Page 1

This Manual is Bookmarked

CUS

R

108026

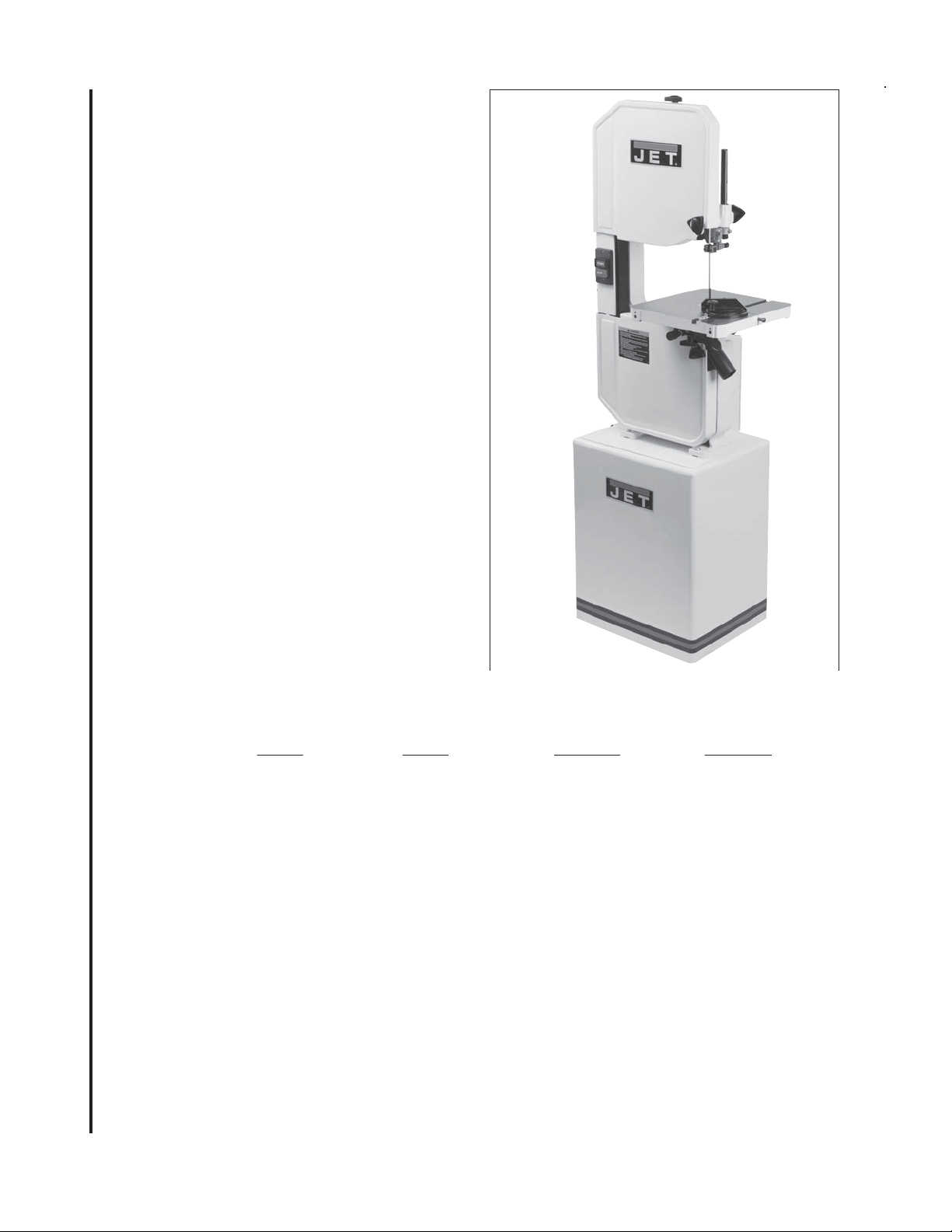

Operating Instructions and Parts Manual

14-Inch Vertical Band Saws

Models: J-8201, J-8203K, J-8201VS, J-8203VS

Model J-8201 shown

WMH TOOL GROUP, Inc.

427 New Sanford Road

LaVergne, Tennessee 30786 Part No. M-414500

Ph.: 800-274-6848 Revision A1 03/09

www.wmhtoolgroup.com Copyright © 2009 WMH Tool Group, Inc.

Page 2

YEAR

DAY

WARRANTY

90

WARRANTY

YEAR

WARRANTY

LIFETIME

WARRANTY

LIFE

YEAR

WARRANTY

YEAR

WARRANTY

Warranty and Service

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our Authorized

Service Centers located throughout the United States can give you quick service. In most cases, any of these WMH Tool

Group Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance

and major repair on your JET® tools. For the name of an Authorized Service Center in your area call 1-800-274-6848.

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check with

your local WMH Tool Group distributor, or visit jettools.com.

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW stands for Metalworking, WW

stands for Woodworking).

Body Repair Kits

Bottle Jacks

90

DAY

Lathe Accessories

Machine Accessories

Mobile Bases

Safety Equipment

Specialty Items

Vise Accessories

1

WARRANTY

YEAR

Air Tools Contractor

Air Tools-Industrial

Air Tools-Light

Industrial

Lubrication

Cable Pullers

Cold Saws

WARRANTY

Hoists-Air

Hoists-Electric

Metal forming

Mill/Drills

Milling Machines

MW Bandsaws

MW Drill Presses

MW Finishing

Equipment

MW Lathes

MW Precision Vises

2

WARRANTY

YEAR

Palet Trucks

Rigging Equip.

Service Jacks

Stackers

Surface Grinders

Tapping

Trolleys-Air

Trolleys-Electric

Web Slings

Winches-Electric

3

YEAR

WW Benchtop

Tools

Warranty reverts to 1 Year Warranty if woodworking (WW) products listed above are used for industrial or

educational purposes.

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Three Year, Five Year and Lifetime Warranties do not cover products used for industrial or educational purposes.

Products with Three Year, Five Year or Lifetime Warranties that are used for industrial or education purposes revert to a

One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse, abuse, negligence or

accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name of

the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the merchandise.

If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price, at our option. We

will return the repaired product or replacement at our expense unless it is determined by us that there is no defect, or that

the defect resulted from causes not within the scope of our warranty in which case we will, at your direction, dispose of

or return the product. In the event you choose to have the product returned, you will be responsible for the shipping and

handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE

EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information

and are not binding. Members of WMH Tool Group reserve the right to effect at any time, without prior notice, those

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever. JET

branded products are not sold in Canada by WMH Tool Group.

Beam Clamps

Chain Hoist Manual

Lever Hoists

WARRANTY

Pullers-JCH Models

Scissor Lift Tables

Screw Jacks

Trolleys-Geared

Trolleys-Plain

Winches-Manual

WW Air Filtration

WW Bandsaws

WW Buffers

5

WARRANTY

YEAR

WW Drill Presses

WW Dust Collectors

WW Dust Filters

WW Dust Fittings

WW Jointers

WW Lathes

WW Planers

WW Sanders

WW Shapers

WW Tablesaws

LIFE

LIFETIME

Fastening Tools

Mechanics Hand Tools

Striking Tools

Vises (no -precision)

Clamps

WARRANTY

®

Page 3

Table of Contents

Cover Page.................................................................................................. 1

General Specifications................................................................................ 4

Warnings and Safety................................................................................... 5

Set-up and Operation.................................................................................. 8

Operating Instructions ............................................................................... 13

Maintenance .............................................................................................. 17

Troubleshooting ........................................................................................ 19

Replacement Parts ................................................................................... 22

Wiring Diagram

3

Page 4

General Specifications

JET’s 14-inch Vertical Band Saws are specially designed to effectively cut a variety of materials including wood, plastic, bakelite, composites, ferrous and

non-ferrous metals. Models J-8201 and J-8203 are

wood and metal cutting band saws.

JET’s Model J-8201VS and J-8203VS 14-inch Variable Speed Band Saws are ideally suited for metal

cutting only with an infinitely variable speed range from

116 to 334 SFPM. The variable speed drive system

allows the operator to fine-tune the blade speed to

the material being cut to maximize the life of today’s

bi-metal blades. These versatile and dependable saws

are capable of contour cutting, straight cutting and

re-sawing, and these band saws can cut delicate

curves in thick or thin stock.

Model Stock Number

J-8201 414500

J-8203 414504

J-8201VS 414502

J-8203VS 414503

4

Specifications

Capacity J-8201 J-8203 J-8201VS J-8203VS

Standard ..............6-in. under guide ..... 6-in. under guide ....... 6-in. under guide ...... 6-in. under guide

With 12-in. Riser ..12-in. under guide ... 12-in. under guide ..... 12-in. under guide .... 12-in. under guide

Blade to frame ..... 13.5-in. .................... 13.5-in. ..................... 13.5-in. ..................... 13.5-in.

Motor

Rating .................. 1 HP 1-Ph ............... 1 HP 3-Ph ................. 1 HP 1-Ph ................ 1 HP 3-Ph

Voltage................. 115 vac .................... 220/440 vac .............. 115 vac .................... 220/440 vac

Speed .................. 1725 rpm ................. 1725 rpm .................. 1725 rpm.................. 1725 rpm

Cutting Speeds

Wood (SFPM) ...... 3300 ........................ 3300 ......................... 2600 ......................... 2600

Metal (SFPM) ....... 39, 57, 78, 107, ....... 39, 57, 78, 107, ........ 116 – 334 ................. 116 – 334

142, 196, 278 .......... 142, 196, 278 ............Variable Speed ......... Variable Speed

Dimensions

Length ................. 20 Inches ................ 20 Inches ..................20 Inches ................. 20 Inches

Width ................... 16 Inches ................ 16 Inches .................. 16 Inches ................. 16 Inches

Height .................. 66 Inches ................ 66 Inches .................. 66 Inches ................. 66 Inches

Height from Floor ..... 66 Inches ................ 66 Inches ..................66 Inches ................. 66 Inches

Table Tilt to Right .....45 Degrees ............. 45 Degrees ............... 45 Degrees .............. 45 Degrees

Table Tilt to Left ....... 10 Degrees ............. 10 Degrees ............... 10 Degrees .............. 10 Degrees

Miter Gauge Groove

Width ...................3/4-Inch ................... 3/4-Inch .................... 3/4-Inch .................... 3/4-Inch

Depth ...................3/8-Inch ................... 3/8-Inch .................... 3/8-Inch .................... 3/8-Inch

Miter Gauge ............. Standard .................. Standard ...................Standard .................. Standard

Blade Dimension

Standard ..............3/8x0.025x92.5 In.... 3/8x0.025x92.5 In. .... 3/8x0.025x92.5 In. ... 3/8x0.025x92.5 In.

