Page 1

This Manual is Bookmarked

Operating Instructions and Parts Manual

Drum Sander

Model 22-44 Pro

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-638003

Ph.: 800-274-6848 Revision A 4/06

www.wmhtoolgroup.com Copyright © WMH Tool Group

Deluxe model shown (with caster s and i nfeed/outf eed tables)

Page 2

WARRANTY AND SERVICE

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of

these WMH Tool Group Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check

with your local WMH Tool Group distributor, or visit jettools.com.

WARRANTY

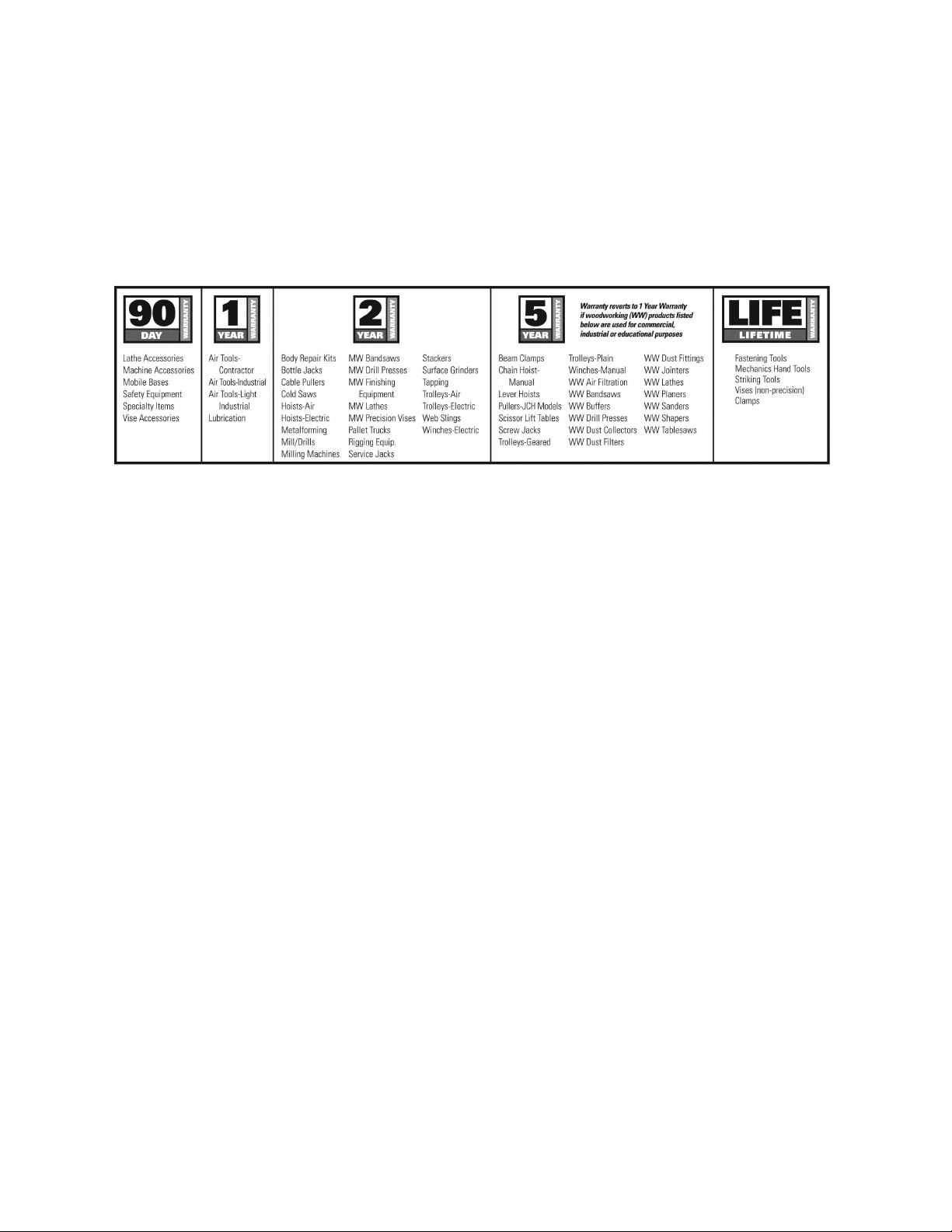

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS C OVERE D?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR

EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND

FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY,

OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE

OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMI TATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as ge neral information

and are not binding. Members of WMH Tool Group reserve the right to effect at any tim e, without prior notice, those

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

® branded products are not sold in Canada by WMH Tool Group.

JET

® t ools. For the name of an Authorized Service Center in

2

Page 3

Table of Contents

Table of Contents....................................................................................................................................3

Warning...................................................................................................................................................4

Introduction..............................................................................................................................................6

Specifications..........................................................................................................................................6

Features and Terminology....................................................................................................................... 7

Unpacking............................................................................................................................................... 8

Contents of the Shipping Container......................................................................................................8

Assembly.................................................................................................................................................9

Install Stand Legs................................................................................................................................. 9

Table Support Sc r ews ..........................................................................................................................9

Install Handwheel...............................................................................................................................10

Install Conveyor Table........................................................................................................................10

Infeed and Outfeed T ables (Optional Accessory )................................................................................10

Leveling the Sander ........................................................................................................................... 11

Dust Collection...................................................................................................................................11

Installing Abrasives............................................................................................................................12

Grounding Instructions...........................................................................................................................14

Extension Cords.................................................................................................................................15

Adjustments...........................................................................................................................................15

Switch Lockout...................................................................................................................................15

Dust Cover.........................................................................................................................................15

Table Height Control ..........................................................................................................................15

Depth Gauge Calibration....................................................................................................................17

Drum Alignment.................................................................................................................................17

Conveyor Belt T ensi on and Trac k ing..................................................................................................19

Trackers.............................................................................................................................................20

Conveyor Belt Replacement...................................................................................................... .........20

Tension Roller Adjustment.................................................................................................................. 21

Adjusting Table Supports....................................................................................................................21

Replacing V-Belt................................................................................................................................22

Rotating Drum Bearings.....................................................................................................................22

Replacing Drum Bearings................................................................................................................... 23

Operation...............................................................................................................................................24

Basic Operati ng P r oc edur e.................................................................................................................24

Setting Depth of Cut...........................................................................................................................24

Establishi ng P r oper Dr um Hei ght........................................................................................................24

Selecting Feed Rates......................................................................................................................... 24

Tips for Maximum Pe rformance..........................................................................................................24

Maintenance..........................................................................................................................................26

Tracker Kit (98- 0080).............................................................................................................................27

Abrasives...............................................................................................................................................28

Optional Accessories .............................................................................................................................33

Replacement Parts................................................................................................................................33

Stand Assembly .................................................................................................................................34

Parts List: Stand A ssembly.................................................................................................................35

Drum Head Assembly.........................................................................................................................36

Parts List: Drum Head Assembly........................................................................................................37

Conveyor and Motor Assem bly...........................................................................................................38

Parts List: Conveyor and Motor Assembly .......................................................................................... 39

Infeed and Outfeed T ables (98- 2201) – Optional Accessory ...............................................................40

Electrical Connections ........................................................................................................................... 41

3

Page 4

Warning

1. Read and understand thi s ent ire manual before attempting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This sander is designed and int ended for use by proper ly t rained and experi enced personnel onl y. If

you are not f amiliar wit h the proper and safe operati on of a sander, do not use unt il proper training

and knowledge have been obtained.

5. Do not use this sander for other than i ts intended u se. If used f or other pur poses, WM H Tool Group

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Always wear appr oved safety glasses/face shields while usi ng this sander. Everyday ey eglasses only

have impact resistant lenses; they are not safet y gl asses.

7. Before operati ng this sander, rem ove tie, ri ngs, watches and other j ewelry, and r oll sleeves up past

the elbows. Rem ove all l oose clothing and confine long hair. Non-slip footwear or anti-skid floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry pr oducts.

• Arsenic and chromium from chemically treated lumber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not oper ate this machine while tir ed or under t he influenc e of drugs, alcohol or any medic ation.

11. Mak e c er tain the switch is in the OFF position before connecting the machine to the power supply.

12. Mak e c ertain the machine is properl y grounded.

13. Mak e all machine adjustments or maintenance with the machine unplugged f r om the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Make sure the sander is firmly secured to the stand or work tabl e before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, br eakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged shoul d

be properly repaired or replaced.

18. Pr ov ide for adequate space surroundi ng work area and non-glare, ov er head lighting.

19. Keep the floor around the machi ne cl ean and free of scrap material, oil and grease.

20. Keep v isitors a safe distance from the work area. Keep children away.

4

Page 5

blahblahblah

21. Mak e y our workshop child proof wit h padloc ks, master switches or by removing starter keys.

22. Giv e your work undivi ded attention. Looking ar ound, carryi ng on a conversation and “ horse-play” ar e

careless acts that can r esul t in serious injury.

23. M aintain a balanc ed stance at all t imes so that you d o not fall or lean against movi ng parts. Do not

overreach or use exc essive force to perform any machine operation.

24. S tand to one side of the conv eyor and m ake sure no one else is standing i n line with t he convey or

while feeding i nto the machine. Should a part sli p while being fed, it may exit t he machine at a high

rate of speed and can cause injuries to anyone standing dir ec tly in front of the infeed.

25. Use the right tool at the corr ect speed and f eed rat e. Do not forc e a tool or att achment to do a job for

which it was not designed. T he ri ght tool will do the job better and saf er.

26. Use recommended accessories; improper accessories m ay be hazardous.

27. Maintain tools with care. Keep abrasives clean for the best and safest performance. Follow

instructions for lubricating the machine and changing accessories.

28. Always feed stock against the rotation of the drum.

29. Keep your hands clear when feeding parts onto the conveyor. The part will be forced down as it

begins to feed, causi ng a pinc hing ac tion bet ween the part and the c onv eyor bed. Nev er reach i nto a

running mac hine. Turn off sander and disconn ect f rom power befor e att empting to ret riev e parts fr om

beneath the drum.

30. Turn of f the m achine and discon nect f rom power bef ore cleani ng. Use a bru sh or com pressed air to

remove chips or debris — do not use your hands.

31. Do not stand on the machine. Serious injur y c ould oc c ur if the mac hine tips over.

32. Never leave the machine r unning unattended. Turn t he power off and do not leave the machine until it

comes to a complete stop.

