Page 1

DISHWASHER MANUAL

INS TALL ATION, OPER ATION, AND MAINTENANCE

MODEL

For operator. Do not discard.

DECEMBER

2005

Page 2

Page 3

Congratulations on the purchase of your new Jet-TechX-35C

dishwasher.

Jet-Tech dishwashers have been used dependably for many years. This manual has

been written to helpYOU, the operator,perform your job more efficiently, because your

job is one of the “most important” in this restaurant. WHY? One reason is that your

product, the dishes and glasses, are the first thing that the customer sees when he sits

down. Clean, sparkling dishes and silverware leave a favorable impression on the

customer when heobserves the table setting. Customers mean profitand profit means

jobs yes, your job,thecook,thewaiters,andthe manager you area part ofateam. The

Jet-Tech dishwasher is a tool which you can use to make your job easier and which will

helpyoudelivercleandishes.

Should you or the individual installing this unit have any questions or

comments, please don't hesitate to contact our Customer Service

Department(888-275-4538x:611).

Thank you for your support.

JET-TECH SYSTEMS

5659 ROYALMOUNT

Montreal, Quebec H4P 2P9

Tel.: 888-275-4538 (888-ASK-4-JET); 514-737-9701

Fax: 514-737-2792

e-mail: service@jet-tech.com

3

Page 4

Conten ts

INTRO PAGE PAGE 3

CONNECTING YOUR NEW X-35C PAGE 5-6

TIMER ADJUSTMENT PAGE 7-8

STARTING INSTRUCTIONS PAGE 9

OPERATING INSTRUCTIONS PAGE 10-11

CLEANING PAGE 12-13

TROUBLESHOOTING PAGE 14-15

CONTACT INFORMATION PAGE 15

PARTS LIST PAGE 16-17

4

Page 5

CONNECTING YOUR NEW X-35C

This dishwasher must be installed on a level, rigid, nonflammable surface.

To ensure that the machine is level, install the feet (shipped in the wash

tank of the machine) and adjust them accordingly. Be sure to provide

adequate space for the water, drain and electrical connections.