Page 5

- Misuse of this machine can cause serious injury.

- For safety, machine must be set up, used and

serviced properly.

- Read, understand and follow instructions in the

Operating Instructions and Parts Manual which

was shipped with your machine.

When Setting up Machine:

- Always avoid using machine in damp or poorly

lighted work areas.

- Always be sure the machine support is se curely anchored to the floor or the work bench.

When Using Machine:

- Always wear safety glasses with side shields

(See ANSI Z87.1)

- Never wear loose clothing or jewelry.

- Never overreach - you may slip and fall.

When Servicing Machine:

- Always disconnect the machine from its electri-

cal supply while servicing.

- Always follow instructions in Operating Instruc tions and Parts Manual when changing acces sory tools or parts.

- Never modify the machine without consulting

JETCorporation.

You - the Stationary Power Tool User - Hold

the Key to Safety.

Read and follow these simple rules for best results and

full benefits from your machine. Used properly,

machinery is among the best in design and safety.

However, any machine used improperly can be rendered

inefficient and unsafe. It is absolutely mandatory that

those who use our products be properly trained in how to

use them correctly. They should read and understand

the Operating Instructions and Parts Manual as well as

all labels affixed to the machine. Failure to follow all of

these warnings can cause serious injuries.

JET’s

WARNING: For your own safety read instruction manual before

operating band saw.

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it

on.

3. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

4. DON’T USE IN DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations, or

expose them to rain. Keep work area well lighted.

5. KEEP CHILDREN AWAY. All visitors should be kept

safe distance from work area.

6. MAKE WORKSHOP KID PROOF with padlocks,

master switches, or by removing starter keys.

7. DON’T FORCE TOOL It will do the job better and

safer at the rate for which it was designed.

8. USE RIGHT TOOL Don’t force tool or attachment

to do a job for which it was not designed.

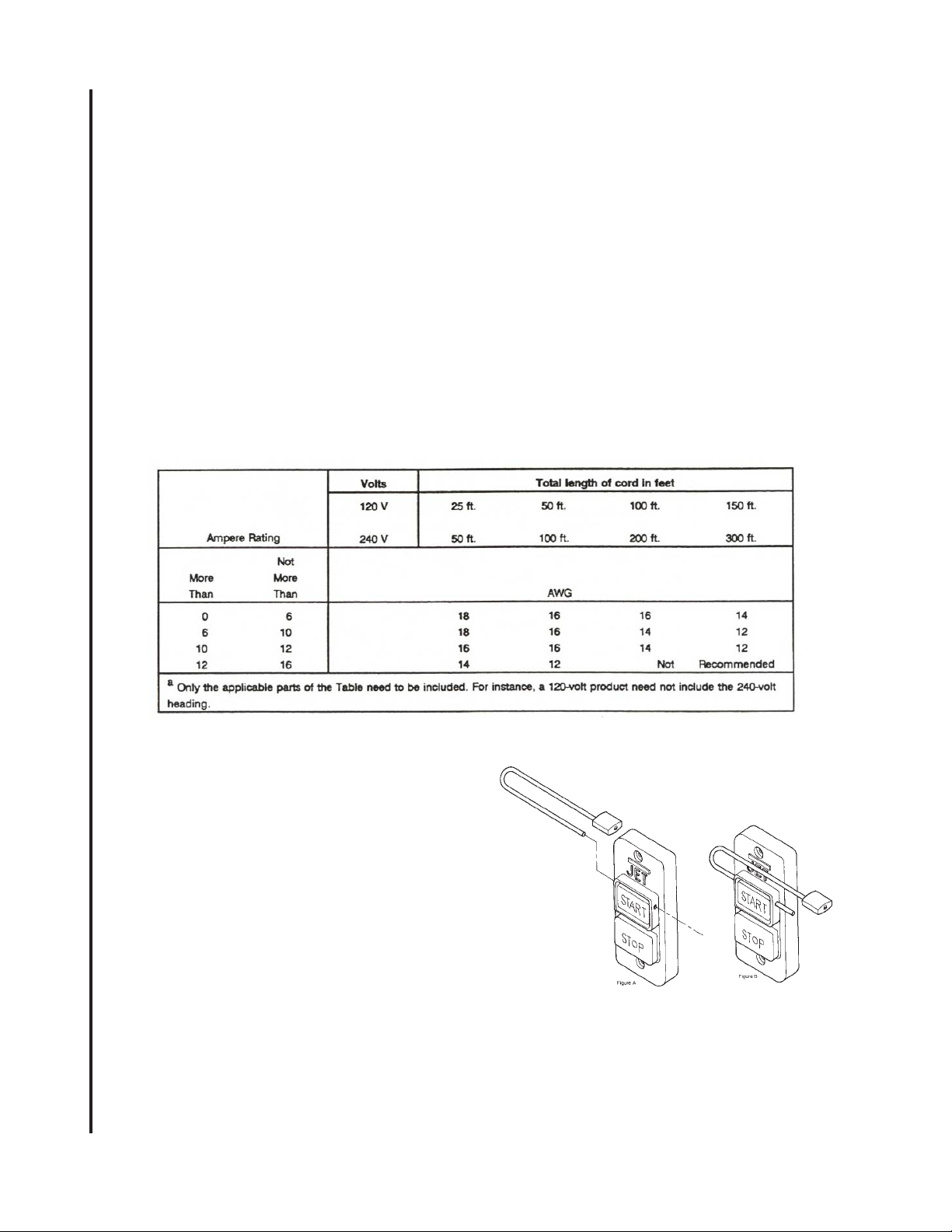

9. USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. Table 1 shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier

gage. The smaller the gage number, the heavier the

cord.

10. WEAR PROPER APPAREL Do not wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair

covering to contain long hair.

11. WEAR EYE PROTECTION. Always use safety

glasses. Also use face or dust mask if cutting operation is dusty. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use clamps or a vise to hold

work when practical. It’s safer than using your hand

and it frees both hands to operate tool.

13. DON’T OVERREACH. Keep proper footing and

balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing; when

changing accessories, such as blades, bits, cutters,

and the like.

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position before plugging in.

17. USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for recommended accessories. The use of improper accessories may cause risk

of injury to persons.

18. NEVER STAND ON TOOL Serious injury could

occur if the tool is tipped or if the cutting tool is unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further use of

the tool, a guard or other part that is damaged should

5

Page 6

be carefully checked to determine that it will operate

properly and perform its intended function - check for

alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or replaced.

20. DIRECTION OF FEED. Feed work into a blade or

cutter against the direction of rotation of the blade or

cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Don’t leave tool until it comes

to a complete stop.

22. DO NOT REMOVE JAMMED CUTOFF PIECES

until the blade has stopped.

23. MAINTAIN PROPER ADJUSTMENT of blade ten-

sion, blade guides and thrust bearings.

24. ADJUST UPPER BLADE GUIDE TO JUST CLEAR

WORKPIECE.

25. HOLD WORKPIECE FIRMLY AGAINST TABLE.

General Electrical Cautions

This saw should be grounded in accordance with

the National Electrical Code and local codes and ordinances. This work should be done by a qualified

electrician. The saw should be grounded to protect

the user from electrical shock.

Caution: For circuits which are far away from the

electrical service box, the wire size must be increased

in order to deliver ample voltage to the motor. To minimize power losses and to prevent motor overheating

and burnout, the use of wire sizes for branch circuits

or electrical extension cords according to the following table is recommended.

a

6

Switch Padlock

Model No. BP-1, Stock No. 709736

Minimum gage for cord

To safeguard your machine from unauthorized

operation and to avoid accidental starting by young

children, the use of a padlock is highly recommended.

Model BP-1 is available from your local authorized

distributor or by calling JETat 800-274-6848.

Ordering Information

Model No BP-1

Stock No. 709736

To lock the main switch in the OFF position, remove

the switch key from the switch. Place the key in a

location that is inaccessible to children and others

not qualified to use the tool.

Figure A Figure B

For three phases tool without locked off feature shall

1. Open the padlock (Fig. A).

have the following instruction:

2. Insert through holes in the start button (Fig. B).

3. Close the padlock.

4. Place the key in a safe place and out of reach

of children.

The installer shall follow local regulations and

National Electrical Code, ANSI/NFPA 70 installation

requirements.

Page 7

Safety Instructions on Sawing Systems

1. Always wear leather gloves when handling saw

blade. The operator shall not wear gloves when

operating the machine.

2. All doors shall be closed, all panels replaced, and

other safety guards in place prior to the machine

being started or operated.

3. Be sure that the blade is not in contact with the

workpiece when the motor is started. The motor

shall be started and you should allow the saw to

come up to full speed before bringing the saw

blade into contact with the workpiece.

4. Keep hands away from the blade area. See

Figure A.

5. Remove any cut off piece carefully while keeping

your hands free of the blade area.

