Page 1

OWNER'S MANUAL

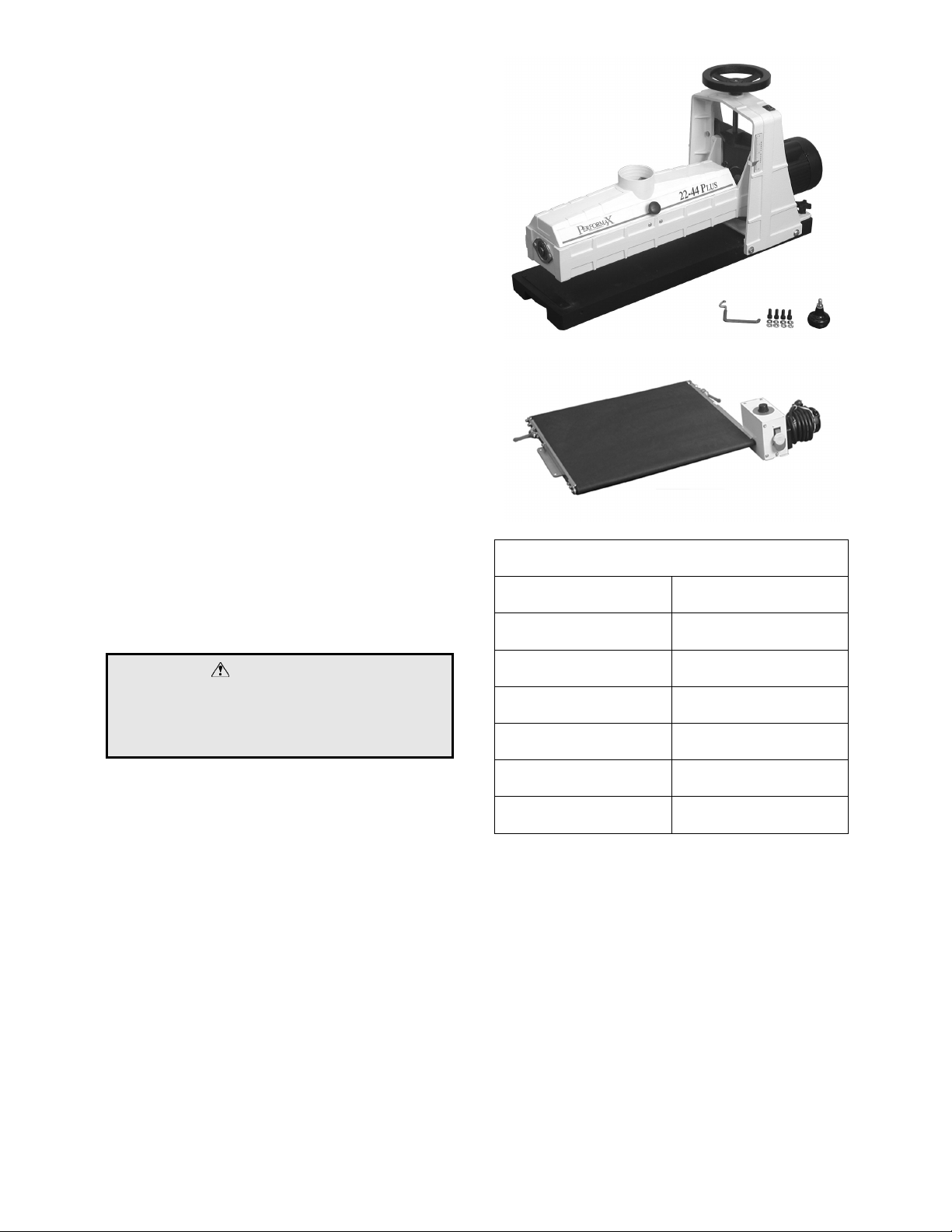

22-44 Plus Drum Sander

(shown with optional accessories)

WMH TOOL GROUP

Consumer/Light Industrial Products Division

P.O. BOX 1349

Auburn, WA 98071-1349

▪

Ph: 1-800-274-6848

E-mail: jet@wmhtoolgroup. co m

www.wmhtoolgroup.com M-649003K 5/03

Copyright © WMH Tool Group

Fax: 1-800-274-6840

Page 2

2

This manual has been pr epar ed f or t he owner and ope rat ors of a 22-44 Pl us Dr um Sander. It s purpo se,

aside from machine operati on, is to promote safety through the u se of acc epted correct operating and

maintenance pr ocedures. Complet ely read the saf ety and maint enance instructions bef ore operati ng or

servicing t he machi ne. To obt ain maxim um lif e and effi cienc y fr om your Perf ormax Sander, and to ai d i n

using the machine saf ely, read this manual thoroughly and follow instructions carefully.

Warranty & Service

The WMH Tool Group warrants ever y pr oduc t it sells. If one of our tools needs service or repai r, one of

our Authorized Repair Stations located throughout the United States can give you quick service.

In most cases, any one of these WM H Tool Group Repair Stations can authori ze warranty repair, assist

you in obtaining parts, or perform routine maintenance and major repair on your JET, Performax, Wilton,

or Powermatic tools.

For the name of an Authorized Repair Station in your area, please call 1-800-274-6848, or v isit

www.wmhtoolgroup.com

More Information

Remember, the WMH Tool Group is consistently adding new product s to the line. For complete, up-t odate product information, check with your local WMH Tool Group distributor, or vi sit

www.wmhtoolgroup.com

WMH Tool Group Warranty

The WMH Tool Group (including Performax, Wilton and Powermatic brands) makes every eff ort to assure

that its products meet high quality and durability standards and warrants to the original retail

consumer/purc haser of our products that each pr oduc t be free f r om defects in materials and workmanship

as follow: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESS SPECIFIED OTHERWISE.

This Warranty does not apply to defects due directl y or indirectly to misuse, abuse, negligence or

accidents, normal wear-and-tear, repair or alterations outside our f aci lities, or to a lack of maintenance.

THE WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN,

ANY IMPLIED WARRANTIES OR MERCHANTIBILITY AND FITNESS ARE EXCLUDED. SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU. THE WMH TOOL GROUP SHALL IN NO EVENT BE

LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXLUSION OR LIMITATION OF INCIDENTA L OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO

YOU.

To take advantage of t hi s warranty, the product or part must be returned f or examination, postage

prepaid, to an Authorized Repair Station desi gnated by our office. Proof of purchase date and an

explanati on of the complaint must accompany the merchandi se. If our i nspect ion discloses a defect, we

will either repair or replace the product, or ref und the purchase price if we cannot readil y and quic kl y

provide a repair or r eplac em ent, if you ar e willing to accept a refund. We will return r epair ed pr oduc t or

replacement at J ET’S ex pense, but if it is determined there is no defect, or that the def ec t resulted from

causes not within the scope of JET’S warranty, then t he user must bear the cost of storing and returning

the product. This warranty gives you specific legal rights; you may also have other rights which v ar y fr om

state to state.