33. Remove loose items and unnecessary work pi ec es from the area before starting the machine.

Familiariz e y our self with the following safety noti c es used in this manual:

This means that if precautions are not heeded, it may result in mi nor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by W MH Tool Group cov ering the safe oper ation and mai ntenance procedure s

for a JET Model 22-44 Pro Drum Sander. This manual contains instructions on installation, safety

precautions, gener al oper ati ng procedur es, mai ntenance i nstructi ons and parts breakdo wn. Thi s mac hine

has been designed and con structed t o provide year s of troubl e free operation if used in accordance wi th

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local supplier or WMH Tool Group. WMH Tool Group can also be reached at our web site:

www.wmhtoolgroup.com.

Specifications

Model Number............................................................................................................................22-44 Pro

Stock Number................................................................................................................................ 638003

Maximum Sandi ng Widt h (i n.) ...............................................................................................44 (2 passes)

Minimum Sanding Length (in.) ...........................................................................................................2-1/4

Maximum Sandi ng Thick ness (in.)............................................................................................................4

Minimum Sanding Thickness (in.) .......................................................................................................1/32

Overall Dimensions (H x W x D)(in.)........................................................................................52 x 41 x 41

Drum Dimensions (diam. x L)(in.)..................................................................................................... 5 x 22

Drum Speed (RPM) ........................................................................................................................... 1600

Drum Bearing Diameter (in.)....................................................................................................................1

Dust Port Diameter (in.)...........................................................................................................................4

Minimum Dust Collection Capacity (CFM)............................................................................................600

Conveyor Motor...................................................................... 43 in.-lbs. Torque, 1/30 HP Direct Drive DC

Conveyor Variable Feed Rate (FPM) ..............................................................................................0 to 10

Motor........................................................................................................TEFC, 1-3/4HP, 1Ph, 110V only

Net Weigh t (lb s.)..................................................................................................................................350

The above specifications were current at the time this manual was publi shed, but because of our policy of

continuous im provement, WMH Tool Group reserv es the right to change specif ications at any tim e and

without pri or notic e, without incurring obligations.

6

Page 7

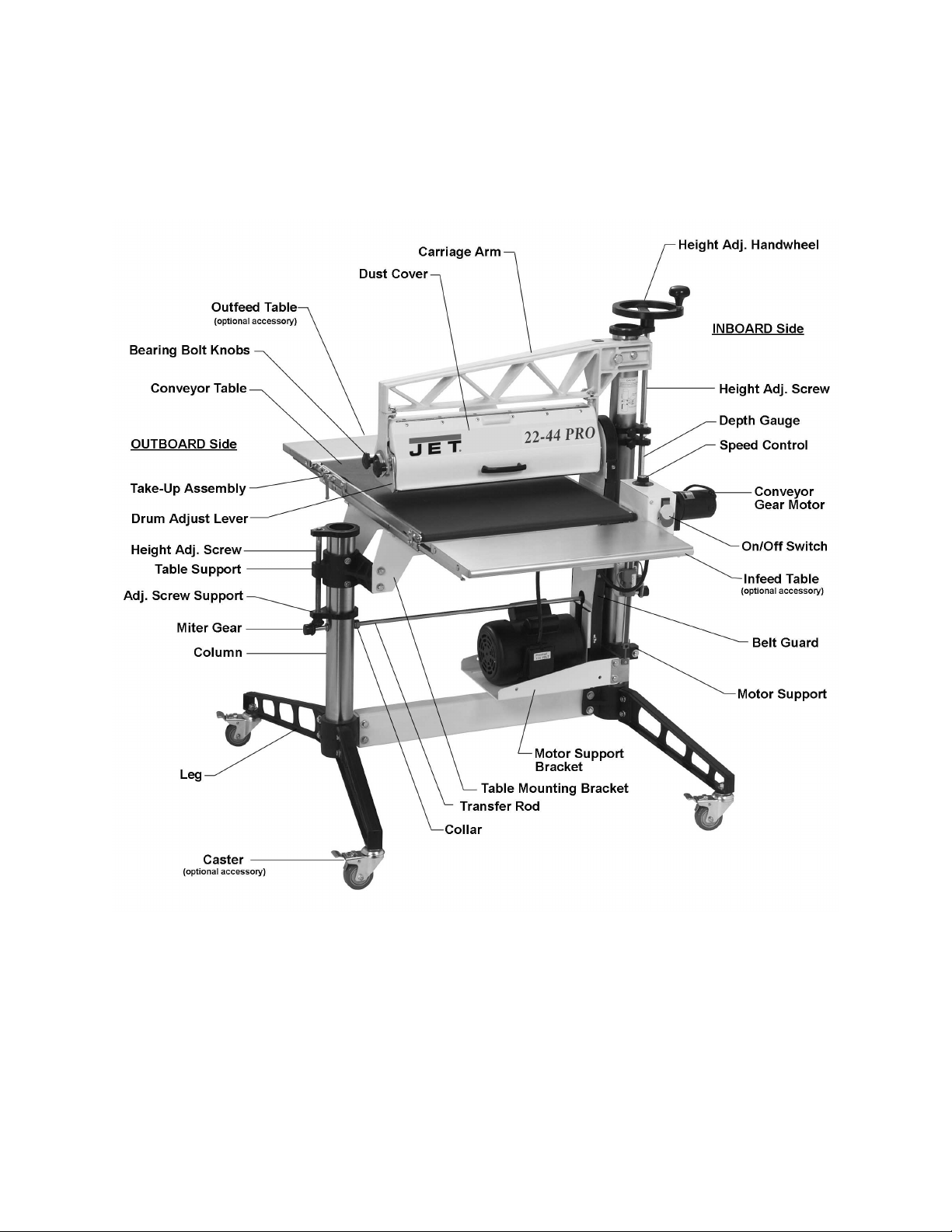

Features and Terminology

The illustrat ion below shows the major components and f eatures of the 22-44 Pro Sander. These are

referenced throughout the manual and will help t o familiar iz e y ou with the operation and functions of the

machine.

Figure 1

7

Page 8

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until the Drum

Sander is assembled and running properly.

Compare the cont ent s of y our cont ainer wit h the

following parts list to make sure all parts are

intact. Mi ssing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Container

1 Drum Sander with stand – A

1 Conveyor Bed Assembl y – B

2 Assembly Fixtur es – C

1 Handwheel – D

1 Handwheel Knob – E

4 Legs – F

4 Leg Glides – G

8 Hex Head Bolts, 3/8”x1- 1/2” – H

4 Hex Head Bolts, 3/8”x1” – J

12 Flanged Lock Nuts, 3/8” – K

20 Flat Washers, 3/8” – L

8 Hex Nuts, 3/8” – M

2 Drum Alignment Templates – N

2 Open-end Wrenches, 9/16”-1/2” – O

2 Hex Wrenches, 4mm and 1/8” – P

1 TufTool – R

1 Owner's Manual (not shown)

1 Warranty Car d (not shown)

Figure 2

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mpl y may cause seri ou s injury.

8

Page 9

Assembly

Tools required for assembly:

Hoist, forklift, or one or more assistants

Wrenches – 9/32”, 1/2” , 9/16”

Hex wrenches – 4mm, 1/8”

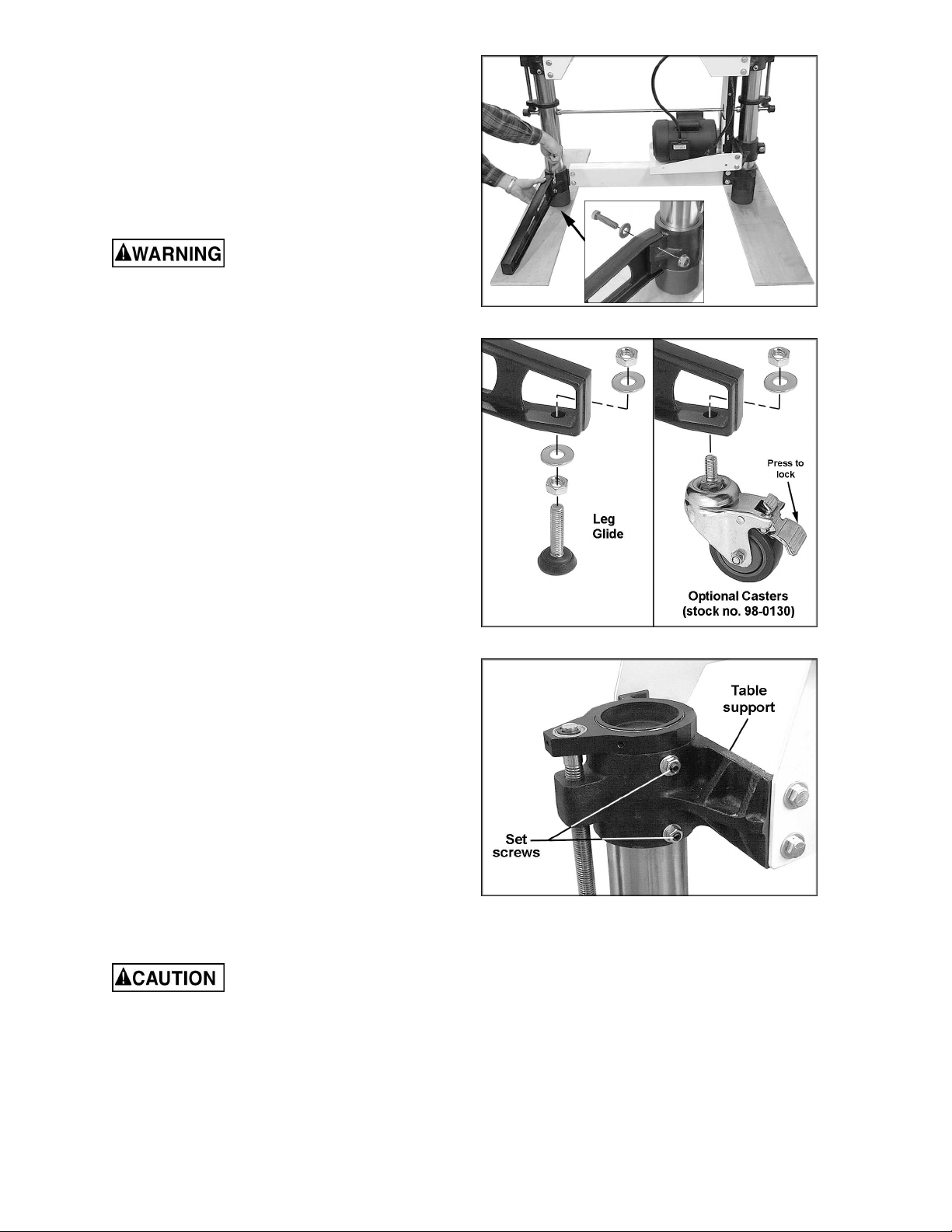

Install Stand Legs

The sander is heavy; use

caution when lift in g.

