Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

10” x 16” Horizontal Band Saw

Models J-7020, J-7040

WALTER MEIER (Manuf acturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M- 414472

Ph.: 800-274-6848 Revision B 03/2012

www.walt er meier.c om Copyright © 2012 Walt er Meier (M anufacturi ng) Inc.

Page 2

1.0 Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET® tools. For the name of an Authorized Service Center in

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local Walter Meier distributor, or visit waltermeier.com.

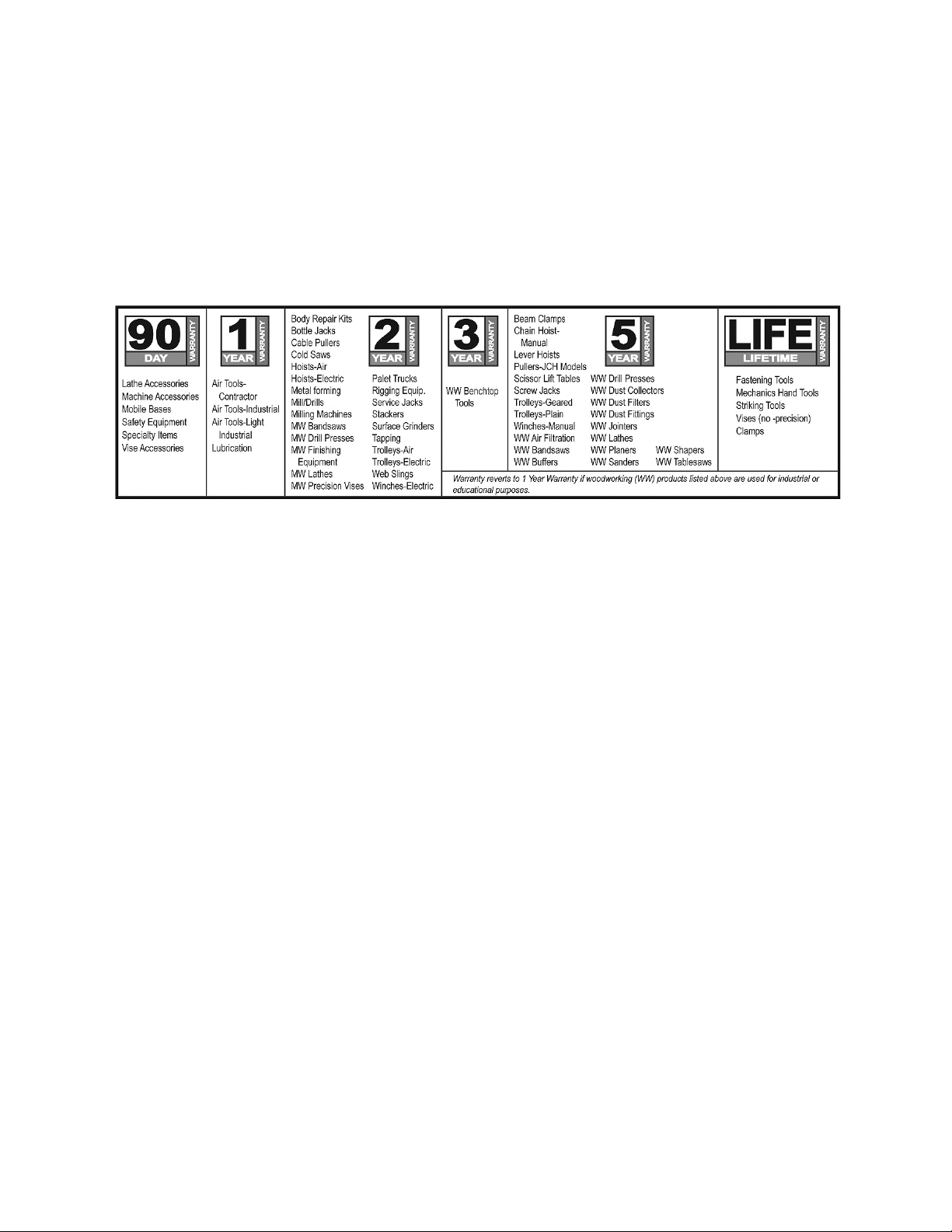

WARRANTY

JET products carry a limited warranty which varies in duratio n based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the e xceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE

LIMITED WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME ST ATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET® branded products are not sold in Canada by Walter Meier.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ............................................................................................................................................ 2

2.0 Table of contents ................................................................................................................................................... 3

3.0 Safety Warnings..................................................................................................................................................... 4

4.0 About this machine and manual ............................................................................................ ............................... 6

5.0 Specifications ......................................................................................................................................................... 6

6.0 Ma chine setup........................................................................................................................................................ 8

6.1 Un crating and spotting ...................................................................................................................................... 8

7.0 Electrical connections............................................................................................................................................ 8

8.0 Operating instructions ........................................................................................................................................... 8

8.1 Controls .............................................................................................................................................................. 8

8.2 Setting blade speed ........................................................................................................................................... 8

8.3 Raising/lowering saw head ............................................................................................................................... 9

8.4 Controlling the cut: Hydraulic feed control ....................................................................................................... 9

8.5 Evaluating cutting efficiency ............................................................................................................................ 10

8.6 Blade selection................................................................................................................................................. 10

8.7 Blade break-in procedures .............................................................................................................................. 10

9.0 Work setup ........................................................................................................................................................... 10

9.1 Securing workpiece for square cuts ............................................................................................................... 10

9.2 Adjusting vise for angle cuts ........................................................................................................................... 10

9.3 Installation and adjustment of work stop........................................................................................................ 11

10.0 Starting the Saw ........................................................................................................ ........................................ 11

10.1 Coolant flow ................................................................................................................................................... 12

10.2 Coolant mixture and quantity ........................................................................................................................ 12

11.0 Adjustments ....................................................................................................................................................... 12

11.1 Blade tracking adjustment............................................................................................................................. 12

11.2 Factory or field procedure ............................................................................................................................. 12

11.3 Blade guide bearing adjustment ................................................................................................................... 13

11.4 Test cutting to verify adjustment accuracy .................................................................................................. 14

11.5 Limit switch adjustment ................................................................................................................................. 14

12.0 Maintenance....................................................................................................................................................... 14

12.1 Cleanin g ......................................................................................................................................................... 14

12.2 Lubrication ...................................................................................................................................................... 15

12.3 Changing blades ............................................................................................................................................ 15

12.4 Changing drive belt........................................................................................................................................ 15

12.5 Replacing drive motor ................................................................................................................................... 16

12.6 Adjusting counterbalance spring .................................................................................................................. 16

12.7 Replacing drive wheel ................................................................................................................................... 16

12.8 Replacing idler wheel or idler bearing .......................................................................................................... 16

12.9 Adjusting blade guides .................................................................................................................................. 16

12.10 Replacing carbide blade guide ................................................................................................................... 17

12.11 Replacing guide bearings ........................................................................................................................... 17

12.12 Replacing blade edge bearings .......................................................................................... ........................ 17

12.13 Replacing wire brush................................................................................................................................... 17

13.0 Tr oublesh ootin g the J-7020/7 040 Band Saws ................................................................................................ 18

14.0 Replacement Parts ............................................................................................................................................ 19

14.1. 1 Base (J-7020/7040) – E xploded Vi ew ...................................................................................................... 20

14.1.2 Base (J-7020/7040) – Parts List............................................................................................................... 21

14.2. 1 Head (J-7020/7040) – E xploded Vi ew ...................................................................................................... 24

14.2. 2 Head (J- 7020/7040) – Parts List .............................................................................................................. 25

15.0 Electrical Connections....................................................................................................................................... 28

15.1 El ectrical Connect ions – si ngle pha se only (model J-7020) ...................................................................... 28

15.2 El ectrical Connect ions – t hree phase only (model J-7040) ........................................................................ 29

3

Page 4

3.0 Safety Warnings

General Cautions

- Misuse of this machine can cause serious injury.

- For safety, the machine must be set up, used and

serviced properly.

- Read, understand and follow the instructions in the

operator’s and parts manual which was shipped

with your machine.

When setting up the machine:

- Always avoid using the machine in da mp or poorly

lighted work areas.

- Always be sure the machine is securely anchored

to the floor or the work bench.

- Always keep the machine guards in place.

- Always put the st art switch in the “OFF” position

before plugging in the machine.

When using the machine:

- Never operate the machine with safety guards

missing.

- Always wear safety glasses with side shields (See

ANSI Z87.1)

- Never wear loose clothing or jewelry.

- Never overreach; you may slip and fall into the

machine.

- Never leave the machine running while unattended.

- Always shut the machine off when not in use.

When servicing the machine:

- Always unplug the machine from the electrical

power before servicing.

- Always follow the instructions in the operators and

parts manual when changing accessory tools or

parts.