The WMH Tool Group sell s thr ough distr ibutors only. Members of the WMH Tool Group r eserve the right

to effect at any time, without prior notice, those alterations to parts, fittings, and accessory equipment

which they may deem necessary f or any r eason what s oever.

Page 3

3

WARNING

Wear eye protection .

Always keep guards in pl ace and in p rop er operati ng condition. Do not operate the machine

without the guards for an y reason .

This sander is intended to be used with wood and wood products only. Use of this sander and a

dust collector with metal products is a potential fire hazard.

Support the workpiece adequately at all times during operat io n; maintain control of the work at all

times.

This drum sander is designed and intended for use by properly trained and experienced

personnel only. If you are not familiar with the proper and safe operation of a drum sander, do not

use until proper trai ni ng and knowl edg e has been obtained.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form a habit of chec ki ng to see that keys and

adjusting wrenche s are removed from the machine before tur ning it on.

• KEEP THE WORK AREA CLEAN. Cluttered areas and benches inv ite accidents.

• DON’T USE IN A DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet loc ations,

or expose them to rain. Keep work area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept a safe distance from the work area.

• MAKE THE WORKSHOP KID PROOF with padlocks, m aster switc hes, or by removing starter keys.

• DON’T FORCE THE MACHINE. It will do the job bett er and saf er at t he rate for which it was

designed.

• USE THE RI GHT TOOL. Don’t force a machine or attachment to do a job for which it was not

designed.

• USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When

using an extensi on c or d, be sure to use one heavy enough to carry the current your machine will

draw. An undersized cord will cause a drop in the line voltage resulting in power loss and

overheating. The table following shows the correct size to use depending on the cord lengt h and

nameplate amper e r ating. If in doubt, use the next heavier gauge. Remember, t he smaller the gauge

number, the heavier the cord.

Volts Total Length of Cord in Feet

120V 25 50 100 150

12-18 Amps 12 Not Recommended

• WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neck ties, rings, bracelet s, or other

jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear protectiv e

hair covering to contain long hair.

• ALWAYS USE SAFETY GLASSES. Also use face or dust masks if the cutting operation is dusty.

Everyday eyeglasses only have impact resistant lenses; they are not safety gl asses.

• DON’T OVERREACH. Keep proper f ooting and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricati ng and c hanging accessories.

AWG

Page 4

4

• ALWAYS DISCONNECT THE MACHINE FROM THE POWER SOURCE BEFORE SERVICI NG.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure the switc h is in the off position

before pluggi ng i n.

• USE RECOMMENDED ACCESSORIES. The use of accessories and attachments not

recommended by JET may cause hazards or risk of injury to persons.

• NEVER STAND ON A MACHINE. Serious injury could oc c ur if t he m ac hine is ti pped.

• CHECK DAMAGED PARTS. Before further use of the mac hine, a guard or other part that is

damaged should be carefully checked to determine t hat it will operate properly and perform its

intended function - check for alignment of moving parts, binding of moving parts, br eak age of parts,

mounting, and any other conditions that may aff ect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

• NEVER LEAVE THE MACHINE RUNNING UNATTENDED. TURN POWER OFF. Don’t leave the

machine until it com es to a c om plete stop.

• SOME DUST CREATED by power sanding, sawing, gr inding, drilling and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paint

• crystalline silica from bricks and cement and other m asonry pr oduc ts, and

• arsenic and chromium from chemically-treated lumber.

• YOUR RISK from those exposures v aries, depending on how often you do this type of work. To

reduce your ex posure t o these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specifically designed to filter out microscopic

particles

• DO NOT operate tool while under the influence of drugs, alcohol or any medication.

• DO NOT sand pieces of material that are too small to be safely supported.

• WHEN sanding a lar ge workpiece, provide addi tional support at table hei ght.

• ADDITIONAL INFORMATION regarding the safe and proper operation of this product is available

from the National S afety Council, 1121 Spring Lake Driv e, Itasca, IL 60143-3201, in the Acci dent

Prevention Manual for Industrial Operati ons and al so i n the safety Data Sheets provi ded by the NSC.

Please also refer to the American National Standards Institute ANSI 01.1 Safety Requirements for

Woodworking M ac hiner y and the U. S. Depar tment of Labor OSHA 1910.213 Regulations.

• ALWAYS feed stock against the r otation of the drum.

• ALWAYS connect and use a dust collector to the drum sander whil e oper ating.

• SAVE THESE INSTRUC TIONS refer to them often and use them to instruct others.