1. Raise the sander from the floor using a

forklift, hoist or an assistant. (Place hoist

straps through the c ar r iage arm or below the

table mounting brackets. If using a forklift,

fork below the tabl e m ount ing br acket s. See

Figure 1, page 7.)

2. Position the assembly fixtures below the

columns so that the wider part of the

plywood faces outward (Figure 3). Lower

the sander columns into the assembly

fixtures.

3. Mount the four legs to the columns, using

3/8x1-1/2 hex head bolts, 3/8 flat washers

and 3/8 flanged lock nuts, using a 9/16”

wrench. See Figure 3. Tighten the flanged

lock nuts securely, making sure the legs

remain in cont act with the plywood.

4. Lift the sander and remove the assembly

fixtures.

5. With the sander raised, install the four leg

glides, (or optional casters, not provided).

See Figure 4. If using the casters, fir st lock

the caster by pressing the large tab, in or der

to remove the hex nut and flat washer.

Figure 3

Figure 4

Table Support Screws

The set screws on the table support s (Figure 5)

have been tightened at the factory to eliminate

free-play between the table supports and the

columns during shipment. All four set screws

must be loosened and re-adjusted before

operating either the height adjustment

mechanism or the conveyor drive. Proceed

as follows:

Failure to follow the below

procedure may resul t in misalignment of th e

drum and/or conveyor bed, or may damage

the miter gears.

1. Loosen each hex nut with an open-end

wrench, then loosen the set screw with a

hex wrench.

Figure 5

9

Page 10

2. Re-tighten the set screw with your fingers

o

until it only li ghtly touches the column tube.

3. Hol d the set screw in positi on with the hex

wrench, and re-ti ghten the hex nut.

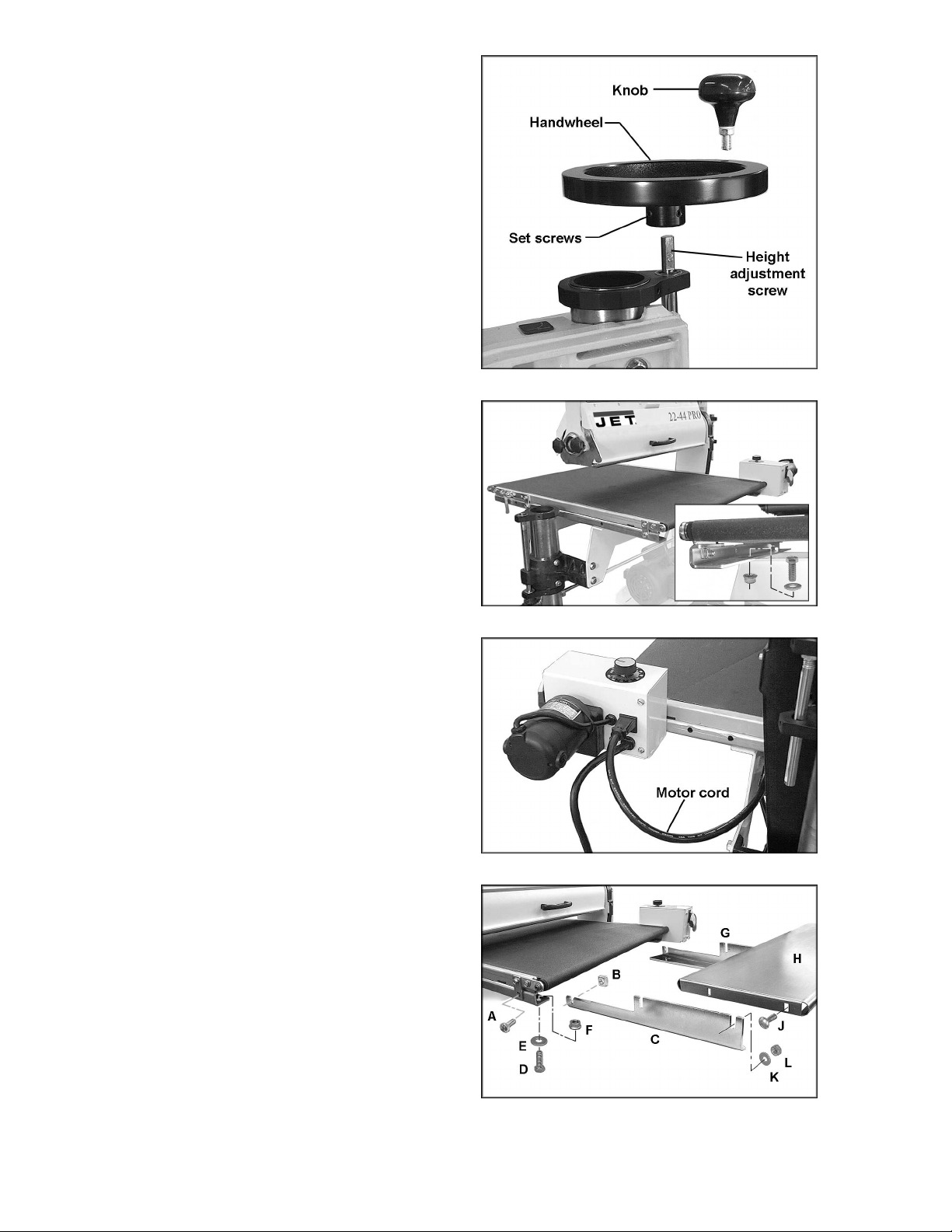

Install Handwheel

Mount the handwheel to the top of the height

adjustment screw (Figure 6). Align one of the set

screws with the flat on the height adjustment

screw, and tighten both set screws.

Install the knob to the threaded hole in the

handwheel, and ti ghten the hex nut agai nst the

handwheel.

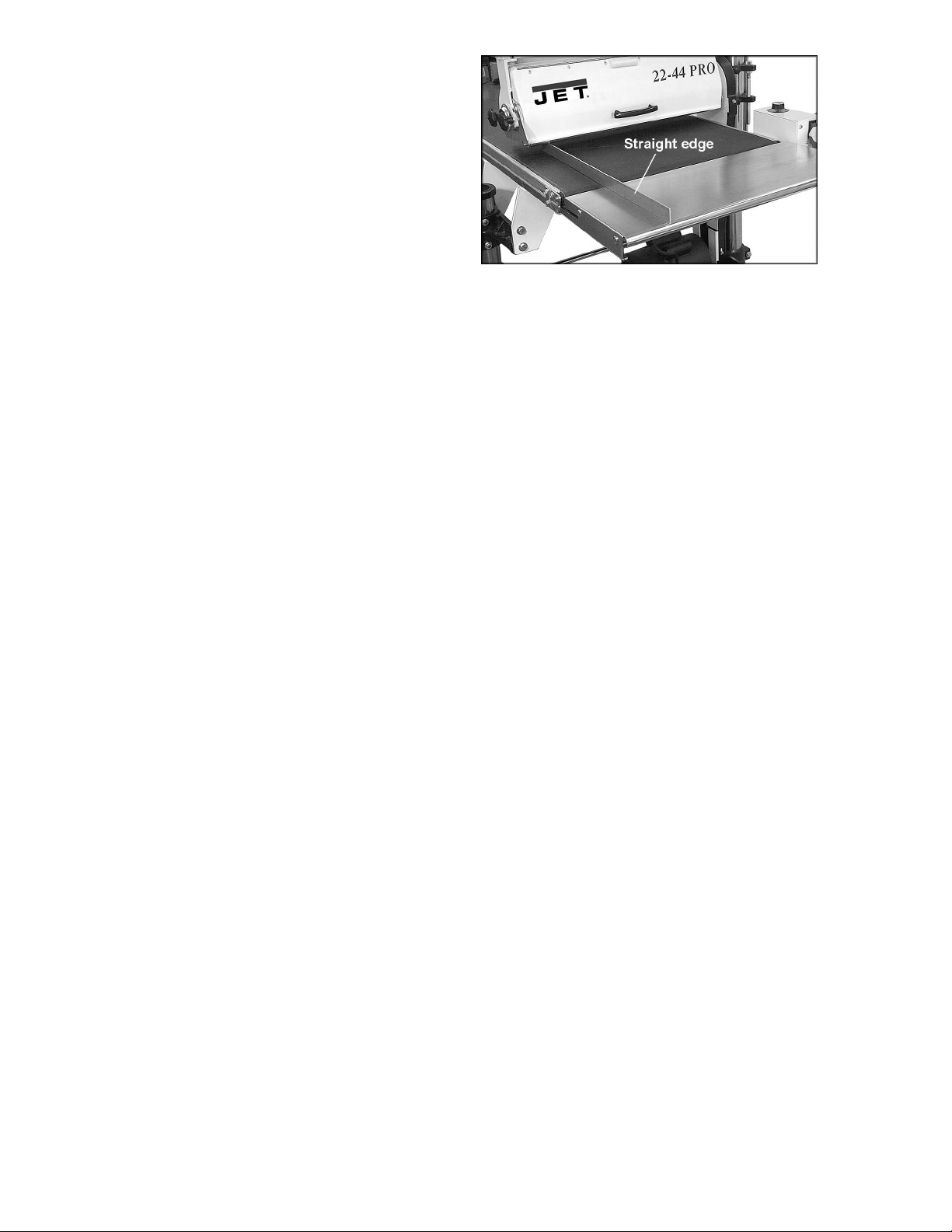

Install Conveyor Table

1. Lower the table mounting brackets by

rotating the handwheel.

2. Remove conveyor table from packaging,

and place it on the m ount i ng bracket s of the

stand. The gear motor should be on the

right, or inboard side of the sander as

shown in Figure 7.

3. Secure the conveyor bed with four 3/8”x1”

hex head bolts, 3/8” flat washers and 3/8”

flanged lock nuts.

4. Plug the motor cord into the control box

receptacle (Fi gur e 8) .

IMPORTANT: The conveyor belt has been

overtight ened for shipping purpose s. It must be

tensioned proper ly befor e operating the sander!

See page 19.

Infeed and Outfeed Tables ( Optional

Accessory)

See Figure 9.

1. Remove the lower hex cap screw (A) and

square nut (B) from the rail on the infeed

side of the sander.

