Jettech Metal Products FX-44 User Manual

FX

-

44

Operation Manual

Congratulations on the purchase of your new Jet-Tech warewasher.

This manual contains all the installation and operational information that

you will require. Should you or the individual installing this unit have any

questions or comments, please contact our

Customer Service Department listed below.

JET-TECH SYSTEMS CORP.

Tel.: +1 514-737-9701

Fax: +1 514-737-2792

e-mail: service@jet-tech.com

MANUFACTURERS LIMITED WARRANTY

MVP GROUP Corporation (MVP) hereby warrants all new warewashers bearing the name “JET-TECH”

and installed within the United States of America, Canada, the European Community, and the UK to be free

from defects in material and workmanship, under normal and regular usage and operation, for a period of one

(1) year for parts and labor. Labor shall be paid to replace any part found to be defective within this same period.

NOTE: Original warranty for Model F-14 is for one (1) year for parts and ninety (90) days for labor following the

date of the original installation

If a defect in material(s) or workmanship is detected; or found to exist within the stated period above, MVP, at

its sole discretion, shall either repair or replace any original equipment manufacturers part which has proven

to fail within the machine; providing that the equipment has not been altered or tampered with in any manner,

has been installed correctly as per the owners manual, and maintained and operated in complete accordance

with this manual.

The labor cost to repair or replace any part proven to be defective, as per above clause(s), shall be covered by

MVP; provided that: the service work was performed by an authorized Jet-Tech service agency; and that this

agency installed an original and genuine Jet-Tech part in the machine. Any repair work performed by a nonauthorized service depot remains the sole responsibility of the user, and MVP will not be held responsible. The

installation of any generic part will not be valid; and therefore voids this warranty. All authorized labor

coverage shall be limited to regular hourly rates only. Any supplemental hourly rates or charges, such as

weekends or emergency premiums remain the responsibility of the user.

Exceptions to above warranty are: (A) Damages resulting from shipping, handling or abuse. (B) Incorrect

installation and/or connections. (C) Adjustments or calibration of any parts. (D) Faults due to lack of regular

maintenance or cleaning of any internal part(s). (E) Replacement of any wearable items such as: peristaltic

squeeze tubing or gaskets. (F) Excessive lime, mineral, alkali or hard water conditions (in excess 1,6-3,2

mmol/l = 160-320 PPM = 9-18 odH), and (G) Poor results due to: use of an incorrect type of detergent (for

non-commercial type applications), and excessive or inadequate water temperature(s) or pressure conditions

or incorrect use.

MVP GROUP C OR PO RAT IO N STATES THAT THERE ARE NO OTHER WARRANTIES, EXPRESSED OR

IMPLIED, THAT ARE NOT SET FORTH HEREIN. MVP SHALL ASSUME NO OTHER RESPONSIBILITY,

EITHER DIRECT OR NON-DIRECT, OR BE LIABLE FOR ANY OTHER OR ADDITIONAL LOSS OR

DAMAGE WHETHER BEING DIRECT OR CONSEQUENTIAL, AS A RESULT OF ITS EQUIPMENT.

The manufacturer reserves the rights to alter design and specifications without notice.

CAP.1

INTRODUCTION ........................................................................................................... 2

CAP.2

2.1 Transport and packing ........................................................................................................ 3

2.2 Handling .............................................................................................................................. 3

CAP.3

3.1 Danger of burns: ................................................................................................................. 3

3.2 Hazardous electric current: ................................................................................................. 3

3.3 Safety devices:.................................................................................................................... 3

CAP.4

4.1 Removal from packing and positioning : ............................................................................. 4

4.2 Electrical connections : ....................................................................................................... 4

4.3 Plumbing connections: ........................................................................................................ 5

4.4 Connection to the drainage : ............................................................................................... 5

4.5 Limit switch connection: ...................................................................................................... 5

4.6 Commissioniing (filling the Booser tank)............................................................................. 5

4.7 Adjusting the controls.......................................................................................................... 6

4.8 Adjusting the amount of rinse aid........................................................................................ 7

4.9 Detergent measuring device (optional) adjustment:............................................................ 8

4.10 Commissioning the detergent and rinse aid measuring device........................................... 9

4.11 Checks and inspections: ................................................................................................... 10

