Page 1

This Manual is Bookmarked

This Manual is Bookmarked

Operating Instructions and Parts Manual

10" Table Saw

Stock Numbers: 708315BTA, -BTB, -BTC, -LSA, -LSB

708315BTA Table Saw shown

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-708315

Ph.: 800-274-6848 Revision D 08/05

www.wmhtoolgroup.com Copyright © WMH Tool Group

ESPAGÑOL – PÁGINA 41

Page 2

This manual has been prepared for the owner and operators of a 708315 Table Saw. Its purpose, aside

from machine operation, is to promote safety through the use of accepted correct operating and

maintenance procedures. Completely read the safety and maintenance instructions before operating or

servicing the machine. To obtain maximum life and efficiency from your JET Table Saw, and to aid in

using the machine safely, read this manual thoroughly and follow instructions carefully.

Warranty

WMH Tool Group warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Repair Stations located throughout the United States can give you quick service.

In most cases, any one of these WMH Tool Group Repair Stations can authorize warranty repair, assist

you in obtaining parts, or perform routine maintenance and major repair on your JET, Wilton, or

Powermatic tools.

For the name of an Authorized Repair Station in your area, please call 1-800-274-6848, or visit

www.wmhtoolgroup.com

More Information

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product

information, check with your local WMH Tool Group distributor, or visit www.wmhtoolgroup.com

WMH Tool Group Warranty

WMH Tool Group (including JET, Wilton and Powermatic brands) makes every effort to assure that its

products meet high quality and durability standards and warrants to the original retail consumer/purchaser

of our products that each product be free from defects in materials and workmanship as follow: 1 YEAR

LIMITED WARRANTY ON ALL PRODUCTS UNLESS SPECIFIED OTHERWISE. This Warranty does

not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-andtear, repair or alterations outside our facilities, or to a lack of maintenance.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN,

ANY IMPLIED WARRANTIES OR MERCHANTIBILITY AND FITNESS ARE EXCLUDED. SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU. WMH TOOL GROUP SHALL IN NO EVENT BE

LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. Proof of purchase date and an

explanation of the complaint must accompany the merchandise. If our inspection discloses a defect, we

will either repair or replace the product, or refund the purchase price if we cannot readily and quickly

provide a repair or replacement, if you are willing to accept a refund. We will return repaired product or

replacement at WMH Tool Group’s expense, but if it is determined there is no defect, or that the defect

resulted from causes not within the scope of WMH Tool Group’s warranty, then the user must bear the

cost of storing and returning the product. This warranty gives you specific legal rights; you may also have

other rights, which vary from state to state.

WMH Tool Group sells through distributors only. WMH Tool Group reserves the right to effect at any

time, without prior notice, those alterations to parts, fittings, and accessory equipment, which they may

deem necessary for any reason whatsoever.

2

Page 3

Table of Contents

Warranty........................................................................................................................................................ 2

Warnings .......................................................................................................................................................4

Kickback Prevention...................................................................................................................................... 6

Protection Tips from Kickback.......................................................................................................................6

Specifications ................................................................................................................................................7

Definitions and Terminology..........................................................................................................................7

Shipping Contents.........................................................................................................................................8

Contents of the Shipping Cartons .............................................................................................................8

Tool Required (Not Included) ....................................................................................................................8

Assembly..................................................................................................................................................... 10

Where to Begin........................................................................................................................................10

Leg Assembly.......................................................................................................................................... 10

Mounting the Shelf...................................................................................................................................11

Rubber Feet.............................................................................................................................................11

Installing the Blade Guard and Splitter.................................................................................................... 12

Aligning the Blade Guard and Splitter .....................................................................................................12

Saw Blade ...............................................................................................................................................13

Attaching the Rip Fence ..........................................................................................................................13

Calibrating the Rip Fence Scale..............................................................................................................13

Stamped Steel Extension Wing...............................................................................................................14

Sliding Extension Wing............................................................................................................................ 15

Left Scale Extension................................................................................................................................16

Right Scale Extension .............................................................................................................................16

Optional Left Table Support ....................................................................................................................17

Handwheel Handle ..................................................................................................................................17

Adjustments ................................................................................................................................................18

90 Degree Positive Stop.......................................................................................................................... 18

Scale Calibration .....................................................................................................................................18

Adjusting Blade Parallel to Miter Gauge Slots ........................................................................................19

Replacing the Blade ................................................................................................................................19

Replacing/Adjusting the Drive Belt .......................................................................................................... 20

Miter Gauge Operation............................................................................................................................21

Electrical Connections................................................................................................................................. 21

Operating Controls...................................................................................................................................... 21

Dust Shroud............................................................................................................................................. 11

45 Degree Positive Stop.......................................................................................................................... 18

Operations................................................................................................................................................... 22

Table Saws ..........................................................................................................................................22

Kickbacks.............................................................................................................................................22

Rip Sawing...........................................................................................................................................23

Crosscutting .........................................................................................................................................24

Bevel and Miter Operations ................................................................................................................. 25

Dust Collection.....................................................................................................................................25

Safety Devices ............................................................................................................................................26

Feather Board..........................................................................................................................................26

Push Stick ............................................................................................................................................26

Filler Piece ........................................................................................................................................... 26

Maintenance................................................................................................................................................ 26

Cleaning ..................................................................................................................................................26

Lubrication................................................................................................................................................... 27

Miscellaneous .............................................................................................................................................27

Troubleshooting ..........................................................................................................................................27

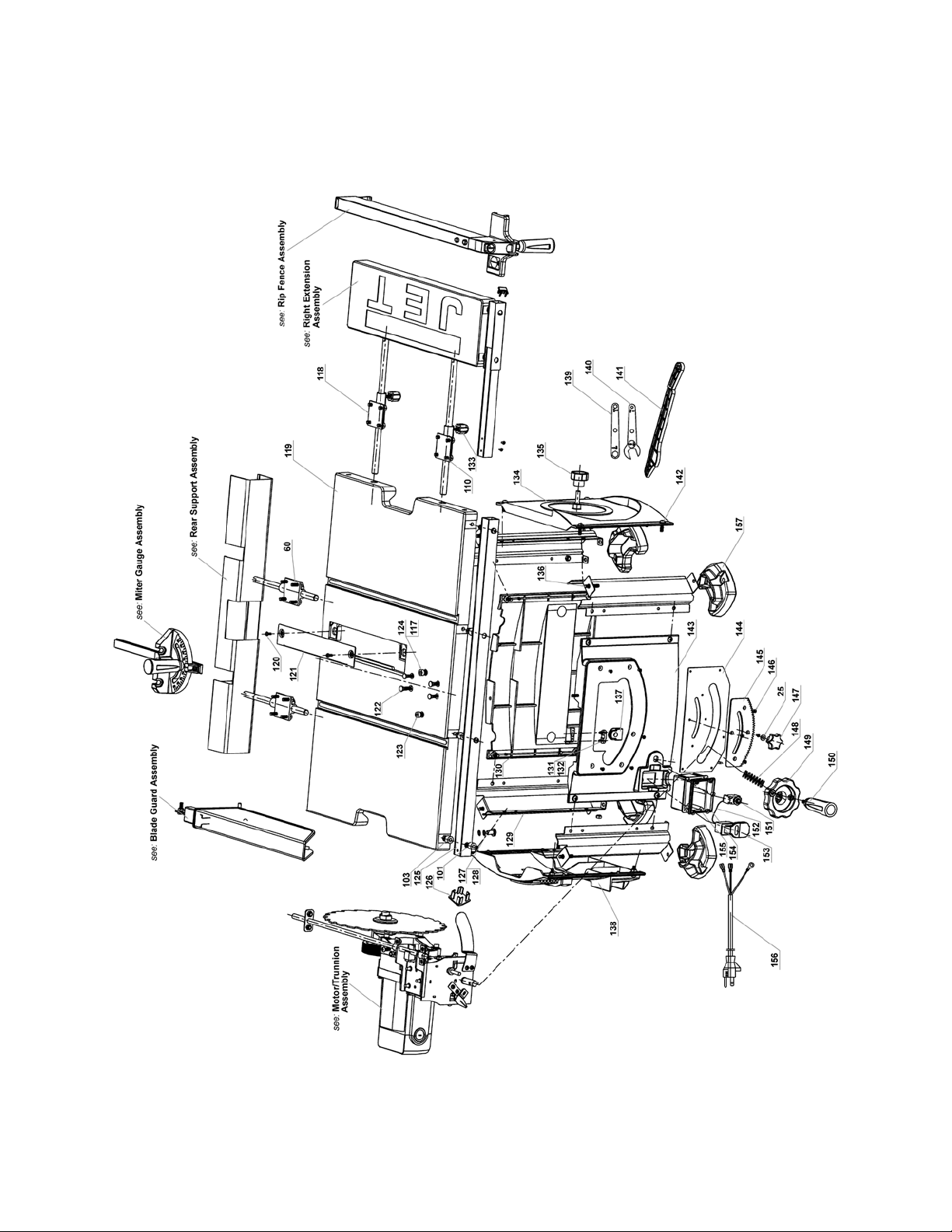

Parts............................................................................................................................................................ 27

Ordering Replacement Parts...................................................................................................................27

3

Page 4

Warnings

1. Read and understand the entire owner's manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This Table Saw is designed and intended for use by properly trained and experienced personnel only.

If you are not familiar with the proper and safe operation of a Table Saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this Table Saw for other than its intended use. If used for other purposes, WMH Tool

Group disclaims any real or implied warranty and holds itself harmless from any injury that may result

from that use.

6. Always wear approved safety glasses/face shields while using this Table Saw. Everyday eyeglasses

only have impact resistant lenses; they are not safety glasses.

7. Before operating this Table Saw, remove tie, rings, watches and other jewelry, and roll sleeves up

past the elbows. Remove all loose clothing and confine long hair. Non-slip footwear or anti-skid floor

strips are recommended. Do not wear gloves.

8. Always use the blade guard on all ''through-sawing'' operations. A through-sawing operation is one in

which the blade cuts completely through the workpiece.

9. Kickback occurs when the workpiece is thrown towards the operator at a high rate of speed. If you do

not have a clear understanding of kickback and how it occurs, DO NOT operate this table saw!

10. Wear ear protectors (plugs or muffs) during extended periods of operation.

11. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber.

12. Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

13. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

14. Make certain the switch is in the OFF position before connecting the machine to the power supply.

15. Make certain the machine is properly grounded.

16. Make all machine adjustments or maintenance with the machine unplugged from the power source.

17. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

18. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

19. Make sure the Table Saw is firmly secured to the floor or bench before use.

20. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should

be properly repaired or replaced.

4

Page 5

21. Provide for adequate space surrounding work area and non-glare, overhead lighting.

22. Keep the floor around the machine clean and free of scrap material, oil and grease.

23. Keep visitors a safe distance from the work area. Keep children away.

24. Make your workshop child proof with padlocks, master switches or by removing starter keys.

25. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

26. Maintain a balanced stance at all times so that you do not fall into the blade or other moving parts. Do

not overreach or use excessive force to perform any machine operation.

27. Use the right tool at the correct speed and feed rate. Do not force a tool or attachment to do a job for

which it was not designed. The right tool will do the job better and safer.

28. Use recommended accessories; improper accessories may be hazardous.

29. Maintain tools with care. Keep saw blades sharp and clean for the best and safest performance.

Follow instructions for lubricating and changing accessories.

30. Turn off the machine before cleaning. Use a brush or compressed air to remove chips or debris — do

not use your hands.

31. Do not stand on the machine. Serious injury could occur if the machine tips over.

32. Never leave the machine running unattended. Turn the power off and do not leave the machine until it

comes to a complete stop.

33. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

5

Page 6

The most common accidents among table saw users, according to statistics, can

be linked to kickback, the high-speed expulsion of material from the table that can strike the

operator. Kickback can also result in operator’s hands being pulled into the blade.

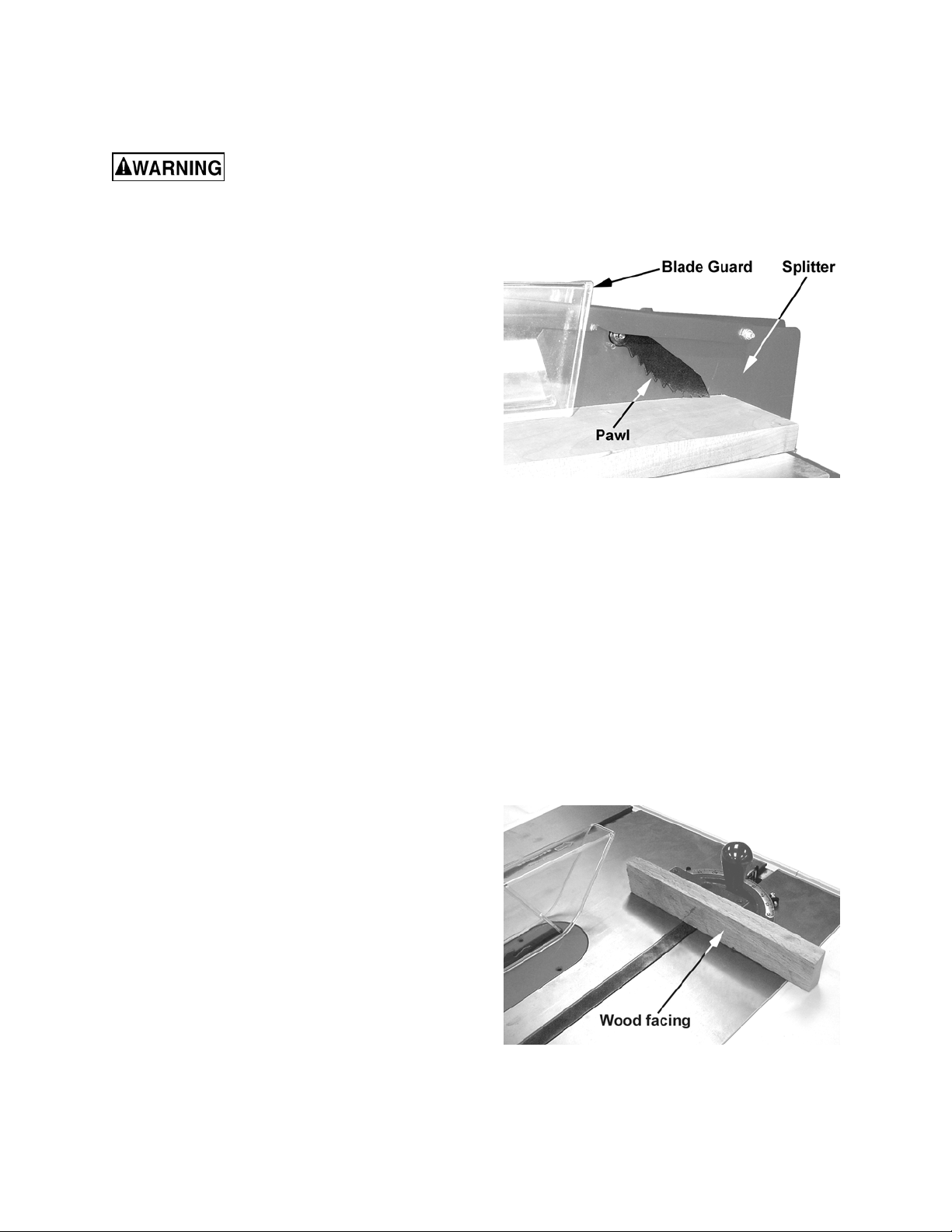

Kickback Prevention

Tips to avoid the most common causes of

kickback:

• Make sure the blade splitter is always

aligned with the blade. A workpiece can bind

or stop the flow of the cut if the blade splitter

is misaligned and result in kickback.

