Jet Tech FX 44 General Manual

JET-TECH SYSTEMS FX 44

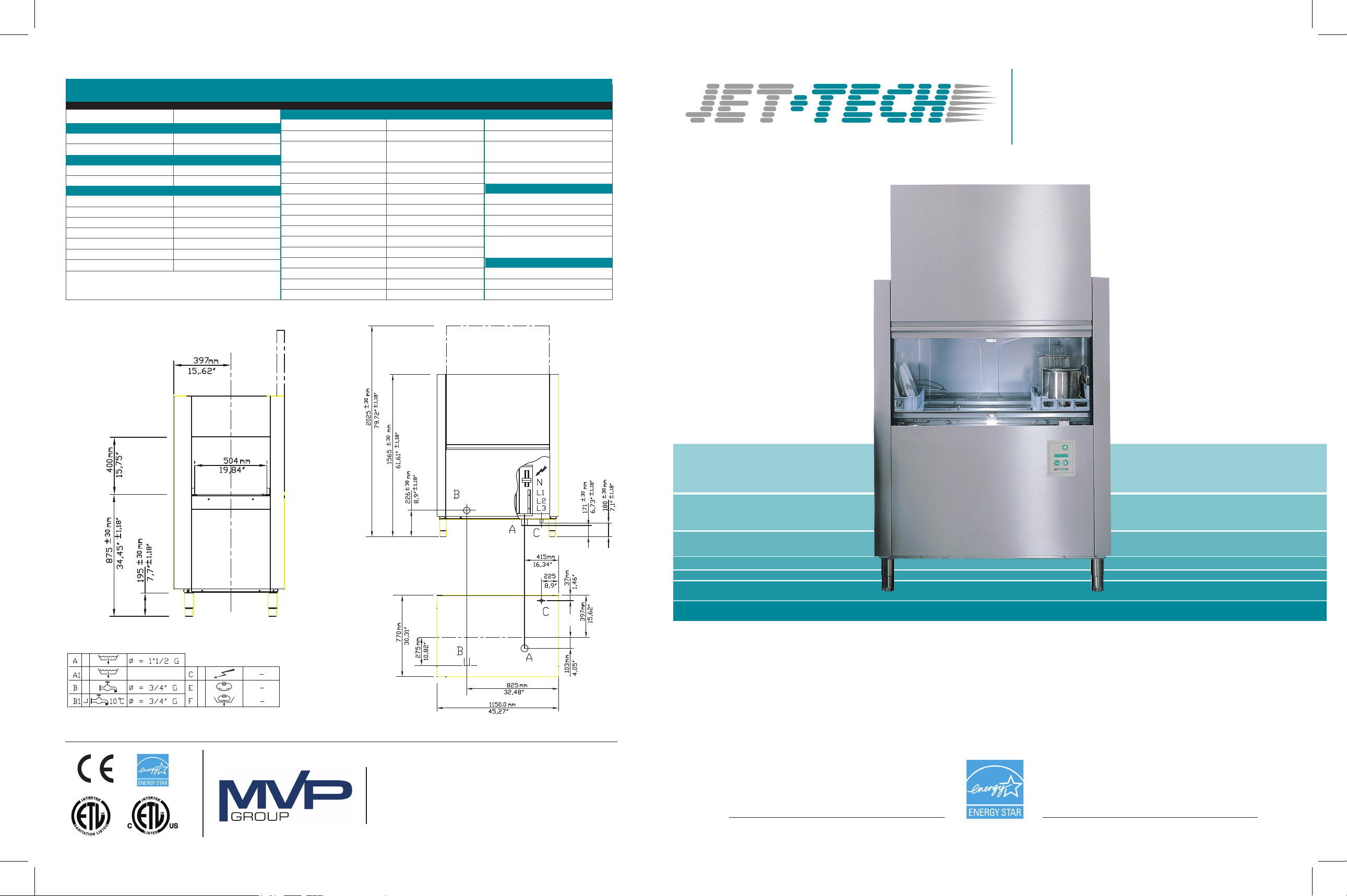

Rack Dimension

Program speed 1

Program speed 2

Washing temperature - tank

Rinsing temperature - booster

Wash tank capacity

Booster capacity

Maximum consumption

Water inlet temp.

Fill pressure

Fill hose connection

Drain hose diameter

20’’ x 20‘’ (500 mm x 500 mm)

WASHING PROGRAM

150 racks/hour

210 racks/hour

TEMPER ATURE

165°F 74°C

190°F 88°C

WATER

18.25 gal (68 litres)

4.5 gal (17 litres)

89.81 gal/h (340 litres/hour)

122°F (50°C)

18-40 lbs (1-3 bar)

G 3/4’’ M

1.5’’ (38 mm)

ELECTRIC SOFTWARE SYSTEMS

Motor

Voltage

Booster

Tank

Rack conveyor motor

Wash pump

Rinse pressure pump

Total load

Min. Amperage power supply

Net weight

Ship weight

Ship width

Ship depth

Ship height

Ship volume

Noise level

2 H.P.

208V 3 phase 60 hz.