4.12 Prevention measure recommendations: ........................................................................... 11

CAP.5

5.1 DISHWASHER USE : ....................................................................................................... 11

5.2 Setting up the dishwasher for use:.................................................................................... 11

5.3 Using the dischwascher: ................................................................................................... 12

5.4 Machine use precautions : ................................................................................................ 13

5.5 Operations to be performed at the end of the work cycle ................................................. 13

CAP.6

6.1 General provisions: ........................................................................................................... 13

6.2 PERIODIC MAINTENANCE (to be performed at least every 20 days) ............................. 13

6.3 DOS AND DO NOTS WITH THE DISHWASHER............................................................. 14

6.4 Self-diagnosis.................................................................................................................... 14

CAP.7

DISHWASHER HANDLING AND TRANSPORT.......................................................... 3

DANGER ZONES AND SAFETY MECHANISMS ........................................................ 3

INSTALLATION ............................................................................................................ 4

DISHWASHER USE ................................................................................................... 11

MAINTENANCE .......................................................................................................... 13

DISMANTLING ........................................................................................................... 14

1

CAP.1 INTRODUCTION

This manual provides important instructions about safe installation, use and maintenance of the dishwasher, so it is

crucial that you read it carefully.

Careful installation and accurate and constant maintenance will ensure you years of safe operation and perfect washing

results of your dishwasher.

Please consult the manufacturer for any need for service. Please keep in mind that non-compliance with the instructions

contained in this manual will cancel the warranty. We recommend you retain this manual for future reference.

We remind you that the warranty does not cover:

Damage caused by transport. If this should occur, the customer must report it to the dealer before the dishwasher in

question is installed.

Damage caused by incorrect installation. It is therefore compulsory that installation and testing be performed by

qualified and skilled personnel.

Damage caused by any use other than that for which the machine has been manufactured.

Damage caused by non-compliance with the provided instructions.

The installer must:

Check for perfect electrical connection and in particular good earthing, as well as the presence of a suitable earthleakage breaker and a circuit breaker.

Make sure that the wall-mounted circuit breaker is easily accessible and close to the machine.

Test the machine and make sure there is no malfunction.

Inform and train the personnel in charge of operating the machine about its use and the hazards it generates.

Agree with the user on a periodic check of the machine according to how much the machine is used

.

TERMINOLOGY

The terms “main switch”, “on-off valve” and “drain line” are used in this manual with the following meanings:

Main switch:

It must be a circuit breaker with thermal magnetic tripping mechanism able to completely cut off the power

supply from the dishwasher.

It must be installed outside the dishwasher but close to it.

It must supply one appliance only.

On-off valve:

Monodirectional on-off gate or ball valve able to quickly and completely turn off the water supply.

It must be installed outside the dishwasher but close to it.

It must supply one appliance only.

Drain line:

It must consist of one flux trap

It must have a suitable size for draining double the flow rate indicated in the table.

2

CAP.2 DISHWASHER HANDLING AND TRANSPORT

2.1 Transport and packing

The dishwasher must be transported using suitable means.

The appliance must be packed in a cardboard box on a wooden pallet.

2.2 Handling

The hitch points are indicated on the packing box.

The dishwasher must be handled using a lift trolley.

Do not sling the dishwasher with ropes.

Identification of the danger zones and relevant type of hazard and general description of the safety measures.

On the booster tank and the rinsing circuit during machine installation and maintenance.

On the main electrical control panel

On washing and rinsing pumps

On electric resistances

Protection of the dishwasher's hazardous parts

The panels are the protection that limits access to the internal components.

The panels are fixed with screws

Residual risks

Do not open the doors of the dishwasher during operation.

Do not introduce bare hands in the washing tank.

Do not remove the machine panels before disconnecting the power supply.

Magnetic microswitch

Device that interrupts filling, washing and rinsing operations when the hood or door is opened.

Thermal amperometric protection element

Motor pumps with incorporated automatic reset thermal switch which cuts off the motor’s electric power supply

Safety thermostat

In case the temperature control breaks, a second safety contact thermostat with manual reset comes into

CAP.3 DANGER ZONES AND SAFETY MECHANISMS

3.1

Danger of burns:

3.2

Hazardous electric current:

3.3

Safety devices:

in case of anomalous operation.

operation and interrupts the resistive elements’ operation.

