Page 1

OWNER’S MANUAL

XACTA FENCE II™ Commercial 30/50

JET EQUIPMENT & TOOLS, INC. P.O. BOX 1349 253-351-6000

A WMH Company Auburn, WA 98071-1349 Fax 253-939-8001

www.jettools.com e-mail jet@jettools.com M-708950X 3/01

Page 2

Important Information

2-YEAR JET offers a two-year limited

LIMITED WARRANTY warranty on this product

REPLACEMENT PARTS

Replacement parts for this tool are available directly form JET Equipment & Tools.

To place an order, call 1-800-274-6848. Please have the following information ready:

1. Visa, MasterCard, or Discover Card number

2. Expiration date

3. Part number listed within this manual

4. Shipping address other than a Post Office box.

REPLACEMENT PART WARRANTY

JET Equipment & Tools makes every effort to assure that parts meet high quality and durability

standards and warrants to the original retail consumer/purchaser of our parts that each such part(s) to be

free from defects in materials and workmanship for a period of thirty (30) days from the date of purchase.

PROOF OF PURCHASE

Please retain your dated sales receipt as proof of purchase to validate the warranty period.

LIMITED TOOL AND EQUIPMENT WARRANTY

JET makes every effort to assure that its products meet high quality and durability standards and warrants to the

original retail consumer/purchaser of our products that each product be free from defects in materials and

workmanship as follows: 2 YEAR LIMITED WARRANTY ON THIS JET PRODUCT. Warranty does not apply to

defects due directly or indirectly to misuse, abuse, ne gligence or accide nts, repairs or alterations outside our

facilities or to a lack of m aintenance. JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED

ABOVE FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN, ANY

IMPLIED WARRANTIES OR MECHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY

NOT APPLY TO YOU. JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR

PROPERY OR FOR INCIDENTAL, CONTINGENT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING FROM

THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT

APPLY TO YOU. To take advantage of this warranty, the product or part must be returned for examination,

postage prepaid, to an authorized service station designated by our Auburn office. Proof of purchase date and an

explanation of the complaint must accompany the merchandise. If our inspection discloses a defect, JET will either

repair or replace the product or refund the purchase price, if we cannot readily and quickly provide a repair or

replacement, if you are willing to accept such refund. JET will return repaired product or replacement at JET’s

expense, but if it is determined there is no defect, or that the defect resulted from causes not within the scope of

JET’s warranty, then the user must bear the cost of storing and returning the product. This warranty gives you

specific legal rights, and you have other rights, which vary, from state to state.

JET Equipment & Tools •••• P.O. Box 1349, Auburn, WA 98071-1349 •••• (253) 351-6000

2

Page 3

XACTA FENCE II™ COMMERCIAL 30/50

Note: This manual also runs through the steps of installing the rails, and extension table.

WARNING

Disconnect the table saw from the power source before attempting any assembly or adjustment!

Failure to comply may cause serious injury!

Contents of the Shipping Containers

1 XACTA FENCE II™

1 Front Rail

1 Rear Rail

1 Guide Rail

3 Black Plastic End Caps

1 Hardware Package

1 Owner’s Manual

1 Warranty Registration Card

Front and Rear Rail Assembly

Note: The hardware should be packed in the

guide rail along with the end caps.