- Never modify the machine without consulting

Walter Meier (Manufacturing) Inc.

You — the stationary power tool user — hold the key

to safety.

Read and follow these simple rules for best results

and full benefits from your machine. Used properly,

JET machinery is among the best in design and

safety. However, any machine used improperly can

be rendered inefficient and unsafe. It is mandatory

that those who use our products be properly trained in

how to use them correctly. They should read and

understand the Operator’s and Parts Manual as well

as all labels affixed to the machine. Failure in

following all of these warnings can cause serious

injuries.

Gene ra l Mach inery Warn i ngs

1. Always wear protective eye wear when operating

machinery. Eye wear shall be impact resistant,

protective safety glasses with side shields which

comply with ANSI Z87.1 specifications. Use of

eye wear which does not comply with ANSI Z87.1

specifications could result in severe injury from

the breakage of the eye protection.

2. Wear proper apparel. No loose clothing or jewelry

which can get caught in moving parts. Rubber

soled, nonslip, footwear is recommended for best

footing.

3. Do not overreach. Failure to maintain a proper

working position can cause you to fall into the

machine or cause your clothing to get caught —

pulling you into the machine.

4. Keep guards in place and in proper working

order. Do not operate the machine with the

guards removed.

5. Avoid dangerous working environments. Do not

use stationary machine tools in wet or damp

locations. Keep work areas clean and well lit.

6. Special electrical precautions should be taken

when working on flammable materials.

7. Avoid accidental starts by being sure that the

start switch is in the “OFF” position before

plugging in the machine.

8. Never leave the machine running while

unattended. The machine shall be shut off

whenever it is not being used.

9. Disconnect the electrical power before servicing,

whenever changing accessories or when general

maintenance is done on the machine.

10. Maintain all machine tools with care. Follow all

maintenance instructions for lubricating and the

changing of accessories. No attempt shall be

made to modify or have makeshift repairs done to

the machine. This not only voids the warranty but

also renders the machine unsafe.

11. If there is any risk of tipping or sliding, the

machinery must be anchored to the floor.

12. Secure your work. Use clamps or a vise to hold

your work, when practical. It is safer than using

your hands and it frees both hands to operate the

machine.

13. Never brush chips away while the machine is in

operation.

14. Keep work area clean. Cluttered areas invite

accidents.

15. Remove adjusting keys and wrenches before

turning the machine on.

16. Use the right tool. Don’t force a tool or

attachment to do a job for which it was not

designed.

17. Use only recommended accessories and follow

manufacturer’s instructions pertaining to them.

Page 5

18. Keep hands in sight and clear of all moving parts

A

and cutting surfaces.

19. All visitors should be kept at a safe distance from

the work area. Make your workshop co mpletely

safe by using padlocks, master switches, or by

removing starter keys.

20. Know the tool you are using; its application,

limitations, and potential hazards.

General Electrical Cautions

This machine should be grounded in accordance with

the National Electrical Code and local codes and

ordinances. The work should be done by a qualified

electrician. The machine should be grounded to

protect the user from electrical shock.

Wi re Sizes

CAUTION: For circuits that are a great distance fro m

the electrical service box, the wire size must be

increased in order to deliver ample voltage to the

motor. To minimize power losses and to prevent

motor overheating and burnout, the use of wire sizes

for branch circuits or electrical extension cords

according to the following table is recommended:

Conductor

length

240 volt lines 120 volt lines

0-50 feet No. 14 No. 14

50-100 feet No. 14 No. 12

Over 100 feet No. 12 No. 8

WG (American Wire Gauge) number

Safet y Inst ruc tions on Sawing Systems

1. Always wear leather gloves when handling

saw blade. The operator shall not wear gloves

when operating the machi ne.

2. All doors shall be closed, all panels replaced,

and other safety guards in place prior to the

machine being started or opera ted.

3. Be sure that the blade is not in contact with the

workpiece when the motor is started. The

motor shall be started and you should allow

the saw to achieve full speed before bringing

the saw bl ade into contact with the workpiece.

4. Keep hands away from the blade area.

5. Remove any cut off piece carefully while

keeping y our hands free of the blade a rea.

6. Saw must be stopped and electrical supply

must be cut off before any blade replacement

or adjustment of blade support mechanism is

done, or before any attempt is made to change

the drive belt s or before a ny per iodic ser vice or

maintenance i s perfor m ed on the saw.

7. Remove all loose items and unnecessary

workpieces from the area before starting

machine.

8. Bring adjustable saw guides and guards as

close as pos sible t o the workpiece.

9. Always wear protective eye wear when

operating, servicing, or adjusting machinery.

Eyewear shall be impact resistant, protective

safety glasses with side shields complying with

ANSI Z87.1 specifications. Use of eye wear

which does not comply with ANSI Z87.1

specifications could result in severe injury

from br eakage of eye prot ection.

10. 10. Nonslip footwear and safety shoes are

recommended.

11. Wear ear protectors (plugs or muffs) during

extended per iods of operation.

12. The workpiece, or part being sawed, must be

securely clamped before the saw blade enters

the workpiece.

13. Remove cut off pieces carefully, keeping

hands away from saw blade.

14. Saw must be stopped and electrical supply

disconnected before reaching into cutting area.

15. Avoid contact with coolant, especially guarding

your eyes.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine da ma ge.

This means that if precautions are not heeded, it may result in serious injury or possibly even

death.

5

Page 6

4.0 About this machine and manual

The JET Models J-7020 and J-7040 Horizontal Cut-Off Band Saws are ruggedly built, precision-oriented

machines designed for either wet or dry applications. The 2-horsepower motor along with the worm gear

reduction drive train in an oil bath, transmits smoot h and positive power to th e blade. This drive sy stem coupled

with the recirculating coolant system keeps the blade running cool and true, which results in longer blade life.

The blade guide system has adjustable six-point contact using a combination of bearing and carbide blocks.

The vise is a rapid acting, three j aw design.

This manual is provided by Walter Meier (Manufacturing) Inc. covering the safe operation and maintenance

procedures fo r the J- 70 20 and J- 7 04 0 Ho r izontal B a nd Saws . T hi s m an ual c o ntains instr uc t ions o n i ns t allat ion,

safety precautions, general operating procedures, maintenance instructions and parts breakdown. Your

machine has been designed and constructed to provide years of trouble-free operation if used in accordance

with the instructions as set forth in this document.

If there are questions or comments, please contact your local supplier or Walter Meier. Walter Meier can also

be reached at ou r web sit e: www .walt ermeier.com.

Retain this manual for fut ure reference. If the machine transfer s ownersh ip, th e m anual sh ould accompany it.

Read and understand the entire contents of this manual before attempting assembly

or operation! Failure to comply may cause serious injury!

5.0 Specifications

Model number ......................................................... J-7020 ..................................... J-7040 ............................... J-7040-4

Stock number......................................................... 414472 .................................... 414478 ..................................414499

Motor and electricals:

Main motor type...................................................... ......totally enclosed fan cooled, induction ....................................

Horsepower ...................................... 1-1/2 HP (1.1kW) ........................... 2HP (1.5kW) ......................... 2HP (1.5kW)

Phase .................................................................. single .............................................. 3 ............................................3

Voltage .......................................................... 115/230V ................................ 230/460V .............................. 230/460V

(prewired 230V) (prewired 230V) (prewired 460V)

Cycle .................................................................... 60Hz ....................................... 60Hz ..................................... 60Hz

Listed FLA (full load amps)............................. 22A/11A ........................................... 6A ......................................... 3A

Start capacitor .................................. 300MFD 250VAC ............................................. -- ........................................... --

Run capacitor .........................................40μF 250VAC ............................................. -- ........................................... --

Starting amps ............................................... 80A / 40A ......................................... 26A ....................................... 13A

Running amps (no load) .............................. 15A / 7.6A ........................................... 8A ......................................... 4A

Power cord length .................................................. 6 ft. .......................................... 6 ft. ........................................6 ft.

