Page 1

OWNER'S MANUAL

HVBS-56M Horizontal/Vertical Bandsaw

JET EQUIPMENT & TOOLS, INC. P.O. BOX 1349 Phone:253-351-6000

A WMH Company Auburn, WA 98071-1349 Fax: 1-800-274-6840

www.jettools.com e-mail jet@jettools.com M-414458 12/2000

Page 2

2

Important Information

1-YEAR JET offers a one-year limited

LIMITED WARRANTY warranty on this product

REPLACEMENT PARTS

Replacement parts for this tool are available directly from JET Equipment & Tools.

To place an order, call 1-800-274-6848. Please have the following information ready:

1. Visa, MasterCard, or Discover Card number

2. Expiration date

3. Part number listed within this manual

4. Shipping address other than a Post Office box.

REPLACEMENT PART WARRANTY

JET Equipment & Tools makes every effort to assure that parts meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our parts that each such part(s) to be free from

defects in materials and workmanship for a period of thirty (30) days from the date of purchase.

PROOF OF PURCHASE

Please retain your dated sales receipt as proof of purchase to validate the warranty period.

LIMITED TOOL AND EQUIPMENT WARRANTY

JET makes every effort to assure that its products meet high quality and durability standards and war rants to the

original retail consumer/purchaser of our products that each product be free from defects in materials and

workmanship as follows: 1 YEAR LIMITED WARRANTY ON THIS JET PRODUCT. Warranty does not apply to

defects due directly or indirectly to misuse, abuse, negligence or accidents, repairs or alterations outside our facilities

or to a lack of maintenance. JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE FROM

THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN, ANY IMPLIED

WARRANTIES OR MECHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW

LIMITATIONS ON HO W LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT

APPLY TO YOU. JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY

OR FOR INCIDENTAL, CONTINGENT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. To

take advantage of this warranty, the product or part must be returned for examination, postage prepaid, to an

authorized service station designated by our Auburn office. Proof of purchase date and an explanation of the

complaint must accompany the merchandise. If our inspection discloses a defect, JET will either repair or replace the

product or refund the purchase price, if we cannot readily and quickly provide a repair or replacement, if you are

willing to accept such refund. JET will return repaired product or replacement at JET’s expense, but if it is determined

there is no defect, or that the defect resulted from causes not within the scope of JET’s warranty, then the user must

bear the cost of storing and returning the product. This warranty gives you specific legal rights, and you have other

rights, which vary, from state to state.

JET Equipment & Tools •••• P.O. Box 1349, Auburn, WA 98071-1349 •••• (253) 351-6000

Page 3

3

WARNING

Read and understand the entire instruction manual before operating machine.

This machine is designed and intended for use by properly trained and experienced personnel

only. If you are not familiar with the proper safe use of bandsaws, do not use this machine until

proper training and knowledge has been obtained.

• Always wear approved safety glasses/face shields while using this machine.

• Make certain the machine is properly grounded.

• Before operating the machine, remove tie, rings, watches, other jewelry, and roll up sleeves above

the elbows. Remove all loose clothing and confine long hair. Do not wear gloves.

• Keep the floor around the machine clean and free of scrap material, oil and grease.

• Keep machine guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

• Do not over reach. Maintain a balanced stance at all times so that you do not fall or lean against

blades or other moving parts.

• Make all machine adjustments or maintenance with the machine unplugged from the power source.

• Use only sharp tools. Dull tools are dangerous

• Replace warning labels if they become obscured or removed.

• Make certain the switch is in the OFF position before connecting the machine to the power supply.

• Give your work undivided attention. Looking around, carrying on a conversation, and "horse-play"

are careless acts that can result in serious injury.

• Keep visitors a safe distance from the work area.

• Use recommended accessories; improper accessories may be hazardous.

• Make a habit of checking to see that keys and adjusting wrenches are removed before turning on

the machine.

• Never attempt any operation or adjustment if the procedure is not understood.

• Keep fingers away from the blade when the machine is running.

• Never hand hold material with the saw in the horizontal position. Always use the vise and clamp it

securely.

• Keep belt guard and wheel covers in place and in working order.

• Never force the cutting action.

• Do not attempt to adjust or remove tools during operation.

• Always provide adequate support for long and heavy material.

• Always use identical replacement parts when servicing.

• Read and understand all warnings posted on the machine.

• This manual is intended to familiarize you with the technical aspects of this bandsaw. It is not, nor

was it intended to be, a training manual.

• Failure to comply with all of these warnings may cause serious injury.

• Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

• Your risk from those exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specifically designed to filter out microscopic particles

Page 4

4

Specifications: HVBS-56M

Stock Number................................................................................................................................ 414458

Horizontal Capacity:

Round @ 90°....................................................................................................................................5”

Round @ 45°....................................................................................................................................3”

Rectangle @ 90° .......................................................................................................................5” x 6”

Rectangle @ 45° .......................................................................................................................5” x 3”

Throat Depth...........................................................................................................................................6”

Vertical Work Table Size......................................................................................................9-5/8” x 9-1/2”

Vise Swivels.........................................................................................................................................45°

Blade Size...............................................................................................................1/2” x 0.025” x 64-1/2”

BladeWheel Diameter............................................................................................................. .........7-3/8”

Speeds........................................................................................................................80, 120, 200 SFPM

Bed Height......................................................................................................................................25-1/2”

Floor Space Required......................................................................................................16-1/4”x 42-1/2”

Motor (UL listed)...........................................................................1/2 HP, 1 Ph, 115/230V, prewired 115V

Net Weight (approx.)......................................................................................................................115 l bs.

Table of Contents Page

Warranty..................................................................................................................................................2

Warnings ....................................................................................................................... ..........................3

Specifications& Table of Contents........................................................................................................... 4

Unpacking & Clean-Up ............................................................................................................................5

Tools Supplied for Assembly....................................................................................................................5

Tools Required for Assembly ...................................................................................................................5

Assembly..............................................................................................................................................5-7

Vertical Cutting Plate Assembly............................................................................................................7-8

Electrical Connections .............................................................................................................................8

Changing Blade Speed............................................................................................................................9

Adjusting Blade Guides............................................................................................................................9

Adjusting Blade Tension..........................................................................................................................9

Changing Blades ...................................................................................................................................10

Adjusting Blade Guide Bearings.............................................................................................................10

Adjusting Blade Tracking.......................................................................................................................11

Adjusting Feed Pressure........................................................................................................................11

Adjusting Automatic Shut-Off.................................................................................................................12

Adjusting the Vise..................................................................................................................................12

Breakdown for Bow Assembly................................................................................................................13

Breakdown for Base Assembly...............................................................................................................14

Parts List..........................................................................................................................................15-17

Wiring Diagram......................................................................................................................................17

The specifications in this manual are given as general information and are not binding. JET Equipment &

Tools reserves the right to effect, at any time and without prior notice, changes or alterations to parts,

fittings, and accessory equipment deemed necessary for any reason whatsoever.