3

CAP.4 INSTALLATION

4.1 Removal from packing and positioning:

Make sure that the dishwasher is in perfect condition. In case of signs of damage, report them to the seller and

haulage contractor. In case of doubt concerning the dishwasher conditions,

do not use it before having it checked by an authorised service centre.

The installation must be performed exclusively by qualified technicians, according to the manufacturer’s

instructions.

Move the dishwasher where you wish to install it and remove the packing.

This dishwasher is designed for fixed connections only.

Position the dishwasher on a flat surface.

Install electrical, hydraulic and drain lines in the washing area according to the instructions provided on the

machine's technical data sheet. Further details are indicated in the paragraphs relative to plumbing and

electrical connections.

Before connecting the dishwasher to the water and electrical supply, make sure that the general features and

data indicated by the manufacturer on the plate on the back of the manual have been complied with as far as

the arrangement of the installation site is concerned.

The floor must be measured taking the overall weight of the machine into consideration. It must also be

NOTE: to connect the dishwasher to work tops, couple the supports on the edges of the tank and fix them using the

screws provided. The connection can be either on the front or side.

perfectly flat.

4.2 Electrical connections :

“The dishwasher shall be installed in accordance with local codes, or in the absence of local codes, installed

in accordance with the applicable requirements in the National Electrical Code, NFPA 70, Canadian

Electrical Code (CEC), Part 1, CSA C22.1, and Standard for Ventilation Control and Fire Protection of

Commercial Cooking Operations, NFPA 96”

When connecting the dishwasher to the power supply, refer to the wiring diagram and the data plate of the

dishwasher.

Make sure that the voltage and frequency of the power supply correspond to those on the plate indicating the

technical characteristics located on the right side of the machine.

Install a “main switch” (not provided) on the electrical line that supplies the dishwasher in compliance with the

requirements of the local electrical standards.

All the electrical connections go to the terminal block located inside the machine, then connect to the mains

using a power cord (not provided) suitably sized for the load (see plate adjacent to the terminal block); the cord

and plug must comply with the requirements of the local electrical standards.

The appliance must also be included in an equipotential system, the connection of which is performed using a

screw marked with the following symbol: . The equipotential conductor must have a section of 10 mm².

An effective earthing system in conformity with the prevention standards in force is a guarantee for operator and

equipment safety.

In the three-phase models, check for correct rotation of the wash pump.

Note: If interventions on the electric circuit must be performed, disconnect from the mains and apply a tag on the switch

indicating the intervention in progress.

4

4.3 Plumbing connections:

To connect the dishwasher to the water network make sure that:

There is a “gate valve” that is able to interrupt the water supply when necessary or in case of repair.

A supply pipe has been envisaged for each user in order to avoid any load or pressure drops.

A pressure reducer complete with by-pass has been installed upstream, if the static pressure is greater than

345 kPa (50 psi).

Then connect the filling solenoid valve to the water supply tap using the hose provided.