• Use the blade splitter during every cut. The

blade splitter maintains the kerf in the

workpiece, which will reduce the chance of

kickback.

• Never attempt freehand cuts. The workpiece

must be fed perfectly parallel with the blade,

otherwise kickback will likely occur. Always

use the rip fence or crosscut fence to

support the workpiece.

• Make sure that the rip fence is parallel with

the blade. If not, the chances of kickback are

very high. Take the time to check and adjust

the rip fence.

• Feed cuts through to completion. Anytime

you stop feeding a workpiece that is in the

middle of a cut, the chance of binding,

resulting in kickback, is greatly increased.

Protection Tips from

Kickback

Kickback can happen even if precautions are

taken to prevent it. Listed below are some tips to

always follow to protect you if kickback DOES

occur:

• Stand to the side of the blade when cutting.

An ejected workpiece usually travels directly

in front of the blade.

• Wear safety glasses or a face shield. Your

eyes and face are the most vulnerable part

of your body.

• Never place your hand behind the blade. If

kickback occurs, your hand will be pulled

into the blade.

• Use a push stick to keep your hands farther

away from the moving blade. If a kickback

occurs, the push stick will most likely take

the damage that your hand would have

received.

Read and understand the entire contents of this manual before attempting

assembly or operation! Failure to comply may cause serious injury!

The specifications in this manual are given as general information and are not binding. WMH Tool Group

reserves the right to effect, at any time and without prior notice, changes or alterations to parts, fittings,

and accessory equipment deemed necessary for any reason whatsoever.

6

Page 7

Specifications

Stock Numbers.................................................................................... 708315BTA, -BTB, -BTC, -LSA, -LSB

Saw Blade Diameter ..................................................................................................................................10”

Arbor Diameter..........................................................................................................................................5/8”

Blade Tilt .....................................................................................................................................left, 90 – 45º

Maximum Cutting Depth at 90º ....................................................................................................................3”

Maximum Cutting Depth at 45° ..............................................................................................................2-1/2”

Dado Capacity...........................................................................................................................................1/2"

Table Height (with Stand)...........................................................................................................................35”

Main Table Size ..........................................................................................................................28”W x 18”D

Extension Size (Aluminum).....................................................................................................5 1/2”W x 18”D

Extension Size (Sheet Metal)........................................................................................................8”W x 18”D

Blade Speed (no load) ...................................................................................................................5000 RPM

Motor ....................................................................................................................................... 120VAC, 60Hz

Gross Weight (BTA)............................................................................................................................. 57 lbs.

Net Weight (BTA) ................................................................................................................................. 50 lbs.

Definitions and Terminology

Arbor: Metal shaft that connects the drive

mechanism to the blade.

Bevel Edge Cut: Tilt of the saw arbor and blade

between 0° and 45° to perform an angled cutting

operation.

Blade Guard: Mechanism mounted over the

saw blade to prevent accidental contact with the

cutting edge.

Crosscut: Sawing operation in which the miter

gauge is used to cut across the grain of the

workpiece.

Dado Blade: Blade(s) used for cutting grooves

and rabbets.

Dado Cut: Flat bottomed groove in the face of

the workpiece made with a dado blade.

Featherboard: Device used to keep a board

against the rip fence or table that allows the

operator to keep hands away from the saw

blade.

Kerf: The resulting cut or gap made by a saw

blade.

Kickback: An event in which the workpiece is

lifted up and thrown back toward an operator,

caused when a work piece binds on the saw

blade or between the saw blade and rip fence

(or other fixed object). To minimize or prevent

injury from kickbacks, see the Operating

Instructions section.

Miter Gauge: A component that controls the

workpiece movement while performing a

crosscut of various angles.

Non-Through Cut: A sawing operation that

requires the removal of the blade guard splitter,

resulting in a cut that does not protrude through

the top of the workpiece (includes Dado and

rabbet cuts).

The blade guard and splitter must be re-installed

after performing a non-through cut to avoid

accidental contact with the saw blade during

operation.

Parallel: Position of the rip fence equal in

distance at every point to the side face of the

saw blade.

Perpendicular: 90° (right angle) intersection or

position of the vertical and horizontal planes

such as the position of the saw blade (vertical)

to the table surface (horizontal).

Push Board/Push Stick: An instrument used to

safely push the workpiece through the cutting

operation.

Rabbet: A cutting operation that creates an

L-shaped channel along the edge of the board.

Rip Cut: A cut made along the grain of the

workpiece.

Splitter: Metal plate to which the blade guard is

attached that maintains the kerf opening in the

workpiece when performing a cutting operation.

Standard Kerf: 1/8" gap made with a standard

blade.

Straightedge: A tool used to check that a

surface is flat or parallel.

Through Sawing: A sawing operation in which

the workpiece thickness is completely sawn

through. Proper blade height usually allows a

1/8" of the top of the blade to extend above the

wood stock.

7

Page 8

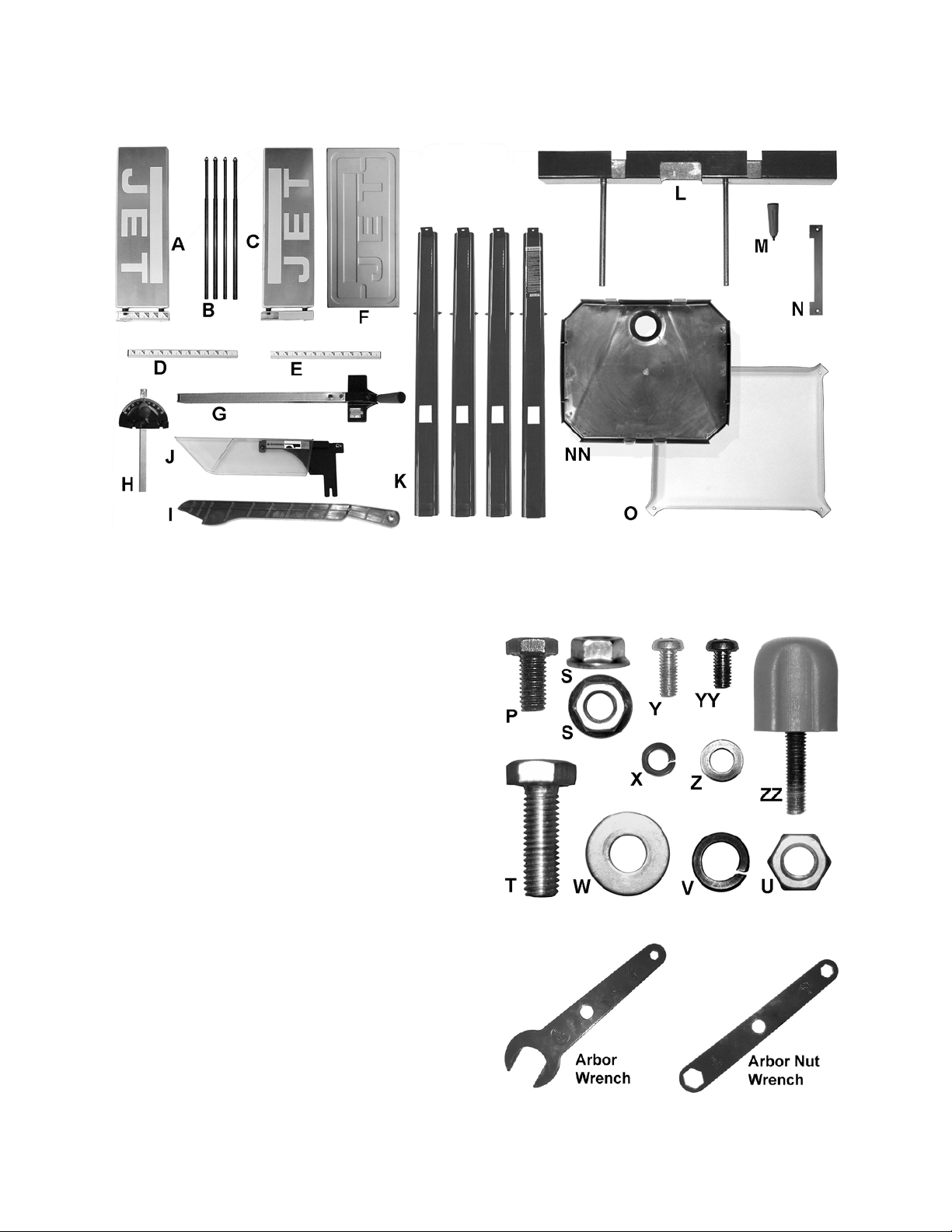

Shipping Contents

Contents of the Table Saw Carton

Contents of the Shipping Cartons

The contents that are contained in the shipping

carton are determined by the model of your

purchase which is determined by the three letter

suffix following the stock number, which is

708315.

Remove all contents from the shipping carton.

Keep the saw table upside down. Do not discard

the carton or packing material until the saw is

assembled and is running satisfactorily.

Important: Packing material is placed inside the

saw to provide support for the motor during

shipping and must be removed.

Compare the contents of the shipping carton

against the Contents Table (following page) for

your particular model. The Index No. in the table

corresponds to the items shown above and this

is your key for identifying each part.

Tool Required (Not Included)

5mm hex wrench (1 ea)

Cross-point Screwdriver (1 ea)

Hardware (actual size)

6mm hex wrench (1 ea)

14mm wrenches (2 ea)

10 mm wrenches (2 ea) or

10mm wrench and socket (1 ea)

Blade Removal Tools

8

Page 9

Shipping Contents

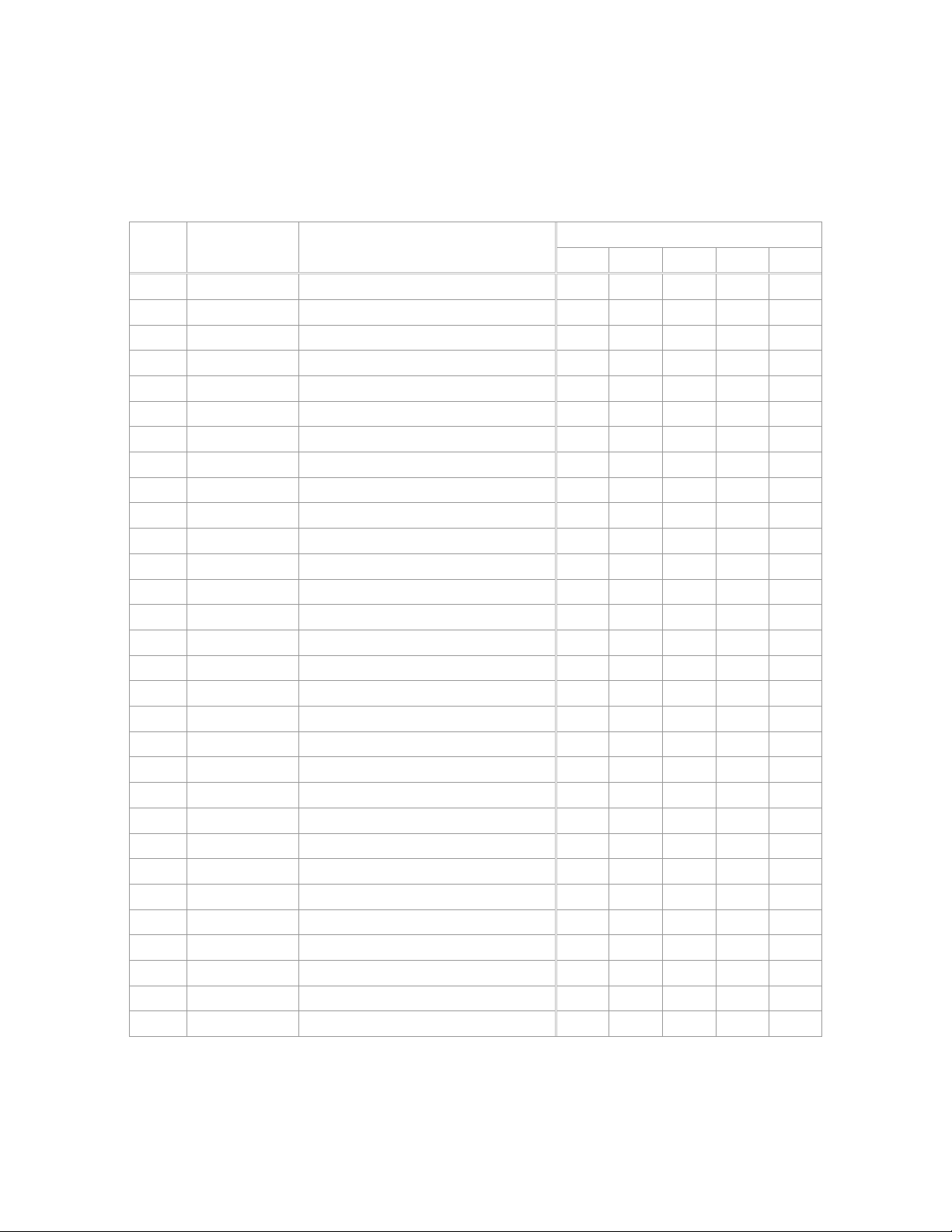

Index

No.

NN 708315-159 Dust Shroud 1

YY TS-2284082 M4x8 Pan Head Screw 1 1 2

Part No. Description

-- Table Saw 1 1 1 1 1

A 708315-LEA Left Extension Wing Assy 1

B 708315-105 Extension Rod 2 2 4

C 708315-REA Right Extension Wing Assy 1 1 1

D Left Scale Extension 1

E Right Scale Extension 1 1 1

F 708315-113 Stamped Steel Extension Wing 1

G 708315-RFA Rip Fence 1 1 1 1 1

H 708315-MGA Miter Gauge 1 1 1 1 1

I 708818 Push Stick 1 1 1 1 1

J 708315-BGA Blade Guard Assembly 1 1 1 1 1

K 708315-111 Leg 4 4

L 708315-RSA Rear Support Assembly 1 1 1 1

M 708315-150 Handle 1 1 1 1 1

N 708315-121A Dado Insert 1 1 1 1 1

O 708315-112 Shelf 1 1

P TS-1482021 M6x12 Hex Cap Screw 12 12

S 708315-158 M6 Hex Flange Nut 16 16

T TS-1490041 M8x25 Hex Cap Screw 2

U TS-1540061 M8 Hex Nut 2

V TS-2361081 M8 Lock Washer 2

W TS-1550061 M8 Flat Washer 2

X TS-1551021 M4 Lock Washer 2 2 4

Y TS-1532032 M4x10 Pan Head Screw 2 2 4

Z TS-1550021 M4 Flat Washer 2 2 4

ZZ 708315-134 Lock Knob 6 4 6 6 6

708315-140 Arbor Wrench 1 1 1 1 1

708315-139 Arbor Nut Wrench 1 1 1 1 1

Contents Table

Quantity

BTA BTB BTC LSA LSB

end one column

9

Page 10

Assembly

Do not plug the table saw into

the power source until all assembly has been

completed! Failure to comply may cause

serious injury!

