JetMove 2xx

at the NANO System Bus

User Information

Article # 60866113 / Edition 2.03.4 March 2005 / Printed in Germany

JetWeb

JetWeb

Revision 2.03.4

Jetter AG reserves the right to make alterations to its products in the interest of

technical progress. These alterations need not to be documented in every single

case.

This user information and the information contained herein have been compiled with

due diligence. Jetter AG shall not be liable for errors contained herein or for incidental

or consequential damage in connection with the furnishing, performance, or use of

this material.

The brand names and product names used in this manual are trade marks or

registered trade marks of the respective title owner.

© Copyright 2005 by Jetter AG. All rights reserved.

2 Jetter AG

JetMove 2xx at the NANO System Bus

How to Contact us:

Jetter AG

Gräterstraße 2

D-71642 Ludwigsburg

Germany

Phone - Switchboard: (+49) 7141/2550-0

Phone - Sales: (+49) 7141/2550-433

Phone - Technical Hotline: (+49) 7141/2550-444

Telefax: (+49) 7141/2550-425

E-Mail - Sales: sales@jetter.de

E-Mail - Technical Hotline: hotline@jetter.de

Internet address: http://www.jetter.de

Jetter AG 3

JetWeb

Significance of this User Information

In any case you encounter difficulties to clearly understand this user information,

please contact the manufacturer.

We would appreciate any kind of suggestion and contributions on your part and

would ask you to inform us or to write us. This will help us to produce manuals that

are more user-friendly and to address your wishes and requirements.

Missing or inadequate knowledge of the user information results in the loss of any

claim of liability on part of Jetter AG. Therefore, the operating company is

recommended to have the instruction of the persons concerned confirmed in writing.

History

Edition Comment

2.03.4 First edition

4 Jetter AG

JetMove 2xx at the NANO System Bus

Description of Symbols

This sign is to indicate a possible impending danger of serious physical damage

or death.

Danger

This sign is to indicate a possible impending danger of light physical damage.

This sign is also to warn you of material damage.

Caution

This sign is to indicate a possible impending situation which might bring damage

to the product or to its surroundings.

This symbol also points to conditions, which must be by all means be given heed

Important!

to, in order to guarantee faultless functioning.

Note!

· / -

You will be informed of various possible applications and will receive further

useful suggestions.

Further, it points to tipps and advice for efficient use of the device and for

optimization of the corresponding software, in order to save you extra work.

Enumerations are marked by full stops, strokes or scores.

Operating instructions are marked by this arrow.

Automatically running processes or results to be achieved are marked by this

arrow.

Illustration of PC and user interface keys.

This symbol refers to further information (data sheets, literature, etc.) on the

subject or product or the like that is being dealt with. Further, this text provides

helpful hints for your guidance through the manual.

Jetter AG 5

JetWeb

6 Jetter AG

JetMove 2xx an NANO-Schnittstelle Inhalt

Table of Contents

1 Introduction 9

1.1 Product Description 9

1.2 System Requirements 9

2 Register Numbering 11

2.1 NANO-B/C/D 11

3 Information on Parameter Values 13

3.1 Decimal Positions 13

3.2 Decimal Positions in Position Values 13

4 Brake 15

5 Axis Setup 17

5.1 Step 1: Motor Settings 17

5.2 Step 2: Settings of the Current Control 20

5.3 Step 3: Axis Definition 21

6 Referencing 23

6.1 Control Mode 24

6.2 Starting the Reference Run 24

6.3 Interrupting the Reference Run 24

6.4 Status Information 24

6.5 Axis Type 25

6.6 Modes of Referencing 25

6.7 Settings of Speed 25

6.8 Speed Reversal 26

6.9 Reference Position 27

6.10 Setting the Specifically Defined Reference Position 28

6.11 Referencing by Means of Zero Pulse ("Zero Mark") Only 29

6.12 Referencing by Means of Reference and Limit Switch 29

6.12.1 Positive direction 29

6.12.2 Negative direction 32

6.13 Referencing by only One Limit Switch 34

6.14 Referencing by Reference Switch Only 35

7 Positioning 37

7.1 Endless Positioning 37

Jetter AG 7

Inhalt JetWeb

8 Oscilloscope Function 39

9 Register Description 41

9.1 Control Parameters 41

9.2 Diagnose Parameters 50

9.3 Positioning Parameters 56

9.4 Referencing - Parameters 71

9.5 Axis Parameters 77

9.6 Amplifier Parameters 90

9.7 Motor Parameters 95

9.8 Monitoring Parameters 102

9.9 Position Control Parameters 106

9.10 Speed Control Parameters 110

9.11 Current Control Parameters 116

List of Appendices

Appendix A: Recent Revisions 125

Appendix B: List of Abbreviations 127

Appendix C: Register Survey - Numerical Sequence 129

Appendix D: Register Survey - Functional Sequence 141

Appendix E: Index of Figures 153

Appendix F: Index 155

8 Jetter AG

JetMove 2xx at the NANO System Bus 1.1 Product Description

Table of Contents 1Introduction

This user information describes the functions of the product JetMove 2xx of

the operating system version V 2.03.

In this manual, connecting the JetMove 2xx to the system bus of Jetter AG and the

operation will be described. Additional information on the contents of this document

is given in the instructions for the specific sizes of the JetMove 200 series.

1.1 Product Description

The JetMove 200 series by Jetter offers modern servo amplifers for being applied

with synchronized servo motors.

1.2 System Requirements

The JetMove 200 amplifiers can be operated by NANO controllers and by the JX6SB-I submodule. This document is valid as of version 2.03 of JetMove 2xx.

The JetMove 2xx amplifiers can directly be connected to the Jetter system bus. It is

still possible to simultaneously operate all non-intelligent JX2-IO and all intelligent

JX2 slave expansion modules made by Jetter AG at the system bus.

