Jet Tech F 22 1PH Installation Manual

DISHWASHER MANUAL

INSTALLATION AND MAINTENANCE

F14F14

F16F16

F18F18

F20F20

For operator. Do not discard.

F22F22

727727

737737

747747

767767

2005

Welcome to JET TECH

“creating endless possibilities!”

This manual was created specifically for you, the end -user.

We have included information to help troubleshoot

problems and facilitate resolving those problems. General

information pertaining to our hi-temp ware washers will be

covered in this section. Specific information on our current

models is available upon request, model by model.

If you find any discrepancy or can’t find certain

information, please contact us. We will be glad to be of

assistance.

JET-TECH SYSTEMS

5771 Ferrier street

Montreal, Quebec H4P 1N3

Tel.: 888 -275-4538 (888-ASK-4-JET); 514-737-9701

Fax: 514-737-2792

e-mail: service@jet-tech.com

2

Contents

WARRANTY.....................................................4

MACHINES SPECS.........................................5

GENERAL INSTALLATION GUIDELINES.......6

CONNECTING YOUR F-14.............................7

CONNECTING YOUR F-16.............................8

CONNECTING YOUR F-18........................9, 10

CONNECTING YOUR F-20............................11

CONNECTING YOUR F-22......................12, 13

CONNECTING YOUR 727

CONNECTING YOUR 737

CONNECTING YOUR 747

CONNECTING YOUR 767

CHEMICAL PUMP ADJUSTMENT............18, 19

CONTROL PANELS

BASICS STEPS TO START

ELECTRICAL STAGES

OPERATION

F18, BASICS STEPS TO OPERATE...............24

F22, BASICS STEPS TO OPERATE...............25

DRAIN PUMP OPERATION

PROBLEM ANALYSIS...................27, 28, 29, 30

HELP LINE

....................................................23

.......................................................31

........................................20

..............................14

..............................15

..............................16

..............................17

............................21

...................................22

.............................26

3

MANUFACTURERS LIMITED WARRANTY

Jet Tech Systems Corporatio n (Jet Tech) hereby warrants all new warewashers bearing the name “JET

TECH” and installed within the continental United States of America or Canada to be free from defects in

material and workmanship, under normal and regular usage and operation, for a period of one (1) year

following the date of original installation, (unless specified otherwise) but in no event can exceed eighteen

(18) months from the date of shipment from the factory.

If a defect in material(s) or workmanship is detected; or found to exist within the stated period above, Jet

Tech, at its sole discretion, shall either repair or replace any original equipment manufacturers part which

has proven to fail within the machine; providing that the equipment has not been altered or tampered with

in any manner, has been installed correctly as per the owners manual, and maintained and operated in

complete accordance with this manual.

The labor cost to repair or replace any part proven to be defective, as per above clause(s), shall be covered

by Jet Tech Systems, within the continental United States of America or Canada; provided that: prior

authorization for this labor was approved by Jet-Tech Systems, the service work was performed by an

authorized Jet Tech service agency; and that this agency installed an original and genuine Jet Tech part in

the machine. Any repair work performed by a non-authorized service depot remains the sole responsibility

of the user, and Jet Tech Systems will not be held responsible. The installation of any generic part wi ll

not be valid; and therefore voids this warranty. All authorized labor coverage shall be limited to regular

hourly rates only. Any supplemental hourly rates or charges, such as weekends or emergency premiums

remain the responsibility of the user.

Jet Te ch Systems Corp. (Jet Tech) hereby states that: warranty travel time shall be limited to, and without

exception, a round-trip total of two (2) hours OR mileage up to a maximum of one hundred (100) miles

round-trip. Any charges exceeding those stated herein must have prior authorization by the factory.

Exceptions to above warranty are: (A) Damages resulting from shipping, handling or abuse. (B) Incorrect

installation and/or connections. (C) Adjustments or calibration of any parts. (D) Faults due to lack of

regular maintenance or cleaning of any internal part(s). (E) Replacement of any wearable items such as:

glasswasher curtains, or peristaltic squeeze tubing or gaskets. (F) Excessive lime, mineral, alkali or hard

water conditions (In excess of 6 grain) and (G) Poor results due to: use of an incorrect type of detergent (for

non-commercial type applications), and excessive or inadequate water temperature(s) or pressure

conditions or incorrect use.