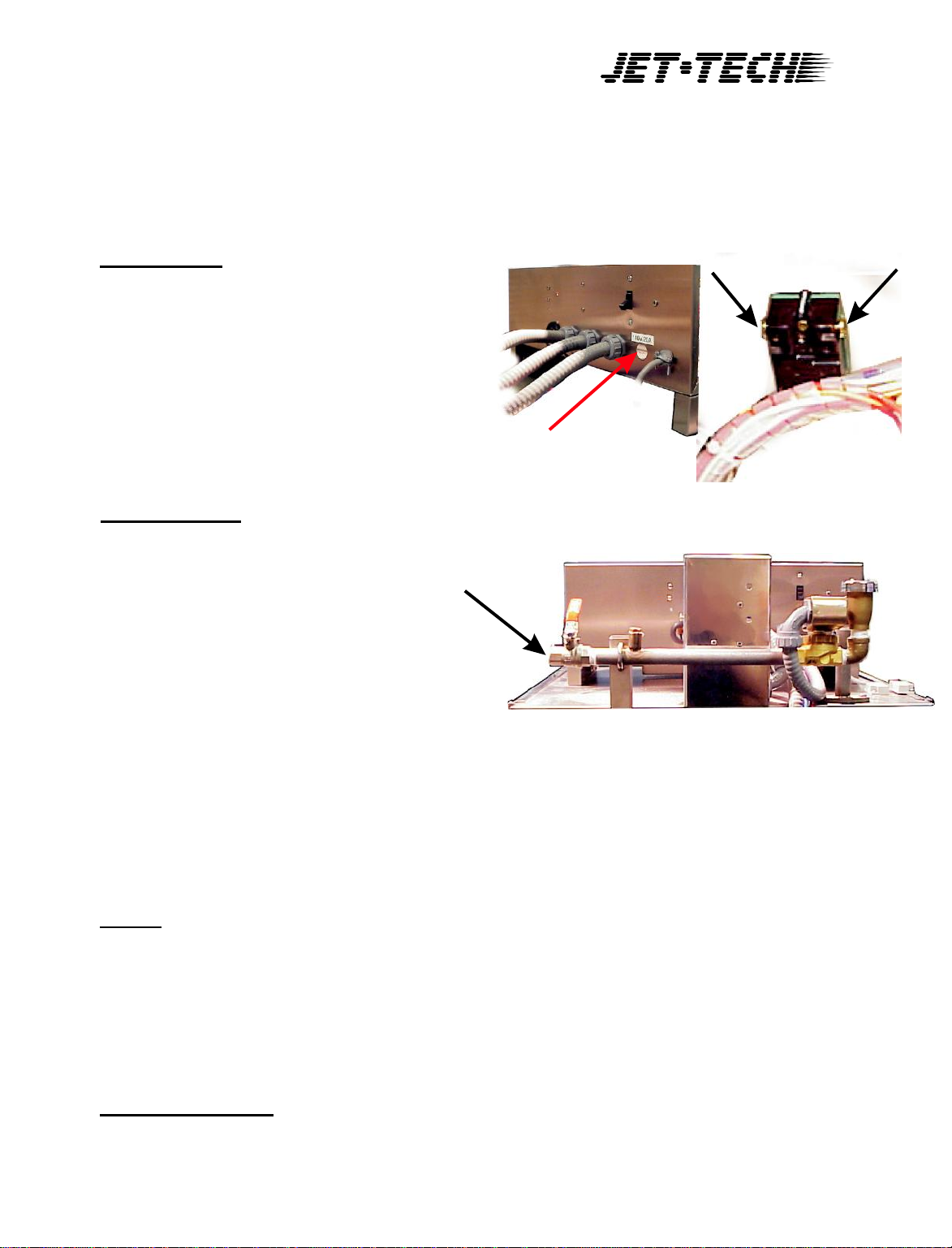

ELECTRICAL

A 115 volt, 60 Hz, Single Phase circuit is

required for this unit. This unit will draw

13 amperes on a 115 volt circuit.

The top cover must be removed for the

electrical hook-up.

The electrical connection will be made

directly on the power switch. Replace the

top cover once the connection is completed.

WATER SUPPLY

The water connection can be made

directly on the shut-off valve on top

of the unit. It will require a 1/2 NPT

male fitting. The flowing water

pressure cannot be less than 18 psi

or exceed 35 psi. If the water

pressure exceeds the prescribed

amount, you will get premature

failure and thus may void the

warranty. The timer will need to adjusted to compensate for the water

pressure. Incoming water temperature must be 140º F +/- 5º( 60º C).

Make sure that the water is free from calcium and hard water deposits. For

these situations, a water softener system is highly recommended. Build-up

of calcium and lime deposits in the washer may occur and servicing will be

required on a more frequent basis which will not be covered by the

warranty.

120

volts

DRAIN

This dishwasher has a gravity drain. A 2" OD connection should be made

under the dishwasher. Please consult your local codes for this type of

installation. It is important not to reduce the size of the pipe.

IMPORTANT NOTE

Reasonable access to and around the machine for service must be provided.

5

Page 6

Disconnecting of hard plumbing or removal of counter tops or cabinets, etc.,

for servicing is not covered by warranty.

CHEMICAL INSTALLATION

All the chemical pumps, located on the control box at the top, are activated by a

timer. Priming switch above will help draw the product in each corresponding

lines. The BLEU tubing is for the rinse-aid, or drying agent. The RED tubing is for

the detergent, and the CLEAR tubing is for the sanitizing solution.

Detergent:

High sequestrant alkaline solution

200 ppm

Sanitizer:

Chlorine solution (min. 120F, 49C) min: 50 ppm

(as NaOCl)

Iodine Solution (min. 75F, 24C) min: 12.5 ppmmax: 25 ppm

Quaternary ammonium solution (min. 75F,

24C)min: 150 ppm - max:400 ppm

Rinse-Aid:

Low foam rinse-aid, surfactant isopropanol

50 ppm

See local health code for appropriate quantities and usage.

Contact your chemical representatives for calibration and supply.