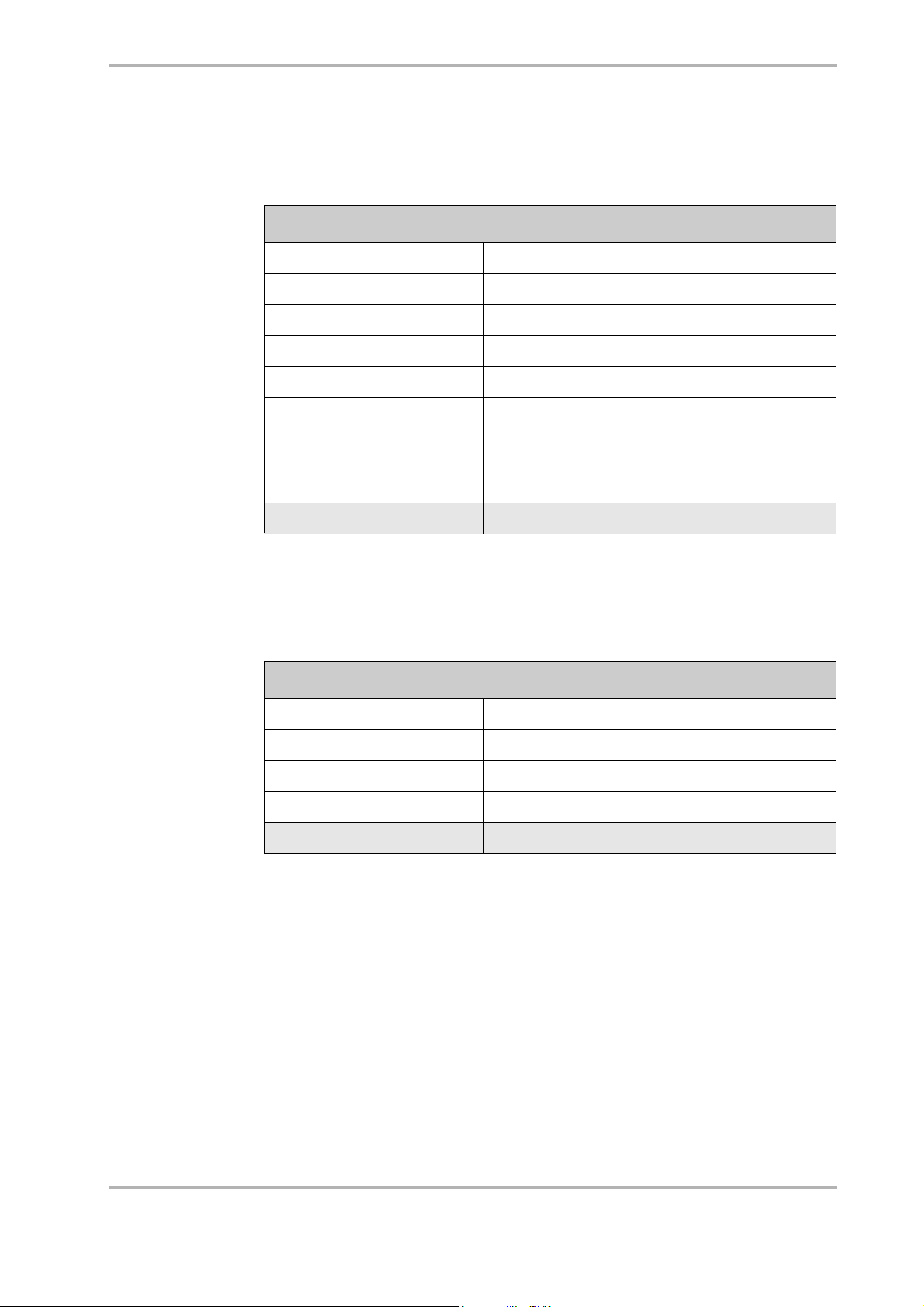

The following table shows the minimum required software versions supporting

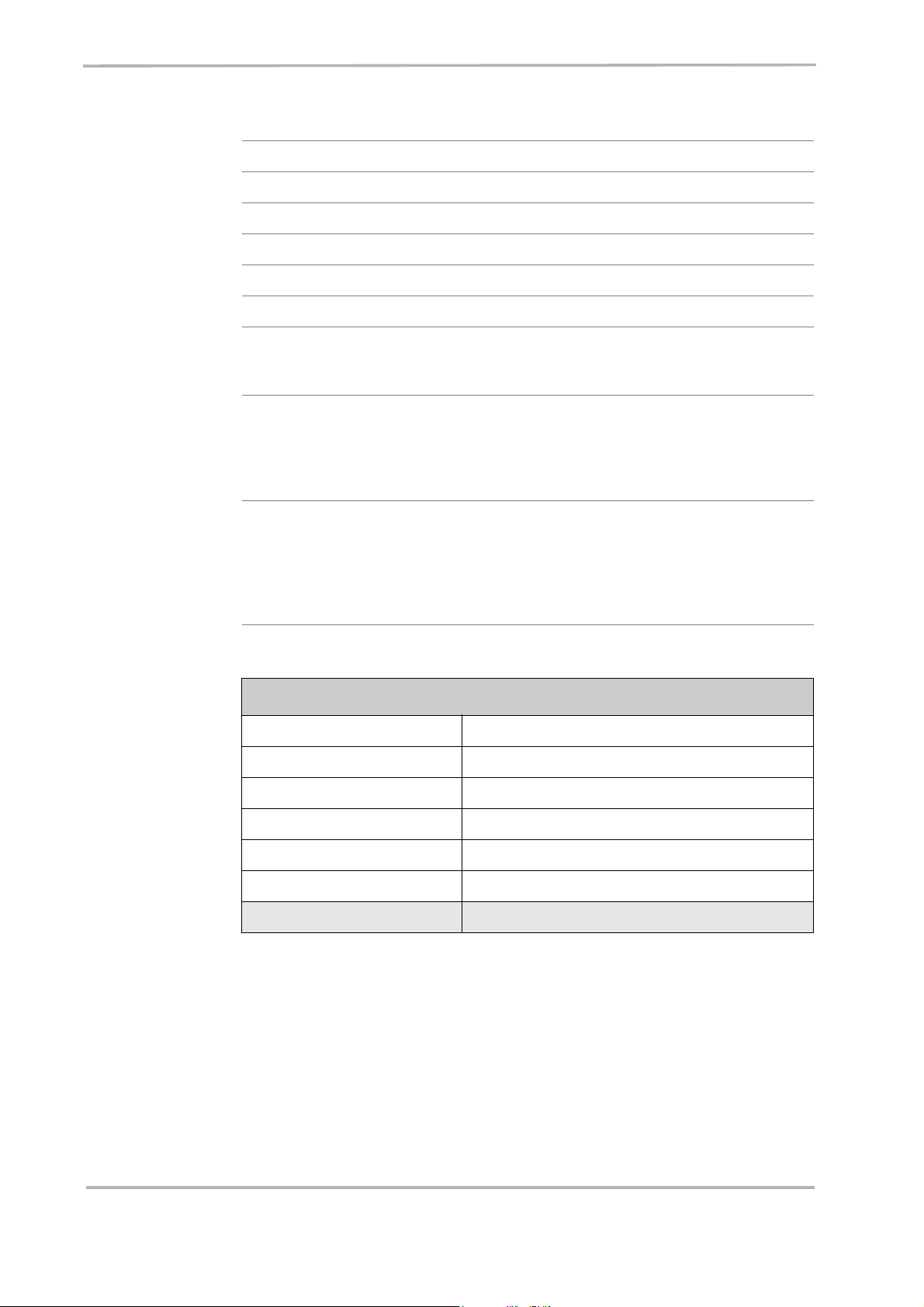

operation of JetMove 2xx on the Jetter system bus.

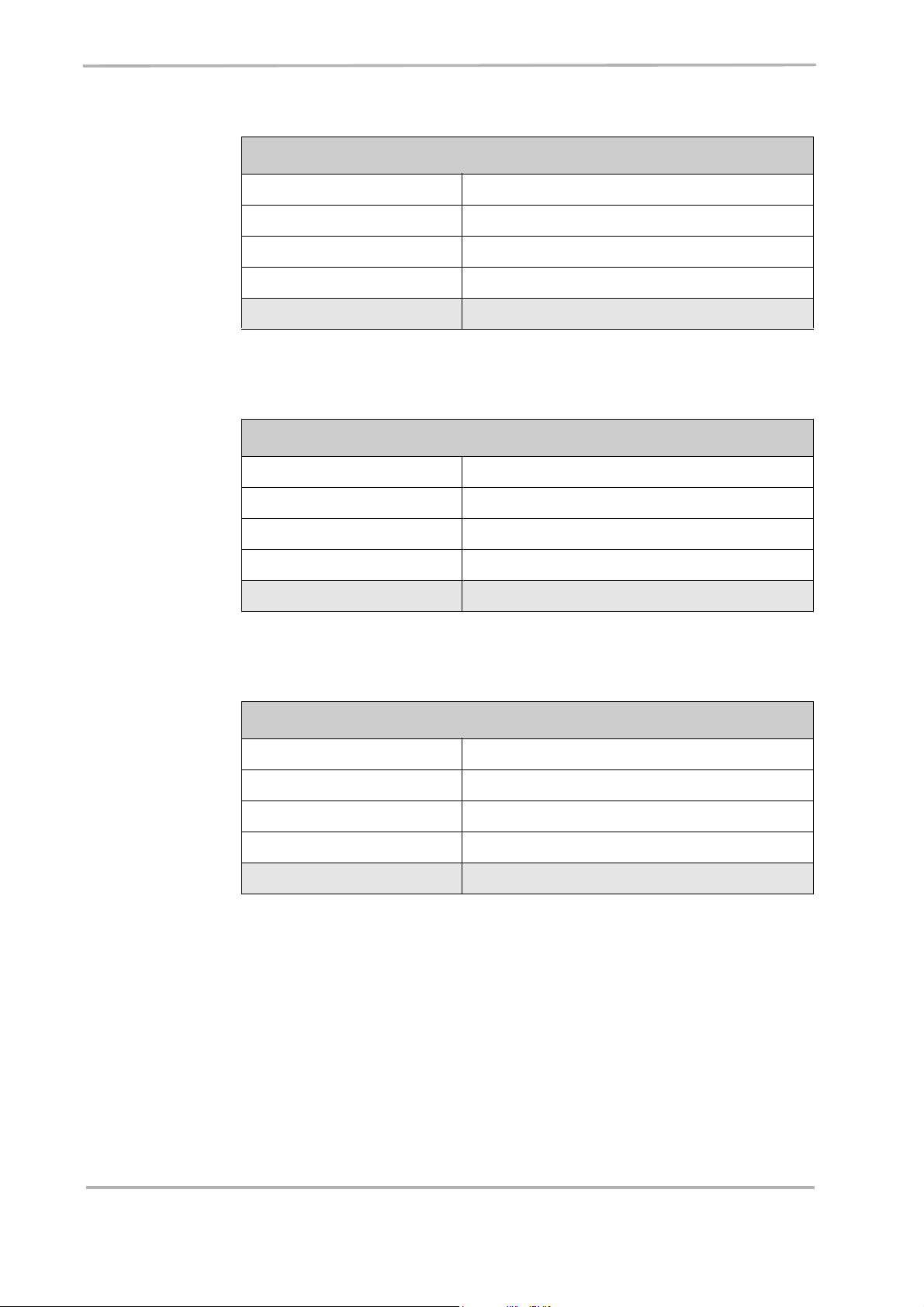

Software versions of controllers

and the JX6-SB-I submodule

Control Minimum Software Version

NANO-B, NANO-C, NANO-D no limitation

JX6-SB-I 2.10

Jetter AG 9

1 Introduction JetWeb

10 Jetter AG

JetMove 2xx at the NANO System Bus 2.1 NANO-B/C/D

2 Register Numbering

2.1 NANO-B/C/D

The following rules for register numbering apply to the controllers NANO-B, NANOC and NANO-D:

The registers are addressed with the help of five-digit numbers. The first two digits

are made up of the slot number of the JetMove 2xx module plus value 10. Below, the

pattern of register numbering will be illustrated.

REG 1xzzz

1x zzz

Module Slot

2 .. X

only intelligent

modules will be

counted.

X = max. permitted

amount of intelligent

modules to be

connected to the CPU

(CPU = slot 1)

Register Number

0 .. 999

Jetter AG 11

2 Register Numbering JetWeb

12 Jetter AG

JetMove 2xx at the NANO System Bus 3.1 Decimal Positions

3 Information on Parameter Values

3.1 Decimal Positions

All parameter values that are exchanged between JetMove 2xx and the controller are

integer values. Integer values are values without decimal positions. Nevertheless,

internal decimal positions, such as position definitions in [°] or [mm]. In order to make

this possible, the integer value that is read by, respectively written to, the parameter,

will contain 1 to 3 decimal positions. The post-comma positions are noted as the one

to three decimal positions of lowest value.

Whether there are decimal positions contained in the parameter value, and how

many there are, can be taken from the register description. The SI unit of parameters

having been set to an SI unit will be noted together with a decimal multiplier.

Example

Parameter "Current Limitation", register 127, unit [Aeff*100]:

Example value: 325 [Aeff*100]

Value applied internally (scaled to an SI-unit A

Value read by the controller = 325

Value written by the controller = 325

If in formulas quoted in this manual a register has been specified as an operand, the

value must generally be used the way for which it has been scaled internally. This

means that in the example quoted above, the value would be 3.25.

) = 3.25

eff

3.2 Decimal Positions in Position Values

Position values, such as software limit switch position or target position, have been

scaled internally to the unit [°] (mechanic degrees) or to the unit [mm]. Which unit is

used depends on the settings of the axis type, on register 191 "Axis Type" (linear or

rotatory).

Independent of the respective unit, the integer position values that are exchanged

between JetMove 2xx and the controller, have got between 1 and 3 decimal

positions. How many decimal places are to be used can be defined via register 870

"Decimal positions for position values". The decimal positions should only be defined

once, namely during axis setup.

Jetter AG 13

3 Information on Parameter Values JetWeb

14 Jetter AG

JetMove 2xx at the NANO System Bus

4 Brake

For the description of connections and electrical data, please refer to the JetMove

2xx operator's manual.

The brake is controlled by means of a relay placed in the amplifier. The following

parameters for handling the brake are available:

• Register 540 "Mode of operation 1"

• Register 548 "Delay at closing the motor brake"

• Register 547 "Delay at releasing the motor brake"

• Register 574 "Control word 2"

• Register 575 "Status word 2"

Via register "Mode of operation 1", a choice can be made between automatic and

manual operation of the brake.

If the default values are kept, automatic operation will be set. While selecting the

mode of operation, the brake will always be controlled at activating and deactivating

the amplifier. At switching on, the relay contacts will be closed; at switching off, the

relay contacts will be released again.

If there is no brake, automatic mode can be set. This would mean, though, that the

relay will always be controlled via the amplifier. Else, you can select the manual

mode to prevent the relay from being controlled.

The control state of the brake can be read out of register 575 "Status word 2" in bit 0

at any time.

If manual mode has been selected, the brake can either be controlled via register 574

"Control word 2" by bit 0 (in automatic mode, setting and resetting the bit is of no

effect), or it can be controlled via an external switch which connects the 24 V voltage

supply to, respectively disconnects it from the brake.

If an external switch has been selected, bit 0 of register 574 "Control word 2" must

always be set in order to always keep the relay contacts closed.