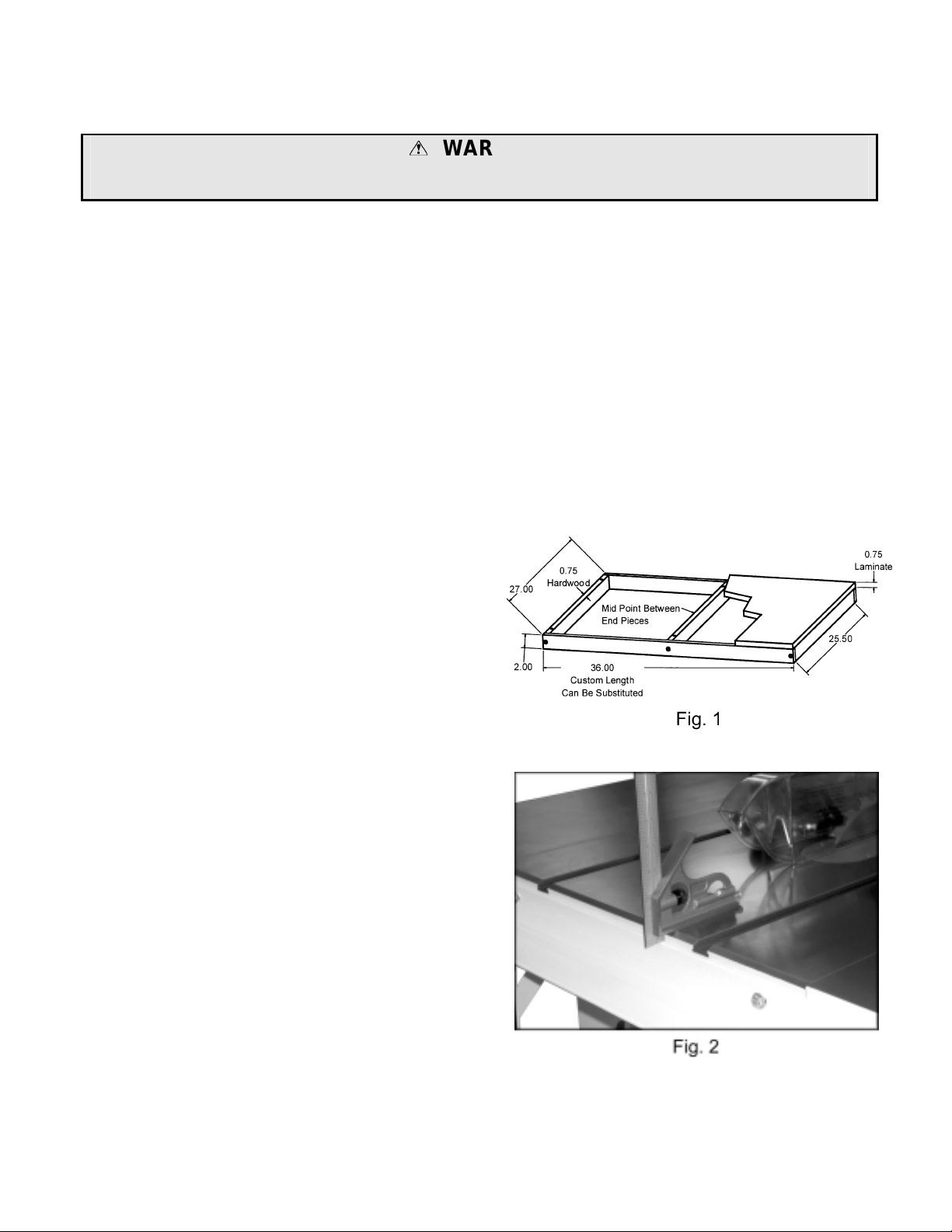

Assembly Note: Depending on the size of the

extension table you are using, you may need to

remove the right side extension wing. You need

to have four bolts attaching the extension table

to the front and rear rails. Use a JET extension

table or one designed and built by the operator.

If you are planning to build a table, see Figure 1

for the dimensions.

Tools Required for Assembly & Adjustment

1 #3 Cross Point Screwdriver

1 7/16” Wrench

1 1/2" Wrench

1 Combination Square & Straight Edge

1 Electric Drill

1 1/4”, 3/16” Drill Bits

2 4”-6” C-Clamps

1 1/4”, 3/16” Allen Wrenches

1. Bolt the front rail to the table (not to the

extension wing at this time) with two 1/4”-20

x 1-1/4” hex cap screws, four 1/4” flat

washers, two 1/4” lock washers and two 1/4”

hex nuts. Tighten just enough to hold the

rail next to the table but keep loose enough

to allow height adjustment.

2. Setting the combination square at 9/16” will

clear the miter gauge slot.

3. Place the combination square on the table

and adjust the rail to approximately 9/16”

below the table surface, see Figure 2.

Note: It is more important to have the

front rail parallel to the table top than

exactly 9/16” below the table top.

4. Tighten hex cap screws.

3

Page 4

Assembly Note: To insure that you have

enough adjustment in the cursor during the final

adjustments, at this time you should bolt the

guide rail to the front rail with two hex cap

screws. Place the fence on the guide rail so

that the cursor lines up at four inches. Measure

from the saw blade to the fence and adjust the

front rail so that you are as close to four inches

as possible. You do not have to adjust the

cursor at this time. Remove the fence and

guide rail and continue with assembly

instructions.