Power plug installed ................................................. no ............................................ no ..........................................no

Power transfer ....................... belt and stepless pulleys .........belt and stepless pulleys ...... belt and stepless pulleys

Motor speed ................................................ 1720 RPM ............................... 1720 RPM .............................1720 RPM

Recommended circuit size

Sound emission ................................................... 80 dB ...................................... 80 dB .................................... 80 dB

Coolant pump:

Horsepower ...........................................1/8HP (0.1kW) ........................ 1/8HP (0.1kW) ...................... 1/8HP (0.1kW)

Phase .................................................................. single .............................................. 3 ............................................3

Voltage .......................................................... 115/230V ................................ 220/440V .............................. 220/440V

Listed FLA (full load amps)............................ 0.5/0.25A .................................. 0.2/0.1A ................................ 0.2/0.1A

Speed ................................................. 2850/3400 RPM ...................... 2850/3400 RPM ....................2850/3400 RPM

Cycle .................................................................... 60Hz ....................................... 60Hz ..................................... 60Hz

Flow rate.....................................................1 gal. p/min ............................. 1 gal. p/min ........................... 1 gal. p/min

1

subject to local/national electrical codes

1

............................ 30A/15A ......................................... 15A ....................................... 10A

6

Page 7

Speeds and capacities:

Blade speed ............................... variable 100-350 fpm .............. variable 100-350 fpm ............ variable 100-350 fpm

Round capacity at 90-degrees .................10” (255mm) ........................... 10” (255mm) ......................... 10” (255mm)

Round capacity at 45-degrees .................10” (255mm) ........................... 10” (255mm) ......................... 10” (255mm)

Rectangular capacity at 90-degrees...... 7”x16”/10”x10” ........................ 7”x16”/10”x10” ...................... 7”x16”/10”x10”

Rectangular capacity at 45-degrees............. 6-1/2”x11” ............................... 6-1/2”x11” ............................. 6-1/2”x 11”

Coolant reservoir capacity ................................... 8 gal. ....................................... 8 gal. ..................................... 8 gal.

Dimensions:

Blade size ............................................... 1x0.035x130” .......................... 1x0.035x130” ........................ 1x0.035x130”

Blade wheel diameter ...............................14” (360mm) ........................... 14” (360mm) ......................... 14” (360mm)

Bed height from floor ......................... 23-1/2” (597mm) ..................... 23-1/2” (597mm) ................... 23-1/2” (597mm)

Floor space required ........................... 75-1/2”x33”x41” ...................... 75-1/2”x 33”x41” .................... 75-1/2”x33”x41”

(1918x838x1042mm) (1918x838x1042mm) (1918x838x1042mm)

Bed working surface ............................. 17-1/2”Wx24”L ........................ 17-1/2”Wx24”L ...................... 17-1/2”Wx24”L

(445x610mm) (445x610mm) (445x610mm)

Overall size........................................ 79”Lx31”Wx41”H .....................79”Lx31”Wx41”H .................. 79”Lx31”Wx41”H

(2007x788x1042mm) (2007x788x1042mm) (2007x788x1042mm)

Shipping crate ................................... 76”Lx30”Wx46”H .....................76”Lx 30”Wx46”H .................. 76”Lx30”Wx46”H

(1931x762x1170mm) (1931x762x1170mm) (1931x762x1170mm)

Materials:

Bed and motor support ....................................cast iron .................................. cast iron ................................ cast iron

Blade wheels ...................................................cast iron ................................. cast iron ................................ cast iron

Bow frame .............................................................steel ........................................ steel ...................................... steel

Stand .....................................................................steel ........................................ steel ...................................... steel

Blade guides.......................carbide blocks/ball bearing ..... carbide blocks/ball bearing ... carbide blocks/ball bearing

Weights:

Net weight .......................................... 927 lb (420.5kg) ...................... 927 lb (420.5kg) ....................927 lb (420.5kg)

Shipping weight ..................................... 973 lb (441kg) ......................... 973 lb (441kg) .......................973 lb (441kg)

.

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, Walter M eier (Manufacturing) Inc., reserves the ri ght to change speci fications at any time and wi thout

prior notice, without incurring obligations.

7

Page 8

6.0 Machine setup

The saw delivered to you has been adjusted at the

factory. A number of test pieces have been cut

using the saw to verify the accuracy of cutting.

Therefore, the only setup operations required

before releasing the saw for service are spotting

the saw and establishing the electrical connections

to the motor.

6.1 Un crat i ng and spotti ng

Spot the saw where it makes the most sense for

the operations you will probably be doing. If you

are going to be doing cut-off work on very long

pieces of stock, allow plenty of room for the stock,

and the infeed and outfeed supports. Remove the

saw f rom the ship ping skid and dis card any holddown devices that were used to secure the saw to

the skid.

7.0 Electr ic al co n nect i on s

NOTE: Local codes take precedence over

recommendations.

8.0 Operating instructions

8.1 Controls

The operating controls for the saw are provided in

a control panel on the left side of the machine. The

control panel is mounted on a pivoting tube. The

pivoting tube allows the operator to position the

control panel in a convenient location.

JET recommends that any

wiring involving hard wiring of the saw to a

branch, or any change of voltage supplied to

the motor be performed by a licensed

electrician.

Observe the following when connecting to the

power source (wiring diagrams are shown in

secti on 15.0):

1. Make sure the saw is disconnected from the

power source, or that the fuses have been

removed or breakers tripped in the circuit in

which the saw will be connected. Place a

warning placard on the f use or circuit breaker

to pr event a ccidental electrical shock .

2. If you are instal ling th e m otor power cor d int o a

receptacle, make sure to use the appropriate

plug.

3. If you are using hard-wired connections to a

junction box, connect the wires in the box, and

close th e box.

4. In stall the fuses or r eset t he break e r.

5. The saw is now ready for service.

It is recomm ended that the single phase band saw

(model J-7020), when operated on 115 v o lt power,

be connected to a dedicated 30 amp circuit with a

30 amp circuit breaker or time-delay fuse marked

“D”. When operated on 230 volt power, use a

dedicated 15 amp circuit with a 15 amp circuit

breaker or ti m e-delay fuse marked “D”.

It is recommended that the three phase band saw

(model J-70 40) on 230 volt power b e connect ed to

a dedicated 15 amp circuit with a 20 amp circuit

breaker or time-delay fuse marked “D”; and for 460

volt power, a dedicated 10 amp circuit with a 20

amp circuit breaker or time- delay fuse mark ed “D”.

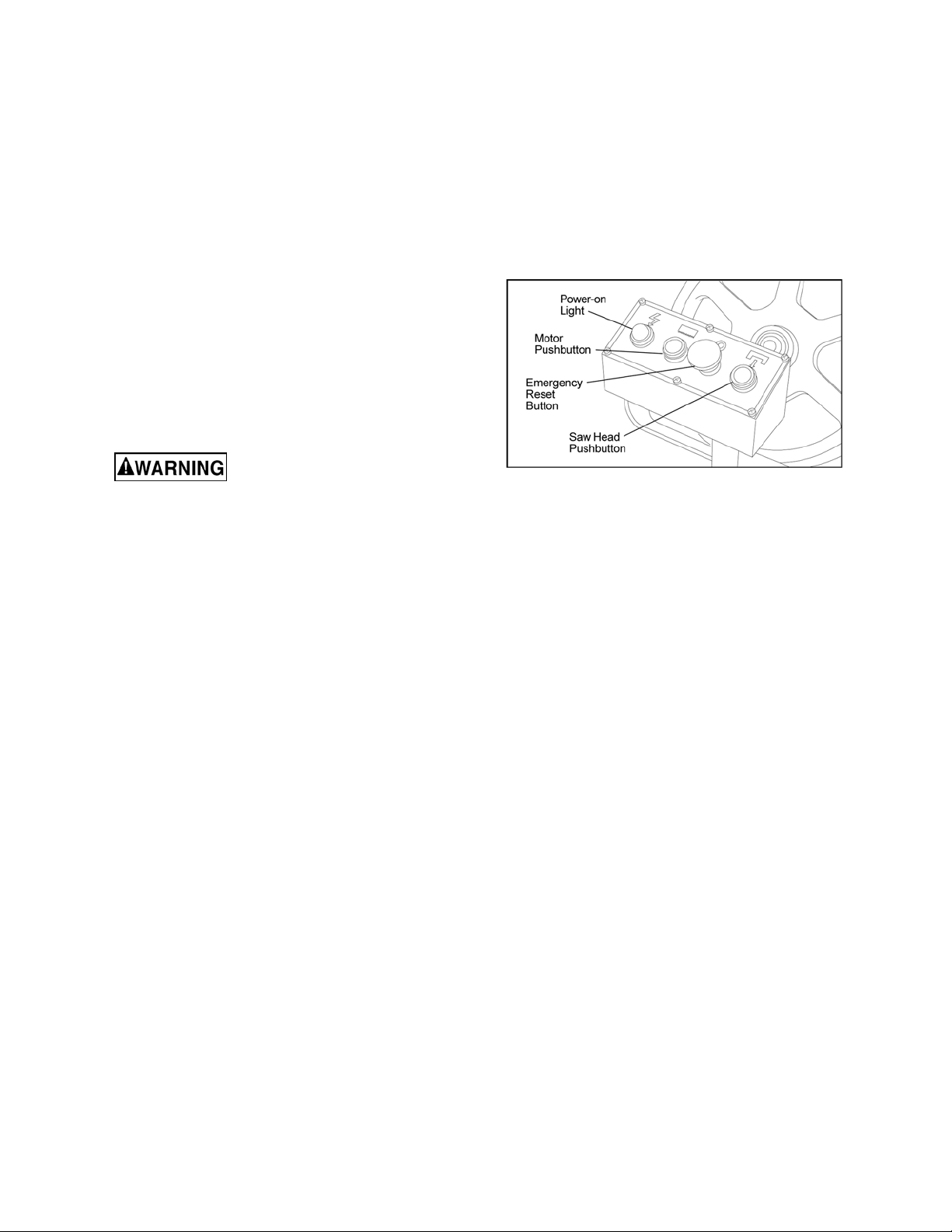

Figur e 1: Control panel

1. A power-on light is provided on the left side of

the control panel. The power-on light indicates

when power is connected to the machine.

