Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

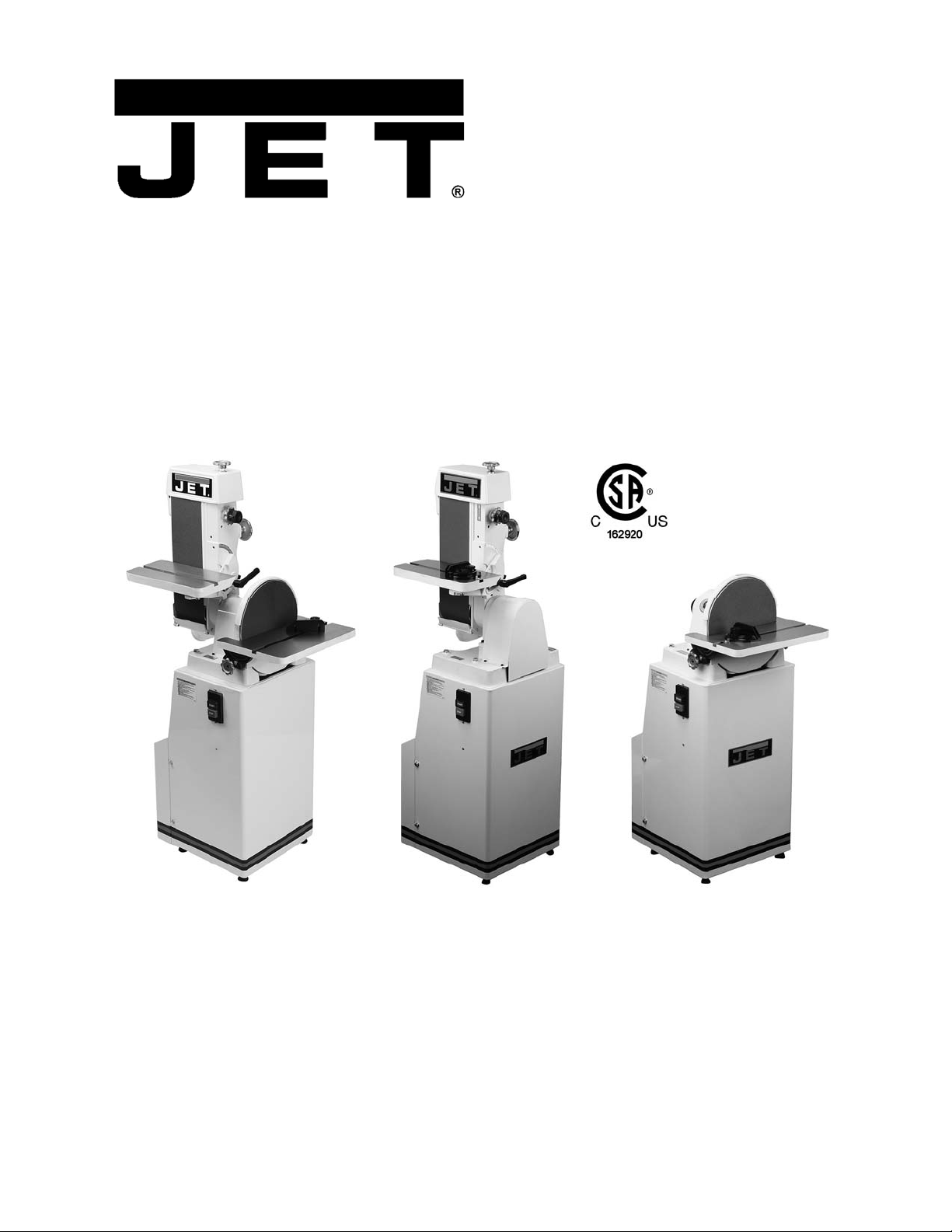

Disc, Belt and Combination Disc/Belt Sanders

Models: J-4200A J-4300A J-4400A

J-4200A-2 J-4301A J-4401A

J-4202A

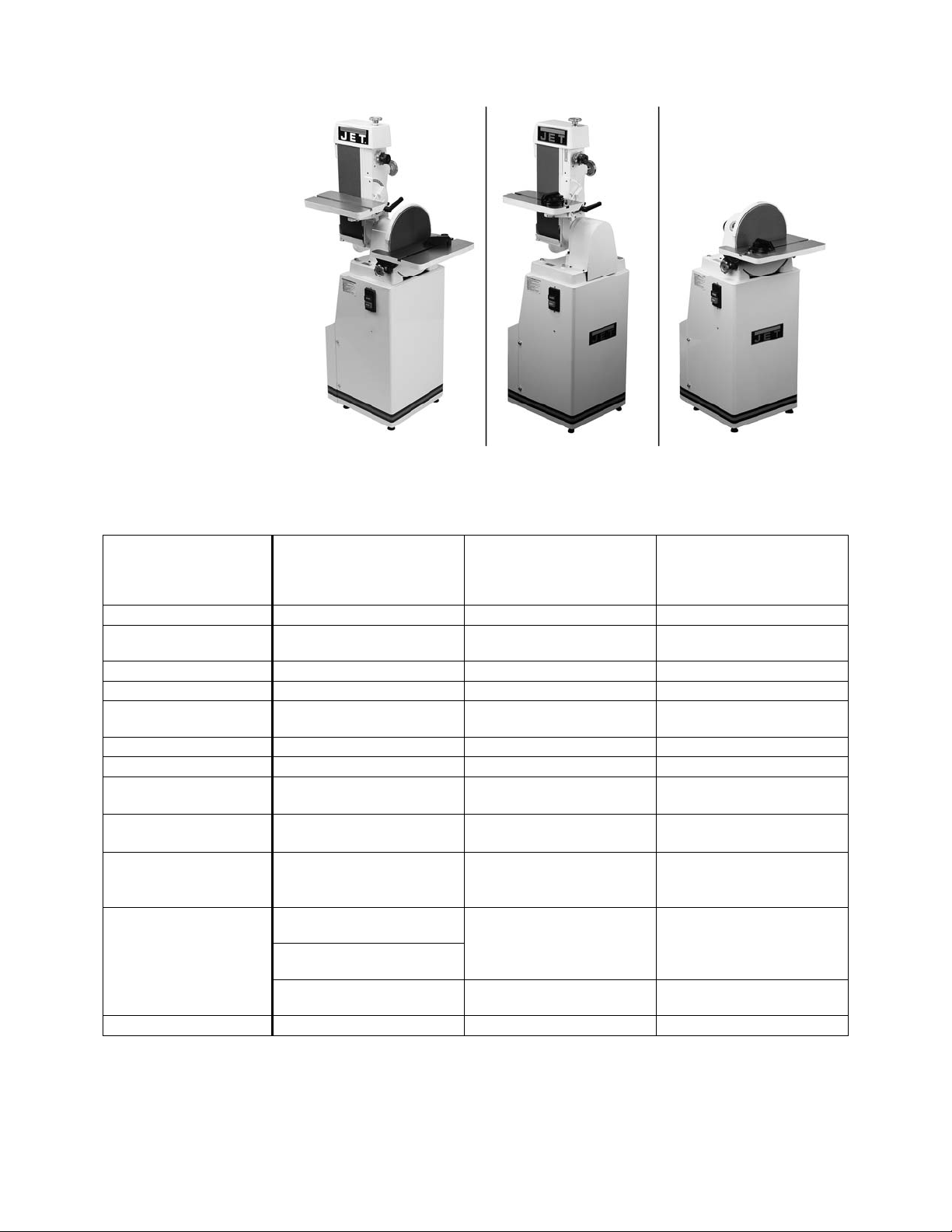

J-4200A Disc/Belt Sander J-4300A Belt Sander J-4400A Disc Sander

WALTER M EIE R (Manufac turing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414551

Ph.: 800-274-6848 Revision B1 01/2013

www.waltermeier.com Copyright © 2013 Walter Meier (Manufacturi ng) Inc .

Page 2

1.0 Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET® tools. For the name of an Authorized Service Center in

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local Walter Meier distributor, or visit jettools.com.