JET TECH SYSTEMS CORPORATION STATES THAT THERE ARE NO OTHER WA RRANTIES,

EXPRESSED OR IMPLIED, THAT ARE NOT SET FORTH HEREIN, JET TECH SYSTEMS

CORPORATION SHALL ASSUME NO OTHER RESPONSIBILITY, EITHER DIRECT OR NON DIRECT, OR BE LIABLE FOR ANY OTHER OR ADDITIONAL LOSS OR DAMAGE WHETHER

BEING DIRECT OR CONSEQUENTIAL, AS A RESULT OF ITS EQUIPMENT.

Warranty:

One year parts & labor (Continental USA and Canada).

Exceptions: Model “F14” - 90 days labor & One year parts.

The manufacturer reserves the rights to alter design and specifications without notice.

4

JET TECH - Technical Data

description F14 F 16 F 18 F 18 DP F 20 F 22 1PH

voltage 110V 60 Hz 220V 60 Hz 220V 60 Hz 220V 60 Hz 220V 60 Hz 220V 60 Hz

maximum absorption 1475 W 2600 W 4550 W 4650 W 6750 W 9750 W

washing pump motor 75 W 184 W 550 W 550 W 1100 W 750 W

drain pump motor 100 W 100 W

booster element 1400 W 2400 W 4000 W 4000 W 6000 W 9000 W

tank element 1400 W 2000 W 2800 W 2800 W 4000 W 6000 W

Amp 13.4 12.9 22.2 22.4 31.5 46.9

Hydraulic data

solenoid valve capacity 2.6 GAL/minute 2.6 GAL/minute 2.6 GAL/minute 2.6 GAL/minute 2.6 GAL/minute 3.7 GAL/minute

booster capacity .66 U.S. GAL .84 US GAL 2.05 U.S. GAL 2.05 U.S. GAL 2.7 U.S. GAL 2.7 U.S. GAL

tank capacity 2.4 US GAL 3.2 US GAL 6.8 US GAL 6.8 US GAL 7.9 US GAL 5 US GAL

water consumption .522 US GAL .522 US GAL .67 US GAL .67 US GAL .8 US GAL 1.1 US GAL

water pressure 20 +/- 5 PSI 20 +/- 5 PSI 20 +/- 5 PSI 20 +/- 5 PSI 20 +/- 5 PSI 20 +/- 5 PSI

water connection "3/4"" NPT" "3/4"" NPT" "3/4"" NPT" "3/4"" NPT" "3/4"" NPT" "3/4"" NPT"

water drain diam.1" diam.1" diam.1" diam.1" diam.1.5" diam.1.5"

Dimensions

high 650 mm 724 mm 840 mm 840 mm 1300 mm 1545 mm

length 630 mm 480 mm 600 mm 600 mm 640 mm 1210 mm

deep 600 mm 510 mm 600 mm 600 mm 650 mm 720 mm

weight 35 Kg. 44 Kg. 68 Kg. 68 Kg. 90 Kg. 180 Kg.

description F 22 3 PH 727 737 747 1 PH 747 3 PH 767

voltage 220V 60 Hz 220V 60 Hz 220V 60 Hz 220V 60 Hz 220v 60 Hz 220V 60 Hz

maximum absorption 9750 W 3050 W 4650 W 10100 W 10100 W2 11550 W

washing pump motor 750 W 550 W 550 W 1100 W 1100 W 2210 W

drain pump motor 100 W 100 W

booster element 9000 W 2400 W 4000 W 9000 W 9000 W 9000 W

tank element 6000 W 2000 W 2800 W 6000 W 6000 W 9000 W

Amp 33.9 14.2 22.4 48.6 35.1 40.1

Hydraulic data

solenoid valve capacity 3.7 GAL/minute 2.6 GAL/minute 2.6 GAL/minute 3.7 GAL/minute 3.7 GAL/minute 3.7 GAL/minute

booster capacity 2.7 U.S. GAL .84 U.S. GAL 2.05 U.S. GAL 2.7 U.S. GAL 2.7 U.S. GAL 2.7 U.S. GAL

tank capacity 5 US GAL 2.1 US GAL 3.15 US GAL 4.75 US GAL 4.75 US GAL 6.6 US GAL

water consumption 1.1 US GAL .522 US GAL .74 US GAL 1.1 US GAL 1.1 US GAL 1.3 US GAL

water pressure 20 +/- 5 PSI 20 +/- 5 PSI 20 +/- 5 PSI 20 +/- 5 PSI 20 +/- 5 PSI 20 +/- 5 PSI

water connection 3/4" NPT 3/4" NPT 3/4" NPT 3/4" NPT 3/4" NPT 3/4" NPT

water drain diam.1.5" diam.1" diam.1" diam.1.5 " diam.1.5 " diam.1.5 "

Dimensions

High 1545 mm 820 mm 850 mm 1445 mm 1445 mm 1900 mm

length 710 mm 500 mm 600 mm 710 mm 710 mm 900 mm

deep 720 mm 510 mm 600 mm 720 mm 720 mm 900 mm

weight 140 Kg. 140 Kg. 68 Kg. 140 Kg. 140 Kg. 220 Kg.