3 x 8000 W

(incl. 1 element exchanger with tank)

9800W

220W

1500W

250W

28000W

90A

1012 lb (459kg)

1210 lb (550kg)

74-7/16’’ (1890 mm)

40-15/16’’ (1040 mm)

81-1/8’’ (2060 mm)

143 cu.ft (4.05 m³)

<70 dBA

Quick ready

Temporized washing

Rinsing economizer

Hours counter (partial and total)

Water exchange signalation

Thermostop

STANDARD

Double walled insulated body

Rinsing pump

Autodrain wash pump

Double filter drain system

Conveyor direction is reversible

in the field

OPTIONAL EQUIPMENT

Detergent level control

Steam exhaust or dryer module

Rinse aid and detergent dispensers

FX 44

44’’ SINGLE TANK CONVEYOR DISHWASHER

with built-in booster

MVP GROUP CORPORATION

5659 Royalmount Ave. Montreal QC, Canada H4P 2P9

Tel: 514.737.9701 / 888.275.4538

Fax: 514.342.3854 / 877.453.8832

sales@mvpgroupcorp.com www.mvpgroupcorp.com

THE ABSOLUTE HIGHEST INNOVATION IN WARE WASHING

The operators of this equipment have at their disposal a

most versatile and innovative instrument; capable of

delivering immediate results to your operation. It is now

possible to obtain increased performance, remarkable

savings in operation costs, as well as a reduced

environmental impact. The Jet-Tech FX 44 conveyor

dishwasher performance stands on three main pillars:

- Hydrowash

- Total Clean Concept

- Integrated Electronic Control System

These three pillars are the result of our care for the most

useful innovation in your kitchen,and that’s the reason we

can assist users in their everyday work and habits.

Versatile and powerful, the FX 44 is capable of washing up

to a maximum of 2,350 dishes/hour. Low consumption and

power requirements, with a selectable double speed,

it is a highly productive instrument. Make this the ideal

solution to combat those tough everyday workloads.

Hydrowash

Hydrowash is our patented washing system that we have developed

to obtain more with less effort. In the traditional rack conveyor most

of the energy generated by washing pumps is wasted in the

collisions between the water jets. FX 44 with Hydrowash design,

effectively minimizes overlapping between the water blades; in this

way the energy that the pump impresses on the water is directed to

the wares to be washed.

Hydrowash arm

Total Clean Concept

The FX 44 dishwashers were

projected to guarantee the maximum

cleanliness, easiness and a total seal

of hygiene. All the tanks are deepdrawn without welds to make the dirt

slide to the drain. The water is treated

by large surface integrated filters that

retain the biggest dirt particles;

conveying them in easily removable

containers. Pumps are self-draining

to avoid any foul odors. The washing

chamber is without manifolds or

sharp edges. There are no places

where dirt can accumulate. The

ordinary maintenance operations

at the end of the shift are

greatly reduced.

The effective surface filter

Powered pre-washing

The powered pre-washing module has a length of 32’’ (820 mm) and

makes use of the extraordinary per formance of the 36 jets and its

patented Hydrowash Washing System. The tank is deep-drawn and can

be easily cleaned, the surface filters are very effective in retaining dirt,

while a second extractable filter is provided on the pump’s suction duct.

An effective thermostatic system keeps the water’s temperature constant,

activating, if required, an integrated heating element in the tank.

No sharp edges inside Inner view Integral double walled structure

JET-TECH RACK CONVEYOR MACHINE

FEATURE

Quick Ready

Rinsing Economizer

Temporized Washing

Hours Counter Partial And Total

Tank Bottom

DESCRIPTION

Filling of tank with hot water from booster

When last basket exits, rinse pumps stops, while

conveyor and wash pump continue to operate

Autotimer - enables to wash 1 basket at a time- when

basket exits, rinse will stop as per rinsing economizer.

Machine will continue to run for few more seconds then

conveyor and wash pump stop completely

Connected to autotimer, indicates on display working

hours of the day and cumulative operating hours to the

date

The prewash surface strainers

ADVANTAGE

Machine ready within shorter time

Minimizes rinse water consuption

Less operating cost when low output

is required

Informs about actual machine usage

Deep drawn inner tank the ultimate in sanitation

Low voltage soft touch

control panel

Control System

FX 44 rack conveyor is equipped with

an ultra modern electronic control

panel. The operation is simple and

intuitive, the LED displays permit you

to visualize the washing and rinsing

temperatures as required by

HACCP standards.

A special push button permits

selection of the most suitable

operation, continuous or single rack.

The panel displays the selfdiagnostic circuit messages that

monitor the main electric components

showing specific error messages at

every malfunction.

Water Change Indication

Thermostop

Double Skin Insulated Body

Rinse Booster Pump

Autodraining Wash Pump

Double Filter Drain System

Conveyor Direct

Is Reversible In The Field

Indicates when tank water has not been changed for 8

hours or more

If correct rinse temperature (176°F.-184°F) has not

been reached, conveyor is stopped and kept on hold

Door is double skin with insulation; body is double skin,

but not insulated

In connection with break tank ensures constant water

pressure and output

Vertical pump self drains dirty water remaining inside;

pumps mounted in an horizontal position do not drain

Total tank filter plus pump filter ensure better quality of

wash water and longer interval between one water

change and the other

Easy change of direction; all necessary parts are

already equipped on the machine; see instructions

Wash water quality control

Constant rinse temperature always

ensured

Less noise and less heat dispersion

Optimum rinse quality

Reduces foul odors from machine

Better quality of wash water

Less inventory for dealer; easy

change in case of mistaken order;

easy conversion in case of re-sale in

future

Loading...

Loading...