Page 1

JET 22-44 Pro-3 Drum Sander

Our JET 22-44 Pro-3 Drum Sander quickly became a

favorite of wood workers because of its durability, huge

capacity, ease of use and exceptional surface smoothing

capabilities. In addition to the wide range of sanding grits,

our variable feed rate and exclusive SandSmart™

technology provide unrivaled control over the sanding

process.

The JET 22-44 Pro-3 Drum Sander has the capacity to

handle surprisingly large jobs despite its 52”-tall by 41”long dimensions. The JET 22-44 Pro-3 Drum Sander can

The JET 22-44 Pro-3 Drum Sander

has the power and versatility to make

your shop more efficient.

sand material up to 4”-thick and 44”-wide (2 passes). The

design of the drum and conveyor also mean that it can handle material as short as 2 ¼”long and down to 1/32”-thick! And, we are so sure of the heavy-duty construction and

design that we cover the JET 22-44 Pro-3 Drum Sander with our

5-year warranty!

Tough Structure

The JET 22-44 Pro-3 Drum Sander is built around a rigid

backbone. Massive 3”-diameter, thick walled steel posts provide

the main vertical support for this 385 lb. machine. A specially

engineered cast iron arm supports the drum assembly, insuring

accurate, repeatable sanding. The table and motor are also rigidly

supported on heavy gauge steel brackets.

The wide stance cast aluminum legs keep the JET 22-44 Pro-3

Built around massive steel

columns, the JET 22-44

Pro-3 is as tough as it is

accurate.

Drum Sander exceptionally stable during use. The high quality

casters at the end of each leg feature

smooth rolling, non-marring

polyurethane tires. Each full swivel

caster has a foot operated lever that locks the swivel and wheel.

A full-width hinged shroud around the drum improves safety

while enhancing dust collection. A 4”-diameter port on the

outfeed side of the shroud lets you connect standard dust

collector hose (no adapters needed) to keep the shop clean and

extend the life of the abrasive.

Even the high end, full swivel

locking casters with their

polyurethane tires are standard

equipment.