5. Bolt the front rail to the right extension wing

with one 1/4”-20 x 1-1/4” hex cap screw, two

1/4” flat w as her, one 1/4” lock washer, and

one 1/4” hex nut.

6. Place the switch bracket assembly behind

the hole in the left extension wing.

7. Insert a 1/4”-20 x 1-1/4” hex cap screw and

1/4" flat washer through the guide rail,

extension wing, and the switch bracket.

Hold in place with a 1/4" flat washer, 1/4"

lock washer and 1/4" hex nut.

2. Place a leg bracket into the outboard end of

the table.

3. Mark all holes to be drilled.

4. Pre-drill all marked holes with a 3/16” drill

bit approximately 1/2” deep. Do not drill

through the table top or table frame!

5. Attach both legs with supplied wood screws,

seeFigure3.

6. Carefully turn the table over and place in

between the front and rear rail.

7. Use two c-clamps to hold the table in place.

8. Place a straight edge on the saw table and

level the extension table to the saw table.

Raise or lower the adjustable feet on the

extension table legs until the extension table

is level with the saw table. Tighten the cclamps to hold in place.

9. Using the existing holes in the front and rear

rail as a guide (two front and two rear), drill

through the table frame using a 1/4” drill bit.

8. Pushtheswitchbracketupashighas

possible and tighten the hex nut firmly.

9. Bolt the rear rail to the table (not to the

extension wings at this time) with two 5/16”

x 1/2” hex cap screws, and two 5/16” flat

washers. These are larger in diameter than

the other screws in the hardware package.

Note: It is not critical for the rear rail to be

absolutely level. It is, however, important for

the rear rail to clear the miter slots and be level

as possible.

10. Bolt the rear rail to each extension wing with

two 1/4”-20 x 1-1/4” hex cap screws , four

1/4” flat washers, two 1/4” lock washers, and

two 1/4” hex nuts.

11. Tighten nuts.

Note: Mount the extension table between the

front and rear rails before mounting the front

guide rail.

10. Attach extension table to the front and rear

rail with four 1/4”-20 x 1-1/4” hex cap

screws, eight 1/4” flat washers, four 1/4”

lock washers, and four 1/4” hex nuts. This

hardware is supplied with the extension

table.

Extension Table Assembly

1. Place the extension table upside down on

top of the table saw.

4

Page 5

Guide Rail Assembly

1. Bolt the guide rail to the front rail with 1/4-20

x 3/4” hex cap screws 1/4" flat washers and

1/4" lock washers. Center the bolt heads in

the slotted holes of the rail so you will have

some lateral adjustment.

2. Measure from the front of the guide rail to

the front of the tablesaw table in a couple

spots to verify that the guide rail is parallel

to the table. Adjust as needed and tighten.

Fence Assembly and Adjustm ents

1. Thread the handle knob into the cam

assembly.

Note: Fence adjustments should be performed

in the order given.

Level with the Saw Table

Note: You may need to re-adjust the clamping

pressure after aligning the fence.

Clamping Pressure

The XACTA FENCE II™ has been adjusted at

the factory to l ock securely when the lock

handle is pushed down. If adjustment is

needed:

1. Unlock the fence.

2. Remove the fence from the guide rail.

3. Turn the fence over.

4. Adjust the two s et screws (A, Fig. 5) until

the fence is held securely when the lock

handle is pushed down.

1. Place the fence on the table and lock it.

2. View the fence from the left side of the saw.

Look for the space between the table and

the fence bottom to be equal along the

entire length of the fence.

3. If adjustment is necessary, unlock the

fence.

4. Raise or lower two nylon adjustment screws

(A,Fig.4)the same number of turns until

the space between the bottom of the fence

and the table is the same. Care must be

taken to raise or lower the fence on each

side equally or the fence may not be 90° to

the table after the height adjustment is

performed.

Parallel to the Miter Slot

1. Place the fence next to the outside edge of

the right miter slot and lock it.

2. The fence should be even with the miter slot

from front to back.

3. If the fence is not even along the length of

the miter slot, unlock the fence, remove it

and turn upside down.

4. Adjust one of the two set screws (A, Fig. 5)

until the fence is even with the miter slot

edge along its entire length when locked.