Jetter AG 15

4 Brake JetWeb

16 Jetter AG

JetMove 2xx at the NANO System Bus 5.1 Step 1: Motor Settings

5 Axis Setup

5.1 Step 1: Motor Settings

Setpoint values Actual values

Operating mode 1:

Bit 0 = Motor brake operating mode R540

Control word 2:

Bit 0 = Motor brake control R574

Delay at closing the

motor brake [ms*100]

R548

Delay at releasing the

motor brake [ms*100]

R547

Operating mode 1:

Bit 4 = Test of the motor

cable R540

Motor temperature [°C]

R562

Position of the motor

shaft [°*100] R565

Status word 2:

Bit 0 = Motor brake position R575

Encoder resolution

R117

Voltage constant

[V*min/1000] R505

Torque constant Kt [Nm/

A*100] R616

Pole pair number

R123

Encoder type

R577

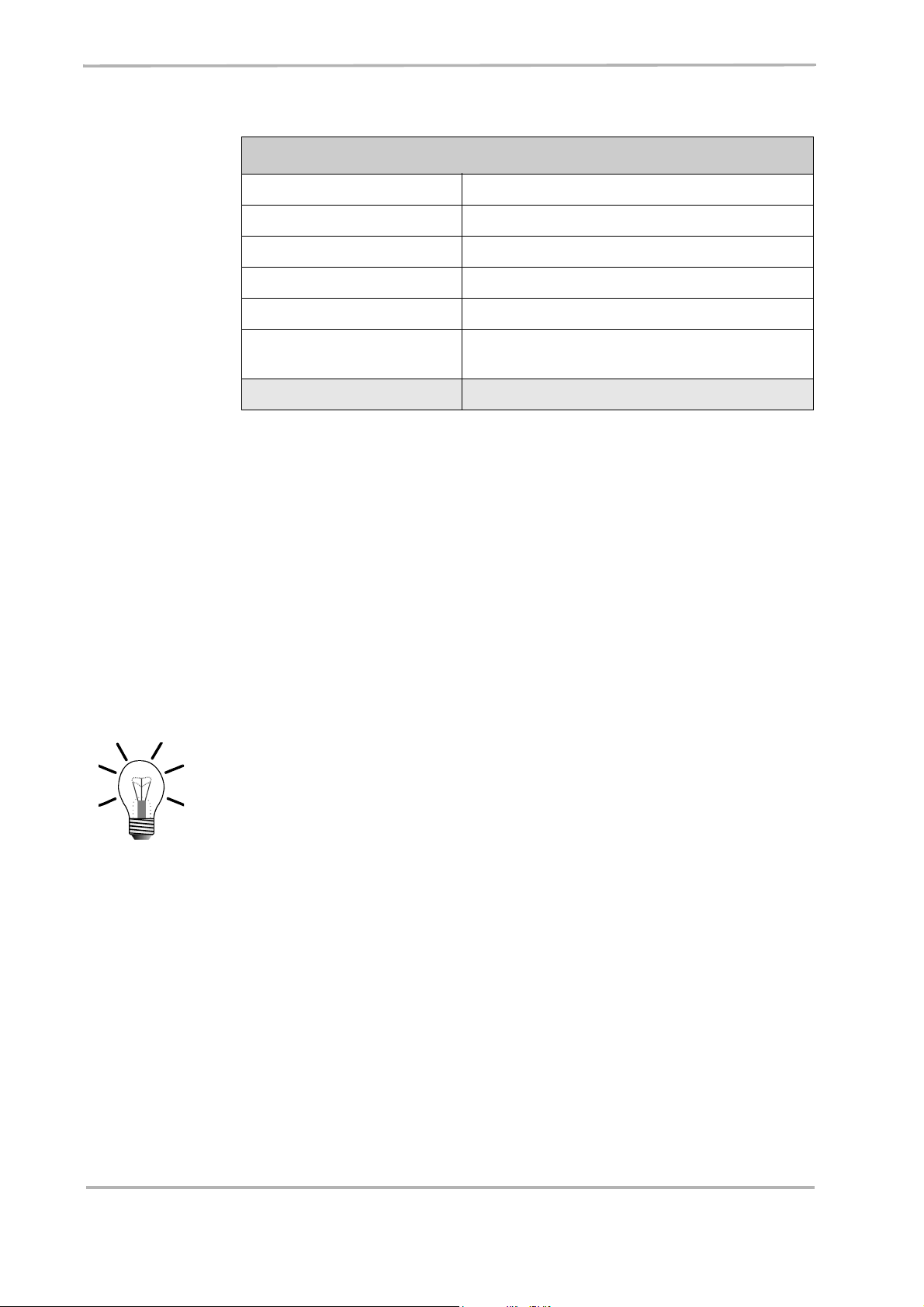

Fig. 1: Motor parameters

Jetter AG 17

5 Axis Setup JetWeb

1 Defining the motor parameters for motors from other

manufacturers

This only applies if no Jetter motor, but motors from other manufacturers are

used

The default commutation offset value is 0. For a motor made by another company it

must possibly be adjusted. If required, an appropriate value must be set by Jetter AG.

Possibly, the pole pair number must be adjusted as well. The default value is 3.

Example:

One Jetter motor has got 6 poles which are energized in pairs; this means there are

3 pole pairs. For further information, please refer to the register description of the

motor parameters as of chapter 9.7 "Motor Parameters", page 95.

2 Defining the brake parameters

Only for motors equipped with a brake

Selecting the operating mode of the brake via operating mode 1. Via bit 0 of operating

mode 1, the operating mode of the brake can be set as follows:

Bit 0: 0 = Manual operation of the brake by the user

(via register 574 "Control word 2")

1 = Automatic operation of the brake by the amplifier

(The brake will automatically be released, respectively

closed, when the amplifier is released, respectively

closed)

The automatic mode is set by default.

Via control word 2, bit 0, the brake can be controlled the same way as in manual

mode:

Bit 0: 0 = Lock the brake

1 = Release the brake

In order to control the brake by control word 2, manual operation must first be set by

means of operating mode 1.

Status word 2, bit 0, will indicate the status of the brake as follows:

Bit 0: 0 = Brake is closed

1 = Brake has been released

18 Jetter AG

JetMove 2xx at the NANO System Bus 5.1 Step 1: Motor Settings

Release and lock times of various brakes differ dependent on the respective motor

manufacturers and motor types. For this reason, it might be necessary to adjust the

delay times for releasing and closing the brake to your requirements. For this, please

refer to delay at releasing the motor brake and delay at locking the motor brake

as of page 97.

3 Setting the motor cable monitoring parameters

Setting the motor cable monitoring via operating mode 1. Via bit 4 of operating mode

1, motor cable monitoring can be set as follows:

Bit 4: 0 = Motor cable monitoring is deactivated by default

1 = Motor cable monitoring is activated

Monitoring is activated by default If motor monitoring is active, a motor cable test will

be carried out at switching on the axis after hardware reset. If the motor cable is

defect, error F03 will be displayed. Possible error causes can be breakage of, or

ground fault on the motor cable.

If long motor cables are used, error F03 can be recognized through the monitoring

function, although none of the listed error causes applies. Only in this case,

deactivating the monitoring function is useful.

4 Setting the voltage constant

If highly dynamic drives are used, the parameter voltage constant should be

adjusted. For this, please refer to the motor data sheet or the rating plate of the

motor. For further information, please refer to the register description of the

parameters as of page 96.

5 Setting the torque constant

The torque constant is necessary for displaying a valid actual torque in register 621

"Actual torque". If the torque constant equals zero, the actual torque equals zero as

well.

Jetter AG 19

5 Axis Setup JetWeb

5.2 Step 2: Settings of the Current Control

Current Limitation [Aeff*100]

R127

Setpoint

values

Continuous rated current

[A

*100]

eff

R618

Overload factor

R619

Current control Kp

R503

Current Setpoint [Aeff*100]

R125

Kp

R503

Actual values

Actual current

[A

*100]

eff

R561

Actual current [%]

R620

Actual torque

[Nm*1000] R621

Tn [ms*100]

R504

Current control Tn

R504

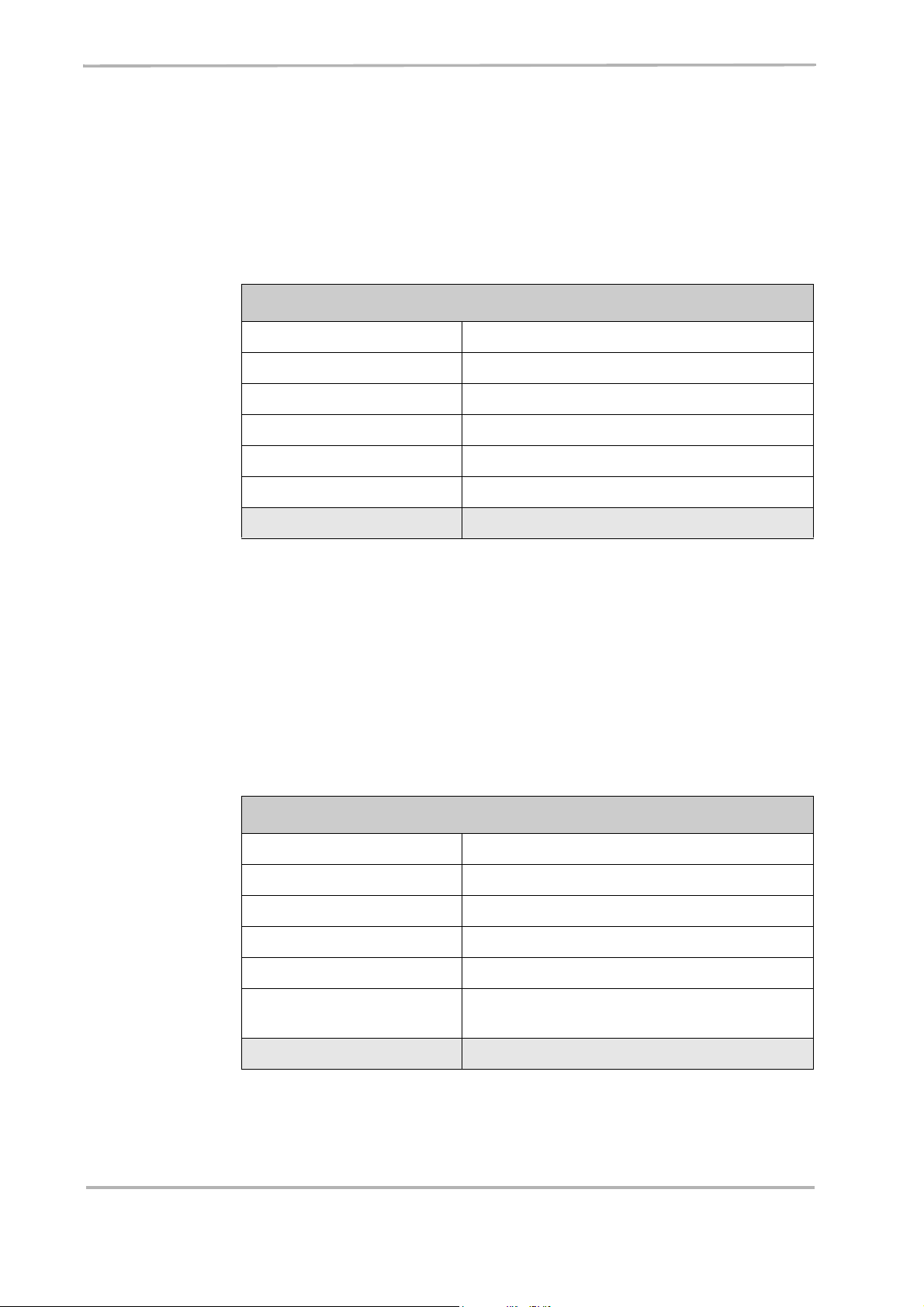

Fig. 2: Current control

20 Jetter AG

Max. output current

[A

*100] R502

eff

JetMove 2xx at the NANO System Bus 5.3 Step 3: Axis Definition

1 Setting the maximum output current

The maximum output current, stored in register 502, is set by input of the continuous

rated current, register 618 (continuous rated current put together of the motor

parameters, as shown on the rate plate, for example), and the overload factor,

register 619. The maximum output current can range between 200 % and 50 % of

the continuous rated current of the amplifier as stored in register 501. The maximum

output current is the product of continuous rated current and the overload factor.

