Page 1

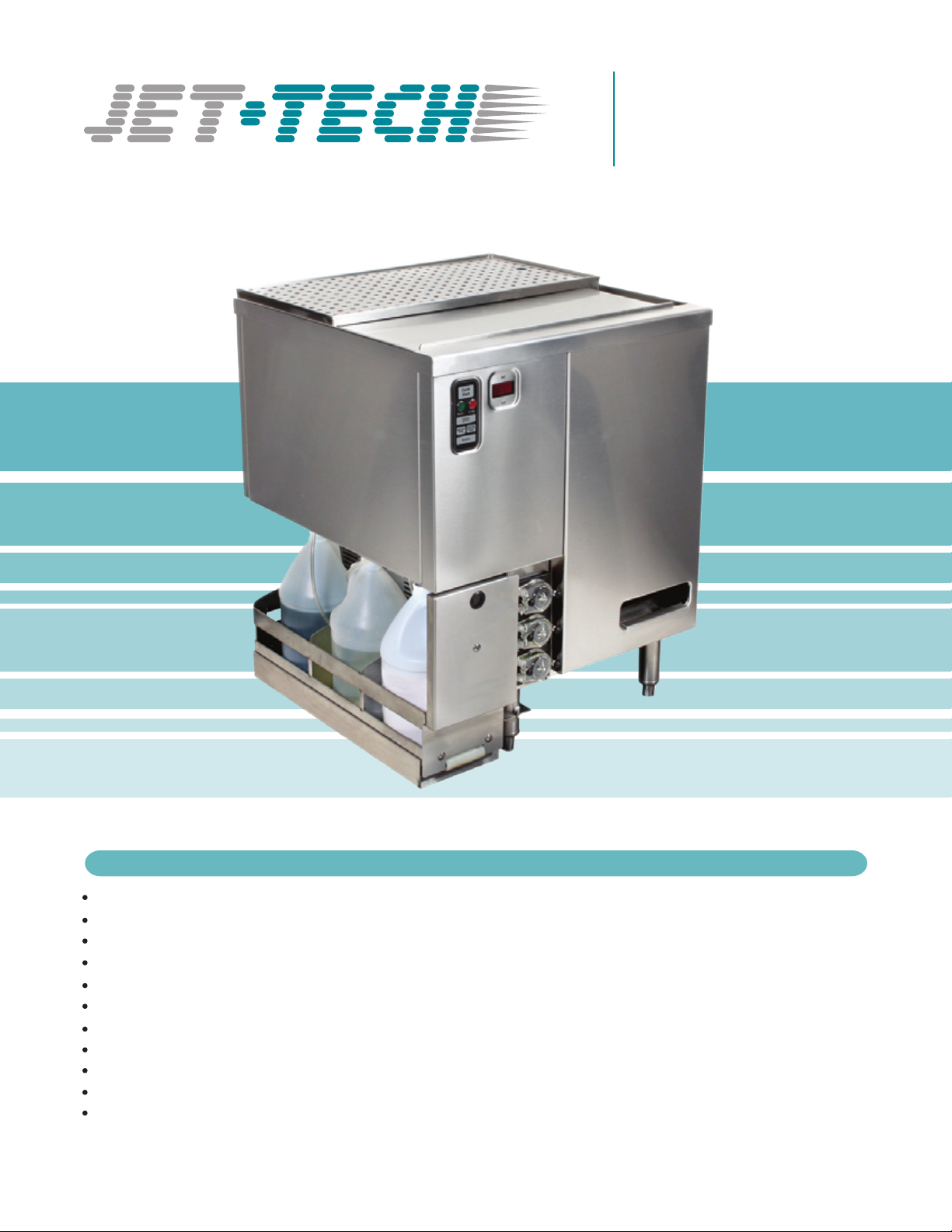

XG-37

ROTARY BAR

GLASSWASHER

Standard Features :

Fill and dump style cycle uses less water and energy than traditional rotary glasswashers.

Unit plugs into standard 120V electrical outlet for an easy installation.

Computer controlled fill cycle allows for 75°F (24°C) rinse, providing clean glasses that are cool to the touch.

The sliding cover and cold water rinse prevent steam from escaping

Unique drainboard top provides integrated glassware landing area.

Exclusive design with side notch provides space for three one-gallon chemical containers within the 24" by 24" foot print.

Conveyor advance switch rotates conveyor one-half turn for easy loading and unloading of glassware.

Covers and drainboard top are easily removable for cleaning access.

Pre-programmed de-liming cycle for easy removal of mineral deposits during maintenance (de-liming agent must be added).

Conveyor and stationary spray box are easily removed for cleaning and visual inspection.

Automatic peristaltic metering pumps accurately dispense detergent, sanitizer, and rinse aid.

during and after the cycle.

Page 2

Unique drainboard top provides integrated glassware

landing area.

Covers and drainboard top are easily removable for cleaning

access.

The sliding cover prevents water and steam from escaping during

operation and reduces operating noise. Additionally, the cold water

rinse eliminates steam billowing out at the end of the cycle.

Easy to clean membrane switch

panel includes :

LESS

59%

Fill and dump style cycle results in up

to 59% less water consumption than

common industry rotary glasswashers.

WATER

Conveyor advance switch that rotates conveyor

one half turn for easy loading and unloading

of glassware.

Priming switches for easy priming of chemical

pumps.

De-liming cycle for easy removal of mineral

deposits during maintenance (de-liming agent

must be added).

No curtain and soft-start conveyor help to ensure no glasses tip

over during operation.

Full 10” of clearance height for washing glassware and pitchers.