Page 5

5

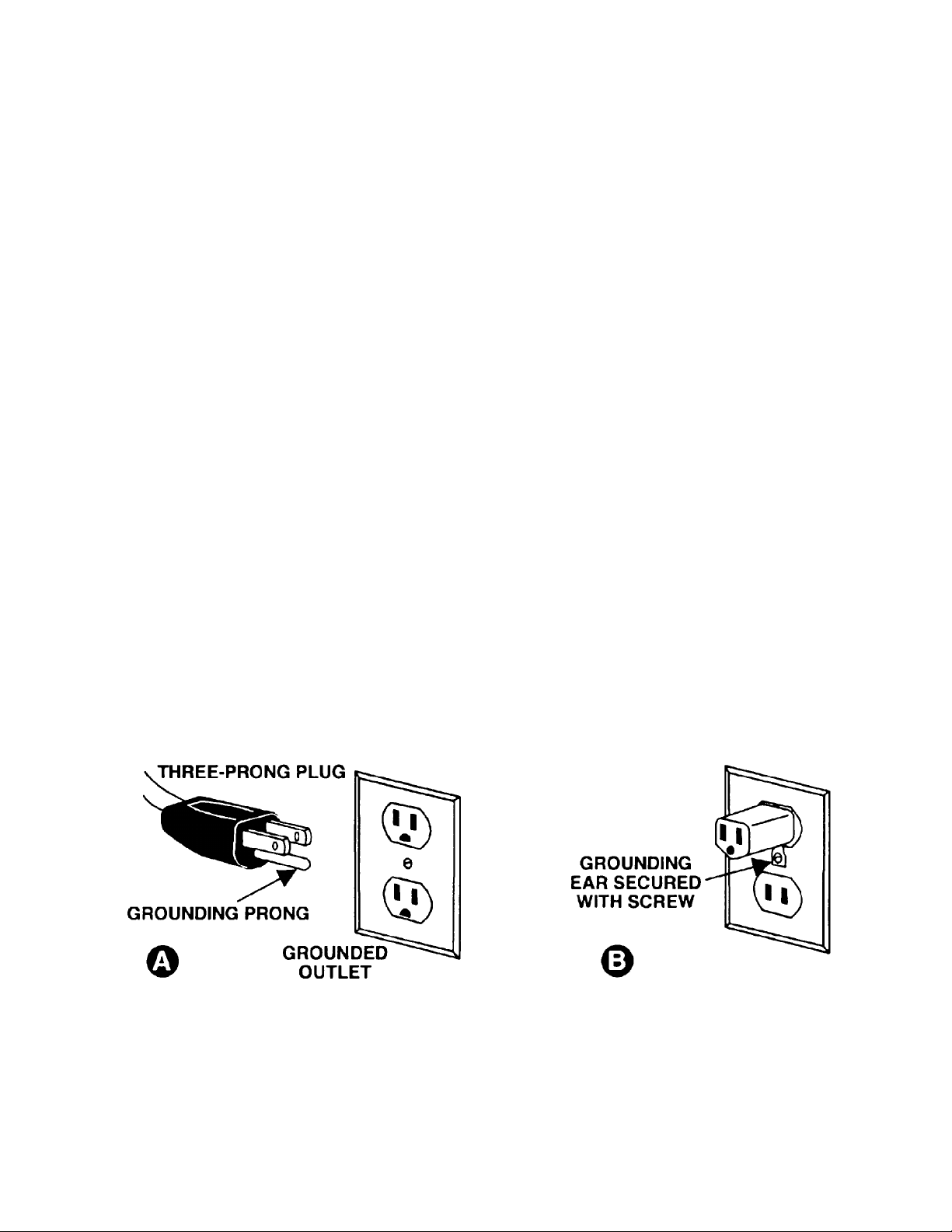

Grounding Instructions

Caution: This tool must be grounded while in use to protect the operator from electric shock.

In the event of a malfunction or breakdown, grounding provi des a path of least resistance for electric

current to reduce t he ri sk of elec tric shock. This tool is equipped with an electric cord having an

equipment-gr ounding conductor and a grounding plug. The plug must be plugged into a matching outlet

that is properly installed and grounded in accor danc e with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, hav e the proper outlet installed by a qualifi ed

electrician.

Improper connection of the equipment- gr ounding conductor can result i n a risk of electric shock. The

conductor, with insulation having an out er surface that is green with or without yellow stripes, is the

equipment-gr ounding conductor. If repair or replacement of the electric cord or plug i s necessary, do not

connect the equi pm ent- gr ounding conductor to a live terminal.

Check with a qualified electrician or service per sonnel if t he gr ounding instructions are not com pletely

understood, or if i n doubt as to whether t he tool is properly grounded. Use onl y three wir e ex tension cords

that have three-prong grounding plugs and three-pole receptacles that ac c ept t he tool’s plug.

Repair or replace a dam aged or worn cord im mediately.

115 Volt Operation

As received fr om the factory, your sander is ready to run at 115 volt operation. This sander, when wired

for 115 volts, is intended for use on a circuit that has an outlet and a plug t hat looks the one illustrated in

Figure A. A tempor ary adapt er , which looks like the adapter as ill ustr ated in Figure B, may be used to

connect this plug to a two-pole receptacle, as shown in Fi gur e B if a properly grounded outlet is not

available. The temporary adapter should only be used until a properly grounded outlet can be installed by

a qualified elec trician. This adapter is not applicable in Canada. The green colored rigid ear, lug, or

tab, extending f rom the adapter, must be connected to a perm anent ground such as a properly grounded

outlet box, as shown in Fi gur e B.

Page 6

6

Specifications 22-44 Plus Drum Sander

Stock Number..............................................................................................................................649003K

Max. Width (in)................................................................................................................. 44 (two passes)

Min. Length (in)..................................................................................................................................2-1/4

Max. Thic kn e ss (in)..................................................................................................................................4

Min. Thickness (in)..............................................................................................................................1/32

Drum (in).......................................................................................................... 5x22 Extrusion, Aluminum

Drum Speed (RPM) ........................................................................................................................... 1700

Dust Chute (in)........................................................................................................................................4

Conveyor Motor .......................................................................... 43 inch-lb torque, direct drive D.C. motor

Conveyor Variable Feed Rate (FPM) .............................................................................0-10 (SandSmart)

Motor (TEFC)....................................................................................................1-3/4 HP, 1Ph, 115V Only

Net Weigh t (lb s)...................................................................................................................................231

Shipping Weigh t (lbs)...........................................................................................................................254

Table of Contents

Warranty..................................................................................................................................................2

Warnings ....................................................................................................................... .......................3-4

Grounding Instructions.............................................................................................................................5

115 Volt Operati on...................................................................................................................................5

Specifications.......................................................................................................................................... 6

Table of Contents....................................................................................................................................6

Contents of the Shipping Carton..............................................................................................................7

Tools Required for Assembly & Adjustments............................................................................................7

Unpacking ...............................................................................................................................................7

Assembly and Set up................................................................................................................................8

Drum Height Control................................................................................................................................8

Conveyor Belt Tension.............................................................................................................................8

Conveyor Belt Tracking............................................................................................................................9

Dust Cover ..............................................................................................................................................9

Checking Drum Alignment .......................................................................................................................9

Aligning th e Drum....................................................................................................................................9

Fine Tuning Drum Alignment.................................................................................................................. 10

Wrapping Abr asive Strips..................................................................................................................10-11

Connecting Sander to a Dust Collector...................................................................................................12

Depth Gauge.........................................................................................................................................12

Setting the Depth of Cut.........................................................................................................................12

Establishi ng the proper Drum Height......................................................................................................12

Selecting SANDSMART™ Feed Rates ...........................................................................................13

Abrasives...............................................................................................................................................13

Selecting Drum Abrasives......................................................................................................................13

Selecting Abrasive Grits.........................................................................................................................14

Stock Feeding Angle..............................................................................................................................14

Multiple Piece Sanding Runs.................................................................................................................14

Edge Sanding........................................................................................................................................14

Sanding Imperfect Stock........................................................................................................................14

Face Frames and Rai sed Panel Doors...................................................................................................14

Monthly Mai ntenance.............................................................................................................................14

Cleaning the Abrasive Strip....................................................................................................................15

Stretching Abrasive Life.........................................................................................................................15

Conveyor Belt Replacement................................................................................................................... 16

Tension Roller Alignment.......................................................................................................................16

Tension Roller Pressure Adjustment......................................................................................................16

Drum Height Control Adjustment............................................................................................................16

Troubleshooting.....................................................................................................................................17

Part’s Breakdown and Part’s List.......................................................................................................18-22

Wiring Diagram......................................................................................................................................23

The specifi cations in this manual are given as general i nformation and are not bi nding. The WMH Tool

Group reserv es the right to effect, at any time and without pri or notice, changes or alt erations to parts,

fittings, and acc essory equi pment deemed necessary for any r eason whatsoever.