Page 5

5

Unpacking and Clean-Up

Note: Read and understand the entire manual

before attempting setup or operation.

1. Remove all contents form the shipping

carton.

2. Inspect contents for shipping damage and

report any damage to your distributor.

3. Wipe bed and vise assembly with clean

cloth to remove excess oil used to prevent

rust.

4. Do not discard any packing material until

saw has been assembled and is running

properly.

Tools Supplied for Assembly

1. Wrench 12/14mm

Tools Required for Assembly

• #2 Cross Point Screwdriver

• 6-8" Adjustable Wrench or Wrench Set

• Pliers - Regular or Needle Nose

• 4mm Angle Hex Wrench

• Ratchet and Sockets will Speed Assembly

Assembly

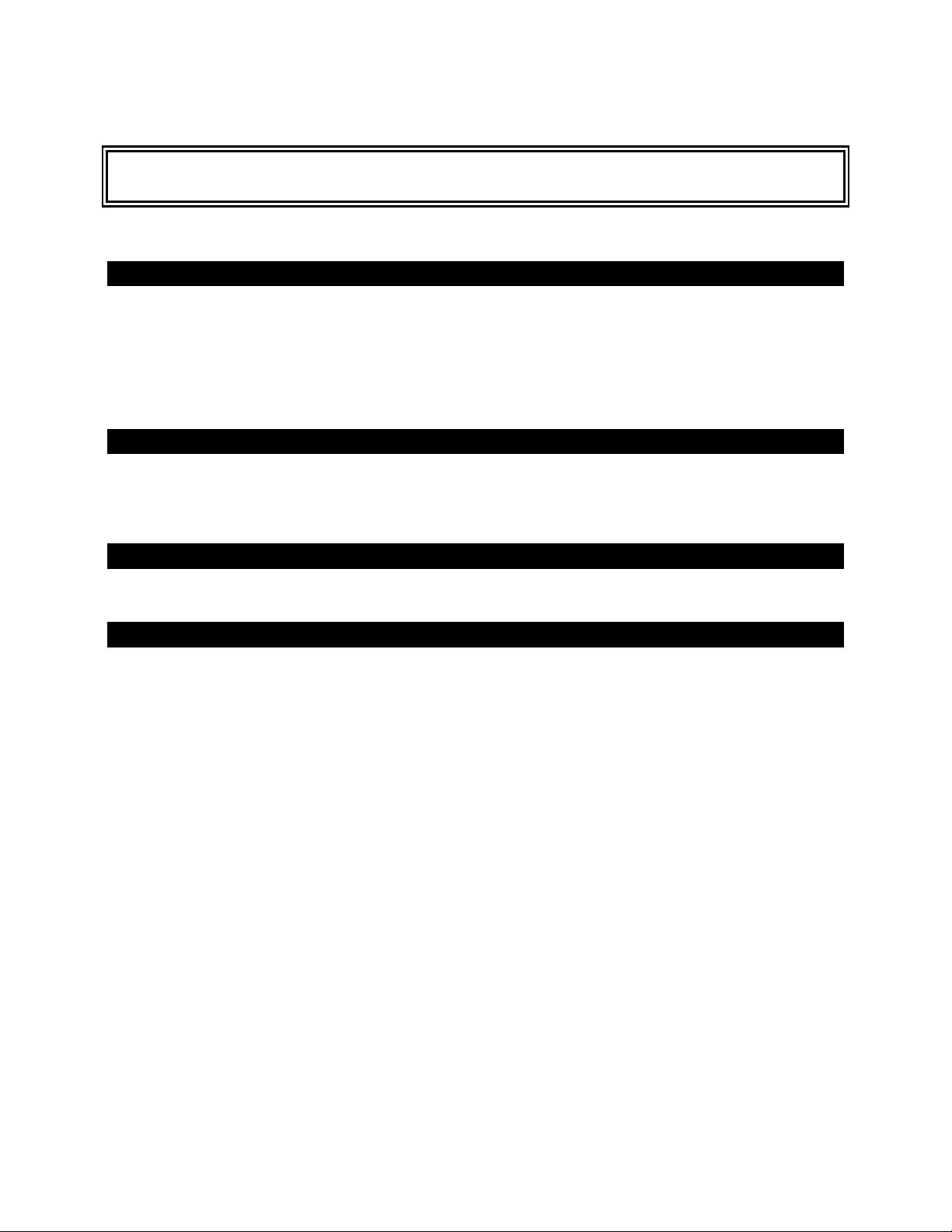

1. With the help of another person turn the saw

over so that it rests on the motor and saw

bow, Figure 1. Place it on a piece of

cardboard, or a surface that will not damage

the saw.

2. Attach a cross brace (A, Fig. 1) to the motor

side of the bed using three 5/16”x1” hex cap

bolts, six 5/16” flat washers, and secure with

three 5/16” hex nuts. Hint: Tighten the nut

(B, Fig. 1) on the end of the bed first

followed by the nuts on the sides.

3. Attach a leg to the cross brace using four

5/16”x3/4” carriage bolts, four 5/16” flat

washers and four 5/16” hex nuts. Use a

12mm wrench to tighten. Repeat for other

leg.

4. Remove the brace (C, Fig. 1) on the

opposite end of the bed and bow using a

10mm wrench.

Page 6

6

5. Attach a cross brace to the opposite end of

the bed using three 5/16”x1” hex cap bolts,

six 5/16” flat washers, and secure with three

5/16” hex nuts. Tighten the nut on the end

of the bed first followed by the nuts on the

sides.

6. Attach a leg to the cross brace using four

5/16”x3/4” carriage bolts, four 5/16” flat

washers and four 5/16” hex nuts. Use a

12mm wrench to tighten. Repeat for other

leg.