Note!

At value input, please mind the value standardization of individual registers, see

register description.

2 Setting the controller parameters Kp and T

The proportional amplification Kp , register 503, and the integral-action time Tn ,

register 504, of the current control must be calculated and input. Formulas for

parameter calculation can be found in the register description.

n

5.3 Step 3: Axis Definition

Setting the axis type

First, the axis type must be set via register 191 "Axis type".

Setting the motion mode

In the motion mode, the definition is made, whether the axis is a standard or a modulo

axis. The mode is set via register 192 "Modulo axis".

Software limit switch

The software limit switch monitoring is NOT active by default. If software limit switch

monitoring is to be carried out, bit 6 of register 540 "Operating mode 1" must be set.

Jetter AG 21

5 Axis Setup JetWeb

22 Jetter AG

JetMove 2xx at the NANO System Bus

6 Referencing

Attention!

The axis could crash into the mechanical limits!

In the following cases, a limit switch will NOT be considered:

• During reference run "With zero pulse only"

• If the axis is positioned on the reference switch

• From the moment of starting the search for the reference position

(reference search) to finding it.

In case of reverse polarity of the hardware limit switches, the limit switch

being positioned in the direction of the reference run will be ignored; this

will cause the axis to crash into the mechanical limits.

Before referencing is started for commissioning, proper functioning of the

hardware limit switches and of the reference switch must be ensured. For

this, please mind correct polarity and assignment to either negative or

positive limit switch. The polarity is defined via register 510 "Digital inputs:

Input polarity".

Definitions

Zero pulse Zero-crossing of the resolver, reset pulse of the

incremental encoder

"Reference switch active"

flank

"Reference switch deactived"

flank

Switch search The first part of referencing: Searching for the

Searching for the reference

position

Key to the following illustrations:

N = Negative limit

switch

P = Positive limit switch V

The reference switch signal will change from

logical zero to logical one

The reference switch signal will change from

logical one to logical zero

reference switch, respectively for a limit switch

The second part of referencing, after having

found the reference or limit switch: Searching for

the reference position, respectively for the zero

pulse

V

ref

ZM

= Speed of switch search

= Speed of search for

reference position

R = Reference switch ZM = Zero pulse ("zero mark")

SP = Starting position NP = Normal position

s = Distance NP

distance

Jetter AG 23

= Normal position: distance

6 Referencing JetWeb

6.1 Control Mode

For referencing, the position control mode must be set. This is done via register 572

"JetMove set operating mode".

6.2 Starting the Reference Run

A reference run is started by means of command 9:

...

REGISTERLOAD (rCommando, zkRefSearch)

WHEN BIT_CLEAR (rStatus, zbBusy) THEN

...

Attention:

During the reference run, command 9 "Search for reference" cannot be given

again.

If the parameters for referencing are changed while a reference run is in process,

they will at first have no effect on this reference run. As of the next reference run,

the alterations will be effective.

6.3 Interrupting the Reference Run

The user can interrupt a reference run by means of the following commands:

• Command 5

• Command 6

• Command 7

6.4 Status Information

If bit 0 "RefOK" of register 100 "Status" is set at starting the reference run, it will be

reset. Bit 1 "Stopped" of register 100 will also be reset.

If referencing has been completed and correct, both bits will be set. If referencing has

been stopped due to an error or by the user (by means of command 6, for example),

only bit 1 "Stopped" will be set, as soon as the axis has come to a standstill again.

Those two bits can be used for continuing the PLC program after starting the

reference run.

24 Jetter AG

JetMove 2xx at the NANO System Bus 6.5 Axis Type

Error Messages

Referencing errors are output in register 170 "Positioning errors". They will not be

displayed at the amplifier by means of F and error number. If a referencing error

occurs, bit 0 "RefOK" of register 100 "Status" will not be set. Bit 1 "Stopped" of

register 100 will be set in case of an error, as soon as the axis has come to a

standstill.

6.5 Axis Type

Referencing is possible without any restrictions both with settings for a linear axis

and with settings for a rotatory axis via register 191 "Axis type". If a modulo axis has

been set in register 192 "Modulo axis", there are no restrictions for referencing either.

6.6 Modes of Referencing

There are various modes of referencing to choose from:

• Referencing by means of zero pulse only

• Referencing by means of reference and limit switch

• Referencing by means of limit switch (there is no reference switch, for example)

• Referencing by reference switch only

The mode of referencing is selected by means of the switch type parameter of

register 161 "Switch type". The modes of referencing will be explained below.

6.7 Settings of Speed

Two different speed values can be set for referencing:

• Speed of the reference switch search set in register 162 "Speed of switch search".

• Speed of searching for the reference position set in register 166 "Speed of

reference search".

The speed setting for switch search will also be used for driving back to the normal

position, see "Setting the Specific Reference Position" below.

Referencing will be started by the speed of switch search. When the switch has been

found, the speed of the reference point search will be set for driving to the reference

position.

Normally, the speed of the reference point search is lower than the speed of the

switch search. These values have also been set by default.

For neither of the two speed settings, there is a specific limitation. Normally, though,

referencing is done in low speed.

The speed values will be set once before referencing; they cannot be changed during

referencing.

Jetter AG 25

6 Referencing JetWeb

S

Fig.: 3 shows a typical motions sequence of various speeds:

+V

+V

- V

- V

ZM

ref

ZM

ZM

ref

N

R

SP

P

Fig. 3: Referencing by various speeds

6.8 Speed Reversal

Besides setting the direction of referencing via register 160 "Direction of referencing",

the rotational direction of the axis can be set via register 540 "Operating mode 1",

bit 5 "Change of rotation". This value applies to all axis motions, not only to

referencing.

Below, referencing for setting a positive rotatory direction will be illustrated. If a

negative direction of rotation has been set, the respective graphic referring to positive

direction of rotation must be used for illustrating features such as the motion

sequence at referencing in negative direction.

26 Jetter AG

JetMove 2xx at the NANO System Bus 6.9 Reference Position

6.9 Reference Position

The reference position can either be the position of the zero pulse ("zero mark") or

the position of the switch flank, if referencing is being carried out without zero pulse.

Zero pulse ("zero mark") or switch flank

In register 165 "Reference mark" it is defined, whether the reference point is to be

the position of the zero pulse ("zero mark") or the position of the switch flank.

We recommend setting the zero pulse ("zero mark") as home position ("reference

mark"). Referring to the zero pulse ("zero mark") offers a much greater repeat

accuracy.

Fig.: 4will illustrate referencing with zero pulse ("zero mark") for the switch types

"reference and limit switch" and "limit switch only":

+V

+V

- V

- V

R

ref

ZM

ZM

ref

P

ZM

Fig. 4: Referencing with zero pulse ("zero mark")

Fig.: 5will illustrate referencing without zero pulse ("zero mark") for the switch types

"reference and limit switch" and "limit switch only":

+V

+V

R

ref

ZM

P

S

- V

ZM

- V

ref

Fig. 5: Referencing without zero pulse ("zero mark")

Jetter AG 27

S

6 Referencing JetWeb

S

6.10 Setting the Specifically Defined Reference Position

There is the possibility of driving to another position in the travel range immediately

after finding the reference position (register 168 "Normal position - distance"). This

position is called normal position.

For "normal position", any position value can be chosen (register 169 "Normal

position - position").

In the following illustration Fig.: 6, the motion sequence of the axis when driving

towards normal position will be shown (NP = normal position, NP distance = normal

position - distance):

N

SP

+V

ref

+V

ZM

- V

ZM

- V

ref

ZM

Fig. 6: Driving towards "normal position"

The speed by which the axis is driving towards normal position is the speed of the

switch search; it is set in register 162 "Speed switch search".

Via register 168 "Normal position - distance", the distance to be covered from

reference to normal position will be input. A negative value causes the axis to move

in negative direction, seen from the reference position.

Via register 169 "Normal position - position", the position will be input that is to be set

as virtual position after having reached "normal position". The virtual position is set

at the reference position, if there is no "normal position" to be driven to; this means

that register 168 = 0.

R

NP distance

NP

P

28 Jetter AG

JetMove 2xx at the NANO System Bus 6.11 Referencing by Means of Zero Pulse ("Zero

6.11 Referencing by Means of Zero Pulse ("Zero Mark") Only

For this reference run, the axis will start in the set referencing direction by the set

reference search speed. When the zero pulse ("zero mark") has been recognized,

the axis will return towards the position of the zero pulse ("zero mark").

During this travel, the motor will make one rotation as a maximum. The setting of the

reference position in register 1x165 "Reference mark" does not take effect here.

Please mind:

During this reference run, limit switches will not be monitored.

N

SP

+V

ref

+V

ZM

- V

ZM

- V

ref

ZM

Fig. 7: Referencing only by means of zero pulse ("zero mark") in positive

direction; the rotatory direction is positive; the starting position is on the

negative side of the zero pulse.

P

6.12 Referencing by Means of Reference and Limit Switch

Prerequisites for this reference run are a reference switch, as well as the positive and

negative limit switch.

The reference run with its respective starting positions and directions will be

explained below.