Page 7

7

Contents of the Shipping Cartons

22-44 Plus Sand er (Box 1)

1. Sander Assembly

1. Plastic Knob

1. TUF Tool

1. Abrasive Stri p ( wrapped on drum)

1. Owner's Manual

1. Warranty Card

1. Hardware Bag

4. 5/16”-18x3/4” Socket Head Cap Screws

4. 5/16” Lock Washers

4. 5/16” Flat Washers

4. 3/8”-16x1” Hex Cap S c r ews

4. 3/8” Flat Washers

1. 1/8” Allen Wrench

1. 6MM Allen Wrench

22-44 Plus Conveyor (Box 2)

1. Conveyor Assembly

Tools Required for Assembly &

Adjustments

1. Flat Head Screwdriver

1. Set of Open End Wrenches

1. Set of Allen Wrenches

1. Adjustable Wrench

WARNING

Read and understand th e entire contents of

this manual before attempting assembly or

operation of the drum sander!

Failure to compl y may cause seri ou s in ju ry!

Unpacking

1. Remove all contents from the shipping

carton(s).

2. Report any damage to y our di stri butor.

3. Do not discard any shipping material until

the sander has been assembled and is

running properly.

Performax 22-44 PLUS Accessories &

Supplies

Stock # Descripti on

609004 Open Stand with Shelf

609005

98-2202 Infeed/Outfeed Tables

98-0130

60-0505 Abrasive cleaning stick

60-0322-P Conveyor belt

Closed Stand with

Shelf & Casters

Caster Set (4) for

Open Stand

Page 8

8

Assembly and Setup

If you purchased the optional Performax 22-44

Plus Stand refer its assem bly instruct ions bef or e

proceeding with the drum and conveyor

assembly.

1. Attach the knob (A , Fi g. 1) to t he handwheel

and tighten with a 9/16” wrench.

2. Place the conv eyor upside down on a table

surface.

3. Raise the drum by turning handwheel (B,

Fig. 2) clockwise.

4. Align four holes in the conv ey or with the f our

holes in the base of drum assembl y .

5. Secure conv eyor in place wit h four 5/16”-18

x 3/4” socket head cap screws (C, Fig. 2),

four 5/16” lock washers and four 5/16” flat

washers.

6. Plug motor cord into the control box

receptacle.

Drum Height Control

Drum height is controlled by the height

adjustment handle (B, Fig. 2). Turning

handwheel in a counter-clockwise direction

lowers the drum.

Turning height adjustment handwheel one

revolution lower s the dr um appr ox imately 1/16”.

Conveyor Belt Tension

Conveyor belt tension adjustment may be

necessary duri ng break i n peri od t o com pensate

for belt stretching.

If conveyor belt can be stopped by hand

pressure applied di rectly to the top of conveyor

bed, the belt is too loose. Insufficient belt

tension will cause slippage of conveyor belt on

the drive roller during sanding operation.

Excessive belt t ension can result in bent rollers,

bent take-up brackets and premature conveyor

belt wear.

After the PowerFeed unit has been installed

adjust the hex nuts (D, Fig. 2) on bot h sides of

the conveyor to obtain a tight, and equally

tensioned conveyor belt. Use the attached

wrench (E, Fig. 2) to adjust the hex nuts.

Page 9

9

Conveyor Belt Tracking

Belt tracking adjustment may be necessary during

break-in period to compens ate for belt stretching.

Abrasive belt tension must be properly adjusted

before adjusting the tracking. Adjust the belt

tracking while conveyor belt is running at its fastest

speed.

Tighten hex nut (A, Fig. 3) on the side the belt is

drifting towards, and loosen hex nut on the opposite

side. Use the attached wrench (B, Fig. 3) to

adjust the hex nuts. Note: Adjustment should be

made in 1/4 turns of t he hex nut. Allow time for the

belt to rea ct to the adjustmen t . Do n ot over adjust .

Dust Cover

To open dust cover push in on the knob (C, Fig

3) and lift.

Checking Drum Alignment

The sanding drum comes preset from the

factory. If a pr oblem with drum alignment occ ur s

follow the below listed instructions.

1. Push in and lift knob (C, Fig. 3) to open

cover and remove abrasiv e strip. If you are

unsure how to do this see the “Wrapping

Abrasive Stri ps” section page 10.

2. Use a metal straight edge, or ruler as a

thickness gauge (D, Fig. 4). Insert the

gauge between the drum and convey or bed

on outer end of drum.

3. Open dust cover and lower sanding drum

while slowly rot ating drum by hand until the

drum lightly contac ts the thickness gauge.

4. Remove thickness gauge and place under

the drum at opposit e end. If drum does not

contact the thickness gauge to the same

degree as the other end of the drum,

alignment is necessary.

Aligning the Drum

1. Loosen the four hex cap bolt s (E, Fig. 5) two

in front and two in back.

2. Lay the thickness gauge under the drum

lengthwise.

3. Adjust the knob, (F, Fig. 5) until drum

contacts the gauge equ ally along i ts surface.

Turn the adjusting knob clockwise to raise

outboard end of drum, and counterclockwise to lower outboard end of drum.

4. When drum is parallel to the conveyor

tighten the four hex cap bolts.

Page 10

10

Fine Tuning Drum Alignment

When sanding boards wider then the drum,

drum alignm ent is critical and must be adj usted

exactly l ev el to slightly high on the outboard end.

This should prev ent any ridges from developing

in the stock. Always test on scrap wood bef ore

sanding workpiece.

Run a piece of scrap wood approximately 6”

wide by 30” - 40“ t hrough the sander side ways

so that the end of board ex t ends past the end of

drum.

Turn board 180 degrees and sand the same

side of the workpiece without changing the

sanding height.

If a ridge i s vi sible due to drum overlap l oosen

the four hex cap bolts (A, Fig. 6) and turn the

adjusting knob (B, Fig. 6) slightly. Turn the

adjusting knob clockwise to raise the outboard

end of the drum. Ti ght en the four hex c ap bolts.

Repeat process until ridge i s gone and the entire

workpiece is sanded.