Figure 6

Figure 7

2. Slide a left hand mounting bracket (C) into

the end of the rail.

3. Align holes and re-i nstall the hex cap screw

(A) and square nut (B). Install a 3/8”x 1” hex

head bolt (D), 5/16” flat washer (E) and

flanged lock nut (F).

4. Ti ghten the hex cap screw (A) fi rst to align

the bracket, then ti ghten the fl anged hex nut

(F) on the 3/8” screw.

5. Instal l a right hand mounting bracket (G) in

the same manner. NOTE: You will have to

pen the control box to remove the screw

from the rail – remov e the front l ower screw

and base panel (# 16 on page 38) of the

control box.

Figure 8

Figure 9

10

Page 11

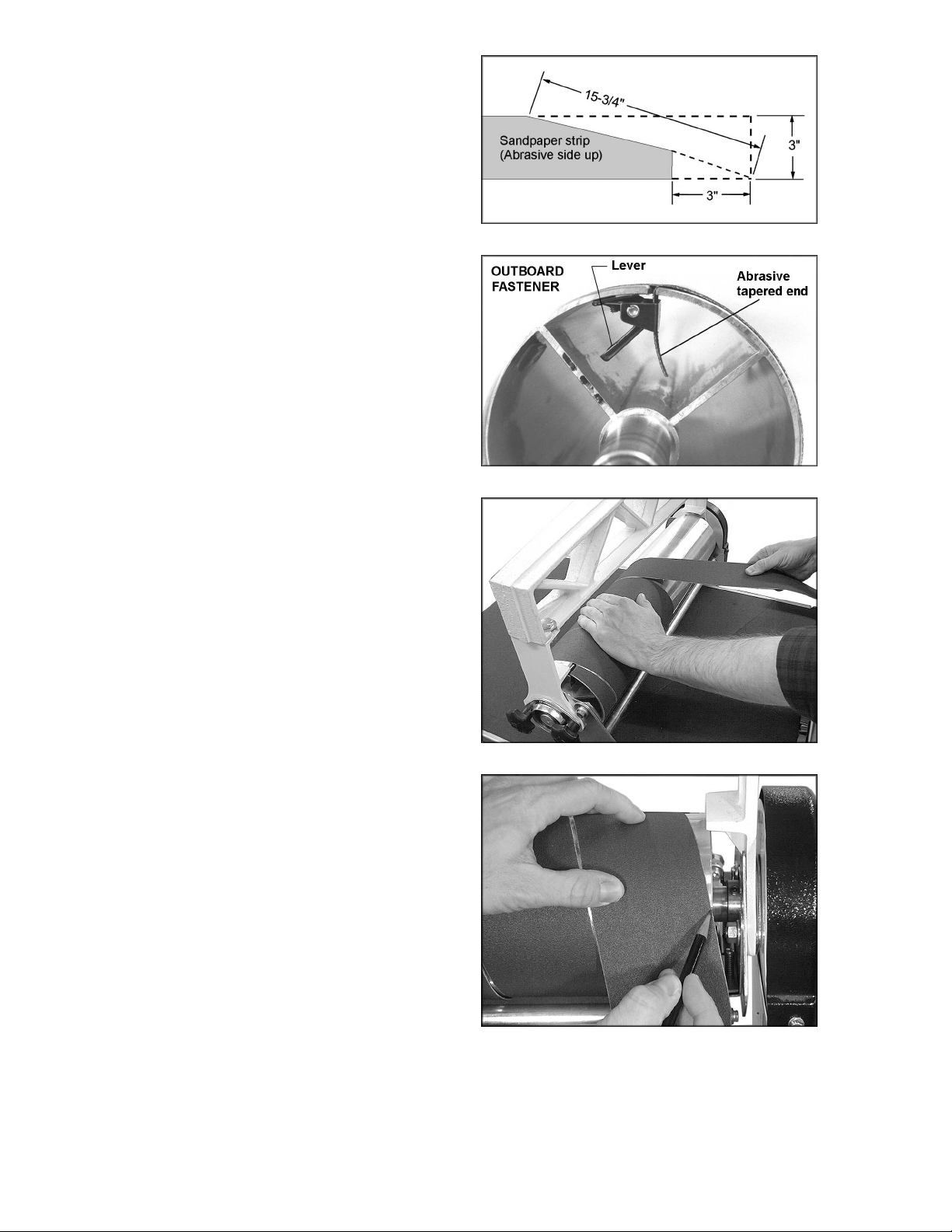

6. Position the table (H, Figure 9) over the

brackets, and install four 1/4”x3/4” square

neck bolts (J) , 1/4” flat washers (K), and 1/ 4”

hex nuts (L). Do not fully tighten yet.

7. The tabl e should be posi tioned ev en with or

slightly bel ow the conveyor belt surface. T o

check position, place a level or str aight edge

near the left side of the conveyor and

extending out over the table, as shown in

Figure 10. Raise t he conveyor table until the

drum holds the straight edge in pl ace, and

adjust the infeed table unt il it i s ev en with or

slightly below the conveyor belt surface.

8. Place the straight edge near the the right

side of the conveyor table and repeat.

Tighten all hex nuts on the infeed table.

9. Mount the outfeed table in the same manner

as described above. (Removal of existing

screws on the rails will not be necessary for

the outfeed side. )

Figure 10

Leveling the Sander

Proper leveling is important for getting the

maximum performance from your sander.

Before making fine adjustments, place the unit

where it will be used in the shop. Then adjust

the four leg glides (see Figure 4) using a

carpenter’s lev el placed on t he conveyor bed i n

both X- and Y-ax i s positi ons. Make sure t he hex

nuts on the leg glides are tightened securely

against the sander legs.

If you are using the optional casters, level the

sander after positioning the machine where it

will be used most often. Place washers on the

casters as needed to shim up the legs. Mar k the

position of the legs on the f loor with tape so the

sander can be returned to the same position.

Dust Collection

Dust collection is mandatory for a safe work

environment and extended abrasive life. The

sander is equipped wit h a 4” dust collecti on port

at the back of the dust c ov er. It is designed t o be

used with standard 4” dust collection hose

connected to a hi gh volume dust c ollec tor wit h a

minimum capaci ty of 600 CF M.

Using a shop v acuum is not recomm ended for

this machi ne, but if used it should be a 16 gallon

or larger canister type shop vacuum. This

requires conv erting t he dust port down to 2-1/ 2”.

An adapter is av ailable from your dealer (stoc k

no. 80-2910) for converting to the 2-1/2” hose.

Do not reduce hose si ze smaller than 2- 1/2”. For

best results, follow recommendations of the dust

collector manufacturer.

11

Page 12

Installing Abrasives

An 80-grit abrasive strip is already installed on

the drum of your sander. Page 28 offers

information on the types of abrasive and their

recommended uses.

Proper attachment of the abrasive strip to the

drum is critical to achieving top performance

from your drum sander. Abrasive strips do not

have to be pre-m easured. The end of t he roll is

first taper ed and attached to the left (out board)

side of the drum. Then the strip is wrapped

around the drum, and the second taper i s made

for attachm ent to the right (inboard) side of the

drum.

NOTE: When using JET Ready-To-Wrap

abrasives, not all of the steps below are

necessary. You can use the original abrasive

strip mounted to the drum as a template for

cutting your own stri ps.

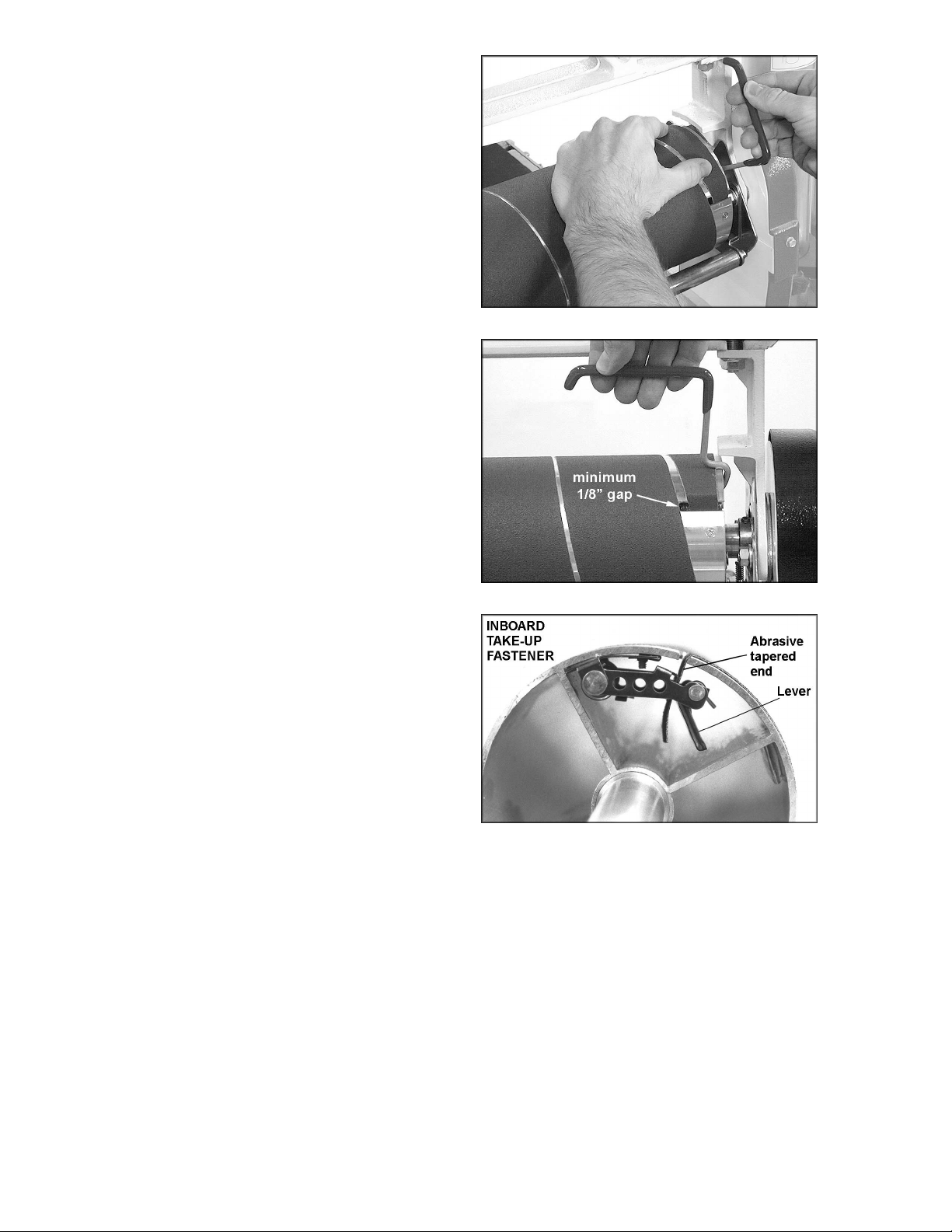

1. Mark and cut a t aper at one end of the roll

as shown in Figure 11. Because the t apered

end should use al l of the l eft (outboar d) slot

width, its end must be trimmed back three

inches as shown.