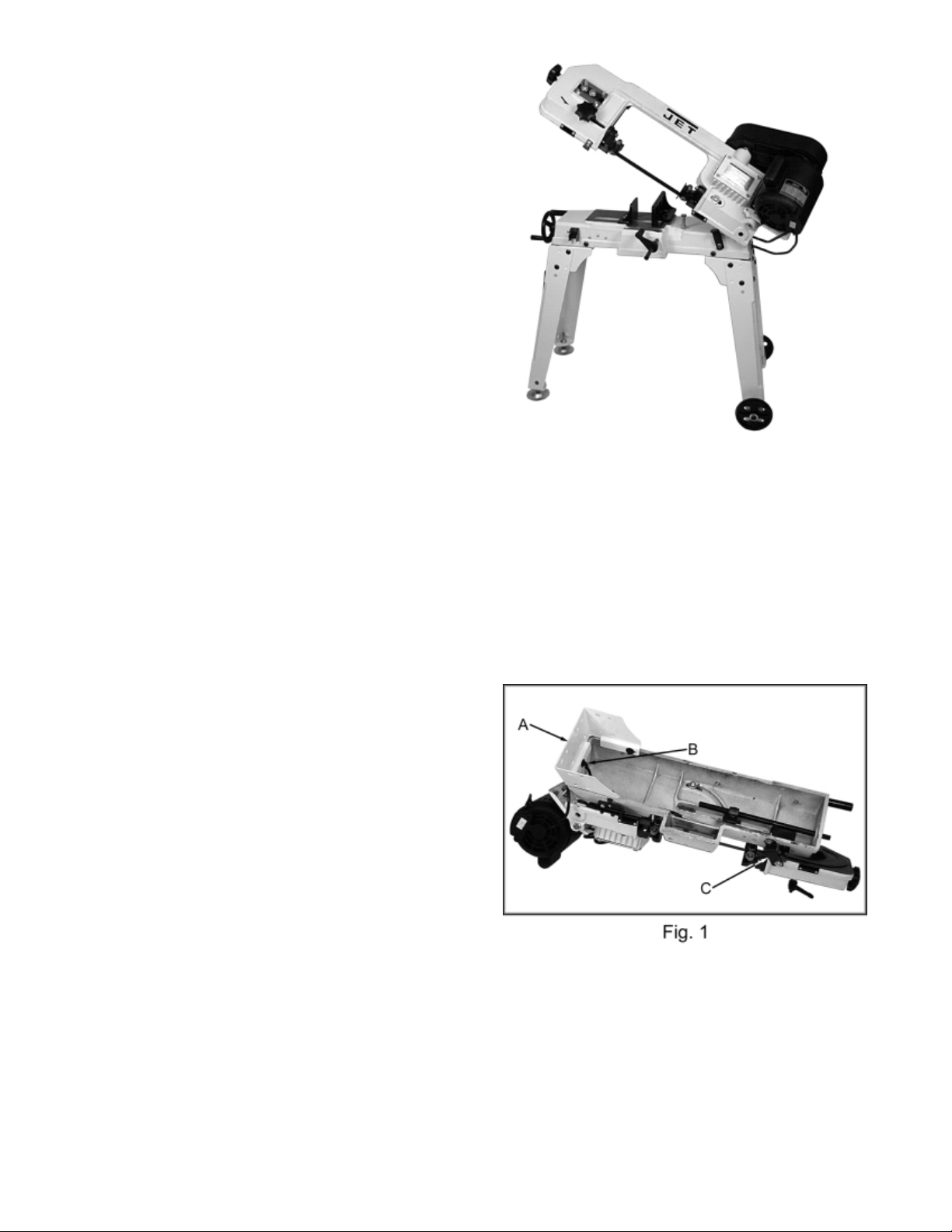

7. Attach the adjustable feet (A, Fig. 2) to the

legs opposite of the motor, using the

provided hardware.

8. Slide the axle (A, Fig. 3) through the legs.

Place a large flat washer (B, Fig. 3) on both

sides of the wheels and place on the axle.

Secure wheels with two split pins (C, Fig. 3).

9. Carefully turn the saw onto its stand and

adjust the feet so the bed is level.

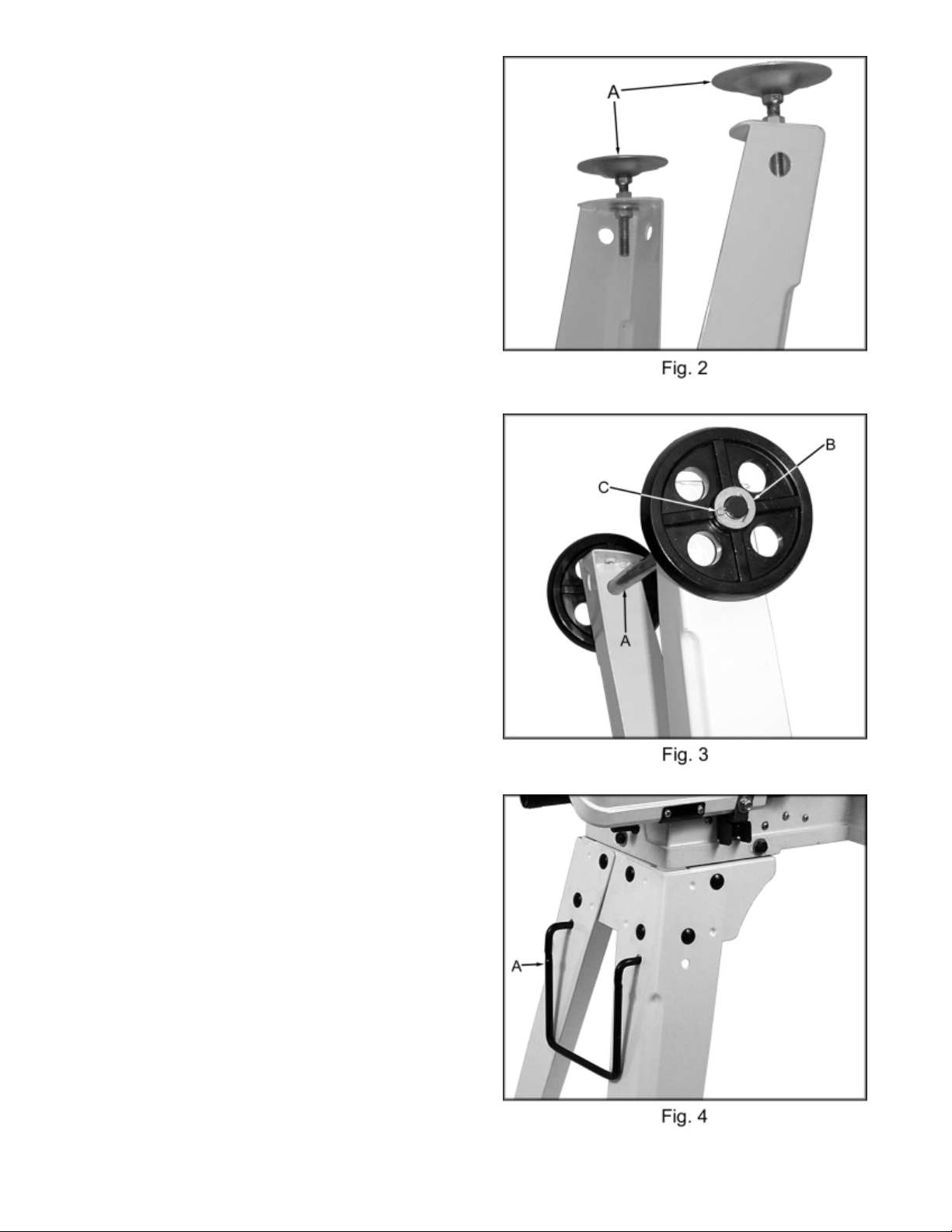

10. Put the handle (A, Fig. 4) through holes in

the stand legs opposite of the wheel

assembly and secure with split pins.