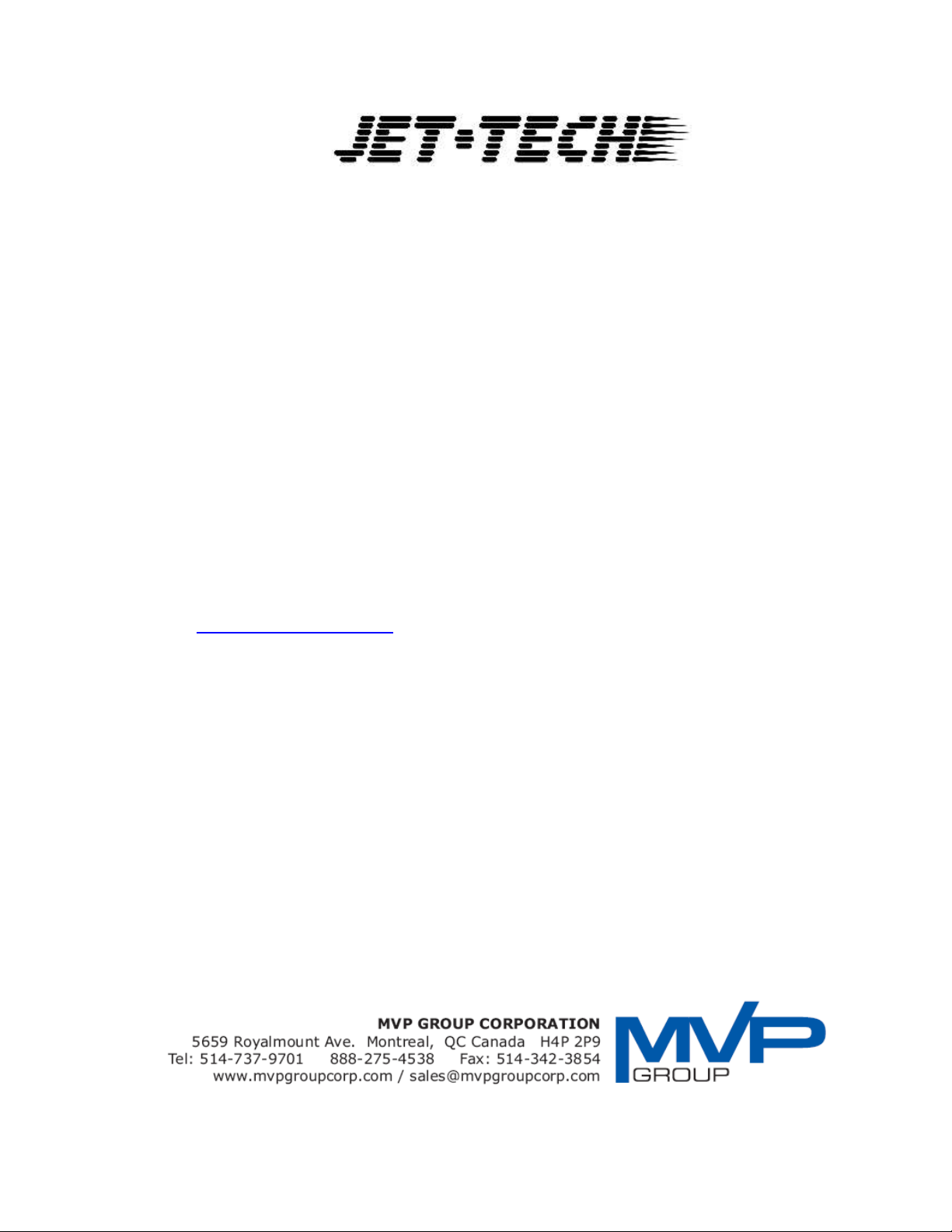

4.4 Connection to the drainage :

The tank empties by gravity, so the drain must be at a lower level than the

machine base.

Connect the machine drains to the sewer system using pipes that resist a

constant temperature of 80°C.

The drain spigot must be connected to a well or a water trap in the floor by a

flexible pipe drain.

4.5 Limit switch connection:

The table below indicates the requirements and default settings of the dishwasher:

Mount the limit switch (found on the side panel of the machine) on the outfeed

surface.

