Screw ............................................. 3/16-24 x 3/8............... 7

68A ........... TS-0208041 ...........SHCS .................................................................. 5/16-18x3/4................. 2

68B ........... 5513513 ................... Spacer, Threaded ................................................ .................................... 1

68C...........5513514 ...................Plate, Bracket....................................................... .................................... 1

68D...........5513515 ...................Pickup, Magnetic.................................................. .................................... 1

68E ........... 5513516 ................... Screw ................................................................... .................................... 2

68F ...........5513521 ...................Plate ..................................................................... .................................... 1

69 .............J-5041320 ................Cover, Pulley........................................................ .................................... 1

69A ........... J-5513517 ................ Bracket, Face Plate.............................................. .................................... 1

70 .............J-5513518 ................Plate, Face ........................................................... .................................... 1

70A ........... 5513519 ................... LED Display 1Ph .................................................. .................................... 1

.................5513736 ...................LED Display 3 Ph................................................. ......................................

70B ........... 5513520 ................... Screw, Locking..................................................... .................................... 2

72 .............9056771 ...................Hex Jam Nut ........................................................3/8-16.......................... 1

75 .............J-5041000 ................Head Casting ....................................................... .................................... 1

76 .............J-5518172 ................Left Mounting Plate .............................................. .................................... 1

77 .............9052831 ...................Socket Set Screw................................................. 3/8-16 x 1.................... 1

78 .............TS-0267101 .............Socket Set Screw................................................. 1/4-20 x 1-1/4.............. 2

80 .............9052971 ...................Socket Set Screw ................................................ 5/16-18 x 5/16............. 1

81 .............5034111 ...................Hand Wheel ......................................................... .................................... 1

82 .............5513737 ...................Shaft speed change lever .................................... .................................... 1

86 .............9129051 ...................Hex Nut ................................................................ 7/16-14........................ 1

87 .............5041470 ...................Collar.................................................................... .................................... 1

88 .............9128071 ...................Hex Head Cap Screw ......................................... 7/16-14 x 3-1/2............1

89 .............J-5032560 ................Motor Mounting Bracket ....................................... .................................... 1

94 .............TS-0680032 .............Washer ................................................................. 5/16 ............................. 8

96 .............5507505 ...................Return Spring Bracket.......................................... .................................... 1

97 .............5507507 ...................Drift Pin ................................................................ .................................... 1

98 .............5507506 ...................Switch Mounting Plate ......................................... .................................... 1

99 .............5507527A.................Quill Assembly (see Note) ................................... .................................... 1

100 ...........J-A5816-100-1-1 ......Motor, 1 PH 115/220............................................ 1725 RPM 60 Hz ........1

.................A5816-100-2 ............Motor, 1PH 115/220............................................. 1725 RPM 50 Hz .......1

.................J-A5818-100-1 .........Motor, 3 PH 220/440............................................ 1725 RPM 50/60 Hz .. 1

101 ...........A5816-01 .................Motor Plate........................................................... .................................... 1

110 ...........A5816-02 .................Connect Box......................................................... .................................... 1

111 ...........A5816-03 .................Strain Relief.......................................................... .................................... 1

Note: ....... Quill assembly includes items 3A, 5, 8, 8-1, 9, and 11.

16

Page 17

Exploded View — Head Models J-A5816 and J-A5818

17

Page 18

Parts List - Head Model J-A3816

Item Part No. Description Size Qty.

1 ...............5507580 ...................Chuck (with Key) .................................................. ....................................1

2A ............. 5507495 ................... Arbor .................................................................... #2 MT x JT3 ............... 1

3A ............. 5507496A.................Spindle Assembly ............................................... .................................... 1

4 ...............J-5053070 ................Quill Band............................................................. .................................... 1

5 ...............9010541 ...................O-Ring.................................................................. .................................... 1

6 ...............9054511 ...................Set Screw............................................................. 5/16-18 x 3/8............... 2

6-1 ............9054511A................. Flat Head Screw ..................................................M6 x 16 ....................... 1

7 ...............5032611 ...................Bearing Retainer ................................................. .................................... 1

8 ...............9100331 ...................Bearing................................................................. 6203ZZ........................ 1

8-1 ............9100331A................. Bearing................................................................. 6204ZZ........................ 1