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE

LIMITED WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECI AL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET® branded produc ts are not sold in Canada by Walter Meier.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety Warnings ............................................................................................................................................. 4

4.0 Machine and Manual Overview ...................................................................................................................... 6

5.0 Specifications ................................................................................................................................................. 7

6.0 Operating instructions .................................................................................................................................... 8

6.1 Belt sander .................................................................................................................................... 8

6.2 Adjusting t he belt sander table....................................................................................................... 8

6.3 Using the indexing lock handle ...................................................................................................... 8

6.4 Adjusting t he belt sander arm ........................................................................................................ 8

6.5 Adjusting disc sander table ............................................................................................................ 9

6.6 Use of the Miter Gauge ................................................................................................................. 9

7.0 Maintenance ................................................................................................................................................. 10

7.1 Belt replacement ......................................................................................................................... 10

7.2 Track mechanism maint enanc e ................................................................................................... 10

7.3 Installing abr asive discs ............................................................................................................... 1 1

7.4 Replacing the v-belt ..................................................................................................................... 11

8.0 Machine setup .............................................................................................................................................. 13

8.1 Basic setup ................................................................................................................................. 13

8.2 Disc table angle adjustment ......................................................................................................... 13

8.3 Disc table miter parallelism adjustment ........................................................................................ 13

8.4 Disc table gap adjustment ........................................................................................................... 1 4

8.5 Belt table miter slot parallelism adjustment .................................................................................. 14

8.6 Belt table angle adjustment ......................................................................................................... 14

8.7 Adjusting or replacing the platen .................................................................................................. 15

9.0 Electrical connections .................................................................................................................................. 15

9.1 Single phase electr ic al hook up .................................................................................................... 16

9.2 Three phase electrical hookup ..................................................................................................... 16

10.0 Troubleshooting ......................................................................................................................................... 17

11.0 Replacement parts ..................................................................................................................................... 18

11.1.1 Model J-4200A B elt and Disc Sander Assembly – Exploded View ........................................... 18

11.1.2 Model J-4200A B elt and Disc Sander Assembly – Parts List ................................................... 1 9

11.2.1 Model J-4300A B elt Sander A ssembly – Exploded View ......................................................... 21

11.2.2 Model J-4300A B elt Sander A ssembly – Parts List .................................................................. 22

11.3.1 Model J-4400A Disc Sander A ssembly – Exploded View ........................................................ 24

11.3.2 Model J-4400A Disc Sander A ssembly – Parts List ................................................................. 25

11.4.1 Base Assembly : All 1 P hase Models – Exploded View ............................................................ 26

11.4.2 Base Assembly : All 1 P hase Models – Parts List..................................................................... 27

11.5.1 Base Assembly : All 3 P hase Models – Exploded View ............................................................ 28

11.5.2 Base Assembly : All 3 P hase Models – Parts List..................................................................... 29

12.1 Electrical schematic – single phase ........................................................................................................... 30

12.2 Electrical schematic – 3 phase ................................................................................................................... 31

3

Page 4

GeneralMachineryWarnings

3.0 Safety Warnings

GeneralCautions

- Misuse of this machine can cause serious injury.

- For safety, the machine must be set up, used and

serviced pr oper l y.

- Read, understand and follow the instructions in the

operator’s and parts manual which was shipped

with your machine.

When setting up the machine:

- Always avoid using the machine in damp or poorly

lighted work areas.

- Always be sure the machine is securely anchored to

the floor.

- Al ways keep the machine guards in place.

- Always put the start switch in the “OFF” position

before plugging in the machine.

When using the machine:

- Never operate the machine with safety guards

missing.

- Always wear safety glasses with side shields (See

ANSI Z87.1)

- Never wear loose clothing or jewelry.

- Never overreach; you may slip and fall into the

machine.

- Never leave the machine running while unattended.

- Alwa ys sh ut th e m achi ne off w hen not in u se.

When servicing the machine:

- Always unplug the machine from the electrical

power before servicing.

- Always follow the instructions in the operators and

parts manual when changing accessory tools or

parts.

- Never modify the machine without consulting

Walter Meier (Manufacturing) Inc.

You — the stationary power tool user — hold the key

to safe ty.

Read and follow these simple rules for best results

and full benefits from your machine. Used properly,

JET machinery is among the best in design and

safety. However, any machine used improperly can

be rendered inefficient and unsafe. It is mandatory

that those who use our products be properly trained in

how to use them correctly. They should read and

understand the Operator’s and Parts Manual as well

as all labels affixed to the machine. Failure in

following all of these warnings can cause serious

injuries.

1. Always wear protective eye wear when operating

machinery. Eye wear shall be impact resistant,

protective safety glasses with side shields which

comply with ANSI Z87.1 specifications. Use of

eye w ear which does not comply with ANSI Z87.1

specifications could result in severe injury from

the breakage of the eye protection.

2. Wear proper apparel. No loose clothing or jewelry

which can get caught in moving parts. Rubber

soled, nonslip, footwear is recommended for best

footing.

3. Do not overreach. Failure to maintain a proper

working position can cause you to fall into the

machine or cause your clothing to get caught —

pulling you into the machine.

4. Keep the guards in place and in proper working

order. Do not operate the machine with the

guards removed.

5. Avoid dangerous working environments. Do not

use stationary machine tools in wet or damp

locations. Keep work areas clean and well lit.

6. Special electrical precautions should be taken

when wor king on flamma ble materials .

7. Avoid accidental starts by being sure that the

start switch is in the “OFF” position before

plugging in the machine.

8. Never leave the machine running while

unattended. The machine shall be shut off

whenever it i s not bein g used.

9. Di sco nnect t he elect rica l power befor e serv icing ,

whenever changing accessories or when general

maintenance is done on the machine.

10. Maintain all machine tools with care. Follow all

maintenance instructions for lubricating and the

changing of accessories. No attempt shall be

made to modify or have makeshift repairs done to

the machine. This not only voids the warranty but

also renders the machine unsafe .

11. If there is any risk of tipping or sliding, the

machinery must be anchored to the floor.

12. Secure your work. Use clamps or a vise to hold

your work, when practical. It is safer than using

your hands and it frees both hands to operate the

machine.

13. Never brush chips away while the machine is in

operation.

14. Keep work area clean. Cluttered areas invite

accidents.

15. Remove adjusting keys and wrenches before

turning the machine on.

16. Use the right tool. Don’t force a tool or

attachment to do a job it was not designed for.

17. Use only recommended accessories and follow

manufacturer’s instructions pertaining to them.

4

Page 5

18. Keep hands in sight and clear of all moving parts

and cutting surfaces.

19. Al l visitors should be kept at a safe distance from

the work area. Make your workshop completely

safe by using padlocks, master switches, or by

removing starter keys.

20. Know the tool you are using; its application,

limitations, and potential hazards.

GeneralElectricalCautions

This machine should be grounded in accordance with

the National Electrical Code and local codes and

ordinances. The work should be done by a qualified

electrician. The machine should be grounded to

protect the user from electrical shock.

WireSizes

Caution: For circuits that are a great dist ance from

the electrical service box, the wire size must be

increased in order to deliver ample voltage to the

motor. To minimize power losses and to prevent

motor overheating and burnout, the use of wire sizes

for branch circuits or electrical extension cords

according to the following table is recommende d:

Conductor

length

240 volt lines 120 volt lines

0-50 feet No. 14 No. 14

50-100 feet No. 14 No. 12

Over 100 feet No. 12 No. 8

AWG (American Wire Gauge) number

SafetyRequirementsforAbrasiveSanding

Machines

Abrasive sanding can be hazardous to operators and

bystanders. Sanding sparks, chips and dust particles

thrown off by the sanding disc can cause serious

injury if contacted or inhaled. To avoid such injuries

you must comply with the following safety

requirements:

1. Al way s wear pr otect ive ey ewear when op erat ing

machinery. Eye wear shall be impact resistant,

safety glasses with side shields which comply

with ANSI Z87.1. Use of eye wear which does not

comply with ANSI Z87.1 specifications could

result in severe injury from the breakage of the

eye prot ection.

2. Wear leather safety gloves, arm guards, leather

aprons and safety shoes.

3. A dust collection system is recommended. The

operator should also wear a dust mask at all

times.

4. Additional precautions may be necessary for

sanding materials which are flammable or have

other hazardous properties. You should always

consult the manufacturer of such materials for

instructions on sanding and handling.

5. Do not force or jam the workpiece into the

sanding disc.

6. Before sanding, always allow the motor to come

up to operating speed, then check the sanding

disc for wobble, run-out, or any unbalanced

condition. If the disc is not operating accurately

and smoothly, immediately stop the motor and

make repairs before attempting any sanding

operations.

7. Abrasive discs must be stored in a controlled

environment . Relative humidity should be 35% to

50% and the temperature should be between 60°

and 80° Fahrenheit. Failure to do so could cause

premature disc fail ure.

8. Examine the face of the sanding disc carefully.

Excessive sanding that wears down to the

backing material can tear the disc. Never use a

disc which shows backing, nicks or cuts on the

surface or edge, or damage due to creasing or

poor handling.

9. W hen i nst all in g a n ew di sc, be c ert ain th e dis c is

accurately centered on the drive wheel. Failure to

do so could cause a serious unbalanced

condition.

10. Alw ay s pr esen t t he w or kpi ec e to th e wh eel wh il e

rest ing t he work piece f irml y on th e table. Fail ure

to do so could result in damage to the workpiece

or t hrowing of the work piece off the wheel.

11. Safety shoes which comply with ANSI Z41.1

should be worn.

12. Personal hearing protection such as ear plugs or

ear muffs should be used to protect against the

eff ect of noise exposure.

5

Page 6

4.0 Machine and Manual Overview

JET Abrasive Finishing Machines are available in three different configurations: disc, belt, and combination disc and

belt. Each configuration is a rugged, heavy-duty machine designed for maximum high production work in an industrial

environment.

The speed of stock removal and the quality of finish achieved is determined largely by the aggressiveness of the

abrasive disc or belt mounted on the machine. With very aggressive grits, these machines are typically considered

grinding machines. With very fine grits, these machines are typically considered sanding machines. Whatever you

call them, and however you use them, the instructions in this manual will help you use them safely and productively.

You will note there are several types of electrical systems available for these machines. All of these systems are

equally effective in providing power to the grinding mechanism – however, local codes and the type of environment in

which the machine is used will often be a factor in your choice of system.

Instructions in this manual assume that you are using one of the Model J-4200A Series Belt and Disc machines. If

you have a disc only, or belt only machine, you can bypass those instructions which do not apply to you.