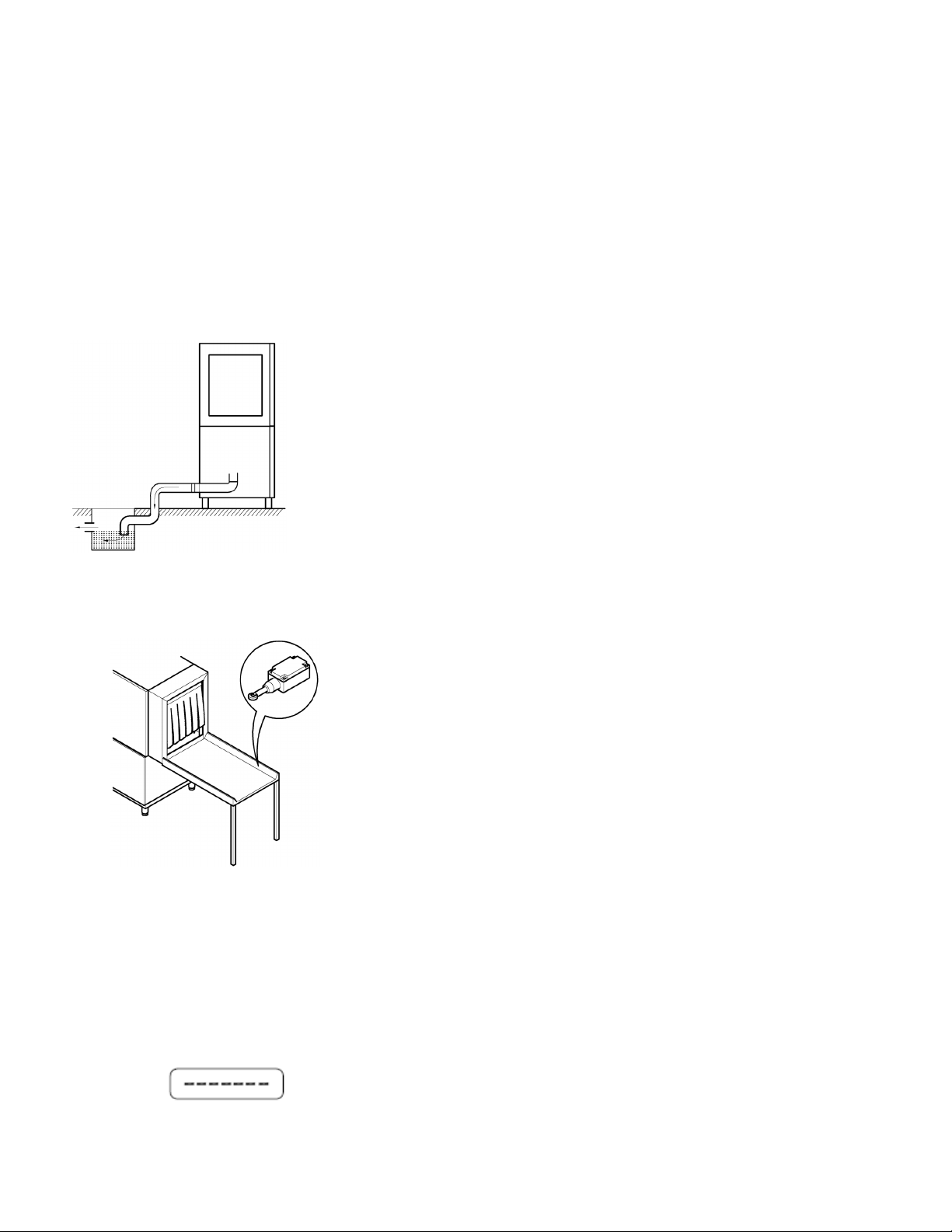

It is necessary to carry out the following Booster Tank filling operation during the installation phase.

1) Energize the machine using the wall-mounted main switch.

The machine emits a beep and displays the uploaded software version, after which some dashes as shown in the

figure appear.

4.6 Commissioniing (filling the Booster Tank):

5

minimum

rinsing temperature

190 °F

(88°C)

inten

sive washing program (speed

1) 150 racks/h

quick

washing

program (speed

2) 200 racks/h

Filling hose 26.4 mm (3/

4

")

Max. incoming

wa

ter temp

e

rature

140 °F

(60 °C)

Max. incoming

wa

ter pres

s

ure 345 k

P

a (50

psi)

Water hardness (r

ecomme

n

ded) 6 (French degrees)

Water fl

ow

rate 20 l/min.

(5.3 gpm)

2) Turn on the machine by pressing the line button and the machine will start to charge water. Wait for

the water to come out of the rinse arms.

Caution: if the tank door is not closed, the machine will not charge the water, so check the door

by looking inside the machine baskets outlet.