9 ...............5041010 ...................Quill ..................................................................... .................................... 1

10 .............9058561 ...................Wavy Spring Washer ........................................... ....................................1

11 .............9074081 ...................Truarc Retainer ................................................... .................................... 1

13 .............9056981 ...................Hex Jam Nut ........................................................1/4-20.......................... 3

16 .............9052711 ...................Self Tapping Screw.............................................. 8-32 x 3/8.................... 4

17 .............5518157 ...................Power Cord (Single Phase) ................................. .................................... 1

17A ........... 5517463 ................... Power Cord (3-Phase) ......................................... .................................... 1

18A ........... 5507500 ................... Switch (Single Phase) .......................................... .................................... 1

.................5507497 ...................Switch (3-Phase).................................................. .................................... 1

19A ........... 5507501 ................... Slotted Machine Screw ........................................ ....................................4

21 .............5518158 ...................Wiring Harness (1-Phase).................................... .................................... 1

.................5517457 ...................Wiring Harness (3-Phase).................................... .................................... 1

24A ........... 5507502 ................... Socket Head Cap Screw ...................................... .................................... 3

25A ........... 5507503 ................... Return Spring Assemlby ...................................... .................................... 1

26A ........... 5507504 ................... Nylon Nut ............................................................. .................................... 1

27 .............5518159 ...................Phillips Screw....................................................... 1/4-20 x 5/16............... 2

28 .............5518160 ...................Cover Plate .......................................................... .................................... 1

29 .............9127731 ...................Socket Set Screw................................................. 5/16-18 x 5/16............. 1

30 .............5024541 ...................Head Lock (Plain Side) ........................................ .................................... 1

31 .............1000771 ...................Lock Nut Assembly .............................................. ....................................1

33 .............9053661 ...................Retainer................................................................ .................................... 1

34 .............5041201 ...................Bearing Spacer .................................................... .................................... 1

35 .............9100321 ...................Bearing................................................................. .................................... 2

36 .............9070291 ...................Knob..................................................................... .................................... 3

37 .............J-5053000 ................Spoke ................................................................... .................................... 3

38 .............J-5507827 ................Feed Shaft Assembly........................................... .................................... 1

40 .............5053100A.................Rod, Graduated ................................................... .................................... 1

41 .............9056381 ...................Jam Nut................................................................ 5/8-11.......................... 3

41-1 ..........9056381A................. Nut ….M10xP1.5/Spring Washer......................... M10 ............................. 1

42 .............9128611 ...................Hex Head Cap Screw .......................................... 1/2-13 x 4.................... 1

44 .............9052191 ...................Socket Set Screw................................................. 5/16-18 x 1/2............... 4

45 .............5032781 ...................Motor Plate Bar .................................................... .................................... 4

46 .............9057111 ...................Whiz Flange Locknut ........................................... .................................... 4

48 .............9056171 ...................Carriage Bolt ........................................................ 5/16-18 x 1-1/2............ 4

49 .............9058051 ...................Split Lock Washer ................................................ 1/2 ID .......................... 4

50 .............9056841 ...................Hex Nut ................................................................ 1/2-13.......................... 4

51 .............5518161 ...................Step Pulley (Motor) .............................................. ....................................1

52 .............5518162 ...................Socket Set Screw................................................. 1/4-20 x 5/16............... 2

53 .............5042011 ...................Key (Motor) .......................................................... .................................... 1

54 .............5518163 ...................Drive Belt.............................................................. .................................... 1

55 .............5518164 ...................Step Pulley (Spindle) ........................................... .................................... 1

55A ........... 5518165 ................... Spindle Pulley Shaft ............................................. .................................... 1

55B ........... 5518166 ................... Key ....................................................................... 5 x 45 .......................... 1

57 .............9058571 ...................Spring Washer .................................................... .................................... 2

61 .............9057461 ...................Washer................................................................. 1/4 ............................... 3

62 .............9052101 ...................Hex Head Cap Screw .......................................... 1/4-20 x 1.................... 4

63 .............J-5518167 ................Mounting Plate ..................................................... .................................... 1

18

Page 19

Parts List - Head Model J-A3816

Item Part No. Description Size Qty.