Where to Begin

Each assembly section will start by listing the

applicable model(s) for that assembly procedure.

The starting point for your particular model,

however, is as follows:

Models LSA, LSB: start with Leg Assembly below.

Models BTA, BTB, BTC: start with Installing the

Blade Guard and Splitter on page 12.

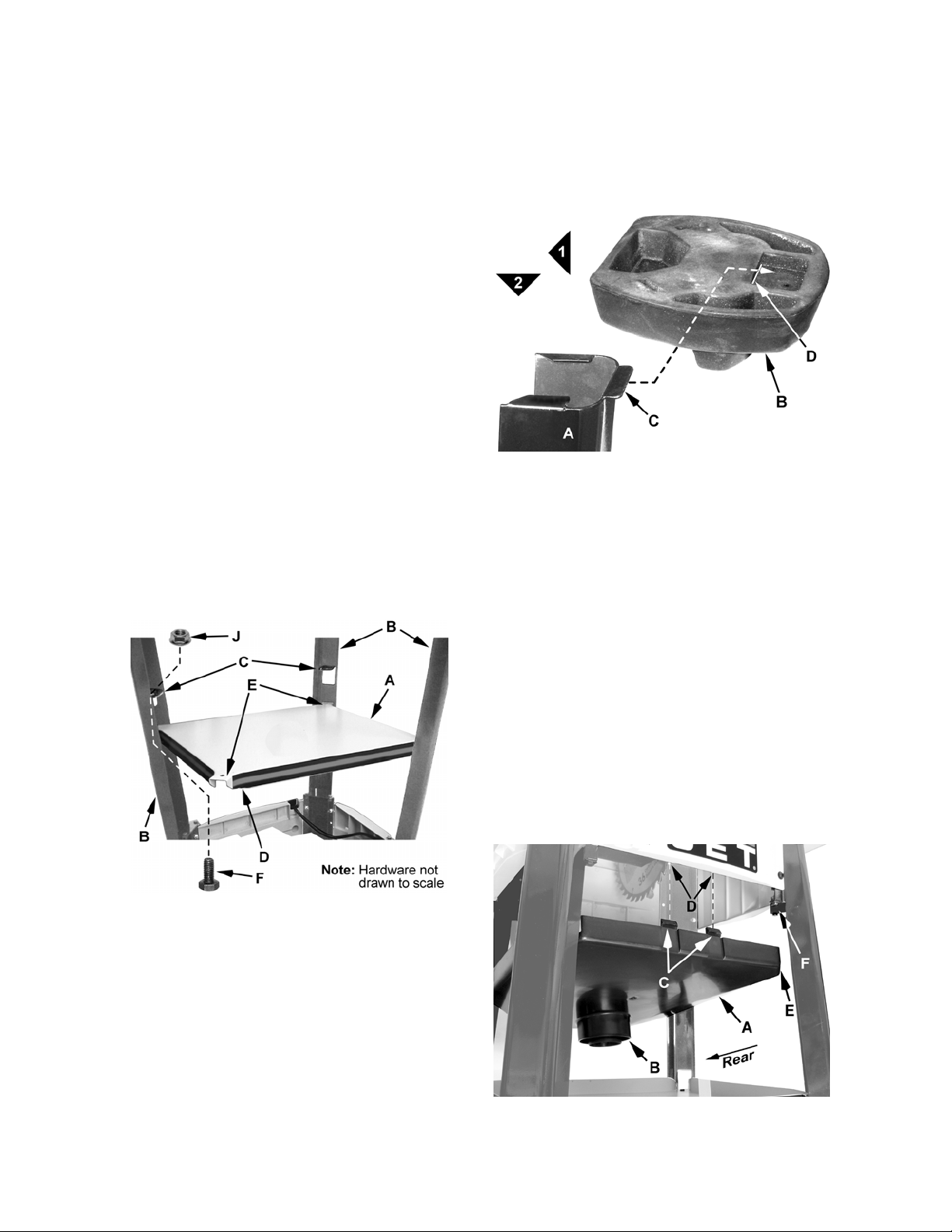

Leg Assembly

Models LSA, LSB

Figure 1

Follow these Leg Assembly instructions if you plan

to use your saw as a floor model. If this saw is to

be used for bench top applications, skip this section

and proceed to the Extension Table section.

Tools required – 10mm socket and wrench

Referring to Figures 1 and 2:

Required hardware (for each leg): two M6x12 hex

cap screws (C) and three M6 flange hex nuts (F).

1. With the saw upside down on the floor, remove

the four rubber feet (A) from each corner of the

base.

2. Take one leg (B) and position it so the outside

tab (G), containing the mounting hole, is

towards the bottom.

3. Mount one leg to a corner of the saw base so

the hole in the outside tab (G) lines up with the

screw (H) and the two holes on the leg's inside

tab (J) rests on top of the base tabs (K) with

the mounting holes lined up.

Note: The leg with the WARNING label must be

mounted on the corner of the saw base that also

has the WARNING label.

4. Insert two hex cap screws (C) through the

mounting holes of the leg tab (J) and base tab

(K). Secure with flange hex nuts (F

tighten only.

). Hand-

1

Figure 2

5. Secure the leg's outside tab (G) to the screw

(H) on the base with a flange hex nut (F

Hand-tighten only.

Mount two more legs in the same manner

described in steps 1–5. Don't mount the last leg

until the shelf is installed as described in the next

section.

).

2

10

Page 11

Mounting the Shelf

Models LSA, LSB

Note: The shelf is easier to install when three legs

have been assembled. The fourth leg should be

assembled after this section is completed.

Required hardware (for assembling all four legs):

four M6 flange hex nuts (J).

Referring to Figure 3:

1. While the saw is still upside down, position the

shelf (A) between the three legs (B) and below

the legs' mounting tabs (D). The sides of the

shelf (D) should point down.

2. Bring the shelf up, positioning the tabs of shelf

(E) against the bottom of the mounting tabs on

the legs (C), and line up the mounting holes.

2. Press the foot down (2) until the foot "snaps"

into position on the leg.

3. Repeat for remaining three legs.

At this time, turn the saw right side up. Place on a

level surface and tighten all screws for the leg and

shelf assembly.

3. From underneath the shelf, insert a hex cap

screw (F) up through the mounting holes of the

shelf and leg tabs. Secure the threaded portion

of the screw protruding through the top side of

the leg mounting tab with a flange hex nut (J),

hand-tightening only at this time.

After the shelf is secured to all three legs,

assemble the final leg (described in previous

section) and then finish by securing the remaining

shelf tab to the leg as well.

Figure 4

Dust Shroud

Model LSB only

Note: Install the dust shroud only if a separate dust

collection or vacuum system will be used.

Referring to Figure 5:

1. Place the dust shroud (A) inside the legs with

the port (B) towards the rear of the saw and

positioned down as shown.

2. Bring the front end of the shroud up so the two

front tabs (C) catch the lip (D) of the base,

securing it in position. The opening at the

corners of the shroud (E) should wrap around

the leg tabs (F).

3. Press the back of the shroud up until the rear

tabs snap into place against lip at the back of

the base.

Figure 3

Rubber Feet

Models LSA, LSB

Referring to Figure 4:

While the saw is still upside down,

1. Place rubber foot (B) on the leg (A), sliding

forward (1) while at the same time allowing the

rear tab (C) of the leg to slide through the

opening (D) in the heel of the rubber foot.

11

Figure 5

Page 12

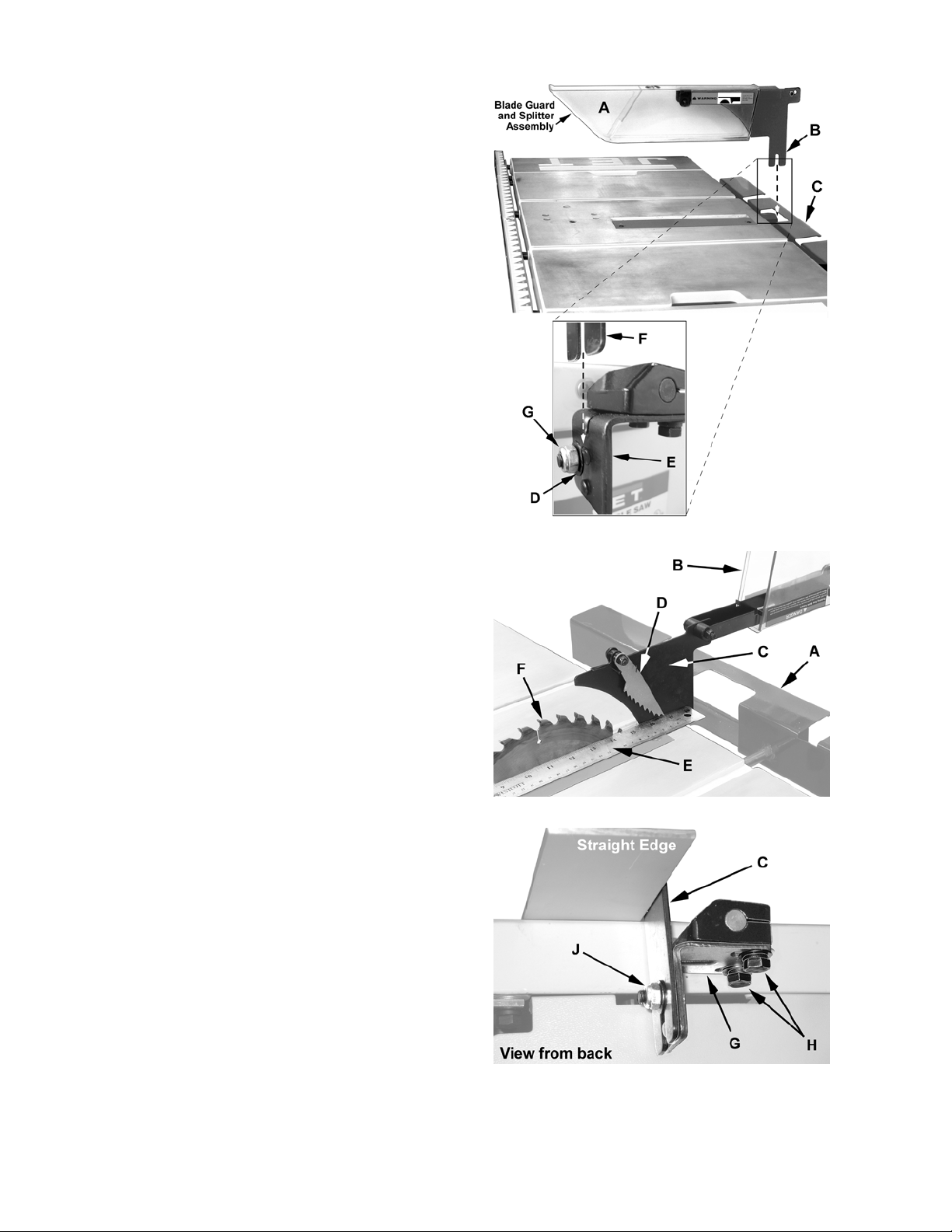

Installing the Blade Guard and Splitter

All models

Referring to Figure 6:

If your table saw came with a back support (C), the

blade guard/splitter installation and alignment will

be facilitated by loosening and sliding the back

support away from the table.

1. Loosen the hex nut (G) on the splitter support

bracket (E) to provide sufficient clearance for

the blade guard and splitter assembly (next

step).

2. Take the blade guard and splitter assembly

and slide the tab of the splitter (B and F) on the

screw of the splitter support bracket (E)

between the flat washer (D) and bracket (E).

3. Tighten the hex nut (G) enough to hold the

blade guard and splitter assembly in place.

Adjustment will be required and is described in the

Adjustment section (see Aligning the Blade Guard

and Splitter).

Figure 6

Aligning the Blade Guard and Splitter

All models

Referring to Figures 7 and 8:

1. Raise the blade guard (B) away from the table.

2. Set a straight edge (E), against the saw blade

(F) on the right side as shown. The anti-kick

pawl (D) needs to be lifted momentarily until

the straight edge is placed in position.

Note: The straight edge needs to rest against

the body of the saw blade and not the saw

teeth.

3. With a 10mm wrench, loosen two hex cap

screws (H) securing the splitter bracket (G) and

adjust the splitter (C) sideways until alignment

with the saw blade (F) is achieved.

4. Tighten the hex cap screws (H).

Make sure the splitter (C) is level with the table and

approximately 1/8" above the table. A 1/8" space

allows the blade guard assembly to tilt to a 45º

angle without contacting the table.

If the splitter level needs adjustment:

Figure 7

5. With two 10mm wrenches, loosen the nut and

screw (J) assembly, adjust the splitter (C) to

1/8" above the table. Tighten the hardware.

Use a square to verify that the splitter is

perpendicular to the table surface and adjust if

required.

12

Figure 8

Page 13

Saw Blade

All Models

The 708315 Table Saw comes with the saw blade

already included and installed from the factory. To

replace a blade, see Replacing the Blade in the

Adjustments section.

