Page 1

LOW TEMP WAREWASHERS

Challenger

OCT 2004

Page 2

Installation

!Having uncrated your machine, check carefully for damage and if any is detected, notify

your carrier and make a claim immediately.

!Remove all tape that has been used to secure parts in place during transit.

!Place Glasswasher in position and level, using the four adjustment screws on legs. Be

sure all adjusting screws are contacting the floor.

!Have your plumber install a cold water line to the fitting marked "SUPPLY' on your Main

Plumbing Group diagram.

!Next the plumber should install a 1 1/2 inch drain line from the Tee marked "DRAIN" on

your Main Plumbing Group diagram to a floor sink or other open drain.

!Your machine comes equipped with a power supply cord complete with the female

receptacle which your electrician can mount in a junction box close enough to the

machine to allow the power cord to reach. Have your electrician run a three wire with

mechanical ground supply line to the above- mentioned junction box and wire this to the

appropriate terminals on the female receptacles. Maximum capacity of the circuit is 20

amps. so an independent circuit and circuit breaker is desirable. Power is 110/208-220 volts

AC.

!Your machine is now ready for operation and at this point it is advisable to have a qualified

service representative attend to assist in start up and training of your personnel.

JET-TECH SYSTEMS

5771 Ferrier street

Montreal, Quebec H4P 1N3

Tel.: 888-275-4538 (888-ASK-4-JET); 514-737-9701

Fax: 514-737-2792

e-mail: service@jet-tech.com

Page 3

Operation

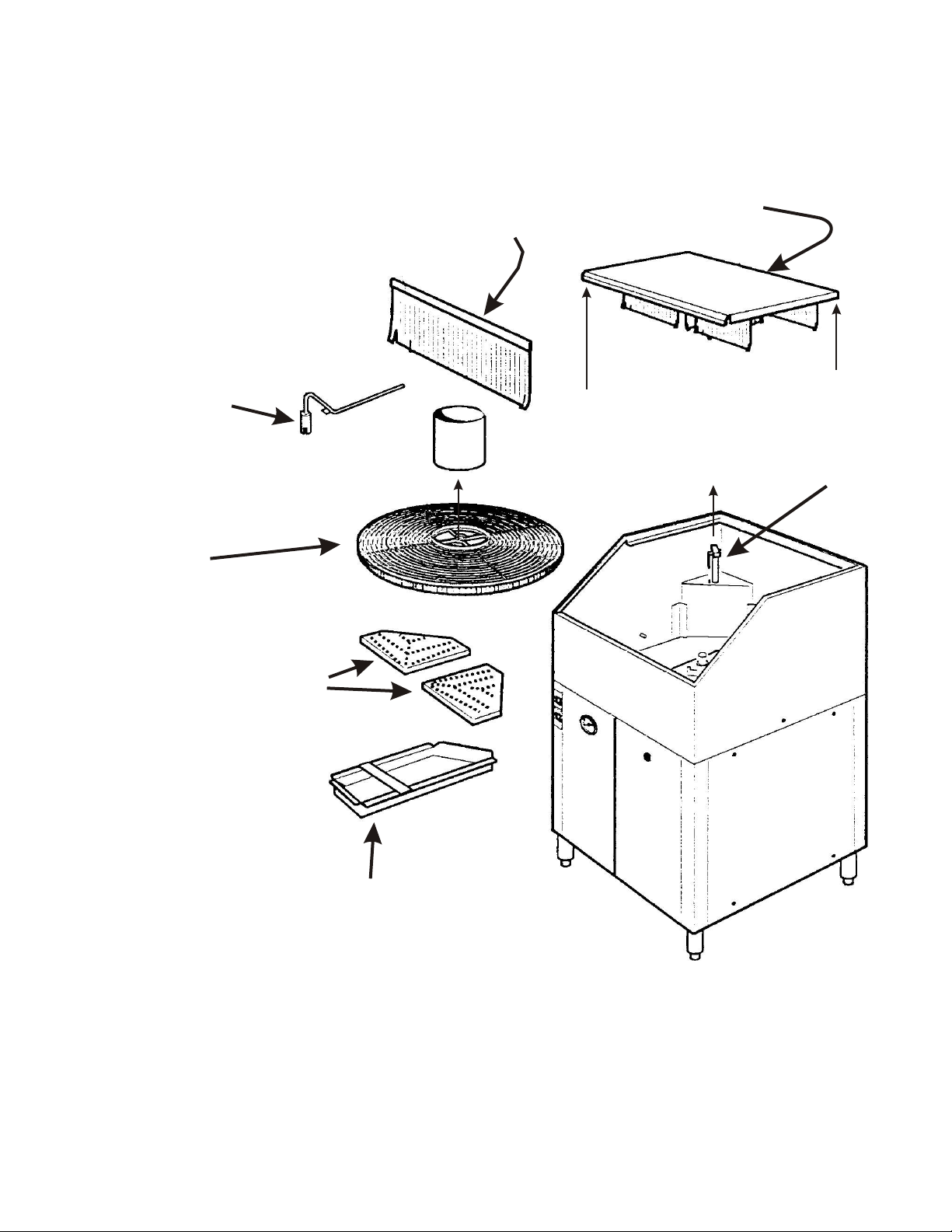

5 1. Before your machine is placed into wet operation it is imperative that you disassemble

the upper washing and rinsing area to insure that all removable parts in transit are

removed. This will also acquaint you with the steps you will take in future to disassemble

and clean your machine.