If there are questions or comments, please contact your local supplier or Walter Meier. Walter Meier can also be

reached at our web site: www.waltermeier.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attempting assembly or

operation! Failure to comply may cause serious injury!

6

Page 7

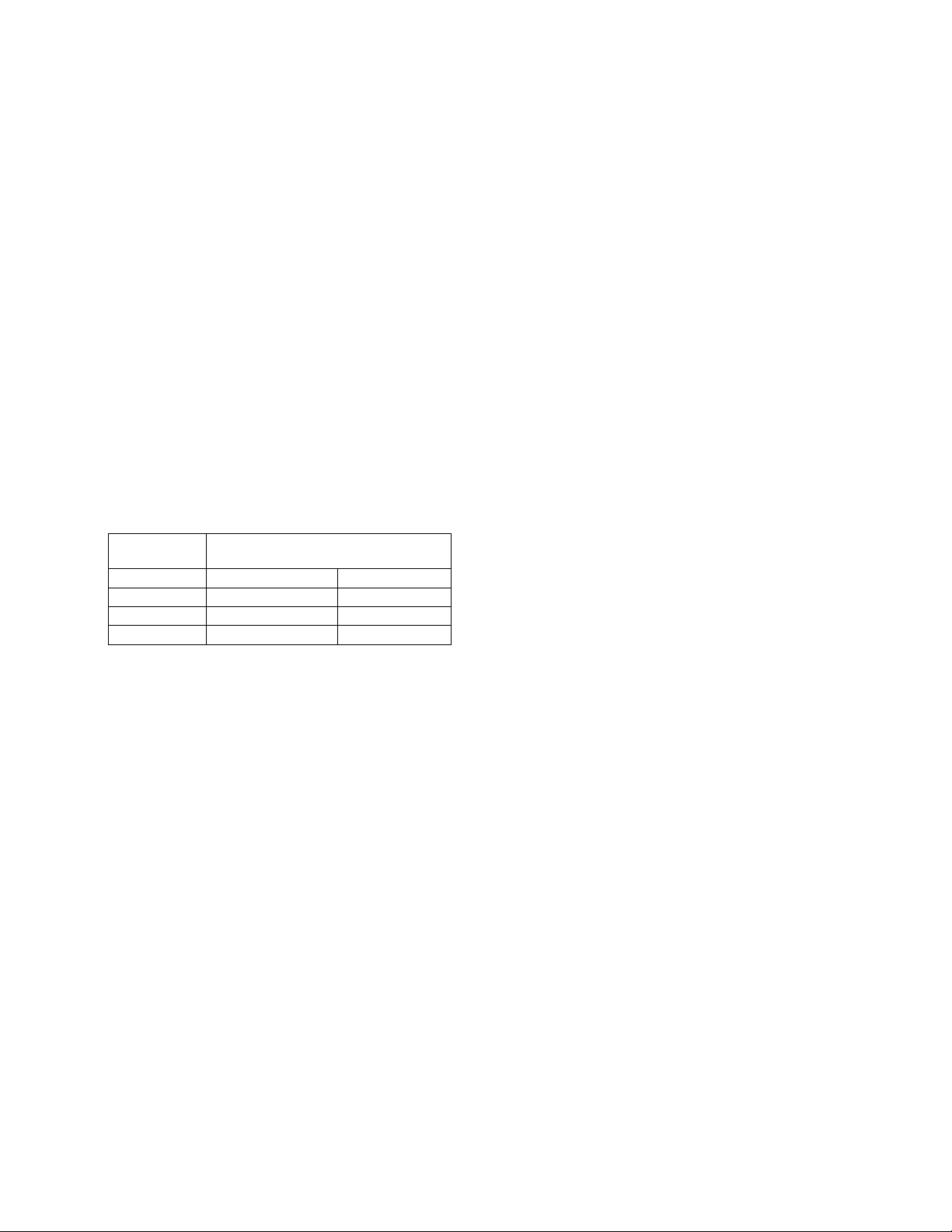

5.0 Specifications

Model Stock No.

J-4200A 414551

J-4200A-2 414552

J-4202A 414553

J-4300A 414600

J-4301A 414601

J-4400A 414602

J-4401A 414603

J-4200A Disc/Belt Sander J-4300A Belt Sander J-4400A Disc Sander

Disc/Belt Sander Belt Sander Disc Sander

Disc:12x16-3/8 in.

Table size

Table tilt (both) 45° down, 20° up 45° down, 20° up 45° down, 20° up

Miter gauge groove

Disc diameter 12 in. (305mm) 12 in. (305mm)

Disc Speed 1960 RPM 1960 RPM

Platen size

Belt size 6x48 in. (152x1214mm) 6x48 in. (152x1214mm)

Belt speed 2850 SFM 2850 SFM

Dimensions

(depth, W, H)

Dimensions w/platen

vertical (depth,W, H)

Dimensions w/platen

horizontal

(depth, W, H)

Motor options

Weight 250 lbs. (113 kg.) 211 lbs. (96 kg.) 164 lbs. (74 kg.)

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, Walter Meier (Manufacturing) Inc., reserves the right to change specifications at any time and without

prior notice, without incurring obligations.

(254x416mm)

Belt: 7 3/8x14 3/4 in.

(187x355mm)

(both) 3/8x3/4 in.

(9.5x19mm)

6-1/4x14-3/4 in.

(159x375mm)

19x16x57-1/2 in.

(475x400x1437mm)

25-1/2x16x43 in.

(637x400x1075mm)

Model J-4200A 1 PH 1.5HP

115/220V (prewired 115V)

Model J-4200A-2 1 PH

1.5HP 220V

Model J-4202A 3 PH 1.5HP

230V/460V (prewired 230V)

7-3/8x14-3/4 in.

(187x355mm)

3/8x3/4 in. (9.5x19mm) 3/8x3/4 in. (9.5x19mm)

6-1/4x14-3/4 in.

(159x375mm)

19x16x57-1/2 in.

(475x400x1437mm)

25-1/2x16x43 in.

(637x400x1075mm)

Model J-4300A 1 PH

1.5HP 115/230V (prewired

115V)

Model J-4301A 3 PH 1.5HP

230V/460V (prewired 230V)

12x16-3/8 in. (254x416mm)

29x17x42-3/4 in.

(1070x725x4250mm)

Model J-4400A 1 PH 1.5HP

115/230V (prewired 115V)

Model J-4401A 3 PH 1.5HP

230V/460V (prewired 230V)

7

Page 8

6.0 Operating instructions

These sanders can be used to remove stock from a

wide variety of machinable materials. Different

materials require different grit types and grades to

achieve the desired stock removal rate and surface

finish. Please consult with your abrasive materials

supplier for specific recommendations on the correct

grit material and grade required for your specific

needs.

When removing stock from soft materials (wood,

plastic, etc.) these machines are typically called

"sanders." When removing stock from hard materials

(cast iron, steel, etc.) they are referred to as

"grinders". The word "sander" is used, more-or-less

consistently, throughout this manual. It refers to the

machines and not the type of abrasive finishing being

performed.

Before operating your sander, please read the basic

instructions on safe machine usage on the preceding

pages.

6.1 Belt sander

The sanding belt must be in good condition, at proper

tension, and tracking correctly, before doing any

sanding, grinding or other abrasive machining

operations. Refer to the section on Track Mechanism

Maintenance if you have any problems with belt

tension or tracking.

6.2 Adjusting the belt sander table

You can tilt the table in a range between 20° upward

and 45° downward. A single locking handle on the

side of the table is used to lock and unlock the table

to permit adjustment.

There are two positive lock stop positions: at 90° (that

is, at a right angle to the platen) and at 45° downward

(essentially 90° + 45° or 135° total to the platen.)

Never adjust the table angle

while the sander is running. Always turn the

motor off before adjusting the table angle.

To Tilt the Belt Sander Table:

1. Unlock the locking handle on the side of the

table.

2. Using the pointer and scale, set the angle to any

required angle between 20° upward and 45°

downward.