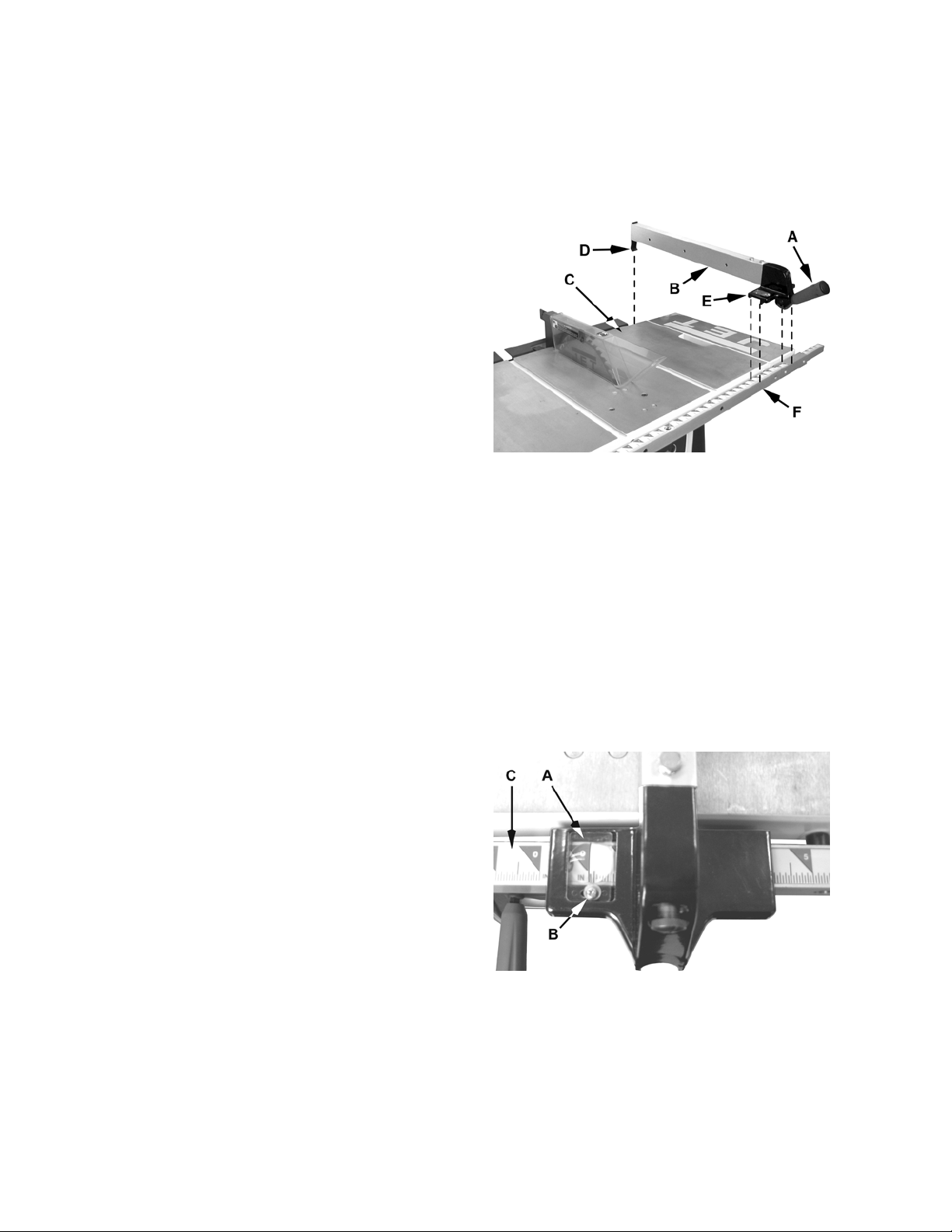

Attaching the Rip Fence

All Models

Referring to Figure 9:

1. Raise the rip fence handle (A) as shown.

2. Position the rip fence (B) over the table (C) as

shown, holding up the front end while engaging

the holding clamp (D) to the rear, then lowering

the front end (E) onto the rail (F).

3. Lower the handle (A) to clamp the fence to the

table

Calibrating the Rip Fence Scale

All Models

1. Attach the rip fence to the table (as described

in the previous section) to the right of the saw

blade, but do not lower the handle to clamp the

fence to the table.

2. Slide the fence against the saw blade.

You will need to raise the blade guard and the

anti-kick pawl to provide clearance for the

fence.

Figure 9

3. With the fence snug against the saw blade,

clamp the fence in position by lowering the

handle.

Referring to Figure 10:

The hairline on the indicator (A) should line up with

0" on the rail (C). If they do not line up:

4. Slightly loosen the screw (B).

5. Slide the indicator until the hairline lines up with

0" on the rail.

6. Tighten the screw.

13

Figure 10

Page 14

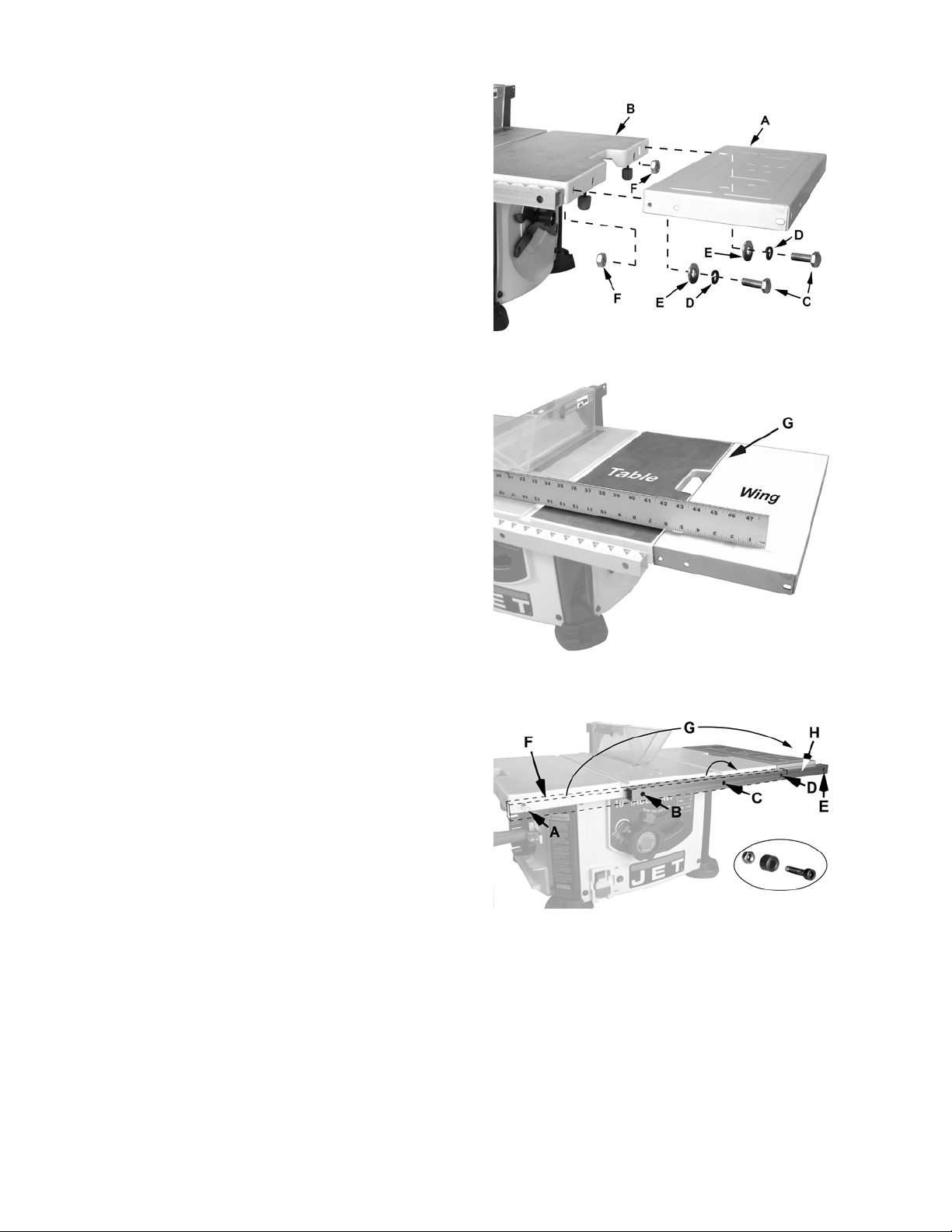

Stamped Steel Extension Wing

Model BTB – the extension wing should look like

(A) in Figure 11

The stamped steel extension wing can be mounted

on the right or left side of the saw table. The

following steps illustrate the right side.

Installation

Referring to Figures 11 and 12:

1. Place the stamped steel extension wing (A)

against the right side of the saw table (B) so

that the mounting holes line up.

2. Place two each M8 lock washers (D) and flat

washers (E) on M8 hex cap screws (C).

3. Insert the screws through the mounting holes

of the extension wing (A) and table (B).

4. Secure with two M8 hex nuts (F) but leave the

assembly loose enough so that the wing can

be moved by hand for adjustment.

Adjustment

5. Place a straight edge across the table and

extension wing near the front as shown in

Figure 12.

Figure 11

6. Raise or lower the extension wing until the

straight edge lies flat across the table and

wing.

7. Move the straight edge so it lies across the

table and wing towards the back (A).

8. Repeat Step 6.

9. When the extension wing is in line with the

table at the front and rear, tighten the screws

(C) and hex nuts (F) with two 14mm wrenches.

Repositioning the Front Rail

Refer to Figure 13.

After the stamped steel extension wing is installed,

the front rail needs to be repositioned to

accommodate the fence when it is positioned over

the extension wing. This is done as follows:

Item F, Fig. 13 shows the initial position of the front

rail.

1. Using a 5mm hex wrench and a 10mm open

end wrench, completely remove the screw,

spacer and lock nut (shown in the inset) that

secure the rail from the two left and far right

mounting holes (A), (B), and (D).

Note: Do not remove mounting hardware from

the third mounting hole (C).

Figure 12

Figure 13

2. Rotate the front rail clockwise (G) until the left

end becomes the right end in front of the

extension wing.

3. Reassemble the three screws, spacers and

lock nuts securing the front rail.

The screws are inserted through the front of

the rail, the spacers are positioned between the

rail and table (or extension), and the lock

washers are fastened to the screw from behind

the lip of the table (or extension).

14

Page 15

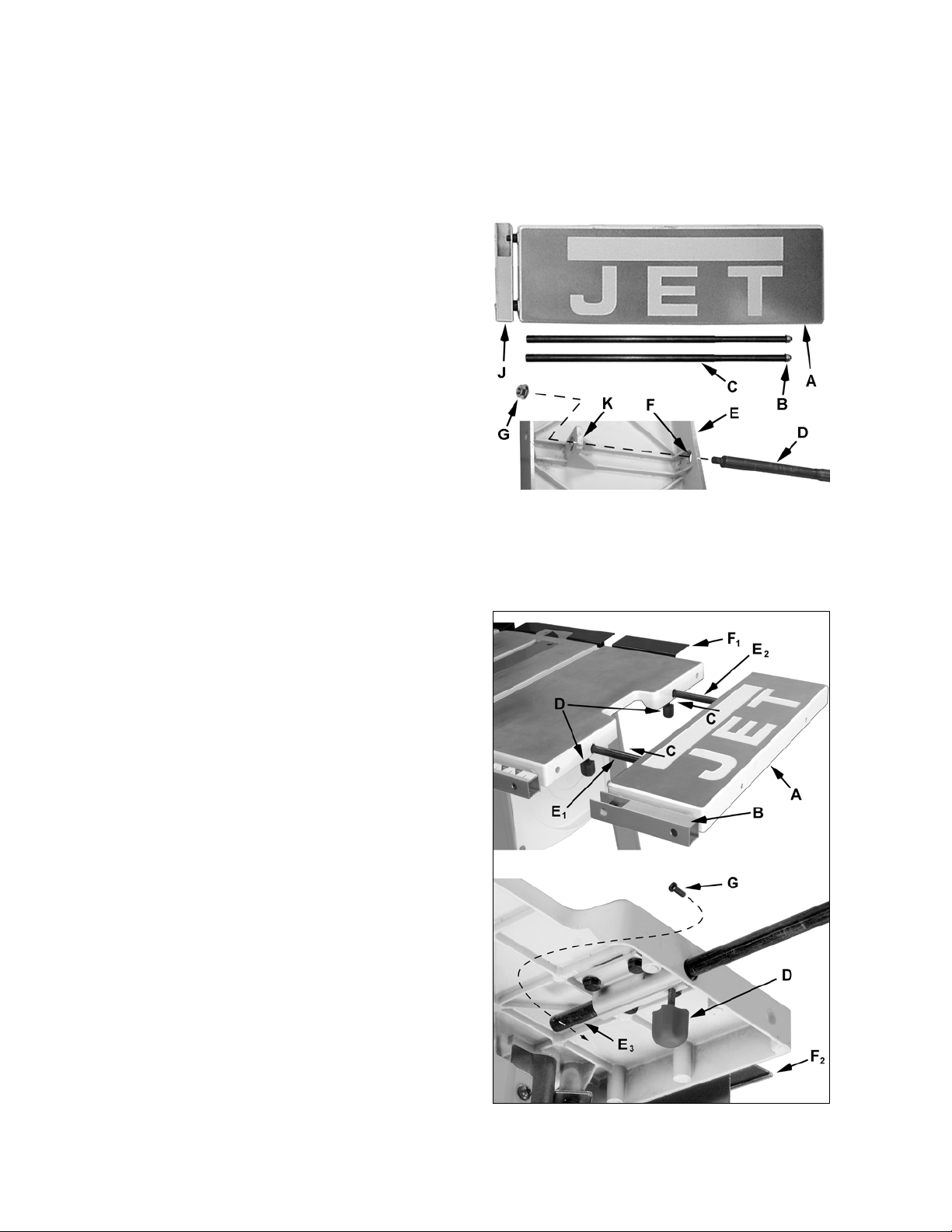

Sliding Extension Wing

Right Wing used on Models BTC, LSA and LSB

Left Wing used on Model LSB

Assembly (if required)

Refer to Figure 14.

For saws using the sliding extension wings, two

extension rods (C) need to be assembled before

mounting to the table. Assembly for the right

extension wing (A), identified by no rule on the rail

(J), is described below. Assembly for the left wing

is the same.

1. Using two 10mm wrenches, remove the lock

nut (B) from the extension rods (C and D).

2. Turn the extension wing (A) over so the JET

logo lays face down and the mounting holes

and tabs (F,K) are visible.

3. Insert the rods (D) through the mounting holes

on the extension wing (F) and tab (K)

The threaded end of the rod (D) should

protrude through the hole in the tab (K).

4. Place hex nuts (G) on the threaded ends of the

extension rods (D), leaving loose enough to

rotate the rods by hand.

5. Rotate the extension rods so that the threaded

holes, located near the ends away from the

extension table, are in line with the top of the

extension table.

Figure 14

6. Secure the extension rods with two 10mm

wrenches, placing one wrench on the hex nut

and the other on the flat indents of the rod.

7. Repeat the above steps for the left extension

wing for models that include it.

Mounting the Right Extension Wing Assembly

Models BTC, LSA and LSB – the right extension

wing looks like A in Figure 15

Referring to Figure 15:

1. Select the right extension table (A), which is

identified by no scale on the guide rail (B).

2. Mount the extension table by sliding the

extension rods into the mounting holes (C) on

the right side of the saw table. The lock

knobs (D) may need to be loosened.

3. From the bottom of the table, thread an M4x8

pan head screw (G) into the hole near the end

of the rear extension rod (E

closest to the rear extension (F

). This is the rod

3

and F2).

1

4. Tighten the lock knobs (D).

Figure 15

15

Page 16

Mounting the Left Extension Wing Assembly

Model LSB only

The left extension table, identified by the scale

(B, Fig. 16) on the rail, is used only with model LSB

The assembly and mounting procedure is the same

manner as for the right extension wing (above).