5 2. Proceed as follows:

A. Remove

front curtain

C. Lift out

limit switch arm

D. Lift out

center drum

& grid

B. Remove Lid

G. Lift up

overflow

standpipe

LH

E. Lift out left and right

RH

wash blocks by lifting

both straight up off their

connecting bosses.

Note: The left wash

block has a greater

number of jets. Be sure

when replacing them

F. Remove wash-tank

screen

Inspect the wash tank directly beneath the wash screen and remove any foreign matter. Lift out

overflow standpipe and replace firmly into the drain.

After inspecting and cleaning the wash and rinse compartment reassemble machine by

reversing the procedure outlined above.

Page 4

Operation (continued)

!You are now ready to turn the water on to your machine. When you open the valve the

plumber has installed in your supply line the water will rise in the wash tank to a point slightly

below the top of the standpipe.??This will allow for a slight overflow each time the machine

is stopped and that water in the upper reaches of the machine flows back down into the

wash tank.

!You can now turn the heater switch to the "ON" position. The water in the

wash tank will automatically be maintained at the proper temperature.

!Your Glasswasher is equipped with automatic detergent, sanitizer and

rinse agent injection. When you open the access door you will see the

three pumps mounted on the left hand wall. Place the suction tube from

the pump marked "Detergent" into a container of glasswasher liquid

detergent recommended by your chemical supplier. This must be a low

foaming, chlorinated detergent. The amount of this detergent added to

the wash water is determined by the conductivity control No. 6 shown on the Electrical

Group Diagram. On this circuit board is a small adjusting

potentiometer which allows the operator to increase or decrease the

amount of detergent added. Your chemical supplier will be able to

assist you in the proper calibration of this control to meet his proper

requirement.

!Take the tube marked "Sanitizer" and place this in a bottle of your

chosen SANITIZER liquid. You may use a common unscented

bleach which is normally a 5 1/2% Sodium Hypochlorite or an

industrial chlorine which normally runs about 12% in strength. The

level of Sanitizer in the rinse line or coming from the spray block

can be titrated or determined by a litmus test.

CAUTION

It is important the standpipe be in place properly before turning

the machine in the on position

Page 5

Maintenance

Daily:

! The wash tank should be drained and cleaned each morning before starting up the

machine.

! To do this remove the equipment in the upper area of the

machine as instructed in Section No.1 and No. 2 of

"Operation" on preceding pages. Lift out the standpipe

and allow the wash solution to run down the drain.

Water from the make up valve will begin flowing into the

tank and provide enough fresh water to clean and flush

the tank. Be sure heater is in the "Off" position.

! The wash tank screen which was removed during the

disassembly should be thoroughly cleaned before

replacing.

! Any dirt in the rinse should also be removed.

! Detergent, Sanitizer and Rinse agent containers stored

in the lower section of the machine should be

checked to insure adequate supply for the coming

day.

Weekly:

! On a weekly basis the spray blocks should be checked

for plugged orifices.

! To do this, remove the front curtain and allow the machine to run. Observe the

sprays coming from both blocks and if any jets are plugged, insert a paper clip

or other similar small wire into the plugged jet to remove the obstruction. This

is normally all that is required and the jet will remain

free. However if the jets appear to be re-plugged in

a short time remove the complete spray block and

disassemble as shown in detail "A" in the Wash &

Rinse Group Diagram in the manual.

Page 6

Stainless Group

1. Lid #C35847

2. Rear Glass Guide RH #C35873

3. Back Panel #C35854

4. Right Panel #C35855

5. Drop in Plate #C35859

6. Legs #C35848

8. Grid Guide #C35852

9. Right Door #C35857

10. Left Door #C35856

11. Left Panel #C35853

12. Front Glass Guide RH #C35850

13. Front Glass Guide LH #C35851

14. Rear Glass Guide LH #C35874

Page 7

Wash and Rinse Group

1. Outside Curtain #C35006

2. Inside Curtain #C35002

3. Grid - Table #C35862

4. Center Drum #C35867

5. Wash Block #C35864

6. Rinse Block #C35865

7. Spray Block Gasket #C35866

8. o-rings #C14316

9. Wing Nut #C35683

10. Tank Screen #C35681

11. Limit Switch Boss #C35018-1

12. Limit Switch Arm #C35875

13. Limit Switch Extension #C35017

Page 8

Main Plumbing Group

1. Water Make-up Valve #C35672

2. Float #C35673

3. Drain Standpipe #C35674

4. Vacuum Breaker #C35043

5. Solenoid Body - Plastic #C35653

6. Coil #C35045-1

7. Wash Pump #C35065-503603-3E 34N

8. Peristaltic Pump head complete #C35675

9. Face Plate for Pump Head #C35585

C35868-TUBE. Pinch/squeeze Tube

10. Back Plate for Pump Head #C35586

11. Spider Gear #C35584

12. Bushing for Spider Gear #C35587

13. Sanitizer Tube #C35868

14. Detergent Tube #C35868

15. Rinse Tube #C35868

16. T-Injection Fitting #C35676

Page 9

Electrical Group

1. Drive Gear Motor #C35840

2. Drive Gear #C35863

3. Micro-switch #C35686

4. Peristaltic Pump Motor #C35807

5. Potentiometer Circuit Board #C35844

6. Probe #C35879

7. Heater #C35145

8. Coil #C35045-1

9. Motor Switch (Green) #C35659

10. Heater Switch (Red) #C35658

11. Temperature Gauge #C43217

12. Transformer #C35739

13. Power Supply Box #C35871

14. Fuse #C35876

15. Heater Relay #C35656

16. Thermostat #C35685

17. Terminal Block #C35870

18. Female Receptacle #C35869

Low water Cut-off #C35842

Page 10

Loading...

Loading...