3. Lock the lock handle.

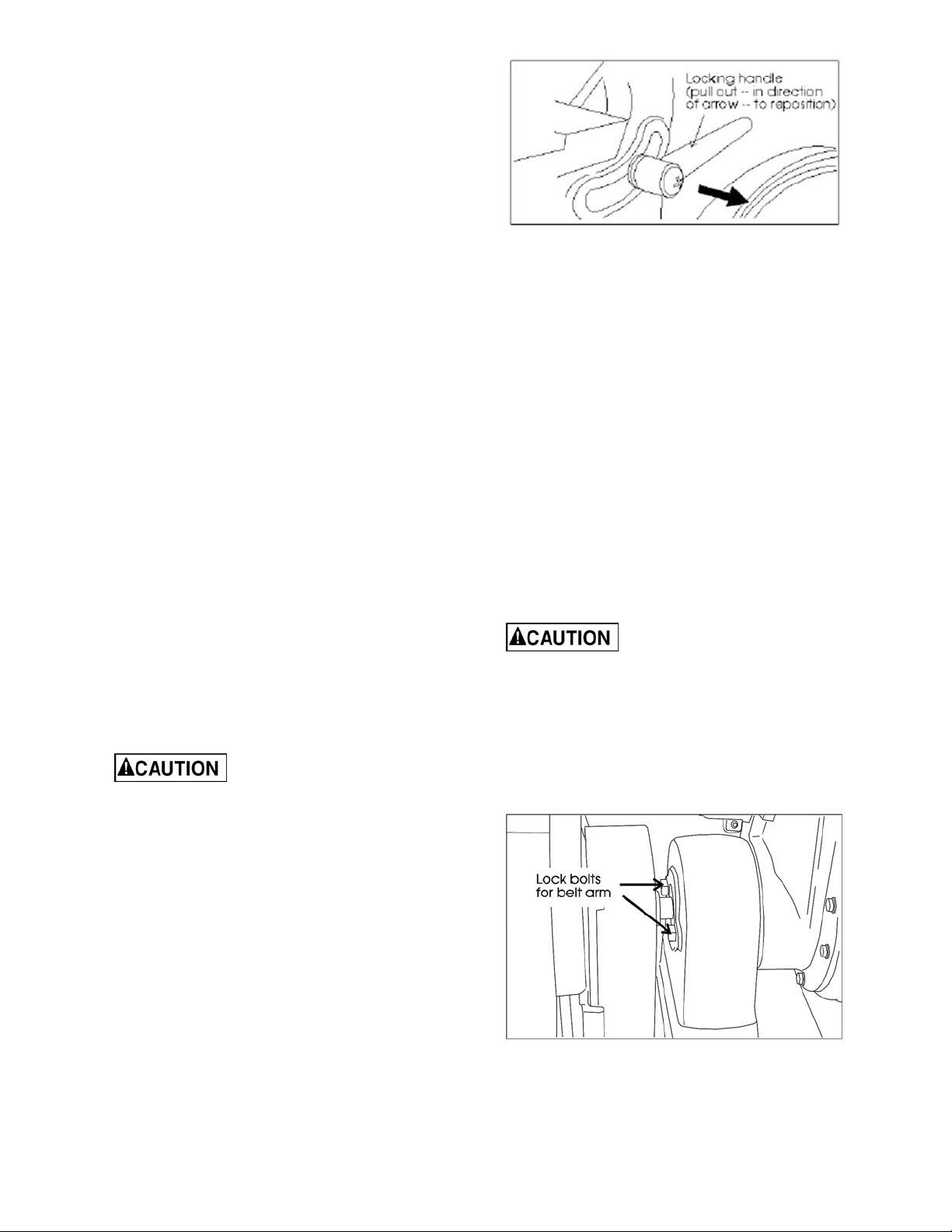

Figure 1: Locking handle for belt table

6.3 Using the indexing lock handle

The lock handle (Figure 1) is spring loaded and can

be repositioned on its shaft to permit easy locking and

unlocking.

To Reposition the Handle:

1. Pull outward against its spring.

2. Rotate the handle to the position you require.

3. Release the handle and its spring will return it to

the correct operating position.

6.4 Adjusting the belt sander arm

The arm which holds the sanding belt can be

positioned at a full vertical position, a full horizontal

position, or at any angle in between which is

convenient to the type of sanding you are doing.

A positive stop mechanism is used to permit quick

adjustment to the vertical or horizontal positions.

Never adjust the arm angle

while the sander is running. Always turn off the

motor before adjusting the arm angle.

To adjust to vertical:

1. Unlock both lock bolts. These are located under

the arbor cover.

2. Move the arm to vertical until it contacts its stop.

3. Tighten both lock bolts, and replace arbor cover.

To Tilt the Table to Exactly 45o:

1. Flip out the stop bracket (see Figure 20).

2. Unlock the locking handle.

3. Move the table until it contacts the stop bracket.

4. Lock the table lock handle.

Figure 2: Lock bolts for belt arm

8

Page 9

To adjust to horizontal:

1. Unlock both lock bolts.

2. Move arm to horizontal until it contacts its stop.

(See F igure 3 . )

3. Tighten both lock bolts and replace arbor cover.

Figure 3: Arm at horizontal – note that the table is

removed. The table may be removed or left in

position, and may also be set to any angle to allow

horizontal sanding of various angles.

To adjust arm to any angle between vertical

and horizontal:

1. Unlock both lock bolts.

2. Use a machinist's protractor and level to set the

arm to the required angle.

3. Tighten both lock bolts and replace arbor cover.

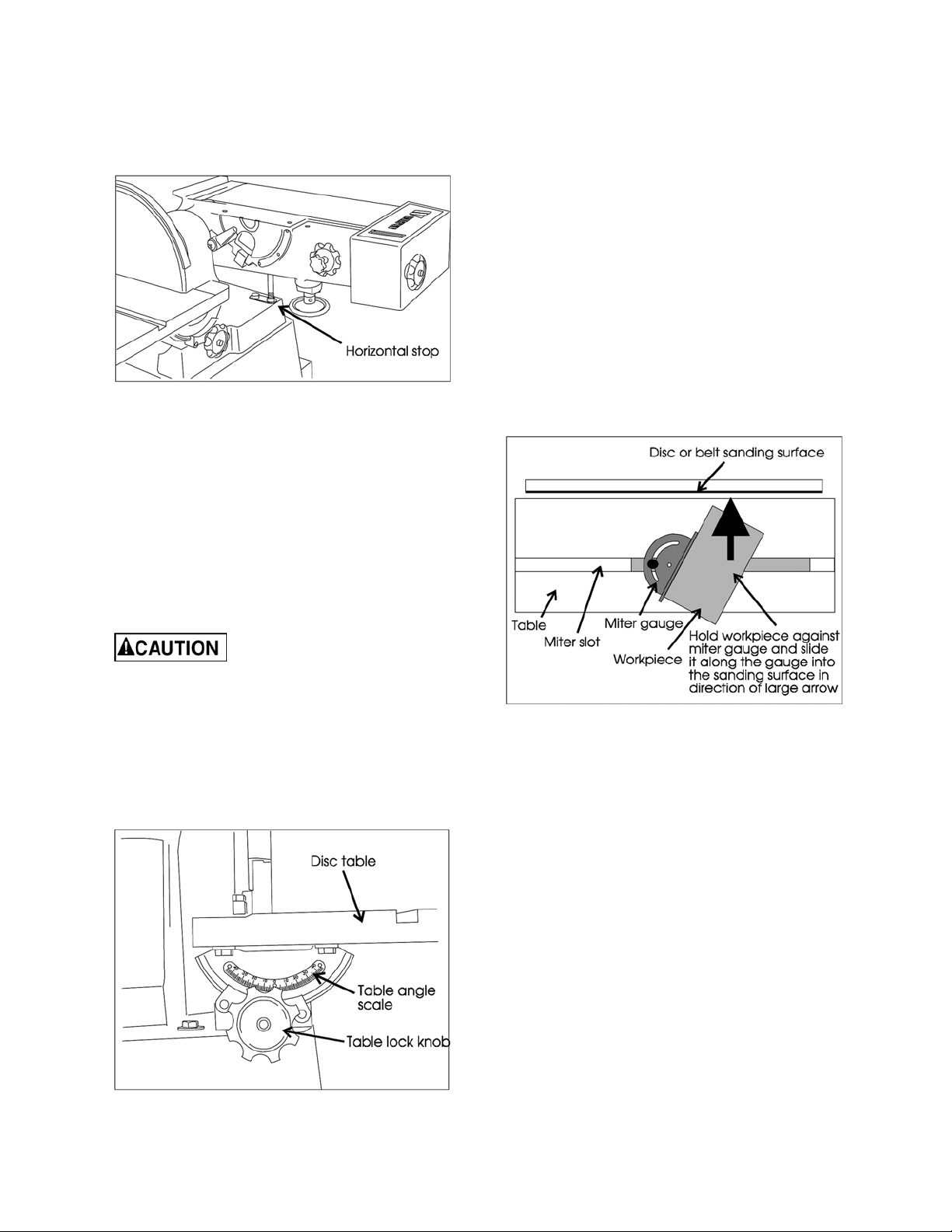

6.6 Use of the Miter Gauge

The miter gauge can be used on either the disc or belt

surfaces to sand accurate angles on workpieces.

When using the gauge alone, you sand a single

angle. However, by tilting the table and using the

miter gauge in combination with the table tilt, it is

possible to sand compound angles, as well.

When grinding a compound angle you should always

check the accuracy of your setup by sanding a piece

of scrap material before doing any finish sanding on

the actual workpiece.

1. Set the angle you wish to sand using the scale on

the miter gauge.

2. Tighten the miter gauge securely so the miter

reference surface will not move while you are

sanding.

3. Place the workpiece against the miter reference

surface and slide it along the reference surface

and into the sanding disc or belt. The basic

method is shown in Figure 5, below.

6.5 Adjusting disc sander table

Never adjust the table angle

while the sander is running. Always turn off the

motor be fore adjusting table angle.

1. Unlock the two locking knobs underneath the

table at each end. ( See Fi gur e 4. )

2. Using the pointer and scale, set the angle to any

required angle between 20° upward and 45°

downward.

3. Lock the two locking knobs underneath the table.

Figure 5: Use of the miter system

Figure 4: Disc sander table adjustment

9

Page 10

7.0 Maintenance

7.1 Belt replacement

1. Di sco nnect t he pow er to t he machi ne to prevent

accidental start-ups. If the machine is plugged

into an outlet, unplug it. If the machine is

hardwired to a branch circuit with a junction box,

rem ove th e fuse or trip th e circ uit br eaker to the

branch.