Wrapping Abrasive Strips

Note: When using Perform ax “Ready to Wrap”

and “Ready to Cut” abrasives, not all of the

steps below are necessary. You can use the

original abr asiv e belt that comes with t he sander

as a template for cutti ng y our own stri ps.

1. Mark and cut a taper at one end of the roll,

see Figure 7.

2. Square off the end of taper, see Figure 7.

3. Raise fastener lever (C, Fig. 8) on the

outboard end of drum, and insert the

tapered end of the abrasive (D, Fig. 8) so

that it uses most of the width of the slot.

Then release the cl ip lever to securel y hold

the strip end to the fastener.

4. The square edge of the abrasive strip should

follow the edge of the drum, see Figure 8.

Page 11

11

5. Wrap abrasiv e strip around the dr um, being

careful not to overlap the windings, see

Figure 9.

6. Mark trailing end of strip where it crosses

the inboard end of drum ( A, Fig. 10) .

7. Remove the abrasive strip and cut a taper

as was done with the starting edge, see

Figure 7. Note: The taper on the rem aining

roll can be used as the t aper for the starti ng

edge of the next stri p to be cut.

8. Rewrap the drum starting at the lef t side as

described in steps 3-5 on the pr ev ious page.

9. Raise fastener lever completely on the

inboard end of drum, and insert the t apered

end of abrasive strip through the sl ot into the

take-up fastener.

Important: Position the abrasive strip with

sufficient room between the inside of slot and

the tapered end of strip to all ow it to be pulled

into the drum as needed, see Figure 11.

The abrasive str ip m ay stretch enough i n use to

allow the take-up fastener to reach its lowest

position so it no longer is able to maintain

tension of the strip. If this occurs, it will be

necessary to reset the take-up lever by raising it,

pushing the strip end into the slot, and then

releasing the cli p lever.

The Tuf Tool (B, Fig. 12) can also be used to

hold the take- up fastener in place while you feed

the sandpaper through the slot. Hold the Tuf

Tool at an angle to insert t he end into t he hole in

take-up f astener. P ull the t ool up and r otat e 90°

to clamp onto the drum, see Figure 12.

Page 12

12

Connecting Sander to a Dust Collector

Dust collection is necessary for all drum

sanders. The Performax 22- 44 P lus is equipped

with a 4” dust collection port at the top of the

dust cover, and is designed to be used with a

standard dust col lector, see Figure 13.

JET offers a variety of Dust Collectors and Air

Filtration Units that will work nicely with your

new sander. Contact your local distributor for

more informati on.

Depth Gauge

The depth gauge indi cat es the distance f rom t he

bottom of the drum to the t op of the convey or .

1. Lower the drum, with sandpaper installed,

until it touches the c onveyor.

2. Loosen hex nut (A, Fig. 14).

3. Adjust the pointer (B, Fig. 14) to read zero

and tighten bolt.

Note: depending on the desired accuracy you

may need to repeat t his process when installing

different sandpaper grits.

Setting the Depth of Cut

Adjusting the Performax 22-44 for proper

contact between the abrasive and the stock is

the most important set-up procedure before

operating the sander. It may take some

experimentation to determine the proper depth

of cut, given the variables of abrasive grit and

type of wood. For best result s, use scrap wood

to practice sanding and to develop skill and

familiarity with the machine before doing finish

work.

A good rule of thumb when sanding with grits

finer than 80 is lower the drum so t hat it contacts

with work piec e but sti ll can be rot ated by hand.

When using grits coarser than 80 grit, you can

lower the drum slightly more. However, a

combination of several variables will determine

the proper depth of cut to use, including the

following:

• Abrasive type and gri t size.

• Width of the piece being processed.

• Hardness of the piec e.

• Feed rate of stock.

Establishing the Proper Drum Height

To establish the proper drum height, place the

board to be sanded under the drum and lower

the drum to the board thickness. Note:

Sanding drum should still rotate by hand.

Without changi ng drum height, finish f eedi ng the

stock under the sander. St art sanding drum and

sand the board at that same position.

Page 13

13

Selecting SANDSMART™ Feed Rates

Begin experimenting with the feed rate set at

about 40%-50% of maximum. The best feed

rate will depend on a number of factors,

including type of stock, grit and depth of cut

used, and whether the stoc k is feed directly inline wit h the conveyor bed or at an angle. If a

“rippl e effect” or inconsistent fi nish is observ ed,

slow down the f eed rate. If the fi nish is smooth

and consistent and the sander is not

overworking, experiment using a faster feed

rate.

The SandSmar t c ontrol ( A, Fi g. 15) cont i nuously

monitors the load on the drum motor, and

automatically regulates the speed of the

conveyor m otor to maintai n the highest f eed r ate

without overl oad. If the load on the drum motor

increases, the SandSm art control will decrease

the conveyor feed rate and will stop the

conveyor under extreme conditi ons. If the load

on the drum decreases, the SandSmart control

will incr ease the feed rate but will not increase it

faster than the m anual setting on the switch dial.

The best and most consistent finish will be

achieved if the convey or does not c hange speed

during operat ion. W hen the “red” indicator light

(B, Fig. 15) comes on, the SandSmart control

has detected too gr eat a depth of cut and/ or too

fast a feed rate. This change in conv ey or speed

may affect the finish surface. If the finish is

affected, make another sanding pass without

changing any settings. If the finish is still

affected, make adjustments by slowing the

conveyor and/ or decreasing the depth of cut and

run the stock thr ough again.

Abrasives

The abrasive material you choose will have a

substantial effect on the performance of your

sander. Variations in paper type, weight,

coating, and dur ability all contribute to achiev ing

your desired finish. For the best sanding resul ts,

Performax offers premium abrasives that have

been tested and cert ified for lowest ov erall cost

and maximum performance. Genuine

Performax abrasives are available in pre-cut

“Ready- to-Wrap” lengths or in the convenient

pre-mark ed “Ready-to-Cut” box.

Selecting Drum Abrasives

It is important to select the proper grit of

abrasives for the type of sanding being

performed t o achiev e maximum sanding resul ts.

As with any sanding operation, first begin

sanding with coarser grit, depending on the

roughness of t he stock, or the amount of stock

to be removed. T hen progressiv el y work toward

finer grits. The chart below shows the general

uses for the v ari ous grit s. Perf orm ax off ers strip

rolls in the eight dif ferent abrasive grits shown.

Grit Common Application

24 Grit Abrasive planing, surfacing rough-

sawn boards, maximum stock

removal, glue r emoval.

36 Grit Abrasive planing, surfacing rough

sawn boards, maximum stock

removal, glue r emoval.

