60880901

User Manual

JC-120MC - Controller

We automate your success.

Introduction

Item # 60880901

Revision 1.26.2

September 2016 / Printed in Germany

This document has been compiled by Jetter AG with due diligence, and based on the known state of the art.

In the case of modifications, further developments or enhancements to products shipped in the past, a revised document

will be supplied only if required by law, or deemed appropriate by Jetter AG. Jetter AG shall not be liable for errors in form

or content, or for missing updates, as well as for damages or disadvantages resulting from such failure.

The logos, brand names, and product names mentioned in this document are trademarks or registered trademarks of

Jetter AG, of associated companies or other title owners and must not be used without consent of the respective title

owner.

2 Jetter AG

JC-120MC Introduction

Address

Assignment to product

How to contact us:

Jetter AG

Graeterstrasse 2

71642 Ludwigsburg

Germany

Phone - Switchboard: +49 7141 2550-0

Phone - Sales: +49 7141 2550-433

Phone - Technical Hotline: +49 7141 2550-444

Fax - Sales: +49 7141 2550-484

E-mail - Sales: sales@jetter.de

E-mail - Technical Hotline: hotline@jetter.de

This User Manual is an integral part of JC-120MC:

Type:

Serial #:

Year of manufacture:

Order #:

To be entered by the customer:

Inventory #:

Place of operation:

Jetter AG 3

Introduction

Significance of this

User Manual

This document is an integral part of the JC-120MC:

Keep this document in a way that it is always at hand until the JC-120MC

will be disposed of.

Pass this document on if the JC-120MC is sold or loaned/leased out.

In any case you encounter difficulties to clearly understand the contents of this

document, please contact Jetter AG.

We would appreciate any suggestions and contributions on your part and

would ask you to contact us at the following e-mail address: info@jetter.de.

Your feedback will help us produce manuals that are more user-friendly, as

well as address your wishes and requirements.

This document contains important information on the following topics:

Transport

Mounting

Installation

Programming

Operation

Maintenance

Repair

Therefore, you must carefully read, understand and observe this document,

and especially the safety instructions.

In the case of missing or inadequate knowledge of this document Jetter AG

shall be exempted from any liability. Therefore, the operating company is

recommended to obtain the persons' confirmation that they have read and

understood this manual in writing.

4 Jetter AG

JC-120MC Contents

Table of Contents

1 Safety instructions 13

Basic safety instructions .............................................................................................................. 14

Instructions on EMI ...................................................................................................................... 16

2 Product description and design 19

Product description of the JC-120MC .......................................................................................... 20

Parts and interfaces of the controller JC-120MC ......................................................................... 21

Order reference/options ............................................................................................................... 22

List of documentation ................................................................................................................... 23

Accessories for the JX3 system ................................................................................................... 25

Physical dimensions .................................................................................................................... 26

3 Identifying 27

3.1 Identification by means of the nameplate ............................................................................... 28

Nameplate .................................................................................................................................... 29

3.2 Electronic Data Sheet EDS ........................................................................................................ 30

EDS file ........................................................................................................................................ 31

EDS registers ............................................................................................................................... 35

3.3 Version registers ........................................................................................................................ 37

Hardware revisions ...................................................................................................................... 38

Software versions ......................................................................................................................... 39

4 Mechanical and electrical installation 41

4.1 Interfaces .................................................................................................................................... 42

Power supply terminal X10 .......................................................................................................... 43

Serial interface port X11 ............................................................................................................... 44

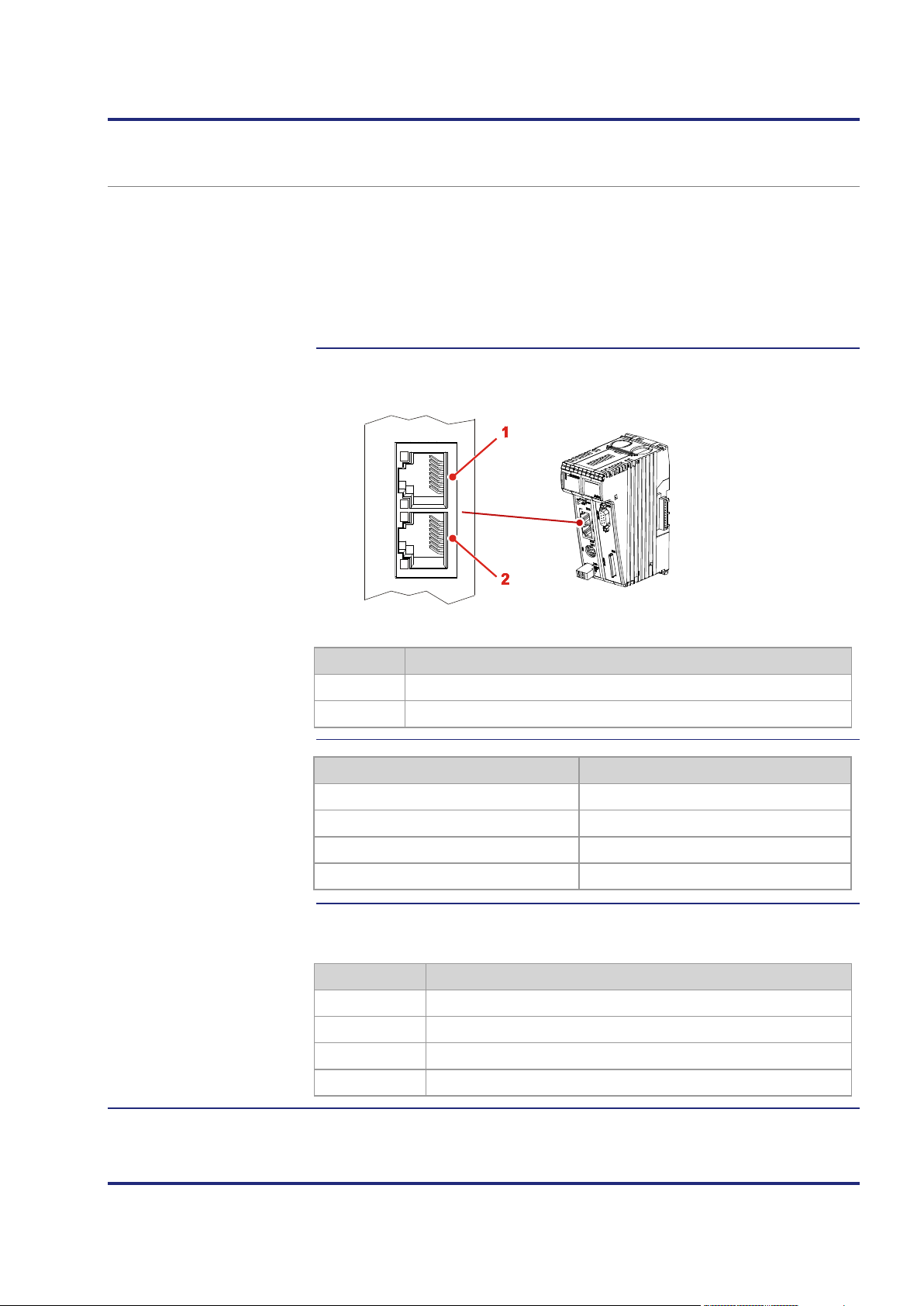

Ethernet ports - Female connectors X14, X15 ............................................................................. 47

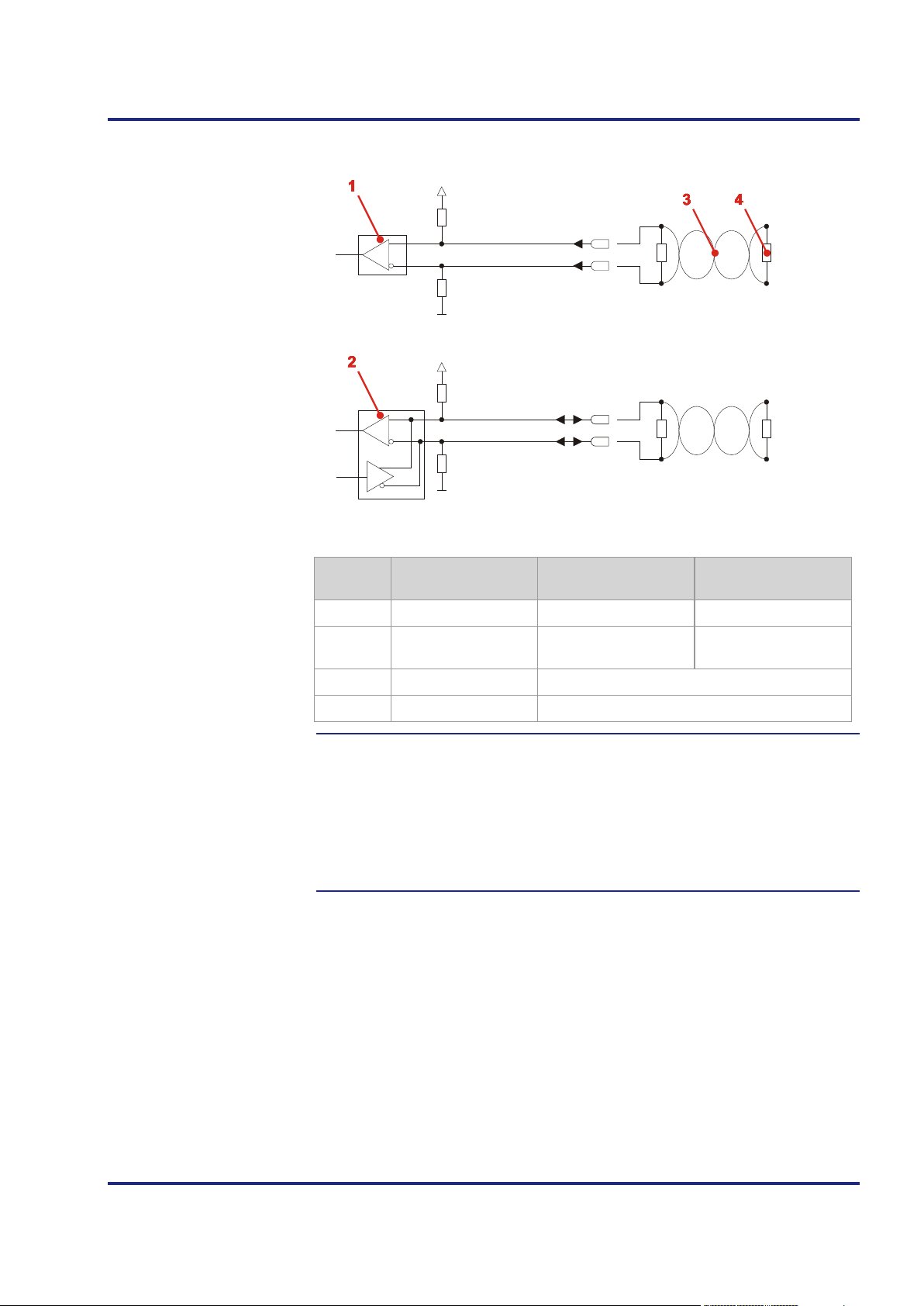

4.2 CAN bus interface - Female connector X19 ............................................................................ 48