5

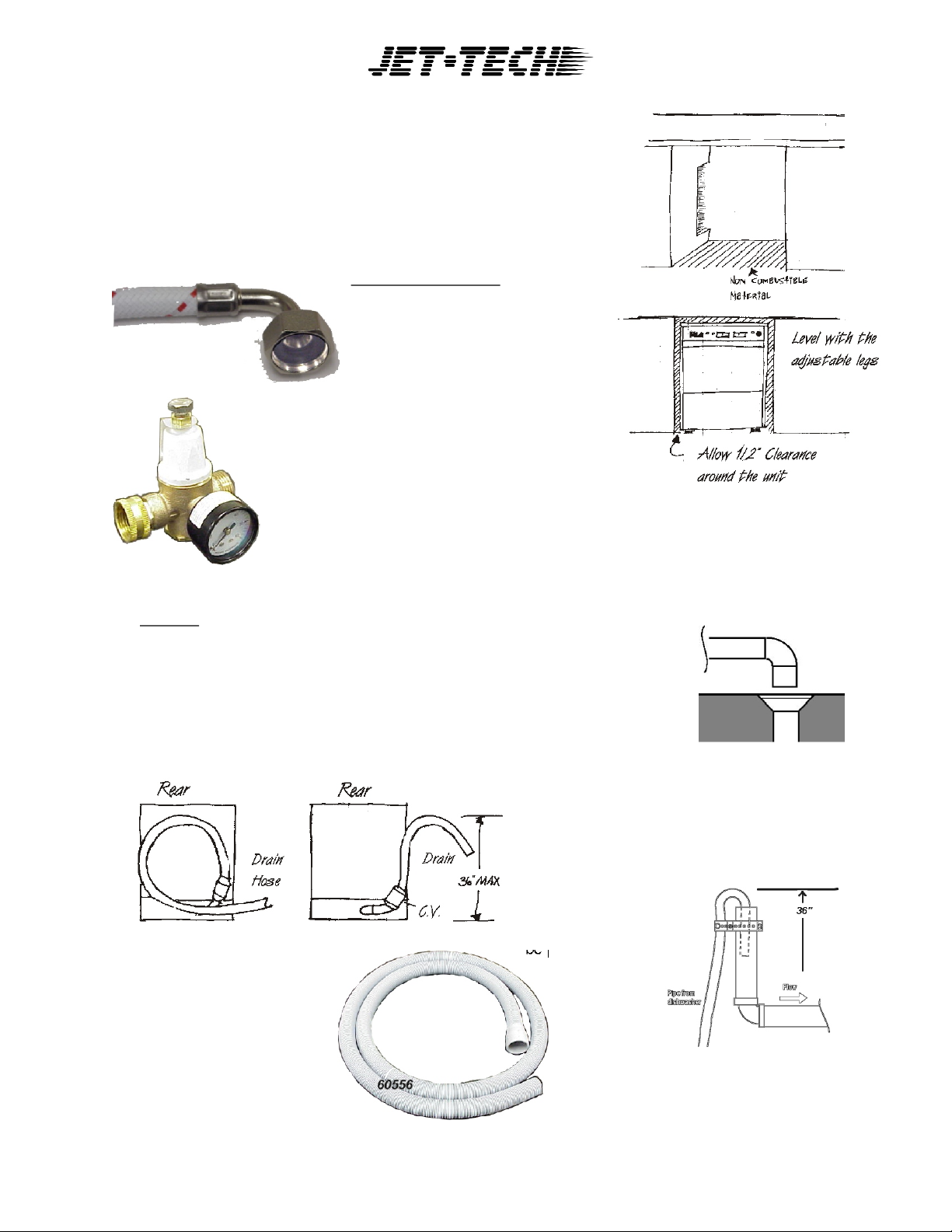

General Installation Guidelines

The unit must be installed on a level surface or allow for easy levelling of the unit.