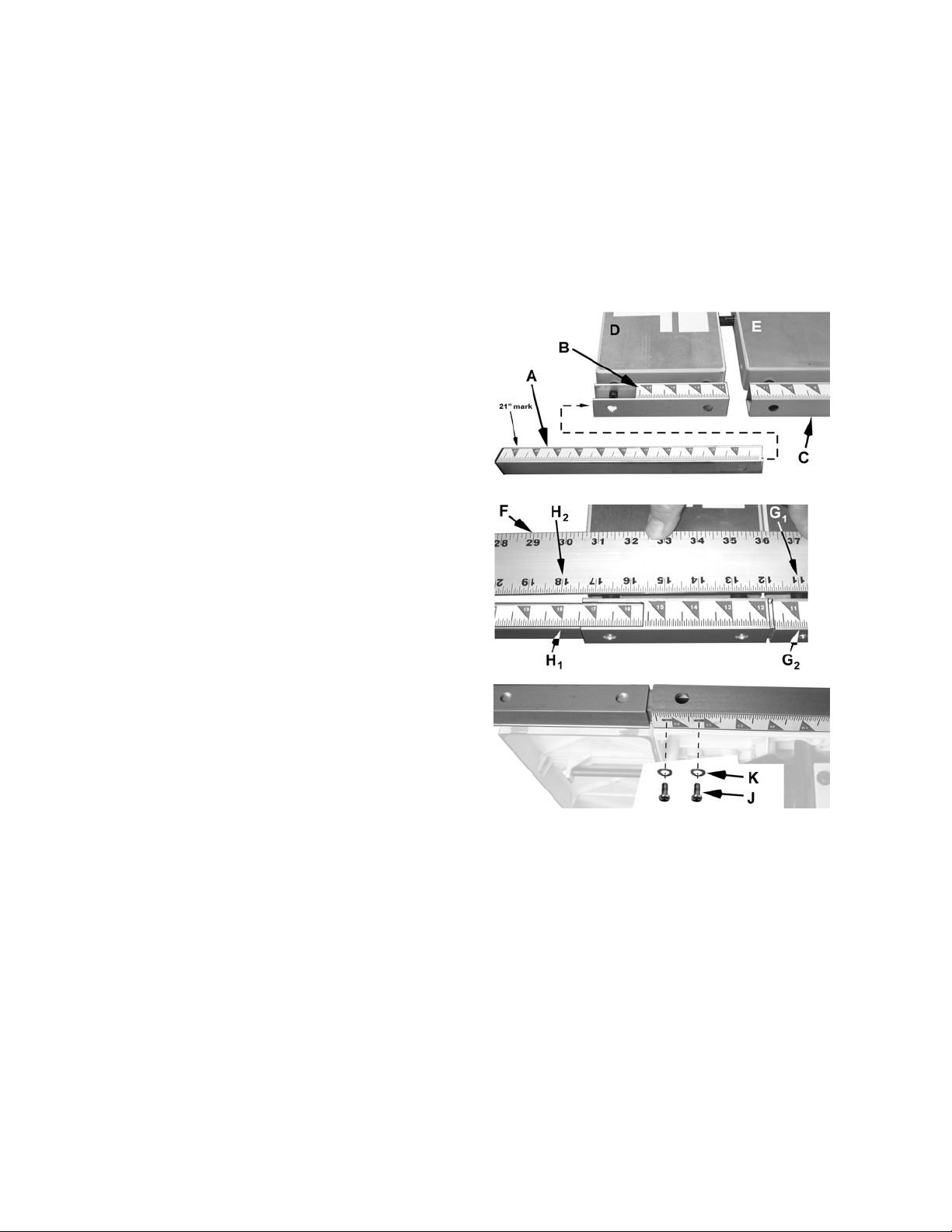

Left Scale Extension

Model LSB only

Referring to Figures 16:

1. If necessary, loosen the extension table lock

knobs and slide the extension table (D) flush

against the saw table (E).

2. Take the left rail extension (A) identified by

scale range 11"–21" and insert into the left

extension table guide rail (B), sliding it all the

way through and into the table guide rail (C).

3. View from underneath and adjust until the two

holes in the rail extension (A) and table rail (C)

are aligned.

4. Insert two each M4x10 pan head screws (J),

M4 lock washers (K) and M4 flat washers (L) to

hold the extension rail in place, but leave loose

enough to permit adjustment (following steps).

5. Place a scale or yardstick (F) across the

extension table and saw table.

6. Align the 11" mark on the ruler (G

mark on the guide rail (G

) and hold ruler firmly

2

) with the 11"

1

in place while performing the next step.

7. Adjust the rail extension (A) until the 18" mark

(H

) is aligned with the 18" mark on the

1

ruler (H

). Release the ruler while making sure

2

the rail extension does not move.

The left rail extension is now properly

calibrated. While holding it in place:

8. Tighten the two screws (K).

Right Scale Extension

Models BTC, LSA and LSB

The assembly steps are the same as for the Left

Scale Extension. For the alignment, use 14" and

21" as the calibration marks.

Figure 16

16

Page 17

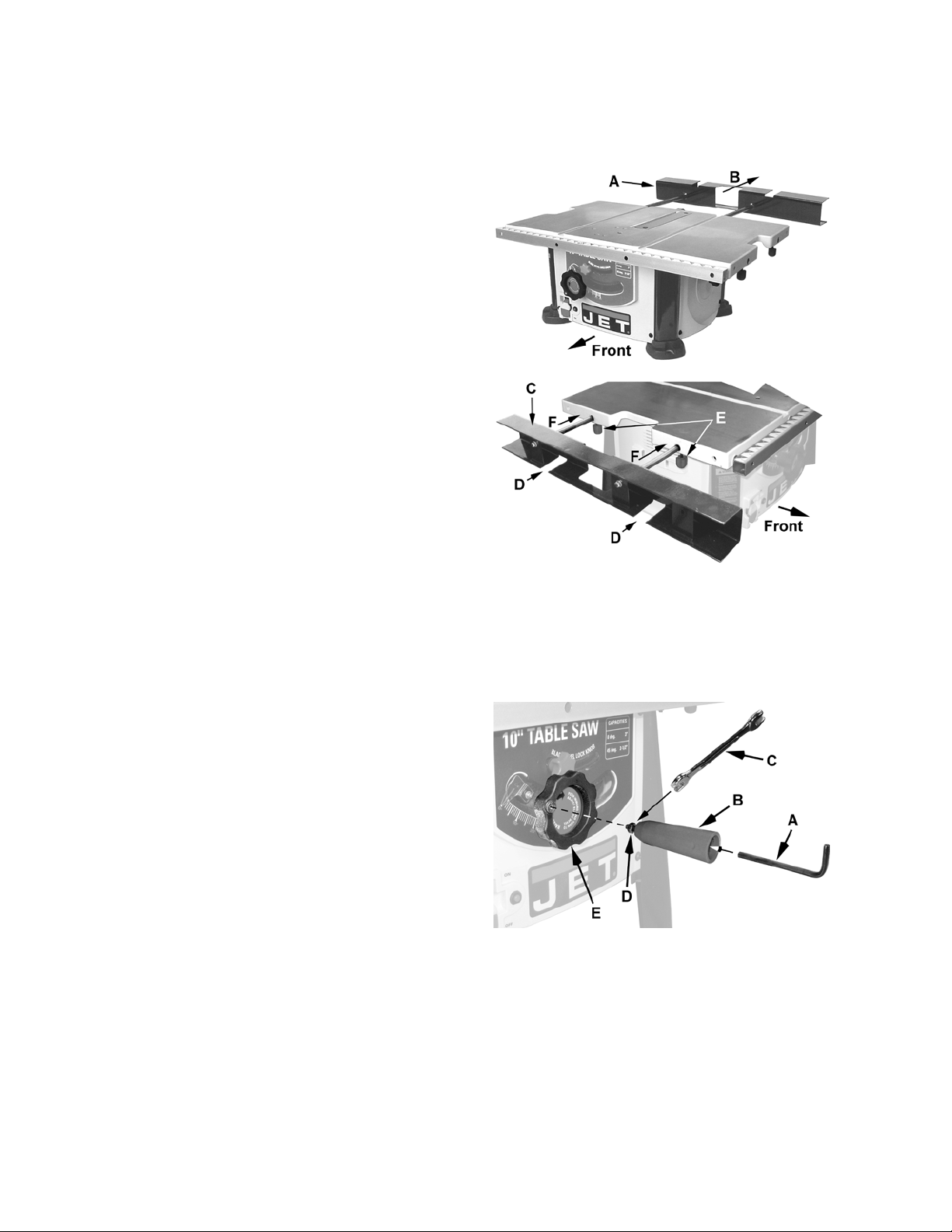

Optional Left Table Support

Models BTB, BTC and LSA

Referring to Figure 17:

Table saw models BTB, BTC and LSA do not come

with a left extension table. However the rear

support assembly (A) can be removed and used as

a left table support if needed. To do this:

1. Loosen two lock knobs underneath the back of

the table that secure the rear support

assembly (A).

2. Remove the rear support assembly by sliding it

back (B).

3. Turn the assembly over so that the flat side of

the rail is on top (C) and the two notches (D)

are on the bottom.

4. Loosen the two lock knobs (E) located on the

left side of the table.

5. Install the rear support assembly by inserting

inserting the extension rods into the two

mounting holes on the left side of the table (F).

Remember that the notches (D) are on the

bottom.

7. Tighten the lock knobs.

Handwheel Handle

All Models

Referring to Figure 18:

Figure 17

1. Insert a 5mm hex wrench (A) in the end of the

handle (B) into the socket head cap screw.

2. Thread into the handwheel (E) until almost

tight.

While still maintaining a hold on the hex

wrench (A):

3. Tighten the hex nut (C) with a 10mm wrench

(D) against the handwheel (E) so that the

handle (B) is secure, but its rotation is still

allowed during operation.

17

Figure 18

Page 18

Adjustments

When working around the saw

blade, always disconnect the saw from the

power source! Failure to comply may cause

serious injury!

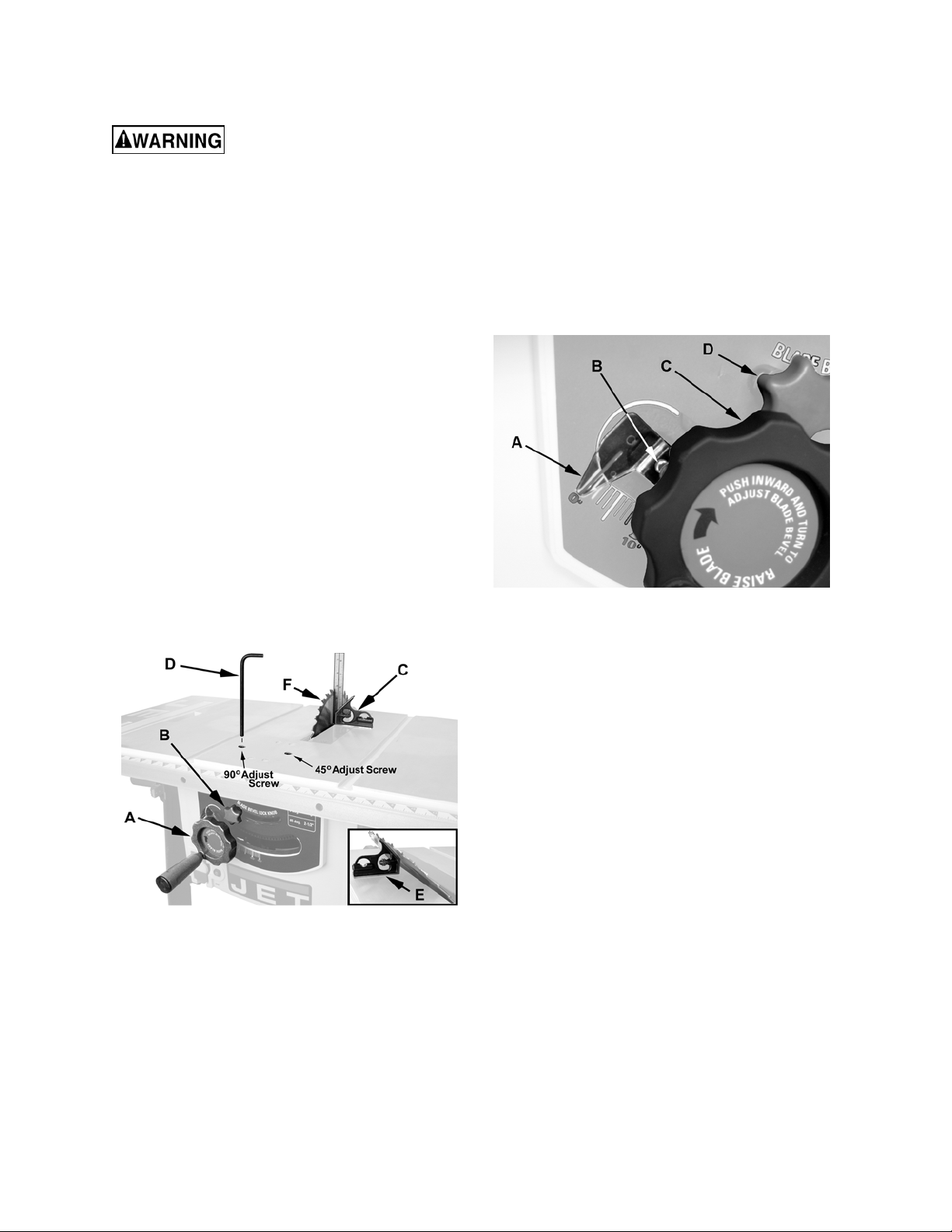

90 Degree Positive Stop

Referring to Figure 19:

1. Turn the handwheel (A) clockwise and raise

the blade to its maximum height.

2. Loosen the blade tilt lock knob (B) by turning

counterclockwise.

3. Push the handwheel (A) in to engage the blade

tilt mechanism; then turn clockwise all the way,

bringing the blade to the 90º position to the

table.

4. Continue holding the handwheel with the blade

in this position. Place a combination square (C)

on the table and against the blade as shown.

If the blade is not 90º to the table:

2. Push the handwheel (C) in to engage the blade

tilt mechanism; then turn clockwise all the way,

bringing the blade to the 90º position to the

table. Hold the handwheel and:

3. Lock the blade tilt lock knob (D).

If the scale does not read exactly 0º:

4. Loosen the screw (B) with an off-set cross-

point screwdriver.

5. Manually adjust the scale (A) until it points

to 0º:

6. Tighten the screw (B).

5. While maintaining the hold on the handwheel,

use a 6mm hex wrench to turn the 90 Adjust

Screw (Figure 19) until the blade is 90º to the

table.

6. Tighten the blade tilt lock knob (B).

Figure 19

Scale Calibration

The scale next to the handwheel needs to be

calibrated after the saw blade has been calibrated

at the 90º positive stop (see previous section) and

the scale does not indicate 0º.

To calibrate the scale (refer to Figure 20):

1. Loosen the blade tilt lock knob (D) by turning

counterclockwise.

Figure 20

45 Degree Positive Stop

Referring to Figure 19:

1. Turn the handwheel (A) clockwise and raise

the blade to its maximum height.

2. Loosen the blade tilt lock knob (B) by turning

counterclockwise.