S

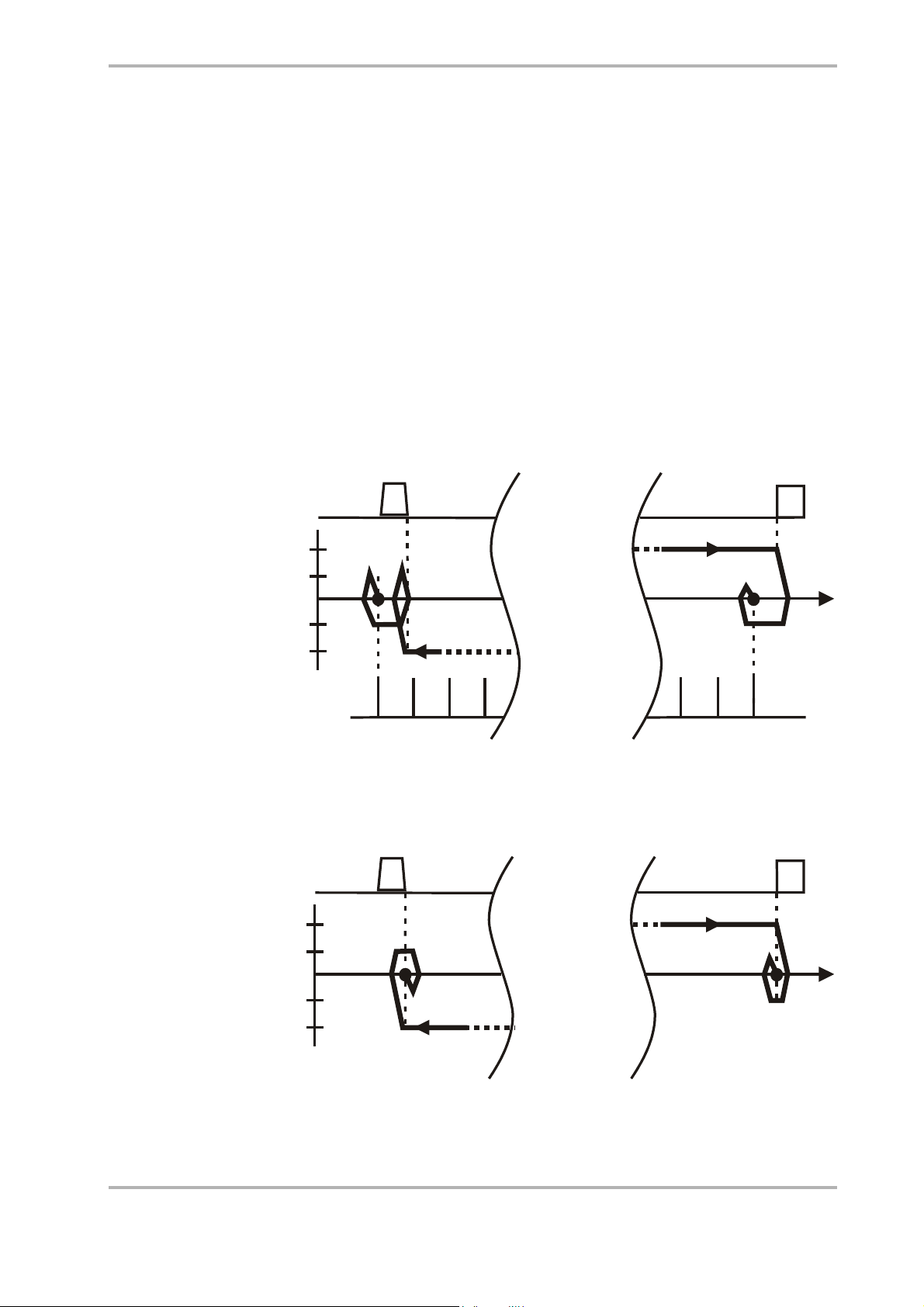

6.12.1 Positive direction

Die Achse wird durch die automatische Referenzfahrt immer so bewegt, dass die

Referenzpunktsuche immer von der negativen Seite des Referenzschalters

durchgeführt wird.

Jetter AG 29

6 Referencing JetWeb

S

Starting from the positive side of the reference switch

– The axis will start by "Speed switch search" in positive direction.

– When the positive limit switch has been recognized, the axis will reverse and

continue in negative direction by "Speed switch search".

– The axis will cross the reference switch, until the "Reference switch deactivated"

flank has been recognized.

– There, the axis will reverse again to drive in positive direction by "Speed reference

search".

– The reference position is set to the first zero pulse after having recognized the

"Reference switch active" flank again. For referencing without zero pulse ("zero

mark"), the reference position is set to the position of the "Reference switch

active" flank.

+V

+V

- V

- V

ZM

ref

ZM

ZM

ref

N

R

SP

P

Fig. 8: Referencing by reference and limit switch in positive direction; the

rotatory direction is positive; with zero pulse ("zero mark"), the starting

position is on the positive side of the reference switch.

Starting from the negative side of the reference switch

– The axis will start in positive direction by "Speed switch search".

– When the reference switch active flank has been recognized, the axis will drive

back in negative direction by "Speed switch search", until it reaches the position,

where the reference switch active flank has been recognized.

– There, the axis will reverse again to drive in positive direction by "Speed reference

search".

– The reference position is set to the first zero pulse after having recognized the

"Reference switch active" flank again. For referencing without zero pulse ("zero

mark"), the reference position is set to the position of the "Reference switch

active" flank.

30 Jetter AG

JetMove 2xx at the NANO System Bus 6.12 Referencing by Means of Reference and Limit

S

S

R

+V

+V

- V

- V

N

SP

ref

ZM

ZM

ref

ZM

Fig. 9: Referencing by reference and limit switch in positive direction; the

rotatory direction is positive; with zero pulse ("zero mark"), the starting

position is on the negative side of the reference switch.

Starting on the reference switch

– The axis will start in negative direction by "Speed switch search".

– When the reference switch has become deactivated, the axis will reverse and

continue in positive direction by "Speed reference search".

– The reference position is set to the first zero pulse after having recognized the

"Reference switch active" flank again. For referencing without zero pulse ("zero

mark"), the reference position is set to the position of the "Reference switch

active" flank.

P

R

SP

+V

+V

- V

- V

N

ref

ZM

ZM

ref

ZM

Fig. 10: Referencing by reference and limit switch in positive direction; the

rotatory direction is positive; with zero pulse ("zero mark"), the starting

position is on the reference switch.

P

Jetter AG 31

6 Referencing JetWeb

S

6.12.2 Negative direction

During automatic referencing, the axis will always be moved so that reference search

is being carried out from the positive side of the reference switch.

Starting from the positive side of the reference switch

– The axis will start in negative direction by "Speed switch search".

– When the reference switch active flank has been recognized, the axis will drive

back in positive direction by "Speed switch search", until it reaches the position,

where the "Reference switch active" flank has been recognized.

– There, the axis will reverse again to drive in negative direction by "Speed

reference search".

– The reference position is set to the first zero pulse after having recognized the

"Reference switch active" flank again. For referencing without zero pulse ("zero

mark"), the reference position is set to the position of the "Reference switch

active" flank.

N

+V

ref

+V

ZM

- V

ZM

- V

ref

ZM

Fig. 11: Referencing by reference and limit switch in negative direction; the

rotatory direction is positive; with zero pulse ("zero mark"), the starting

position is on the positive side of the reference switch.

R

SP

P

Starting from the negative side of the reference switch

– The axis will start in negative direction by "Speed switch search".

– When the negative limit switch has been recognized, the axis will reverse and

continue in positive direction by "Speed switch search".

– The axis will cross the reference switch, until the "Reference switch deactivated"

flank has been recognized.

– There, the axis will reverse again to drive in negative direction by "Speed

reference search".

– The reference position is set to the first zero pulse after having recognized the

"Reference switch active" flank again. For referencing without zero pulse ("zero

mark"), the reference position is set to the position of the "Reference switch

active" flank.

32 Jetter AG

JetMove 2xx at the NANO System Bus 6.12 Referencing by Means of Reference and Limit

S

S

R

+V

+V

- V

- V

N

SP

ref

ZM

ZM

ref

ZM

Fig. 12: Referencing by reference and limit switch in negative direction; the

rotatory direction is positive; with zero pulse ("zero mark"), the starting

position is on the negative side of the reference switch.

Starting on the reference switch

– The axis will start in positive direction by "Speed switch search".

– When the reference switch has become deactivated, the axis will reverse and

continue in negative direction by "Speed reference search".

– The reference position is set to the first zero pulse after having recognized the

"Reference switch active" flank again. For referencing without zero pulse ("zero

mark"), the reference position is set to the position of the "Reference switch

active" flank.

P

R

SP

+V

+V

- V

- V

N

ref

ZM

ZM

ref

ZM

Fig. 13: Referencing by reference and limit switch in negative direction; the

rotatory direction is positive; with zero pulse ("zero mark"), the starting

position is on the reference switch.

P

Jetter AG 33

6 Referencing JetWeb

S

S

6.13 Referencing by only One Limit Switch

If the limit switch has been found when driving in referencing direction, the axis will

be referenced there.

The limit switch being positioned in negative direction will be ignored, until the axis

has reversed on the limit switch positioned in positive direction. When the axis has

reversed and the limit switch being positioned in the new direction has been

recognized, the axis will be stopped and an error will be output in register 170

"Positioning Error" (bit 18 "Reference: Limit switch positive" or bit 19 "Reference:

Limit switch negative").

Starting in positive direction

P

+V

+V

- V

- V

N

SP

ref

ZM

ZM

ref

ZM

Fig. 14: Referencing by limit switch only; positive direction, positive rotatory

direction, starting position preceeding the positive limit switch.

P

SP

+V

+V

- V

- V

N

ref

ZM

ZM

ref

ZM

Fig. 15: Referencing by limit switch only; positive direction, positive rotatory

direction, starting position on the positive limit switch.

34 Jetter AG

JetMove 2xx at the NANO System Bus 6.14 Referencing by Reference Switch Only

S

S

Starting in negative direction

P

+V

+V

- V

- V

N

SP

ref

ZM

ZM

ref

ZM

Fig. 16: Referencing by limit switch only; negative direction, positive rotatory

direction, starting position preceeding the negative limit switch.

P

+V

+V

- V

- V

N

SP

ref

ZM

ZM

ref

ZM

Fig. 17: Referencing by limit switch only; negative direction, positive rotatory

direction, starting position on the negative limit switch.

6.14 Referencing by Reference Switch

Only

The axis drives to the reference switch to be referenced there. When, during the

reference run, the limit switch being positioned in the referencing direction has been

recognized, the axis will be stopped and an error will be output in register 170

"Positioning Error" (bit 18 "Reference: Limit switch positive" or bit 19 "Reference:

Limit switch negative"). The limit switch being positioned in negative direction will be

ignored.

This type of referencing is used with a conveyor belt, for example, which is to be reset

to zero after each turnover.

For the sequence of motions, please refer to chapter 6.12 "Referencing by Means of

Reference and Limit Switch", page 29.

Jetter AG 35

6 Referencing JetWeb

36 Jetter AG

JetMove 2xx at the NANO System Bus 7.1 Endless Positioning

7 Positioning

7.1 Endless Positioning

Attention!

Endless positioning is only allowed, if the axis is set to modulo mode.

Transition can be made from endless positioning to Ptp-positioning. Yet, it is not

possible to make transition from a running Ptp-positioning endless positioning.

Command 57 "Reversing of an endless positioning" will not consider the changes in

the positioning parameters, such as speed, which have been made after starting the

endless positioning.

Jetter AG 37

7 Positioning JetWeb

38 Jetter AG

JetMove 2xx at the NANO System Bus

8 Oscilloscope Function

The following registers can be used for oscilloscope recording in JetSym both as

recording and as trigger parameters:

• Register 109 "Actual position"

• Register 111 "Set speed value"

• Register 112 "Actual motor speed"

• Register 119 "Actual tracking error"

• Register 125 "Set current value"

• Register 129 "Actual mechanic speed"

• Register 130 "Set position value"

• Register 560 "DC link voltage"

• Register 561 "Actual current value"

• Register 562 "Motor temperature"

• Register 563 "Device temperature"

• Register 564 "Ballast workload"

• Register 565 "Motor shaft position"

• Register 566 "Device input current"

• Register 567 "Supply voltage"

• Register 568 "Controller card temperature"

Jetter AG 39

8 Oscilloscope Function JetWeb

40 Jetter AG

JetMove 2xx at the NANO System Bus 9.1 Control Parameters

9 Register Description

9.1 Control Parameters

Register 101: Command

Function Description

Read Latest command

Write Issuing a new command

Amplifier status No specific status

Validity Wait for the busy-bit in the status to be reset

Value range 0 ... 32.767

Value after reset 0

ATTENTION:

When a command has been issued, the PLC program cannot make another access

to the amplifier, unless the busy-bit in the status register has been reset by the

amplifier.

