Page 1

OWNER’S MANUAL

DISHWASHER INSTALLATION AND MAINTENANCE

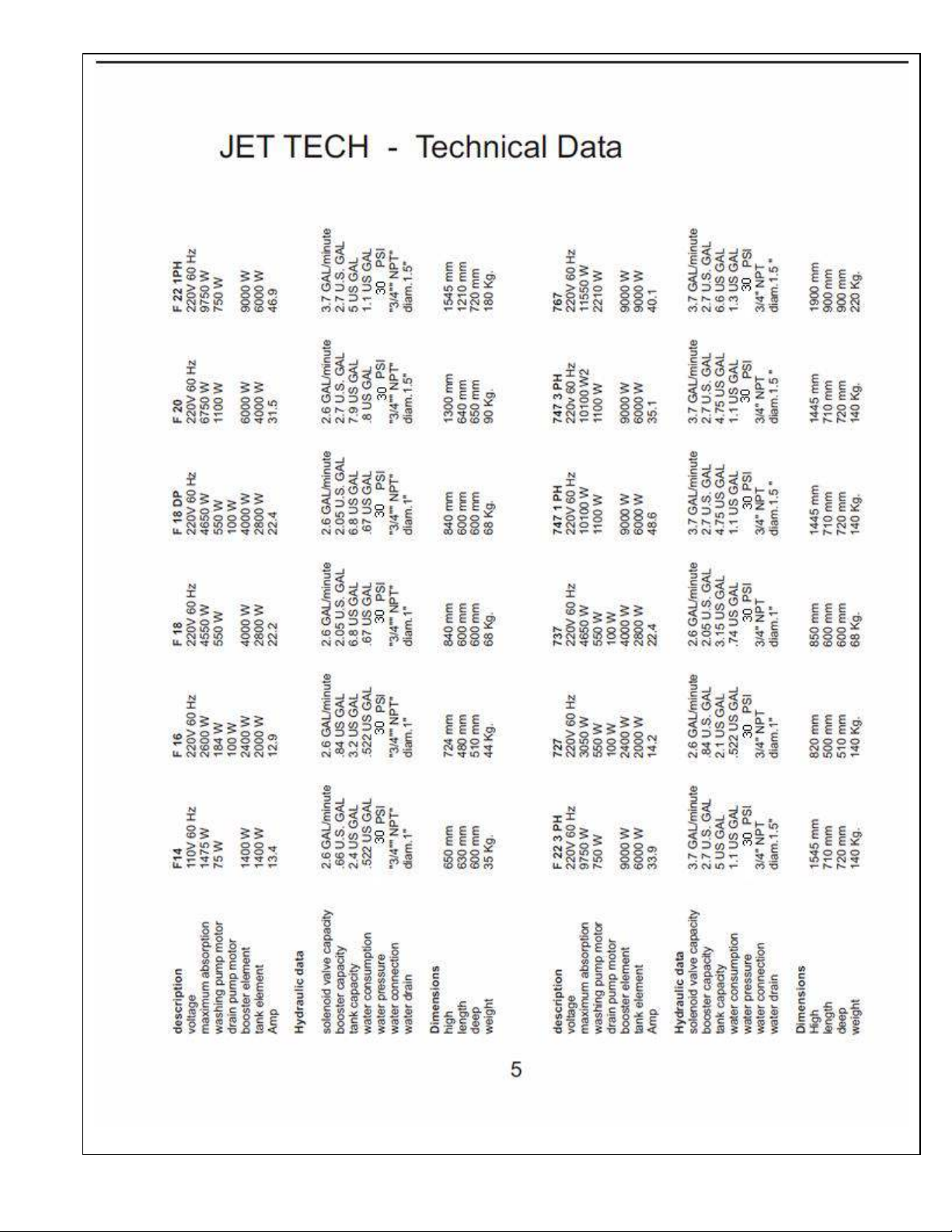

F14

F16

F18

For operator. Do not discard.

F20

F22

727

737

747

767

Page 2

Welcome to JET-TECH

“Creating endless possibilities!”

We have included information to help troubleshoot

problems and facilitate resolving those problems.

General information pertaining to our hi-temp ware

washers will be covered in this

manual.

Specific

information on our current and older models is available

upon request, model by model.