Page 7

7

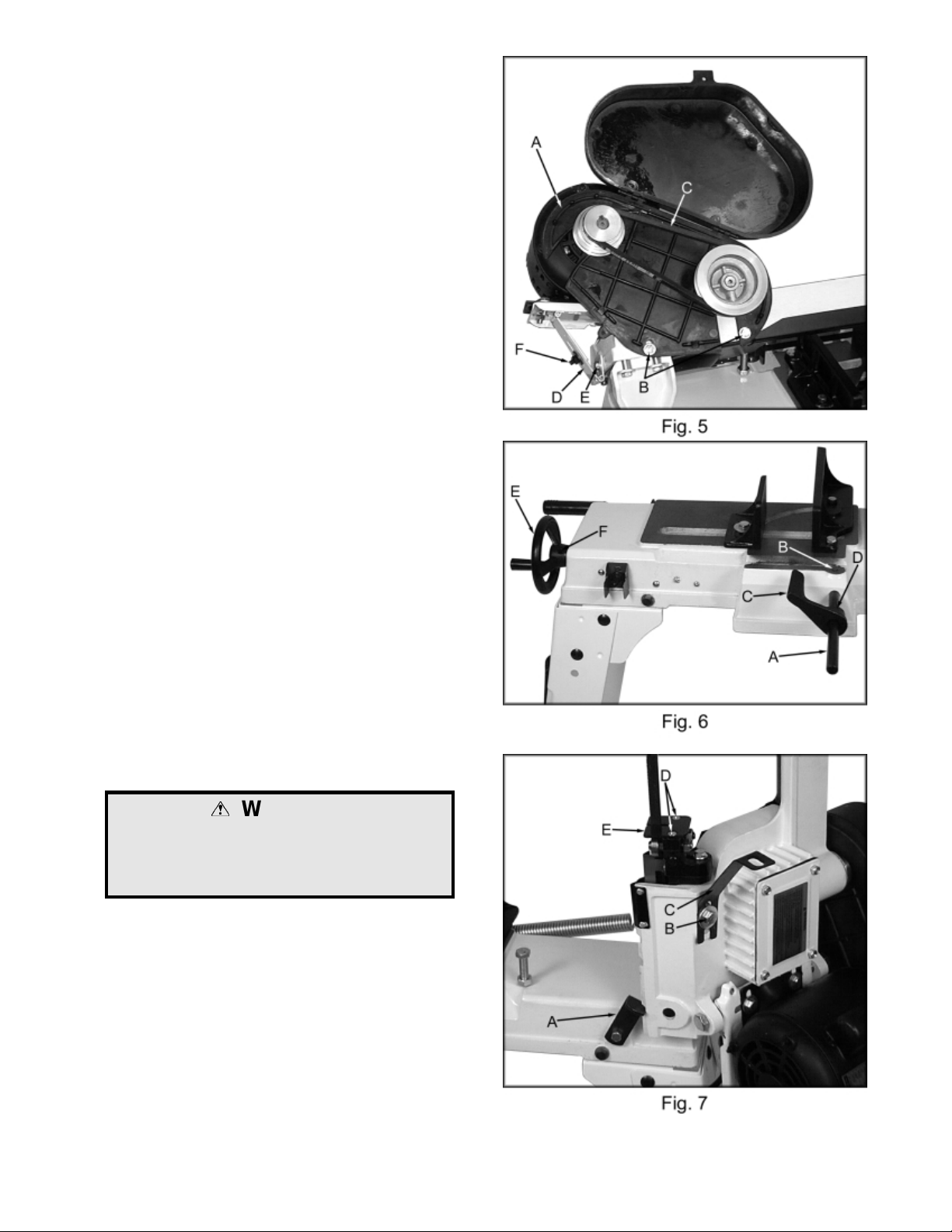

11. Slide pulley cover (A, Fig. 5) around motor

shaft and worm gear shaft. Secure with two

hex cap screws and washers (B, Fig. 5).

12. Lift motor with one hand while the other

hand places V-belt (C, Fig.5) on both pulleys.

13. Attach the tension bracket (D, Fig. 5) to the

saw bow with one 5/16”x3/4” hex head bolt

and flat washer (E, Fig. 5).

14. Connect the two tension brackets with one

5/16”x3/4” carriage bolt, one 5/16” flat

washers and one 5/16” hex nut (F, Fig. 5).

Hint: Insert the carriage bolt from the inside

so the hex nut is easy to access with a

wrench.

15. Tension belt by pressing down on the motor

while tightening hex nut (F, Fig. 5) until

finger pressure on the belt between the two

pulleys causes approximately 1/2" deflection.

Close pulley cover. Don’t over tighten the

belt.

16. Insert stop rod (A, Fig. 6) into bed and

tighten set screw (B, Fig. 6). Slide stock

stop (C, Fig. 6) onto rod and tighten set

screw (D, Fig. 6) to hold in place.

17. Slide handwheel (E, Fig. 6) onto shaft and

secure by tightening set screw (F, Fig. 6).

Make sure set screw seats on flat portion of

shaft.

Vertical Cutting Plate Assembly

Note: These steps are only necessary when

using the bandsaw in the vertical mode.

WARNING

Disconnect the bandsaw from the power

source before making any repairs or

adjustments!

Failure to comply may cause serious injury!

1. Disconnect the bandsaw from the power

source.

2. Raise the arm to the vertical position and

lockin place withlever (A, Fig. 7).

3. Loosen bolt (B, Fig. 7) and insert bracket (C,

Fig. 7). Tighten bolt just enough to hold the

bracket in place.

Page 8

8

4. Remove two screws (D, Fig. 7) and plate (E,

Fig. 7).

5. Guide blade through slot in table (A, Fig. 8)

and fasten table with two screws (B, Fig. 8).

6. Fasten support bracket to underside of table

using screw (C, Fig. 8) and hex nut.