6. Saw must be stopped and electrical supply must

be cut off before any blade replacement or adjustment of blade support mechanism is done, or

before any attempt is made to change the

drive belts or before any periodic service or maintenance is performed on the saw.

7. Remove loose items and unnecessary

workpieces from area before starting machine.

8. Bring adjustable saw guides and guards as close

as possible to the workpiece.

9. Always wear protective eye wear when operating, servicing, or adjusting machinery. Eyewear

shall be impact resistant, protective safety

glasses with side shields complying with ANSI

Z87.1 specifications. Use of eye wear

which does not comply with ANSI Z87.1 specifications could result in severe injury from

breakage of eye protection.

See Figure B

10. Nonslip footwear and safety shoes are recommended. See Figure C.

11. Wear ear protectors (plugs or muffs) during

extended periods of operation. See Figure D.

12. The workpiece, or part being sawed, must be

securely clamped before the saw blade enters

the workpiece.

13. Remove cut off pieces carefully, keeping hands

away from saw blade.

14. Saw must be stopped and electrical supply cut

off or machine unplugged before reaching into

cutting area.

15. Avoid contact with coolant, especially guarding

your eyes.

B

C

DA

7

Page 8

Introduction

Setup and Operation

This manual includes operating and maintenance instructions for the JET14-Inch Vertical Band Saws,

Models J-8201, J-8203, J-8201VS, and J-8203VS. This

manual also includes parts listings and illustrations

of replaceable parts.

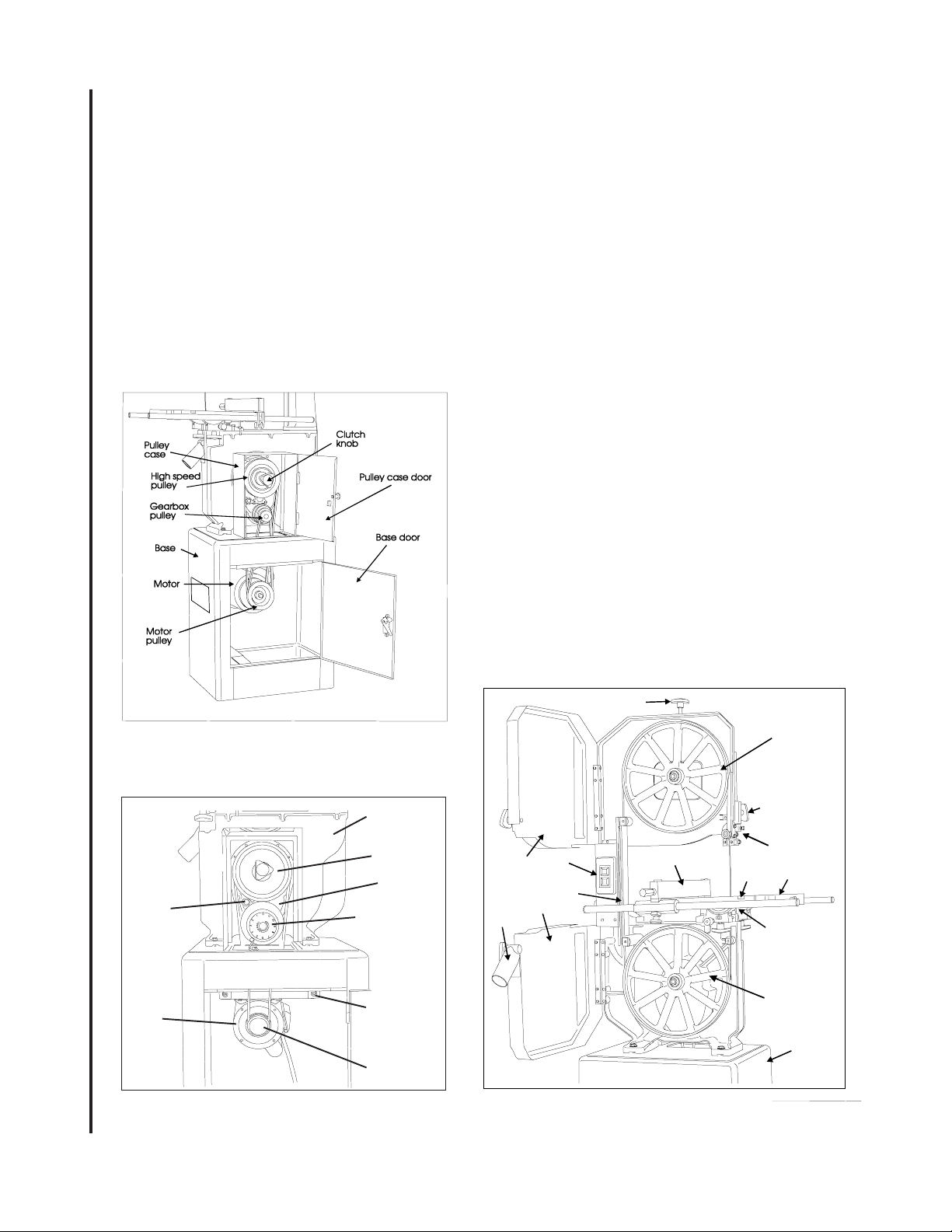

Band Saw Features

Refer to Figures 1 through 3 for key features of the

band saw machine. Refer to the Specifications section for additional information on the features and capabilities of the saw.

Set-up

The band saw is shipped with the saw frame

separated from the saw base. Set-up of the band

saw involves installing the frame and setting-up the

saw on the shop floor.

Assembly of Band Saw

The saw is shipped as two separate units — saw

frame and base. The saw frame must, therefore,

be assembled to the base.

1. Remove loose parts from the saw base and

sawframe.

2. Place the base in the location in the shop and

bolt the base to the floor. (See following

section on spotting saw.) Put shims under the

hold-down bolts as required to make sure the

saw is level.

3. Place the saw frame on the base. Be sure the

pulleys on the saw frame and pulleys in the

base are aligned with each other.

4. Install the four bolts, upper washers, lower

washers, lock washers and nuts that secure

the frame to the base finger tight. Using a

straight edge, align the pulleys. Then tighten

the four attachment bolt and nuts.

5. Loosen the motor mounting bolts and install

the drive belt(s).

Blade tension adjustment

8

Figure 1: Band Saw Features (Rear View)

(Models J-8201/J-8203)

Saw Head

Clutch Knob

Gearbox

Oil Level

Gauge

Drive

Motor

Variable Speed

Control

Pivoting

Motor

Mounting

Plate

Motor Pulley

Figure 2: Band Saw Features (Rear View)

(Models J-8201VS/J-8203VS)

Upper

wheel

switch

guard

Blade guard

Lower wheel guard

Dust chute

Figure 3: Band Saw Features (Front View)

(All Models)

knob

Optional rip

fence

Upper drive

wheel

Upper

blade

guide

support

assembly

Lock Knob

Upper blade

guide and

support

assemblyON/OFF

Miter

Table

slot

Lower drive

wheel

Lower blade

guide and

support

assembly

Base

Page 9

6. Tension the belts (refer to Changing Drive Belt

Position).

7. Check gearbox fluid level in sight gauge. If

required, add lubricant to bring level halfway up

the sight gauge. (Two containers of Shell

Spirax 90 HD gear oil are packed with the saw.

The containers have sufficient amount of

lubricant to fill the gearbox.)

8. Check blade tension and support mechanism

adjustment (refer to Changing Saw Blades).

9. Plug the motor cable into the switch box on the

saw frame. For 3-phase motors, follow the

instructions in the Electrical section to complete the electrical hookup.

NOTE: Observe all electrical codes. Local codes or

difficult environmental conditions may demand special electrical hook-ups. Always use a licensed

electrician for any special electrical hook-up.

Setting-up Saw

The saw should be bolted securely to the shop floor

to make sure the saw is stable when sawing long,

heavy or unwieldy work pieces. Always use extra

support for long or heavy stock.

There are lugs in the bottom of the saw base for use

in bolting down of the saw. After positioning the saw,

open the door in the base and mark the positions of

the four lug holes. Move the saw to expose the marks.

Prepare for attachment as required by the attachment

method being used. Install the applicalbe fasteners.

Install shims as required to level the saw. Tighten the

fastners to secure the saw to the floor.