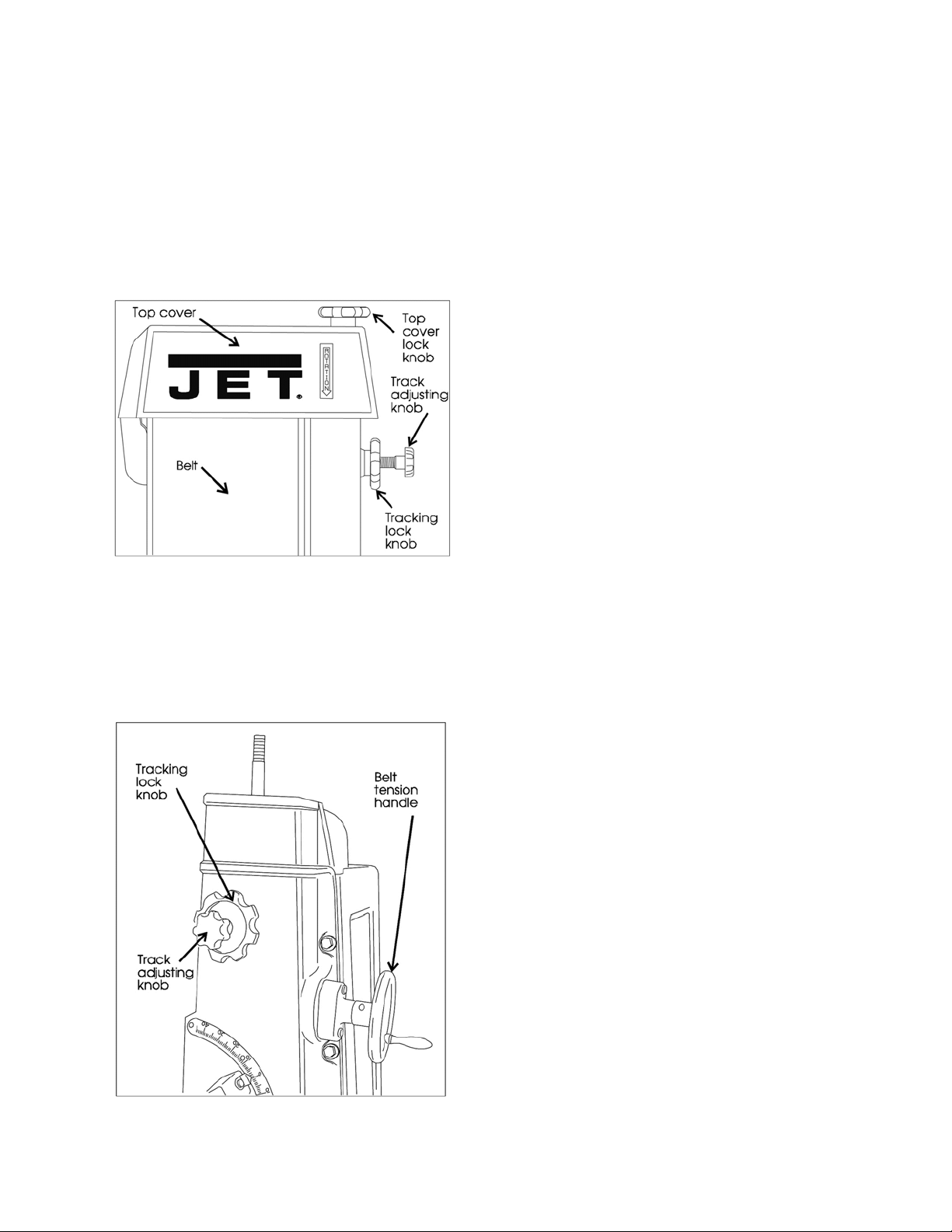

2. Remove the lock knob and top cover (See Figure

6).

Figure 6: Top cover components

3. Remove the side guard and table.

4. Release the belt tension by turning the tension

handle in a counterclockwise direction (See

Figure 7). If the handle is difficult to turn, perform

Track mechanism maintenance according to the

instruction s in se c tion 7.2.

5. Remove the belt.

6. Check the drums and platen for scoring or signs

of wear which might require service or

replacement.

7. Check the height of the platen with a straight

edge. If it is not 1/32 inch above the drums,

adjust it according to the instructions in Platen

Replacement or Adjustment in the Machine

Setup section of this manual.

8. Check the drums for looseness which might

cause tracking problems. Correct any loose

condition by tightening or replacing any parts as

required.

9. Slip the new belt onto the drums and platen.

10. Adjust the tension handle clockwise until the belt

is flat against the platen and there is no curling or

buckling of the belt in the middle.

11. Turn the drums by hand to see if the belt tracks

more-or-less true. JUST BECAUSE THE OLD

BELT TRACKED CORRECTLY DOES NOT

MEAN THE NEW BELT WIL L. Always check the

tracking when replacing a belt.

12. To adjust the tracking:

12.1. Plug the machine back into the outlet or

reestab lis h power in t he br anch.

12.2. Loosen the tracking lock knob.

12.3. Jog the motor on and off as necessary to

observe the tracking, and turn the tracking knob

as necessary to make the belt track in the center

of the platen and drums. Turn the tracking knob

clockwise to move the belt toward the right and

counterclockwise to move the belt toward the left.

12.4. When the belt seems to be tracking

correctly, turn the motor on and leave it running

while fine tuning the tracking.

12.5. Lock the tracking lock knob.

12.6. When the lock knob is secure, turn the

power off and disconnect the machine from the

outlet or branch as in Step 1, above.

13. Replace the table, side guard, top cover and lock

knob by reversing steps 3 and 2, above.

14. If you have not already done so, reconnect the

power to the machine and return it to service.

Figure 7: Belt adjustment components (Note top cover

removed for removal and replacement of belt.)

7.2 Track mechanism maintenance

Whi le th e use of a dust coll ect ion sy stem can ext end

service intervals, an accumulation of dust will almost

certainly require periodic cleaning of the tracking

mechanism. The more continuous the use of the

machine, the more frequently this maintenance

should be performed.

As mentioned in the preceding section, the need for

required maintenance is often indicated by difficulty in

adjusting the tension/tracking mecha nism.

1. With the belt removed according to the

instructions in section 7.1 Belt replacement, pull

out the upper tracking system and clean away all

10

Page 11

built up material in the upper part of the bracket

casting.

2. Take the two keys off of the idler pin bracket,

wipe off, and re-grease.

3. Reverse the above steps to make the machine

ready for reinstallation of the belt according to the

Belt replacement instructions.

7.3 Installing abrasive discs

1. Disconnect power to the machine to prevent

accidental start-ups.

2. Peel off the old abrasive disc.

3. Clean the drive disc surface using naptha or a

similar nonflammable solvent that will dry filmfree.

4. Pull the protective backing half off the new

abrasive disc.

5. Position the new disc carefully so it is centered

acc urately on th e drive disc. (See F igu re 8.)

6. When accurately centered, remove the rest of the

protective backing and press the abrasive disc

firmly against the drive disc so complete

adhesive contact is made.

7. Reconnect the power to the machine.

Figure 9: Removing belt guard

Figure 8: Installing new abrasive disc

7.4 Replacing the v-belt

1. Disconnect power to the machine to prevent

accidental start-ups.

2. Remove the belt guard (Figure 9) and disc table.

3. Remove the table tilt lock knob (Figure 10).

4. Loosen the four motor bolts so the motor can

slide on its plate.

Figure 10: Disc table lock knob

5. Remove th e belt from the mo tor pulley.

6. Remove three of the base mounting bolts, then

loosen the fourth bolt slightly. This allows you to

rotate the machine on the machine base (See

Figure 11).

7. Remove the two bolts, underneath the machine

casting, that secure the disc guard to the casting

(See Figure 11).

11

Page 12

Figure 11: Rotating the machine casting to remove

the disc guard bolts

Figure 12: Locating the set screws that secure the

disc to the arbor

8. Through the hole in the disc guard casting, locate

and remove the TWO set screws that secure the

drive disc to the arbor (Figure 12). One set screw

clamps on the arbor key and the other clamps on

the arbor shaft, itself. Be sure you loosen both of

them.

9. Sli de the disc and its guard off of the machi ne,

together (See Figure 13).

10. The V-belt can now be removed from the drive

arbor.

11. Install the new belt on the top pulley.

Figure 13: Removing the guard and drive disc,

together.

12. Slide the disc and guard back into position.

13. Reinstall the disc guard bolts underneath the

table.

14. Position the drive disc so that it is no more than

1/16 inch away from the table, then tighten BOTH

of the set screws by inserting the hex wrench

through the hole in the disc guard casting.

15. Rotate the machine back onto its base and

secure it with all four mounting bolts.

16. Inst all the bel t over the b ott om pulley.

17. Tension the belt so that when pressed, in the

mid dle of its t r avel , it ha s no mo r e th an o n e bel t's

width of movement – then tighten the four motor

bolts.

18. Observe the alignment of the motor pulley and

arbor pulley. If necessary, correct their alignment

by shifting the motor slightly on its mount (which

involves loosening and retightening the mounting

bolts and checking tension) or by shifting the

pulley slightly on the motor shaft (which involves

loosening the motor pulley set screw and sliding

the pulley into alignment) or by moving the arbor

pulley slightly on its shaft (See Figure 14).