TM

Figure 11

Figure 12

2. Squeeze the fastener lever (Figure 12) on

the outboard end of drum, and insert the

tapered end of the abrasive so that i t uses

most of the width of the slot. Release the

fastener l ever to securely hol d the strip end

to the fastener.

3. Begin wrapping the strip around the drum.

The tapered edge of the strip end should

follow the edge of the dr um.

4. Continue to wrap the abrasive in a spiral

fashion by rotati ng the drum with one hand

and guiding the strip with the other (Figure

13). Successiv e windings of the strip should

be flush with previ ous windings without any

overlap.

5. Mark the trailing end of the strip where it

crosses the ri ght (inboard) end of the drum

(Figure 14).

6. Remove the abrasive strip from the drum,

and cut a taper as was done with the

starting edge (see Figure 11). Note: The

taper on the rem aining roll can be used as

the taper for the starting edge of the next

strip to be cut.

Figure 13

7. Rewrap the drum beginning at the left, as

described in steps 2-4 .

Figure 14

12

Page 13

8. You can use your f i ngers to work the i nfeed

take-up fastener, but it will be more

convenient to use the TUFTool supplied

with your sander. Hol d the T UFT ool with t he

red end pointi ng away from y ou (Figure 15)

and insert its hook into the outside hole of

the fastener lever (see Figure 17).

9. Lift the lever with the TUFTool, pulling the

lever up until it touches the inside of the

drum.

10. Turn the TUFTool counterclockwise and

lower it ont o the abrasiv e strip, making sure

it is holding t he paper tight (Figure 16).

11. Insert the t apered end of the abrasiv e strip

into the slot and fastener. It may be

necessary to trim the tapered end of the

abrasive strip so that it does not “bottom

out” against the i nsi de of the drum.

IMPORTANT: Leav e a gap – at least 1/ 8” –

between the tapered strip and the closed

end of the slot (Figure 16) to allow strip to

be pulled into the fastener as needed. If

necessary, trim the outside edge of the

abrasive strip.

Figure 15

12. Hold the abrasive in place with your left

hand, lift up the TUFTool and turn it

clockwise while maintaining upward

pressure. Slowly move the TUFTool away

from you slightl y, then down, while easing it

out of the hole. This rel eases the lever i n its

proper positi on (Figure 17).

All abrasive strips will stretch in use and may

stretch enough to allow the take-up lever to

reach its lowest position so that it can not

maintain tension on the strip. If this occurs,

follow the abov e procedures to re-set the takeup lever.

Always remove TUFTool from machine before

operating.

Figure 16

Figure 17

13

Page 14

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

In the event of a malfunction or breakdown,

grounding provi des a path of least r esistance f or

electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and a

grounding plug. The plug must be insert ed into a

matching outlet that is properly installed and

grounded in accordanc e wit h al l loc al codes and

ordinances.

Do not modify the plug provided. If it will not fi t

the outlet, hav e the proper outlet installed by a

qualified elec trician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conductor . If repai r or replac ement of

the electric cord or plug is necessary, do not

connect the equi pment-grounding conduc tor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool i s properly grounded. Us e only

three wire extensi on c or ds that have three-prong

grounding plugs and three- pole recept acles that

accept the tool’s plug.

Repair or replace a damaged or worn cord

immediately.

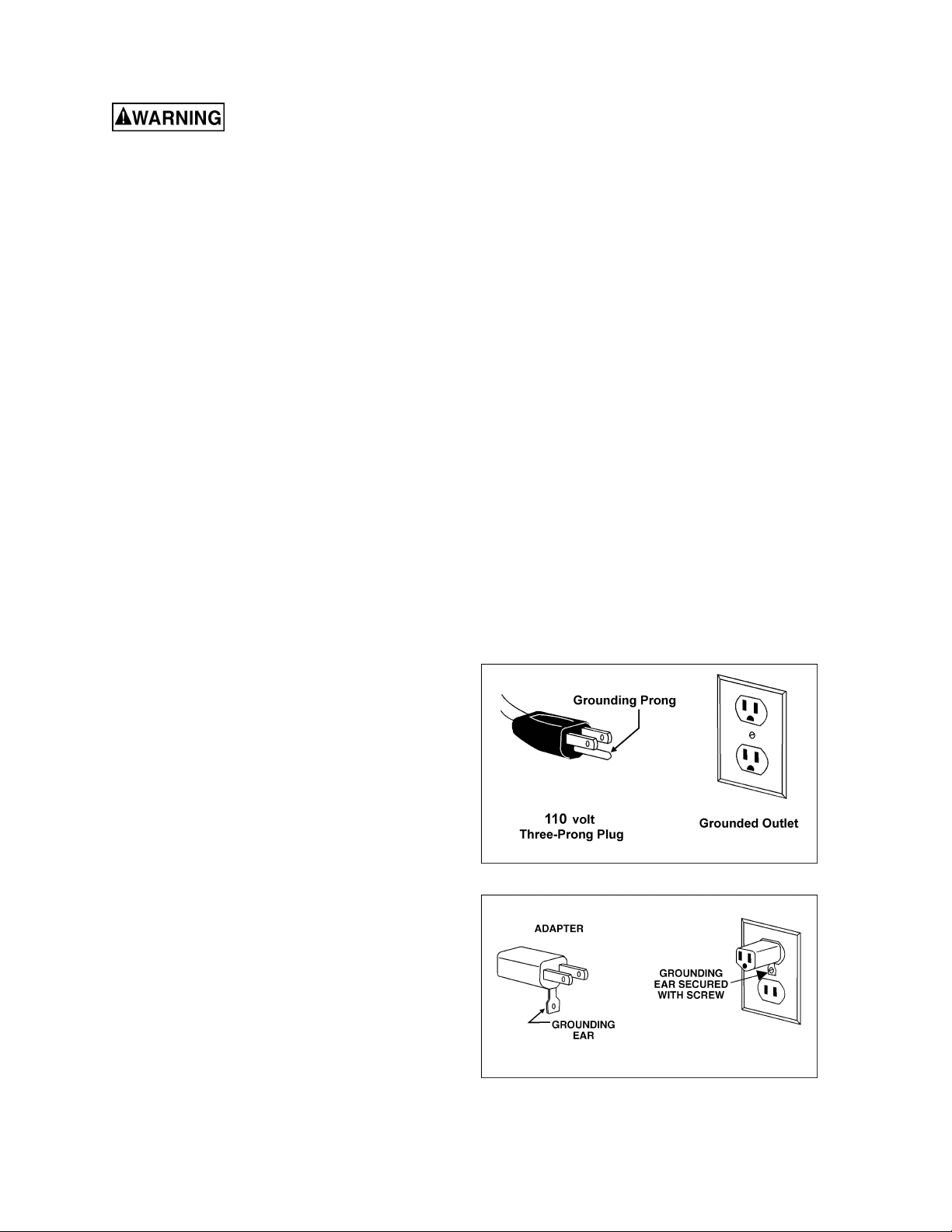

As received from t he factory, your drum sander

is intended for use on a 20 am p, 110V dedicated

circuit, whic h has an outlet and a plug that l ook

like the ones illustr ated in Fi gure 18. The sander

cannot be rewired to voltages other t han fact or y

settings.

A temporary adapter, which looks like the

adapter ill ustrated in Figure 19, m ay be used to

connect this plug to a two-pole receptacle, as

shown in Figure 19, if a properly gr ounded outlet

is not available. The temporary adapter should

only be used until a properly grounded outlet

can be installed by a qualified electrician. This

adapter is not applicable in Canada. The

green colored rigid ear, lug, or tab, extending

from the adapter, must be connected to a

permanent ground s uch as a pr operl y grounded

outlet box, as shown in Fi gur e 19.

Figure 18

Figure 19

14

Page 15

Extens ion Cords

If an extension cord is necessary, make sure the

cord rating i s suitable for the am perage listed on

the machine's motor plate. An undersize cord

will cause a drop in line voltage resulting in loss

of power and overheating.

The chart in Figure 20 shows the correct size

cord to use based on cord length and motor

plate amp rating. If in doubt, use the next

heavier gauge. T he smaller the gauge num ber,

the heavier the cor d.

Recommended Gauges (AWG) of Extension Cords

Extension Cord Length *

25

50

75

100

150

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

feet

feet

feet

feet

feet

200

feet

Adjustments

Switch Lockout

Unauthorized use of the sander can be

prevented by pulling out the key (Figure 21).

Press switch to OFF position before removing

the key. When the k ey is removed, the drum c an

not be started. (Note, however, that the

conveyor belt can still run when the key is

removed).

To replace the key , slide it back into the switch

until it snaps.

Dust Cover

To access the drum, lift the front of the dust

cover using t he handle and pu sh back the f ront

cover all the way to secure it in open position.

The dust port shoul d be on the bac k or outfeed

side of the sander.

When removing the dust cover for initial drum

alignment or other reasons, lift the front cover

half-way and pull the dust cover out from the

outfeed side of sander. The edges will pop out

when the dust cover is pulled from the carriage

leg brackets. Reverse this procedure to re-install

the dust cover.

The dust cover should not require removal for

fine tuning alignments or for changing or

cleaning the abrasives.

21 to 30 10 NR NR NR NR NR

*based on limit ing t he li ne vol tag e drop t o 5V at 150 % of th e

rated amp eres.

NR: Not Recommended.

Figure 20

Figure 21

Table Height Control

NOTE: Read “Table Support Screws”, page 9,

before operating the handwheel.

The table height and depth of c ut are controlled

by the height adj ustm ent handwheel (see Fi gure

6). Rotating t he handwheel raises or l ower s both

sides of t he table si multaneousl y by transf erri ng

the handwheel rotation through the miter gear

and transfer r od assembly.

Check the operation of the height adjustment

mechanism. If it does not operate smoothly or

easily, check the following:

15

Page 16

• The set screws in the table supports have

been loosened and readjust ed ( see page 9).