If you find any discrepancy or can’t find certain

information,

assistance.

of

MVP GROUP CORPORATION

JET-TECH

5659

Montreal, Quebec H4P

Tel.: 888 -275-4538 (888-ASK-4-JET); 514-737-9701

Fax:

E-mail: service@jet-tech.com

SYSTEMS

Royalmount Avenue

877-452-8832;

please contact us. We will be glad to be

2P9

514-737-2792

2

Page 3

Contents

WARRANTY.....................................................4

MACHINES SPECS.........................................5

GENERAL INSTALLATION GUIDELINES........6

CONNECTING YOUR F-14..............................7

CONNECTING YOUR F-16..............................8

CONNECTING YOUR F-18........................9, 10

CONNECTING YOUR F-20............................11

CONNECTING YOUR F-22......................12, 13

CONNECTING YOUR 727..............................14

CONNECTING YOUR 737..............................15

CONNECTING YOUR 747..............................16

CONNECTING YOUR 767..............................17

CHEMICAL PUMP ADJUSTMENT............18, 19

CONTROL PANELS........................................20

BASICS STEPS TO START............................21

OPERATION.............................................22, 23

F18, BASICS STEPS TO OPERATE...............24

F22, BASICS STEPS TO OPERATE...............25

DRAIN PUMP OPERATION.............................26

PROBLEM ANALYSIS...................27, 28, 29, 30

HELP LINE.......................................................31

3

Page 4

MANUFACTURERS LIMITED WARRANTY

MVP GROUP CORPORATION (Jet-Tech Systems) hereby warrants all new warewashers bearing

the name “JET-TECH” and installed within the continental United States of America or Canada to be

free from defects in material and workmanship, under normal and regular usage and operation, for a

period of one (1) year following the date of original installation (unless specified otherwise)

no event can exceed eighteen (18) months from the date of shipment from the factory.

This warranty is valid ONLY for the original owner of the “Jet-Tech” unit and is not transferrable.

If a defect in material(s) or workmanship is detected or found to exist within the above stated

period, MVP Group Corp., at its sole discretion, shall either repair or replace any original

equipment manufacturers part which has proven to fail within the machine, providing that the

equipment has not been altered or tampered with in any manner, has been installed correctly as

per the owner’s manual and maintained and operated in complete accordance with this manual.

The labor cost to repair or replace any part proven to be defective, as per above clause(s), shall be

covered by MVP Group Corp., within the continental United States of America or Canada provided

that prior authorization for this labor was approved by MVP Group Corp., the service work was

performed by an authorized MVP Group Corp., service agency and that this agency installed an

original and genuine Jet-Tech part in the machine. Any repair work performed by a non-authorized

service depot remains the sole responsibility of the user and MVP Group Corp., will not be held

responsible. The installation of any generic part will not be valid and therefore voids this

warranty. All authorized labor coverage shall be limited to regular hourly rates only. Any

supplemental hourly rates or charges, such as weekends, holidays or emergency premiums remain

the responsibility of the user.

MVP Group Corp., (Jet-Tech) hereby states that warranty travel time shall be limited to and

without exception, a round-trip total of two (2) hours OR mileage up to a maximum of one hundred

(100) miles (160 KM) round-trip. Any charges exceeding those stated herein must have prior

authorization by the factory or will be at the customer’s expense.

Exceptions to above warranty are: (A) Damages resulting from shipping, handling or abuse. (B)

Incorrect installation and/or connections. (C) Adjustments or calibration of any parts. (D) Faults due

to lack of regular maintenance or cleaning of any internal part(s). (E) Replacement of any wearable

items such as peristaltic squeeze tubing or gaskets. (F) Excessive lime, mineral, alkali or hard

water conditions (In excess of 6 grain) and (G) Poor results due to use of an incorrect type of

detergent or rinse additive (for non-commercial type applications or products containing chlorine)

and excessive or inadequate water temperature(s) or pressure conditions or incorrect use.

MVP GROUP CORPORATION STATES THAT THERE ARE NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, THAT ARE NOT SET FORTH HEREIN, MVP GROUP

CORPORATION SHALL ASSUME NO OTHER RESPONSIBILITY, EITHER DIRECT OR NON DIRECT OR BE LIABLE FOR ANY OTHER OR ADDITIONAL LOSS OR DAMAGE WHETHER

BEING DIRECT OR CONSEQUENTIAL, AS A RESULT OF ITS EQUIPMENT.

but in

Warranty

: One year parts & labor (Continental USA and Canada).

Exceptions

: Model “F-14” - 90 days labor & One year parts.