Female connector X19 - Pin assignment ..................................................................................... 49

Specification of the Y cable .......................................................................................................... 51

JX2 system bus cable specification ............................................................................................. 53

Line length and baud rate of the JX2 system bus........................................................................ 55

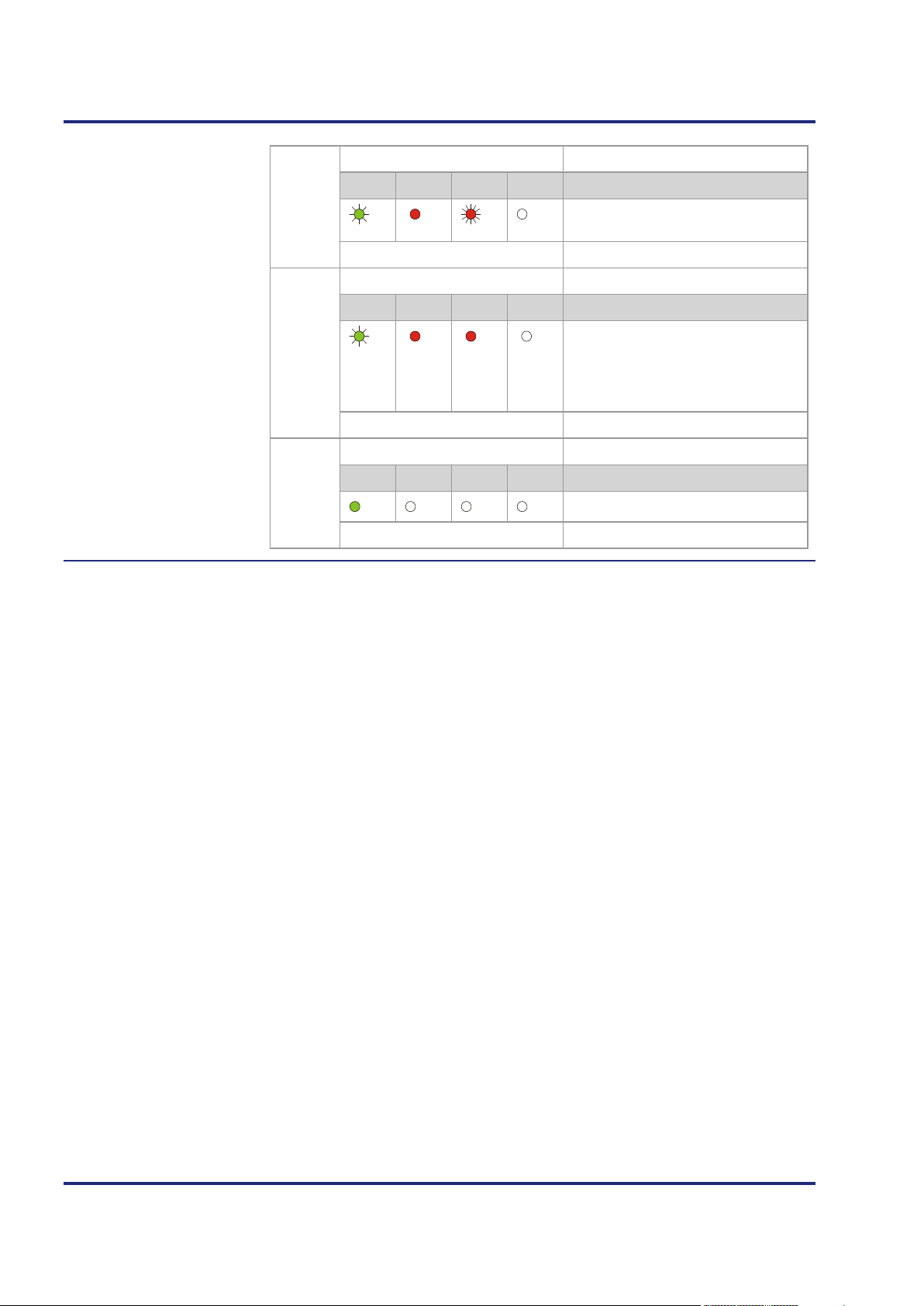

4.3 LEDs indicating various states ................................................................................................. 56

LEDs of the controller .................................................................................................................. 57

LEDs of the controller during boot process .................................................................................. 59

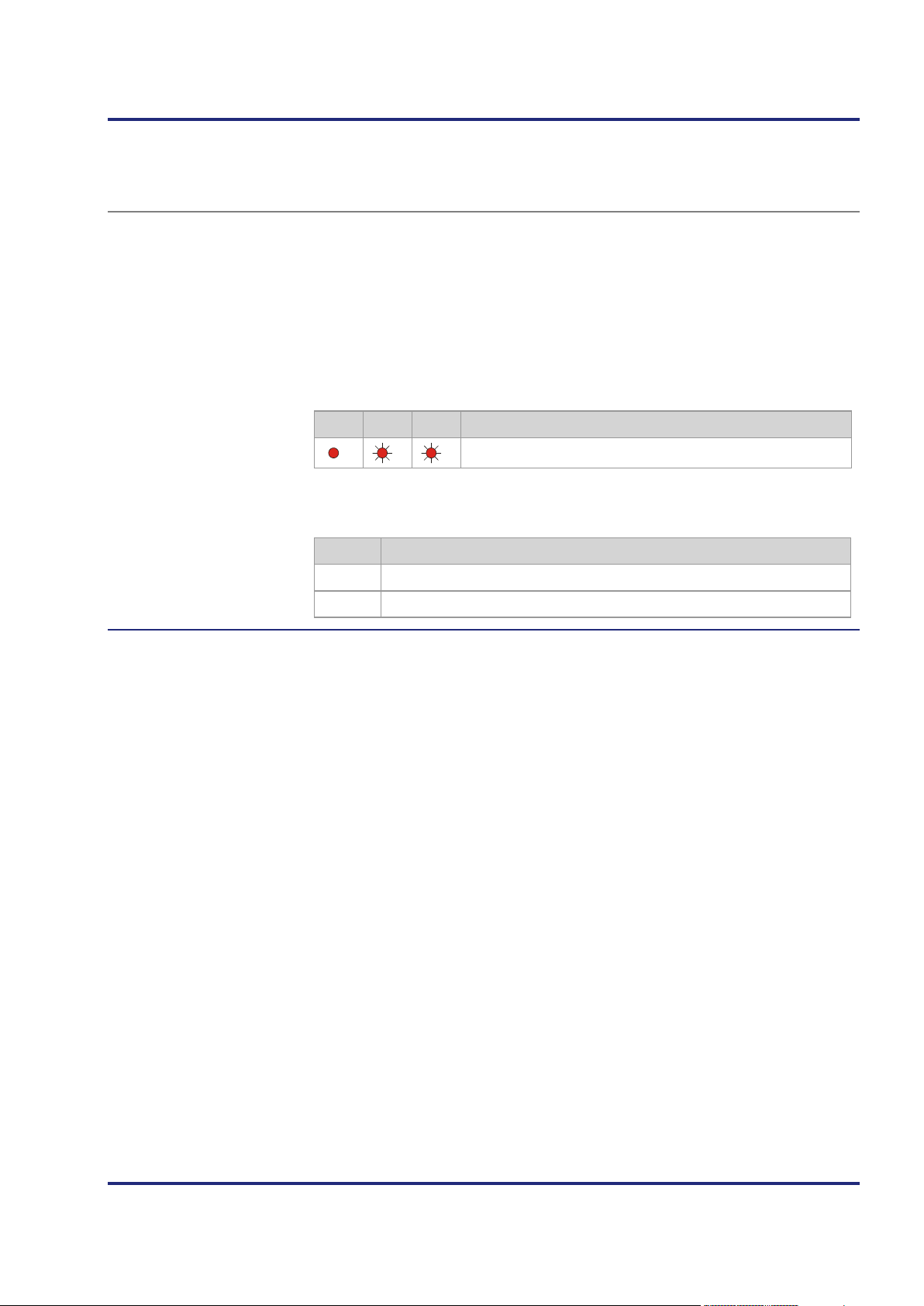

LED indications on the controller after an IP address conflict has been detected....................... 61

Status LEDs - Ethernet interface .................................................................................................. 62

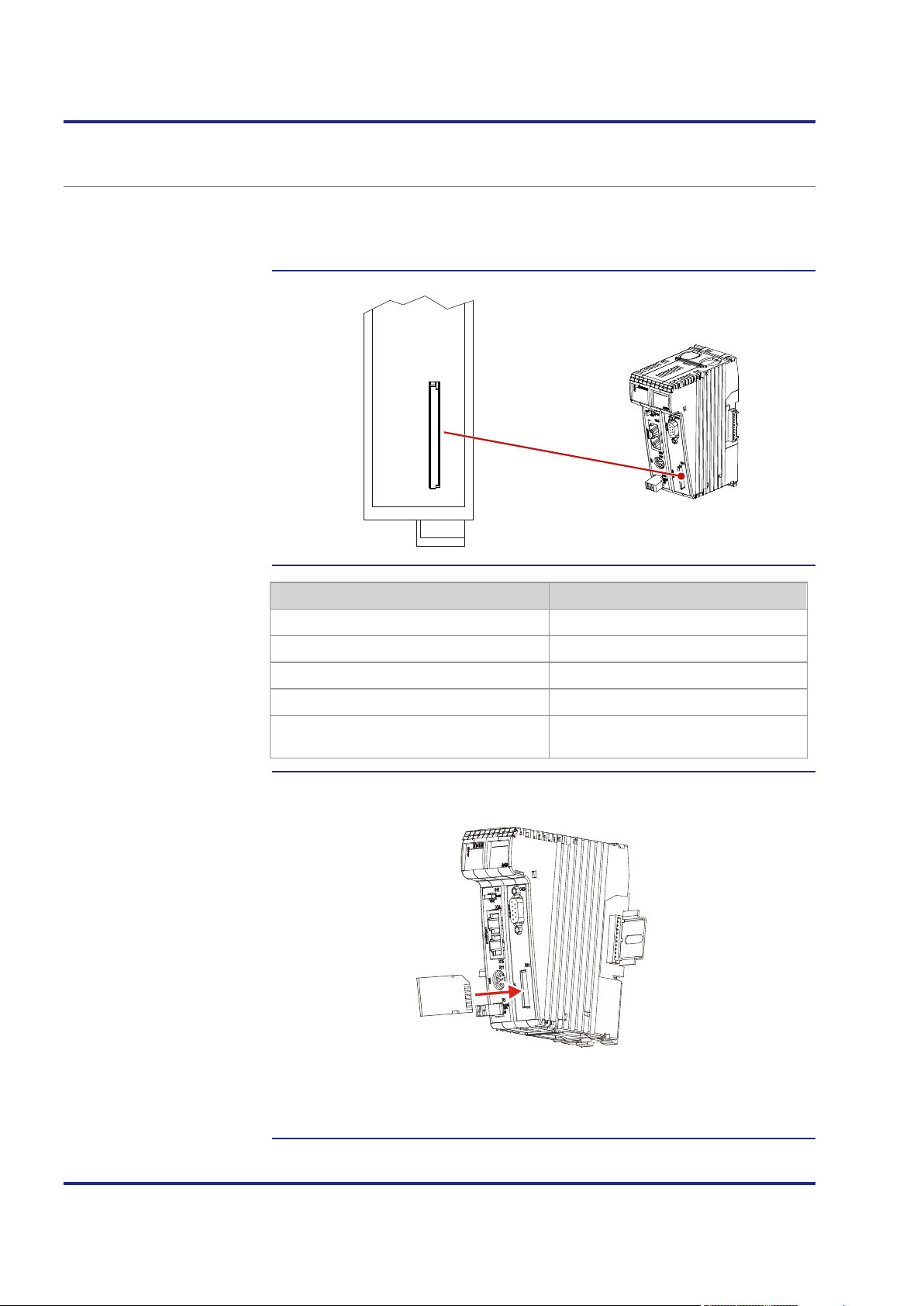

4.4 Controls and SD memory card ................................................................................................. 63