• The sander has been leveled (page 11).

• Moving parts of the height adjustment

mechanism are well lubricated, including

miter gears, columns, and threaded

adjusting screws.

If the table height mechanism still does not

operate smoothly, try the following:

1. Further l oosen t he set screws on the front of

the table supports (see Figure 5).

2. Lubricate thoroughly by appl yi ng penetrating

lubricant to the table supports where they

contact the columns, and to all contact

points of adj usting screws and transfer rod

(see Figure 1). Also apply grease to the

miter gears.

3. If the height adjustment still feels stiff, check

for misalignment of adjusting screw

supports and table supports which could

cause binding on t he adjusti ng screws. The

adjusting screw suppor ts can be adjusted by

loosening the set scre ws which secure t hem

to the columns, and rot ating the supports to

proper positi on.

4. Check the miter gear alignment. The miter

gears can be adjusted on their shafts by

prying off their protective caps with a flat

blade screwdriver, and loosening the set

screws on the gears. Check that the gear

mesh is not too tight or too loose, and that

the gear teeth ali gn with the opposing gear.

Note that the c ollars located on t he transfer

rod (see Figure 1, page 7) should be

positioned to control the lateral movement of

the transfer rod to maintain accurate miter

gear alignm ent and mesh.

The mesh of the miter gears should be

smooth and even. If it is not, adjust the

gears for good mesh. Test for smooth

operation.

5. Next, check the position of the height

adjustment screws: First raise the conveyor

table. Then check the retaining ring at the

top of the height adjustment screw on the

outboard side (Fi gure 24), and the ret aining

ring under the height adjustment handl e on

the inboard side of the machine. Both

retaining rings should be snug on their

respective bearings.

If there is a space between the retaining r ing

and the bearing, tighten one set screw in

each of the table supports before performing

the following adjustment:

Figure 24

16

Page 17

6. If one height adjustment screw is loose,

remove the mi ter gear from t he transfer rod

on that side. T urn down the threaded hei ght

adjustment screw rod until it is snug. Make

sure both sides are snug on top and

retaining rings under the adjustment screw

supports are in place. Re-install the miter

gear. Loosen the set screws in the table

supports and test for smooth operation.

Depth Gauge Calibration

The depth gauge (A, Figure 25) measures the

distance between the conveyor table and the

sanding drum for thickness dimensioning of

boards. To calibr ate the depth gauge:

1. Loosen the locking knob (B) of the lower

depth gauge support (C) and lower i t so that

it rests on top of the table support (E).

2. Raise the conv eyor t able until it touc hes the

sanding drum. Then loosen the l oc k ing knob

(D) of the upper depth gauge support and

position the “ 0” mark of the scale even wit h

the top of the lower depth gauge support.

3. Tighten the upper depth gauge support in

position.

Once calibrat ed, the locking knob ( B, Figure 15)

of the lower depth gauge support can be

loosened, allowing the lower depth gauge

support to ri de on top of the table support. The

depth can then be r ead where the scale ent ers

the lower depth gauge support.

The depth gauge can also be used as a stop

gauge as follows: Position the lower depth

gauge support (C, Fi gure 25) along the scale to

a desired finish thickness. Then tighten the

lower depth gauge support with the locking k nob

to prevent the conveyor table from being r aised

above that point.

Figure 25

Drum Alignment

The sanding drum must be aligned parallel to

the conveyor table for proper machine

operation. The sanding drum has been prealigned at the factory and should not require

immediate adjustment, although it is

recommended that you confirm the alignment

before operating the sander. Proceed as foll ows:

First inspect the alignment with a gauge of some

kind. The following procedure uses a steel

straight edge as a gauge. See Figure 26.

1. Unplug sander fr om power source.

2. Remove the dust cover and remove the

abrasive strip from the drum.

Figure 26

17

Page 18

3. Insert the gauge between the drum and

conveyor bed at one end of the drum

(Figure 26). Raise the conveyor bed while

slowly rotati ng drum by hand until the drum

lightly contacts the thickness gauge.

4. Move thickness gauge to the opposite end

of the drum. If the drum does not contact t he

thickness gauge equall y at both ends of the

drum, alignm ent is necessary. See below.

Initial Drum Alignment

1. Release v-belt tension from motor by

loosening pinch bolt of motor support

(Figure 27).

2. Loosen two lower #10-32 screws in belt

guard (Figur e 27 shows one of the screws).

Slide motor support up the column and retighten pinch bol t.

3. Because the tension roller suspension

assembly (Figure 28) mounts to the drum

bearing bolts which are used to adjust the

drum, it is necessary to align the sanding

drum and tension rollers at the same time.

Loosen outboard beari ng bolt knobs (Fi gure

28) and the inboard bear ing bolts.

Figure 27

4. With all four bearing bolts loosened, note

that the drum will adjust about 1/2” on each

end. Position drum alignment templates

(Figure 28) on the conveyor and below the

drum with one t emplate at eac h end of the

drum.

5. Raise the conv eyor bed so that the drum i s

resting on both templates but leaving the

drum within its range of adjustment. To

check this, you should be able to lift either

end of the drum off the t emplates and, with

light hand pre ssure on the drum , attempt to

slide templat es with a screw driver to make

sure drum is act ually resti ng on the template

and not just in its lowest position.

6. In t his position, the drum shoul d be resting

on the templates and both tension rollers

resting on the conv eyor surface. Re-ti ghten

bearing bolts and restore v-belt tension.

Tighten pinch bolt in motor support and

tighten two lower screws in belt guard

(Figure 27).

Fine-Tuning Drum Alignment

The 22-44 Pro i s equipped with a dr um adjuster

mechanism that allows easy fine tuning or

changing of drum alignment without repeating

the intial dr um ali gnm ent proc edur e.

Figure 28

1. Raise drum adj ustment lever (Figur e 29) so

that it just engages the side of drum

carriage leg.

Figure 29

18

Page 19

2. Slightly loosen bearing bolt knobs. (An

internal tooth lock washer is placed under

the head of each bearing bolt to prevent

tension roll ers from droppi ng out of posi tion

if knobs are loosened slightly. If tension

rollers do drop, simply raise to a position

equal to that of the i nboard end of the drum

and slightly tighten knobs.)

3. With the bearing bolt knobs slightly

loosened, raise drum adjustment lever to

raise the outboard end of drum, or lower

drum adjustm ent lev er to lower the outboard

end of drum.

4. After adjustment is made, re-tight en bearing

bolt knobs and check dr um ali gnm ent.

The drum adjustment lever is useful when

sanding boards wider t han the dr um (see Fi gure

30). Here the drum ali gnm ent is critical and must

be adjusted to ex actly level to slighly high on t he

outboard end. Test alignment with scrap wood

approximately 6” wide by 24” to 40” long. Run

board through sander sideways so that end of

board extends beyond end of drum. Rotate

board 180° and sand t he other end. If a ridge is

visible due to the drum overlap, then raise

outboard end of dr um and test again until ridge

is eliminated.

Conveyor Belt Tension and Tracking

Tension and tracking adjustments may

occasionally be necessary during break-in and

normal operation to compensate for belt

stretching.

Tension. To adjust the tension of t he conveyor

belt, first adjust the take-up screw nut (Figure

31) using the attac hed wrench. Do this on both

sides of the conveyor to obtain approximately

equal tension on both sides of the belt when

taut. Insufficient belt tension will cause slippage

of conveyor belt on the drive roller during

sanding operation; the conveyor belt is too loose

if it can be stopped by hand pressure applied

directly to the top of the conveyor belt.

Excessive bel t tension c an result in bent roll ers,

bent brackets, and/ or premature wearing of the

bushings or belt .

Tracking. Belt tracking adjustments are made

while the conveyor belt is running. After the

proper belt t ension i s obt ained ( see above), tur n

the conveyor on and set it at the f astest speed

setting. Watch for a tendency of the conveyor

belt to drift to one side of the conveyor. To

adjust track ing, tight en the t ake-up scre w nut on

the side toward which the belt is drifting, and

loosen the take-up screw nut on the opposite

side an equal amount.

Figure 30

Figure 31

19

Page 20

Adjusting t he take-up screw nuts on ei ther side

T

m

of the conveyor all ows belt tracking adj ustments

to be made without aff ecting belt tension.

NOTE: Adjust t ake-up screw nuts only 1/ 4 turn

at a time. T hen all ow time f or t he belt t o react to

the adjustments before proceeding further. Try

to avoid over adj ustm ents.

Trackers

he sander comes equipped with “Trackers”,

ceramic guides that reduce the amount of

adjustments needed to keep the conveyor belt

tracked (centered) on the conveyor bed. See

Figure 32. These guides have a magnetic

backing to keep them in place. If a Tracker

wears through, it can be reversed by turning it

over. Page 27 contai ns more inform ation about

re-setting trackers.

Conveyor Belt Replacement

1. To replace a worn conveyor belt, lower

conveyor table to its lowest position using

the height adjustment handle. Unplug the

achine from the wall receptacle, and

unplug the motor cord from the control box

receptacle.

2. Loosen the conveyor take-up screw nuts

(see Figure 31) to relieve belt tension, and

slide the driven roller fully inward.

3. Remove the four bolts that attach the

conveyor table to the table mounting

brackets. Lift up the conveyor table and

remove it from machine. Avoid tearing the

belt on any edges underneat h the conv eyor

bed.

4. Install new belt, and re-install conveyor

table. Take care not to damage the

Trackers. T ensi on and trac k new belt.

NOTE: If the conv eyor belt continually tracks to

one side of the machine, reversing the belt on

the conveyor bed may remedy the probl em. To

make sure the conveyor bed is not twisted,

place a level on the conveyor bed. If it is twisted,

see page 11 for instructions on leveling the

machine. If there i s still a problem, proceed with

the steps below:

Figure 32

Step 1: Check the conveyor drive roller and t he

driven roll er to make sure they are parallel to the

surface of the conveyor bed. To do this, first

center the conv ey or belt on the be d. Then l ay a

straight-edge on the exposed edge of the

conveyor bed on the left (outboard) side,

extending i t over t he roller. See Figure 33. Not e

the distance between the roller and the

straightedge.

Figure 33

20

Page 21

Step 2: Now repeat St ep 1 on the right (inboard)

side of conveyor. Compare the measurements

from side to side. If they are not equal, loosen

one of the brac kets that hold the roll er in place.

Tip this bracket until the distance between the

roller and the straight-edge are equal f rom side

to side, then tight en the bracket.