50 Grit

60 Grit

80 Grit Surfacing, light dimensioning,

100 Grit Light surfacing, removing light planer

120 Grit Light surfacing, minimal stock removal.

150 Grit Finish sanding, minimal stock removal.

180 Grit Finish sanding only, not for stock

220 Grit Finish sanding only, not for stock

Surfacing and dimensioning boards,

truing warped boards

removing planer ri pples.

ripples.

removal.

removal.

Page 14

14

Sele c ting Abra sive Gr its

The amount of stock to be removed i s a major

consideration when choosing the grit grade to

start with. Grits of 24, 36, 50, 60 and 80 are

primarily designed for stock removal. Grits 24

and 36 will remove the most material in one

pass, whether you are d oing abrasiv e planning,

cleaning up glued panels, or flattening stock.

Grits from 100 through 220 are primarily

finishing grits designed to remove the scratch

pattern from the previous grit used. For best

results, never skip more than one grit grade

when progressing through a sandi ng s equenc e.

For fine work, such as furniture, try not to skip

any grit gr ades during the sanding pr ocess. In

general, premium quality abrasives such as

genuine Performax abrasives will produce a

better finish with a less noticeable scratch

pattern. Note: Grits that are too fine can

sometim es burnish the wood a nd leave a gl ossy

surface that will not accept stains ev enly. This

will vary by type of wood. Oak, for example, is

susceptible to burnishing because of its open

pores.

Stock Feeding Angle

The optimum stock feeding angle, when

sanding, is at a 60 degree angle (Fig. 13).

However, even a sl ight stock feeding angl e will

provide more effective stock removal, less

loading of abrasives, longer abrasive life,

potentially faster feed rates and reduced m otor

loads.

When finish sanding the workpiece should be

fed through in li ne wit h the grai n on the fi nal one

or two passes for the optim um finish.

Multi pl e- Piece Sandin g Runs

When abrasiv e planing (or t hickness sanding) a

run of sim ilar pieces that you want to h ave the

same thick ness, it is best t o sand all the pi eces

at the same time. This way you will be able to

determine the thickness of the thinnest piece

and process all pieces to that same thickness.

Be aware that the sander will remove cups and

crowns in the work piece; consider this when

measuring the processing stock to the same

thickness.

Edge Sanding

When edge sanding, the Performax sander will

mimic the opposite edge of the stock which is

lying on the conv eyor belt. Because of this, it is

important for the stock edge to have been r ipped

at the proper angle to the face before the

sanding process. When edge sanding stock that

is less than 3/4” wide, or m ore than 2” hi gh, it is

good procedure to stack and clamp several

pieces together to prevent them from sl ipping, or

tipping.

Sanding Imperfect Stock

When sanding stock with a c up or crown, place

the crown up. Thi s will stabilize the stock to hel p

prevent ti pping or roc ki ng duri ng sanding. ( Af ter

the crown has been rem oved and t he top is fl at,

turn the stock ov er and sand the oppo site side. )

To avoid personal inj ury, t ake speci al c are when

sanding stock that is twisted, bowed or

otherwise v aries in thickness f rom end to end. If

possible, support such stock as it is being

sanded to keep it from slipping, or tipping. Use

extra rol ler stands, hel p from another person, or

hand pressure on the stock to minimize

potentially hazardous situations.

Face Frames and Raised Panel Doors

It is v ery important t o have the proper abrasive

contact when doi ng this type of san ding. If t he

sander is set t o take an ex cessive depth of cut,

the result can be a gouge, or dip as the drum

goes from sanding the rails at full width to

sanding just a f ew inches of width on the sti les.

To prevent this problem, make sure that when

using abrasives fi ner then 80 grit the drum is in

contact wit h the wood, but can sti ll be spun by

hand.

Monthly Maintenance

For best results, perform the following

recommended maintenance procedures on a

monthly basis:

• Lubricate conv eyor bushings and check for

wear.

• Lubricate all movi ng parts, such as threaded

rods, washers, and bushings.

• Clean sawdust from the conveyor belt and

sandpaper.

• Blow dust f rom motors and switches. B low

dust from the inside of sanding drum to

prevent vibration. Be careful not to disturb

the drum balanci ng weights.

• Check all setscrews for tightness on parts

such as bearings, conveyor and couplings.

Page 15

15

Cleaning Abrasive Strips

A sandpaper cleaning stick may be used to

remove deposits and help extend sandpaper life.

To use, operate the sanding drum with the dust

cover open.

Caution: For your own safet y, always wear eye

protecti on while performing sandpaper cleani ng,

and take all precautions to avoid any c ontact of

hands, or clot hing with uncovered drum s. Hold

the cleani ng stick against t he rotating dr um and

move it along t he drum surface. It i s good idea

to use a shop brush or air nozzle to rem ove any

cleaning stick crumbs from the drums before

resuming sanding oper ations.

Cloth-backed abrasives can be cleaned by

soaking in pai nt thinner, or mineral spiri ts for 20

minutes to one hour. Then use a nylon brush to

remove any buildup.

Stretching Abrasive Life

Abrasive lif e can also be inc reased by rem oving

the abrasive strip from the drum and r eversing it.

To do this, r emove the strip and use what was

the trailing end as the starting end on the left

(outboard) si de of t he drum . Rev er sing the st ri p

will provide a fresh set of cutting edges on the

drum.

Perf ormax 22-44 Abrasives

“Ready-to-W rap” 24 – 220 Grit, contains 3 precut wraps.

Ready-to-Wrap

60-2024 24 Grit 60-2120 120 Grit

60-2036 36 Grit 60-2150 150 Grit

60-2060 60 Grit 60-2180 180 Grit

60-2080 80 Grit 60-2220 220 Grit

60-2100 100 Grit

“Ready-to-Cut ” 50 – 220 Grit, c ontains 14 wraps.

24 & 36 Grit contains 10 wraps.

Ready-to-Cut (Aluminum oxide)

60-9036 36 Grit 60-9120 120 Grit

60-9060 60 Grit 60-9150 150 Grit

60-9080 80 Grit 60-9180 180 Grit

60-9100 100 Grit 60-9220 220 Grit

Ready-to-Cut “Blue” (longer life)

60-8024 24 Grit 60-8080 80 Grit

60-8036 36 Grit 60-8100 100 Grit

60-8050 50 Grit 60-8120 120 Grit

60-8060 60 Grit

Page 16

16

Conveyor Belt Replacement

To replace the conv ey or belt:

1. Disconnect the machine from the power

source. Unplug motor cord from control

box.

2. Raise drum to highest position using the

handwheel (A, Fig. 16).

3. Remove the belt tension by loosening the

take-up nuts (B, Fig. 16).

4. Unscrew the four socket head cap screws

(C, Fig. 16) that attach the conveyor and

remove the convey or from the bed.