2. An emergency stop button is provided on the

control panel. The emergency stop button

provides a means to rapidly cut off electrical

power.

3. The saw motor pushbutton switch starts the

saw motor and the E-stop button stops the

saw motor.

4. A green pushbutton switch is provided to the

right of the emergency stop pushbutton. The

pushbutton opens an electro-magnetic valve in

the hydraulic cylinder circuit. Opening the

valves a llows t he saw head to move downward

and put the saw blade in contact with the

workpiece.

5. A red release button on the electro-magnetic

valve provides a means to lower the saw head

when power to the machine has been

disconnected (see Figure 4) .

6. The rate at which the saw head moves

downward is controlled by a hydraulic feed

rate control located on the top, rear of the saw

head (see Figure 3).

7. A coolant pump switch is provided on the

electrical equipment box on the back of the

machine (see figur e 2).

8.2 Set t ing blade speed

1. The blade speed is controlled by an

adjustment mechanism on the right end of the

saw. Speed increases when the adjustment

8

Page 9

knob is turned counterclockwise. Speed

decreases when the knob i s turned clockwise.

2. A placard on the drive belt guard provides

recommended speeds for v arious ma teria ls.

3. A speed indicator is provided on the barrel of

the adjustment mechanism. The indicator

provides speed indications in feet per minute

and meters per minute. (The meters per

minute values are shown in parenthesis on the

indicator.)

4. The feed rates on the placard are expressed in

me ters pe r minute . The f eed rate grad uatio ns

available on the indicator may not match the

recommended feed rate. An approximate

speed may therefore be required. For

example, to set a speed rate of 25 meters per

minute, the indicator would be set about

midway between 21 meters-per-minute and

the 30 meter s-per- m inute gr aduation s.

To change speed, the saw

motor must be ope rating.

5. Turn the speed adjustment knob to the desired

rate setting as determined by the material

being cut.

8.4 Controlling the cut: Hydraulic

feed contro l

The weight of the saw arm provides all the force

needed to move the saw blade through the

workpiece. In fact, if the full weight of the arm is

allow ed to make the cut, rapid bl ade wear and poor

cutting accuracy will result. A hydraulic feed control

is provided that gives the operator a means to

control the speed and efficiency of cut ting.

The hydraulic cylinder is attached between the saw

base and the saw head. The hydraulic cylinder

resi sts movement of t he saw head in th e downward

direction. However, the hydraulic cyl inder offers no

resi stance when the saw head is ra ised upward.

The amount of downward force can be controlled

by using the feed rate control valve. When the

valve is opened slightly, the saw head will move

downward. The further the valve is opened, the

fast er the saw head will mov e downward.

The feed control is adjusted by the operator until

the saw is operating efficiently. This is usually

determined by observing the chip formation. (See

section 8.5, Evaluating cutting efficiency, fo r more

information.)

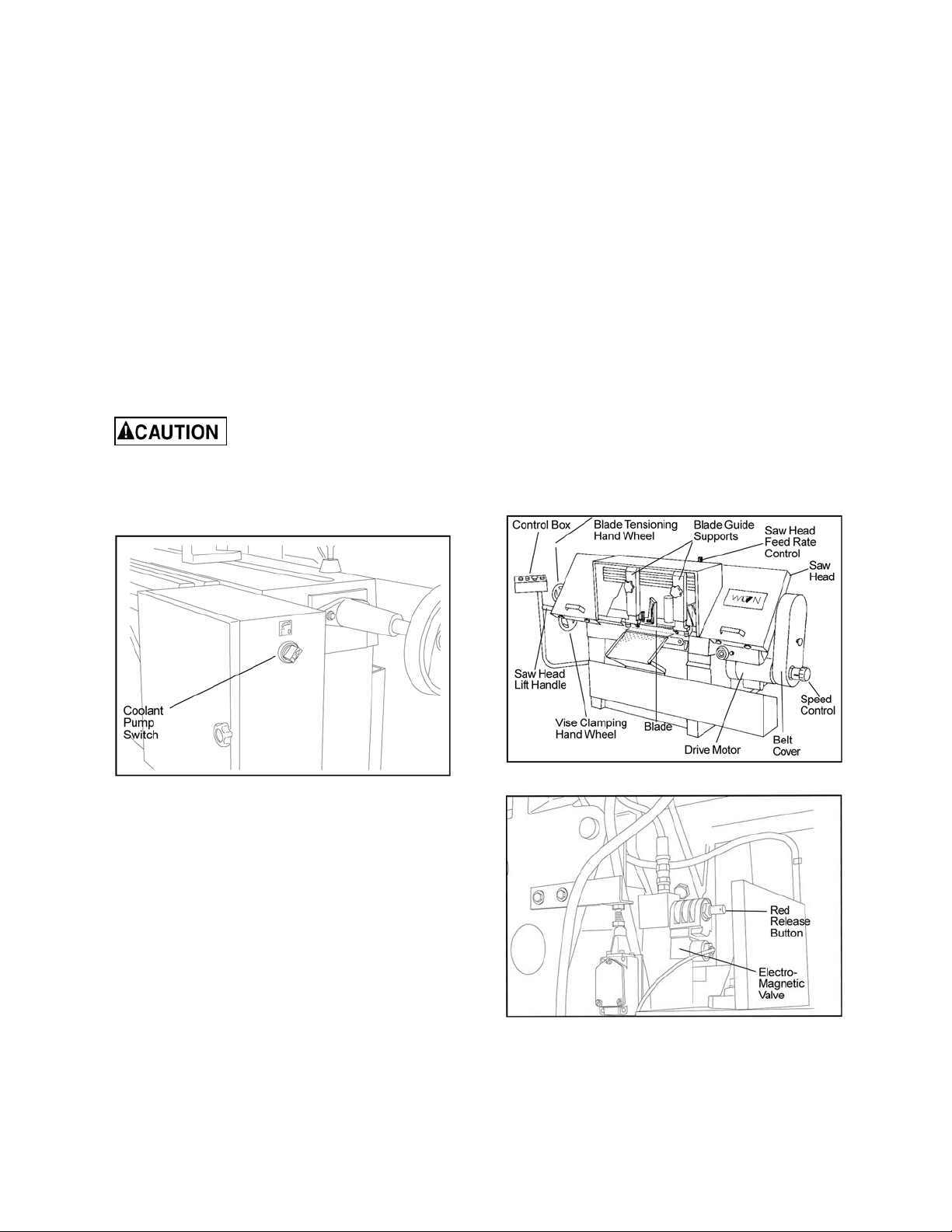

Figur e 2: Coolant pump swit ch

8.3 Rai si ng/lo wering saw head

1. Lift the saw head using the handle on the far

left side of the saw head.

2. To lower the saw head, press the green

pushbutton on the right side of the control

panel.

3. To adjust the feed rate, adjust the feed rate

control valve knob on the top of the saw head

(see Fi gure 3) .

4. To lower the saw head with power off, pull and

turn the red knob (manual override) on the

elect ro-magnetic valve ( see Figur e 4).

Figur e 4: Lowering head with p ower off

Figur e 3: Controls

9

Page 10

8.5 Evaluating cut ting effici ency

Is the blade cutting efficiently? The best way to

determine this is to observe the chips formed by

the cut ting blade.

If the chip formation is powdery, then the feed rate

is much too light, or the bla de is dull.

If the chips formed are curled, but colored — that

is, eith er blue or straw-colored fr om heat gen erated

durin g the cut — then th e feed rat e is too h igh.

If the c hips are sli ghtl y cu rle d and ar e not c o lor ed

by heat — the blade is sufficiently sharp and is

cutting at its most efficient rat e.

8.6 Blade selecti on

The cut-off saw is provided with a saw blade that is

adequate for a variety of cut-off jobs on a variety of

common materials. A 4/6 vari tooth bi-metal blade

(5674011) and a 6/10 vari tooth bi-metal blade

(5674021) are ava il able from JET.

See sect. 8.2, Setting blade speed, for the

recommended speeds for various materials. These

selections , whi le appropriate for many shop cutting

needs, do not encompass the wide variety of

blades of special configuration (tooth pitch and set)

and special alloys for cutting unusual or exotic

materials.