It must be installed on a non-combustible surface.

All Panels must remain on the equipment when the installation is finished.

An install kit is available for most models.

Information about the kit is available at your reseller.

This instruction Manual must remain with the operator.

Electrical

- Based on the local electrical code, wires must be large enough to carry

the electrical load used by the dishwasher. The electrical breaker must be

large enough to protect those wires. Normally the breaker size or fuse size

should not exceed %110 of total current load (ex.: 23 amps requires max

fuse size of 25 amps).

- All units must be grounded.

- Except for the F14(110 volts), all the high-temp dishwashers do NOT

require a neutral.

- For tri-phase model, three live wire are required and the rotation of the pump(s)

must be verified.

-Only a licensed electrician can make sure the unit is installed with the proper set-up,

according to local codes.

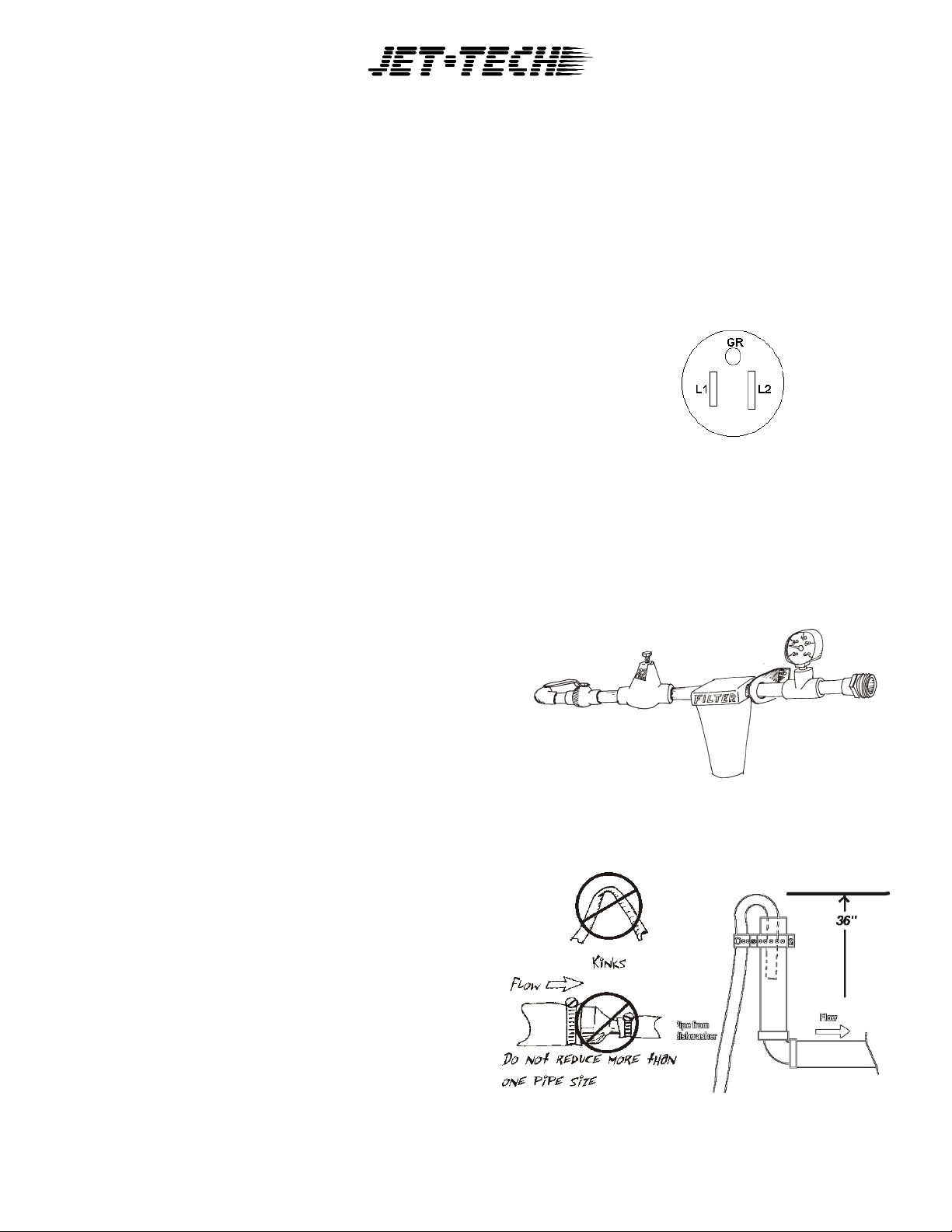

Water supply

- To get best results, supply 140 F at all time.