Function description of mode selector S11 .................................................................................. 64

SD card slot X61 .......................................................................................................................... 66

4.5 Installing, replacing and removing the module ...................................................................... 68

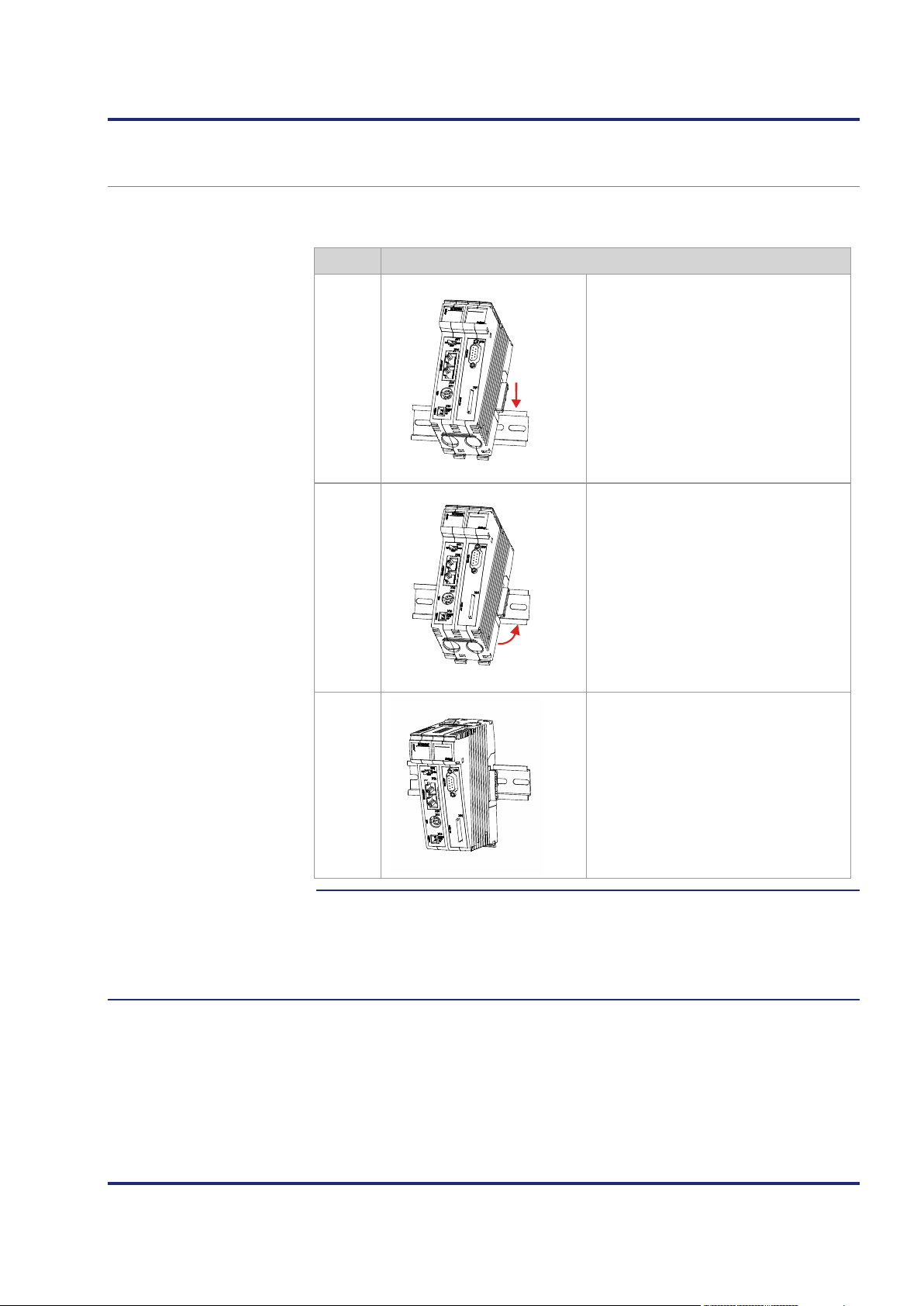

Installing the JC-120MC on a DIN rail .......................................................................................... 69

Replacing the controller JC-120MC ............................................................................................. 70

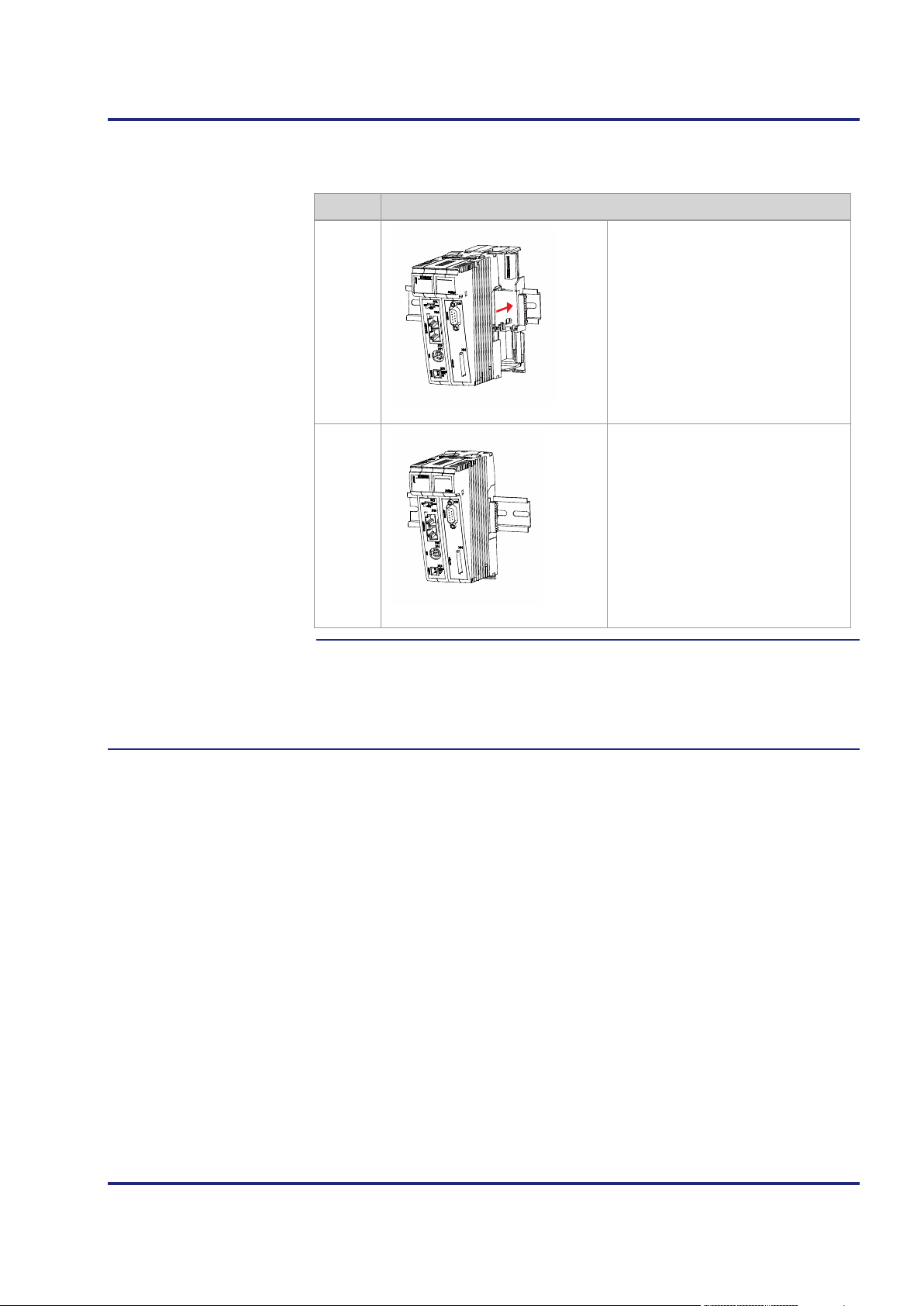

Removing the JC-120MC from the DIN rail ................................................................................. 72

4.6 IP configuration .......................................................................................................................... 73

Factory settings ............................................................................................................................ 74

The configuration memory ........................................................................................................... 75

Jetter AG 5

Contents

The configuration file ................................................................................................................... 76

Configuration registers ................................................................................................................ 80

Changing the IP address of the controller ................................................................................... 81

Setting the default IP address 192.168.10.15 ............................................................................. 82

Setting the IP address via configuration file ................................................................................ 83

Setting the IP address via configuration file and DIP switch ....................................................... 84

Setting the IP address via registers to be non-volatile ................................................................ 86

Setting the IP address during runtime ......................................................................................... 88

IP address in the GNN operating mode ...................................................................................... 89

Using names for IP addresses .................................................................................................... 91

4.7 Engineering of JX3 station equipped with a JC-120MC ........................................................ 93

4.7.1 Limitations to be taken into account when engineering a JX3 station ................................ 94

Limitations of the maximum number of modules......................................................................... 97

Limitations of the modules' data exchange rates ........................................................................ 98

Limitation depending on the power consumption of the modules ............................................. 101

4.8 Configuring the JX2 system bus ........................................................................................... 106

4.8.1 Wiring the JX2 system bus..................................................................................................... 107

Line length and baud rate of the JX2 system bus ..................................................................... 108

JX2 system bus topology .......................................................................................................... 109

Power supply of JX2-I/O modules .............................................................................................. 110

Power supply of JX2 slave modules .......................................................................................... 112

4.9 Connecting displays and HMIs ............................................................................................... 113

Overview of displays and HMIs .................................................................................................. 114

Connecting a display or HMI ...................................................................................................... 11 5

Connecting several displays or HMIs: Multi-display mode ......................................................... 116

Multi-display mode - Wiring ........................................................................................................ 117

Interface cable JC-DK-Xm.......................................................................................................... 119

Interface cable KAY_0386-xxxx ................................................................................................ 121

Interface cable KAY_0533-0025................................................................................................ 123