3. Push the handwheel (A) in to engage the blade

tilt mechanism and turn counterclockwise all

the way, bringing the blade to the 45º position

to the table.

4. Continue holding the handwheel with the blade

in this position. Place a combination square (E)

on the table and against the blade as shown.

If the blade is not 45º to the table:

5. While maintaining the hold on the handwheel,

use a 6mm hex wrench to turn the 45 Adjust

Screw (Figure 19) until the blade is 45º to the

table.

6. Tighten the blade tilt lock knob (B).

18

Page 19

Adjusting Blade Parallel to Miter Gauge

Slots

When working around the saw

blade, always disconnect the saw from the

power source! Failure to comply may cause

serious injury!

The saw blade was adjusted at the factory to be

parallel to the miter gauge slots and should not

need adjustment. However, if upon inspection it is

determined that adjustment is required, follow the

steps below.

1. Using the handwheel (A, Fig. 19), raise the saw

blade as high as it will go.

Referring to Figure 21:

2. Place the base of a combination square (A)

pressed against the edge of the miter slot (B).

Extend the sliding rule (C) so it just touches the

tooth at the near end of the blade (D), then

tighten the locking screw on the combination

square to secure the sliding rule.

3. Move the square to the far end of the blade (E).

Figure 21

If a gap appears or if the base of the

combination square will not rest against the

edge of the miter slot, adjustment is required

as follows:

Saw blades are sharp. Be

extremely careful when working around them!

Failure to comply may cause serious injury!

Referring to Figure 22:

4. From underneath the table saw, loosen 3 (of 4)

screws (A) that secure the motor to the base.

5. Carefully move the saw blade until the blade is

parallel to the miter gauge slot. Check by

repeating steps 2 and 3. When adjustment is

complete, securely tighten the screws (A).

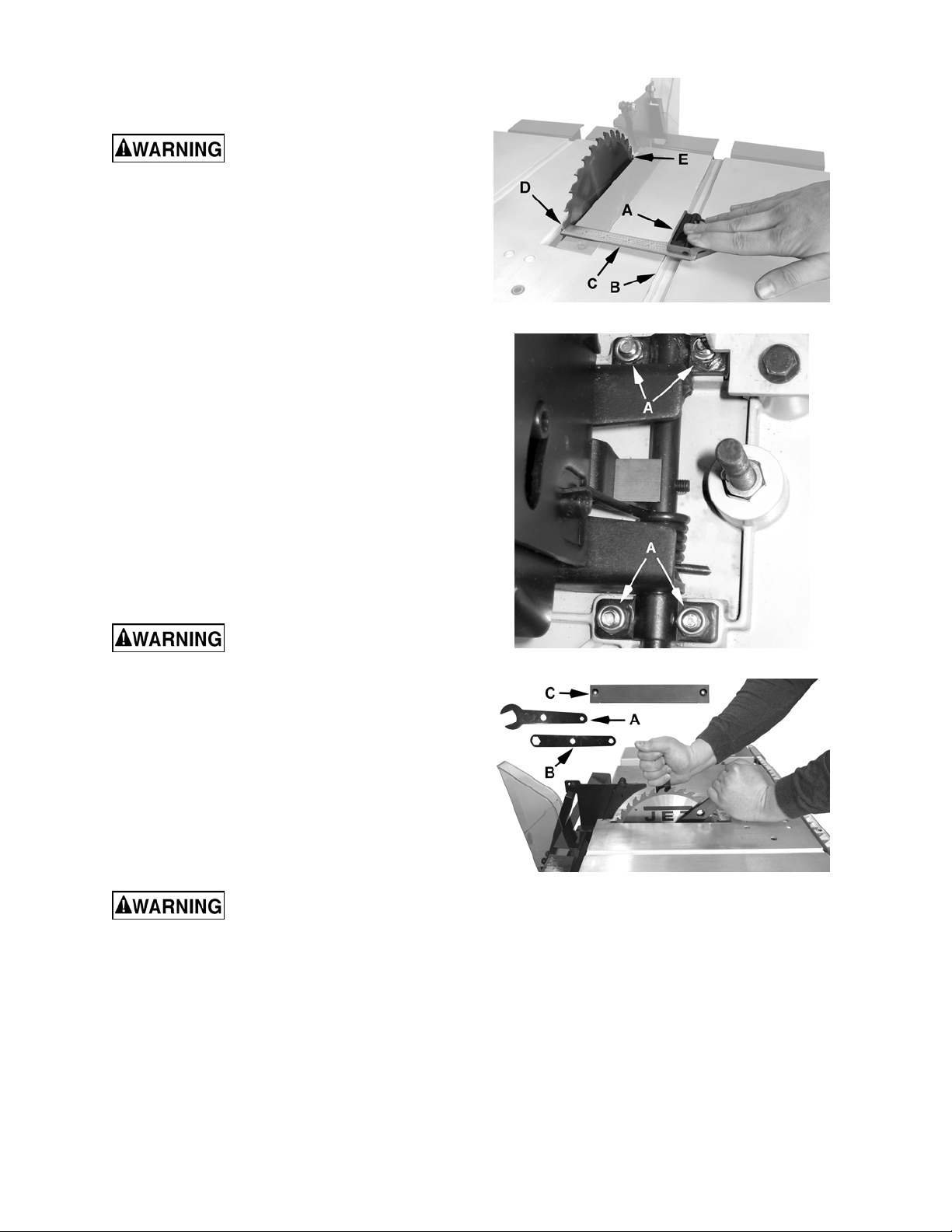

Replacing the Blade

When installing or changing the

saw blade, always disconnect the saw from the

power source! Failure to comply may cause

serious injury!

1. Using the handwheels, raise the blade arbor

fully and lock the saw at zero degrees (see

steps 1–3 in the 90 Degree Positive Stop

section); then tighten the blade tilt lock knob

(B, Fig. 19).

2. Remove the two insert screws and lift the table

insert (C, Fig. 23) out of the pocket of the

table.

Figure 22

Figure 23

3. Place the open end arbor wrench (A, Fig. 23)

on the flat sides of the inside blade flange to

keep the saw arbor from rotating. Rotate the

arbor nut counterclockwise with the closed

arbor nut wrench (B, Fig. 23) and remove the

arbor nut and outer flange.

4. Replace the old blade with a new one, making

certain that the teeth are pointing down at the

front of the table (refer to D, Fig. 21).

5. Assemble the outer flange, arbor nut and

securely tighten the arbor nut clockwise while

holding the arbor steady with the open end

arbor wrench.

19

Page 20

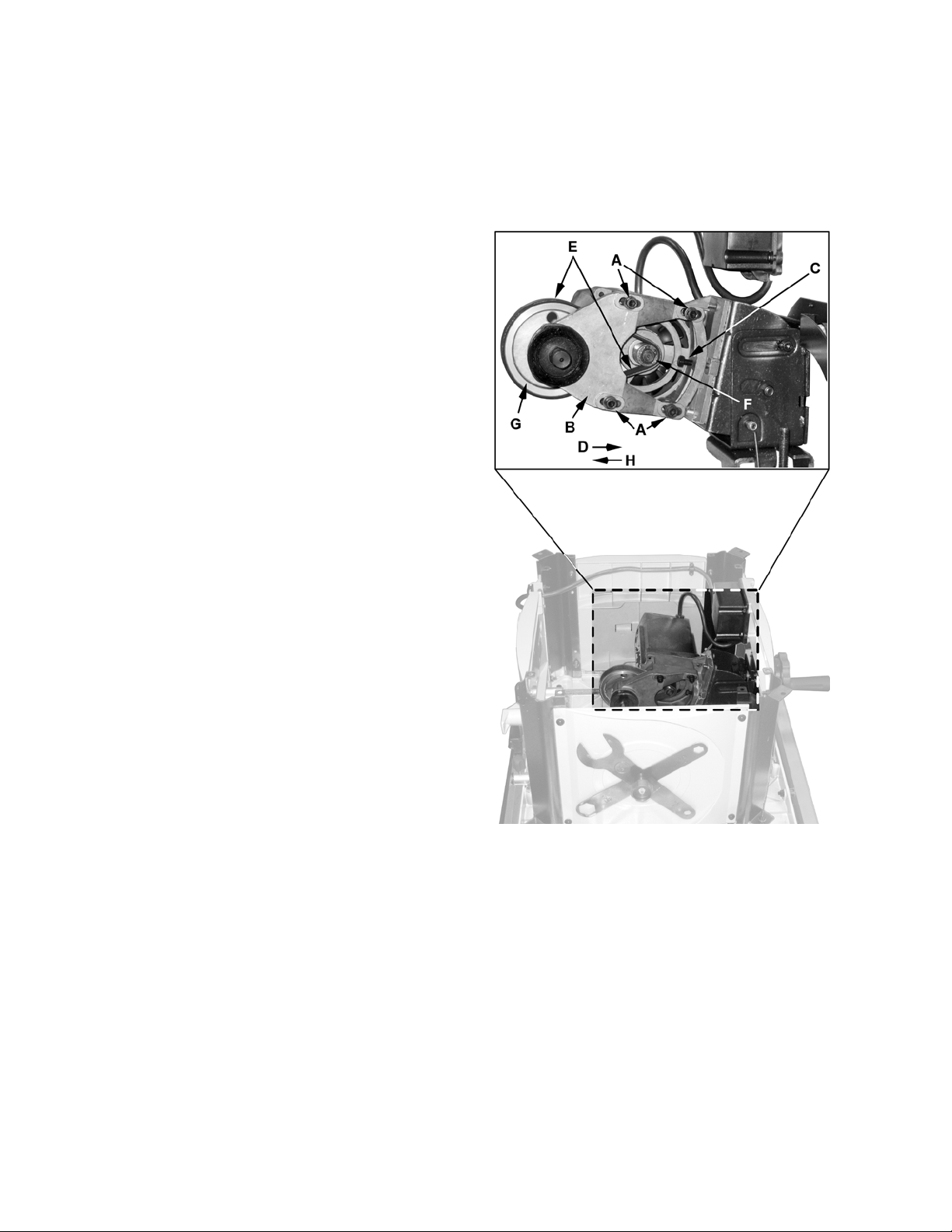

Replacing/Adjusting the Drive Belt

For Replacement and Adjustment

1. Remove the saw blade (see Replacing the

Blade on page 19).

2. Using the front handwheel, lower the blade

arbor to its lowest position (rotate handwheel

counterclockwise).

3. Remove the blade guard and splitter (see

Installing the Blade Guard and Splitter section

on page12), then turn the saw upside down.

4. Remove the dust shroud if applicable.

Referring to Figure 24:

5. With a 5mm hex wrench, loosen four socket

head cap screws (A) that secure the arbor

support (B) to the motor casing.

If adjusting belt tension only (no belt replacement),

skip steps 6 – 10 and proceed to step 11.

6. With a 10mm wrench, loosen the tension adjust

screw (C) by turning counterclockwise.

7. Push the arbor support (B) forward (D) to

relieve tension on the belt (E).

8. Remove belt (E) from the motor and arbor

pulleys (F, G).

9. Replace the old belt with a new belt making

sure that it sits properly on both pulleys.

10. Pull the arbor support (B) back (H), placing

tension on the belt, and hand-tighten the four

mounting screws (A).

Adjustment

11. With a 10mm wrench, turn the tension adjust

screw (C) to place proper tension on the belt.

Adjustment is sufficient when moderate finger

pressure on the belt between the pulleys

results in approximately 1/4" deflection.

12. Tighten the four mounting screws (A) with a

5mm hex wrench.

After the Adjustment

13. Replace the dust shroud (page 11) if

applicable.

14. Turn the table saw right-side up.

15. Replace and adjust the blade guard and splitter

(refer to the Installing the Blade Guard and

Splitter and Adjusting the Blade Guard and

Splitter sections on page 12).

16. Replace the saw blade (Replacing the Blade

on page 19).

Figure 24

20

Page 21

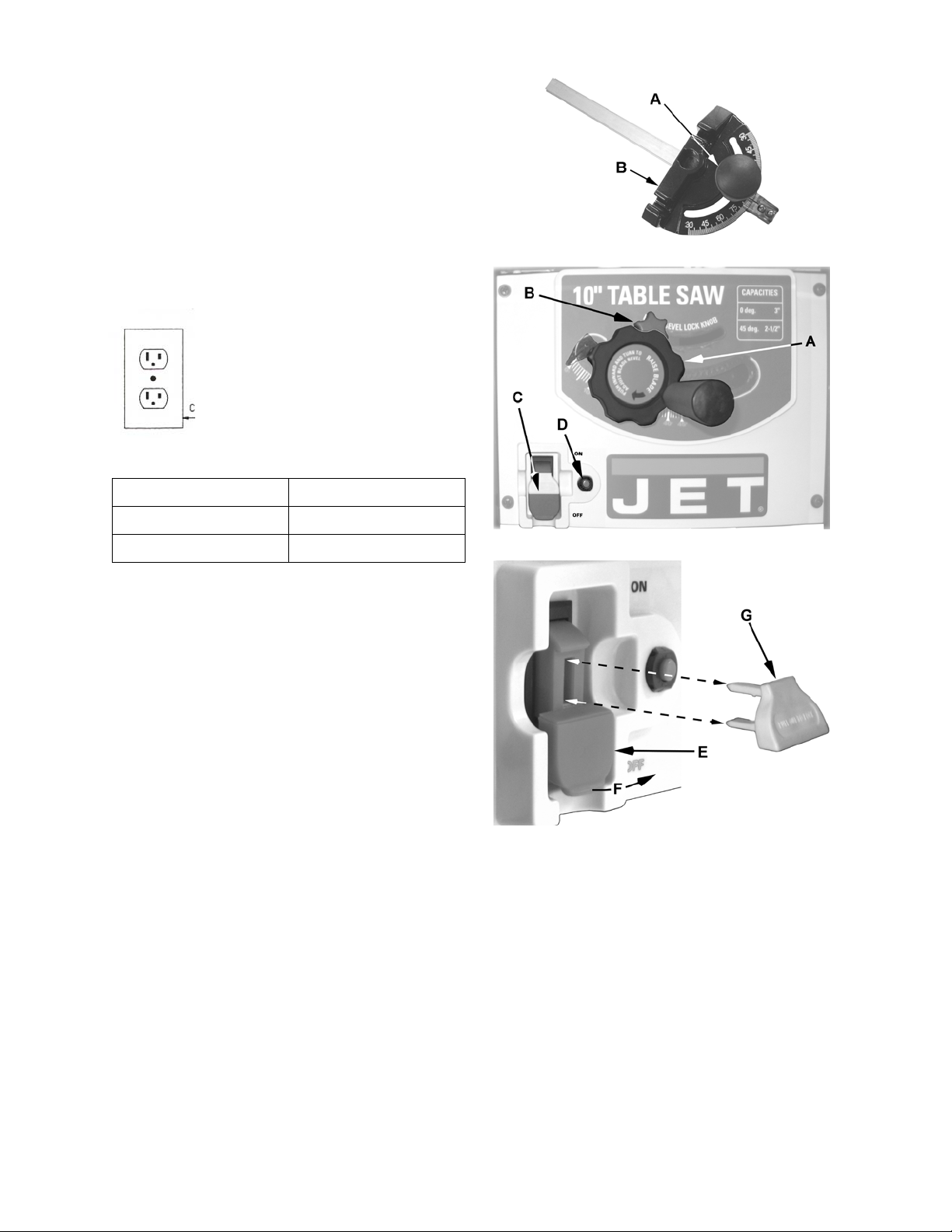

Miter Gauge Operation

Operate the miter gauge by loosening the lock

knob (A, Fig. 25) and turning the miter body

(B, Fig. 25) to the desired angle.