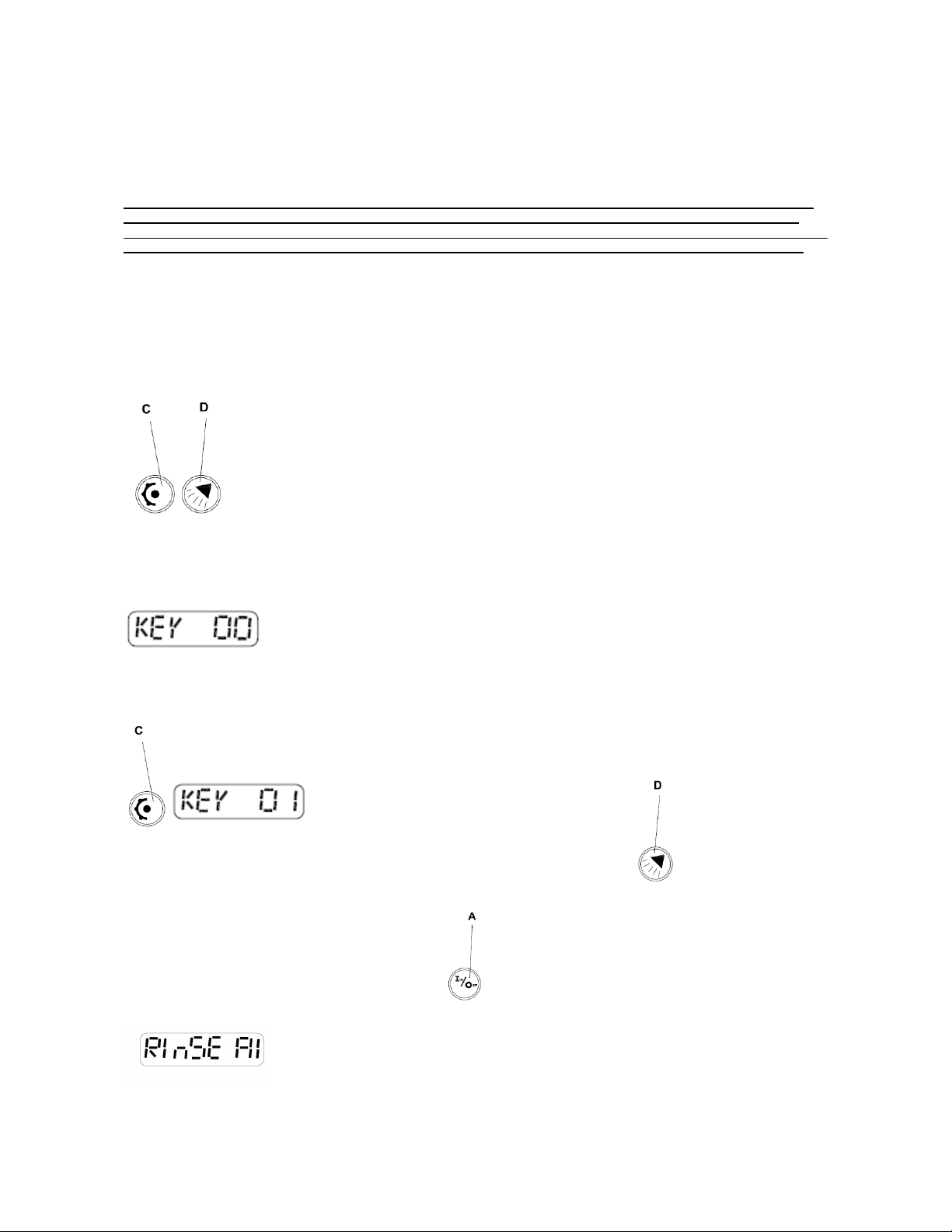

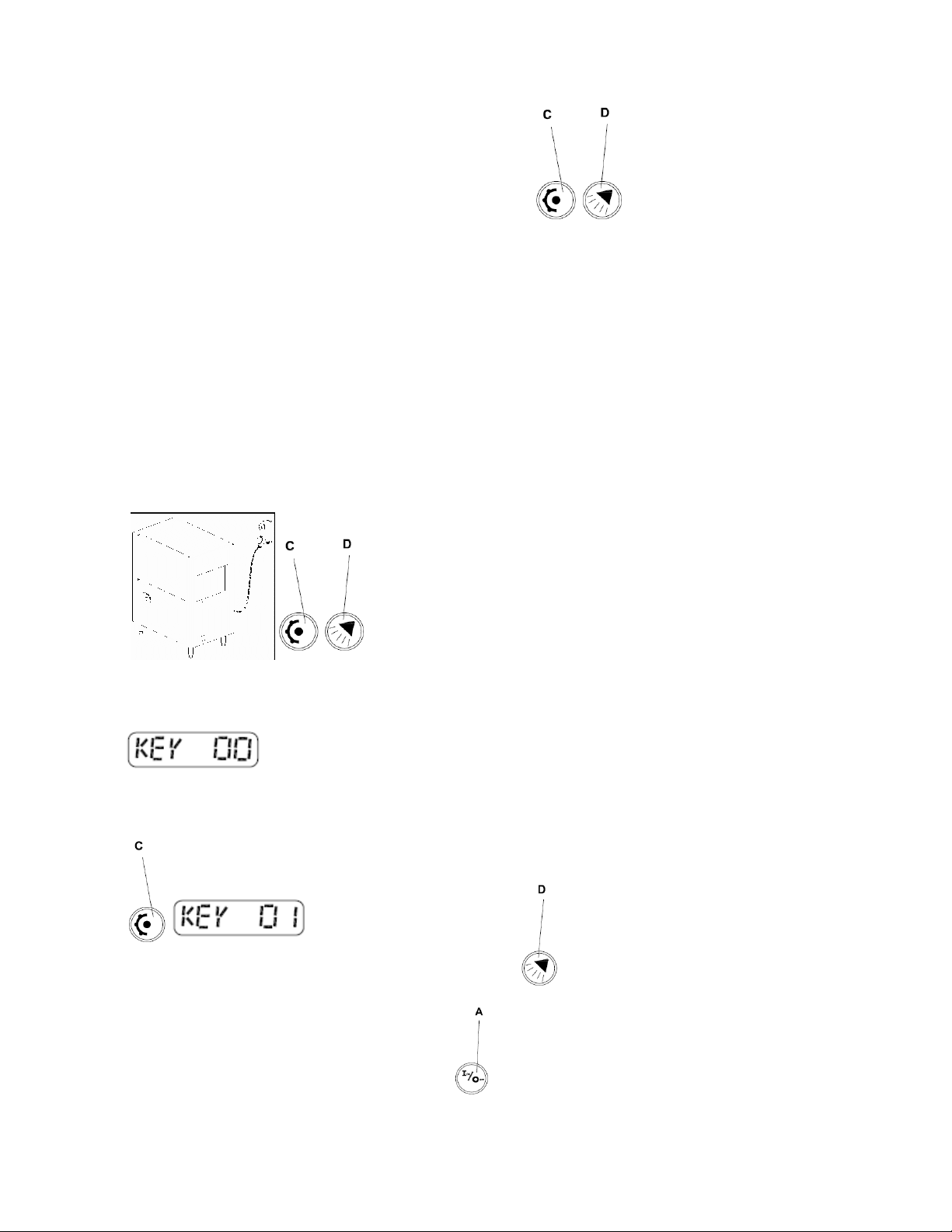

the machine, open one of the machine doors, and at the same time press buttons C and D for a few seconds

until the wording Key 00 appears.

3) Now the booster tank should be full, so start the quick heating of the booster. Turn off

4) Go to Key 01 by pressing button C and confirm with D.

5) The wording QUIK READY NO will appear afterwards. Press C to change the status to Yes.

Keep the line button pressed until you see this again: . Then re-start the machine

and the quick heating will be activated. Lastly, wait until the machine is completely filled

.

4.7 Adjusting the controls

The table below indicates the requirements and default settings of the dishwasher:

minimum washing temperature

Min. incoming water pressure

For viewing the temperatures and operating times:

By keeping the C button pressed for approximately 4 seconds, the instant temperature of the booster and of

the tank can be viewed. The number of daily hours and of the machine's working totals of the machine’s life

will also run across the display.

170 °F (75°C)

100 kPa (14.5 psi)

6

Warning for machines without measuring devices:

“This machine must be operated with an automatic detergent feeder and, if applicable, an automatic chemical sanitizer

feeder, including a visual means to verify that detergents and sanitizers are delivered or a visual or audible alarm to

signal if detergents and sanitizers are not available for delivery to the respective washing and sanitizing systems. Please

see instructions for electrical and plumbing connections located in this manual and in the feeder equipment manual.”

The quantity of rinse aid can be adjusted by determining the measuring device on/off time.