A c oar se b lad e co uld be us ed fo r a s ol id st eel b ar

but a finer tooth blade would be used on a thin-wall

tube. In general, the blade choice is determined by

the thickness of the material; the thinner the

materi al, the finer the tooth pitch.

A minimum of three teeth should be on the wor k

piece at all times for proper cutting. The blade

and workpiece ca n be damaged if t he teet h are

so far apart that they straddle the wor kpiece.

For very high production on cutting of special

materials, or to cut hard-to-cut materials such as

stainless steel, tool steel, or titanium, you can

ask your industrial distributor for more specific

blade recommendat ions. Also, the supplier w ho

provides the workpiece material should be

prepared to provide you with very specific

instructions regarding the best blade (and

coolant or cutting fluid, if needed) for the

material and shape supplied.

1. Clamp a round section workpiece in the vise.

The workpiece should be 2 inches or larger in

diameter.

2. Set the saw on low speed. Start the cut with a

very light feed rate.

3. When the saw has completed 1/3 of the cut,

increase the feed rate slightly and allow the

saw to complete the cut.

4. K eep the sam e hydr aulic cylind er s etting and

begin a second cut on the same or similar

workpiece.

5. When the blade has completed about 1/3 of

the cut, increase the feed rate. Watch the chip

formation until cutting is at its most efficient

rate and allow the saw to complete the cut

(see sect. 8.5, Evaluating blade efficiency).

The bl ade is no w cons ide red read y fo r regul ar

service.

9.0 Work setup

9.1 Securing wo rkpiece fo r square

cuts

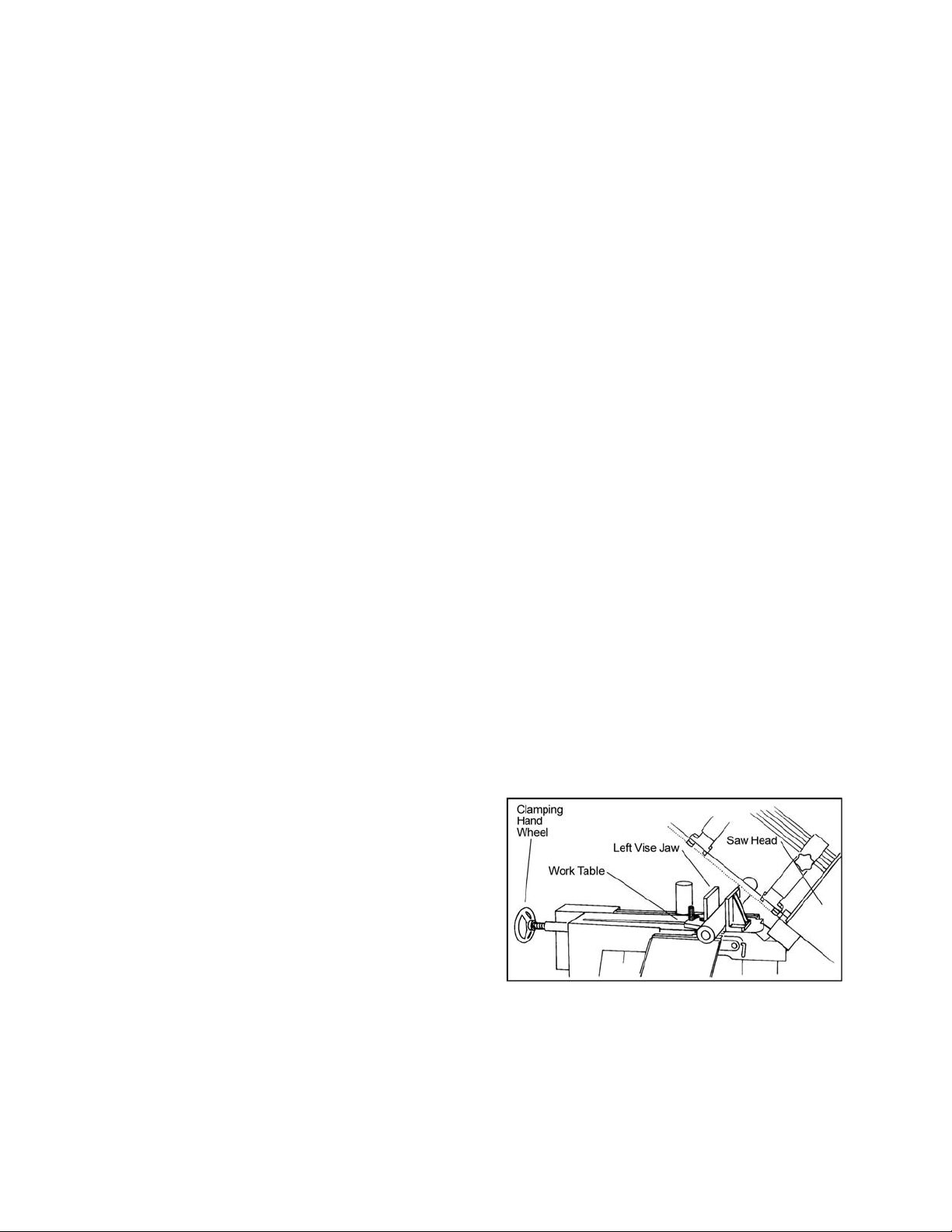

1. Raise the saw head (refer to Figure 5).

2. Slide the left vise jaw f ar enough to the left to

allow the workpi ece to be pla ced in t he vise.

3. Place the workpiece on the work table. If the

workpiece is long, provide support at the other

end. It may also be necessary to provide

additional downward clamping to hold the

workpiece securely on the work table.

4. Turn clamping hand wheel clockwise to clamp

the workpiece in position against the fixed

(right) vise jaw.

5. After completing the cut, turn the clamping

hand wheel counterclockwise and slide the left

jaw away from th e workpiece.

8.7 Bl ade break-in procedures

New blades are very sharp a nd, therefore, have

a tooth geometry which is easily damaged if a

careful break-in procedure is not followed.

Consult the blade manufacturer’s literature for

break-in of spec ific blades o n specific materials.

However, the following procedure will be

adequate for br eak- in of JET-supplied blades on

lower alloy ferrous materials.

Figure 5: Securing workpiece

9.2 Ad justing vise for an gl e cuts

1. Referring to Figure 6, loosen the angle locking

screw and the pi vot screw on the le ft vise jaw.

2. Turn the locking handle on the round, anglesetting block counterclockwise to unlock the

10

Page 11

block. Slide the block until the pointer on the

block is aligned with desired angle (see Figure

7). Tighten the locking handle to set the angle.

3. Set the workpiece in the vise. Put the front end

of the workpiece against the corner of the right

vise jaw. Put the rear end of the workpiece

against the angle-setting block.

4. Turn clamping hand wheel clockwise until the

left vise jaw is parallel with the workpiece.

Tighten the pivot screw and angle locking

screw on the left vise jaw. Clamp the

workpi ece in position.

5. After completing the cut, turn the clamping

hand wheel counterclockwise and slide the left

jaw away from th e workpiece.

Figur e 6: Adjust ing vise

2. Ti ghten “wi ng” scr ew to secur e rod in place.

3. I nstall the stop post in the channel on the back

of the stop L-bracket. Install the locking lever

in the threaded hole in the stop post. Snug-up

the locking lever.

4. Install the locking knob in the hole in the side

of th e stop L-bra cket.

5. Slide the assembled stop L-bracket onto the

stop rod. Position the stop post against the

work piece and tighten the knob in the stop Lbracket. The stop post can be moved left or

right as required to place it against the work

piece.

10.0 Startin g th e Saw

Never operate saw without

blade cover s in place and se cured.

Make sure blade is not in

co ntact with work piece wh en m otor is star ted.

Do not drop the saw head on workpiece or

forc e saw blade through the workpiece.

1. Raise the saw head. With the saw motor off,

pull the red release button on the electromagnetic valve and check the rate at which the

saw he ad lower s .

Figur e 7: Angle setting b lock

9.3 Installation and adjustment of

wo rk st op

Figure 5: The w ork st op is used to set up the

saw fo r mak ing m ultip le c uts o f t he sam e le ngt h

(see figure 8). I nstal l and adjust t he wor k stop

as follows:

Figur e 8: Work stop

1. I nsert the end of the stop rod in the hole in the

fron t ri ght side of the work table.

2. Raise sa w head. Push in r ed release but ton.

3. Clamp the workpiece in the vise. (See Figure

9 for ex amples of w orkpieces in the vise.)

4. Be sure the blade is not in contact with the

Figur e 9: Placing w orkpi eces in vise

workpi ece when the motor is star ted.

11

Page 12

5. Start t he mo tor and allow t he saw to c om e up

to speed.