Note: Always make test cuts. Do not rely solely on

miter gauge indicator marks.

Electrical Connections

This saw has a motor that operates on 120VAC

and is equipped with a power cord that plugs into a

standard grounded 3-prong 120VAC

outlet as shown.

Before hooking up to the power

source, be sure the switch is in the

off position.

If an extension cord is used, select

one with a rating appropriate for the

job from the chart below.

0012 Gauge Cord 000 – 25 feet

Figure 25

0010 Gauge Cord 000 – 50 feet

008 Gauge Cord 000 – 100 feet

Extension Cord Chart

Operating Controls

On/Off Switch – The on/off switch is located on the

front panel of the saw base (C, Fig. 26). To turn the

saw on move the switch to the up position

(F, Fig. 27). To turn the switch off move the switch

to the down position.

Locking Key – When the saw is not in use, the

switch should be locked in the off position. To lock

the switch in the off position, pull out the safety key

(G, Fig. 27). The saw will not start with the key

removed. However, if the key is removed while the

switch is in the on position, it can be turned off

once. The saw will not restart until the key has

been reinserted into the switch.

Overload Protection – This saw is equipped with

a resetable overload relay button (D, Fig. 26). If the

motor shuts off or fails to start due to overloading or

low voltage, turn the switch (C, Fig. 26) to the off

position and let the motor cool down for at least five

minutes. After the motor has cooled down, push the

reset button (D, Fig. 26) to reset the overload

device. The saw should now start when the switch

is returned to the on position.

Blade Height/Tilt Handwheel – The handwheel

located on the front of the saw (A, Fig. 26) sets the

blade height and tilt.

To raise or lower the blade, simply turn the hand-

Figure 26

Figure 27

wheel (A, Fig. 26) clockwise or counterclockwise.

To tilt the blade:

1. Press the handwheel in.

2. Loosen the blade tilt lock knob (B, Fig. 26) by

turning counterclockwise.

3. Still pressing the handwheel in, turn clockwise

or counterclockwise to set the blade between

0º (blade 90º perpendicular to table) and 45º

(left tilt).

When the desired blade angle is set,

4. Continue holding the handwheel (A, Fig. 26) in

until the lock knob (B, Fig. 26) is tightened.

21

Page 22

Operations

Before turning the saw on,

make sure that the table is free of tools,

hardware and debris. These items can

become projectiles and cause serious injury.

Table Saws

Familiarize yourself with the location and

operation of all controls and adjustments and the

use of accessories such as the miter gauge and

rip fence.

Kickbacks

Serious injury can result from kickbacks which

occur when a work piece binds on the saw blade

or binds between the saw blade and rip fence or

other fixed object. This binding can cause the

work piece to lift up and be thrown toward the

operator.

Listed below are conditions, which can cause

kickbacks:

Confining the cutoff piece when crosscutting

or ripping.

Releasing the work piece before completing

the operation or not pushing the work piece

all the way past the saw blade.

Not using the splitter when ripping or not

maintaining alignment of the splitter with the

saw blade.

Using a dull saw blade.

Not maintaining alignment of the rip fence so

that it tends to angle toward rather than

away from the saw blade front to back.

Applying feed force when ripping to the

cutoff (free) section of the work piece

instead of the section between the saw

blade and fence.

As the machine receives use, the operation

of the anti-kickback pawls should be

checked periodically (Figure 26). If the pawls

do not stop the reverse motion of a

workpiece, resharpen all the points.

Where possible, keep your face and body

out of line with potential kickbacks including

when starting or stopping the machine.

Figure 28

Dull, badly set, improper, or improperly filed

cutting tools and cutting tools with gum or resin

adhering to them can cause accidents. Never

use a cracked saw blade. The use of a sharp,

well maintained, and correct cutting tool for the

operation will help to avoid injuries.

Support the work properly and hold it firmly

against the gauge or fence. Use a push stick or

push block when ripping short, narrow (6" width

or less), or thin work. Use a push block or miter

gauge hold-down when dadoing or molding.

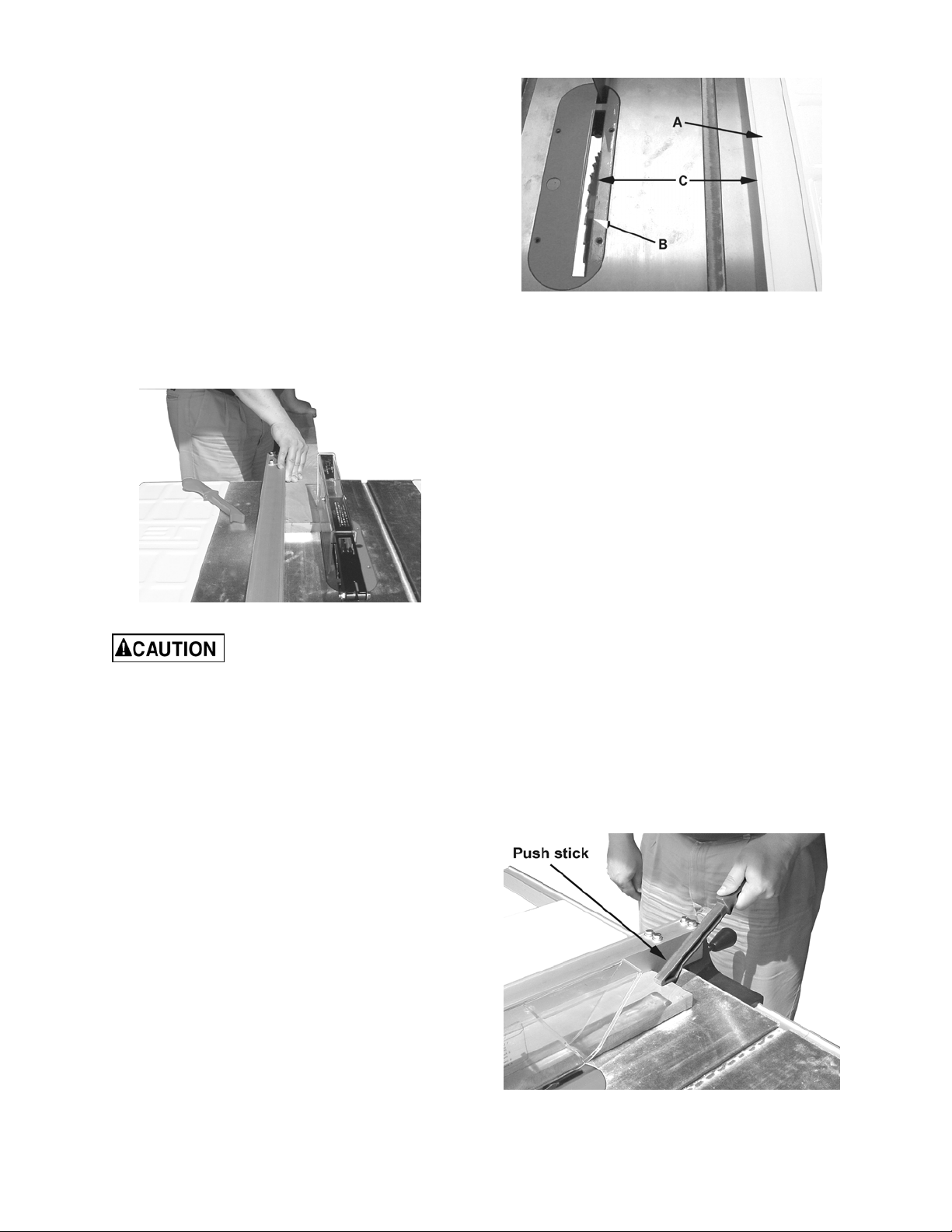

For increased safety in crosscutting, use an

auxiliary wood facing (Figure 29) attached to the

miter gauge using the holes provided in the

gauge.

Ripping wood that is twisted (not flat), or

does not have a straight edge, or a twisted

grain.

To minimize or prevent injury from kickbacks:

Avoid conditions listed above.

Wear a safety face shield, goggles, or

glasses.

Do not use the miter gauge and rip fence in

the same operation unless provision is made

by use of a facing board (auxiliary block) on

the fence so as to allow the cutoff section of

the workpiece to come free before the next

cut is started (see Figure 35).

Figure 29

Never use the fence as a length stop when

crosscutting. Do not hold or touch the free end

or cutoff section of a workpiece. On through-

22

Page 23

sawing operations, the cutoff section must NOT

be confined.

Always keep your hands out of the line of the

saw blade and never reach back of the cutting

blade with either hand to hold the workpiece.

Bevel ripping cuts should always be made with

the fence on the right side of the saw blade so

that the blade tilts away from the fence and

minimizes the possibility of the work binding and

the resulting kickback.

Rip Sawing

Ripping is where the work piece is fed with the

grain into the saw blade using the fence as a

guide and a positioning device to ensure the

desired width of cut (Figure 30).

Figure 31

The rip fence (A, Fig. 31) should be set for the

width of the cut (C, Fig. 31) by using the scale

on the front rail, or by measuring the distance

between the blade (B) and fence (A). Stand out

of line with the saw blade and workpiece to

avoid sawdust and splinters coming off the blade

or a kickback, if one should occur.

If the work piece does not have a straight edge,

nail an auxiliary straight edged board on it to

provide one against the fence. To cut properly,

the board must make good contact with the

table. If it is warped, turn the hollow side down.

Figure 30

Before starting a ripping cut,

be sure the fence is clamped securely and

aligned properly.

Never rip freehand or use the miter gauge in

combination with the fence.

Never rip workpieces shorter than the saw

blade diameter.

Never reach behind the blade with either

hand to hold down or remove the cutoff

piece with the saw blade rotating.

Always use the blade guard, splitter and antikickback pawls. Make sure the splitter is

properly aligned. When wood is cut along the

grain, the kerf tends to close and bind on the

blade and kickbacks can occur.

Note: A caution decal is installed on the guard

and splitter assembly warning of the hazard of

misalignment.

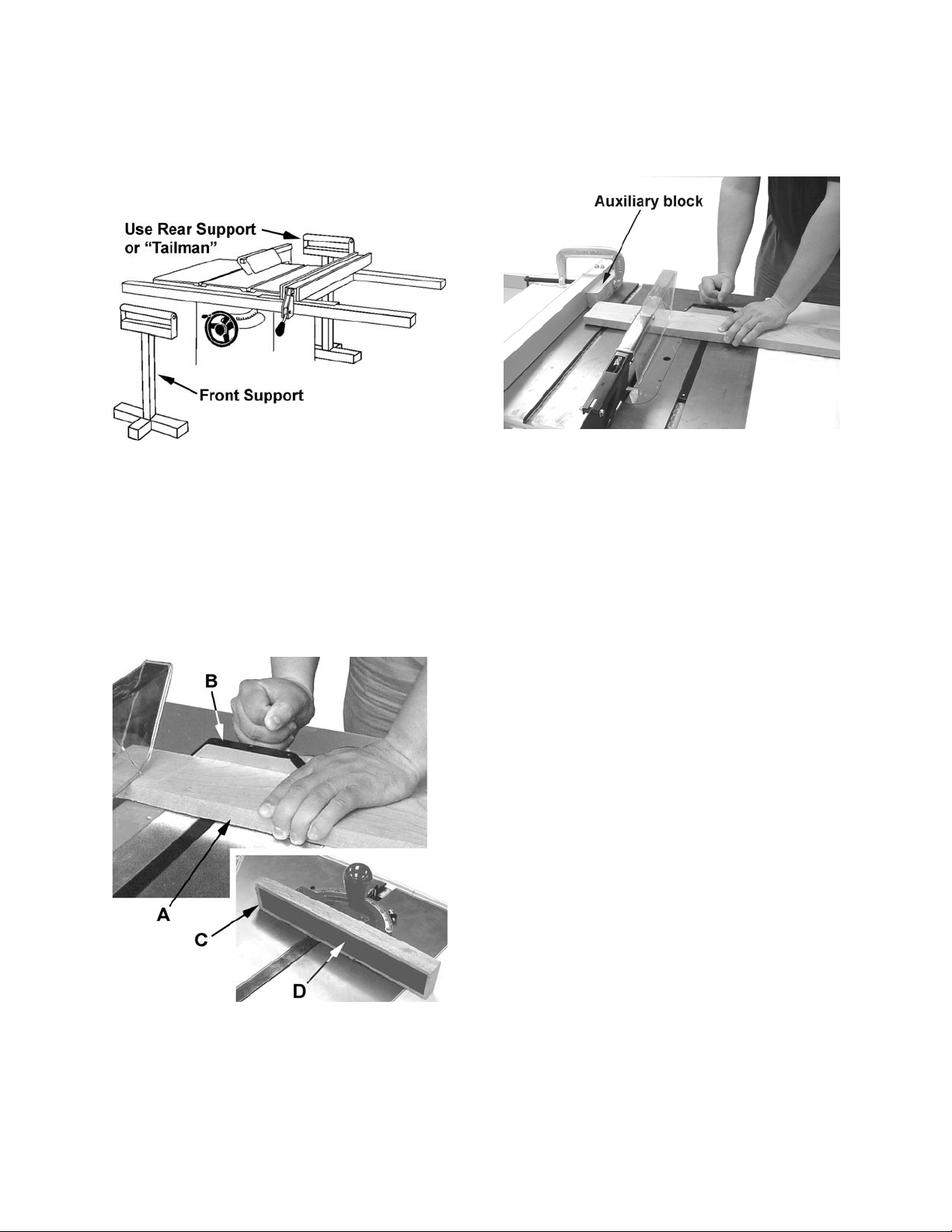

In ripping, use one hand to hold the board down

against the fence or fixture, and the other to

push it into the blade between the blade and the

fence. If the workpiece is narrower than 6" use a

push stick or push block to push it through

between the fence and saw blade (Figure 32).

Never push in a location such that the pushing

hand is in line with the blade. Move the hand

serving as a hold-down a safe distance from the

blade as the cut nears completion. For very

narrow ripping where a push stick cannot be

used, use a push block or auxiliary fence.

Always push the workpiece completely past the

blade at the end of a cut to minimize the

possibility of a kickback.

23

Figure 32

Page 24

When ripping long boards, use a support at the

front of the table, such as a roller stand, and a

support or "tailman" at the rear as shown in

Figure 33.

Have the blade extend about 1/8" above the top

of the workpiece. Exposing the blade above this

point can be hazardous.