5 Initial commissioning 125

Preparatory work for initial commissioning ................................................................................ 126

Initial commissioning of a JC-120MC ........................................................................................ 127

Configuring error states ............................................................................................................. 129

Configuration in JetSym ............................................................................................................ 130

6 File system 135

6.1 Properties ................................................................................................................................. 136

Flash disk - Properties ............................................................................................................... 137

SD card - Properties .................................................................................................................. 138

6.2 User administration ................................................................................................................. 139

Administration of users .............................................................................................................. 141

As-delivered condition/Predefined users and keys ................................................................... 143

Assigning locks .......................................................................................................................... 144

Assigning names to keys/locks ................................................................................................. 146

6.3 Reviewing the flash disk capacity used ................................................................................ 148

Flash disk capacity used ........................................................................................................... 149

6.4 Operating system update and application program ............................................................ 152

6.5 Formatting and checking........................................................................................................ 153

Formatting the flash disk ........................................................................................................... 154

Formatting the SD card ............................................................................................................. 155

Checking the SD card ............................................................................................................... 156

6 Jetter AG

JC-120MC Contents

7 FTP server 157

Logon ......................................................................................................................................... 158

Example: Windows FTP client ................................................................................................... 159

8 FTP client 161

8.1 Programming ............................................................................................................................ 162

Initializing the FTP client ............................................................................................................ 163

Establishing a connection to the FTP server ............................................................................. 164

Terminating a connection ........................................................................................................... 166

Reading a file ............................................................................................................................. 167

Writing to a file ........................................................................................................................... 169

Deleting a file ............................................................................................................................. 171

Changing directories .................................................................................................................. 173

Creating a directory .................................................................................................................... 175

Deleting directories .................................................................................................................... 177

Determining the current directory............................................................................................... 179

8.2 Registers ................................................................................................................................... 181

Register numbers ....................................................................................................................... 182

Registers - Description ............................................................................................................... 183

9 HTTP server 187

9.1 Server Side Includes ................................................................................................................ 188

First entry in the HTML file ......................................................................................................... 189

Inserting real-time controller values ........................................................................................... 190

Example of an HTML page ........................................................................................................ 195

10 Programming 197

Abbreviations, module register properties and formats ............................................................. 198

10.1 Memories - Overview ............................................................................................................... 199

Operating system memory ......................................................................................................... 200

File system memory ................................................................................................................... 201

Application program memory ..................................................................................................... 202

Memory for volatile application program variables .................................................................... 203

Memory for non-volatile application program registers .............................................................. 204

Memory for non-volatile application program variables ............................................................. 205

Registers on I/O modules .......................................................................................................... 206

Memory for non-volatile registers on the backplane module ..................................................... 207

Special registers ......................................................................................................................... 208

Inputs and outputs ...................................................................................................................... 209

Flags .......................................................................................................................................... 210

10.2 Register and I/O numbers with a JC-120MC ......................................................................... 211

Registers and module registers ................................................................................................. 212

Register and I/O numbers of JX3 modules connected to a JC-120MC ..................................... 214

Register numbers of JX2 slave modules connected to the JX2 system bus ............................. 215

Registers and I/O numbers of JX2-I/O modules on the JX2 system bus .................................. 216

Register and I/O numbers of IP67-I/O modules on the JX2 system bus ................................... 217

Registers and I/O numbers of CANopen® modules on the JX2 system bus ............................ 218

Register and I/O numbers of JX3 modules connected to a JX3-BN-ETH ................................. 219

Registers and I/O numbers of JX3 nodules from the JX3-BN-ETH perspective ....................... 221

10.3 Jetter Ethernet system bus ..................................................................................................... 222

The Global Node Number .......................................................................................................... 224

Jetter AG 7

Contents

10.3.1 Acyclic data interchange ........................................................................................................ 225

Command group NetCopy() ...................................................................................................... 227

Command group NetBit() .......................................................................................................... 229

Network registers ...................................................................................................................... 230

Registers located on JX3 modules ............................................................................................ 232

Indirect addressing of remote modules ..................................................................................... 234

Addressing with variable destination window ............................................................................ 236

Register description - Acyclic data interchange ........................................................................ 238

10.3.2 Cyclic data interchange .......................................................................................................... 241

Publish/subscribe ...................................................................................................................... 243

Publish/subscribe - Registers .................................................................................................... 245

Network registers, network inputs and outputs ......................................................................... 251

10.3.3 Hardware Manager .................................................................................................................. 254

Hardware Manager .................................................................................................................... 255

10.3.4 Error handling at the Jetter Ethernet system bus ............................................................... 256

Acyclic data interchange - Error logging ................................................................................... 257

Error message during CRC computing ..................................................................................... 258

Error message on part of a subscription ................................................................................... 259

Controller evaluates errors reported by a remote network node............................................... 260

10.3.5 JetIPScan - Register description ........................................................................................... 261

Register numbers ...................................................................................................................... 262

Global status - Register description .......................................................................................... 263

Warnings and errors - Register description ............................................................................... 266

Configuration - Register description .......................................................................................... 270

10.3.6 Administrating the connections of the JetIP/TCP and STX debug server ........................ 272

Automatic termination of connections ....................................................................................... 273

Register ..................................................................................................................................... 275

10.3.7 Executing an ARP request ..................................................................................................... 276

Executing an ARP request ........................................................................................................ 277

10.3.8 JetSync blockage .................................................................................................................... 278

Description of system command registers ................................................................................ 279

Description of the JetSync blockage system commands .......................................................... 282

10.4 General system registers ....................................................................................................... 284

Description of system command registers ................................................................................ 285

Description of system commands ............................................................................................. 288

10.5 Startup delay register.............................................................................................................. 293

Setting the startup delay ............................................................................................................ 294

10.6 Real-time clock (RTC) ............................................................................................................. 295

Technical specifications ............................................................................................................. 296

Programming ............................................................................................................................. 297

10.7 Runtime registers .................................................................................................................... 304

Description of the runtime registers .......................................................................................... 305

10.8 Monitoring interface activities ............................................................................................... 307

Operating principle .................................................................................................................... 308

Programming ............................................................................................................................. 310

10.9 Controlling HMIs with alphanumeric displays ..................................................................... 312

10.9.1 Connectable HMIs ................................................................................................................... 313

Overview of displays and HMIs ................................................................................................. 314

10.9.2 Registers .................................................................................................................................. 315

Register numbers ...................................................................................................................... 316

Registers - Overview ................................................................................................................. 317

10.9.3 Configuring the screen size ................................................................................................... 319

Configuring the screen size manually ....................................................................................... 320

10.9.4 Displaying texts ....................................................................................................................... 321

STX Instructions for displaying texts ......................................................................................... 322

Device numbers ........................................................................................................................ 324

8 Jetter AG

JC-120MC Contents

Cursor position ........................................................................................................................... 326

Clearing the screen .................................................................................................................... 328

10.9.5 Displaying numerical values................................................................................................... 330

STX instruction for displaying numerical values ........................................................................ 331

Device numbers ......................................................................................................................... 332

Cursor position ........................................................................................................................... 334

Setting the length of the display field ......................................................................................... 336

Setting the sign option ............................................................................................................... 337

Setting the number of decimal places ........................................................................................ 338

Setting the format of numerical values ...................................................................................... 339

10.9.6 Entering numerical values ...................................................................................................... 340

STX instruction for the input of numerical values ...................................................................... 342

Device numbers ......................................................................................................................... 343

Cursor position ........................................................................................................................... 345

Setting the length of the input field ............................................................................................ 347

Setting the maximum number of decimal places ....................................................................... 348

Setting the suggested value ....................................................................................................... 349

Polling the number of decimal places ........................................................................................ 350

UserInput - Polling the status ..................................................................................................... 351

UserInput - Aborting the instruction............................................................................................ 352

10.9.7 Querying the keys .................................................................................................................... 353

Assigning keys ........................................................................................................................... 354

Registers of basic flag numbers ................................................................................................. 358

10.9.8 Activating/deactivating LEDs ................................................................................................. 360

Assigning LEDs .......................................................................................................................... 361

Registers of LED register numbers ............................................................................................ 362

10.9.9 Monitor functions ..................................................................................................................... 364

Overview of displays and HMIs .................................................................................................. 365

Meaning of keys in monitor function .......................................................................................... 366

Displaying and changing variables ............................................................................................ 367

Configuring the monitor function ................................................................................................ 369

10.10 Controlling printer and serial interfaces ............................................................................... 371

10.10.1 Supported serial interfaces..................................................................................................... 372

Overview - Interfaces ................................................................................................................. 373

10.10.2 Registers ................................................................................................................................... 374

Register numbers ....................................................................................................................... 375

Registers - Overview .................................................................................................................. 376

10.10.3 Module numbers - Interface modules .................................................................................... 377

Configuring module numbers ..................................................................................................... 378

10.10.4 Outputting texts ....................................................................................................................... 379

STX instructions for outputting texts .......................................................................................... 380

Device numbers ......................................................................................................................... 382

10.10.5 Outputting numerical values .................................................................................................. 383

STX instruction for outputting numerical values ........................................................................ 384

Device numbers ......................................................................................................................... 385

Setting the length of the display field ......................................................................................... 386

Setting the sign option ............................................................................................................... 387

Setting the number of decimal places ........................................................................................ 388

Setting the format of numerical values ...................................................................................... 389

10.11 JX2 system bus ........................................................................................................................ 390

Module array and module codes of connected modules ........................................................... 391

JX2 system bus - Baud rate ....................................................................................................... 394

Dummy modules on the JX2 system bus .................................................................................. 396

Monitoring intervals on the JX2 system bus .............................................................................. 397

JX2 system bus - Description of non-volatile registers .............................................................. 399

Register description of modules connected to the JX2 system bus .......................................... 403

Jetter AG 9

Contents

Register description - Error logging on the JX2 system bus ..................................................... 405

Register description - Timeout and interval times for modules on the JX2 system bus............ 408

Register description - Retry counter for JX2 system bus modules ............................................ 411

Register description - Versions of JX2 system bus drivers ....................................................... 412

10.12 JX3 system bus ....................................................................................................................... 413

Module array and module codes of connected modules .......................................................... 414

Dummy modules on the JX3 system bus .................................................................................. 416

JX3 system bus - Description of non-volatile registers ............................................................. 417

Register description - Modules detected on the JX3 system bus ............................................. 418

Register description - Error logging on the JX3 system bus ..................................................... 419

Register description - Timeout intervals on the JX3 system bus .............................................. 421

Register description - Versions of JX3 system bus drivers ....................................................... 422

10.13 E-mail ........................................................................................................................................ 423

10.13.1 Configuring the E-mail feature ............................................................................................... 424

Structure of the configuration file ............................................................................................... 425

Section [SMTP] ......................................................................................................................... 426

Section [POP3] .......................................................................................................................... 428

Section [DEFAU LT ] ................................................................................................................... 430

Configuration file - Examples .................................................................................................... 431

10.13.2 Creating e-mails ...................................................................................................................... 432

Name of the e-mail template file ............................................................................................... 433

Structure of the e-mail template file ........................................................................................... 434