19. W hen the pulleys are accurately aligned, reinstall

the belt guard.

20. R eest ablish electrical power t o the machine.

12

Page 13

Figure 14: Loosening pulley set screws to allow the

adjustment of pulley on arbor shaft.

8.0 Machine setup

8.2 Disc table angle adjustment

1. Disconnect power to the machine to prevent

accidental start-ups.

2. Loosen the table locking knobs on either end of

the table.

3. Using a machinist's square against the table and

disc, set the table at exactly 90° to the disc (See

Figure 15).

4. Tighten the table locking knobs.

5. Check the pointer. If it is not exactly on the zero

mark, loosen the pointer attaching screw, adjust

the pointer, and retighten the screw.

6. Reconnect the power to the machine.

8.1 Basic setup

1. Position the machine where it will be located on

the shop floor. When positioning the machine,

consider the type of work which will be done on it

so you allow sufficient room not only for the

wor kpieces, but also for service to the ma chin e.

2. Open the door in the base of the machine and,

using the holes in the base as a template, mark

the floor for the position of the hold-down bolts.

3. Mo ve the m achi ne to expo se the h old- down bol t

marks and install anchors for the hold-down

bolts.

4. Put the machine back over the hold-down

anchors and bolt the machine securely to the

shop floor. THIS MUST BE DONE FOR SAFE

OPERATION OF THE MACHINE.

5. Establish an electrical service connection to the

machine. This will vary according to the model

purchased. ALL ELECTRICAL CONNECTIONS

SHOULD BE MADE BY A QUALIFIED

ELECTRICIAN WHO IS FAMILIAR WITH YOUR

STATE AND LOCAL CODES. Many models of

thes e mac hi nes m a k e us e o f hi g h volt ag es whi c h

pose a significant risk of serious injury or DEATH

if proper knowledge and precautions are not

used. Electrical instructions are included in

section 9.0 Electrical connections.

6. Machines with belts are shipped with the belts in

slack condition. During the electrical hookup

phase of machine setup, the belt will have to be

tightened and checked for tracking. See the Belt

Replacement section for instructions on this

procedure.

Figure 15: Using a square to check the disc table

scale.

8.3 Disc table miter parallelism

adjustment

1. Disconnect power to the machine to prevent

accidental start-ups.

2. Set the table angle to zero.

3. Place a scale or adjustable machinist's square

against either the left or right edge of the disc

face and measure the distance to the miter slot

edge (See Figure 16).

Figure 16: Using an adjustable square to set the table

parallelism.

13

Page 14

4. Move the measuring device to the opposite edge

of the disc and measure the distance to the miter

slot.

5. Adjust the table by loosening the four attachment

screws under the table, then move the table until

the distance between the miter slot and the disc

is equal on both sides (See Figure 17).

6. Tighten the four attachment screws.

7. Reconnect the electrical power to the machine.

Figure 17: Table attachment screws – loosen to

adjust miter groove parallelism.

8.5 Belt table miter slot parallelism

adjustment

1. Disconnect power to the machine to prevent

accidental start-ups.

2. Set the table angle to zero.

3. Place a scale or adjustable machinist's square

against either the left or right edge of the belt or

platen and measure the distance to the miter slot

edge (See Figure 19).

4. Move the measuring device to the opposite edge

of the belt or platen and measure the distance to

the miter slot.

5. Adjust the table by loosening the three

attachment screws under the table, then move

the t a bl e u n t il t he d i st a nc e b et ween t h e m i t er s lo t

and belt or platen is equal on both sides.

6. Tighten the three attachment screws.

7. Reconnect the electrical power to the machine.

8.4 Disc table gap adjustment

1. Using a scale, check the gap between the edge

of the table and the face of the disc. It should be

very close to 3/32 inch. If it is much more or less

than that distance, adjust it as follows:

2. Disconnect the elect r ical pow er to t he mac hine.

3. Using the access hole on the top of the disc

guard, locate and loosen the two set screws that

secure the disc to the shaft.

4. Slide the disc in or out along its shaft until the

table-to-disc gap is 3/32 inch (See Figure 18).

5. Tighten both set screws.

6. Reconnect the electrical power to the machine.

Figure 18: Table-to-disc gap measurement.

Figure 19: Using an adjustable square to check and

set miter slot parallelism on the belt table.

8.6 Belt table angle adjustment

1. Loosen the table locking handle and tilt the table

upward to about 15°.

2. Flip out the stop bracket (See Figure 21).

3. Lower the table until its adjusting screw touches

the stop bracket.

4. Place a m achinist's square against the table and

belt or plat en.

5. If adjustment is required, turn the adjusting screw

(Figure 20) until the table is exactly square to the

platen.

6. Check the pointer. If it is not on 0°, loosen the

pointer screw and adjust the pointer until it is on

0°.

7. Tighten the pointer screw.

8. Loosen the table lock handle and tilt the table

until its stop contacts the 45° stop position.

9. Using a machinist's protractor set on 135° (90° +

45°) adjust the screw until the table and platen

are in correct adjustment. DO NOT reset the

pointer after this operation.

14

Page 15

Figure 20: Location of adjustment (socket head)

screws and pointer attachment screw for table angle

adjustment.

Figure 21: Locations of stop lugs and stop bracket for

zero and 45° table positions.

8.7 Adjusting or replacing the platen

1. Disconnect th e elec trical power to t he ma chine t o

prevent accidental start-ups.

2. Remove the top cover, side guard and belt as

outlined in section 7.1, Belt replacement.

3. Remove the table by unscrewing the locking

handling and lifting the complete table assembly,

from the machine.

4. If you are replacing the platen, remove the three

screws that hold it to its mount -- then install the

new platen and replace the mounting screws

finger tight.

5. If you are only adjusting the platen, loosen the

three mounting screws to allow adjus tment .

6. Using a straight edge as shown in Figure 22,

adjust the platen height until i t i s 1/32 inch higher

than the crown of both the drive and idler drums.

7. Tighten the platen adjustment screws.

8. Reinst all the ta ble an d belt .

9. Check and adjust, if necessary, the tracking of

the belt according to instructions in section 7.1,

Belt replacement.

10. Reinstall the guards and covers.

11. Check and adjust the table angles and miter slot

squareness according to table adjustment

instructions in this manual.

12. Reconnect the electrical power to the machine.

Figure 22: Method for adjusting height of platen

above drive and idler drums.

9.0 Electrical connections

Caution: JET sanders are available in a wide variety

of el ectric al configura tions to meet the n eeds of the

purchaser with respect to power available and

compliance with electrical codes. Each machine is

tested at the factory for operation before shipment

and the power cord is tagged with the power

requirements for the machine, as shipped.

HOWEVER, before attempting any electrical hookup,

you should be certain:

1. The electrical characteristics of the service

branch match the requirements of the motor.

2. The service branch is equipped with wires of the

required gauge or size.

3. The branch circuit intended for the machine is

protected with a time delay fuse or circuit breaker

with rated amperage just slightly greater than the

full load current of the motor.

MOTOR AMPERAGE full load current

Phase Voltage Amperage

1 115 20

1 220 10

3 220 5.2

3 440 2.6

15

Page 16

All electrical service work on

your JET sander should be performed by a

qualified, licensed electrician who is familiar with

all safe standard electrical installation practices

and all applicable electrical codes. This includes

local electrical codes which may affect the

connection and operation of the sander in your

specific manufacturing operation.

9.1 Single phase electrical hookup

When connecting your machine to single phase

power, you may be connecting to either 115 or 230

volts, depending upon the motor type provided. Local

codes may, or may not, permit the use of a plug type

of connection for your machine. Where a plug

connection is permitted, the following installation

practices must be followed:

1. The plug used must be a grounding type of plug.

That is, on a 115 volt single phase connection,

the plug must be a three-prong plug with two flat,

parallel blades for the power wires and a single

rounded or U-shaped prong for the ground

connection. On 230 volt single phase

connections, the lug must be a three prong plug

with two flat blades in tandem to carry the

current, and a third round or U-shaped prong for

the ground connection.

2. The service branch to which the plug is

connected must be a branch with a separate

ground wire so the grounding prong of the plug

can be connected to ground effectively.

Note: Local electrical codes in many jurisdictions

DO NOT ALLOW THE USE OF PLUG TYPE

CONNECTIONS FOR SINGLE PHASE POWER

WHEN THE MACHINE IS USED IN A COMMERCIAL

OR INDUSTRIAL ESTABLISHMENT.

In t hese c ases you m ust connect y our machi ne to the

service branch using a hardwired junction box

connection.

machine connection is made and the time delay fuse

or circuit breaker should be a value just slightly higher

than the maximum load current draw.

9.2 Three phase electrical hookup

1. Be certain the power to the branch you are

connecting is off and locked out, so power cannot

be reestablished accidentally.

2. Connect the ground wires. These wires will be

eit her g reen, or green with a w hit e stri pe.

3. Connect the remaining three cable wires to the

three po wer wi res in the serv ice branc h.

4. Reestablish the power to the branch.

Motorrotation

The motor should be turning counterclockwise, the

belt sander should be moving downward and the disc

sander should be turning clockwise. If this is the case,

the machine can be considered wired correctly. If the

motor is not turning in the correct direction, take the

following corrective action:

1. Disconnect power in the branch again and be

certain it cannot be accidentally turned on while

you correct the wiring.