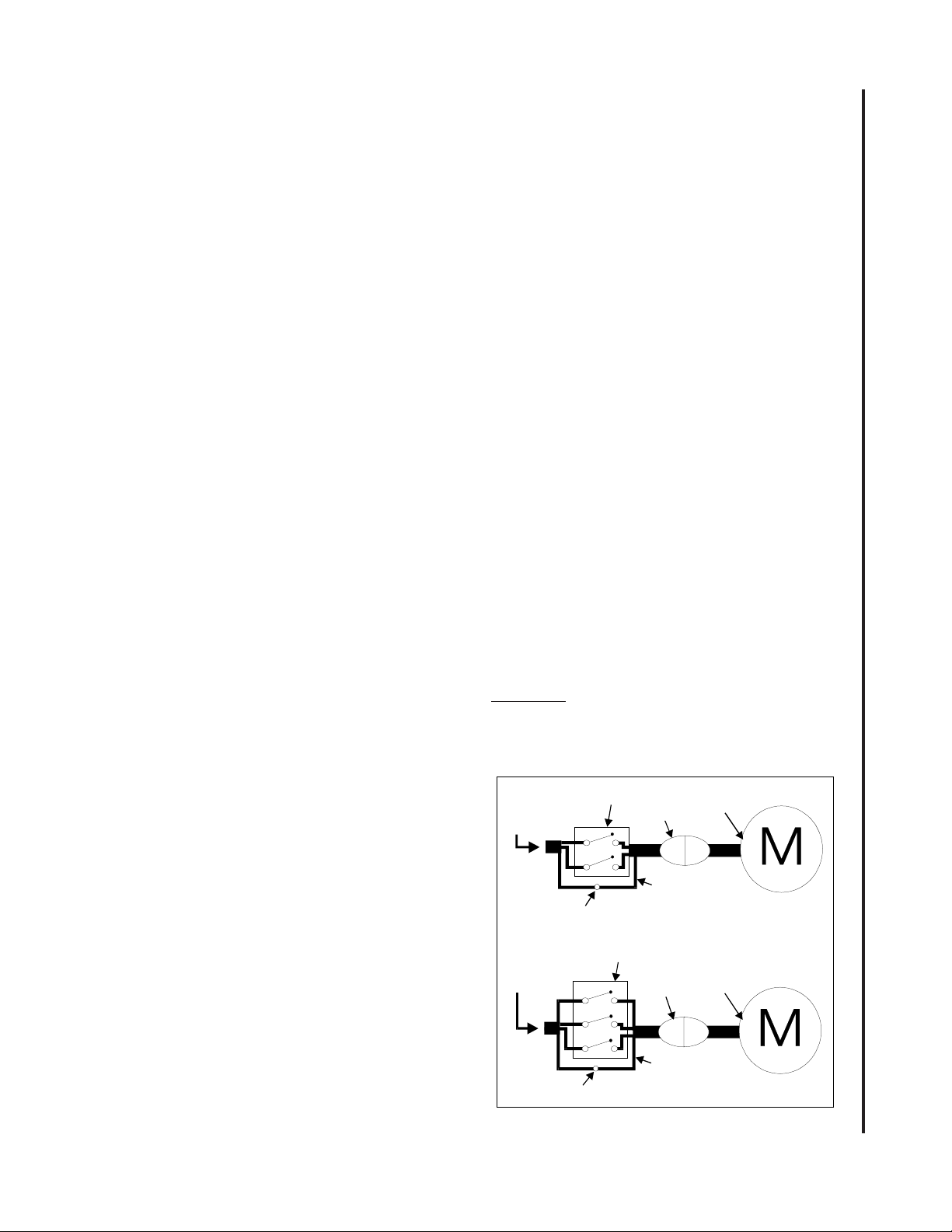

Electrical

Models J-8201 and J-8201VS are delivered with a 115

volt single phase motor. Models J-8203 and J-8203VS

are delivered with a 220/440 volt, 3-phase motor.

Connecting to 3-phase power

1. Disconnect and lock out the branch circuit to

the saw before attempting electrical connections.

2. Connect the green or green-with-white-trace

wire to the branch circuit ground wire.

3. Connect the remaining three wires to the

power wires in the 3-phase branch circuit.

4. Reestablish power in the electrical branch.

5. Turn on power to the saw motor using the

switch.

6. Observe the direction of the blade. It should

be going DOWNWARD, into the slot on the

table. If it is not going downward, the power

wires are hooked-up incorrectly.

7. To correct hook-up, disconnect and lock out

power to the branch, again. Reverse any two

of the power wires on the hook-up to the saw

cable.

8. Reestablish power in the branch and turn the

saw on again. The blade should now be going

downward into the table slot.

Note: local electrical codes or other codes may re-

quire direct connection to a covered, protected junction box, or other electrical hook-up method. Especially under difficult industrial conditions, specialized electrical connections may be necessary.

For special electrical hook-ups, a licensed electrician should be used to connect the saw to power.

CAUTION: KNOW AND OBSERVE ALL LOCAL

AND OTHER APPROPRIATE ELECTRICAL

CODES WHEN ATTACHING THIS BAND SAW

TO YOUR POWER SUPPLY.

1-ph.

power

source

Switch

Plug

Motor

9

When the saw is a 115 volt model, it is supplied with

a standard 115 volt plug and power cord which can be

plugged into any suitable branch circuit.

When the saw is equipped with a 3-phase motor there

will be no plug on the 4-wire cable to the saw switch

box. Instead, follow these instructions to connect the

3-phase motor to the power source:

3-ph.