Inserting real-time controller values .......................................................................................... 436

10.13.3 Sending an e-mail .................................................................................................................... 441

10.13.4 Registers .................................................................................................................................. 442

Overview of registers ................................................................................................................. 443

Registers - Description .............................................................................................................. 444

10.14 Sorting data .............................................................................................................................. 447

10.15 Modbus/TCP ............................................................................................................................ 448

10.15.1 Modbus/TCP server ................................................................................................................. 449

Addressing ................................................................................................................................ 450

Supported commands - Class 0 ................................................................................................ 452

Supported commands - Class 1 ................................................................................................ 453

Supported commands - Class 2 ................................................................................................ 454

10.15.2 Modbus/TCP client .................................................................................................................. 455

10.15.3 Modbus/TCP client with STX variables ................................................................................. 457

10.16 User-programmable serial interface ...................................................................................... 459

10.16.1 Interface ................................................................................................................................... 460

Serial interface port X11 ............................................................................................................ 461

10.16.2 Functioning principle of the user-programmable serial interface ..................................... 464

Functioning principle ................................................................................................................. 465

10.16.3 Registers .................................................................................................................................. 468

Register numbers ...................................................................................................................... 469

Registers - Description .............................................................................................................. 470

10.16.4 Programming ........................................................................................................................... 477

Configuring the interface ........................................................................................................... 478

Sending characters ................................................................................................................... 479

Sending texts ............................................................................................................................. 480

Sending values .......................................................................................................................... 481

Receiving characters ................................................................................................................. 482

Receiving values ....................................................................................................................... 483

10.17 User-programmable IP interface ............................................................................................ 484

10.17.1 Programming ........................................................................................................................... 486

Initializing the user-programmable IP interface ......................................................................... 487

Establishing a connection .......................................................................................................... 488

Sending data ............................................................................................................................. 492

10 Jetter AG

JC-120MC Contents

Receiving data ........................................................................................................................... 494

Terminating a connection ........................................................................................................... 497

10.17.2 Registers ................................................................................................................................... 498

Register numbers ....................................................................................................................... 499

Register description ................................................................................................................... 500

10.18 CANopen® STX API ................................................................................................................. 503

STX function: CanOpenInit() ...................................................................................................... 507

STX function: CanOpenSetCommand() .................................................................................... 509

STX function: CanOpenUploadSDO() ....................................................................................... 511

STX function: CanOpenDownloadSDO() ................................................................................... 514

STX function: CanOpenAddPDORx() ........................................................................................ 517

STX function: CanOpenAddPDOTx() ........................................................................................ 522

Heartbeat monitoring ................................................................................................................. 526

CANopen® object dictionary ...................................................................................................... 530

10.19 User-programmable CAN-Prim interface ............................................................................... 534

Restrictions regarding the CAN-Prim interface .......................................................................... 535

User-programmable CAN-Prim interface - Operating principle ................................................. 539

Internal processes of the CAN-Prim interface ........................................................................... 540

Register description - CAN-Prim interface ................................................................................. 541

CAN message box - Description of registers for direct access ................................................. 546

CAN message box - Description of registers for indirect access ............................................... 552

Using the CAN-Prim interface .................................................................................................... 556

Using CAN-ID masks ................................................................................................................. 559

RTR frames via CAN-Prim interface .......................................................................................... 560

11 Automatic copying of controller data 562

11. 1 Operating principle .................................................................................................................. 564

Activating the AutoCopy feature................................................................................................. 565

Executing AutoCopy commands ................................................................................................ 566

Terminating AutoCopy mode ...................................................................................................... 568

11. 2 autocopy.ini - Structure ........................................................................................................... 569

Section [OPTIONS] .................................................................................................................... 570

Command sections .................................................................................................................... 571

Example of a command file ........................................................................................................ 579

11. 3 Log file ...................................................................................................................................... 582

File contents ............................................................................................................................... 583

11. 4 Data files ................................................................................................................................... 584

File format .................................................................................................................................. 585

12 OS update 587

12.1 Updating the operating system of the controller .................................................................. 588

OS update by means of JetSym ................................................................................................ 589

Operating system update via FTP ............................................................................................. 590

Automatic OS update from an SD card ..................................................................................... 591

Operating system update from within the application program ................................................. 592

12.2 OS update of a JX module....................................................................................................... 593

OS update by means of JetSym ................................................................................................ 594

Operating system update via FTP ............................................................................................. 595

Automatic OS update from an SD card ..................................................................................... 596

Operating system update from within the application program ................................................. 597

13 Application program 599

Application program - Default path ............................................................................................ 600

Jetter AG 11

Contents

The application program is stored to the SD card ..................................................................... 601

Loading an application program ................................................................................................ 602

14 Motion Control 603

15 Quick reference - JC-120(MC) 605

Appendix 621

A: Technical specifications ......................................................................................................... 622

JC-120MC: Technical data ........................................................................................................ 623

Physical dimensions .................................................................................................................. 625

Operating parameters - Environment and mechanics .............................................................. 626

Operating parameters: Enclosure ............................................................................................. 627

DC power supply inputs and outputs ........................................................................................ 628

Shielded data and I/O lines ....................................................................................................... 629

B: Index ......................................................................................................................................... 630

12 Jetter AG

JC-120MC Safety instructions

Introduction

Contents

1 Safety instructions

This chapter informs the user of basic safety instructions. It also warns the

user of residual dangers, if there are any. Furthermore, it contains information

on EMC.

Topic Page

Basic safety instructions ............................................................................... 14

Instructions on EMI ....................................................................................... 16

Jetter AG 13

1 Safety instructions

engineering, such as industrial electronics technician.

Introduction

Intended conditions of

Usage other than

Personnel qualification

Modifications and

Basic safety instructions

This device complies with the valid safety regulations and standards.

Jetter AG attaches great importance to the safety of the users.

Of course, the user should adhere to the following regulations:

Relevant accident prevention regulations

Accepted safety rules

EC guidelines and other country-specific regulations

Usage according to the intended conditions of use implies operation in

use

intended

accordance with this User Manual.

The controller JC-120MC is used to control machinery, such as conveyors,

production machines, and handling machines.

Operate the controller JC-120MC only within the limits and conditions set forth

in the technical specifications. The operating voltage of the controller

JC-120MC is classified as SELV (Safety Extra Low Voltage). Therefore, the

JC-120MC controller is not subject to the EU Low Voltage Directive.

The device must not be used in technical systems which to a high degree

have to be fail-safe.

The JC-120MC is no safety-related part as per Machinery Directive

2006/42/EC. This device is not qualified for safety-relevant applications and

must, therefore, NOT be used to protect persons.

If you intend to operate the device at ambient conditions not being in

conformity with the permitted operating conditions, please contact Jetter AG

beforehand.

Depending on the life cycle of the product, the persons involved must possess

different qualifications. These qualifications are required to ensure proper

handling of the device in the corresponding life cycle.

Product life cycle Minimum qualification

Transport/storage:

Mounting/installation:

Commissioning/

programming:

Operation:

Decommissioning/

disposal:

Trained and instructed personnel with knowledge in

handling electrostatic sensitive components.

Specialized personnel with training in electrical

Trained and instructed experts with profound

knowledge of, and experience with, electrical/drive

engineering, such as electronics engineer for

automation technology.

Trained, instructed and assigned personnel with

knowledge in operating electronic devices.

Specialized personnel with training in electrical

engineering, such as industrial electronics technician.

For safety reasons, no modifications and changes to the device and its

alterations to the module

functions are permitted.

Any modifications to the device not expressly authorized by Jetter AG will

14 Jetter AG

JC-120MC Safety instructions

Transport

Storing

Repair and maintenance

Replacing modules

Disposal

result in a loss of any liability claims to Jetter AG.

The original parts are specifically designed for the device. Parts and

equipment from other manufacturers have not been tested by Jetter AG

and are, therefore, not released by Jetter AG.

The installation of such parts may impair the safety and the proper functioning

of the device.

Any liability on the part of Jetter AG for any damages resulting from the use of

non-original parts and equipment is excluded.

The JC-120MC contains electrostatically sensitive components which can be

damaged if not handled properly.

To exclude damages to the JC-120MC during transport, the backplane module

must be mounted to it, and it must be shipped in its original packaging, as well

as in apt protective packaging..

Use an appropriate outer packaging to protect the JC-120MC against

impact or shock.

In case of damaged packaging inspect the device for any visible damage.

Inform your freight forwarder and Jetter AG.

When storing the device observe the environmental conditions given in the

technical specification.

The operator is not allowed to repair the device. The device does not contain

any parts that could be repaired by the operator.

If the device needs repairing, please send it to Jetter AG.

When replacing the JC-120MC, class of protection IP20 is not ensured. Do not

touch any electronic components once a module housing has been removed

from the backplane module.

If you touch the EMC clip, you may damage this clip. A damaged clip may

result in lower noise immunity.

When disposing of devices, the local environmental regulations must be

complied with.

Jetter AG 15

1 Safety instructions

Noise immunity of a

Measures

Instructions on EMI

system

The noise immunity of a system is determined by the weakest component of

the system. For this reason, correct wiring and shielding of cables is of

paramount importance.

Measures for increasing EMI in electric plants:

Attach the JC-120MC to a DIN rail to EN 60715 having got the dimensions

35 x 7.5 mm.

The DIN rail must be electrically conducting and grounded by either of the

two ways:

• Directly:

The following instructions are excerpts from Application Note 016:

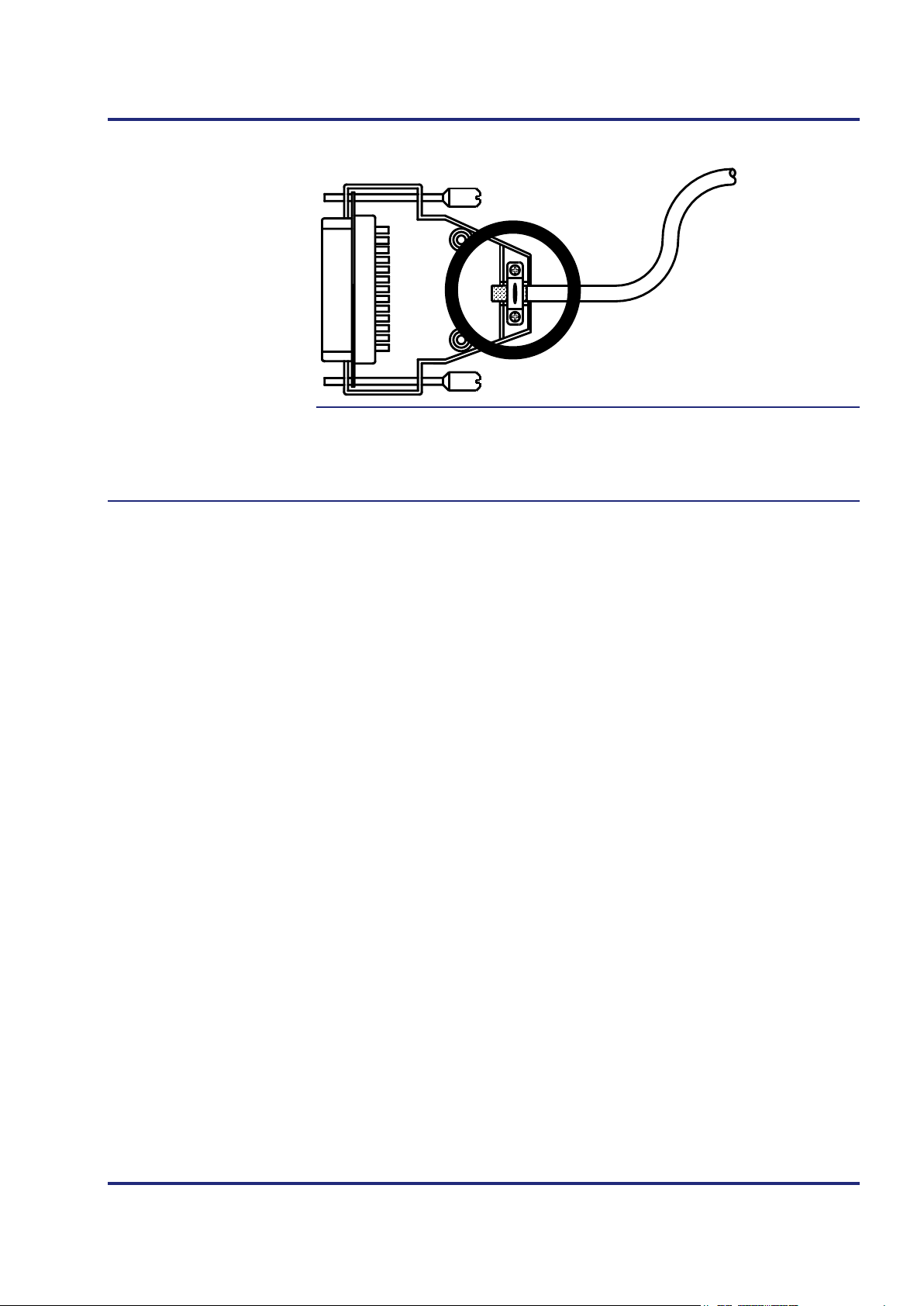

When male connectors are used:

• Via rear panel of the electric cabinet

Also refer to Application Note 016 EMC-compatible installation of electric

cabinets by Jetter AG.

Physically separate signal and power lines. Jetter AG recommend

spacing greater than 20 cm. Cables and lines should cross each other at

an angle of 90°.

The following line cables must be shielded:

Analog lines, data lines, motor cables coming from inverter drives (servo

output stage, frequency converter), lines between components and

interference suppressor filter, if the suppressor filter has not been placed at

the component directly.

Shield cables at both ends.

Unshielded wire ends of shielded cables should be as short as possible.

The entire shield, must, in its entire perimeter, be drawn behind the

isolation, and then be clamped under the earthed strain relief with the

greatest possible surface area.

Draw the shield, in its entire perimeter, under the shielding clamp of the

metallized connector housing (impedance shielding), respectively of the

EMC gland bushing, its greatest possible surface area being clamped

under a strain relief.

Only use metallized connectors, e.g. Sub-D with metallized housing. Make

sure that the strain relief is directly connected with the housing here as

well.

16 Jetter AG

JC-120MC Safety instructions

Downloading Application

Note 016

You can download Application Note 016 EMC-Compatible Installation of

Electric Cabinets from the Jetter AG homepage http://www.jetter.de. In order

to download Application Note 016, browse the following path: Downloads Application Notes.

Jetter AG 17

JC-120MC Product description and design

Introduction

Contents

2 Product description and design

This chapter covers the design of the device, as well as how the order

reference is made up including all options.

Topic Page

Product description of the JC-120MC .......................................................... 20

Parts and interfaces of the controller JC-120MC ......................................... 21

Order reference/options ................................................................................ 22

List of documentation.................................................................................... 23

Accessories for the JX3 system ................................................................... 25

Physical dimensions ..................................................................................... 26

Jetter AG 19

2 Product description and design

With 8 axes, the cycle time is 4 ms.

bus a maximum of 6 servo axes is supported)

2 Ethernet ports with integrated switch

Powerful programming language JetSym STX

60,000 (option -R: 120,000)

1 serial port (RS-232/422/485)

1 additional CAN port (CANopen®)

Up to 16 JX3 modules can directly be added.

Modbus/TCP

SD memory card

The controller JC-120MC

Product features

Scope of delivery

Product description of the JC-120MC

The JC-120MC is a high-end compact controller covering all areas of industrial

automation thanks to its high performance in combination with motion control.

Besides traditional controller functions, JC-120MC offers a motion control

feature which allows for programming axis groups and complex path controls.

The features of the JC-120MC are listed below:

4, 8 or an unlimited number of axes

(on the CAN bus: 16 axes max.)

With 4 axes, the cycle time is 2 ms.

Up to 12 servo axes with path control (on the CAN

Non-volatile registers:

Program/data memory: 24 MB

Either 1 JX2 system bus port or 1 CAN port

(CANopen®)

Real-time clock

The following items are included in the scope of delivery of the controller

JC-120MC:

Item no. Quantity Description

Depending on

options

60870409 1 2-pin connector, spring-cage technology

60870411 10 Terminal labels

60880619 1 Installation manual

60870410 1 Keying pins

1 Controller JC-120MC

20 Jetter AG

JC-120MC Product description and design

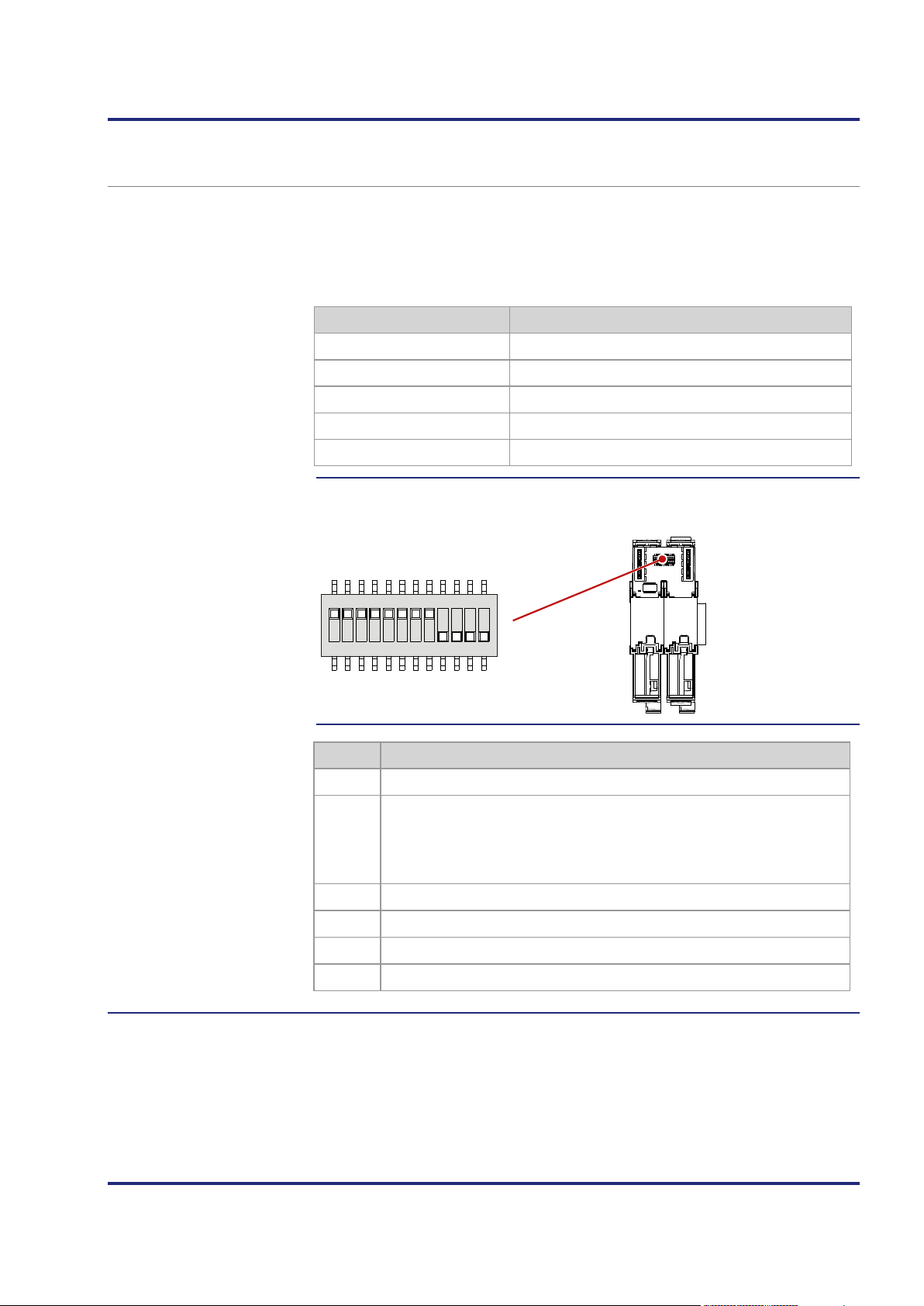

Parts and interfaces

Parts and interfaces of the controller JC-120MC

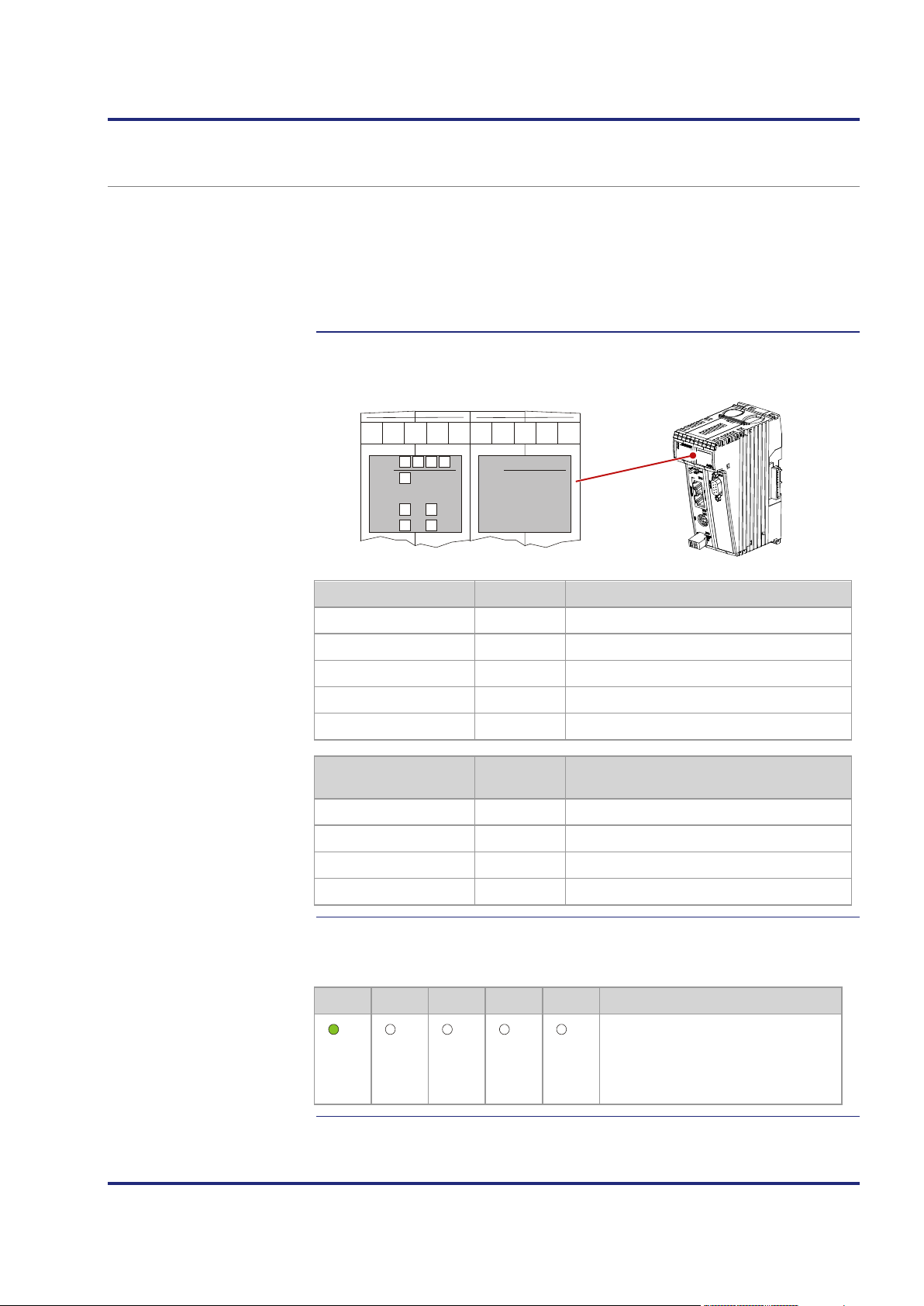

The controller JC-120MC features the following parts and interfaces:

Number Part Description

1

Upper latch Lets you remove the module enclosure from

the backplane module

2

X19 JX2 system bus interface and CANopen®

bus interface

3

4

5

6

7

Backplane module For installing the module on a DIN rail

X11 9 Connector for additional JX3 modules

Module enclosure

DIN rail latch For removing the JC-120MC from the DIN rail

Lower latch Lets you remove the module enclosure from

the backplane module

Not visible in the illustration

8

9

10

11

12

X61 SD card slot

X10 Power supply

X11 Serial interface

X14, X15 Two Ethernet ports

LED Diagnostic and status LEDs

Jetter AG 21

2 Product description and design

Order reference

Ordering additional

Integrated Web server

Modbus/TCP

Order reference/options

The order reference consists of the name of the controller and the desired

options. Each of the options given below supplements the controller

JC-120MC. The order reference only reflects existing options.

JC-120MC - A - R

Element Description

JC-120MC Controller with Motion Control feature

Specify your desired options in the order. The controller cannot be equipped

options

and e-mail feature

with additional features afterwards.

The integrated Web server and e-mail feature of the JC-120MC support the

following functions by default:

HTTP Server: This feature lets the user download the homepages into the

controller via FTP.

SMTP client: This feature lets the controller send e-mails.

The JC-120MC supports the Modbus/TCP protocol. The controller can act as

both server and client.

A Number of axes: 4, 8 or unlimited;

if option unlimited is chosen, A is not applicable, e.g. JC-120MC-R

Path control: Up to 12 servo axes

R Additional memory option: 120,000 non-volatile registers

22 Jetter AG

JC-120MC Product description and design

stp file with 3D illustrations

Product descriptions of JX2 modules, IP 67 modules, as well as

third-party modules

Introduction

Engineering

Engineering a

List of documentation

Various documents and software tools support you in engineering, installing

and programming the JC-120MC controller. You can download these

documents and software tools from the Jetter AG homepage

http://www.jetter.de.

The following documents and files support you in engineering the controller:

Industrial automation catalog

Product description

Technical specifications

Manual on the controller JC-120MC

The document at hand

CAD data of the controller JC-120MC

dxf file with 2D illustrations

JX2 station on the

JX2 system bus

The following document and the following software tool support you in

engineering a JX2 station on the JX2 system bus:

Manual on the controller JC-120MC

System bus topology

JX2 system bus specification

System bus configurator

Excel file for designing the system bus

SysBus_Configuration_xxx_e.xls (xxx: Version)

Jetter AG 23

2 Product description and design

Installing the controller on a DIN rail

Terminal assignment

Specification of terminals

Diagnostics via LEDs

Programming Tool

Engineering a

Installation

Programming

JX3 station on the

JX3 system bus

The following document and the following software tool support you in

engineering a JX3 station on the JX3 system bus:

Manual on the controller JC-120MC

Engineering a JX3 station

Product descriptions of JX3 modules

System bus configurator

Excel file for designing the JX3 system bus

JX3-SysBus_Configurator_xxx_e.xls (xxx: Version)

The following documents support you at installing the controller:

Installation manual

It is included in the boxed controller JC-120MC and contains

information on:

Manual on the controller JC-120MC

The document at hand

The following document and software tool support you at programming the

controller:

Manual on the controller JC-120MC

The document at hand

JetSym

24 Jetter AG

JC-120MC Product description and design

Labelling strips

Keying pins

Strain relief for

End clamp for DIN rail

Screwdriver

Accessories for the JX3 system

Ten labelling strips are included in the scope of delivery of the JC-120MC.

BU_10_E_BLZF_GE_RM

3.5

Order reference DIV_DEK_5/5_MC-10_NEUT_WS

Item no. 60870411

Packaging unit 100 pcs.

Order reference DIV_BL_SL_3.5_KO_OR

Item no. 60870410

Order reference DIV_BL_3.5_ZE_8

Item no. 60870963

Order reference DIV_CLIPFIX_35

Item no. 60863970

Typ e SD 0.4 x 2.5 - DIN 5264-A

Order reference DIV_SCHRAUBENDREHER_2,5*75

Item no. 60871712

Jetter AG 25

2 Product description and design

SD

U1

U3

U2

U4

J

C

-

3

6

0

Physical dimensions

Minimum clearances

Module width

Mounting orientation

Physical dimensions

At mounting the JC-120MC, keep the minimum clearance above and below

the controller. This way, there must be enough room to press the latches of the

backplane module when replacing modules.

Minimum clearance, above: 30 mm

Minimum clearance, below: 25 mm

The width of the JC-120MC is 56 mm. When the JC-120MC is attached to a

JX3 station, its width increases by 50 mm.

The orientation of the JC-120MC is vertical.

26 Jetter AG

JC-120MC Identifying

Purpose of this chapter

Prerequisites

Information for hotline

Contents

3 Identifying

requests

This chapter is for supporting you in identifying the following information with

regard to JC-120MC:

Determining the hardware revision

Retrieving Electronic Data Sheet (EDS) information. The EDS holds

numerous remanent production-relevant data.

Determining the OS version of the device and its software components

To be able to identify the JC-120MC, the following prerequisites must be

fulfilled:

The controller is connected to a PC.

The programming software JetSym 5.2.1 or higher is installed on the PC.

If you wish to contact the hotline of Jetter AG in case of a problem, please

have the following information on the JC-120MC ready:

Serial number

OS version number

Hardware revision

Topic Page

Identification by means of the nameplate ..................................................... 28

Electronic Data Sheet EDS .......................................................................... 30

Version registers ........................................................................................... 37

Jetter AG 27

3 Identifying

Introduction

Contents

3.1 Identification by means of the nameplate

The nameplate is attached to the housing of the JC-120MC and contains

details, such as hardware revision number and serial number. If you wish to

contact the hotline of Jetter AG in case of a problem, please have this

information ready.

Topic Page

Nameplate ..................................................................................................... 29

28 Jetter AG

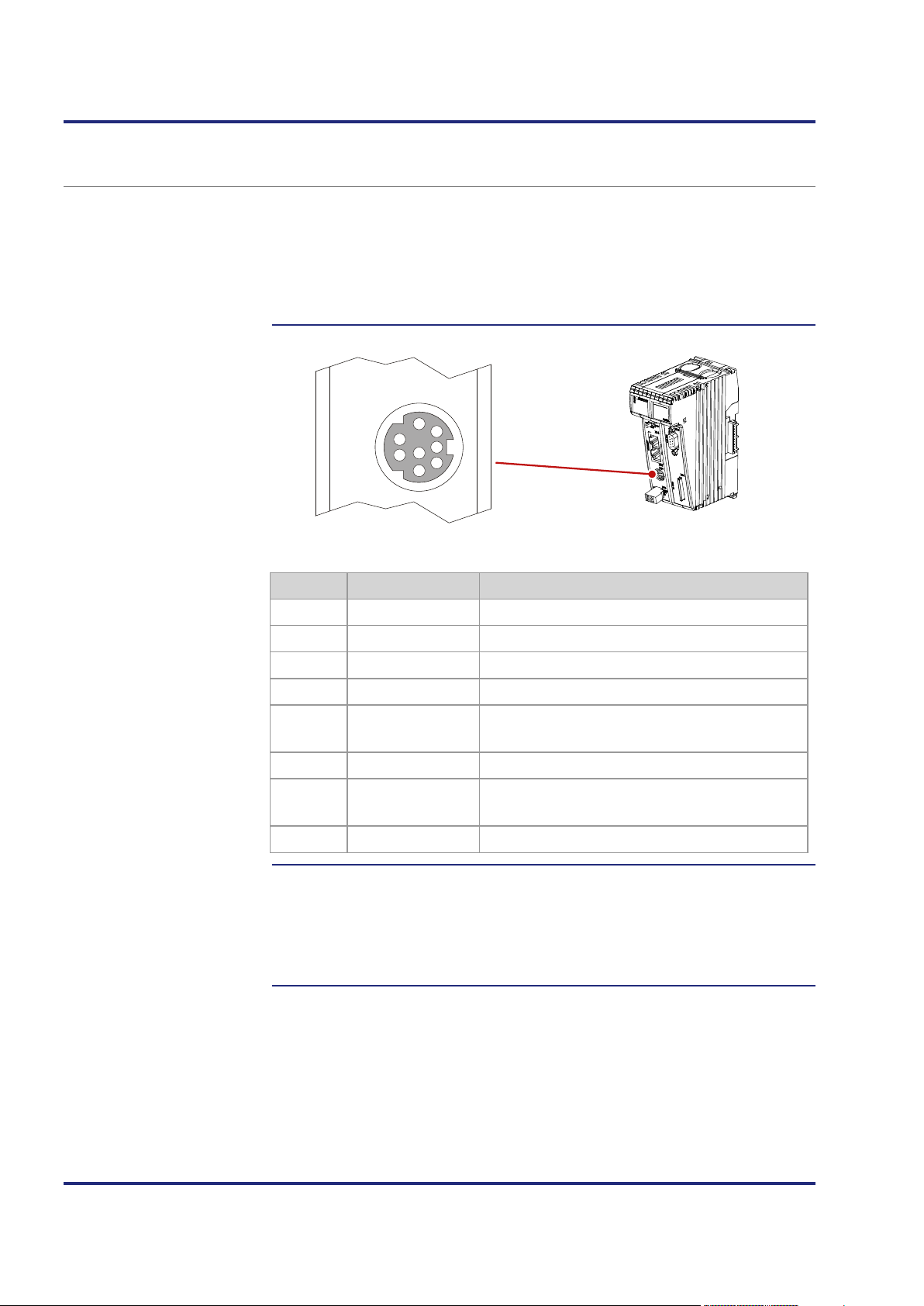

JC-120MC Identifying

S

. /

N.