2. Reverse ANY TWO of the power wires to the

machine.

3. Rees tab l ish the p ower to the machi ne.

4. Turn the machine on. The motor should now be

turning in the correct direction.

Voltageconversion

Three phase machines are pre-wired for 230V or

460V per customer request. If it becomes necessary

to change the voltage:

1. Remove back cover from the base and place

machine on its side.

Motorrotation

The motor's rotation should result in the belt sander

moving downward and the disc sander rotating

counterclockwise.

Voltageconversion

Single phase machines are pre-wired for 115V or

230V per customer request. If it becomes necessary

to change the voltage, remove the back cover from

the base and place the machine on its side. Remove

the terminal cover from the motor. Rewire the motor

acc or din g to th e mot o r c onnec ti on di agr am in s ecti o n

12.1. Different electrical plugs are required depending

on which voltage you select. This completes the

voltage conversion process.

Circuitprotection

Where the service branch is protected with a fuse or

circuit breaker that has too high a value to offer

protection to the motor supplied, a fuse or circuit

breaker box should be used at the point where the

2. Remove terminal cover from motor. Rewire the

motor according to the motor connection

diagram in section 12.2.

3. Replace the current magnetic switch with the

460V switch (p/n 4202A-5095, purchased

separately – see your dealer or contact W alter

Meier to order).

4. This completes the voltage conversion

process.

Circuitprotection

Where the service branch is protected with a fuse or

circuit breaker that has too high a value to offer

protection to the motor supplied, a fuse or circuit

breaker box should be used at the point where the

machine connection is made and the time delay fuse

or circuit breaker should be a value just slightly higher

than the maximum load current draw.

16

Page 17

10.0 Troubleshooting

Symptom Possible Cause Correction

Motor will not r un Voltage is too lo w. Check power suppl y for prop er v olt a g e.

Branch circuit fuse is blown or circuit

breaker is tripped.

Branch is shut down for service. Check all personnel and machines on

Open circuit in the wiring. Inspect all wire connections for loose or

Motor is defective. Replace the motor.

Switch is defective. Replace the switch.

Motor stalls easily Low voltage. Check for proper voltage at the motor;

Fuse blown (three phase motors only). Replace the blown fuse.

Improper wiring. Check for proper connections.

Abrasive belt or disc

slows down although

motor keeps running at

working speed

Poor tracking Tracking is out of adjustment. Adjust the belt tracking.

Belt is slipping. Replace the belt.

Too much belt tension. Loosen the tension until the belt is just taut.

Determine the reason for the blown fuse or

tripped circuit breaker; then replace the fuse

or r eset the breaker.

the branch to be certain someone has

not shut down the branch for service. DO

NOT repl ace th e fuse or reset the br eaker

unless you are certain no personnel are

working on the machines, wires or controls in

the cir cuit .

open connections.

correct as necessary.

Not enough belt tension. Tighten the tension until the belt is more taut.

Belt is jointed improperly. Check belt for an irregular seam or shape.

Lack of crown on the drive roller. Remove the belt and put a straight edge

along the drive roller. There should be a

slight crown (high spot toward the middle of

the roller.) If the crown has worn away,

replace th e r oll er.

Worn bearings. Check all the bearings for excessive heat or

loose shafts. Replace if necessary.

Unsteady belt Slack in the abrasive belt Adjust the belt tension.

Short belt life Excessive pressure applied while

grinding.

Working on only one side of the belt or

only in one area of the disc.

Incorrect abrasive material or grit size. Check with your abrasives supplier for

CAUTION: For all of the electrical faults and corrections in the above table JET recommends the use of a qualified

and licensed electrician for all circuit tracing, diagnosis and repair.

Allow the belt to do the cutting. Excessive

pressure only dulls the grit and removes it

from the cloth.

Use all surface areas of the abrasive cloth.

recommendations on the type and

coarseness of the abrasive required for the

wor kpieces y ou ar e sanding or gri ndi ng.

17

Page 18

11.0 Replacement parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1-800-2746848 Monday through Friday (see our website for business hours, www.walt erm eier.com). Having t h e Model Number

and Serial Number of your machine available when you call will allow us to serve you quickly and accurately.

11.1.1 Model J-4200A Belt and Disc Sander Assembly – Exploded View

18

Page 19

11.1.2 Model J-4200A Belt and Disc Sander Assembly – Parts List

IndexNo PartNo Description Size Qty

1 ................ J-5508427 ................. Bracket..................................................................... ...................................... 1

2 ................ 5511833 .................... Square Nut............................................................... M10 ............................... 1

3 ................ 5051081 .................... Spring ...................................................................... ...................................... 1

4 ................ 5051091 .................... Sleeve ...................................................................... ...................................... 1

5 ................ 5051131 .................... Collar ....................................................................... ...................................... 1

6 ................ 5508431 .................... Shaft with Collar....................................................... ...................................... 1

7 ................ J-5051151 ................. Cap .......................................................................... ...................................... 1

8 ................ TS-2361051 .............. Lock Washer ............................................................ M5 ................................. 2

9 ................ TS-1513051 .............. Socket Head Flat Screw .......................................... M5x25 ........................... 2

10 .............. 5051721 .................... Hand Wheel ............................................................. ...................................... 1

12 .............. TS-1550071 .............. Flat Washer ............................................................. M10 ............................... 2

13 .............. J-5508432 ................. Tilting Table ............................................................. ...................................... 1

14 .............. 5508450 .................... Hand Knob ............................................................... ...................................... 4

15 .............. 5508429 .................... Belt Adjustment Knob .............................................. M10 ............................... 1

16 .............. 5511824 .................... Drive Screw ............................................................. Ø2x5 ............................. 5

17 .............. 5508437 .................... Stop Lock ................................................................. ...................................... 1

18 .............. 5511828 .................... Groove Pin ............................................................... Ø5x45 ........................... 1

19 .............. 5051351 .................... Tilting Scale ............................................................. ...................................... 1

20 .............. TS-1523011 .............. Socket Set Screw .................................................... M6x6 ............................. 2

21 .............. 5511827 .................... Groove Pin ............................................................... Ø4x8 ............................. 2

22 .............. 5051331 .................... Segment .................................................................. ...................................... 1

23 .............. 5511725 .................... 4200 Arbor Pulley .................................................... ...................................... 1

24 .............. TS-1504061 .............. Socket Head Cap Screw.......................................... M8x30 ........................... 4

25 .............. TS-2361081 .............. Lock Washer ............................................................ M8 ................................. 4

26 .............. J-5508433 ................. Trunnion................................................................... ...................................... 1

27 .............. TS-1550061 .............. Flat Washer ............................................................. M8 ................................. 9

28 .............. TS-2361081 .............. Lock Washer ............................................................ M8 ................................. 9

29 .............. TS-1490041 .............. Hex Cap Screw ........................................................ M8x25 ........................... 3

30 .............. 5508435 .................... Stud ......................................................................... M10 ............................... 1

31 .............. TS-1550071 .............. Flat Washer ............................................................. M10 ............................... 4

32 .............. 5508436 .................... Acorn Nut and Handle ............................................. ...................................... 1

33 .............. TS-2361061 .............. Lock Washer ............................................................ M6 ................................. 3

34 .............. TS-1482031 .............. Hex Cap Screw ........................................................ M6x16 ........................... 3

35 .............. 5508439 .................... Preload Bushing ...................................................... M54 ............................... 1

36 .............. BB-6205ZZ ................ Ball Bearing ............................................................. 6205ZZ.......................... 1

37 .............. J-5508438 ................. Bearing Housing ...................................................... ...................................... 1

38 .............. TS-2210951 .............. Hex Cap Screw ........................................................ M10x140 ....................... 2

39 .............. 5051421 .................... Key........................................................................... 5x5x70 mm ................... 1

40 .............. 5508441 .................... Drive Shaft ............................................................... ...................................... 1

41 .............. 5051451 .................... Key........................................................................... 5x5x35 mm ................... 1

42 .............. 4200A-042................. Key........................................................................... 5x5x55 mm ................... 1

43 .............. BB-6204ZZ ................ Ball Bearing ............................................................. 6204ZZ.......................... 1

44 .............. 5051471 .................... Retaining Ring ......................................................... S20................................ 1

45 .............. VB-A59 ...................... V-Belt ....................................................................... 17610 ............................ 1

46 .............. TS-2245081 .............. Socket Head Flat Screw .......................................... M5x8 ............................. 4

47 .............. J-5508444 ................. Belt Guard Assembly ............................................... ...................................... 1

49 .............. TS-1540071 .............. Hex Nut, Full ............................................................ M10 ............................... 5

50 .............. 5508446 .................... Stop Pin ................................................................... ...................................... 1

51 .............. J-5508447 ................. Base......................................................................... ...................................... 1

52 .............. TS-2210801 .............. Hex Cap Screw ........................................................ M10x80 ......................... 4

53 .............. TS-1550071 .............. Flat Washer ............................................................. M10 ............................... 8

54 .............. TS-2361101 .............. Lock Washer ............................................................ M10 ............................... 6

55 .............. 5051841 .................... Garnet Belt............................................................... ...................................... 1

56 .............. J-5508455 ................. Deflector Plate ......................................................... ...................................... 1