7. Tighten bolt (B, Fig 7).

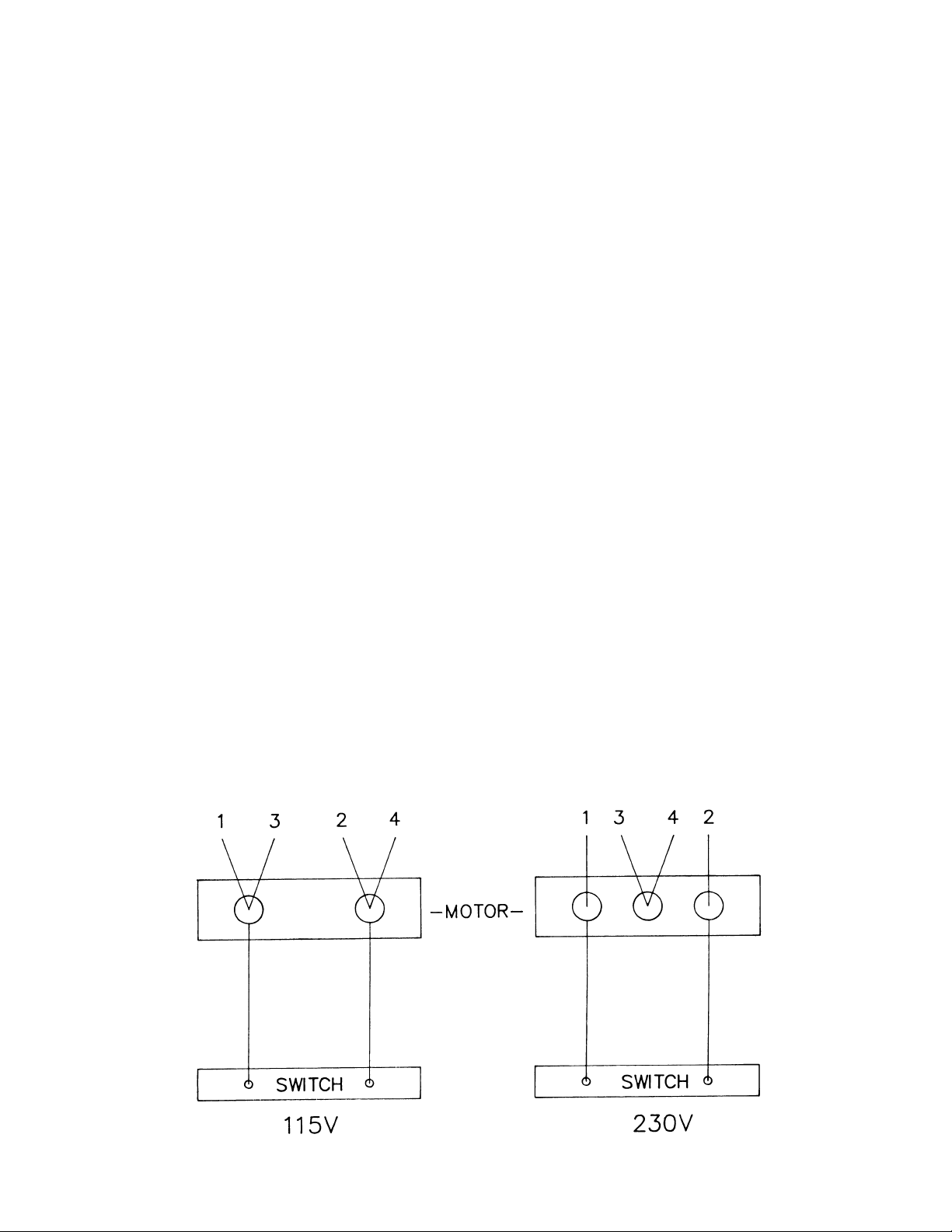

Electrical Connections

WARNING

All electrical connections must be completed

by a qualified electrician.

Failure to comply may cause serious injury!

The HVBS-463 bandsaw is rated at 115/230V

and comes from the factory prewired 115V.

To switch to 230V operation, follow the wiring

diagram found on the inside of the motor

junction box. The plug on the end will have to

be replaced with a plug that is rated at 230V.

This bandsaw is designed for use on a circuit

with an outlet that looks like (A, Fig. 9). The

bandsaw has a grounding prong as illustrated in

(B, Fig. 9). A temporary adapter (C, Fig. 9) may

be used to connect the plug to a two pole

receptacle (D, Fig. 9) if a properly grounded

outlet is not available. The temporary adapter

should only be used until a properly grounded

outlet can be installed by a qualified electrician.

The green colored lug must be securely

fastened to the cover plate screw.

Before hooking up to the power source, be sure

the switch is in the off position.

Page 9

9

Changing Blade Speed

1. Disconnect the machine from the power

source.

2. Place saw arm in the horizontal position.

3. Loosen tensioning plate hex nut (A, Fig.10).

4. Open pulley cover (B, Fig. 10). Lift motor

with one hand while placing the belt (C, Fig.

10) on the desired pulley combination.

5. Tension belt by pressing down on the motor

while tightening hex nut (A, Fig. 10) until

finger pressure on the belt between the two

pulleys causes approximately 1/2" deflection.

Close pulley cover. Don’t over tighten the

belt.

6. Close pulley cover and connect to power

source.

The general rule for band saw blade speed is

the harder the material being cut, the slower the

blade speed. Reference Figure 11 for a guide to

blade speed for a type of material being cut.

the blade guide assemblies as far apart as

possible. Lock in place.

4. Depress blade. Finger pressure should

cause approximately .004" deflection. Turn

blade tension knob (B, Fig. 12) until the

proper tension is achieved. Re-position

guides for cutting material.

Adjusting Blade Guides

1. Disconnect machine from the power

source.

2. Loosen knob (A, Fig. 12) and slide blade

guide assembly (B, Fig. 12), as close as,

possible without interference to the material

being cut. Tighten knob.

3. Loosen bolt (C, Fig.12) and slide blade

guide assembly (D, Fig. 12), as close as,

possible without interference to the material

being cut. Tighten bolt

Adjusting Blade Tension

1. Disconnect machine from the power

source.

2. Open blade cover and observe the position

of the blade on the wheel. If the blade is not

next to the wheel flange, adjust blade

tracking following the steps under "Adjusting

Blade Tracking".

3. If the blade is next to the wheel flange,

loosen the blade guide assembly lock knob

and hex head bolt (A & C, Fig. 12) and slide

Page 10

1

Changing Blades

1. Disconnect machine from the power

source.

2. Raise the saw arm to the vertical position

and lock in place with lock lever.

3. Open blade cover by removing the small

knob found on the topside of the bow.

4. Remove red blade guards by removing two

screws.

WARNING

It is essential these two guards be installed

after the new blade has been fitted. Failure

to comply may cause serious injury!

5. Release tension on the blade by turning

tensioning knob (B, Fig. 12), and remove the

blade.