64 .............9138011 ...................Self Tapping Screw.............................................. #10 x 3/4 Type A......... 4

69 .............J-5518168 ................Pulley Cover (w/door & latch) .............................. .................................... 1

70 .............J-5518169 ................Face Plate ............................................................ .................................... 1

75 .............J-5041000 ................Head Casting ....................................................... .................................... 1

76 .............J-5518167L ..............Left Mounting Plate .............................................. .................................... 1

86 .............9129051 ...................Hex Nut ................................................................ 7/16-14........................ 1

87 .............J-5041470 ................Collar .................................................................... .................................... 1

88 .............9128071 ...................Hex Head Cap Screw ......................................... 7/16-14 x 3-1/2............1

89 .............J-5032560 ................Motor Mounting Bracket ....................................... .................................... 1

94 .............9055281 ...................Rubber Washer .................................................... .................................... 4

96 .............5507505 ...................Return Spring Bracket.......................................... .................................... 1

97 .............5507507 ...................Drift Pin ................................................................ .................................... 1

98 .............5507506 ...................Switch Mounting Plate ......................................... .................................... 1

99 .............5507527A.................Quill Assembly (see Note) ................................... .................................... 1

100 ...........J-5507812 ................Motor, 1 PH 115/220............................................ 1725 RPM 60 Hz ........ 1

.................J-5514604 ................Motor, 1PH 115/220 .............................................1725 RPM 50 Hz ....... 1

.................J-5507813 ................Motor, 3 PH 220/440 ............................................1725 RPM 50/60 Hz .. 1

Note: Quill assembly includes items 5, 7, 8, 8-1, 9, 10 and 11.

19

Page 20

Exploded View — Head Model J-A3816

69

27

26A

18A

28

25A

19A

24A

98

21

16

96

42

70

To Motor

55

55B

29

17A

11

8

5

3

3

4

57

33

Power

44

55A

45

46

75

89

49

76

62

44

50

30

61

54

63

45

31

64

36

49

37

38

50

17

100

51

52

53

94

47

48

87

9

9

9

Note

︵

8-1

1

︶

86

88

41

5

40

6-1

6

4

41-1

3A

97

2A

1

20

Page 21

Parts List – Base Floor Models J-A3816, J-A5816 and J-A5818

Item Part No. Description Size Qty.

1............... 1000771................... Locknut......................................................................................................1

2............... 5003751................... Table Lock (Plain Side) .............................................................................1

3............... J-5507508................ Table..........................................................................................................1

4............... 5507509................... Hex Head Cap Screw ................................................................................1

5............... TS-0061091............. Cap Screw ............................................................7/16-14 x 3-1/2 ............1

6............... J-5041470................ Collar .........................................................................................................1

7............... 9129051................... Hex Nut.................................................................7/16-14 ........................1

8............... J-5507528................ Base...........................................................................................................1

9............... 5507510................... Standard Column.......................................................................................1

................. 5511850................... Short Column.............................................................................................1

10............. J-5507511................ Flange (Base/Column)...............................................................................1

11............. 5630771................... HHCS....................................................................1/2-12 x 1-1/2 ..............4

12............. J-5507571................ Cover Plate ................................................................................................1

13............. 5507570................... Bushing......................................................................................................1

14............. 5507513................... Worm, Table Raiser...................................................................................1

15............. 5507514................... Gear, Table Raiser ....................................................................................1

16............. 5507515................... Shaft, Table Raiser....................................................................................1

17............. 5507516................... C-Ring, Table Raiser .................................................................................2

18............. TS-0050051 ............ SHCS....................................................................1/4 x 1..........................4

19............. 5507518................... Socket Head Set Screw........................................5/16-18 x 3/8 ...............1

20............. J-5507519................ Crank, Table Raiser...................................................................................1

21............. 5507520................... Handle, Table Raiser.................................................................................1

22............. 5507521................... Rack...........................................................................................................1

23............. J-5507522................ Rack Ring..................................................................................................1

25............. 5507816................... Table Raiser Assembly..............................................................................1

21

Page 22

Exploded View – Base Floor Models J-A3816, J-A5816 and J-A5818

22

Page 23

Notes

23

Page 24

WMH Tool Group, Inc.

427 New Sanford Road

LaVergne, Tennessee 30786

Phone: 800-274-6848

www.wmhtoolgroup.com

24

Loading...

Loading...