Crosscutting should never be done freehand nor

should the fence be used as an end stop unless

an auxiliary block is clamped to the front of the

blade area such that the cutoff piece comes free

of the block before cutting starts (Figure 35).

Figure 33

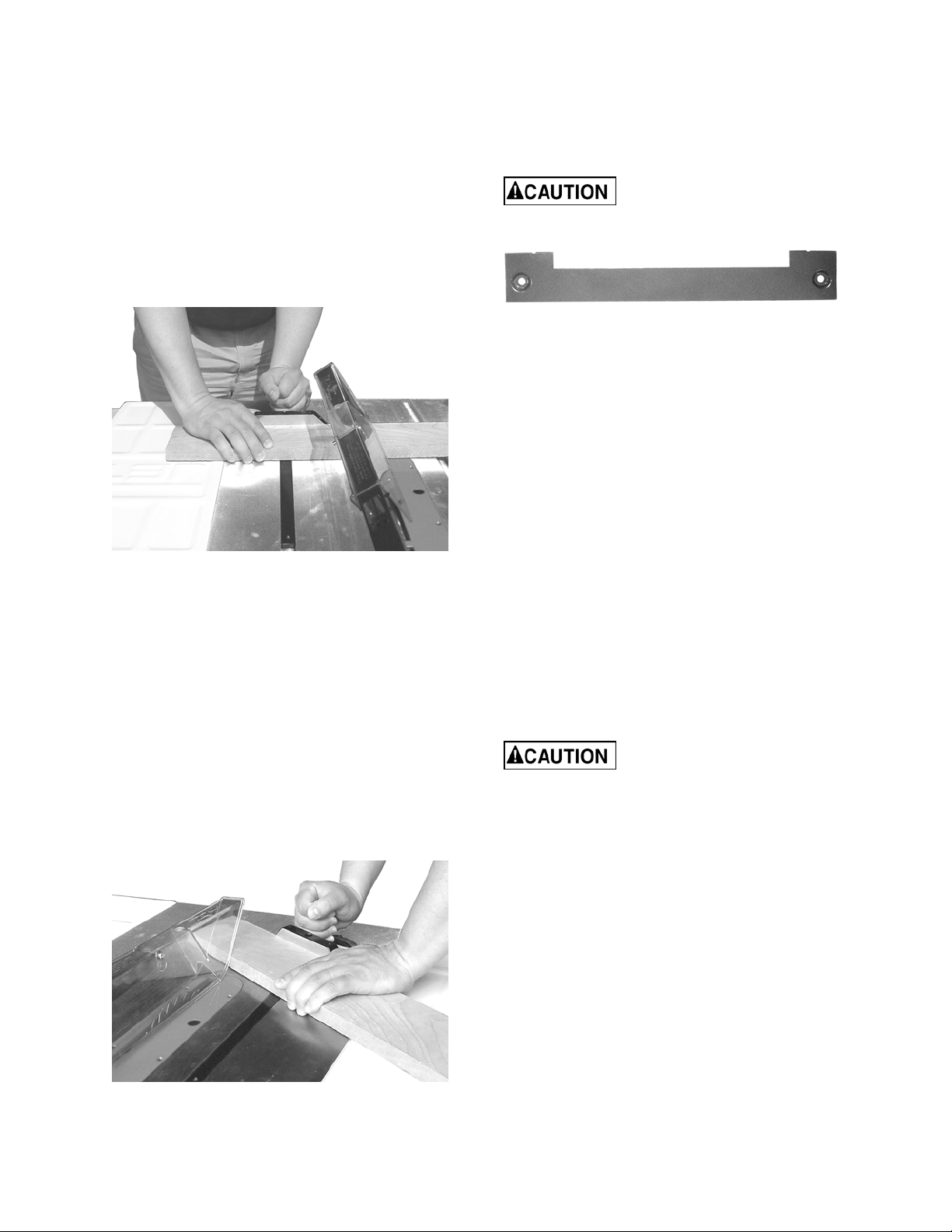

Crosscutting

Crosscutting is where the workpiece (A, Fig. 34)

is fed cross grain into the saw blade using the

miter gauge (B, Fig. 34) to support and position

the workpiece.

To improve the effectiveness of the miter gauge

in crosscutting, mount an auxiliary wooden

extension face (C, Fig, 34) with a glued-on strip

of sandpaper (D, Fig. 34) to the miter gauge.

Length stops should not be used on the free end

of the workpiece in the cutoff area.

Do not crosscut workpieces shorter than 6".

Before starting a cut, be sure the miter gauge is

securely clamped at the desired angle. Hold the

workpiece firmly against the table and back

against the miter gauge. Always use the saw

guard and splitter and make sure the splitter is

properly aligned.

For 90 degree crosscutting, most operators

prefer to use the left-hand miter gauge slot.

When using it in this position, hold the workpiece

against the gauge with the left hand and use the

right hand to advance the workpiece. When

using the right hand slot for miter and compound

crosscutting so that the blade tilts away from the

gauge, the hand positions are reversed.

When using the miter gauge, the workpiece

must be held firmly and advanced smoothly at a

slow rate. If the workpiece is not held firmly, it

can vibrate causing it to bind on the blade and

dull the saw teeth.

Figure 35

Provide auxiliary support for any workpiece

extending beyond the table top with a tendency

to sag and lift up off the table.

Have the blade extend about 1/8" above the top

Figure 34

of the workpiece. Exposing the blade above this

point can be hazardous.

24

Page 25

Bevel and Miter Operations

Bevel Cut – A bevel cut is a special type of

operation where the saw blade is tilted at an

angle less than 90 degrees to the table top

(Figure 36). Operations are performed in the

same manner as ripping or crosscutting except

the fence or miter gauge should be used on the

right-hand side of the saw blade to provide

added safety in avoiding a binding action

between the saw blade and the table top. When

beveling with the miter gauge, the workpiece

must be held firmly to prevent creeping.

Figure 36

Crosscut – Crosscuts made at an angle to the edge of the workpiece are called miters (Figure 37). Set the miter gauge at the required angle, lock the miter gauge, and make the cut the same as a normal crosscut except the workpiece must be held extra firmly to prevent creeping.

Note: When making compound miters (with

blade tilted) use the miter gauge in the right

hand slot to provide more hand clearance and

safety.

Have the blade extend only 1/8" above the top of

the workpiece. Exposing the blade above this

point can be hazardous.

Dado Cutting – Dadoing is cutting a wide groove into a workpiece or cutting a rabbet along the edge of a workpiece. A dado insert, shown in Figure 38, is necessary for this type of operation.

Do not use the standard table

insert for dadoing operations.

Figure 38

The process of cutting 1/8" to 1/2" grooves in

workpieces is accomplished by the use of a

stacked dado blade set or an adjustable type

blade mounted on the saw arbor. By using

various combinations of the stacked dado

blades, or properly setting the dial on an

adjustable blade, an accurate width dado can be

made. This is very useful for shelving, making

joints, tenoning, etc. The guard, splitter, and

anti-kickback pawls supplied with the saw

should be used for all cutting operations where

they can be used. When performing operations

where the guard can not be used, as in some

dadoing operations, alternative safety

precautions should be taken. These include

push sticks, feather boards, filler pieces, fixtures,

jigs and any other appropriate device that can

be utilized to keep operator's hands away from

the blade. Upon completion of the operation

requiring removal of the guard, the entire guard

assembly must be placed back on the machine

in its proper working order.

Never use a dado head in a

tilted position. Never operate the saw without

the blade guard, splitter and anti-kickback

pawls for operations where they can be

used.

Dust Collection

If your saw is equipped with a dust shroud, a

dust collection or vacuum system (not included)

should be used during operation. The port on

the dust shroud can accommodate 2.5-inch or

4-inch hoses (Figure 39).

The dust shroud should be checked and cleaned

often to remove dust and chips in order to

prevent blockage from buildup.

Figure 37

25

Page 26

Figure 39

Safety Devices

Feather Board

The feather board (Figure 40) should be made

of straight grain hardwood approximately 1" thick

and 4" to 8" wide depending on the size of the

machine. The length is developed in accordance

with intended use. Feather boards can be

fastened to the table or rip fence by use of

C-clamps. If this method of fastening is used,

provide slots in the feather board for adjustment.

(The illustration shows a method of attaching

and use of the feather board as a vertical comb.

The horizontal application is essentially the

same except that the attachment is to the table

top.)

Push Stick

A push stick is provided with this saw and

should be used as an added level of safety for

the operator.

Filler Piece

A filler piece (Figure 41) is necessary for narrow

ripping and permits the blade guard to remain on

the machine. It also provides space for the safe

use of a push stick.

Figure 40

Figure 41 – Filler Piece

Maintenance

Always disconnect power to

the machine before performing maintenance.

Failure to do this may result in serious

personal injury.

Cleaning

Clean the 708315 Table Saw according to the

schedule below to ensure maximum

performance.

Note: The following maintenance schedule

assumes the saw is being used every day.

Daily:

Clean pitch and resin from the saw blade.

Weekly:

Clean motor housing with compressed air.

Wipe down the table surface, grooves and

fence rails with a dry silicon lubricant.

26

Page 27

Lubrication

Miscellaneous

Lubricate the areas indicated below every 12

months.

Lubricate blade angling trunnions with 6 or 7

drops of light machine oil.

Lubricate the blade height trunnion with 6 or

7 drops of light machine oil.

Check all adjustments after lubricating.

Troubleshooting

Symptom Possible Cause Correction

Low voltage. Check power line for proper voltage. Motor will not start

Open circuit in motor or loose

connection.

Motor will not start: fuses

or circuit breakers blow.

Motor stalls resulting in

blown fuses or tripped

circuit.

Machine slows when

operating.

Loud, repetitious noise

coming from machine.

Blade is not square with

the miter slot or fence is

not square to the blade.

Blade does not reach 90

degrees.

Short circuit in line cord or plug. Inspect cord or plug for damaged insulation

Short circuit in motor or loose

connections.

Incorrect fuses of circuit breakers in

power line.

Motor overloaded. Reduce load on motor. Motor overheats.

Air circulation through the motor

restricted.

Short circuit in motor or loose

connections.

Low voltage. Correct the low voltage conditions.

Incorrect fuses of circuit breakers in

power line.

Motor overloaded. Reduce load on motor.

Applying too much pressure to

workpiece.

Pulley setscrews or keys are missing or

loose.

V-belt is defective. Replace V-belt.

Blade is warped. Replace saw blade.

Table top is not parallel to the blade. Adjust table parallel to the blade.

Fence is not parallel to the blade. Adjust fence parallel to the blade.

90 degree stop bolt is out of adjustment. Adjust the 90 degree stop bolt.

Table out of alignment. Align the table.

Blade position is incorrect. Adjust the blade position.

Always be aware of the condition of your

machine. Routinely check the condition of the

following items and repair or replace as

necessary:

Mounting bolts

Power switch

Saw blade

Blade guard

Inspect all lead connections on motor for loose

or open connections.

and shorted wires.

Inspect all connections on motor for loose or

shorted terminals or worn insulation.

Install correct fuses or circuit breakers.

Clean out motor to provide normal air

circulation.

Inspect connections on motor for loose or

shorted terminals or worn insulation.

Install correct fuses or circuit breakers.

Feed workpiece slower.

Inspect keys and setscrews. Replace or tighten

if necessary.

Parts

Ordering Replacement Parts

To order parts or reach our service department, call 1-800-274-6848 between 7:30 a.m. and 5:30 p.m.

(CST), Monday through Friday. Having the Model Number and Serial Number of your machine available

when you call will allow us to serve you quickly and accurately.

27

Page 28

Motor/Trunnion – Parts List

Index No. Part No. Description Size Qty

1 ...............708315-1..................Motor ................................................................... .................................... 1

2 ...............708315-2..................Brush Assembly................................................... .................................... 2

3 ...............708315-3..................Motor Sheave....................................................... .................................... 1

4 ...............708315-4..................Retaining Ring ..................................................... ....................................1

5 ...............708315-5..................Key....................................................................... 3x6.5x16 .................... 1

6 ...............TS-1490011 .............Hex Cap Screw .................................................... M8x12 .........................1

7 ...............TS-1550061 .............Flat Washer..........................................................M8 ............................... 1

8 ...............708315-8..................Arbor Sheave ....................................................... .................................... 1

9 ...............708315-9..................Belt....................................................................... .................................... 1

10 .............TS-2286252 .............Pan Head Screw .................................................. M6x25 ......................... 1

11 .............TS-1540041 .............Hex Nut ................................................................M6............................... 7

12 .............BB-6002Z.................Bearing................................................................. 6002Z ......................... 1

13 .............708315-13 ................Arbor Support....................................................... .................................... 1

14 .............708315-14 ................Arbor Shaft ........................................................... .................................... 1

15 .............TS-1503111 .............Socket Head Cap Screw...................................... M6x50 ......................... 2

16 .............BB-6003Z.................Bearing................................................................. 6003Z ......................... 1

17 .............TS-1532042 .............Pan Head Screw .................................................. M4x12 ......................... 3

18 .............708315-18 ................Cover Plate .......................................................... .................................... 1

19 .............708315-19 ................Arbor Flange ........................................................ .................................... 1

20 .............708315-20 ................Saw Blade ............................................................10”x36T....................... 1

21 .............708315-21 ................Arbor Collar .......................................................... .................................... 1

22 .............708315-22 ................Arbor Nut.............................................................. .................................... 1

23 .............TS-1503081 .............Socket Head Cap Screw...................................... M6x35 ......................... 2

24 .............TS-1551041 .............Lock Washer ........................................................M6............................... 4

25 .............TS-1550041 .............Flat Washer.......................................................... M6............................... 4

26 .............TS-1482051 .............Hex Cap Screw .................................................... M6x25 ........................ 1

27 .............TS-2236801 .............Socket Head Cap Screw...................................... M6x80 ......................... 1

28 .............708315-28 ................Motor Bracket....................................................... .................................... 1

29 .............708315-29 ................Spacer.................................................................. .................................... 1

30 .............708315-30 ................Spacer.................................................................. .................................... 1

31 .............708315-31 ................Shaft Support ....................................................... .................................... 1

32 .............708315-32 ................Nut........................................................................M10 ............................ 4

33 .............TS-1550071 .............Flat Washer.......................................................... M10............................. 1

34 .............708315-34 ................Special Washer .................................................... .................................... 1

35 .............708315-35 ................Spacer.................................................................. .................................... 2

36 .............TS-1503061 .............Socket Head Cap Screw...................................... M6x25 ......................... 2

37 .............708315-37 ................Bracket ................................................................. .................................... 1

38 .............TS-2284082 .............Pan Head Screw .................................................. M4x8 ........................... 2

39 .............TS-1550021 .............Flat Washer.......................................................... M4............................... 2

40 .............TS-1551021 .............Lock Washer ........................................................M4............................... 2

41 .............708315-41 ................Roll Pin................................................................. M3x18 ......................... 1

42 .............708315-42 ................Raising Shaft........................................................ .................................... 1