WARNING

Whenever manipulating chemicals, use appropriate protection (eyes and

hands) as these chemicals are corrosive.

Dertegent

RedTube

Sanitizer

Clear tube

P

riming

Switches

Rinse-Aid

BlueTube

6

Page 7

ADJUSTING THE TIMER

The timer is the brain of the dishwasher. It controls all the major components,

allowing them to perform their

necessary function at given times

during the length of the wash cycle.

The timer is located at the top, in the

control box, on the right. To get access

to the timer, you will need to unscrew

to top cover, and remove it. Make sure

the power is off at the breaker before

removing the top cover.

The timer is installed on a hinged

plate, allowing it to be move up for

better access. A small red, curved key

can be found attached to the timer.

Insert the key as shown in the picture,

and engage the tooth in the groove of

the wheel. Hold it down and turn the

dial in the direction of the arrow. It is

very important to turn the dial in the

direction of the arrow. If you try to turn

it the other way, you will feel some

resistence, and if you force it will break the internal

mechanism.

The numbers on the dial are degrees (0-360). Using the

plastic arrow on the dial, advance the wheel to the

desired place.

KEY

7

Page 8

Factory setting.

DRAIN 180-200

FILL 190-250

DET 10-20

SANI 220-222

RINSE 220-222

KEY

REFERENCE TABLE

Degrees = Seconds

0 = 0

45 = 11

90 = 22

135 = 34

180 = 45

225 = 56

270 = 67

315 = 79

360 = 90

PLASTIC

ARRO

W

DIA

WHEELS

L

8

Page 9

DISHWASHER OPERATION

STARTING INSTRUCTIONS

1) Start-upofthe Jet-TechDishwasher

a) Lift doors about two inches from the bottom.

b) Turn power ON. The switch is located at the back of the control panel.

c) Drain water if it is cold by pushing the drain button on the control panel until all

the water is out of the machine.

d) Open doors fully to inspect interior.

e) Check and clean the drain screen

f) Replace it properly into the sump housing

g) Check wash arm spray tips. If they're clogged, clean with a toothpick and

rinse at the sink

h) Check that chemical lines run to chemical containers:

i) Red detergent line

ii) Blue rinse additive line

iii) Clear/white sanitizer line

i) Replace wash arms..

j) Close doors to about two inches from the bottom.

k) Press the fill switch, and fill for about 20 seconds.

l) Check the water temperature (it should be approximately 140 degrees F or 60

degrees C).

m) Open doors fully, and insert the tray of dishes into the machine and close the

doors.

i) Start the machine by closing the door completely.

After the machine stops, the cycle light will switch off, raise the doors, remove the

tray, and allow dishes to dry before stacking.

The Jet-Tech Dish machine will complete the wash and rinse cycle and automatically

feedtheproper amountofchemicals,andturnitself off.

PRIMING

SWIT

CHES

CYCLE

LIGHT

WASH COUNTER

CHEMICAL PUMPS

THERMOMETER

FILL/DRAIN

DIAL

SWIT

CH

9

Page 10

OPERA

TING INSTRUCTIONS

Dishes are

cost over $5.00.

preparing

A

.

necessaryto

hand, the

the

dishwashing operation.The

scrappingistokeep

going

scrappingisdonebyhandorwitharubber

spatula.The

scrappingofdishes

machineisideal for

soil

not

operatio n.It

time

will

operationifthe

used,

this

method

is

not available

be

provided

hand

expensive. An average

Be

verycareful

and

handling dishes

Scrappin g.Scrapping operations are

remove,mechanically or by

remaining

into

the

dishwashing

use of a

removedbythe hand

also

be

requiredinthe

plusabetter job

. W

ater scrappingisa must,

, a

for youtodoathorough job

scrapping

food

from

excessive garbage from

machine. Hand

pre-rinse

before

removing

saves

water scrapping

rubber spatula or

the

dishes

labor

can

they

full

be

.

plate

when

.