:

20

08

0

13

0

06

00

3

9

JC-120x-x

Part No.:10000704

Rev.: 02.00.00

1

3

2

4

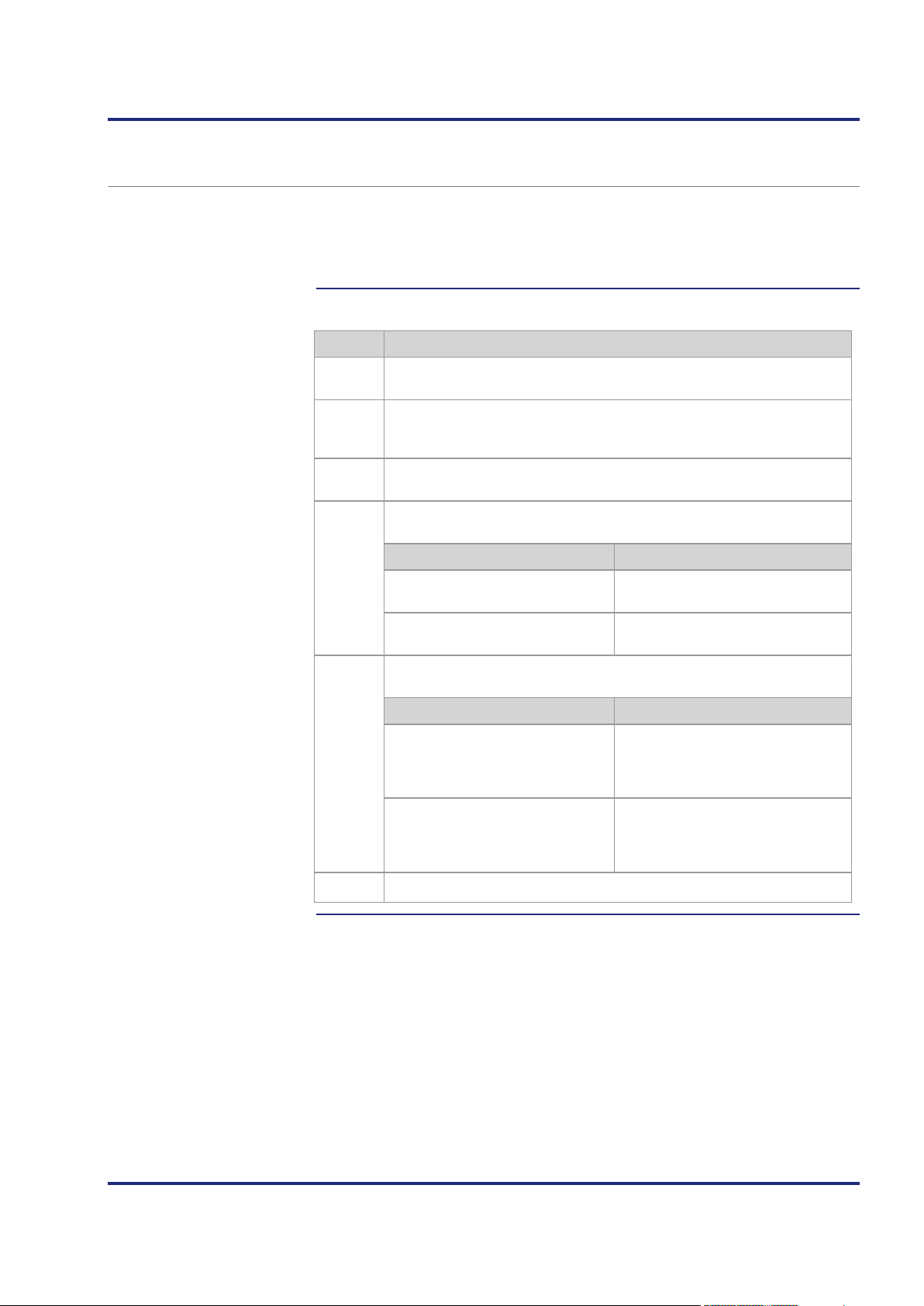

Nameplate

Nameplate

The nameplate of a JC-120MC controller contains the following information:

Number Description

1

2

3

4

Serial number

Controller name

Hardware revision

Item number

Jetter AG 29

3 Identifying

Introduction

Contents

3.2 Electronic Data Sheet EDS

Each JC-120MC features an Electronic Data Sheet (EDS). Numerous

production-relevant data are permanently stored in the EDS. The EDS data

can be read out via files in the file system of the JC-120MC or via special

registers.

Topic Page

EDS file ......................................................................................................... 31

EDS registers ................................................................................................ 35

30 Jetter AG

JC-120MC Identifying

Introduction

Properties

Path to EDS files

File structure

EDS file

EDS data can be retrieved from the file eds.ini.

You can access this file through the file system of the controller.

For an FTP connection, the user needs administrator rights (user admin) or

system rights (user system).

The EDS file of the controller is located in the folder System.

The EDS file of JX3 modules is located in the directory of the

corresponding module /System/JX3-ModuleXX.

This file is read-only.

Formatting the flash disk or SD card does not influence this file.

The illustration below shows an example of the contents of the directory

System holding the EDS files of the controller and JX3 modules:

In the directory JX3-ModuleXX of the JX3 modules, the OS of which can be

updated by transferring an OS file *.os, there is the directory OS which is not

shown in the image.

The EDS file is a text file the entries of which are grouped into several

sections.

Jetter AG 31

3 Identifying

Example

Section

[IDENTIFICATION]

This is an example of an EDS file belonging to a JetControl 120MC:

;Jetter AG Electronic Data Sheet

[IDENTIFICATION]

Version = 2

Code = 879

Name =

PcbRev = 00

PcbOpt = 00

OSVersionMin = 0.0.0.0

BLVersionMin = 0.0.0.0

[PRODUCTION]

Version = 0

SerNum = 20150120000000

Day = 2

Month = 6

Year = 2015

TestNum = -1

TestRev = 255,255,255,255

[FEATURES]

Version = 1

MAC-Addr = 00:50:CB:00:00:00

Serial = 1

Switch = 1

STX = 1

NVRegs = 60000

JX3 bus = 1

CAN = 1

SD card = 1

MotionControl = 1

Axes = -1

Web = 1

ModbusTCP = 1

SDLed = 1

UserLeds = 1

RTC = 1

The general hardware configuration can be seen from section

[IDENTIFICATION].

Name Example Function

32 Jetter AG

Version 2 Version of this section

Code 879 Module code for JC-120MC

Name JC-120MC Corresponds to the information on the

nameplate

JC-120MC Identifying

Section [PRODUCTION]

Section [FEATURES]

Name Example Function

PcbRev 00 Hardware revision

PcbOpt 00 Hardware option

OSVersionMin 0.0.0.0 The JC-120MC is available as of this OS

version

BLVersionMin 0.0.0.0 The JC-120MC is available as of this

bootloader version

The serial number and production date can be seen from section

[PRODUCTION].

Name Example Function

Version 0 Version of this section

SerNum 20150602000000 Corresponds to the information on the

nameplate

Day 02 Production date: Day

Month 06 Production date: Month

Year 2015 Production date: Year

TestNum -1 Internal usage

TestRev 255,255,255,255 Internal usage

In the section [FEATURES] special properties of the controller are specified.

The OS of the controller will ignore properties of missing entries in the file.

Name Example Function

Version 1 Version of this section

MAC Addr 00:50:CB:00:00:00 Ethernet MAC address

Serial 1 The serial interface is available

Switch 1 Mode selector RUN/STOP/LOAD is available

STX 1 Runtime environment for the application

program is available

NVRegs 60000 Number of non-volatile registers

JX3 bus 1 Bus interface for JX3 modules is available

CAN 1 Bus interface for JX2 modules is available

SD card 1 Slot for the SD memory card is available

MotionControl 1 Motion Control feature is available

Axes -1 Number of supported JX2 axis modules

Web 1 Web server and e-mail client are available

ModbusTCP 1 Modbus/TCP client and server are available

SDLed 1 The LED for the SD memory card is available

UserLeds 1 User-specific LEDs are available

Jetter AG 33

3 Identifying

Example: JX3 modules

Related topics

Name Example Function

RTC 1 A real-time clock is available

Examples of EDS files for JX3 modules: Please refer to the manual of the

corresponding module.

EDS registers (see page 35)

34 Jetter AG

JC-120MC Identifying

Introduction

Register numbers

Readable data

EDS registers

EDS registers let you retrieve entries in the Electronic Data Sheet (EDS).

The basic register number is dependent on the controller. The register number

is calculated by adding the number of the module register (MR) to the number

of the basic register.

Device Basic register number Register numbers

JC-120MC 100000 100500 ... 100817

The following table lists the EDS registers of a controller, as well as their

connection to the entries in the EDS file /System/eds.ini. By means of this

register array, you can have the EDS of the controller or of a JX3 module

displayed. For this, you must select the controller or the desired JX3 module

via module registers 500 and 501. The contents of the selected EDS are then

displayed in the following registers.

Register Section in the

EDS file

Name in the

EDS file

Description

MR 500

MR 501

MR 600

MR 601

MR 602

through

MR 612

MR 613

MR 614

MR 700

MR 701

through

MR 707

MR 708

MR 709

MR 710

MR 711

MR 712

- - Functional group:

- - Module number

IDENTIFICATION Version Version of this section

Code Module code

Name Module name or controller name

PcbRev Hardware revision

PcbOpt Hardware option

PRODUCTION Version Version of this section

SerNum Serial number

Day Production date: Day

Month Production date: Month

Year Production date: Year

TestNum Internal usage

TestRev Internal usage

0: CPU

1: JX3 modules

(if MR 500 > 0)

Jetter AG 35

3 Identifying

EDS file of JX3 modules

Related topics

Register Section in the

EDS file

MR 800

MR 801

FEATURES Version Version of this section

MAC Addr MAC address (manufacturer

Name in the

EDS file

Description

section)

MR 802

MR 803

MR 804

MR 805

MAC Addr MAC address (device section)

Serial Serial interface

Switch Mode selector RUN/STOP/LOAD

STX Runtime environment for the

application program

MR 806

MR 807

MR 808

MR 809

MR 810

MR 811

NVRegs Number of remanent registers

JX3 bus Bus interface for JX3 modules

CAN Bus interface for JX2 modules

SD card SD card slot