power

source

Green or green

with white trace

Ground lug

Switch

Plug

Green or green

with white trace

Ground lug

Figure 4: Wiring Diagrams

Motor

Page 10

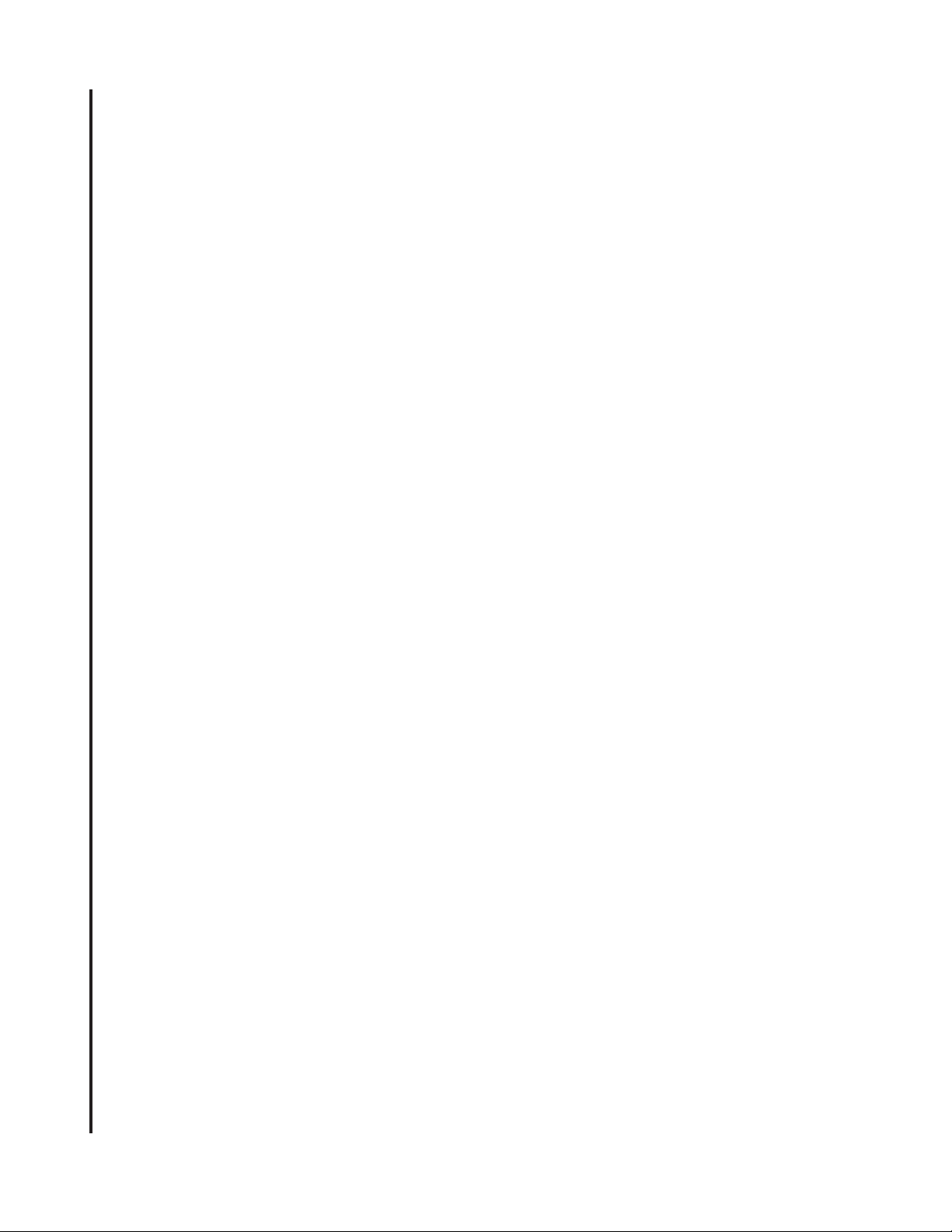

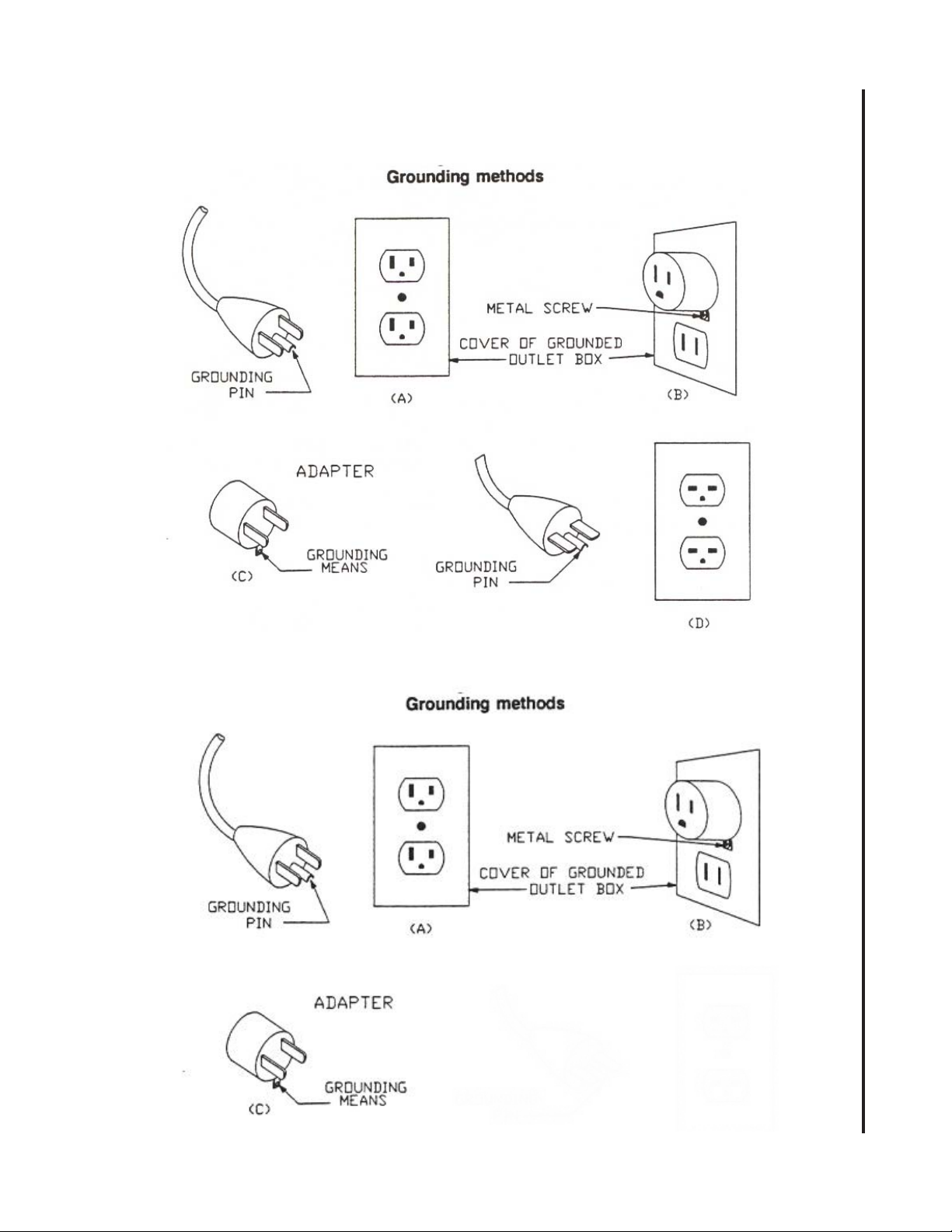

GROUNDING INSTRUCTIONS

1. All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current

to reduce the risk of electric shock. This tool is

equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug

must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the

outlet; have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor with insulation having an outer surface that is

green with or without yellow stripes is the equipmentgrounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is

properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool’s plug.

2. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

less than 150 volts:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in Sketch A.

The tool has a grounding plug that looks like the plug

illustrated in Sketch A. A temporary adapter, which

looks like the adapter illustrated in Sketches B and

C, may be used to connect this plug to a 2-pole receptacle as shown in Sketch B if a properly grounded

outlet is not available. The temporary adapter should

be used only until a properly grounded outlet can be

installed by a qualified electrician.(This adapter is

not permitted in Canada) The green-colored rigid

ear, lug, and the like, extending from the adapter must

be connected to a permanent ground such as a properly grounded outlet box.

3. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

between 150 – 250 volts, inclusive:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in Sketch A.

The tool has a grounding plug that looks like the plug

illustrated in Sketch A. Make sure the tool is connected to an outlet having the same configuration as

the plug. No adapter is available or should be used

with this tool. If the tool must be reconnected for use

on a different type of electric circuit, the reconnection

should be made by qualified service personnel; and

after reconnection, the tool should comply with all

local codes and ordinances.

10

Repair or replace damaged or worn cord immediately.

4. Permanently connected tools:

This tool should be connected to a grounded metal

permanent wiring system; or to a system having an

equipment-grounding conductor.

Page 11

For 115/230V

For 115 only

11

Page 12

12

Installing Optional Frame Riser

NOTE: Refer to the illustrations in the Replacement

Parts section for location of the parts used on

the frame riser.

1. Remove the saw blade (refer to Changing Saw

Blades).

2. Remove the two screws at the top and bottom

of the blade guide that holds the blade guide on

the frame.

WARNING: The saw must be turned off and

power disconnected any time the rubber

protectors are being changed.

3. Unplug the electrical cord or open the circuit

breaker in the branch circuit.

4. Support the upper frame and wheel assembly

with a strap attached to an overhead crane.

Use additional straps to be sure the frame

assembly will be held in a stable position when

it is lifted off the lower frame assembly.

5. Remove the nut on the bolt that clamps the

upper frame to the lower frame and remove the

bolt, two washers and nut.

6. Lift the upper frame high enough off of the

lower frame to clear the riser casting.

7. Be certain the mating surfaces of the lower

frame, riser, and upper frame are all clean and

free from dirt and debris.

8. Position the riser casting over the lower frame.

Make sure the locating dowels are inserted in

the mating holes in the riser casting.

9. Lower the upper frame onto the riser casting.

Make sure the locating dowels fit into their

mating holes.

10. Put the new (longer) attaching bolt and top

washer through the upper frame and riser, into

the lower frame.

11. Put a washer and nut on the bolt and tighten

securely.

12. Attach the bracket hooks to the top and bottom

of the blade guard using self-tapping screws.

13. Attach the blade guide using the screws that

held the original (shorter) guard.

14. Remove the old (shorter) blade guide post

assembly from the upper frame.

15. The guide support assembly with the carbide

guides and blade support bearings should be

transferred to the new, longer support rod.

Several other new parts are included for this

component. (Refer to the parts illustrations for

more detail.)

16. Install a new 105-inch blade (refer to Changing

a Blade). Make sure blade tension and tracking

are checked and adjusted as required.

18. Install the extension plug cable between the

motor plug and switch plug.

19. Plug the electrical cord into the power

source or close the circuit breaker on the

branch circuit. Operate the band saw to

verify blade tracking.

Installing Optional Rip Fence

The rip fence slides on two rails attached at the

front and rear of the work table. Install the fence

mechanism as follows:

NOTE: Refer to the illustrations in the Replace-

ment Parts section for location of the parts

used on the rip fence.

1. Slide the rails into the fence.

2. Ease the fence and rails into position on the

table.

3. Using the four spacers and four attachment

bolts, attach the rails securely to the saw

table.

4. The fence can now be adjusted and used

according the instructions in Adjustment and

Use of Optional Rip Fence.

Page 13

Operating Instructions

Operating Controls

START/STOP Switch

Figure 6 provides suggested blade speeds for

various

types of materials. The recommended speeds

should be decreased 30 to 50% when using

carbon steel blades. (The chart provides speeds

that are based on cutting a 4-inch thick work piece

using a bi-metal blade without cutting fluid.)

The START/STOP switch (refer to Figure 5) is

used to turn on the band saw drive motor. The

START switch has a molded guard which prevent

inadvertent pressing of the START pushbutton.

START/STOP Switch

Guarded START

Switch

E-Stop

Figure 5. START/STOP Controls

The STOP pushbutton is not guarded to allow use

as an E-stop in an emergency.

Variable Speed Control

The variable speed control (refer to Figure 9) is

used to change the speed of the saw blade. Refer

to Adjusting Blade Speed for additional information on the use of the variable speed control.

Operating Instructions

Saw blades

The JET14-inch saws accept blades from 1/8-inch

wide to 3/4-inch wide. The narrower widths are

used for cutting shapes or circles; the wider widths

are used for straight cuts.

For straight cuts, use the widest available saw

blade. A wide blade provides cutting stability, and

allows for more accurate and straighter cuts.

Blade speed effects the efficiency of the cut and

the service life of the blade. Good shop practice

requires that work-hardening materials, such as

stainless steel, require the cut be completed in a

single pass. Otherwise, the effect of stopping the

cut can result in hardening of the cut interface.

Other materials such as wood require higher blade

speeds to prevent fiber tearing. The chart in

The following conditions should also be considered:

1. Increase speed 15% for materials 1/4-inch

thick, 12% for 3/4-inch thick, 10% for 1 1/4inch thick, and 5% for 2 1/2-inch thick.

2. Decrease speed 12% when cutting 8-inch thick

material.

To avoid tooth breakage, select a blade-tooth pitch

that will have two or more teeth in contact with the

workpiece at all times.

Different blade materials and tooth geometry (pitch

and set) permit sawing a wide range of common

and exotic materials. Contact your industrial

distributor for recommendations on specialized

blades. Using the corrrect blade can save you

time, trouble, and the possibility of dulling and

pemature discarding of the blade you normally

might use. NOTE: Always use a sharp blade.

SHARP BLADES ARE CHEAP INSURANCE

AGAINST POOR CUTTING EFFICIENCY AND

ACCELERATED MACHINE WEAR.

Material being cut

Structural steel shapes

Low carbon steel

Medium carbon steel

High carbon steel

Cr-moly steel

Ni-Cr-moly steel

Chromium steel

Cr-vanadium steel

Tool steel

Stainless steel

Free machining steel

Cast iron

Copper alloy (CU-Zm)

Bronze

Al-bronze

Monel

Titanium alloy

Aluminum (soft)

Aluminum (T-6+)

Carbon

Slate

PTFE sheet, rod, rounds

Hard rubber

Plywood

Other woods

Figure 6. Blade Speed to Material Chart

Speed (SF/M) range

165

160-165

115

90-100

105-135

90-115

80-140

105-115

40-80

40-70

80-100

55-90

55

90

40

40-45

25-40

3000

3000

3000

80-160

3000

3000

3000

3000

13

Page 14

Adjustments

Adjusting Blade Support/Guide Height

The upper blade support and guide mechanism

can be adjusted to accomodate the height of the

work piece.

1. To adjust the support, loosen the knob that

clamps the support rod, then move the support

up or down in its holder. (Refer to Figure

location of the support mechanism.

2. Adjust the support so there is space between

the support and work piece. Space of approximately 1/8-inch is generally appropriate.

Adjusting Blade Tension

Blade tension is set by a spring loaded tension

mechanism on the upper drive wheel. Check the

level of the tension device before cutting. The

tension for various blade widths as indicated on the

casting on the tension device.

Figure 8. Table Tilt Mechanism and Angle Gauge

Adjusting Table Angle

(Refer to Figure 8.) The angle gauge is under the

front of the table. The angle gauge shows the

angle of the table relative to the saw blade. The

table is mounted on trunnions that allow

adjustment downward 45 degrees, and upward 10

degrees. Loosen the two trunnion lock knobs

slightly to adjust the table angle and retighten the

lock knobs.