dishes

purpose of

hose

go

small particles

scrapping

because

scrapping

method

assured

can

prior

for

wet

into

the

less

is

using

butifit

glove can

to

of

of

B

. R

dishesinthe

most

Everysur

by

scrubbing actioninthe time

being sprayed by

dishes

will

will

BeaPRO doitright

acking Dishes.P

rack

important jobs

face

of a

the machine

won't

not

require

be

cleaned

save

sorting

before

the

soiled dish

sprays

detergent

you

time.

during

and

washingasecond

the

roperly

washingisone

operator

to provide

the wash cycle and

first

10

placing

must

must

be

sufficient

that

the

solution.P

Many

time.

of the

Be

the

of the

per

form.

reached

dish

is

iling

dishes

time.

sure

to

Page 11

rack

all

the

sized plates.If

properly,itwill

Noteinthe

are

rackedwith

sprays

food

face

and

faced

waster

the

inaproperly

rack.Allowtoairdry.Glass washingisver

importan t.A

impressio n

ser

placedinthe

compartment.

into

speed

chemical

the

from the top

contact

of the

R

acking

other

downsoas

andsothat

internal sur

ved

his

the

rinse

the

proper glass

be

easier

illustration

overlapping

spray

sur

faces

dishes).

Glasses. Glasses, cups, bowls

deep

glassofwater.They should

drying

representative

dishes

nottocarryout

the

faces

. R

sized

compartmentalized

customer may

of an

establishment

racks

water

upside downineach

The

rinse

to prevent

process. (Note:Y

rack

you

sort

and

and

save

you

that

the

and

that

arm

will

strikethe

of the

must

sprays

ack glasses

for

dishes (the

be

rack

wash

can

work

and cups

gain

his

when he

additiveisinjected

spotting

can

help you

your

glasses

rack

time.

plates

the

ed

on

glass

first

be

and

our

select

.)

y

is

R

acking Flatware.Flatware

may

be

washedinmany

recommended

soakedinadeep

usingapre-soak

adheringofsoilonflatware

tarnishin g.A

useful for

egg,syrup.Itisrecommended

minutes

possible.After pre-soaking

placedina wash

to prevent them from“nesting”which

provides maximum exposure to the wash

process.

the removal of

be

that

pan,

detergent.

pre-soak

allotted for pre-soaking,if

basketwith

ways.It

all

flatware

generally

and reduce

detergentisespecially

protein

, the

is

be

pre-

a bus pan,

This

will

prevent

oil

such as

that

30

flatware

handles down

11

is

Page 12

C

.

Stacking

storage of

sanitizedisveryimportan t.A

per

fectly

contaminated from the

A

void

Minimize handling

food

procedure).

than12inches;

destroy

plates

washed

storing

contact

the

.

and Storage.

dishes that are being

but at

dishes

sur

faces

Do

not stack plates

their

porcelain

riskofbeing

handling after washing

where

the

combined

dishes

(towel

sur

face

they

The

stacking

washed and

dish

may

be

may

be

soiled

with

the hand on the

dryingisan

and

dishes higher

weight

on the bottom

can

and

.

.

incorrect

D.

times of the

dishwashing

inspection

the

material

on the

pre-rinse

drain

materialispresent

determine

upper and

not

uniform spray pressures

soiled dishes

nozzles

removed

loosen

arm can

water

flowing

toothpick or small

Cleaning

drain

clogged

screen and

from the screen.

tabletojar

hose

stopper sets to

Cleaning

If

thereisany question

being clearoffood

and cleaned.To remove

nut

be

into

the hug and obser

. Clogged

the Jet-T

day should

machine.Follow

procedures

Cleaning

. Check the seat

. R

thatitis

the Wash Arms

lower spray

with

food

.

and

pull

checkedfor

food

makesurenoforeign

e-install drain

the

arm

jets

wire

ech

Dishwashe r.Certain

be

reser

ved

the

cleaning

listed

thoroughly

proper position

can

and the

below.

the

Drain

Do

not

loose.

arms to

scraps.

will

outofspray

Use

casting

insure

Otherwise,full

not

be

as to the

scraps,

lockedjets

ving that

be

cleared

entire

Screen R

clean

bang the screen

the faucet

screen and

- Inspect

delivered

to clean the

and

emove

all

foreign

where the

.