Commands:

The following commands are available:

1 Activating the output stage

2 Deactivating the output stage

3 Set the reference (actual position = the target position has been set, also

considering the tracking error)

5 Stop positioning by the maximum deceleration rate that is permitted (see

R180)

6 Stop positioning by the deceleration ramp (R106)

7 Stopping an axis motion by the emergency stop ramp (R549)

ATTENTION:

When the ramp has been covered, the output stage will automatically be

deactivated.

8 Acknowledging an error

9 Search for reference

10 Starting an absolute positioning run

11 Starting an absolute positioning run related to time

12 Changing an absolute target position

Jetter AG 41

9 Register Description JetWeb

The following commands are available:

13 Changing a speed value

15 Changing an acceleration value

16 Changing a deceleration value

20 Starting a relative positioning run

22 Changing a relative target position

32 Starting the setup mode

33 Stopping the setup mode

(The stop will not be made unless the next target position has been

reached)

56 Starting an endless positioning run

ATTENTION:

Endless positioning is only allowed, if the axis is set to modulo mode.

The direction of rotation is defined via register 142.

57 Reversing an endless positioning run

PLEASE NOTE:

Command 57 is used in order to reverse an endless positioning run that

has already been started. This means that the actual motion direction

will be reversed.

Register 515: Dig. outputs - switch status

Function Description

Read Value of the actual switch status

Write New value of the switch status

Amplifier status No specific status

Validity Immediately

Value range bit-coded, 24 bits

Value after reset 0

This only applies to JetMove 215/208

By means of this register, the status of the outputs can be queried, while other

outputs can be set and reset.

Meaning of the values:

0 : The output has been / will be reset

1 : The output has been set / will be reset

42 Jetter AG

JetMove 2xx at the NANO System Bus 9.1 Control Parameters

Meaning of the individual bits:

Bit 0: Output 1

Bit 1: Output 2

Bit 2: Output 3

Bit 3: Output 4

Register 516: Dig. registers for setting outputs

Function Description

Read Value set last

Write New set value

Value range bit-coded, 24 bits

Value after reset 0

This only applies to JetMove 215/208

By means of this register, only outputs can be set. If only individual outputs are to be

set, this register will make faster setting of outputs possible than if register 515 were

used.

Meaning of the values:

0 : The output will not be affected

1 : The output is set

Meaning of the individual bits:

Bit 0: Output 1

Bit 1: Output 2

Bit 2: Output 3

Bit 3: Output 4

Jetter AG 43

9 Register Description JetWeb

Register 517: Dig. outputs are reset by this register

Function Description

Read Latest reset value

Write New reset value

Value range bit-coded, 24 bits

Value after reset 0

This only applies to JetMove 215/208

By means of this register, only outputs can be reset. If only individual outputs are to

be reset, this register will make faster resetting of outputs possible than if register 515

were used.

Meaning of the values:

0 : The output will not be affected

1 : The output will be reset

Meaning of the individual bits:

Bit 0: Output 1

Bit 1: Output 2

Bit 2: Output 3

Bit 3: Output 4

Register 540: Operating mode

Function Description

Read Present state value of drive mode 1

Write New state value of drive mode 1

Amplifier status The amplifier must be deactivated

Validity Immediately

Value range bit-coded, 16 bits

Value after reset 0b 00000010 1001x011

44 Jetter AG

JetMove 2xx at the NANO System Bus 9.1 Control Parameters

ATTENTION:

If JetMove 2xx is used together with a NANO-CPU, bit 9 must always be set. The bit

has been set by default. In order to prevent important bits from being reset

unintentionally, we recommend to set, respectively reset, the bits one by one.

Meaning of the individual bits:

Bit 0: Automatic control of the brake by means of the amplifier

0 = Manual control by the user (via register 574, bit 0)

1 = Automatic control by the amplifier

Value after reset: 1

Bit 1: Automatic control of the ventilator placed in the amplifier

0 = The ventilator is always switched on

1 = Depending on the respective temperature, the ventilator will

automatically be switched off or switched on

Value after reset: 1

Bit 2: Reserved

Bit 3: Phase monitoring

Here, the decision is made, whether, in 3-phase-mode, phase monitoring

is to be activated or not. If phase monitoring has been activated, yet not

all three phases are pending, error message F02 will be output.

0 = Phase monitoring has been deactivated

1 = Phase monitoring has been activated

Value after reset for JetMove 215: 1

Value after reset for JetMove 203, 206: 0

Bit 4: Motor cable test

Here, a decision is made, whether the motor cable test is to be carried out

or not. Switching off might be necessary in case of long motor cables.

When the motor cable test has been activated, and if a ground fault of the

motor or a motor cable break have been detected, error message F03 will

be output.

0 = Motor cable test has been deactivated

1 = Motor cable test has been activated

Value after reset: 1

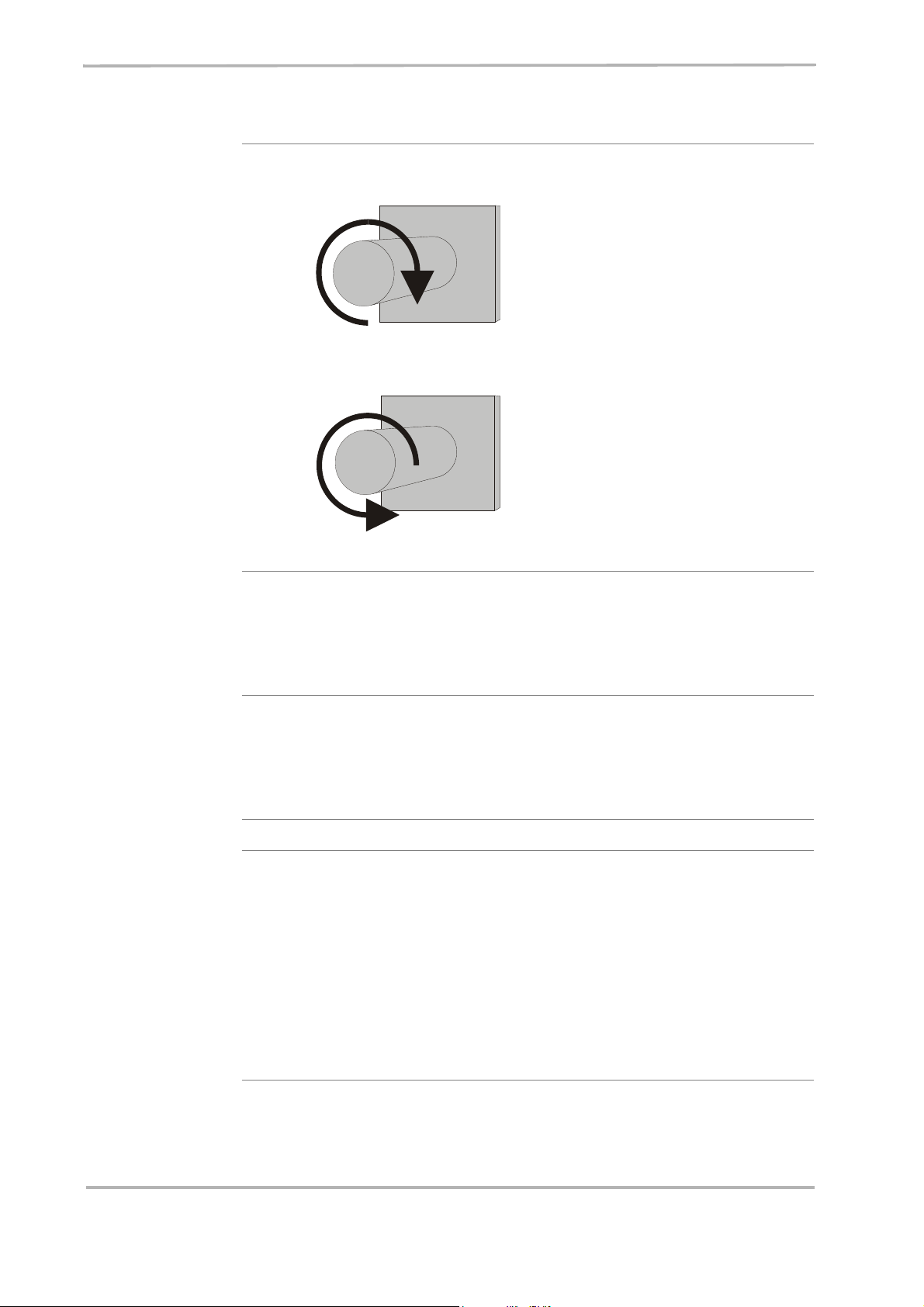

Bit 5: Speed reversal

By means of this bit, for all axis motions (position, speed and current

control), the direction of rotation will be conversed.

ATTENTION:

Please mind correct assignment of the hardware limit switches

Jetter AG 45

9 Register Description JetWeb

Meaning of the individual bits:

0 = Positive direction of rotation (clockwise rotation of the motor shaft,

looking at the shaft from the A-side; the set values are positive)

1 = Negative direction of rotation (counterclockwise rotation of the motor

shaft, looking at the shaft from the A-side; the set values are positive)

Value after reset: 0 (Positive direction of rotation)

Bit 6: Software limit switch

0 = The software limit switch evaluation has been deactivated

1 = The software limit switch evaluation has been activated

Value after reset: 0

Bit 7: Hardware limit switch

0 = The hardware limit switch evaluation has been deactivated

1 = The hardware limit switch evaluation has been activated

Value after reset: 1

Bit 8: Reserved

Bit 9: JetMove 2xx at the NANO / ConMove

ATTENTION:

If JetMove 2xx is used together with a NANO-CPU, this bit must always

be set.

0 = JetMove 2xx at ConMove

1 = JetMove 2xx at NANO

Value after reset: 1

46 Jetter AG

JetMove 2xx at the NANO System Bus 9.1 Control Parameters

Register 541: Operating mode of the 7-segment

display

Function Description

Read Number of the actual operating mode

Write New number of the operating mode

Value range 0 ... 1

Value after reset 0

See JetMove 2xx operator's manual

Meaning of the values:

0 : Normal operation

1 : Installation

Register 572: Set operating mode

Function Description

Read Number of the presently set operating mode

Write Number of the newly set operating mode

Amplifier status The amplifier must be deactivated

Validity When the amplifier is activated again

Value range 101, 102, 103

Value after reset 103

Here, the operating mode is set, in which the controller is to be run.