If water temperature is 120F, the dishwasher must be

allowed an extra two (2) minutes between washes.

- Running pressure must not exceed 25 PSI (20 ~5)

- Water should be free of minerals and other

sediments.

- Hook-up is made with ¾ NPT. It is recommended to

use metal breaded reinforced hose.

- If a hot water tank has to be installed to supply the

dishwasher, the average rate of water consumption is 30 gallons per hour.

Drain connection

- If the unit uses a gravity drain, it has to drain in

an open floor drain.

- The drain hose to be used can not be allowed to

collapsed.

- Do not reduce more than one pipe size.

- Follow local codes for proper waste disposal.

- Allow for easy removal for cleaning and servicing.

Hard plumbing the unit is strongly discouraged.

6

Connecting your new F-14

This dishwasher must be installed on a level, rigid, nonflammable surface. Ensure

that the machine is level by installing the feet (shipped in the wash tank of the

machine) and adjusting the levelling. Be sure to provide adequate space for

water, drain and electrical connections. The rear panel must be removed for the

hook ups and must be put back after the connections are made.

ELECTRICAL SUPPLY

A 115 Volt - 15 Amp circuit breaker is required for this washer (please

make sure that this outlet is grounded). A standard power-cord with plug

is provided for your convenience for the 115 Volt version.

NOTE: -If you have purchased the optional 208 Volt version. -The circuit

used for this unit should be independent from any other equipment.

WATER SUPPLY

A 3/4” NPT coupling is required with 25 psi. dynamic pressure. A water

pressure regulator is required to maintain this pressure. The water pressure

cannot be less than 15 psi or exceed 25 psi. If the water pressure exceeds the

prescribed amount, you will get inconsistent washing temperature, premature

failure and thus may void the warranty.

Incoming water temperature must be 140º F ( 60º C). An easily accessible shutoff valve is recommended --- making installation, service and repairs easier.

This type hose is standard for most warewashing machines. Fittings should be

available from your local hardware or plumbing supply house.

Flexible hoses must be used to make installation, servicing and

maintenance easier.

Make sure that the water is free from calcium and hard water

deposits. For these situations, an on-line water cartridge system is

highly recommended. Build-up of calcium and lime deposits in the

washer may occur and servicing will be required on a more

frequent basis which will not be covered by the warranty.

Electrical

Drain outlet

Water inlet connection

DRAIN CONNECTION

This washer has a gravity type drain. Since this unit is a 'countertype' installation, your flexible drain hose, should be connected to the

drain outlet elbow at the rear of the unit behind the rear access panel;

and extended through the side opening directly into a floor drain or

sink (see Figure )

All panels must be back on the unit when the installation

is finished.

DO NOT manually fill wash tank with water. Let the dish-washer fill

itself when the power is turned ON.

7

Connecting your new F16DP

This glasswasher must be installed on a level, rigid, nonflammable

surface. Ensure that the machine is level by installing the feet

(shipped in the wash tank of the machine) and adjusting the levelling.

Be sure to provide adequate space for water, drain and electrical

connections.

WATER SUPPLY

A 3/4”NPT fitting is required with 25 psi. dynamic pressure. A water

pressure regulator is required. The water pressure cannot be less than

15 psi or exceed 25 psi. If the water pressure exceeds the prescribed

amount, you will get inconsistent washing temperature, premature

failure and thus may void the warranty.

Incoming water temperature must be 140º F ( 60º C). An easily

accessible shut-off valve is recommended --- making installation, service and

repairs easier. This type hose is standard for most warewashing machines.

Fittings should be available from your local hardware or plumbing supply house.

Flexible hoses must be used to make installation, servicing and maintenance

easier.

Make sure that the water is free from calcium and hard water deposits. For these

situations, an on-line water cartridge system is highly recommended. Build-up of

calcium and lime deposits in the washer may occur and servicing will be required

on a more frequent basis which will not be covered by the warranty.

DRAIN

· F-16 DP: This glasswasher is equipped with an automatic drain

pump that will pump the drain water to a maximum height of 36" (0.9

meter). Drain pump equipped machines have a white button on the

control panel beside the green power button. DRAIN PUMP

MODELS ARE FACTORY BUILT. GRAVITY DRAIN UNITS

CANNOT BE CONVERTED TO PUMPED DRAIN UNITS.