5

Page 6

90°°°° to the Table

1. Place the fence on the saw table and lock it.

2. Place a square on the table next to the

fence. The fence should be 90° to the table,

Figure 6.

3. If adjustment is necessary, unlock the

fence, and turn one of the two nylon

adjustment screws (A, Fig. 7) until the fence

is 90° to the table.

4. Lock the fence and check the adjustment

again.

Cursor Adjustment

1. Disconnect the table saw from the power

source.

2. Raise the saw blade above the tabletop.

3. Unlock the fence and slide it to

approximately four inches from the saw

blade.

4. Lock the fence.

5. Measure the distance between the saw

blade and the inside of the fence.

6. Adjust the cursor to read the distance just

measured and tighten the cursor assembly

to the fence.

7. Take a test cut and confirm the adjustment

is correct.

Note: If the cursor does not have enough travel

to give the correct measurement loosen the

guide rail and adjust as needed. If you still do

not get the correct measurement loosen the

front rail and adjust as needed. If you have to

adjust the front rail you will need to go through

the front rail assembly instructions again.

This adjustment must be checked whenever a

different blade is installed.

After installing the XACTA FENCE II™ press

the black plastic end caps into the openings of

the guide rail. There is also an end cap for the

fence, but this should already be installed.

6

Page 7

Parts List for the JET XACTA FENCE II™Commercial 30/50

Index Part

No. No. Description Size Qty.

1..........XF-1................................. Side Plate...................................................... ...................................2

2..........XF2-2W ........................... Fence Body Assembly ................................... ...................................1

3..........XF2-3............................... Pad Set......................................................... ...................................1

4..........XF-4................................. Brass Plated Pan Head Machine Screw.........10-32 x 3/4 ...............12

5..........XF-5................................. Nylon Adjustment Screw................................ ...................................2

8..........TS-0271031..................... Set Screw...................................................... 3/8 x 3/8.....................2

9..........800708950D..................... Cursor........................................................... ...................................1

9A........800708950C..................... Cursor Bracket.............................................. ...................................1

10........TS-081D022..................... Pan Head Phillips Machine Screw.................10-32 x 3/8.................2

11........TS-069204....................... Flat Washer...................................................No. 10.........................4

12........TS-056008....................... Hex Machine Screw Nut................................10-32..........................2

............ TS-081D021..................... Flat Phillips Machine Screw........................... 10-32 x 3/8.................2

13........TS-0640071..................... Nyloc Nut ...................................................... 1/4-20.........................1

14........TS-0050081..................... Hex Cap Bolt................................................. 1/4 x 1-3/4..................1

15........TS-0060081..................... Hex Cap Bolt................................................. 3/8 x 1-3/4..................1

16........TS-0640091..................... Nyoc Nut .......................................................3/8-16.........................1

18........3215301........................... Foot............................................................... ...................................1

19........3076232........................... Locking Cam................................................. ...................................1

20........6430055........................... Knob w/Stud.................................................. ...................................1

21........6813092........................... Spring............................................................ ...................................1

............ XF-EC.............................. Black Plastic End Cap (not shown)................ ...................................3

............ XF2-21W ......................... Front Rail (not shown)................................... 50”..............................1

............ XF2-21-30W .................... Front Rail (not shown) ...................................30”............................ ..1

............ XF2-22W ......................... Rear Rail (not shown).................................... 50”..............................1

............ XF2-22-30W .................... Rear Rail (not shown).................................... 30”..............................1

............ XF-23W ........................... Guide Rail (not shown).................................. 50”..............................1

............ XF-23-30W ...................... Guide Rail (not shown).................................. 30”..............................1

............ XF-24............................... Measuring Tape (not shown).......................... ...................................1

............ XF-HK-N.......................... Hardware Kit (not shown)............................... ...................................1

XF-HK-N Hardware Kit contents:

6.....1/4-20 x 1-1/4” hex cap screws

12...1/4” lock washers

22...1/4” flat washers

6.....1/4-20 hex nuts

1 5/16-18 x 1/2 hex cap screws

2.....5/16” Flat Washers

6.....1/4-20 x 3/4” hex cap screws

The specifications in this manual are given as general information and are not binding. JET Equipment

and Tools reserves the right to effect, at any time and without prior notice, changes or alterations to

parts, fittings, and accessory equipment deemed necessary for any reason whatsoever.

7

Page 8

Parts Breakdown

8

Loading...

Loading...