Page 2

Motors and Switching

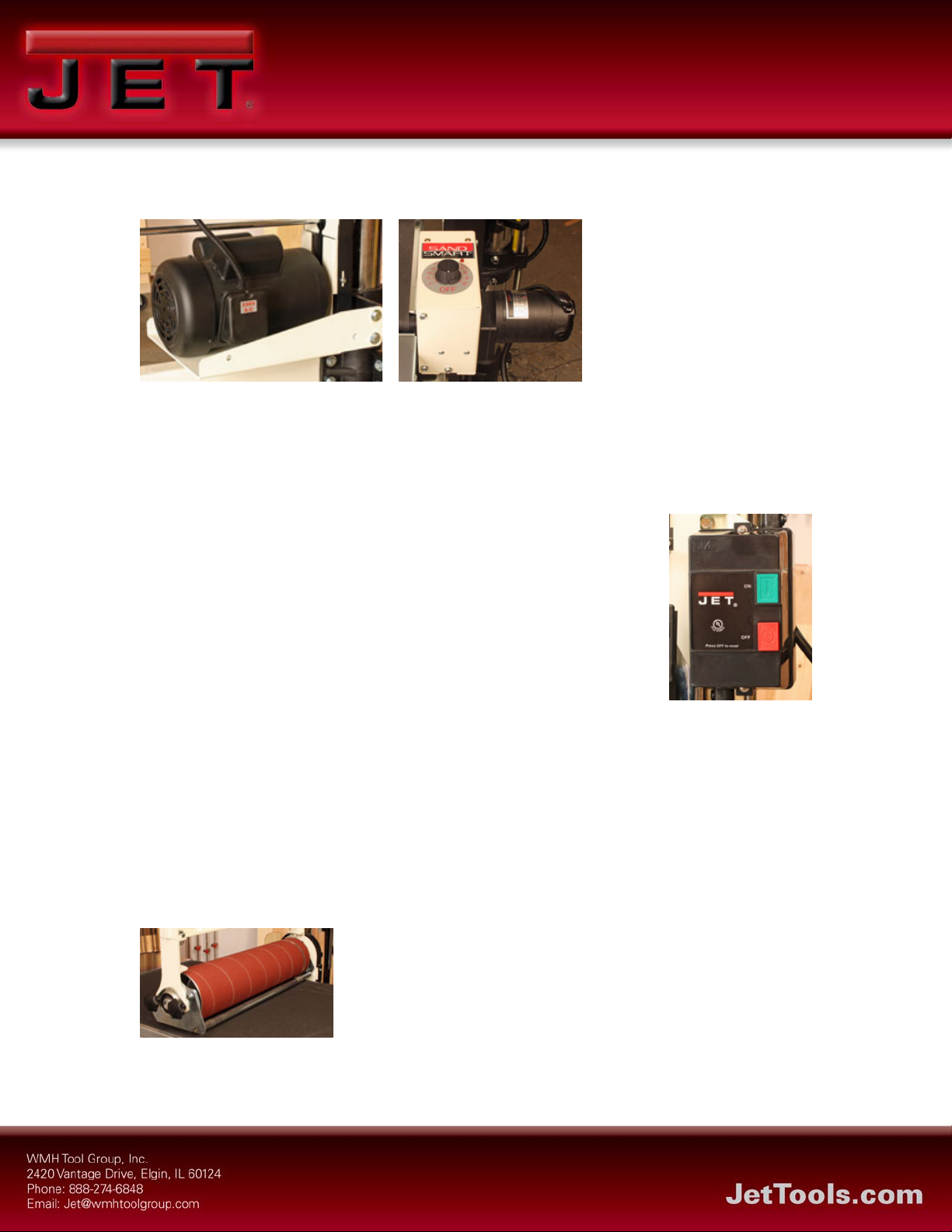

The JET 22-44 Pro-3

Drum Sander uses two

independent motors, one

turning the sanding drum

and the other the conveyor

belt. The larger motor for

the drum produces 3 HP on

The 3 HP primary motor that drives the drum (left) and the 1/30 HP motor that

controls the conveyor (right) make the JET 22-44 Pro-3 more versatile. Using

the separate conveyor motor also allowed adding our exclusive SandSmart

circuitry.

1 phase, 230V (only)

power. This TEFC (totally

enclosed fan cooled) motor

is rated using a continuous

duty cycle to provide the clearest indication of its true power. This continuous duty cycle

design also means the motor will stand up to extended heavy usage.

The conveyor belt is driven by a 1/30 HP DC motor. Using this

special variable speed motor also allowed the development of our

patented SandSmart™ technology discussed in detail later in this

article

Using these two high quality motors means you have plenty of

power for even the toughest jobs. They also provide the flexibility

and control you need for precision sanding.

The JET 22-44 Pro-3 Drum Sander is controlled with an industrial

style magnetic switch that protects the motor from potentially

harmful power fluctuations. This switch also has a safety function

because it prevents the machine from restarting on its own should

the power go out and then come back on unexpectedly. Once the

The industrial style

magnetic switch protects

the motor from

variations in the

electrical power and you

from unexpected restarts

should the power go out

and then come back on.

power goes out, the operator must push the On button to restart the

JET 22-44 Pro-3 Drum Sander.

Precision Drum

The JET 22-44 Pro-3 Drum Sander is built around our

heavy-duty 5”-diameter aluminum drum that has been

precision machined to insure straightness and balance. The

drum spins at 1600 RPM and is adjustable in height and

downward pressure to virtually eliminate snipe. That insures

The precision machined drum

insures sanding very flat, smooth

surfaces without vibration.

the smoothest possible surface and maximum abrasive life.

The 22" wide drum is supported on both ends by sealed,

Page 3

permanently lubricated ball bearings. The drum assembly is

mounted in a truss-like carriage arm for superior strength and

rigidity. This system also makes aligning the drum to the table

surface easy. That means consistent performance with minimal

adjusting by the operator.