5. Slide the conveyor belt off of the conveyor

and replace with a new belt.

Tension Roller Alignment

1. Remove abrasive strip (D, Fig. 17) from

drum.

2. Loosen all four bear ing hex nuts (E, Fig. 17).

3. Thi s will all ow the tension rol lers to drop to

the lowest positi on.

4. Lower the sanding drum so it just touches

the conveyor bed.

5. Turn the drum height handle one complete

revolution to raise the drum.

6. Retighten bearing hex nuts.

Tension Roller Pressure Adjustment

You can also adjust the spring loaded screws,

found on the pressure roller brackets, to

increase or decrease rol ler pressure. If y ou are

having snipe marks at the leading end of the

board adjust the outfeed roller pressure. If the

snipe mark occurs on the trailing end of the

board adjust infeed roller pressure.

Drum Height Control Adjustment

If the height control mechanism does not

operate easil y or smoot hly, or ther e is ex cessiv e

vertical movement or deflection of the drum

carriage, perform the following adjustments.

1. Tighten all four lock nuts (F, Fig. 18) and

then loosen 1/8 to 1/ 4 tur n.

2. Thoroughly lubricate the mating surfaces

and height adjustment screw.

Page 17

17

Troubleshooting Guide

Problem Possible Cause Solution

Conveyor belt does not

move.

Conveyor rollers run

intermittently.

Abrasive Strip Comes

off Drum.

Abrasive Strip Loose.

Abrasive Loads up

Prematurely.

Line or Groov e in Stock. 1. Inconsistent feed rate. 1. Do not stop or change feed rate.

Wood Burns.

Board slips on conveyor

belt.

Sander motors slow or

stall

Rippled sanded surface

A. Non uniformly

spaced ripples.

B. Uniformly spaced

ripples.

Gouging of wood.

Snipe 1. Improper tensi on r ollers setting 1. S ee tension roller adjustment.

Motor overload

protector trips or shop

wiring breaker trips.

Shaft coupler not attached. Attach shaft coupler.

Align shaft fl ats of gear motor and

Shaft coupling loose.

1. Slack in abrasive strip on drum.

2. Abrasive improperly wrapped.

1. Strip caught on insi de edge of

slot, or on inboard si de of drum .

2. Strip not cut proper ly .

1. Excessive dept h of cut.

2. Excessive feed rate.

3. Inadequate dust collection.

4. Inadequate abrasive.

1. Abrasive stri p ov erl apped.

2. Excessive dept h of cut.

3. Depth of cut excessive for fine

grit.

4. Feed rate too slow.

5. Abrasive loaded.

6. Worn abrasives.

1. Tension roller s too high.

2. Excessive feed rate.

3. Dirty or word conveyor belt.

1. Improper convey or belt tension.

2. Excessive dept h of cut.

3. Excessive feed rate.

A. Uneven feed rate.

B. Conveyor bed flexing or

vibration.

1. Inconsistent feed rate.

2. Stock slipping on conveyor.

3. Workpiece not pr oper ly

supported.

1. Excessive load on sanding dr um

and motor.

2. Too many tools on circuit.

3. Excessive length or inadequate

size extension cor d.

drive roller and tighten shaft coupling

set sc rew s.

1. Remov e slack in st rip.

2. Read section on wrapping

abrasive strips.

1. Re-adjust stri p end in sl ot and/or

trim abrasive edge.

2. Recut and install abrasive strip.

1. Reduce depth of cut.

2. Use slower feed rat e.

3. Increase airfl ow at dust ports.

4. Use open-coat abrasive.

1. Re-wrap abrasiv e str ip.

2. Reduce depth of cut.

3. Use coarser grit or reduce depth

of cut.

4. Increase feed r ate.

5. Clean abrasives.

6. Replace abrasives.

1. Lower tension rol lers.

2. Reduce feed rate.

3. Replace conv eyor belt.

1. Adjust belt t ensi on.

2. Reduce depth of cut.

3. Reduce feed rate.

A1. Conveyor bel t slipping, see

above.

A1. Board slips on conveyor, see

above.

A1. Power feed gear motor stalls,

see above.

B1. Reduce depth of c ut.

B1. Reduce f eed r ate.

B1. Check for loose bolts, shaft

coupling set screws or out of

balance drum.

1. Maintain constant feed rate (by

hand).

2. Excessive dept h of cut

(PowerFeed) or inadequate hold

down pressure.

3. Add work supports for long

workpieces.

1. Allow motor to cool and reset

overload butt on.

2. Have a certified electrician

correct the shop wiring pr oblem.

3. Use a shorter heavier gauge

extension cord.

Page 18

18

Drum Head Assembly

Page 19

19

Drum Head Assembly

Index Part

No. No. Description Size Qty.

1..........70-4102........................Motor, 1-3/4 HP, 110-120 Volt w/Cord.... ...............................................1

2..........72-6104........................Strain Relief........................................... ...............................................1

3..........72-5345........................Cord, Motor To Control Box................... ...............................................1

4..........30-9025........................Slide, Moto r Mount................................. ...............................................1

5..........30-9024........................Carriage, Drum...................................... ...............................................1

6..........TS-0060061.................Screw, Hex Head Cap ...........................3/8-16x1 1/4”...........................9

7..........TS-0680041.................Washer, F lat..........................................3/8”.......................................11

8..........30-9023........................Shroud................................................... ...............................................1

9..........30-9026........................Stud....................................................... 5/16-24x1 3/4”.........................4

10........50-3090-01................... Washer, Oili te 5/1 6 ”I.D........................... ...............................................8

11........TS-0209061.................Screw, Socket Head Cap....................... 3/8-16x1 1/4”...........................4

12........12-2003-05................... Nut, Hex, Lock Nylon Insert....................5/16-24....................................4

13........30-9027........................Screw, Height Adjustment ......................5/8-18UNC..............................1

14........50-9000........................Bearing, Th ru st......................................51103......................................1

15........30-9028........................Handle-Wheel, Height adjustment.......... ...............................................1

16........TS-0270051.................Set Screw..............................................5/16-18x1/2”............................ 2

17........80-2324........................Washer, Fla t-N ylon................................5/8”I.D.....................................1

18........20-1180-02................... Collar, Locking Shaft.............................. ...............................................1

19........10-4020-04................... Screw, Set Socket Head (Collar)............5/16-18x1/4”............................2

20........94-1668........................Label, Height-Direction .......................... ...............................................1

21........94-2270........................Label, Depth Gauge...............................4”............................................1

22........20-0762-02................... Key ........................................................3/16 SQ x3/4”..........................2

23........50-2207........................Coupling................................................ ...............................................2