6. Place new blade between the blade guide

assemblies and around each wheel. Make

sure blade teeth are pointing in the proper

direction, Figure 13. Tension enough to

hold in place.

3. Loosen nut (B, Fig. 14) and turn nut (C, Fig.

14) to adjust eccentric bearing to a

clearance of .001". Tighten nut (B, Fig. 14)

to l ock.

4. Connect machine to power source.

7. Install red blade guards with two screws.

8. Tension blade fully, see “Adjusting Blade

Tension”.

9. Place two to three drops of lightweight oil on

the blade.

10. Connect machine to the power source.

11. Run saw and make sure blade is tracking

properly, see "Adjusting Blade Tracking".

As a general rule, the thinner the material to be

cut, the more teeth per inch on the blade. A

minimum of three teeth should be in contact with

the material at all times during the cut. If the

teeth straddle the material, severe damage can

result to the material and the blade.

Adjusting Blade Guide Bearings

1. Disconnect machine from the power

source.

2. Loosen bolt (A, Fig. 14) and adjust assembly

so that back roller bearing is

approximately .002" - .003" from the back of

the blade. Tighten bolt.

0

Page 11

1

Adjusting Blade Tracking

WARNING

Blade tracking adjustment requires running

the saw with the back cover open! This

adjustment must be completed by qualified

personsonly!

Failure to comply may cause serious injury!

Blade tracking has been set at the factory and

should not need adjustment. If blade tracking

needs to be adjusted:

1. Confirm that blade tension is set properly.

To adjust, see section titled " Adjusting

Blade Tension".

2. Make sure the saw is in its slowest speed,

see “Changing Blade Speeds”.

3. Move saw arm to the vertical position and

lockin place withthe lock lever.

4. Confirm that blade tension is set properly.

To adjust, see section titled " Adjusting

Blade Tension".

feed pressure. If they are still burned and heavy,

reduce the blade speed. Optimum feed

pressure has been set when the chips are curled,

silvery, and warm.

5. Open blade cover by removing the knob

found on the top side of the bow.

6. Run saw and observe blade. Blade should

run next to but not tightly against wheel

flange.

7. Loosen bolts (A, Fig. 15).

8. Turn set screw (B, Fig. 15) while observing

blade tracking on wheel. Turn set screw

clockwise to track closer to wheel flange.

Turn set screw counter-clockwise to track

away from the wheel flange. Hint: start

with ¼ turns on the set screw. The tracking

is sensitive.

9. Once tracking is set, tighten bolts (A, Fig.

15).

Adjusting Feed Pressure

1. Turn handle (A, Fig. 16) clockwise to

decrease cutting pressure and counterclockwise to increase cutting pressure.

A good indication of proper feed pressure is the

color and shape of the cutting chips. If the chips

are thin or powdered, increase the feed pressure.

If the chips are burned and heavy, decrease the

1

Page 12

1

Adjusting Automatic Shut-Off

2. Place saw arm in the horizontal position.

The saw should stop after the cut has been

completed:

• If the saw completes the cut and continues

to run, adjust the stop tip (A, Fig. 17) down.

• If the saw shuts off before the cut is

complete, adjust the stop tip (A, Fig. 17) up.

• If the saw stops cutting but continues to run,

adjust the stop bolt (B, fig. 17) down.

The saw is properly adjusted when the saw

shuts off just after the blade has finished the cut.

Adjusting the Vise

1. To open and close the vise use the

handwheel (C, Fig. 17).

2. The vise can be adjusted for square and

miter cuts. Loosen the hex cap bolts and

adjust the vise for the cut.

3. Remove screws (A, Fig. 18) from the gear

box and remove cover plate and gasket.

4. Hold a container under the lower right corner

of the gear box with one hand while slowly

raising the saw arm with the other. Drain

completely.

5. Place arm in the horizontal position. Wipe

out remainingoil witha rag.

6. Fill gear box with approximately 1/2 pint of

MOBIL SHC 634.

7. Replace gasket and cover. Fasten cover

with bolts.

3. Adjust the blade guides so they are as close

as possible to the material without interfering.

4. There is a scale on the back side of the bed

to aid in setting up the vise for 90° cuts or a

particular miter. Hint: Always check the

vise setup with a combination square,

against the blade and vise, so that you can

verify the vise settingis correct.

Lubrication

Ball bearings on the blade guide assemblies and

the blade wheels are permanently sealed and

require no lubrication.

Lubricate the vise lead screw as needed with #2

tube grease.

Gear box oil will have to be changed after 90

days of operation. There after, change every six

months.

To change the gear box oil:

1. Disconnect machine from the power

source.