The drum is equipped with patented abrasive take-up fasteners that

make changing the abrasive strips fast and easy. We also include

our exclusive Tuf Tool™ that makes operating the take-up

Our special Tuf Tool

makes changing abrasive

strips easier.

fasteners a no-strain event.

Table and Feed

The generous 23”-wide

by 30 ¾”-long

conveyor platform is

augmented by the

included 10”-deep by

The expansive conveyor surface is expanded even further with the included steel

extension tables. (left) Easy to use conveyor belt tension adjusters (right) even have

the necessary wrench captured on the bolt!

24”-wide steel

extension tables. That

provides 51” of overall

support that handles

the big jobs with ease.

The conveyor belt features easy to use tension and tracking adjusters. Each adjuster has a

built-in wrench captured on the threaded shaft so you never have to look for a tool to

make a small adjustment! Plus, our patented conveyor belt TRACKERS™ dramatically

reduce the need for manual belt adjustments.

The specially designed, no-give conveyor belt moves over a

precision flattened steel bed so the wood is always on a true

surface. That means super smooth, consistent sanding for the

best possible results.

The JET 22-44 Pro-3 Drum Sander uses a separate feed

motor to drive the conveyor belt. That insures consistency but

also allowed us to develop our EXCLUSIVE SandSmart™

variable-feed control system. This infinitely variable feed rate

control operates between 0 to 10 feet per minute so you can

use the best rate for the job. The SandSmart™ technology

also prevents straining the machine by sensing the load on the

conveyor and automatically reducing the feed rate to help

Our exclusive SandSmart

circuitry protects against

overloads by automatically

slowing the feed rate to prevent

damage to the wood, abrasive

strip or motor.

prevent burning of the wood or the abrasive.

Page 4

Table Height

A large, 7 ¾”-diameter cast-iron handwheel

adjusts the table height within its 4” range.

Each full turn of the handwheel changes

table height by 3/32" for ultra precise

sanding thickness control. The handwheel

The large handwheel (left) makes table height changes

effortless. The tool-free depth stop (right) makes

sanding several boards to a precise thickness virtually

automatic.

operates a screw and gear drive that controls

both ends of the table to keep it level for

maximum sanding accuracy.

An easy to use depth stop is built onto the

support post and makes sanding many boards to a specific thickness fast, easy and very

accurate. The depth stop is tool free so you can concentrate on sanding rather than finding

a wrench!

Digital Read Out

The DRO (digital read out) comes pre-installed on the JET 22-44 Pro3 Drum Sander (#649600). This digital measuring device makes

setting ultra precise sanding depths, or returning to one with 0.01”

resolution simple and easily repeatable. The DRO can be set to

display either inch or mm readings with the push of a button. The

battery as well as a spare is supplied with the machine.

The DRO has several distinct functions. Probably the most commonly

used function is the “Absolute Measurement”. Sand a piece of wood

on the JET 22-44 Pro-3 Drum Sander, measure that thickness with

digital calipers and then set the DRO to that dimension. You can then

sand other pieces to match that thicknesses quickly with exceptional

accuracy.

The included DRO

has several functions,

not the least of which

is allowing ultra

precise table to drum

settings.

The DRO also has a “Relative Measurement” that can show the amount of material to be

removed from a previously sanded board. “Hold” records a setting so you can return to it

later. “TOL” (tolerance) allows setting upper and lower tolerance limits. All of the

functions and their setting procedures are fully described in the instruction manual.

A gamut of great features including an extra powerful 3-HP motor, large capacity

conveyor with infeed and outfeed tables and the precision of a dead flat table, balanced

aluminum sanding drum backed with a DRO height adjustment system. As well the JET

22-44 Pro-3 comes equipped to be mobile with heavy duty double locking casters. The

JET 22-44 Pro-3 is a great machine for anyone tackling jobs that require large pieces to

be sanded from the hobbyist woodworker to the small job shop.

Loading...

Loading...