Follow these instructions:

4.8 Adjusting the amount of rinse aid

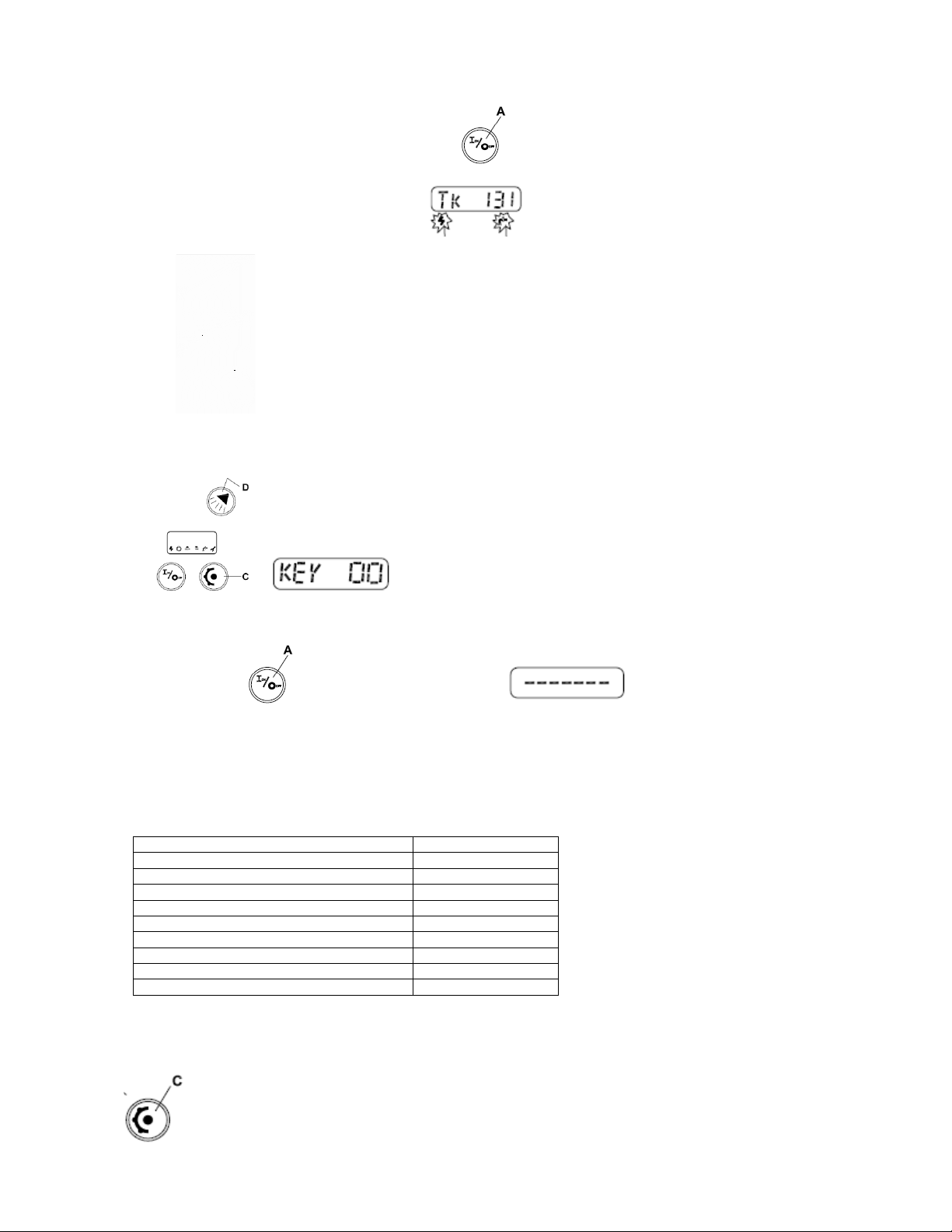

Turn off the machine, open the door and keep the C and D buttons pressed for 5 seconds.

The following will then appear:

Display the following by using the C button:

Confirm the entry to the main menu mode using the D button

Then scroll the various menu items using the A button until the following appears:

“rinse aid” with the on time expressed in seconds specified.

7

The on time can be modified by acting on the following buttons:

The measuring device operation is disabled when the value 0 is set.

The set time will be automatically saved. To exit this mode just keep the A button pressed until the machine-off dashes

are displayed.

We recommend you set the most appropriate value according to the manufacturer’s recommended dose.

Perform a few test washes to complete the adjustment stage.

4.9 Detergent measuring device (optional) adjustment:

The quantity of detergent can be adjusted by determining the measuring device on/off time.

Follow these instructions:

Turn off the machine, open the door and keep the C and D buttons pressed for 5 seconds.

The following will then appear:

Display the following by using the C button:

Confirm the entry to the main menu mode using the D button

Then scroll the various menu items using the A button until the following appears:

8

Loading...

Loading...