24........10-4010-04................... Set Screw..............................................1/4-20x1/4”..............................4

25........50-2209........................Spider, Coupling.................................... ...............................................1

26........80-3138........................Knob, Fine Tune Adj ustm ent.................. ...............................................1

27........TS-0060081.................Hex Head Cap Screw ............................3/8-16x1 3/4............................1

28........20-3216........................Spring.................................................... ...............................................1

29........30-9022........................Base, Conveyor Mount ing...................... ...............................................1

30........20-0778........................Retaining Ring....................................... STW25....................................2

31........40-3169........................Pointer, Depth Gauge............................ ...............................................1

32........50-3089........................Bearing, Drum.......................................NTN 6205 ...............................2

33........TS-0720091.................Washer, Lock.........................................3/8” .........................................4

34........10-1205........................Bolt Carriage Head................................5/16-18x1”...............................4

35........11-0206........................Washer, Lock.........................................5/16” .......................................9

36........12-2000-05................... Hex Nut.................................................5/16-18....................................5

37........40-0304........................Bracket, Tension Roller.......................... ...............................................2

38........40-0308-01................... Bracket, Right-Tension Roller................ ...............................................2

39........40-0308-02................... Bracket, Left-Tension Roller................... ...............................................2

40........80-1060........................Pad, Bracket-Tension Roller.................. ...............................................2

41........20-3211........................Spring, Ten sion Roller........................... ...............................................4

42........10-4008-16................... Screw, Fillister Head-Phillips..................#8-32x1”..................................4

43........40-3166........................Catch, Dust Cover ................................. ...............................................1

44........50-3105........................Bushing, Oilite 5/16”I.D.......................... ...............................................4

45........30-3051-06................... Roller, Tension ...................................... ...............................................2

46........30-3002........................Drum, Sanding....................................... ...............................................1

47........21-1173........................Fastener, Abrasive-Out board................. ...............................................1

48........21-1172........................Fastener, Abrasive-Inboard.................... ...............................................1

49........10-3003........................Screw, Flat Head-Phillips.......................6-32x3/8”.................................2

50........80-2003........................Cover, Dust ........................................... ...............................................1

51........80-3137........................Knob, Dust Cover .................................. ...............................................1

52........40-3168........................Latch, Dust Cover.................................. ...............................................1

53........80-3131........................Knob...................................................... ...............................................1

54........2244PLUS-254............. Pin, Hinge..............................................#3x80......................................2

55........2244PLUS-255............. Pan Head Machine Screw......................1/4-20x3/4”..............................3

56........11-1000-04................... Washer, Lock-Int. Tooth.........................1/4” .........................................2

Page 20

20

57........12-2000-04................... Hex Nut.................................................1/4-20 .....................................2

58........11-1002-04................... Flat Washer...........................................1/4 ..........................................2

59........12-9001........................Hex Nut, Nylon Insert Lock.....................#6-32......................................2

60........2244PLUS-260............. Hex Nut.................................................3/8-16 .....................................1

Page 21

21

Conveyor And Motor Assembly

Page 22

22

Conveyor And Motor Assembly

Index Part

No. No. Description Size Qty.

1..........323759.........................Gear Motor............................................90 Volt DC............................... 1

2..........72-6014........................Strain Relief........................................... ...............................................1

3..........72-5336........................Cord Set................................................110-120V-75”..........................1

4..........TS-0680031.................Flat Washer...........................................5/16.........................................4

5..........10-4010-08...................Socket Head Cap Screw ........................#10-32x1/2”.............................4

6..........98-0080........................Tracker Kit............................................. ...............................................2

7..........72-2250-01...................Knob...................................................... ...............................................1

8..........72-2250-02...................Label, S peed A djusting.......................... ...............................................1

9..........40-4018........................Guard, wiring......................................... ...............................................1

10........72-2250........................SandSmart Cont r oller ............................ ...............................................1

11........40-4904........................Bracket, Housing- Controller.................. ...............................................1

12........20-0777........................Screw, Pan Head Self-Tapping.............. 5/32x1/2”.................................2

13........72-2120........................Receptacle,110-120Volt......................... ...............................................1

14........TS-081D022................. Pan Head Machine Screw......................#10-32x1/2”.............................1

15........TS-073203...................Washer, Lock. Int.-Tooth Washer...........#10 .........................................2

16........TS-0560081.................Hex Nut.................................................#10-32 ....................................2

17........10-9002........................Screw, Hex Head-Slotted.......................#10-32x1/2”.............................5

18........10-3103........................Screw, Phil Pan Head............................#6-32x1/2................................2

19........72-2004........................Switch, ON/ OFF-Dru m........................... ...............................................1

20........30-0122........................Coupler, Shaft........................................ ...............................................1

21........10-4010-04................... Set Screw..............................................1/4-20x1/4”..............................2

22........40-4903........................Bracket, Base- Controller....................... ...............................................1

23........40-4022W.................... Cover, Base-Control Housing................. ...............................................1

24........10-4004-12................... Bolt, Hex Washer Head..........................1/4-20x3/4”............................12

25........20-1161-01................... Washer, Wave.......................................1/4” .........................................4

26........11-1002-04................... Flat Washer...........................................1/4”.........................................4

27........40-0003........................Bracket, Take Up-Slide.......................... ...............................................2

28........50-3105........................Bushing, Oilite 5/16”I.D.......................... ...............................................4

29........30-3010-01................... Roller, Driven......................................... ...............................................1

30........40-0260........................Wrench.................................................. ...............................................2

31........12-2000-04................... Hex Nut.................................................1/4-20 .....................................2

32........11-1000-04................... Washer, Lock-Int Tooth..........................1/4” .........................................2

33........10-4007-24................... Screw, Round Head- Slotted..................1/4-20x1 3/4” ...........................2

34........40-4004........................Bracket, Take Up-Base.......................... ...............................................2

35........TS-0720081.................Lock Washe r ..........................................5/16.........................................4

36........30-3050-01................... Roller, Driven-Rubber Cover ed.............. ...............................................1

37........40-0005........................Bracket, Support-Drive Roller................. ...............................................1

38........40-4010........................Bed, Conveyor....................................... ...............................................1

39........TS-0208041.................Socket Head Cap Screw........................ 5/16-18x3/4”............................4

40........60-0316........................Belt Conveyor (Not Shown).................... ...............................................1

41........72-2250-03................... Washer, Flat..........................................5/16.........................................1

42........72-2250-04................... Nut, Hex................................................5/16-24....................................1

43........72-2250-05................... Set Screw-Slotted..................................#8-36UNFx5/16”...................... 1

Page 23

23

Wiring Diagram

Loading...

Loading...