14

NOTE: by adjusting the positive leveling stop on

the table leveling mechanism, it is possible to tilt

the table upward 10 degrees. When returning

to 0 degrees, the table leveling mechanism

must be reset after completing the sawing

operation (refer to Machine Set-up).

WARNING: When cutting at an angle with a

tilted table, provide a guide against which

the material being cut can rest. Cutting

“freehand” at an angle, can result in injury

and maintaining an accurate cut is it difficult.

Leveling Work Table

The table can be adjusted to level the table relative

to the saw bleade. Use the following method:

WARNING: The saw must be turned off and

power disconnected any time the gearbox

lubricant is being drained or filled.

1. Unplug the electrical cord or open the circuit

Figure 7. Saw Blade Tension and Tracking Mechanism

Page 15

breaker in the branch circuit.

2. Move the upper blade guide assembly to the

very top of its travel.

3. Make sure the blade is straight, and fully

tensioned. (A damaged or worn blade may

provide a poor reference surface for squaring

the table.)

4. Loosen the table lock knobs and hold the

table firmly against its positive leveling stop.

6. Using a machinist’s square, check to make

sure the table is 90 degrees to the blade.

USING LEATHER PROTECTIVE GLOVES,

turn the upper drive wheel to check the

squareness at a minimum of three points on

the blade

7. If the table is not level, unlock the lock nut on

the table leveling bolt.

8. Turn the leveling bolt as required to make the

table square to the blade.

9. Lock the leveling bolt lock nut and recheck the

table level. When the table is level...

10. Lock the table lock knobs securely and

recheck for level. Adjust as necessary until

the table is level while everything is tightened

to working tightness.

11. With everything locked down, look at the

pointer for the angle gauge. It should be

exactly on the zero mark of the gauge (Figure

12). If not, loosen the pointer screw, adjust the

pointer until it is on zero, then tighten the

pointer screw while holding the pointer securely in position on zero.

Adjusting Miter Gauge Slot Parallelism

The miter slot should be parallel to the side of the

blade. If the saw is not cutting straight when using

the miter gauge, the miter slot may not be parallel.

1. Put a straight edge against the blade. Make

sure to position the blade so tooth offset does

not affect the straight edge.

2. Measure from both ends of the miter slot to the

straight edge.3. If the measurements are

not equal at both ends of the slot, loosen six

bolts securing the table to the table trunnions

(see Figures 12 and 13.)

4. Adjust the table until it is parallel with the blade.

5. Tighten the trunnion attaching bolts.

Adjusting Blade Speed

(Models J-8201/J-8203)

Figure 6 on page 9 provides blade speeds for

various materials. To adjust the blade speed,

change the clutch position of the clutch (in or out)

and the position of the drive belt on the pulleys on

the motor and reduction gearbox shafts.

Adjusting Blade Speed

(Models J-8201VS/J-8203VS)

See Figure 9 at bottom of this page.

1. The blade speed is controlled by an adjustment mechanism on the right end of the

saw. Speed increases or decreases as the

knob is turned

2. A placard on the drive belt guard (shown

below) provides recommended speeds for

various materials.

3. A speed indicator is provided on the barrel of

the adjustment mechanism. In surface feet per

minute; Position 0 = 334, 1 = 262, 2 = 216, 3 =

171, 4 = 137, and 5 = 116.

4. Turn the speed adjustment knob to the desired

setting as determined by the material being

cut.

Changing Clutch Position

WARNING: NEVER attempt to shift the clutch

mechanism while the saw is running. The

saw must be turned off before clutch shifted.

15

Front View

Variable

Speed

Control

Figure 9. Variable Speed Control

Speed

Indicator

Top View

Page 16

1. Turn the main switch to off.

2. Pull the door open on the pulley case.

3. Turn the clutch handle clockwise and push in,

to engage the high speed pulley drive. Or, turn

the clutch handle clockwise, and pull out, to

engage the reduction gearbox drive.

5. Release the weight of motor so the motor

pivots downward. The weight of the motor is

provide adequate belt tension.

6. Plug the electrical cord into the power source

or close the circuit breaker on the branch

circuit.

16

NOTE: When pushing or pulling the clutch knob,

the dogs on the clutch mechanism are being

engaged. Take the time make sure the clutch

handle is all the way in, or all the way out, so the

clutch dogs are in full engagement when the saw

is started.

4. Close the pulley case door.

5. Plug the electrical cord into the power source or

close the circuit breaker on the branch circuit.

Changing Drive Belt Position

WARNING: The saw must be turned off and

power disconnected before changing drive

belt positions.

Refer to Figure 9, below.

1. Unplug the electrical cord or open the circuit

breaker in the branch circuit.

2. Open the door on the machine base and the

door on the pulley case.

3. Push up on the motor to pivot the motor

upward and slacken the drive belt.

4. Move the drive belt to the desired pulley

position.

NOTE: Never force the belts to change pulley

location without pivoting the motor to loosen the

motor belt. Failure to do so can cause damage

to the drive mechanism, and accelerate belt

wear and possibly result in belt failure.

Changing Pulley-to-Belt Position

WARNING: NEVER attempt to change pulley

shaft positions while the saw is running.

The saw must be turned off and power

disconnected any time pulley shaft poistions

are being changed.

1. Unplug the electrical cord or open the circuit

breaker in the branch circuit.

2. Open the door on the machine base and the

door on the pulley case.

3. Push up on the motor to pivot the motor

upward and slacken the drive belt.

4. With the motor drive belt loose, remove both

pulley drive belts.

5. Both of the pulleys are secured to their shafts

with two set screws. These are located in the

bottoms of the V-grooves on the pulleys.

Using a hex wrench, loosen (but do not

remove) all four set screws.

6. Pull the pulleys straight off each shaft.

7. Put the lower pulley on the upper shaft and the

upper pulley on the lower shaft.

8. Push the upper pulley firmly against the

reduction gearbox and tighten the two set

screws which secure it to the shaft.

9. Using a straight edge against the pulley

flanges, make certain the bottom pulley is

aligned with the upper pulley. Then tighten the

two set screws that secure the lower pulley to

the shaft.

Figure 10. Clutch to Pulley Speed Settings

Page 17

10. Install the belts as required (refer to Figure 10).

11. Release the weight of motor so the motor

pivots downward. The weight of the motor will

provide adequate belt tension.

12. The weight of the motor should provide

sufficient tension so the the middle of the small

drive belt is displaced approximately the

thickness of the belt. (The high speed belt is

adjusted at the same time as the smaller belt.)

13. Set the drive clutch to the desired position (IN

or OUT).

14. Close the access doors.

15. Plug the electrical cord into the power source

or close the circuit breaker on the branch

circuit.

Using Miter System

A miter gauge is provided with the band saw. The

miter gauge slips into a slot in the face of the work

table. The miter gauge can be adjusted from 0 to

45 degrees.

Adjust the miter gauge as follows:

1. Loosen the clamping screw on the miter

gauge.

2. Adjust to desired angle.

3. Tighten the clamping screw.

Using Rip Fence

1. Unlock the fence by loosening the lock knob

(ref. 7) and handle (ref. 10.)

2. Slide the fence on its guides until it is the

required distance from the blade.

3. Tighten the lock knob and handle, slightly.

4. Using a machinist’s square, measure the

distance between the edge of the miter slot

and both the front and rear of the rip fence.

Adjust so both distances are equal.

5. Check the fence-to-blade gap, again. Readjust the fence, if necessary, until the blade gap

is correct and the fence is parallel with the

miter slot.

6. Tighten the fence firmly using the lock knob

and handle.

Using the Dust Control Chute

Maintenance

This section contains periodic maintenance

recommendations and maintenance procedures.

Changing Saw Blade

WARNING: The saw must be turned off and

power disconnected any time saw blades

are being changed.

1. Unplug the electrical cord or open the circuit

breaker in the branch circuit.

2. Pull open both upper and lower drive wheel

guards (refer to Figure 1).

3. Release blade tension completely by turning

the tension handle fully counterclockwise.

4. Remove table leveling pin. The pin has a tight

push fit in its slot; it is not threaded. (Refer to

Figure 13.

5. Use a screwdriver to pop out the table insert.

6. Loosen the set screws that lock the guide

blocks. Move the guide blocks outward. Then

turn the micro-adjusting knob to move the

blade support bearing to the very rear of its

travel.

7. Using a hex wrench, loosen the set screw that

locks the lower blade guide and support

assembly. Move the assembly to the very rear

of its travel by using the micro-adjusting knob

on the back side of the assembly (refer to

Figure 11).

Blade support

bearing

Support

bearing

microadjusting

knob

Blade

Guide block

set screws

Guide block

support

microadjusting

knob

Carbide guide blocks

17

On the lower side of the table, below the cutting

position of the blade, is a plastic tube which can be

attached to a shop vacuum, or to a shop dust

control system. The dust control chute can be seen

in several of the figures used to illustrate the

operation of the saw.

Figure 11. Upper Blade Guides

8. Using a hex wrench, loosen the carbide blade

guide set screws. Open up a reasonably large

gap between the guides; do this on both the

upper and lower blade guides.

Page 18

9. USING LEATHER GLOVES AND ANSI Z87.1

EYEWEAR TO PROTECT YOURSELF FROM

THE CUTTING BLADE, carefully remove the

blade from the drive wheels. Remove the

blade out of the saw table through the table.

10. Hang the removed blade in a safe place.

NOTE: Clean out the interior of the saw with a

shop vacuum. Examine the bearings and other

exposed mechanisms of the saw.

11. Using protective gloves, carefully ease the

replacement blade into the table slot and over

the upper and lower drive wheels.

NOTE: It is possible to install the blade upside

down. Make sure the teeth on the blade are

pointing downward.