6. Slowly set the saw down onto the workpiece.

Adjust cutting speed with feed rate control

valve.

7. DO NOT DROP THE SAW HEAD OR FORCE

THE CUT. Let the weight of the saw head

provide the cutting force.

8. The saw will auto maticall y shut of f at the end

of the cut.

10.1 Coolant flow

The coolant pump must be

submerged before o p erating to prevent d am age

to t he pum p.

1. The blade guides are fitted with coolant

fittings. Coolant is provided to the fittings

thro ugh interc onnec ting tub ing . The co olant is

dispensed directly onto the saw blade.

2. Adjust the coolant flow valves on the top, rear

of the saw head as required to provide the

desired flow. The flow should be no more than

the blade can draw into the workpiece by

blade movement.

3. The coolant flow can be stopped in two ways:

1) By using the coolant pump switch on the

elect rica l equi pm ent box, or

2) By closing the coolant flow valves on the

top, rear of the saw h ead.

To change the blade, refer to sect. 12.3, Changing

blades. To adjust blade tracking, refer to the

following procedures.

11.1 Bl ad e t racking adjust ment

Blade tracking has been tested at the factory.

Adjustment is rarely required when the blade is

used properly or if the blade is correctly welded.

(See Figure 10 for location of blade tracking

adjustment screws.)

Figur e 10: Blade track ing and tensionin g

11.2 Factory or field procedure

1. Raise the saw head enough to allow the saw

motor to operate.

2. Loosen four knobs securing the blade cover.

Lift the cover and swing it backward.

3. Remove the blade guard mounted on the left

blade gui de support.

10.2 Coolant mixture and quantity

The general purpose coolant is a mixture of water

soluble oil and water. Mix one part of soluble oil

(TR IM SOL ) to t e n part s of wate r (one quart o il , ten

quarts of water). Eleven quarts of coolant are

required for th e coolant pu m p to operate properly .

There are numerous coolants on the market that

are formulated for special applications. Consult

your local distributor for details in the event you

have a long range production task, or are required

to cut some of the more exotic materials.

11.0 Adjustments

The efficient operation of the cut-off saw is

dependent upon the condition of the saw blade. If

the performance of the saw begins to deteriorate,

the first item that you should ch eck is th e blade.

If a new blade does not restore the machine’s

cutting accuracy and quality, refer to sect. 13.0,

Troubleshooting (or the blade manufacturer’s

guide) for c ond itions to c onside r and ad justme nts

that can be m ade to increase the life of the blade.

4. Remove b oth blade guide bearing bra ckets.

NOTE: Maintain proper tension at all times

using the blade tensio ning mechanism.

5. Loosen the center locking screws in all three

hex adjustment screws on the blade tensioning

mechanism (see Figure 10).

While performing the

following, keep the blade

from rubbing excessively on the shoulder of

the wheel. Excessive rubbing will damage the

wheel and/or the blade.

6. Start the saw. Slowly turn the single hex

adjustment screw at the rear of the tracking

me chanis m to tilt the idle r whee l. Do no t turn

either of the other two adjustment screws.

Turn the adjustment screw until the blade is

touchi ng the shoul der of th e idler w heel.

NOTE: Turning the screw inward causes the blade

to move toward the shoulder of the wheel. Turning

the screw outward causes the blade to move away

from t he shoul der.

7. Turn the single hex adjustment screw so the

blade sta rts t o m ove away from the shoulder of

wheel – then turn the single hex adjustment

12

Page 13

screw in the other direction so the blade stops,

then moves slowly tow ard the sh oulder .

Keep fingers clear of blade

and wheel to avoid injury.

8. Turn t he single hex adjustment screw to stop

the motion of the blade on the wheel as it gets

closer to the wheel shoulder. Put a 6-inch

length of paper between the blade and the

wheel as shown in Figure 11. The paper

should not be cut as it passes between the

wheel shoul der and the bla de.

Turn the single hex adjustment screw a

9.

small amount. Repeat the insertion of the

paper between the wheel shoulder and the

blade until the paper is cut in two pieces.

13. Install the two blade guide bearing brackets.

Position the guides so the bearings just touc h

the bla de.

14. In stall the left blade guard.

15. Close the saw head cover. Tighten all four

knobs.

11.3 Bl ad e guide bearing adjustment

Proper adjustment of the blade guide bearings is

critical to efficient operation of the cut-off saw. The

blade guide bearings are adjusted at the factory.

They should rarely require adjustment. When

adjustment is required, adjust immediately. Failure

to maintain proper blade adjustment may cause

seri ous blade da m age or inaccurat e cuts.

It is always better to try a new blade when cutting

performance is poor. If performance remains poor

after changing the blade, make the necessary

adjustments.

If a new blade does not correct the problem, check

the blade guides for proper spacing. For most

efficient operation and maximum accuracy, provide

0.001 inch clearance between the blade and the

guide bearings. The bearings will still turn freely

with this clearance. If the clearan ce is incorrect, the

blade may track off the dri ve wheel.

Figure 11: Checking blade-to-wheel clearance

using paper strips

NOTE: Y ou may have to repeat the check wit h

the paper several times bef or e the blade a nd t he

shoulder cuts the paper into tw o pieces. Do not

hurry the adjustment. Patience and accuracy

here will pay off with better, more accurate,

quieter cutting and much longer machine and

blade life.

10. When the paper is cut, turn the hex adjustment

screw slightly in the counterclockwise

direction. This assures that the blade is not

touchi ng the shoul der of th e w heel.

11. Shut off the saw.

Check the blade to make sur e

the welded section is the same thi ckness as the

rest of the blade. If the blade is thicker at the

weld, the guide bearings may be damaged.

If required, adjust the guide bearings as follows:

1. The inner guide bearing is mounted on a

concentr ic bushin g and cannot be adjusted.

2. The outer guide bearing (closest to the

operator) is mounted on an eccentric bushing

and can be adjusted.

3. Hold the bushing wi th a 3/4-inch wrench and

loosen the center locking screw with an Allen

wrench (see Figure 12).

12. Hold the hex adjustment screws with a wrench

and tighten the center locking screws. Make

sure the hex adjustment screws do not move

while tightening the center screws.

Figur e 12: Adjustment of guide bearings

13

Page 14

Figur e 13: Blade- to-bearing orientat ion

4. Position the bearing by turning the bushing.

Set the clearance at approximately 0.001 inch.

(The blade should be in a vertical position

between t he bearings. (See Fi gure 13.)

5. Tighten the center locking screw with an Allen

wrench while holding the eccentric bushing in

posit ion with the 3/4- inch wrench.

6. Use the same procedure to adjust the other

guide bear ing.

7. When the adjustment is correct, the guide

bearings should rotate freely with slight

pressur e of the finger (wi th the bl ade stopped).

8. Adjust bla de-edge beari ngs so they just tou ch

the back edge of the blade (see Figure 18).

11.4 T est cuttin g to verify ad justmen t

accuracy

Test cuts can be used to determine whether or not

you have adjusted the blade accurately. Use 2inch ro und bar sto c k to p e rf o rm thes e te s t cuts, as

follows:

sho uld b e no mo re than 0 .003 inch, per side,

per i nch of stock diameter.

Figur e 14: Cutting a te st disc

11.5 L i mit swi t ch ad justmen t

1. The limit switch is provided to shut off the saw

motor when the workpiece is cut th rough.

2. To set the limit switch, loosen the jam nut on

the lim it swi tch stop ( Figure 15).

3. Adjust the stop as required and retighten jam

nut.

1. With the bar stock securely clamped in the

vise, make a cut through the bar stock. (See

Figure 14.)

2. Mark the top of the bar stock.

3. Move the bar stock about 1/4-inch past the

blade so you can begin a second cut.

4. Rotate the bar stock 180 degrees so the mark

you made is now at the bottom of the cut .

5. Mak e a cut through the bar st ock.

6. Use a micrometer to measure the thickness

variation of the disk you have cut from the bar

stock. Measure at the top and bottom of the

disk.

7. The saw blade can be considered correctly

adjusted when the variation measure is no

more than 0.012 inch across the face of the

disk.

8. If you do not have a piece of 2-inch bar stock

available for a test cut, use a larger diameter

test piece rather than a smaller one. The

maximum thickness variation on any test piece

Figur e 15: Limit switch adjustm ent

12.0 Maintenance

12.1 Cleaning

1. Clean off any preservative on machine

surfaces.

2. A fte r cleaning , co at the machine d s urface s of

the cut-off saw with a medium consistency

machine oil. Repeat the oil coating process at

least every six months.

14

Page 15

3. C lean up acc umul ate d s aw c utt ing s af te r use .

Make sure the le ad scre w is kept free of saw

cuttings and other materi al that would cause

damage.