the

that they are

to the

spray

they should

the arm,

base.The

by

all

with

arm can

arm

running

jets

a

or

and

be

are

be

12

Page 13

flushed out by

R

emember

cleaning

After

cleaned,

insertedinthe

thumb screws.Too-

in

spray

E

. Empty the ScrapTray. R

scrap

Change the

an

F

. Check

machine and watch detergent

rinse

into

insure

the cycle. R

blue

sanitizer

cycle

base

tray

hour,if

additive deliverytubes where

the

open

that

tube

. Check temperatureatthe end of the

for

removing the end

to replace the end

the arm.

the arm has

re-install

drawer

tray

it's

the chemicals

emember:

rinse

140 degreesF(60

and check

bearing support

.

and

after

verybusy.

Operatio n

sump on the machine. Watch to

additive;and

been

tight

screws can

thoroughly

each

mealorelse

. Operate the

are delivered

red

degrees C).

tube detergent;

plugs

.

plugs after

thoroughly

that

arm

. Hand

emove

sanitizer

clear/white

break

rinse

they

tighten

the

out

is fully

off

.

once

, and

extend

during

tube

G

. Cleanup.

check the chemical

Also inspect

items

period

H. R

should

during his regular call.Do

the

that

night

. You

emember:

be saved

trash bin

Wipe

down the machine and

levelinthe

the machine

cause

are

now

for pickup by

.

trouble

ready

The

chemical

IMPORTANT

Always

chlorineinthe water

tank

drain

the dishwasher at

after awhile

will

.

13

container s

for

leaks

duringarush

to wash

containers

the

not throw

night

damage

or other

dishes

ser

viceman

them

. The

the

.

.

in

wash

Page 14

TROUBLE SHOOTING THE JET-TECH DISHWASHER

A

. W

B

. Out of Chemicals

C

. Dishes/Glasses

on't

Start

1. Check the master

2. Check

3.

Only

1. Check

blue

Note

restaurant

1. Before

machine. Check to

dishwasher

F.If

temperatureisokay

2. Check

from Jet-T

final

wash arm

circuit

after checking

back

-up

product

that

check before

labeltoblue

sometime

manager.

you

call

must

your

water

ech

calls

tips.If

breaker which ser

are

have

for

you

they are clear,callus, the Jet-T

switch

supply

extra

Not Clean

the Jet-T

be

softener

hot/soft

on the

steps 1 and 2,

of chemicals.

tube, and

productisleftinthe storage areaatthe

ech

ser

sure that you

hot water delivered

, then

call

proceed

for

saltorobvious

water,If

the Jet-T

backofcontrol

vices the

clear/white

vice people,

ech

dishwashe r.Makesureitis

call

the Jet-T

REMEMBER:Redproduct

have

at least

from the

to step 2.

the

water

ser

vice people. 3. Check the screen and

panel to

ech

product

clear

120 degreesFwater.The

primaryheaterat120 140 degrees

malfunctio n

softener appearsokay,

ech

ser

makesure thatitis

“on”.

ser

vice people.

labeltored

labeltoclear/white

direction

your

temperature gauge on the

. Y

our ser

vice people.

vice agreement

of the

thereisone

“on”.

tube,

tube.

Jet-T

ech

D. Machine W

1. Check

E

. W

1.

If itisrunning

call

us!

F

. W

1. Check the

ser

vice people.

G

. W

1.

Someone

Check

it

willbeinside

the Jet-T

under

ater Running

Call your

ater

won't

ater

Coming Out of the Door

inside

ech

people.

on't

Hold W

the

on the

from the scrap accumulator

plumber the

Drain

drain

Lift

didn't

the scrap accumulator

the scrap

ater

drain ball

from the Machine

sump

the

drain ball

replace the end

tray

foraknife

Floor

drainisclogged.

for

obvious

manuall y

next

to the machine.

(going

, spoon,

clogging.If it

, the

all

plugs

on the wash armordidn't tight

drawer.If

fork,or foreign materia l

(The

trayatbase

appears

water should

over)

the end

plug

Simply

replaceit.

of the

clear,call

drainin6

came

off

, then

dishwasher) don't

the Jet-T

seconds

during

If itislost,call

remove

ech

or less

en them. 2.

operation

us

.