1" ID flexible drain hose* is recommended to facilitate maintenance and servicing of the

machine. It is important not to reduce the size of this hose. A 1" check-valve* may be

required. There should be sufficient hose length to permit the machine to be pulled out

for service.

ELECTRICAL

A 208-240 volt, 60 Hz, Single Phase circuit is required for this unit. Check the

rating plate on the machine for amp draw. In spite of the fact that the rating

plate shows 208 volts, the unit is designed function properly on 208 volts to

240 volts.

The terminal block is located at the back of the machine. Open the plastic

cover, pass the cable through the cable strain relief and connect the wires to

the L1, L2 & Ground. There should be sufficient cable length to permit the

machine to be pulled out for service. DO NOT turn on the power to the

machine until the water supply & drain lines have been connected. DO NOT

manually fill wash tank. Let it fill itself.

Water In

IMPORTANT NOTE

Reasonable access to and around the machine for service must be provided. Disconnecting of hard plumbing

or removal of counter tops or cabinets, etc., for servicing is not covered by warranty.

* - not supplied

All panels must be on the unit when the installation is finished.

L1

L2

Water

out

8

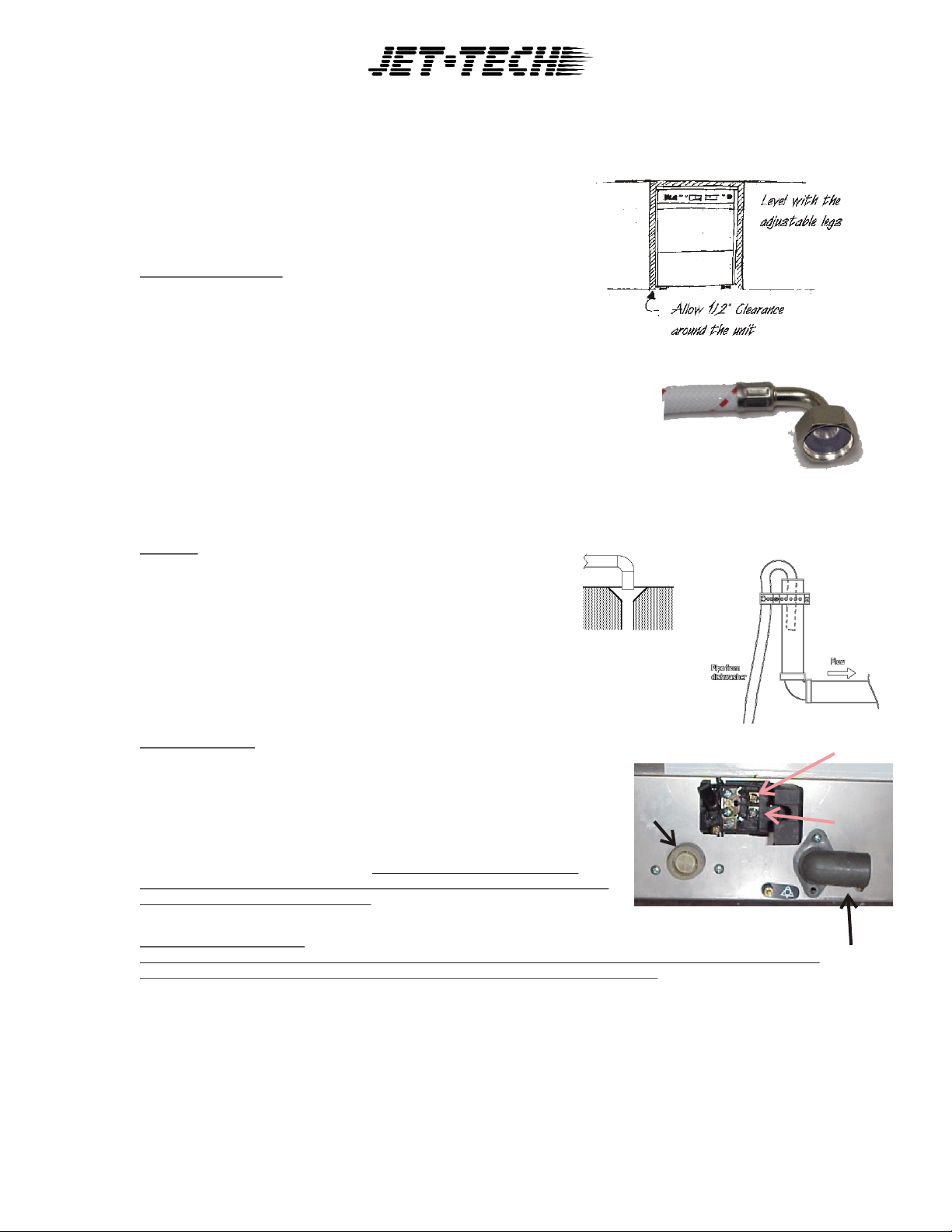

Connecting your new F-18, F18DP

This dishwasher must be installed on a level, rigid, nonflammable

surface. Ensure that the machine is level by installing the feet

(shipped in the wash tank of the machine) and adjusting the levelling.

Be sure to provide adequate space for water, drain and electrical

connections.

WATER SUPPLY

A 3/4” NPT fitting is required with 25

psi. dynamic pressure. A water pressure

regulator is required. The flowing water

pressure cannot be less than 15 psi or

exceed 25 psi. If the water pressure

exceeds the prescribed amount, you will

get inconsistent washing temperature,