4. Clean the chip sludge from the coolant tank.

The frequency should be determined by how

often the saw is used.

12.2 Lubrication

Lubrica te th e follow ing components at the specified

frequ encies a nd using th e lubri cants as defined:

1. Ball bearings: the bearings are lubricated and

sealed—periodic lubrication is n ot required.

2. Blade guide bearing: The bearings are

lubricated and sealed—lubrication is not

required. Inspect periodically.

3. Idler wheel bushing: The bearings are

lubricated and sealed—lubrication is not

required. Inspect periodically.

4. Lead screw bearing housing: Lubricate with

light oil monthly (see exploded figure, section

14.1.1).

5. Lead screw: Lubricate with light oil monthly

(see exploded figure, section 14.1. 1).

6. Hydraulic cylinder pivot: Lubricate with light oil

every 6 months (see exploded figure, section

14.1.1).

7. Blade tension screw: Lubricate with grease

every 6 months (see exploded figure, section

14.2.1).

8. Blade brush bearing: Lubricate with light oil

monthly (see expl oded figure, section 14.2. 1).

9. Gear box: check oil on ce a year.

10. Change coolant on a frequency appropriate to

the type of coolant being used. Oil based

coolants can sour. Refer to the coolant

supplier’s instructions for change frequ ency.

11. Coolant tank: Clean every 6 months or as

required.

12.3 Changing blades

1. Turn the blade tensioning hand wheel

clockwise to relieve tension on the blade.

Loosen the blade enough to remove the blade

from the idler and drive wheels. Remove the

blade from b etween the bla de guides.

2. Install the new blade between the blade guide

bearings and the carbide blade guides. Install

the bla de over th e drive and i dler wheels.

3. Turn the blade tensioning hand wheel

counterclockwise to tighten the blade. Tighten

the blade until the blade tension indicator

reads 2000 pounds.

4. Operate the saw at low speed and observe the

tracking of the blade. If tracking needs to be

adjusted, refer to sect. 11.1, Blade tracking

adjustment.

5. Adjust the bearings on the upper edge of the

blade until they just contact the blade (see

Figure 18).

6. Check the guide bearings and the carbide

guides to make sure they are just contacting

the sides o f the blade.

7. I nstall the left blade guard making sure there is

ample cleara nce with the blade.

8. Make a te st c ut to make s ure the b lade tracks

properly during operation. Adjust tracking as

required (see sect. 11.1, Blade tracking

adjustment).

12.4 Changing drive belt

1. Disconnect the electrical power source from

the cut-off saw to prevent any possibility of

accidental motor start-up.

2. Set the arm at the full horizontal position.

3. Remove the knob on the drive belt cover.

Remove the drive belt cover to expose the Vbelt and pull eys.

4. Remove two screws, nuts, and washers from

back of saw head support. Push on the motor

support bracket to pivot the motor upward to

loosen the tension on the bel t.

5. Remove the worn belt.

Shut off all electrical power to

machine.

1. Loosen four knobs securing the blade cover.

Lift the cover and swing it backward.

2. Remove the blade guard mounted to the left

blade gui de support.

Always wear leather gloves

when handling saw blade to avoid injury from

saw teeth.

6. Put the replacement belt in the pulleys. Allow

the motor to piv ot downward.

7. Install the two screws, nuts, and washers in

back of saw head support and through the

motor support bracket.

8. Install the drive belt cover. Install and tig hten

the knob on th e drive belt cover.

15

Page 16

12.5 Replacing drive motor

1. Disconnect the motor from all electrical power.

Unpl ug the m oto r if it is p lugge d into a s ocke t.

Shut o ff the po we r to the branch and remove

the co nnectio n to the junctio n box if the mo tor

is har d wired to the branch .

2. Remove the drive belt from the drive motor

pulley (see sect. 12.4, Changing drive belt).

3. Remove motor pulley.

4. Open the motor junction box and disconnect

the power cord wires from their terminals.

5. Remove the nuts, washers and bolts that

secure th e m otor t o the mounting plate.

6. 6. Installation of a new motor is a reversal of

the above steps.

12.6 Adjusting counterbalance

spring

1. The counterbalance spring is located at the

right, rear of the saw head. The

counterbalance spring is used to adjust the

amount of down force the saw head puts on

the workpiece when the feed rate control valve

is fully open.

2. Raise the saw arm to its full upright position

and lock it in position.

3. To adjust t he tensi on on the spring, l oosen the

two nuts on the threaded rod of the spring

pivot post. Adjust the tension as required.

12.8 Rep lacing idler wh eel or idl er

bearing

1. Remove the saw blade (see sect. 12.3,

Changing blades).

2. Remove t he screw, spring washer, an d washer

from the idler shaft.

3. Remove the idler wheel. Remove the bearing

from t he idler wheel.

4. Inspection: Examine the drive edge and

shoulder of the idler wheel for damage.

Replace th e wheel if damaged.

5. Inspect bearings for damage and smooth

operation. Replace if faul ty.

6. I nstall the bearing in the idler wheel. Install the

idl er wheel on t he idl er shaft .

7. I nstall the screw, spring washer and washer in

the idler shaft.

8. Install the bla de (sect. 12.3, Changi ng bla des).

12.9 Ad j ustin g b lade guides

The cut-off saw has adjustable blade guide

supports (see Figure 16). The blade guide

supports allow you to set the blade guides for

varyin g widths of workpi eces.

To make accurate cuts and prolong blade life, the

blade guide supports should be set to just clear the

workpi ece to be cut.

4. Tighten the two nuts against the pivot post.

5. The saw can now be retur ned to service.

12.7 Replacing drive wheel

1. Remove the blade (see sect. 12.3, Changing

blades).

2. Remove t he screw, spring washer, an d washer

from t he speed re ducer shaft.

3. Pull the wheel from the speed reducer shaft.

Remove the drive key from the speed reducer

shaft.

4. Inspection: Examine drive edge and shoulder

of the wheel for damage. Replace the wheel if

damaged.

5. Install the key in the keyway in the speed

reducer shaft. Align the keyway in the wheel

with the key in the speed reducer shaft.

Reinstall the wheel on the speed reducer

shaft.

6. I nstall the screw, spring washer and washer in

the end of the speed redu cer shaft.

7. Install the blade (see sect. 12.3, Changing

blades).

Figur e 16: Blade guid e supports

1. Loosen the knob on the blade guide support

and slide the guide left or right as required.

Repeat for the ot her blade guide.

2. Set the blade guide supports as required to

accommodate the width/diameter of the

workpiece. The blade guides should be

positioned so the guides do not contact the

workpiece as the saw head moves downward

throu gh the workpiece.

16

Page 17

12.10 Rep lacing carbide blade gu ide

Refer to Figure 17.

1. Remove the cap screw and remove the

carbide gu ide. Di scard th e carbi de guide.

2. Install the replacement carbide guide on the

guide bearing support. Install the cap screw.

Set the guide so it just contacts the side of the

saw blade.

3. Using a mac hinist's square, check squareness

of th e blade t o the tabl e.

Figur e 17: Carbid e blade guide s and guide

bearings

12.11 Rep lacing guide b earings

Referring to Figure 17, remove the cap screw from

the bearing being replaced. Separate the bushing

and cap screw from the bearing. Discard the

bearing.

NOTE: There is a light press fit between the

bearin g and th e bushing.

2. Insert the capscrew into the new bearing.

Replace the spring washer onto the capscrew

and re-install into the floating block.

3. If re-adjustment is necessary, loosen the pivot

cap screw and m ove the floating b lock s o that

the blade edge is close to the guide support,

but cannot touch the bottom surface of it when

the saw blade is cutting a workpi ece.

Figur e 18: Blade ed ge bearing replac ement

12.13 Replacing wire brush

1. Loosen four knobs securing the blade cover.

Lift the cover and swing it backward.

2. Remove the attaching screw, spring washer

and washer. Remove and discard the brush

(see Fi gure 19) .

3. Install replacement brush and secure with

screw, spr ing washer and washer.

4. Close the blade cover and secure with four

knobs.

1. Install bushing in replacement bearing. Install

cap screw through bushing and into guide

support.

2. I f the bearing being replaced is on an eccentric

bushing, install the bearing on the operator

side of the blade.

3. Turn the eccentric bushing in the guide

support u ntil the bearing contacts the blade.

12.12 Rep lacing blade edge bearin gs

1. Remove the capscrew from the blade edge

bearing being replaced and discard the

bearing. Be careful not to lose the spring

washer that separates the bearing from the

floa tin g block ( see Figure 18).

Figur e 19: Wire bru sh

17

Page 18

13.0 Troubleshooting the J-7020/7040 Band Saw s

A

A

A

A

A

A

Symptom Possible Cause Correction

Excessiv e blade

breakage

Premature blade

dulling

Bad cu ts

(out-of-square)

Materi al loose in vise. Clamp work securely .