Meaning of the values:

101 : Current control (only the current control is active)

A set current value can be input via register 125

102 : Speed control (current control and speed control are active)

A set speed value can be input via register 111

103 : Position control (current control, speed control and position control

are active)

Jetter AG 47

9 Register Description JetWeb

Register 573: Actual mode of operation

Function Description

Read Value of the actual operating mode

Write Illegal

Value range 100 ... 103

Value after reset 100

Here, the actual operating mode the controller had when the output stage was

switched on last, can be read.

Meaning of the values:

100 : The output stage has not been activated yet

101 : Current control (only the current control is active)

102 : Speed control (current control and speed control are active)

103 : Position control (current control, speed control and position control

are active)

Register 574: Control word 2

Function Description

Read Value of the actual control word

Write New value of the control word

Value range bit-coded, 24 bits

Value after reset 0

Meaning of the individual bits:

Bit 0: Manual control of the brake

0 = Lock the brake

1 = Release the brake

(A requirement for manual control: In register 540 "Operating mode 1", bit

0 must be set to "Manual operation by the user".)

48 Jetter AG

JetMove 2xx at the NANO System Bus 9.1 Control Parameters

Register 575: Status word 2

Function Description

Read Value of the actual status word

Write Illegal

Value range bit-coded, 24 bits

Value after reset 0

Meaning of the individual bits:

Bit 0: Brake

0 = The brake is locked / the relay contacts have been released

1 = The brake has been released / the relay contacts are locked

Jetter AG 49

9 Register Description JetWeb

9.2 Diagnose Parameters

Register 100: Status

Function Description

Read Present status

Write Illegal

Value range bit-coded, 24 bits

Value after reset 0

From here, the amplifier status can be read. It contains information on the most

important amplifier parameters.

Meaning of the individual bits:

Bit 0: RefOK

Bit 1: Stopped

Bit 2: Destination window

Bit 3: -

Bit 4: Hardware limit switch negative

Bit 5: Hardware limit switch negative

Bit 6: Reference switch

Bit 7: Software limit switch, negative

Bit 8: Software limit switch, positive

Bit 9: -

Bit 10: The power section is ready for operation

Bit 11: Power has been released

Bit 12: Setup mode active

Bit 13: Busy bit:

(For all commands, register 180, register 181, register 184)

Bit 14: The maximum positioning speed has been reached (the axis has driven

beyond the range of the ramps)

Bit 15: Acceleration ramp

Bit 16: Deceleration ramp

Bit 17: -

Bit 18: There is an error or warning

50 Jetter AG

JetMove 2xx at the NANO System Bus 9.2 Diagnose Parameters

Meaning of the individual bits:

Bit 19: Errors

Bit 20: Danger

Bit 21: The pulse has been released (hardware release)

Register 170: Error referencing / positioning

Function Description

Read Actual errors

Write Illegal

Value range bit-coded, 24 bits

Value after reset 0

Actual errors can be read here during referencing or positioning.

Attention!

A number of these errors will NOT be shown on the display of the JetMove 2xx.

Meaning of the individual bits:

Bit 16: Referencing: Max. distance reference search

The permitted maximum distance of reference search has been

exceeded. The distance can be set via register 167 "Max. distance

reference search".

Bit 17: Referencing: Max. distance switch search

The permitted maximum distance of switch search has been exceeded.

The distance can be set via register 164 "Max. distance switch search".

Bit 18: Referencing: Positive limit switch

Reference switch type consisting of reference and limit switch:

The positive limit switch has been found after changing direction at the

negative limit switch during a reference run in negative direction.

Reference switch type, with limit switch only:

The positive limit switch has been found after changing direction at the

negative limit switch during a reference run in negative direction.

Reference switch type, with reference switch only:

The positive limit switch has been found during a reference run in

positive direction.

Jetter AG 51

9 Register Description JetWeb

Meaning of the individual bits:

Bit 19: Referencing: Negative limit switch

Reference switch type consisting of reference and limit switch:

The negative limit switch has been found after changing the direction at

the positive limit switch during a reference run in positive direction.

Reference switch type, with limit switch only:

The negative limit switch has been found after changing direction at the

positive limit switch during a reference run in positive direction.

Reference switch type, with reference switch only:

The negative limit switch has been found during a reference run in

negative direction.

Register 580: Warnings mask

Function Description

Read Actual warnings mask

Write New warnings mask

(this can only be changed with an expert's access

authorization, see register 576)

Value range bit-coded, 24 bits

Value after reset 0b 00000000 00000000 00111111

In the warnings mask, a definition can be made of which warnings are to be displayed

and which are not. The assignment of bits can be taken out of the description of

register 581 "Warnings".

Meaning of the values:

0 : The warning will not be displayed

1 : The warning will be displayed

52 Jetter AG

JetMove 2xx at the NANO System Bus 9.2 Diagnose Parameters

Register 581: Warnings

Function Description

Read Actual Warnings

Write Warnings are reset

Value range bit-coded, 24 bits

Value after reset 0

Meaning of the individual bits:

Bit 0: W00 Warning threshold for ballast

Bit 1: W01 Warning threshold for device temp.

Bit 2: W02 Warning threshold for motor temp.

Bit 3: W03 Overload PFC

Bit 4: W04 Input overcurrent

Bit 5: W05 Warning threshold for board temp.

Register 582: AutoClear mask for warnings

Function Description

Read Actual AutoClear mask

Write New AutoClear mask

Value range bit-coded, 24 bits

Value after reset 0b 00000000 00000000 00111111

Definitions to be made via AutoClear mask:

• Which warnings are to be automatically reset by the amplifier itself, as soon as

they are not relevant any more

• Which warnings are to be manually reset by the user

Manual resetting is carried out by writing into the respective bit in register 581

"Warnings". The assignment of bits can be taken out of the description of register 581

"Warnings".

Meaning of the values:

0 : The warning will automatically be reset by the user

1 : The warning will automatically be reset by the amplifier

Jetter AG 53

9 Register Description JetWeb

Register 585: Error 0 ... 15

Function Description

Read Actual errors numbered 00 through 15

Write Illegal

Value range bit-coded, 16 bits

Value after reset 0

Meaning of the individual bits:

Bit 0: F00 Hardware error

Bit 1: F01 Internal voltage supply error

Bit 2: F02 One mains phase has failed

Bit 3: F03 Motor or cable fault

Bit 4: F04 DC link overvoltage U

Bit 5: F05 Current overload

Bit 6: F06 Overload internal ballast resistor

Bit 7: F07 Shutdown threshold for device temp.

Bit 8: F08 Shutdown threshold for motor temp.

Bit 9: F09 Encoder error

Bit 10: F10 Overspeed

Bit 11: F11 Current overrange

Bit 12: F12 Earth fault

Bit 13: F13 AVR EEPROM failure

Bit 14: F14 AVR timeout

Bit 15: F15 Pulse enable failure

ZK

54 Jetter AG

JetMove 2xx at the NANO System Bus 9.2 Diagnose Parameters

Register 586: Error 16 ... 31

Function Description

Read Actual errors numbered 16 through 31

Write Illegal

Value range bit-coded, 16 bits

Value after reset 0

Meaning of the individual bits:

Bit 0: F16 Input overcurrent

Bit 1: F17 Software limit switch

Bit 2: F18 Limit switch hardware error

Referencing: The same hardware limit switch is pressed twice within a

short time.

Bit 3: F19 Timeout ext. error reaction Errors

Bit 4: F20 U

Bit 5: F21 U

Bit 6: F22 Drive blocked

Bit 7: F23 Tracking error

Bit 8: F24 Power supply 24 V failure

Bit 9: F25 Power supply 15 V failure

Bit 10: F26 Power supply 5 V failure

Bit 11: F27 Power supply AVR failure

Bit 12: F28 Error in power charging circuit (this is only possible with JetMove

215)

, DC link voltage min. trip

ZK

, DC link voltage max. trip

ZK

Jetter AG 55

9 Register Description JetWeb

9.3 Positioning Parameters

Register 102: Target position

Function Description

Read Actual target position

Write New target position

Amplifier status No specific status

Validity At the next positioning run or at command 12

Value range R183 ... R182 [°] or [mm]. The unit depends on

the setting of the axis type. The value contains an

adjustable decimal factor between 1 and 1,000;

this means that the least significant decimal

positions serve as decimal positions when the

internal unit [°] or [mm] is assigned to the value.

Value after reset 0 [°]

Here, the target position for the next point-to-point positioning is specified. Here, the

point-to-point positioning can be either absolute or relative. The register can be

written into during a positioning run.

The target position is used at the following commands:

• Command 10 "Starting an absolute positioning run"

• Command 11 "Starting an absolute positioning run related to time"

• Command 12 "Changing an absolute target position"

• Command 20 "Starting a relative positioning run"

• Command 22 "Changing a relative target position"

Attention!

Positioning is not started yet by writing into the target position. Only the

respective command will cause the positioning run to be started.

The target position of a positioning run that is already in process can be changed. In

order to change the target position, the new target position must be written into the

register; then, one of the following commands must be issued:

56 Jetter AG

JetMove 2xx at the NANO System Bus 9.3 Positioning Parameters

Point-to-point positioning - absolute

• Command 10 "Starting an absolute positioning run"

The entire positioning will be calculated again. New general conditions can

change the behaviour, e.g. speed, of the new positioning run compared to the

former one.

• Command 11 "Starting an absolute positioning run related to time"

The entire positioning will be calculated again. New general conditions can

change the behaviour, e.g. speed, of the new positioning run compared to the

former one.

• Command 12 "Changing an absolute target position"

Positioning will only be newly calculated regarding the new target position. New

general conditions will not be considered; speed, for example, remains

unchanged.

Point-to-point positioning - relative

• Command 20 "Starting a relative positioning run"

The entire positioning will be calculated again. New general conditions can

change the behaviour, e.g. speed, of the new positioning run compared to the

former one.

• Command 22 "Changing a relative target position"

Positioning will only be newly calculated regarding the new target position. New

general conditions will not be considered; speed, for example, remains

unchanged.

Leading over from endless to point-to-point positioning:

• Command 10 "Starting an absolute positioning run"

The entire positioning will be calculated again.

Yet, it is not possible for a running point-to-point positioning to be led to endless

positioning.

Jetter AG 57

9 Register Description JetWeb

Register 103: Target speed

Function Description

Read Actual target speed

Write New target speed

Amplifier status No specific status

Validity At the next positioning run or at command 13

Value range 0 ... R184 [°/s] or [mm/s]

(The unit is dependent on the axis type)

Value after reset 0 [°/s]

Here, the target speed for all positioning runs, point-to-point positioning and endless

positioning is specified. The register can be written into during a positioning run.

The target speed is used at the following commands:

• Command 10 "Starting an absolute positioning run"

• Command 13 "Changing a speed"

• Command 20 "Starting a relative positioning run"

• Command 56 "Starting endless positioning"

Attention!

If, during a positioning run, a register is written into, the new target speed will not

be of any effect, unless the respective command has been issued.

The target speed of a positioning run that is already in process can be changed. For

this purpose, the new target speed must be written into the register, and command

13 "Changing a speed" must be issued.