premature failure and thus may void the warranty.

Incoming water temperature must be 140º F ( 60º

C). An easily accessible shut-off valve is

recommended --- making installation, service and

repairs easier. This type hose is standard for most

warewashing machines. Fittings should be available

from your local hardware or plumbing supply house.

Flexible hoses must be used to make installation, servicing and maintenance easier.

Make sure that the water is free from calcium and hard water deposits. For these

situations, an on-line water cartridge system is highly recommended. Build-up of calcium

and lime deposits in the washer may occur and servicing will be required on a more

frequent basis which will not be covered by the warranty.

DRAIN

· F-18: This dishwasher has a gravity drain. Maximum height of the floor drain

should not exceed 6" (15cm). A 1.5" ID flexible drain hose* is recommended to

facilitate maintenance and servicing of the machine.

· F-18 DP: This dishwasher is equipped with an automatic drain pump that will

pump the drain water to a maximum height of 36" (0.9 meter). A 1" ID flexible

drain hose* is recommended to facilitate maintenance and servicing of the

machine. It is important not to reduce the size of this hose. A 1" check-valve*

may be required on

drain pump equipped models. Drain pump

equipped machines have a white button on

the control panel beside the green power

button. Conversion is not possible in the

field.

There should be

sufficient hose

length to permit

the machine to

be pulled out for

service.

Gravity Drain

Pumped Drain

9

More next page

Installation F-18 , continued

ELECTRICAL

A 208-240 volt, 60 Hz, Single Phase circuit is required

for this unit. This unit will draw 22.3 amperes on a 220

volt circuit. In spite of the fact that the rating plate

shows 208 volts, the unit is designed function properly

on 208 volts to 240 volts.