57 .............. TS-2361051 .............. Lock Washer ............................................................ M5 ................................. 2

58 .............. TS-1513021 .............. Socket Head Flat Screw .......................................... M5x12 ........................... 2

59 .............. J-5508454 ................. Drive Drum Guard.................................................... ...................................... 1

60 .............. 5508456 .................... Dust Deflector .......................................................... ...................................... 1

61 .............. TS-2361101 .............. Lock Washer ............................................................ M10 ............................... 3

62 .............. TS-1491021 .............. Hex Cap Screw ........................................................ M10x20 ......................... 3

19

Page 20

IndexNo PartNo Description Size Qty

63 .............. J-5508457 ................. Platen....................................................................... ...................................... 1

64 .............. TS-1514011 .............. Socket Head Flat Screw .......................................... M6x12 ........................... 2

65 .............. J-5051601A ............... Side Guard............................................................... ...................................... 1

66 .............. TS-1540231 .............. Hex Nut .................................................................... M24x18 ......................... 1

67 .............. 9058121 .................... Lock Washer, Ext..................................................... M24 ............................... 1

68 .............. 5051981 .................... Spacer ..................................................................... ...................................... 1

69 .............. 5051971A .................. Drive Drum............................................................... ...................................... 1

70 .............. 5508458 .................... Clamp Ring .............................................................. ...................................... 1

71 .............. 5544728 .................... Drum Spacer............................................................ ...................................... 2

72 .............. 5051031 .................... Tension Lever Pin .................................................... ...................................... 1

73 .............. 5051021 .................... Belt Tension Lever ................................................... ...................................... 1

74 .............. BB-6202ZZ ................ Ball Bearing ............................................................. 6202ZZ.......................... 2

75 .............. 5508461 .................... Idler Drum Shaft with Lock Nut ................................ ...................................... 1

76 .............. TS-2342121 .............. Nylon Lock Hex Nut ................................................. M12 ............................... 2

77 .............. 5508460 .................... Bearing Lock Nut ..................................................... ...................................... 1

78 .............. J-5051591A ............... Idler Drum Guard ..................................................... ...................................... 1

79 .............. 5508462 .................... Stud ......................................................................... ...................................... 3

80 .............. 5508463 .................... Clamp Bar ................................................................ ...................................... 2

81 .............. J-5052121 ................. Bottom Guard .......................................................... ...................................... 1

82 .............. TS-2361061 .............. Lock Washer ............................................................ M6 ................................. 4

83 .............. 5052061B .................. Idler Drum Spacer.................................................... ...................................... 2

84 .............. J-5508459 ................. Idler Pin Bracket ...................................................... ...................................... 1

85 .............. TS-0367061 .............. Roll Pin .................................................................... 1/4”x1-1/4”..................... 2

86 .............. 5052001 .................... Block ........................................................................ ...................................... 2

87 .............. 5052061A .................. Idler Drum ................................................................ ...................................... 2

88 .............. 5508434 .................... Pointer ..................................................................... ...................................... 1

89 .............. 5508451 .................... Clamp with Pins ....................................................... ...................................... 2

90 .............. 4200A-090................. Roll Pin .................................................................... Ø6x45 ........................... 4

91 .............. J-5508453 ................. Disc Guard ............................................................... ...................................... 1

92 .............. TS-2239551 .............. Socket Head Cap Screw.......................................... M10x55 ......................... 2

93 .............. 5051741 .................... Pointer ..................................................................... ...................................... 1

94 .............. TS-1523031 .............. SHSS ....................................................................... M6x10 ........................... 2

95 .............. 5051641 .................... Disc, Aluminum ........................................................ ...................................... 1

96 .............. 5051631 .................... Garnet Disc .............................................................. ...................................... 1

97 .............. 5051681 .................... Trunnion................................................................... ... ................................... 2

98 .............. TS-1490041 .............. Hex Cap Screw ........................................................ M8x25 ........................... 4

99 .............. J-5508449 ................. Table ........................................................................ ...................................... 1

100 ............ 5051701 .................... Tilting Table Scale ................................................... ...................................... 1

101 ............ 5052271 .................... Deluxe Miter Gauge ................................................. ...................................... 1

102 ............ TS-1550071 .............. Flat Washer ............................................................. M10 ............................... 2

103 ............ TS-1482032 .............. Hex Cap Screw ........................................................ M6x16 ........................... 4

104 ............ 4200A-104J ............... JET Logo Plate ........................................................ ...................................... 1

105 ............ 4200A-105................. Label, Direction ........................................................ ...................................... 2

106 ............ TS-1482081 .............. Hex Cap Screw ........................................................ M6x40 ........................... 2

107 ............ TS-1540041 .............. Hex Nut, Full ............................................................ M6 ................................. 2

108 ............ TS-1523021 .............. Socket Head Flat Screw .......................................... M6x8 ............................. 1

111 ............ 5511818 .................... Flat Head Screw ...................................................... M5x6 ............................. 4

113 ............ 4200A-113................. Sponge .................................................................... 300x 7.5mm, t=2mm ...... 2

20

Page 21

11.2.1 Model J-4300A Belt Sander Assembly – Exploded View

21

Page 22

11.2.2 Model J-4300A Belt Sander Assembly – Parts List

IndexNo PartNo Description Size Qty

1 ................ J-5508427 ................. Bracket..................................................................... ...................................... 1

2 ................ 5511833 .................... Square Nut............................................................... M10 ............................... 1

3 ................ 5051081 .................... Spring ...................................................................... ...................................... 1

4 ................ 5051091 .................... Sleeve ...................................................................... ...................................... 1

5 ................ 5051131 .................... Collar ....................................................................... ...................................... 1

6 ................ 5508431 .................... Shaft with Collar....................................................... ...................................... 1

7 ................ J-5051151 ................. Cap .......................................................................... ...................................... 1

8 ................ TS-2361051 .............. Lock Washer ............................................................ M5 ................................. 2

9 ................ TS-1513051 .............. Socket Head Flat Screw .......................................... M5x25 ........................... 2

10 .............. 5051721 .................... Hand Wheel ............................................................. ...................................... 1

12 .............. TS-1550071 .............. Flat Washer ............................................................. M10 ............................... 1

13 .............. J-5508432 ................. Tilting Table ............................................................. ...................................... 1

14 .............. 5508450 .................... Hand Knob ............................................................... ...................................... 2

15 .............. 5508429 .................... Belt Adj. Knob .......................................................... M10 ............................... 1

16 .............. 5511824 .................... Drive Screw ............................................................. Ø2x5 ............................. 3

17 .............. 5508437 .................... Stop Lock ................................................................. ...................................... 1

18 .............. 5511828 .................... Groove Pin ............................................................... Ø5x45 ........................... 1

19 .............. 5051351 .................... Tilting Scale ............................................................. ...................................... 1

20 .............. TS-1523011 .............. Socket Set Screw .................................................... M6x6 ............................. 2

21 .............. 5511827 .................... Groove Pin ............................................................... Ø4x8 ............................. 2

22 .............. 5051331 .................... Segment .................................................................. ...................................... 1

23 .............. 5511725 .................... 4200 Arbor Pulley .................................................... ...................................... 1

24 .............. TS-1504061 .............. SHCS ....................................................................... M8x30 ........................... 4

25 .............. TS-2361081 .............. Lock Washer ............................................................ M8 ................................. 4

26 .............. J-5508433 ................. Trunnion................................................................... ...................................... 1

27 .............. TS-1550061 .............. Flat Washer ............................................................. M8 ................................. 3

28 .............. TS-2361081 .............. Lock Washer ............................................................ M8 ................................. 3

29 .............. TS-1490041 .............. Hex Cap Screw ........................................................ M8x25 ........................... 3

30 .............. 5508435 .................... Stud ......................................................................... M10 ............................... 1

31 .............. TS-1550071 .............. Flat Washer ............................................................. M10 ............................... 4

32 .............. 5508436 .................... Acorn Nut and Handle ............................................. ...................................... 1

33 .............. TS-2361061 .............. Lock Washer ............................................................ M6 ................................. 3

34 .............. TS-1482031 .............. Hex Cap Screw ........................................................ M6x16 ........................... 3

35 .............. 5508439 .................... Preload Bushing ...................................................... M54 ............................... 1

36 .............. BB-6205ZZ ................ Ball Bearing ............................................................. 6205ZZ.......................... 1

37 .............. J-5508438 ................. Bearing Housing ...................................................... ...................................... 1

38 .............. TS-2210951 .............. Hex Cap Screw ........................................................ M10x140 ....................... 2

39 .............. 5051421 .................... Key........................................................................... 5x5x70 .......................... 1

40 .............. 5508442 .................... Drive Shaft ............................................................... ...................................... 1

41 .............. 5051451 .................... Key........................................................................... 5x5x35 .......................... 1

42 .............. TS-1482034 .............. Hex Cap Screw ........................................................ M6x16 ........................... 4

43 .............. BB-6204ZZ ................ Ball Bearing ............................................................. 6204ZZ.......................... 1

44 .............. 5051471 .................... Retaining Ring ......................................................... S20................................ 1

45 .............. VB-A59 ...................... V-Belt ....................................................................... 17610 ............................ 1

46 .............. TS-2245081 .............. Socket Head Flat Screw .......................................... M5x8 ............................. 4