Changing a target speed value is also considered, when, during a positioning run

already in process, the following commands are given:

• Command 10 "Starting an absolute positioning run"

• Command 20 "Starting a relative positioning run"

• Command 56 "Starting endless positioning"

This is only permitted, if the running positioning is an endless positioning; during

a running point-to-point positioning, this command must not be issued.

58 Jetter AG

JetMove 2xx at the NANO System Bus 9.3 Positioning Parameters

Register 104: Positioning time

Function Description

Read Actual positioning time

Write New (set) positioning time

Amplifier status No specific status

Validity Next positioning started by command 11

Value range 0 ... 32,767 [s]

Value after reset 0 [s]

Instead of issuing a speed via register 103, it is also possible to set a time for pointto-point positioning. Then, the speed will result from the actual position, the target

position, the content of register 2, and the time set for this.

The amplifier will enter the calculated speed into register 103 "Target Speed"; it will

be used at the following positioning run, if the contents of register 103 are not

changed.

Positioning related to time is started by issuing command 11 "Starting an absolute

positioning run related to time".

The target speed of a positioning run that is already in process can be changed. For

this purpose, the new positioning time must be entered into the register and

command 11 must be issued. It is insignificant, whether the positioning running at

that moment has been started by issuing command 11 or not. Please mind, though,

that the speed of the new positioning run can be different from the former one.

A positioning run started by command 11 can be influenced and altered by changing

the positioning parameters and by issuing the respective commands.

Jetter AG 59

9 Register Description JetWeb

Register 105: Acceleration

Function Description

Read Actual acceleration

Write Set acceleration

Amplifier status No specific status

Validity At the next positioning run or at command 15

Value range 0 ... R180 [°/s²] or [mm/s²]

(The unit is dependent on the axis type)

Value after reset 500 [°/s²]

Here, the acceleration for individual positioning runs is specified. The acceleration

value is used for starting a positioning run and for the change of speed during a

positioning run. This means that, even if, during positioning, the speed is being

decelerated, still the acceleration value is used for this deceleration. The

deceleration value of register 106 will only be used for deceleration when driving

towards the target position and for carrying out command 6 "Stop positioning (user

ramp)".

The target speed is used at the following commands:

• Command 10 "Starting an absolute positioning run"

• Command 11 "Starting an absolute positioning run related to time"

• Command 15 "Changing an acceleration value"

• Command 20 "Starting a relative positioning run"

• Command 56 "Starting endless positioning"

Attention!

A low value results in a long ramp, while a great value results in a short ramp.

Two ramp types can be selected for acceleration:

• sine-square ramp (sine-square shaped speed profile)

or

• linear ramp (linear speed profile)

The ramp type can be selected by means of register 140 "Ramp type". The sinesquare ramp has been set as the default ramp type.

A sine-square ramp guarantees a soft and jerk-free start. When driving a sine-square

ramp, the specified value will be reached in the middle of the acceleration process.

If a linear ramp is driven, acceleration will remain constant; the speed will increase

in linear mode during the entire acceleration process.

60 Jetter AG

JetMove 2xx at the NANO System Bus 9.3 Positioning Parameters

In the illustration below, various settings for acceleration by sine-square ramp will be

shown.

v in 1/min

6,000

The set acceleration value

is reached here

0

1,000 3,000

2,000

4,000

t in ms

Fig. 18: Acceleration process

The acceleration rate of a positioning run that is already in process can be changed.

For this purpose, the new acceleration rate must be written into the register, and

command 15 "Changing a speed" must be issued. Yet, this change will not take effect

on the actual acceleration ramp, but on the ramp that is to follow.

Changing an acceleration value is also considered, when, during a positioning run

already in process, the following commands are given:

• Command 10 "Starting an absolute positioning run"

• Command 11 "Starting an absolute positioning run"

• Command 20 "Starting a relative positioning run"

• Command 56 "Starting endless positioning"

This is only permitted, if the running positioning is an endless positioning; during

a running point-to-point positioning, this command must not be issued.

Jetter AG 61

9 Register Description JetWeb

Register 106: Deceleration

Function Description

Read Actual delay

Write Set delay

Amplifier status No specific status

Validity At the next positioning run or at command 16

Value range 0 ... R180 [°/s²] or [mm/s²]

(The unit is dependent on the axis type)

Value after reset 500 [°/s²]

Here, the deceleration rate when driving towards the target for positioning runs is

specified. The deceleration value will only be used for driving towards the target

position and for carrying out command 6 "Stop positioning (user ramp)". For a

change of speed during positioning, the acceleration value specified in register 105

will be used. This means that, even if, during positioning, the speed is being

decelerated, still the acceleration value is used for this deceleration.

The deceleration for driving towards the target is used at the following commands:

• Command 6 "Stop positioning (user ramp)"

• Command 10 "Starting an absolute positioning run"

• Command 11 "Starting an absolute positioning run related to time"

• Command 16 "Changing a deceleration value"

• Command 20 "Starting a relative positioning run"

Attention!

A low value results in a long ramp, while a great value results in a short ramp.

Two ramp types can be selected for deceleration when driving towards the target:

• sine-square ramp (sine-square shaped deceleration profile)

or

• linear ramp (sine-square shaped speed profile)

The ramp type can be selected by means of register 140 "Ramp type". The sinesquare ramp has been set as the default ramp type.

A sine-square ramp guarantees soft and jerk-free deceleration. When driving a sinesquare ramp, the specified value will be reached in the middle of the deceleration

process.

62 Jetter AG

JetMove 2xx at the NANO System Bus 9.3 Positioning Parameters

When driving a linear ramp, the deceleration when driving towards the target (not the

deceleration profile) has got a sine-square-shaped speed profile. This way, soft and

jerk-free deceleration will be guaranteed as well. When driving a sine-square ramp,

the specified value will also be reached in the middle of the deceleration process.

In the illustration below, various settings for deceleration by sine-square ramp when

driving towards the target will be shown.

v in 1/min

6,000

The set deceleration value

will be reached here

0

0

1,000

2,000

3,000

4,000

t in ms

Fig. 19: Deceleration process when driving towards the target

Register 107: Destination window

Function Description

Read Present destination window

Write New destination window

Amplifier status No specific status

Validity At the next positioning run or after changing the

target position

Value range 0 ... 8,388,607 [°] or [mm] (the unit is dependent

on the settings of the axis type. The value

contains an adjustable decimal factor between 1

and 1,000; this means that the least significant

decimal positions serve as decimal positions

when the internal unit [°] or [mm] is assigned to

the value.

Value after reset 1 [°]

Here, the destination window for the target area of a point-to-point positioning can be

set. If , after positioning, the axis has reached the destination window, bit 2

"Destination window" will be set in register 100 "Status". The bit will not be reset,

unless a new positioning (point-to-point positioning) has been started.

Jetter AG 63

9 Register Description JetWeb

Destination window 5 mm around

destination position 100 mm

95

100

105

s in mm

Fig. 20: Example of a destination window

Attention!

If a point-to-point positioning is stopped before the axis has reached the

destination window, the destination window bit will not be set. In this case, bit 1

"Stopped" can be used in register 100 "Status".

Faster program flow can be achieved by using the destination window range. The

program can be continued, as soon as the axis has reached the destination window.

The general progression condition would be as follows:

...

REGISTER_LOAD (rmTargetPosition, 90000) // Target position 90000

// (° or mm)

REGISTER_LOAD (rmCommand, 10) // Start ptp positioning

WHEN BIT_CLEAR (rmStatus, 13) THEN // Wait, until busy-bit

// has been reset

WHEN BIT_SET (rmStatus, 2) THEN // Wait, till dest. wind. bit

// has been set

...

Difference between destination window bit and "Stopped" bit

The destination window bit is set, as soon as the actual position of the axis has

reached the destination window. The "Stopped" bit will be set, as soon as the internal

set position (not the actual position) has reached the target position. The settings of

the destination window take no effect on the "Stopped" bit.

64 Jetter AG

JetMove 2xx at the NANO System Bus 9.3 Positioning Parameters

Register 109: Actual position

Function Description

Read Actual position

Write Illegal

Value range R183 ... R182 [°] or [mm] (The unit depends on

the setting of the axis type. The value contains an

adjustable decimal factor between 1 and 1,000;

this means that the least significant decimal

positions serve as decimal positions when the

internal unit [°] or [mm] is assigned to the value.

Value after reset 0 [°]

From here, the actual axis position can be read out. This parameter is often used as

a progression condition.

Example:

...

WHEN REG rmActPosition > 10000 THEN // Wait, until the actual

// pos. is greater than 10000

// (° or mm)

OUT 101 // Set output 101

...

If the axis has not been set to modulo mode in register 192 "Modulo axis", the actual

position will not exceed the travel range, which has been set via register 182 "Travel

range limit positive" and register 183 "Travel range limit negative". Neither will there

be an overflow. At the limits of the travel range, the axis will be stopped automatically.

Endless positioning is not permitted here.

If the axis has been set to modulo mode in register 192 "Modulo axis", there will be

an overflow of the actual position, when the travel range limits have been exceeded;

the actual position will be continued at the value of the other travel range limit. The

axis will continue travelling as before. Endless positioning is only permitted for a

modulo axis.

Jetter AG 65

9 Register Description JetWeb

Register 129: Actual speed

Function Description

Read Actual mechanical speed

Write Illegal

Value range -R184 ... R184 [°/s] or [mm/s]

(The unit is dependent on the axis type)

Value after reset 0 [°/s]

From here, the actual axis speed can be read out.

Register 131: Setup mode - delay

Function Description

Read Present delay value

Write New delay value

Amplifier status No specific status

Validity Immediately

Value range 1 ... 65,535 [ms]

Value after reset 1,000 [ms]

Here, the delay time for setup mode will be specified. The delay time is the duration

of waiting at every target position in setup mode, until the next point-to-point

positioning towards the other target position is started.

66 Jetter AG

JetMove 2xx at the NANO System Bus 9.3 Positioning Parameters

Register 132: Setup mode - position 1

Function Description

Read Actual position 1

Write New position 1

Amplifier status No specific status

Validity At the next start into the direction of position 1

Value range R183 ... R133 [°] or [mm] (The unit depends on

the setting of the axis type. The value contains an

adjustable decimal factor between 1 and 1,000;

this means that the least significant decimal

positions serve as decimal positions when the

internal unit [°] or [mm] is assigned to the value.

Value after reset 0 [°]

Here, position 1 (left position) is specified for the setup mode.

Register 133: Setup mode - position 2

Function Description

Read Actual position 2

Write New position 2

Amplifier status No specific status

Validity At the next start into the direction of position 2

Value range R132 ... R182 [°] or [mm] (The unit depends on

the setting of the axis type. The value contains an

adjustable decimal factor between 1 and 1,000;

this means that the least significant decimal

positions serve as decimal positions when the

internal unit [°] or [mm] is assigned to the value.

Value after reset 100 [°]

Here, position 2 (right position) is specified for the setup mode.

Jetter AG 67

9 Register Description JetWeb

Register 140: Accel / decel ramp type

Function Description

Read Actual ramp type