NOTE: The blade should be “free standing” at the

cutting throat; the upper and lower blade guides

should not touch the blade at any point. Also,

make sure the blade is in the slot in the blade

guard on the left side of the machine frame.

Refer to Figure 1 to identify the blade guard.

Table leveling

Trunnion

attachment

bolts

Blade guide

microadjusting

knob

Blade

support

bearing

Front

trunnion

lock

knob

bolt

Carbide

blade guide

Guide

block

support

Figure 12. Lower Blade Guide Support

Rear View

Front trunnion

Blade support

bearing microadjusting knob

Rear

trunnion

lock

knob

Table leveling

pin

Lower blade

support bearing

Leveling

bolt lock

nut

18

12. Apply tension to the blade using the tension

knob. The tension levels for various blade

widths are shown on the markings on the

tension device. Refer to Figure 3 for a view of

the tension system.

13. Slowly turn the upper drive wheel by hand,

while OBSERVING THE BLADE TRACKING.

The blade should track, more or less, in the

center of the drive wheel. If the blade does not

track true, adjust the tracking to keep the blade

centered.

14. Unlock the tilt adjustment knob by loosening

its locking wing nut. Both the adjustment knob

and wing nut are identified in Figure 7.

15. Turn the tilt adjustment knob (usually a VERY

LITTLE at a time) to adjust the tilt of the upper

drive wheel. Do this while turning the upper

wheel by hand, and adjusting until the blade

stays centered on the wheel.

16. Tighten the tilt mechanism locking wing nut.

17. Using the micro-adjusting knob, move the

lower blade support assembly (Refer to Figure

12) forward until the support bearing just

contacts the back edge of the saw blade.

18. Adjust the lower carbide blade guides until they

just contact the sides of the blade. Make sure

the guides DO NOT CONTACT THE TOOTH

PORTION OF THE BLADE. The guides

should touch only the flat part of the blade.

After correctly positioning the carbide guide

blocks, tighten the set screws securely.

Trunnion

attachment

bolt

rear

trunnion

Guide block

microadjusting

knob

Front

trunnion

lock knob

Carbide guide block

Rear trunnion

lock knob

Figure 13. Lower Blade Guide Supports

Front View

19. Adjust the upper support assembly so the

support bearing just contacts the back edge of

the saw blade.

20. Adjust the upper carbide blade guides until they

just make contact with the blade BEHIND THE

TOOTH AREA OF THE BLADE. Then tighten

the set screws securely.

21. Replace the table insert.

22. Insert the table pin into its slot.

23. Close the drive wheel guards.

24. Plug the electrical cord into power source or

close the circuit breaker on the branch circuit.

25. Turn on the power and observe the action of

the blade to sure the blade is correctly adjusted.

Page 19

Draining and refilling the reduction

gearbox.

Blade

Guide block

set screws

Carbide guide block

Figure 14. Lower Blade Support Assembly

Blade support bearing

Guide block

support set

screw

Support

bearing

shaft

Replacing drive wheel rubber

protectors

The rubber rings that cover the drive wheels are

called protectors. The protectors protect the wheel

from blade damage and provide a high friction

drive force on the tensioned blade. Over a long

period of service, the protectors wear and may

require replacement.

WARNING: The saw must be turned off and

power disconnected any time the gearbox

lubricant is being drained or filled.

1. Unplug the electrical cord or open the circuit

breaker in the branch circuit.

2. Open the door in the base.

3. Push up on the motor to loosen the drive belts.

4. Remove the pipe plug at the bottom of the

gearbox. Drain the oil into a suitable container

for safe and appropriate disposal.

5. Replace the drain plug.

6. Open the filler plug.

7. Add lubricant until the level is halfway up the

sight gauge window (refer to Figure 15). Use

Shell Spirax HD 90 gear lubricant.

8. Replace the filler plug.

9. Replace the drive belts. Allow the motor to

pivot downward to apply tension to the belts.

10. Close the access door.

11. Plug the electrical cord into the power source

or close the circuit breaker on the branch

circuit.

WARNING: The saw must be turned off and

power disconnected any time the rubber

protectors are being changed.

1. Unplug the electrical cord or open the circuit

breaker in the branch circuit.

2. Remove the blade according to the step-bystep instructions on blade replacement.

3. Remove the rubber protectors from the drive

wheels. Use a flat screwdriver blade or knife

blade to loosen the protectors, being careful

not to nick or score the aluminum drive

wheels.

4. Clean the surface of the drive wheels. Use a

solvent such as mineral spirits as required to

achieve a clean, dry surface for the new

protectors.

5. Carefully slip the replacement protectors onto

the drive wheels.

6. Replace the saw blade and return the saw to

service by following the steps in Changing

Saw Blades.

7. Plug the electrical cord into the power source or

close the circuit breaker on the branch circuit.

Oil Level Gauge

Figure 15. Gearbox Oil Level Gauge

Gear Box Pulley

Periodic Maintenance

Refer to the Periodic Maintenance chart for maintenance that should be performed at various time

intervals.

Troubleshooting

Refer to the Troubleshooting charts for equipment

fault, probable cause and suggested remedy.

19

Page 20

Periodic Maintenance

20

Item

Saw blade

Lower drive

wheel

Upper drive

wheel

Drive wheel

rubber protectors

Drive belts

Action

Listen for sound of

missing teeth

Observe cutting

action for cleanness

and accuracy

Listen for a poor weld

— a “click” as it

passes through the

guide blocks

Watch for signs of

slippage on the drive

wheels (blade occasionally slows or

comes to a stop while

sawing)

Check bearing area

for leakage of lubricant

Check bearing area

for leakage of lubricant

Check for cleanliness

Check for smooth

surfaces and adherence to drive wheel

surface

Interval

Whenever

operating saw

Whenever

operating saw

When changing

blade

Whenever

sawing

Monthly

Monthly

Daily and when

changing blade

Monthly or when

blade slippage

occurs

Maintenance

Replace blade when teeth are

broken

Replace blade when bent — or worn

— Use a wider blade for more

accurate straight cuts

Use a different blade or dress the

weld with a grinder.

Be sure you are using the correct

blade tension — Check drive wheel

rubber strips for cleanliness and

adherence to drive wheel — replace if

necessary

Replace bearing if leakage occurs

Replace bearing if leakage occurs

Wipe or brush clean

Clean when necessary — replace if

damaged or excessively worn

Reduction

gearbox

Blade support

bearings

Carbide blade

guides

Check for glazing

Check sight glass for

level — should be to

halfway point on sight

glass

Check for wear,

damage or lubricant

leakage

Check for excessive

wear

Monthly, or when

slippage occurs

(squealing belt)

Daily

Annually

Monthly and when

changing blade

When changing

blade

Replace a glazed belt — DO NOT USE

BELT DRESSING

Fill up to half-way point on sight glass

with Shell Spirax HD 90

Drain and refill with Shell Spirax

HD 90

Replace when necessary

Replace if excessively worn

Page 21

Troubleshooting

Fault

Excessive blade

breakage

Premature blade

dulling

Probable cause

1. Material loose in vise.

2. Incorrect speed or feed.

3. Teeth too coarse for material.

4. Incorrect blade tension.

5. Saw blade contacts workpiece

before the saw is started.

6. Blade rubs on the wheel flange.

7. Misaligned guides.

8. Cracking at weld.

1. Blade teeth too coarse.

2. Blade speed too high.

3. Hard spots in workpiece or scale

on/in workpiece.

4. Work hardening of material

(especially stainless steel).

5. Insufficient blade tension.

6. Operating saw without pressure

on workpiece.

Suggested remedy

1. Clamp work securely.

2. Refer to Figure 6 or check

Machinist’s Handbook for speed/

feed appropriate for the material

being cut.

3. Check Machinist’s Handbook for

recommended blade type.

4. Adjust blade tension to the point

where the blade just does not slip

on the wheel.

5. Start the motor before placing the

saw on the workpiece.

6. Adjust blade tracking.

7. Adjust guides.

8. Longer annealing cycle.

1. Use a finer tooth blade.

2. Try a lower blade speed.

3. Increase feed pressure (hard

spots). Reduce speed, increase

feed pressure (scale).

4. Increase feed pressure by reducing spring tension.

5. Increase tension to proper level.

6. Do not run blade at idle in/on

material.

Bad cuts

(out-of-square)

Bad cuts (rough)

1. Feed pressure too fast.

2. Guide bearings not adjusted

properly.

3. Inadequate blade tension.

4. Dull blade.

5. Incorrect blade speed.

6. Blade guide assembly is loose.

7. Blade guide bearing assembly

loose.

8. Blade track too far away from

wheel flanges.

9. Guide bearing worn.

1. Blade speed too high for feed

pressure.

2. Blade is too coarse.

1. Decrease pressure.

2. Adjust guide bearing clearance to

0.001 inch (0.002 inch maximum).

3. Gradually increase blade tension.

4. Replace blade.

5. Check blade speed

(see Figure 6).

6. Tighten blade guide assembly.

7. Tighten blade guide bearing

assembly.

8. Adjust blade tracking.

9. Replace worn bearing.

1. Reduce blade speed and feed

pressure.

2. Replace with finer blade.

21

Page 22

Troubleshooting (Continued)

Blade is twisting

Unusual wear on

side/back of blade

Teeth missing/

ripped from blade

Motor running too

hot

1. Blade is binding in the cut.

2. Blade tension too high.

1. Blade guides worn

2. Blade guide bearings not

adjusted.

3. Blade guide bearing bracket is

loose.

1. Blade tooth pitch too coarse for

workpiece.

2. Feed too slow; feed too fast.

3. Workpiece vibrating.

4. Gullets loading up with chips.

1. Blade tension too high.

2. Drive belt tension too high.

3. Blade too coarse for workpiece

4. Blade too fine for workpiece

5. Speed reducer requires lubrication.

1. Decrease feed pressure.

2. Decrease tension on blade

1. Replace blade guides.

2. Adjust blade guide bearings.

3. Tighten blade guide bearing

bracket.