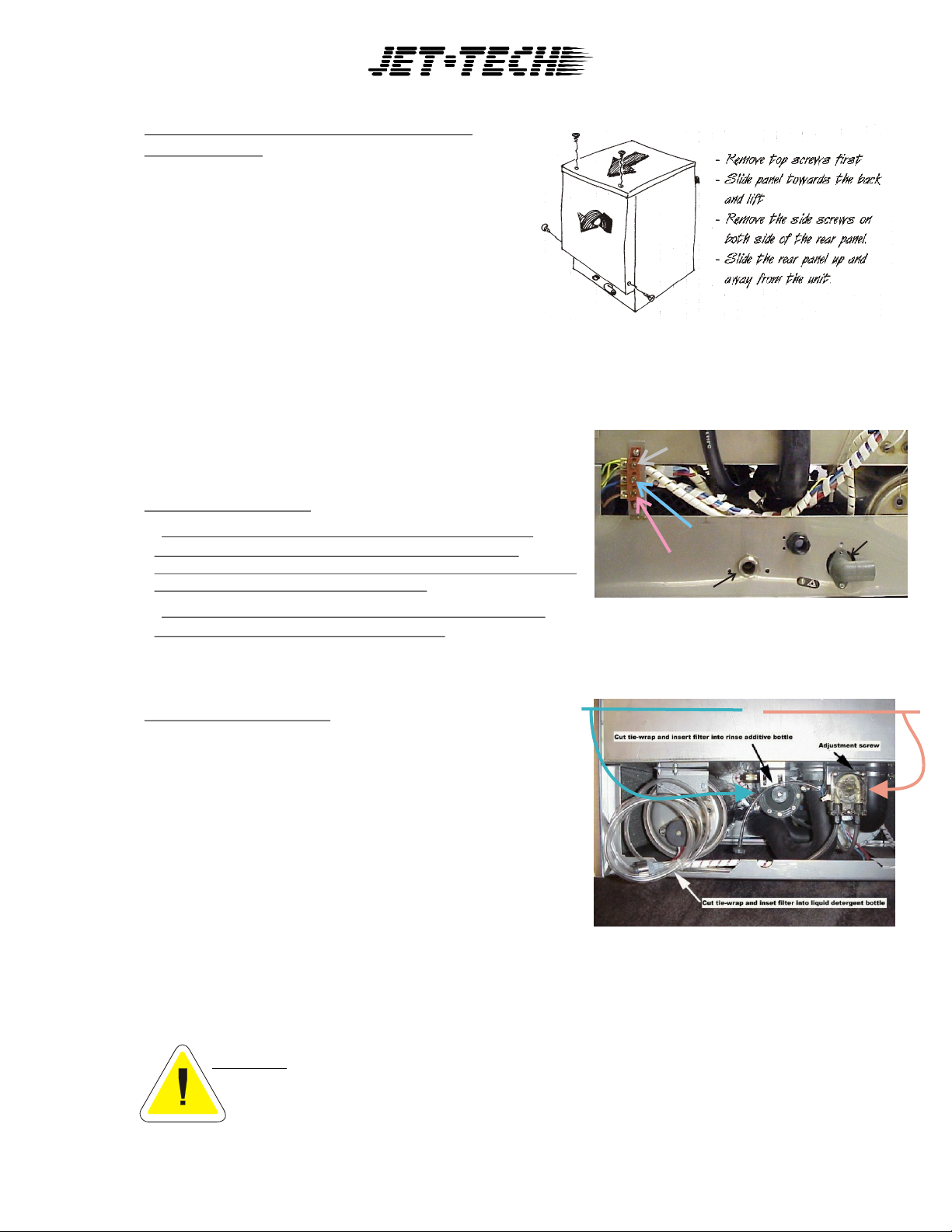

The top & back panels must be removed for the

electrical hook -up. The top panel is secured by two

phillips head screw. Once the screws removed, the

panel should be slid to the back and lifted. The back

panel is also held by two screws. Remove them, pull

the bottom away from the machine and lift the panel.

The terminal block is located inside the back cover. Pass the cable through the cable strain relief and

connect the wires to the terminals L1 (brown wire), L2 (blue wire) & Ground (yellow & green wire). Replace

the top & back panels being careful not to pinch or kink any

wires or hoses. There should be sufficient cable length to

permit the machine to be pulled out for service.

G

IMPORTANT NOTE

*Reasonable access to and around the machine for

service must be provided. Disconnecting of hard

plumbing or removal of counter tops or cabinets, etc., for

servicing is not covered by warranty.

L1

L2

Water In

Water

Out

*DO NOT fill dishwasher manually with water. Let the

dishwasher fill itself with power button.

*All panels must be on the unit when the installation is finished.

* - not supplied

Chemical Installation

Rinse-Aid PumpRinse-Aid Pump

Detergent PumpDetergent Pump

· The rinse pump is standard equipment on all JET-TECH

machines and automatically injects rinse additive into the rinse

water for the final rinse.

· The rinse pump is located in the base of the machine. The

front, lower panel (below the door) snaps off to access the rinse

pump. Cut the cable tie, remove the filter at the end of the tube,

insert tube in the container that is supplied, and put the filter

back. The bottle fits nicely in the cubicle on the right.

- Any surfactant isopropanol can be used. This chemical can be

found at any chemical supplier. Never use a chlorinated

product (sanitizer or bleach) as it will destroy the pump.

The detergent pump is peristaltic type with clear cover casing. It situated next to the rinse-aid pump. The

clear feed tube will have to be cut free and fed through the bottom of the dishwasher opening. The weighted

filter has to be inserted in a jug of detergent solution. Any sodium hydroxide can be used.

If liquid detergent is not what you want to use, a crystal(powder) type detergent can be used.

WARNING

Whenever manipulating chemicals, use appropriate protection (eyes and hands) as these

chemicals are corrosive.

10

Loading...

Loading...