Tension Roller Adjustment

Snipe marks result from too much t ension roller

pressure and are identified as a visible line

running across the width of the board

approxim ately 2-1/4” from t he end of the board.

If a snipe mark occurs on the leading edge of

the board, adjust t he outfeed tension r oller. If a

snipe mark occurs on the trailing end of the

board, adjust the i nfeed tension roller.

Tension roller pressure can be decrea sed i n one

of two ways:

Method 1: Loosen spring retaining screws

(Figure 34). Do not disengage screws entirely.

Method 2: Raise height of tension rollers as

follows. Repeat “Initial Drum Alignment”

procedure (page 18) , using the drum alignment

templates under the drum, except place a few

sheets of paper under the tension roller(s)

needing adjustment. Do NOT place the paper

under the drum or alignment templates. Ti ghten

bolts. Repeat this procedure until the snipe is

eliminated.

Figure 34

Improperly adjusted tension

rollers (i.e. those set too high, rendering

them non-functional) could allow kickback or

slippage of pieces bein g san ded.

Adjusting Table Supports

1. If the convey or table does not ri se and l ower

easily, measure the distance between the

top of the base column support and the

bottom of the table support on both the

inboard and the outboard side of the

machine. See Figur es 35 and 36.

2. Compare these m easurements; they shoul d

be within 1/16”. If they are not, disengage

the miter gear on the inboard side of the

transfer rod (Figure 35) by prying off the

protective cap with a screwdriver and

loosening the set screw in t he gear ’s collar.

3. Adjust the conveyor table height using the

height adjustment handle to get the same

measurement on both sides. Then reengage the miter gear on the transfer rod,

tighten the set screw, and replace the

protective cap.

Figure 35

Figure 36

21

Page 22

If the conveyor table is still difficult to raise or

lower, the table supports may need to be recentered on the col umns. To do t his, loosen the

four 3/8”x1” hex head bolts in each table support

that connects it t o the table mounting br ackets,

adjust and tight en the set scre ws (see Figure 5)

to hold the table support in position. Then

tighten the hex head bol ts and re-l oosen the set

screws. Re-align drum (see page 17).

Replacing V- Belt

1. Unplug machine from power source.

2. Remove the outer half of belt guard by

removing the six #10-32 screws with a 5/ 16”

wrench. Sli de the belt guard away f rom the

v-belt. See Figure 37.

3. Use a flat blade screwdriver to pry off the

protective cap over the inboard mi ter gear,

and loosen the set screw in the gear’s

collar. Remove the miter gear and loosen

outboard coll ar (Figure 38). Slide cross bar

toward outboard side as shown.

4. Loosen v-belt tension by loosening pinch

bolt in motor support (Figure 38) and raise

motor. Re move v-bel t fr om pulleys .

5. Install new v-belt and tension the belt by

using the weight of the motor only. Make

sure the pulleys are aligned. Replace

transfer rod and miter gear; tighten set

screw on mit er gear and replace protect ive

cap. Tighten collar on transfer rod.

6. Install the outer half of the belt guard and

tighten the six screws.

Rotating Drum Bearings

Bearings should be replaced when they allow

excessive play of the drum, make excessive

noise or otherwise indicate failure.

If clicki ng noises in the beari ngs are a problem ,

rotating may be a solution instead of

replacement, as follows:

Figure 37

Figure 38

1. Unplug sander fr om power source.

2. Loosen the set scre ws in the bearing coll ar

(Figure 39). Leav e the set screw wrench in

one of the set screws. Then rot ate the drum

within the bearing and tighten the set

screws.

3. If the cl icki ng persi sts, or if t he drum shaf t is

tight in t he bearing and cannot rotate, t hen

loosen the bearing bolts. Repeat step 2.

After the dr um is rotated wit hin the bearing,

tighten the bearing bolts first and then the

set sc rews.

Figure 39

22

Page 23

4. After the machine has run for about 30

minutes, stop to check that the set screws

and bearing bolt s are still tight.

NOTE: It may be necessary to re-align the

tension roll ers after rotating the drum bear ings.

See page 18.

Replacing Drum Bearings

If the beari ngs are squealing or ar e loose, they

may need replacing.

1. Unplug sander from power source and

remove dust cov er.

2. Rai se conv ey or tabl e unti l t he sanding drum

rests on the conveyor .

3. Outboard: Remove the two knobs and

washers that are holding the bearing in

place. Loosen the two set screws in the

bearing coll ar and slide the bearing off the

end of the drum (Figure 41) .

4. Install a new bearing on the shaft of the

drum and tighten the bolts. Tighten the set

screws in the beari ng collar. Make sure the

bolts go through the drum shield and

tension roller support brackets (see

exploded view, page 36) .

Figure 40

5. Inboard: Remov e outer half of belt guard by

removing the six #10-32 screws in the

guard. Sli de t he belt guard away f rom t he vbelt.

6. Release v-belt tension by loosening pinch

bolt in motor support and r aising motor.

7. Loosen the set screw in the driven pulley

and remove the pull ey fr om the shaft.

8. Rem ove t he bolt s holdi ng t he inboar d (ri ght)

bearing in place. See Figure 40. Slide the

inner half of t he upper belt guard off the end

of the shaft along wit h the bearing.

9. Install the new bearing on the shaft and

install the inner half of the upper belt guard

in the same manner as it was removed.

Make sure the bol ts go through the tension

roller brackets and drum shield. Install the

new inboard bearing.

10. Center the drum between the carriage legs

before tightening bolts. Tighten the bolts in

the bearing and the set screws in the

bearing collar.

11. Instal l the driv en pull ey (shown in Figure 40)

making sure it aligns wit h the drive pulley on

the motor. Tighten the set screw.

12. Install the outer half of the belt guar d cover

and tighten the six #10-32 screws.

Figure 41

13. Ali gn the drum and tension v-belt according

to instructions in this manual.

14. Check all bolts and set screws for tight ness,

and check them again after sanding for 30

minutes.

23

Page 24

Operation

Start sanding drum and sand the stock at that

same positi on.

Before using your drum sander, review the

previous pages in this manual on initial set-up

and adjustment. In this section, you will learn

how to operate the machine. Make sure an

abrasive strip is mounted and a dust collection

system is connect ed.

Basic Operating Procedure

1. Set depth of cut.

2. Start dust collection system.

3. Start drum.

4. Start conveyor and select feed rate.

5. Feed stock through m ac hine.

To feed stock through the 22-44 Pro, rest and

hold the board to be sanded on the conveyor

belt, allowing the conveyor belt to carry the

board into the dr um. Once the stoc k is halfway

through, reposition yourself to the outfeed side

of the mac hine to receive and c ontrol the board

as it exits.

Setting Depth of Cut

Adjusting the drum sander f or the proper contac t

between the abrasiv e and the stock determ ines

the mechanical depth of cut.

It may take some ex perimentation t o determine

the proper depth of cut, given the variables of

abrasive grit, type of wood, and feed rate. For

best results, use scrap wood t o pract i ce sanding

and to develop skill and familiarity with the

machine befor e doing finish work.

A combination of several variables will

determine the proper depth of cut to use,

including t he following:

1. Abrasive type and gri t size.

2. Width of the piece being processed.

3. Hardness of the piec e.

4. Feed rate of the conv ey or belt.

Establishing Proper Drum Height

The depth of cut is cont roll ed by t he table hei ght

adjustment handle which raises or lowers the

conveyor table under the drum.

A good rule of thumb when sanding with grits

finer than 80 i s to place the stock to be sanded

under the drum and raise conveyor table until

the drum contacts the stock. Drum should still

rotate by hand. Without changing drum

height, finish feeding the stock under the

sander.

Do not start drum while in

contact with stock!

For sanding with gri ts coarser than 80, you can

raise the conveyor table slightly.

Always maintain control of stock. Through

practice you will learn the proper depth of cut

considering t he v ari ables above.

Selecting Feed Rates

Selecting proper feed rate is an essential step

after fir st adjusting for dept h of cut. The vari able

feed rate c ontroller of the c onveyor belt adjusts

the load on the machine; it can be infinitely

adjusted withi n its specified range for maximum

operating performance. A faster f eed rat e all ows

faster sanding but fewer revol utions of t he drum

per inch of sandi ng. A slower f eed rate prov ides

more revolutions of the dr um per inch of sanding

to allow a greater depth of cut and smooth

sanding.

Begin experimenting with the feed rate set at

about 40% to 50% of maximum. The best f eed

rate will depend on a number of factors,

including type of stock, grit and depth of cut

used, and whether the stock is fed directly in line

with the conveyor bed or at an angle. If the drum

motor is lugging down, if the conveyor belt is

slipping, or if you observe a ripple eff ect on the

stock, slow down the feed rate. If the finish is

smooth and the machine is not overworking, you

can experiment wit h usi ng a faster feed rate.

Also try a faster feed rate or less depth of cut if

the stock you are work ing begins to show burn

marks. With cherry, hard maple or other

hardwoods, using a shallower dept h of cut and a

faster feed rate will help minimize burn marks.

Slightly angling the stock as it is fed into the

machine will al so hel p pr ev ent burning the stock.

Because of the wide range of variables, it is

important to experiment with your specific

conditions and m ak e adjustm ent s to achi ev e the

optimum feed rate. If problems occur, first

check and adjust the feed rate, referring to the

“Troubleshooting” sections in this manual.

Tips for Maximum Performance

The versatili t y designed i nto t he 22-44 Pro dr um

sander allows it to be used for a wide v ariety of

tasks that will boost the return on your

investment. For example, its capabilities range

from taking the place of a planer to thickness

rough stock, to speeding up fine sanding work

often done with slower, dust-generating hand

sanders.

24

Page 25

Learning how to use its adjustments and

controls will allow you to fine-tune the machine

for maximum results. The best results come

from experimenting with different abrasive grits

and machine adj ustments to fit the job at hand.

Following i s a list of useful tips which can hel p

you improve performance of your sander.

Dust Collection

When connecti ng dust coll ect ors, remem ber that

straight pi pe will not restrict airflow as much as

flexible tubing. Y’s and elbows will restrict airflow

less than T’s. Also, a hose smaller than 2-1/2”

diameter shoul d not be used.

Multi pl e- Piece Sandi ng Run s

When abrasiv e planing (or t hickness sanding) a

run of sim ilar pieces that you want to h ave the

same thickness, it is best to determine the

thickness of the thinnest piece and process all

pieces to that same thickness in one session. Be

aware that the sander will remove cups and

crowns in the workpiece; consider this when

measuring and processing stock to the same

thickness.