1. Use blade with finer tooth pitch.

2. Increase feed pressure and/or

blade speed.

3. Clamp workpiece securely.

4a. Use blade with a coarse tooth

pitch—reduce feed pressure.

4b. Brush blade to remove chips.

1. Reduce tension on blade.

2. Reduce tension on drive belt.

3. Use blade with fine tooth pitch.

4. Use blade with coarse tooth pitch.

5. Check speed reducer.

22

Excessive speed

reducer noise/

vibration

1. V-belt is too tight.

1. Reset V-belt tension.

Replacement Parts

This section provides exploded view illustrations that show the replacement parts for the JETModel J-8201,

J-8203, J-8201VS, and J-8203VS Vertical Band Saws. Also provided are parts listings that provide part

number and description. The numbers shown on the illustration relate to the item number in the facing parts

listing.

Order replacement parts from:

WMH TOOL GROUP, Inc.

427 New Sanford Road

LaVergne, Tennessee 30786

Ph.: 800-274-68489

www.wmhtoolgroup.com

Identify the replacement part by the part number shown in the parts listing. Be sure to include the model

number and serial number of your machine when ordering replacement parts to assure that you will receive the

correct part.

Page 23

Exploded View and Parts Listing– Base– Models J-8201 and J-8203

In No. Part No. Description Size Qty.

1 ......... J-5513834 ..................... Close Stand ........................................................................................... 1

........... J-5507565 ..................... Closed Stand Assembly w/o Motor ........................................................ 1

2 ......... J-5513835 ..................... Door ...................................................................................................... 1

3 ......... 5513836 ........................ Lock ...................................................................................................... 1

4 ......... 5513837 ........................ Washer .................................................................................................. 1

5 ......... 5513838 ........................ Pan Head Bolt .....................................................M4x5 ........................ 2

........... 5513858 ........................ Lock Assembly (included #3, 4 and 5) ................................................... 1

6 ......... 5513839 ........................ Pad........................................................................................................ 2

7 ......... J-5513861 ..................... Motor Bracket ....................................................................................... 1

8 ......... J-5784391 ..................... Motor ................................................................... 115/230V, 1Ph .......... 1

........... J-5784411 ..................... Motor ................................................................... 230/460V, 3Ph.......... 1

9 ......... 5784421 ........................ Motor Cord .......................................................... 1Ph .......................... 1

........... 5784431 ........................ Motor Cord .......................................................... 3Ph .......................... 1

10 ....... 5513842 ........................ Strain Relief ...........................................................................................2

11 ........ 5784281 ........................ Strain Relief Plate .................................................................................. 1

12 ....... J-5513845 ..................... Pulley Cover .......................................................................................... 1

13 ....... 5513846 ........................ Knob ...................................................................................................... 1

15 ....... TS-1523011 ................... Set Screw ........................................................... M6x6 ........................ 2

16 ....... 5784682 ........................ Pulley .................................................................................................... 1

17 ....... 5513859 ........................ Key...................................................................... 5x5x40 ..................... 1

18 ....... 5513847 ........................ Hex Nut ............................................................... M5 ............................ 4

19 ....... 5513848 ........................ Hex Nut ............................................................... M8 ............................ 5

20 ....... 5513849 ........................ Carriage Bolt ....................................................... M8x16 ...................... 4

21 ....... 5784331 ........................ Hex Head Bolt .....................................................M6x12 ...................... 1

22 ....... 5513851 ........................ Hex Head Bolt .....................................................M8x25 ...................... 2

23 ....... 5782761 ........................ Pan Head Bolt .....................................................M5x12 ...................... 6

24 ....... 5513853 ........................ Flat Washer ........................................................ M5 ............................ 8

25 ....... 5513855 ........................ Flat Washer ........................................................ M6 ............................ 1

26 ....... 5513856 ........................ Flat Washer ........................................................ M8 ............................ 9

27 ....... 5513856 ........................ Lock Washer .......................................................M8 ............................ 6

28 ....... 5513857 ........................ Nylon Nut ............................................................ M8 ............................ 2

29 ....... 5784683 ........................ Carriage Bolt ....................................................... M8x50 ...................... 1

23

Page 24

24

Exploded View and Parts List – Base –Models J-8201VS and J-8203VS

In No. Part No. Description Size Qty.

1 ......... J-5513860 ..................... Close Stand ........................................................................................... 1

2 ......... J-5513835 ..................... Door ...................................................................................................... 1

3 ......... 5513836 ........................ Lock ...................................................................................................... 1

4 ......... 5513837 ........................ Washer .................................................................................................. 1

........... 5513858 ........................ Lock Assembly (included #3, 4 and 5) ................................................... 1

5 ......... 5513838 ........................ Pan Head Bolt .....................................................M4x5 ........................ 2

6 ......... 5513839 ........................ Pad........................................................................................................ 2

7 ......... J-5784684 ..................... Motor Bracket ....................................................................................... 1

8 ......... J-5784391 ..................... Motor ................................................................... 115/230V,1Ph ........... 1

........... J-5784411 ..................... Motor ................................................................... 230/460V,3Ph ........... 1

9 ......... 5784421 ........................ Motor Cord .......................................................... 1Ph .......................... 1

........... 5784431 ........................ Motor Cord .......................................................... 3Ph .......................... 1

10 ....... 5513842 ........................ Strain Relief ...........................................................................................2

11 ........ 5784281 ........................ Strain Relief Plate .................................................................................. 1

12 ....... J-5784685 ..................... Doorframe .............................................................................................. 1

13 ....... J-5784686 ..................... Cover ..................................................................................................... 1

14 ....... 5784687 ........................ Knob ....................................................................M5x12 ...................... 2

15 ....... 5784688 ........................ Motor VS Pulley .................................................................................... 1

16 ....... 5784689 ........................ Locate Plate .......................................................................................... 1

17 ....... 5513859 ........................ Key...................................................................... 5x5x40 ..................... 1

18 ....... 5513847 ........................ Hex Nut ............................................................... M5 ............................ 4

19 ....... 5513848 ........................ Hex Nut ............................................................... M8 .......................... 12

20 ....... 5513849 ........................ Carriage Bolt ....................................................... M8x16 ...................... 4

21 ....... 5784690 ........................ Motor Pulley .......................................................................................... 1

22 ....... 5513851 ........................ Hex Head Bolt .....................................................M8x25 ...................... 8

23 ....... 5782761 ........................ Pan Head Bolt .....................................................M5x12 ...................... 6

24 ....... 5513853 ........................ Flat Washer ........................................................ M5 ............................ 8

25 ....... TS-1523031 ................... Set Screw ........................................................... M6x10 ...................... 2

26 ....... 5513856 ........................ Flat Washer ........................................................ M8 .......................... 16

27 ....... 5513856 ........................ Lock Washer .......................................................M8 .......................... 12

28 ....... TS-1490021 ................... Hex Cap Screw ................................................... M8x16 ...................... 1

29 ....... 5784692 ........................ Rubber Foot .......................................................................................... 4

30 ....... 5784693 ........................ Special Washer ..................................................................................... 4

Page 25

Exploded View – Saw Head – Models J-8201K, J-8203K, J-8201VS, and J-8203VS

25

Page 26

26

Parts List – Saw Head – Models J-8201K, J-8203K, J-8201VS, and J-8203VS

In No. Part No. Description Size Qty.

1 ......... J-5782511 ..................... Upper Arm, Frame ................................................................................. 1

2 ......... J-5783041 ..................... Base ...................................................................................................... 1

3 ......... 5783241 ........................ Dowel Pin .............................................................................................. 4

4 ......... 5782521 ........................ Upper Wheel Sliding Bracket ................................................................ 1

5 ......... 5782591 ........................ Blade Tension Adjustment Knob ............................................................ 1

6 ......... 5782611 ........................ Tension Spring ....................................................................................... 1

7 ......... 5782571 ........................

8 ......... 5782541 ........................ Pivot Pin ................................................................................................ 2

9 ......... 5782531 ........................ Upper Wheel Hinge w/ Shaft.................................................................. 1

10 ....... J-5782631 ..................... Inner Upper Wheel Guard ...................................................................... 1

11 ........ 5782821 ........................ Stud....................................................................................................... 2

12 ....... 5782741 ........................ Fixed Bolt ..............................................................................................2

13 ....... 5782751 ........................ Catch ..................................................................................................... 2

14 ....... 170080 .......................... Stud Latch ............................................................................................. 2

15 ....... TS-1522021 ................... Set Screw ........................................................... M5x8 ........................ 2

16 ....... 5782831 ........................ Blade Guard .......................................................................................... 1

17 ....... 5782841 ........................ Retainer ................................................................................................. 2

18 ....... J-5782891 ..................... Outer Upper Wheel Guard ..................................................................... 1

19 ....... 5782861 ........................ Hinge (Upper) ........................................................................................ 1

20 ....... 5782921 ........................ Knob ....................................................................M8 ............................ 2

21 ....... 5782661 ........................ Upper Wheel ......................................................................................... 1

22 ....... 5782691 ........................ Wheel Protector .................................................................................... 2

24 ....... 5783161 ........................ Lower Wheel ......................................................................................... 1

25 ....... 5782722 ........................ Saw Blade for Metal Cutting ................................ 92-1/2 x 14T/in ......... 1

........... 5782732 ........................ Saw

26 ....... J-5783111 ......................Lower Wheel Guard ............................................................................... 1

27 ....... 5783121 ........................ Dust Chute ............................................................................................ 1

28 ....... 5783081 ........................ Hinge (Lower) ........................................................................................ 1

30 ....... 5783351 ........................ Guide Post ............................................................................................ 1