Can wash up to 18 glasses per minute, easily handling the output

of multiple bartenders using typical glassware. (A complete cycle

is 2 minutes, 15 seconds)

Durable water recirculating

pump has stainless steel

housing and impeller

(shown with cover removed)

LESS

87%

Fill and dump operation means no

maintenance heater and low utility bills.

Uses up to 87% less energy than

common industry rotary glasswashers.

Virtually no idle energy use.

Pumped wash and rinse ensures

water line pressure variances do not

affect wash results.

ENERGY

XG-37 is equipped with

a slide-out chemical bottle

rack for easy access

to chemical bottles.

Page 3

Specifications :

General Plumbing [Hot water and cold water required]

• Plumb with 1/2" water supply. Adapt to 3/8" FMPT

• Minimum water pressure is 25 PSI

• Maximum water pressure is 100 PSI. Install water pressure regulator if line pressure is over 100 PSI. Water valve on unit

has built-in strainer and flow control to provide consistent

volume between 25 and 100 PSI

• Install separate water shut-off valve

• Unit has built-in air gap - vacuum breaker is not required

• Consumption is 3 gallons per cycle

Hot Water Supply

• Maximum temperature is 150ºF (66ºC)

• Minimum temperature is 130ºF (54ºC)

Cold Water Supply

• No minimum temperature requirement

Drain

• 1-1/2" tailpiece.

• Use open type floor drain for maximum drainage

Electrical

• 120V, single phase, 60Hz, 6-foot grounded cord included

• Dedicated 15 amp circuit recommended

• Power requirements - 3.5 amps

Detergent*

• Extra heavy duty, non-foaming, commercial liquid dishwashing

detergent is required - .30% concentration

• Consult local chemical supplier to match detergent with local

water conditions

Sanitizer*

• Liquid chlorine bleach (sodium hypochlorite - 5.25% solution)

adjusted to 50 ppm

Rinse Aid*

• Liquid Rinse Aid adjusted for proper sheeting

Operation / Capacity

• 120°F (49ºC) minimum wash temp and rinse temp adjustable

down to 75°F (24ºC)

• 2 minute 15 second cycle

• 2-3/4" diameter bar glasses - 41 per cycle

• 2-1/2" diameter bar glasses - 49 per cycle

••Maximum glass height 10"

Materials

• 20 gauge stainless steel parts include: cabinet

• 18 gauge stainless steel parts include: floor and tanks

• 16 gauge stainless steel parts include: leg mounting brackets

and legs

• 11 gauge stainless steel parts include: drive wheel

Service Access

Front panel is removable for service

* Detergent, Sanitizer, and Rinse Aid containers are stored externally.

The side cut-out in the machine provides space for three one-gallon

chemical containers within the 24 “ x 24" foot print of the machine.

The XG-37 has a fill and dump style cycle but the comparisons to traditional fill & dump style

machines end there. In addition to the cold water rinse, this glasswasher is specifically

designed to align with underbar equipment. It also has a sliding cover for access to glassware,

which improves bartender work flow by eliminating the door extending into the aisle.

Automatic peristaltic metering

chemical pumps:

Front-mounted for easy visual

inspection.

Accurately dispense detergent,

sanitizer, and rinse aid.

Third chemical pump included for

use with rinse aid to ensure

no spotting.

Switch turns of the

machine if the cover is

slid open during the

spray portion of the cycle

to prevent over spray.

The cycle resumes if the

cover is closed within

30 seconds.

Removable front

and side panels for easy

service access.

Control board

Delays cycle start until incoming water is at least 120°F (49°C) to ensure

excellent wash results.

Allows lengthened fill time without increasing overall cycle time for installations

with less than normal water volume.

Allows 75°F (24°C) cold water rinse temperature for clean glasses that are cool

to the touch.

Permits easy chemical pump adjustments.

Slide-out circuit board tray allows for easy service access.

Optional Accessory

Export transformer 220V/50Hz electrical (price on request)

Page 4

Drain stopper is controlled by a quiet and

reliable gear motor with linkage cam

instead of a noisy solenoid valve.

Conveyor easily lifts out

for cleaning access.

Chemical fill is easily visible by

sliding the cover open during the

fill portion of the wash and rinse cycle.

Special mounting bracket allows

for easy service access to water

recirculating pump.

Incoming water line has built-in

air gap so no separate vacuum

breaker accessory is required.

Dimensions :

24"

Sliding

Door

Open

10-3/32"

14.75"

24"

PLAN VIEW

7"

Mechanicals :

NOTE: 1. In all cases, consult local plumbing, electrical and health

codes for regulations which may not be consistent with the

information on the front of this specification sheet

2. The utility connections are made from the floor at the bottom

of the unit approximately 7" to 8" high.

3. The Jet-Tech policy of constant quality improvement means

specifications are subject to change without notice.

Stationary spray box simply

unlatches for easy visual

inspection and cleaning.

30" 30.75"

6"

FRONT VIEW SIDE VIEW

24"

7"

24"

10.625"

5"

2

3

4.312"

1

1 = DRAIN

2 = HOT WATER

3 = COLD WATER

4 = ELECTRICAL

WARRANTY: 1 year parts and labor. Certain conditions apply. See Owner's Manual for details.

WARRANTY: 1 year parts and labor. Certain conditions apply. See Owner's Manual for details.

MVP GROUP CORPORATION

5659 Royalmount Ave. Montreal QC, Canada H4P 2P9

Tel: 514.737.9701 / 888.275.4538

Fax: 514.342.3854 / 877.453.8832

sales@mvpgroupcorp.com www.mvpgroupcorp.com

10.5"

7.5"

15.531"

4

9"

Loading...

Loading...