Sanding Multiple Pieces At Once

When sanding multiple pieces simultaneously,

make sure to stagger (step) the pieces across

the width of the conveyor belt. This provides

better contact with the tension rollers. Try to

process only multiple piec es of similar thickness.

If there is a signif icant thickness difference, t he

thinner pieces can slip on the conveyor belt if

they do not contac t the t ension roll ers. Al so note

that pieces thicker than 3/4” should be longer

than the minimum normally recommended to

prevent tipping of the stock.

extra rol ler stands, hel p from another person, or

hand pressure on the stock, to minimize

potentially hazardous situations.

Face Frames and Raised Panel Doors

It is v ery important t o have the proper abrasive

contact when doing this type of sanding. If the

machine is set t o take an excessiv e depth of cut,

the result can be a gouge or dip as the drum

goes from sanding the rails at full width to

sanding just a f ew inches of width on the sti les.

To prevent this, make sure that when using

abrasives finer than 80 grit the drum is in contac t

with the wood but can still be spun by hand. If

there is room , angli ng t he stock on t he conveyor

belt can also help. Slowing the conveyor feed

when coming to a rail in the stock can help

prevent a di p or goug e. Thi s all ows the abra siv e

to work the wider width with less effort, and to

achieve better consistency of the finished

surface.

Stock Feeding Angle

Some pieces, because of their dimensions, will

need to be f ed into the machi ne at a 90° angle

(perpendicular to the drum). However, even a

slight offset angle of the stock will provide for

more effective stock removal. The optimum

feeding angle for stock removal is about 60°

(see Figure 42).

Edge Sanding

When edge sanding, the sander will mimic the

opposite edge of t he stock which is lyi ng on the

conveyor belt . Bec ause of this, i t is im port ant f or

the stock edge to have been ripped at the proper

angle to the face before the sanding process.

When edge sanding stock that is less than 3/4”

wide or more t han 2” high, it is good procedure

to stack and clamp several pieces together to

prevent them from slipping or tipping on the

conveyor belt.

Sanding Imperfect Stock

When sanding stock with a c up or crown, place

the crown up. This will stabilize the stock to help

prevent tipping or rocking during sanding. After

the crown has been rem oved and t he top is fl at,

turn the stock ov er and sand the opposit e side.

To avoid personal inj ury, t ake speci al c are when

sanding stock that is twisted, bowed, or

otherwise v aries in thi ckness from end t o end. If

possible, support such stock as it is being

sanded to keep it from slipping or tipping. Use

Figure 42

Angling the workpiece for stock removal

provides other advantages, such a s les s l oading

of certai n areas of the drums due to glue lines or

mineral streaks in the stock, m ore even wear of

abrasive stri ps, potenti ally faster f eed rates, and

lighter l oads on the m otor. Note that to get the

best final finish, however, the stock should be

fed through t he machine so it will be sanded in

line wit h the grain of the wood on the fi nal one or

two passes.

25

Page 26

Maintenance

For best results, perform the following

recommended pr oc edur es on a monthly basis:

Before doing maintenance on

the machine, disco nnect it from the el ectri cal

supply by pulling out the plug or switching

off the main switch! Failure to compl y may

cause serious injury.

Keeping the Machine Clean

For best results, make cleaning the machine a

regular shop procedure. Allowing excess buildup of dust and debris can adversely affect

performance through the loading of the

abrasives, slippage on the conveyor table,

and/or the accumulation of material inside the

drums which can thr ow off the center of balance.

Leave the dust col lector on when c leaning dust

from the drums. Also brush the conveyor belt

after cleaning operations. If not cleaned, the

conveyor belt could allow stock to slip during

sanding operations.

• Lubricate conv eyor bushings and check for

wear.

• Lubricate all movi ng parts, such as threaded

rods, washers, and col umn t ubes. (Beari ngs

are pre-sealed and requi r e no lubrication.)

• Clean sawdust from the abrasive strip and

brush dust from t he conveyor belt.

• Blow dust from motors and switches. Blow

dust from insi de of sanding dr um , which may

cause vibration or offset the center of

balance.

• Check all set screws for tightness on parts

such as table support s, bearings, conv eyor

coupler, casti ngs, pulleys and miter gears.

26

Page 27

Tracker Kit (98-0080)

Trackers dramatically reduce tracking adjustments of conveyor belts. They are already

installed on your sander. The following

information is for re-setting or replacing your

trackers, should that become necessary. Refer

to Figure 43.

1. Di sconnect power to sand er, and di sconnect

motor cord from contr ol box r ec eptacle.

2. Lower conveyor table as far as it will go.

3. Loosen t he conveyor take-up screw nuts to

relieve conveyor belt tension and slide

driven roll er fully inward. Slide c onveyor belt

to one side of bed.

4. Remove the f our bolts holding t he conveyor

table to the sander base.

5. Lift conveyor table and slide it out of the

sander. Turn conveyor table upside down.

Be careful not to damage t he conveyor belt.

6. On t he underside of the convey or bed, there

are U-channels welded to the bed. The

Tracker is positioned on the inside of the

first U-c hannel on the infeed side of sander

(the U-channel closest to the rubber covered

drive roll er and gear m ot or). T he back of the

Tracker is magnetized and will stick to the

side wall of the convey or bed. Do not install

Tracker if the edge of the conveyor belt is

damaged or torn.

7. With the first Tracker installed, slide the

conveyor belt into the bottom slot of the

Tracker. Note: When installed pr operl y, onl y

the bottom lip of the Trac ker will be visible.

The top slot is to be used if the bottom slot

wears out.

8. Install second Tracker opposite t he first. Use

both Trackers unless the second one does

not fit in conveyor or if conveyor belt is

damaged.

9. Turn conveyor table right-side up and reposition it onto the sander. Re-attach the

four mounting bolts and tighten. Caution:

Be careful not to knock Tracker(s) out of

conveyor bed when turning conveyor over.

10. Make sure all switches are off. Connect

power to sander and plug i n m otor.

11. Tension the conveyor belt using take-up

screw nuts. If both Trackers are i nstalled, it

is very important to have equal tension on

both sides of the conveyor belt. Tighten both

sides of take-up screw nuts until equal

tension is obtained.

12. To check tension, turn on conveyor full

speed and place both hand s on conv eyor. If

conveyor belt can be stopped, continue

tensioning until conveyor belt cannot be

stopped by both ha nds on the bel t whil e the

conveyor is operat ing at full speed.

13. Make sure conveyor belt runs smoothly

inside Tracker slot and that the magnet is

holding the Tr ac k er in positi on.

14. Conti nue to watch tracking of conv eyor and

adjust only if necessary, making sure to

keep equal tension on conveyor belt at all

times and not allowing conveyor belt to

buckle under conv ey or bed.

Figure 43 (underside of c onv ey or s hown)

27

Page 28

A

Abrasives

The abrasive material you choose will have a

substantial effect on the performance of your

sander. Vari ations i n paper type, weight, coat i ng

and durability all contribute to achieving your

desired finish.

JET Abrasives are available in Ready-To-

TM

Wrap

Ready-To-Cut pr e-marked box. Your JET dealer

can recommend the best choice for your

application.

Selecting Drum Abrasives

It is important to select the proper grit of

abrasive for the type of sanding being perform ed

to achieve maximum results. As with any

sanding operation, first begin sanding with a

coarser grit, depending upon the roughness of

the stock or the am ount of stock to be rem oved.

Then progressiv ely work toward finer grit s. The

chart (Figur e 44) sho ws the general u ses f or t he

various grits. JET offers abrasives in the ten

different grits shown – consult the stock

numbers on page 32 to order.

The amount of stock to be removed i s a major

considerati on when choosing the grit grade with

which to begin. Grits 24, 36, 50 and 60 are

primarily designed for stock removal. Grits 24

and 36 will remove the most material in one

pass, whether you are doing abrasive planing,

cleaning up glued panels, or flattening stock.

Grits from 100 through 220 are primarily

finishing grits designed to remove the scratch

pattern from the previous grit used. For best

results, never skip more than one grit grade

when progressing through a sandi ng s equenc e.

For fine work, such as furniture, try not to skip

any grit grades during the sanding process.

pre-cut lengths or in the convenient

In general, premium quality abrasives will

produce a better finish with a less noticeable

scratch pattern.

NOTE: Grits that are too fine can sometimes

burnish the wood and leave a glossy surface

which will not accept stains evenly. This will vary

by type of wood. Oak, for example, is

susceptible to burnishing because of its open

pores.

Cleaning Abrasive Strips

Regularly cl ean the abr asive stri ps on the drum s

with commercially available cleaning sticks,

following the manufacturer’s directions. When

cleaning, also brush the stick crumbs from the

drum while it is still rotating.

In some cases, build-ups resulting from burns

can also be removed with Plexiglas held on

edge over the rotating drum.

Always wear eye protection

while performing sandpaper cleaning, and

take all precautions to avoid any contact of

hands or clothing with the rotating drum.

Cloth-backed abrasives can be cleaned by

soaking in pai nt thinner or mineral spirits for 20

minutes to 1 hour, then u sing a brus h to rem ov e

any build-up. Dr y the abrasive strips completely

before using. Any used solvents should be

discarded in compliance with environmental

regulati ons.

Increasing Abrasive Life

Abrasive life can be increased not only by

cleaning, but by r em ov ing the abrasive strip from

the drum and reversing it. To do this, remove t he

strip and use what was the trailing end as the

starting end on the left (outboard) side of the

drum. Rever sing the stri p will provi de a fresh set

of cutting edges on the abrasive.

brasive Selection Guide

Grit Common Application

24........Abrasive planing, surfacing rough-sawn boards, maximum stock r em ov al , glue removal.

36........Abrasive planing, surfacing rough-sawn boards, maximum stock r em ov al , glue removal.

50........Surfacing and dimensioning boar ds, trueing warped boards

60........Surfacing and dimensioning boar ds, trueing warped boards.

80........Light dimensioning, removal of planer ripples.

100......Light surfacing, removal of planer ripples.

120......Light surfacing, minimal stock removal.

150......Finish sanding, minimal stock rem ov al.

180......Finish sanding only, not for stock removal.

220 ..... Finish sanding only, not for stock removal.

Figure 44

28

Page 29

Troubleshooting: Motor and Electrical Problems

Trouble Probable Cause Remedy

Check plug connections. Connect

Sander will not star t.

Drum motor

overloads.

No incoming power.