Incor rect speed or fee d. Check ma chinist’ s handbook for

speed/feed appropr iate for the mater ial

being cut.

Teeth too coa rse for m aterial. Check machi nist’s handbook for

recommended bl ade type.

Incor rect bl ade tension.

Saw blade is in contact with

workpiece before the saw is sta rted.

Blade ru bs on the wheel fl ange.

Misaligned guides.

Cracking at we ld. Lo nger anneal i ng cycle .

Blade teeth too coarse. Use a fin er toot h blade.

Blade speed t oo high . Try a low er blade speed.

Inadequate feed pressure. Decrease spring tension.

Hard spots i n workpiece or scale

on/in workpiece.

Work hardenin g of material

(especia lly stainless st eel).

Insuffici ent blade tension. Incr ease tension to proper level.

Operati ng saw with out pressure on

workpiece.

Workpiece not squ are with blade.

Feed pressure t oo fast. Decrease pressu re.

Guide bearin gs not adjusted

properly.

Inadequate blade tension. Gradually increase blade tension.

Span between the tw o blade guides

too wide.

Dull blade. Replace bla de.

djust blade tension to the poin t where th e

blade ju st does not slip on th e wheel.

Start the motor before placin g the saw on

the workpiece.

djust blade tr acking.

djust gu ides.

Incr ease feed pr essure ( hard spots).

Reduce speed, increa se feed pre ssure

(scale).

Incr ease feed pr essure by reducing sprin g

tension.

Do not run blade at idle in/on material.

djust vise so it is square wi th the blade.

(Always cla m p work tightly in vise.)

djust gu ide bear ing cl earance to 0.001

inch ( 0 .002 in ch maximum ).

Move blade gu ide bar closer to work.

Incor rect bl ade speed. Check blade speed.

Blade gui de assembly is loose. Tighten blade guide a ssem bly.

Blade gui de bearing assembly loos e. Tight en blade gui de bearing assembly.

Blade tracks too far away fr om wheel

flanges.

Guide bearing worn. Replace worn bearing.

Bad cuts ( rough) Blade speed t oo high for feed

pressure.

Blade is too coarse. Replace wi th fi ner blade.

Blade is twisting

Blade is binding in the cut. D ecrease feed pres sure.

Blade ten sion too high. Decrease tension on blade.

djust blade tr acking.

Reduce blade speed and feed pressure.

18

Page 19

Symptom Possible Cause Correction

A

A

Unus ual wear o n

side/ back of blade

Teeth missi ng/ripped

from bl ade

Motor ru nnin g too hot Blade ten sion t oo high. Reduce t ensi on on blade.

No coolant flow Pump motor is burned ou t. Repla ce pump.

Blade gui des worn Replace bla de guides.

Blade gui de bearings not adjusted.

Blade gui de beari ng brack et is loose. Tigh ten blade guide bearing bra cket.

Blade tooth pitch too coarse for

workpiece.

Feed too slow; feed too fa st. Incr ease feed pr essure and/or blade

Workpiece vibrati ng. Clamp workpiece secur ely.

Gullets loading up with chips. Use blade with a coarse t ooth pitch —

Dri ve belt tension too high . Reduce tension on dri ve belt.

Blade too coa rse for workpi ece

(e sp ecia lly w ith tubular stock).

Blade too fine for workpiece

(esp ec ially with heavie r, so f t

material).

Speed reducer gea rs require

lubrication.

Screen/filter on pump is clogged. Clean screen/ fi lter .

Impeller is loose. Tighten impeller.

djust blade guide bear ings.

Use blade with finer tooth pitch.

speed.

reduce fee d pressure.

Brush blade to remove chips.

Use blade with fine t ooth pi tch.

Use blade with coarse tooth pit ch.

Check speed reducer.

Excessive speed

reducer n oise/v ibration

Coolant level too low.

V-belt is too tight. Reset V-belt tension.

Countering spring not tensioned

properly.

dd coolant to reserv oir.

Increase spring tension.

14.0 Repla cement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1800-274-6848 Monday through Friday (see our website for business hours, www.waltermeier.com). Having the

Model Number and Serial Number of your machine available when you call will allow us to se rve you quickly

and accurat e ly.

19

Page 20

14.1.1 Base (J-7020/70 40) – E xploded View

20

Page 21

14.1.2 Base (J-7020/70 40) – P art s List

Index No Part No Description Size Qty

1 .............. J-5712251 ...............Foot, Left............................................................................................ 1

2 .............. J-5712261 ...............Foot, Right ......................................................................................... 1

3 .............. J-5712271 ...............Coolant Reservoir ............................................................................... 1

3-1 ........... 5519485 ..................Stopper (PT 3/8") ................................................................................ 1

4 .............. J-5712281 ...............Coolant Pump 115/220, 1-Phase ......................................................... 1

................ J-5712921A .............Coolant Pump 220/440, 3-Phase ......................................................... 1

4-1 ........... 5519486 ..................Adapter (PT 3/8") ................................................................................ 1

5 .............. 5712291 ..................Pan Head Screw ..............................................1/4" x 5/8”................... 2

7A............ 5512101 ..................Filter Screen w/Screw ......................................................................... 1

8 .............. 5712331 ..................Hose ................................................................5/16" .......................... 1

8-1 ........... 5519487 ..................Hose Clamp ....................................................................................... 6

9 .............. 5712341 ..................Chip Pan ............................................................................................ 1

10 ............ J-5712351 ...............Pump Bracket ..................................................................................... 1

11 ............ J-5712361 ...............Work Table......................................................................................... 1

11-1 ......... 5519491 ..................Label, Made in Taiwan ........................................................................ 1

11-2 ......... 5519492 ..................Rivet ................................................................2mm ........................ 14

11-3 ......... TS-1482011 ............Hex Cap Screw ................................................M6x 10....................... 1

11-4 ......... TS-1550041 ............Wash er ............................................................M6 ............................. 1

11-5 ......... TS-2361061 ............Spring Washer..................................................M6 ............................. 1

12 ............ 5712371 ..................Screw ..............................................................1/4" x 7/8" .................. 1

13 ............ 5712381 ..................Hex Cap Screw ................................................1/2" x 1" ..................... 4

13-1 ......... 5712391 ..................Spring Washer..................................................1/2" ............................ 4

14 ............ 5712641 ..................Washer ............................................................1/2" ............................ 4

15 ............ J-5712411 ...............Electrical Control Box .......................................................................... 1

15-1 ......... 5519488 ..................Hex Cap Screw ................................................5/16" x 3/4"................. 3

15-2 ......... TS-0720081 ............Spring Washer..................................................5/16" .......................... 3

15-3 ....... TS-0680031 ............Wash er ............................................................5/16 " .......................... 3

15-4 ......... 5519501 ..................Label, P ump Switch ............................................................................ 1

16 ............ 5712421 ..................Work Stop Bracket .............................................................................. 1

17 ............ 5712431 .................Work Stop Rod .................................................................................. 1

18 ............ 5712441 ..................Locking Screw .................................................................................... 1

19 ............ 5712451 ..................Screw ..............................................................1/2" ............................ 1

20 ............ J-5712461 ...............Pump Cover ....................................................................................... 1

21 ............ 5712471 ..................Hand Wheel Assembly ........................................................................ 1

21-1 ......... 5519494 ..................Set Scre w ........................................................5/16 " x1/2" .................. 1

22 ............ J-5712481 ...............Lead Screw Br acket ............................................................................ 1

23 ............ 5712491 ..................Screw ..............................................................5/16" x 1/4"................. 2

23-1 ......... TS-0720081 ............Spring Washer..................................................5/16" .......................... 2

23-2 ......... TS-0680031 ............Wash er ............................................................5/16 " .......................... 2

24 ............ 5712511 ..................Vise Lead Screw ................................................................................. 1

24-1 ......... 5519710 ..................Key ..................................................................5x5x20mm ................. 1

24A.......... 5514806 ..................Collar with Pin .................................................................................... 1

25 ............ 5712521 ..................Lead Scr ew Bracket ............................................................................ 1

26 ............ 5712531 ..................Acme Nut ........................................................................................... 1

27 ........... 5712541 ..................Button ................................................................................................ 1

28 ............ 5712551 ..................Retainer ............................................................................................. 2

29 ............ 5712561 ..................Screw ..............................................................M5 x 8........................ 1

30 ............ 5712571 ..................Needle Bearing.................................................CB3020...................... 2

30-1 ......... 5519495 ..................Bu shin g............................................................4mm .......................... 1

30-2 ......... 5519496 ..................Bush ................................................................2mm .......................... 1

31 ............ 5712581 ..................Washer ............................................................1/2" ............................ 2

32 ............ 5712591 ..................Pivot Shaft ......................................................................................... 1