.

,

14

Page 15

H. Machine W

1. You can

locatedatthe

I

. Machine W

on't Shut

turn

off the machineinan emergencybyturning

back

on'tFill

1. Check valveatthe top,

ser

vice people.

J

.

Spray

Arms W

1. Check the

bags,orfiber

on't Spin

bearings for obstruction s.They are

from

Off

of the

napkins

control

box.

makesure

or straw

handleisturned

wrappers.

off the master

on.

If itis,

easily

cloggedbygrit,string

switch

callusthe Jet-T

from tea

ech

K.

Dishes

1.

Makesure water

2. Determine

rinse

.

3.

Makesure thatnoother

Are Coming Out Soapy

that

temperatureisabove

120 degreesF;

machineisdraining properlysothat

source of detergentisfinding

no soapy

IMPORTANT NOTES

L

ocate

and

clearly identify

fuse box

Only qualified and/or licensed technicians can repair this piece of equipment.

panels

removed

or breaker

will

expose

before removing the panels. The water

wires

switches.

and

the water

live curren t

shut

. The

-off valve

breaker

that supplies

switch shouldbeswitched offorfuses

supply

must alsobeturned off.

the dishwasher and the

CONTACT INFORMATION

MODEL

Phone:

1-888-275-4538

514-737-9701

Fax:

514-737-2792

SERIAL

DATE INSTALLED

SERVICE

hot water disperses

water carries

its'

way

into

the

rinsecycle.

Removing

:

X-35C

:________________

:___/___/___

:

suds.

into

the

15

CHEMICALS

:

Page 16

Part# Description PRICE

07-2703 door guide

07-9004 thermometer w/capillary

19-5043 1/2" vacuum breaker

44-0110 peristaltic pump cover

44-0141 clear squeeze tube (10" ea.req'd)

44-0150 pump shaft seal

44-0220 FEET red detergent line

44-0230 FEET blue rinse line

44-0240 FEET #3 clear vinyl line

44-0256 thumbscrew

44-0258 thumbscrew adaptor

44-0264 spray arm bearing

44-0266 23" spray arm

44-0290 mounting cast iron - PUMP

44-0300 pump cover sm cast iron

44-0310 impeller open l cast iron

44-0330 3x17"bucket probe (pvc 1/4")per ft

44-0350 12"X1 1/2" clear sump hose

44-0360 O-ring for pump

44-0370 3/16 barb fitting

44-0400 1 h.p. motor

44-0441 rocker switch

44-0461 3/8" Cycle light-estimate

44-0470 insta start relay

44-0480 insta start socket

44-0491 90 second timer

44-0500 mercury relay

44-0510 drain solenoid

44-0520 peristaltic pump 48 rpm motor

44-0560 110 ac counter

44-0570 hose clamp

44-0571 1/2" PVC 90º CONNECTOR

44-0572 1/2" PVC STR. CONNECTOR

44-0573 FEET 1/2" nonmetallic conduit

44-0581 door switch magnet

44-0590 cube relay timer

44-0620 3/8" brass plugs

44-0630 30 amp switch

44-0640 bulkhead fitting

44-1110 1/2" close nipple brass

44-1130 1/2" street 90 deg brass

44-1180 1/2" water solenoid

44-1220 1-1/4" male adapter

44-1660 momentary toggle switch

16

Page 17

44-1670 rubber boot

44-1720 fill/drain label

44-1820 ball valve 1/2" FIP

44-1830 1/2" brass 90º elbow

44-1880 teflon tape

44-1891 3/8" romex connector

44-1900 4" cable ties

44-2020 TR-1 open rack (12.41 cdn)

44-2030 TR-3 plate rack (12.41 cdn)

44-4020 Panduit DNF14-187-M terminal

44-6010 bolts- pump cover to mounting

44-6010 bolts- mounting to motor

44-6030 screw- s/s pump cover

17

Page 18

Rm0508

Loading...

Loading...