2

Page 13

1

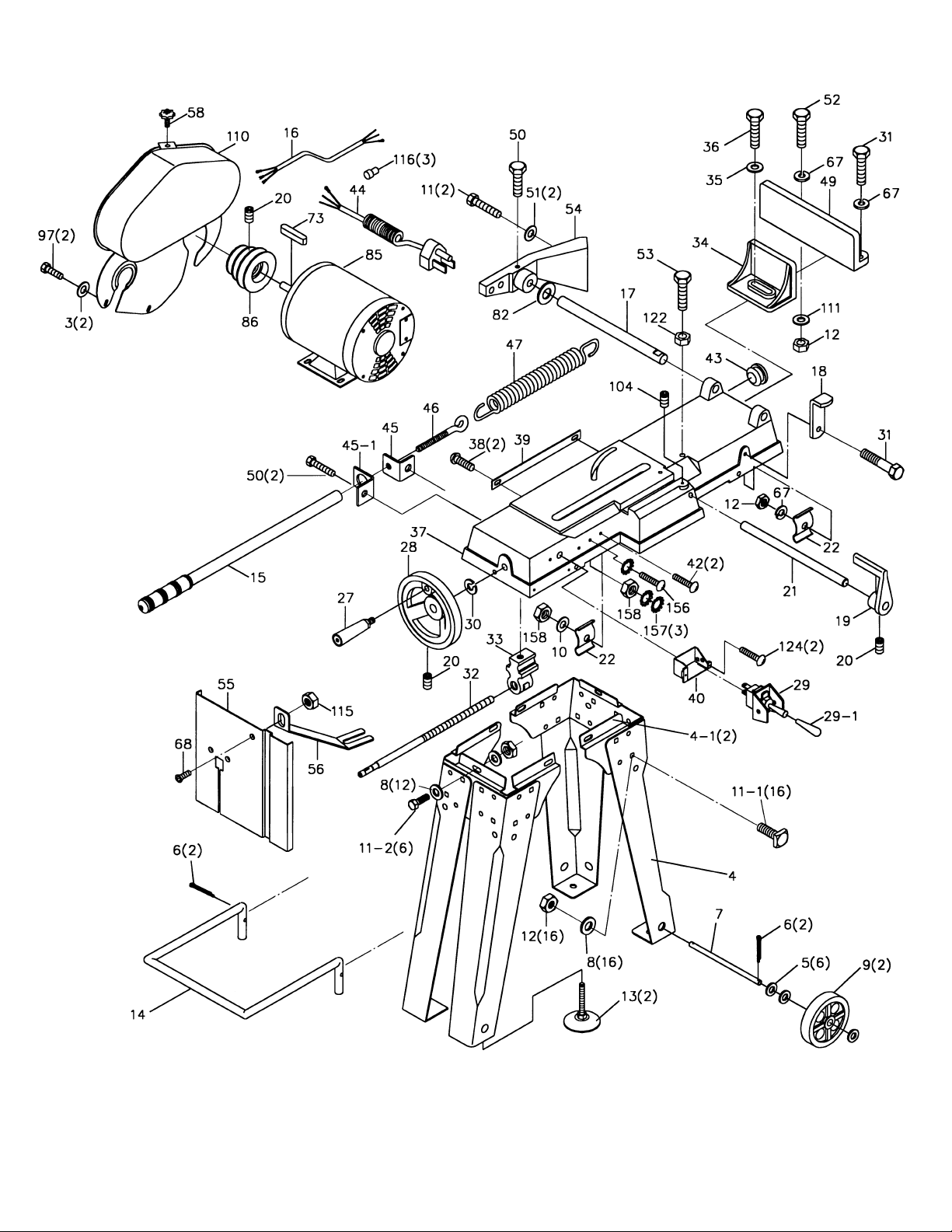

Breakdown for Bow Assembly

3

Page 14

1

Breakdown for Base Assembly

4

Page 15

1

Parts List for the HVBS-56M Bandsaw

Index Part

No. No. Description Size Qty.

1..........TS-0051031..............................Hex Cap Bolt......................................... 5/16”x3/4”...................4

2..........TS-0561011..............................Hex Nut................................................. 1/4”.............................1

3..........TS-0680021..............................Fl at Washer...........................................1/4”.............................5

4..........HVBS56M-04............................Stand Leg ............................................. ...................................4

4-1.......HVBS56M-04-1.........................Cross Brace .......................................... ...................................2

5..........HVBS56M-05............................Washer................................................. ...................................6

6..........HVBS462-006...........................Cotter Pin.............................................. 1/8”x1”........................4

7..........HVBS56M-07............................Axle....................................................... ...................................1

8..........TS-0680031..............................Fl at Washer...........................................5/16” .........................36

9..........HVBS56M-09............................Wheel ................................................... ...................................2

10........HVBS56M-010..........................Washer................................................. 1/4”x5/8”.....................1

11........TS-0051051..............................Hex Cap Bolt......................................... 5/16”x1”......................4

11-1.....HVBS56M-11-1 .........................Carriage Bolt......................................... 5/16”x3/4”.................16

11-2.....TS-0051051 ..............................Hex Cap Bolt......................................... 5/16”x1”......................6

12........TS-0561021..............................Hex Nut................................................. 5/16”.........................22

13........HVBS56M-013..........................Adjustable Foot..................................... ...................................2

14........HVBS462-014...........................Fl oor Stand Handle ............................... ...................................1

15........HVBS462-015...........................Adjusting Rod........................................ ...................................1

16........HVBS462-016...........................Electric Cord ......................................... ...................................1

17........HVBS462-017...........................Pivoting Rod.......................................... ...................................1

18........HVBS462-018...........................Support Plate........................................ ...................................1

19........HVBS462-019...........................Stock Stop............................................. ...................................1

20........TS-0270021..............................Socket Set Screw.................................. 5/16”x5/16”.................4

21........HVBS462-021...........................Stock Stop Rod..................................... ...................................1

22........HVBS462-022...........................Wire Relief Retainer.............................. ...................................2

25........TS-0051031..............................Hex Cap Bolt......................................... 5/16”x3/4”...................1

27........HVBS462-027...........................Wheel Handle....................................... ................................... 1

28........HVBS462-028...........................Hand Wheel.......................................... ...................................1

29........HVBS56M-029..........................Toggle Switch Assembly ....................... ...................................1

29-1.....HVBS56M-029-1.......................Plastic Cover......................................... ................................... 1

30........HVBS462-030...........................E-Ring................................................... E10.............................1

31........HVBS462-031...........................Screw.................................................... 5/16”x1”......................3

32........HVBS462-032...........................Lead Screw........................................... ...................................1

33........HVBS462-033...........................Vise Nut................................................ ...................................1

34........HVBS462-034...........................Moveable Vise Plate.............................. ...................................1

35........TS-0680041..............................Fl at Washer...........................................3/8”x1”........................6

36........TS-0090061..............................Hex Cap Bolt......................................... 3/8”x1-1/4”..................1

37........HVBS462-037...........................Bed....................................................... ...................................1

38........HVBS462-038...........................Cross Round Head Screw..................... 3/16”x3/8”...................2

39........HVBS462-039...........................Scale..................................................... ...................................1

40........HVBS462-040...........................Electric Cord Clip .................................. ...................................1

42........HVBS56M-042..........................Screw.................................................... M4x16 ........................2

43........HVBS462-043...........................Rubber Ring.......................................... ...................................1

44........HVBS462-044...........................Electric Cable........................................ ...................................1

45........HVBS462-045...........................Nut Plate............................................... ...................................1

45-1.....HVBS56M-045-1.......................Spring Handle Bracket........................... ...................................1

46........HVBS462-046...........................Spring Adjusting Screw ......................... ...................................1

47........HVBS462-047...........................Spring................................................... ................................... 1

48........HVBS462-048...........................Cross Round Head Screw..................... 3/16”x3/8”...................4

49........HVBS462-049...........................Mitering Vise Plate................................ ...................................1

50........TS-0081031..............................Hex Cap Bolt......................................... 5/16”x3/4”...................6

51........TS-0680031..............................Fl at Washer...........................................5/16”...........................3

5

Page 16

1

Index Part

No. No. Description Size Qty.

52........TS-0081071..............................Hex Cap Bolt......................................... 5/16”x1-1/2”................1

53........TS-0091071..............................Hex Cap Screw..................................... 7/16”x2”......................1

54........HVBS56M-054..........................Pivot Bracket......................................... ...................................1

55........HVBS462-055...........................Vertical Cutting Plate............................. ................................... 1

56........HVBS462-056...........................Stand for Vertical Cutting Plate.............. ...................................1

57........HVBS56M-057..........................Adjustable Bracket Assembly LH........... ...................................1

58........HVBS462-058...........................Knob..................................................... 1/4”.............................1

59........HVBS56M-059..........................Blade Back Safety Cover....................... ...................................1

60........HVBS462-060...........................C-Clip.................................................... S10.............................4

61........BB-6000ZZ................................Ball Bearing...........................................6000ZZ.......................6

62........HVBS462-062...........................Guide Pivot........................................... ...................................2

............HVBS462-062A.........................Center Shaft Assembly(Includes: #60-62).................................1

62-1.....HVBS462-062-1........................Centrifugal Guide Pivot.......................... ...................................2

............HVBS462-062-1A......................Eccentric Shaft Assembly (Includes: #60,61,62-1) .....................1

63........HVBS462-063...........................Bearing Shaft Pin.................................. ...................................2

64-1.....HVBS462-064-1........................Blade Seat Left...................................... ...................................1

64-2.....HVBS462-064-2........................Blade Seat Right................................... ...................................1

65........HVBS56M-065..........................Adjustable Bracket-Assembly RH.......... ...................................1

66........HVBS462-066...........................Lock Knob............................................. ................................... 1

67........TS-0720081..............................Lock Washer......................................... 5/16”...........................3

68........TS-0813051..............................Fl at Head Machine Screw......................1/4”X3/4”.....................3

69........HVBS462-069...........................Bearing Guard....................................... ...................................1

70........TS-0561031..............................Hex Nut................................................. 3/8”.............................8

71........HVBS462-071...........................Blade Wheel Drive................................. ...................................1

72........HVBS462-072...........................Bearing Cover....................................... ...................................2

73........HVBS462-073...........................Key ....................................................... 5x5x25........................2

74........HVBS56M-060..........................C-Clip.................................................... S15.............................1

75........HVBS462-075...........................Hex Cap Bolt (w/Washer)...................... 1/4”x1/2”.....................8

76........HVBS462-076...........................Switch Cut Off Trip................................ ...................................1

77........HVBS462-077...........................Idle Blade Wheel................................... ...................................1

78........TS-0680031..............................Fl at Washer...........................................5/16”...........................2

79........HVBS462-079...........................Blade Tension Knob.............................. 3/8”.............................1

80........HVBS462-080...........................Spring................................................... ................................... 1

81........HVBS56M-081..........................Saw Bow............................................... ........................... ........1

82........HVBS56M-082..........................Washer................................................. ...................................1

83........TS-0070031..............................Cap Screw............................................ 1/2”x1-1/2”..................2

84........HVBS56M-084..........................Motor Mount Plate................................. ...................................1

84-1.....HVBS56M-084-1.......................Tension Bracket.................................... ...................................1

85........HVBS463-085...........................Motor .................................................... 1/2 HP, 1Ph................1

............HVBS463-085-01......................Capacitor Cover (not shown) ................. ...................................1

............HVBS462-085-02......................Capacitor (not shown) ........................... ................................... 1

86........HVBS462-086...........................Motor Pulley.......................................... ................................... 1

87........BB-6202ZZ................................Ball Bearing...........................................6202ZZ.......................6

88........HVBS462-088...........................Bearing Bushing.................................... ...................................1

89........OS-15375 .................................Oil Seal................................................. ...................................2

90........HVBS462-090...........................Transmission Wheel Shaft..................... ...................................1

91........HVBS462-091...........................Worm Gear........................................... ...................................1

92........HVBS462-092...........................Gear Box Gasket................................... ...................................1

93........HVBS462-093...........................Gear Box Cover.................................... ...................................1

94........HVBS462-094...........................Worm Gear (w/Shaft)............................ ................................... 1

95........HVBS462-095...........................Spring Pin............................................. ...................................1

96........HVBS462-096...........................Bearing Bushing.................................... ...................................1

97........TS-0050011..............................Hex Cap Bolt......................................... 1/4”x1/2”.....................3

98........HVBS56M-098..........................Clamp................................................... ...................................2

6

Page 17

1

Index Part

No. No. Description Size Qty.

99........HVBS462-099...........................Spacer.................................................. ...................................1

100......HVBS462-100...........................Flat Cross Head Screw..........................5/32”x3/8”...................8

101......HVBS462-101...........................Worm Gear Pulley ................................. ................................... 1

102......TS-0720081.............................. Lock Washer......................................... 5/16”...........................2

103......HVBS462-103...........................Blade Tension SlidingPlate................... ...................................1

104......TS-0270051.............................. Socket Set Screw.................................. 5/16”x1/2”...................3

105......HVBS462-105...........................Spring Pin............................................. ...................................1

106......HVBS462-106...........................Sliding Plate Draw Block ....................... ...................................1

107......HVBS462-107...........................Blade Wheel Shaft................................. ...................................1

108......HVBS462-108...........................Shaft Block............................................ ...................................1

109......HVBS462-109...........................Blade Tension SlidingGuide ................. ...................................2

110......HVBS462-110...........................Motor Pulley Cover Assembly................ ...................................1

111......TS-0680031.............................. Fl at Washer...........................................5/16”...........................1

112......VB-A22.....................................V-Belt .................................................... A22.............................1

113......414301......................................Blade .................................................... ...................................1

114......TS-0680041.............................. Fl at Washer...........................................3/8”.............................4

115......TS-0561011.............................. Hex Nut................................................. 1/4”.............................1

116......HVBS463-170...........................Wire Plug.............................................. ...................................3

117......HVBS463-171...........................Hex Screw.............................................3/8”x1-1/4”..................1

120......HVBS462-120...........................Bushing................................................. ...................................1

122......TS-0561041.............................. Hex Nut................................................. 7/16”...........................1

123......TS-0050031.............................. Cap Screw............................................ 1/4”x3/4”.....................1

124......HVBS463-124...........................Machine Screw......................................3/16”x3/4”...................2

126......HVBS462-126...........................Bushing................................................. ...................................1

132......HVBS462-132...........................Blade Guard-Right................................. ...................................1

132-1...HVBS462-132A.........................Blade Guard-Left................................... ...................................1

156......HVBS462-156...........................Round Head Screw ............................... 3/16”x3/4” ...................1

157......HVBS462-157...........................Star Washer.......................................... 3/16”...........................3

158......HVBS463-158...........................Hex Nut................................................. 3/16”...........................3

159......HVBS462-159.................. Round Cross Head Screw ............................. 3/16” .........................1

............HVBS56M-BS...........................Blade S peed Label (not shown)............. ...................................1

............ HVBS56M-ID ............................I.D. Label (not shown) ........................... ...................................1

............ HVBS56M-WL...........................Warning Label (not shown).................... ...................................1

............ JM-56M.....................................Stripe Decal (not shown) ....................... ...................................1

Wiring Diagram

7

Loading...

Loading...