The manufacturer reserves the rights to alter design and specifications without notice.

4

Page 5

5

Page 6

Page 7

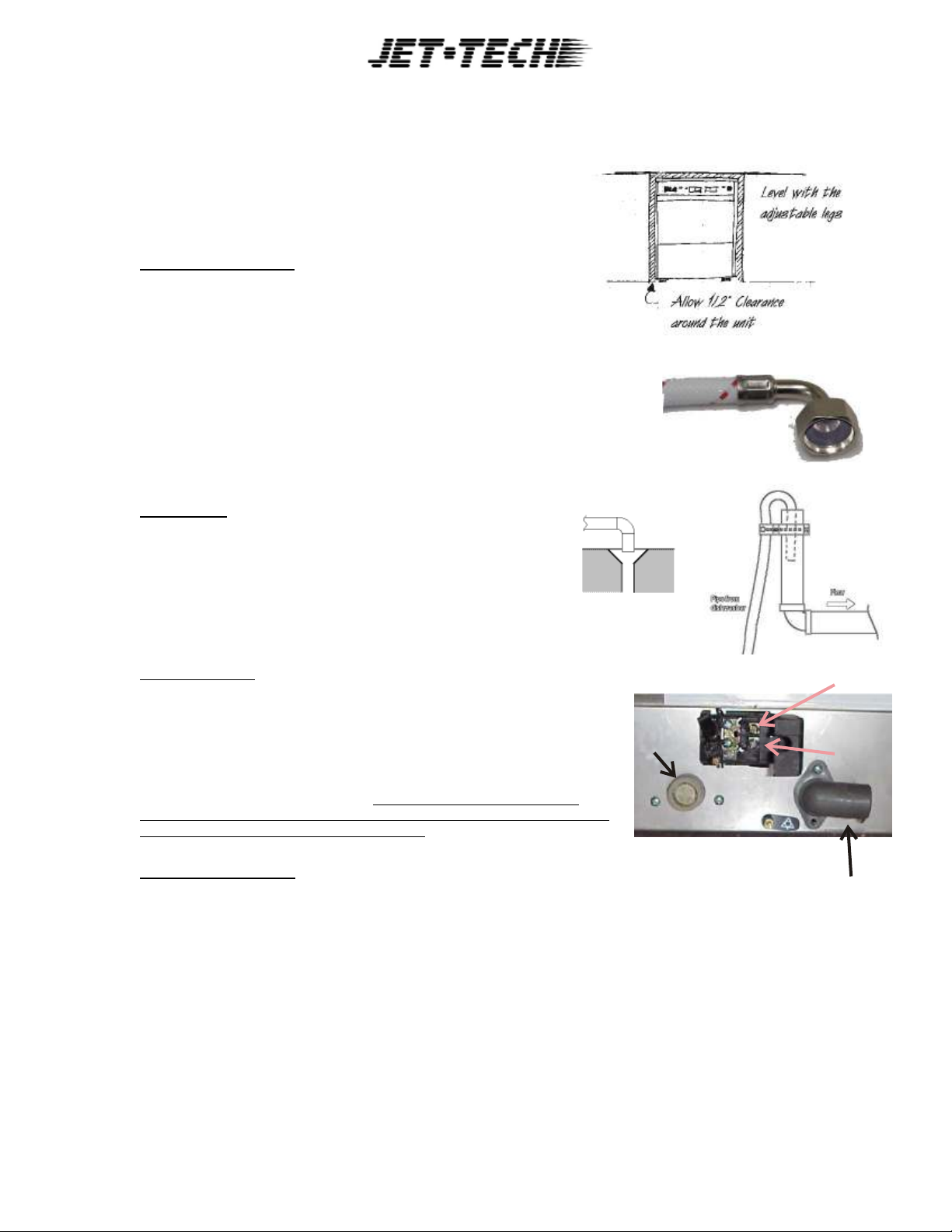

Connecting your new F-14

This dishwasher must be installed on a level, rigid, nonflammable surface. Ensure

that the machine is level by installing the feet (shipped in the wash tank of the

machine) and adjusting the leveling. Be sure to provide adequate space for

water, drain and electrical connections. The rear panel must be removed for the

hook ups and must be replaced after the connections are made.

ELECTRICAL SUPPLY

A 115 Volt - 20 Amp circuit breaker is required for this washer. A power-

cord with NEMA 5-20 plug is provided for your convenience.

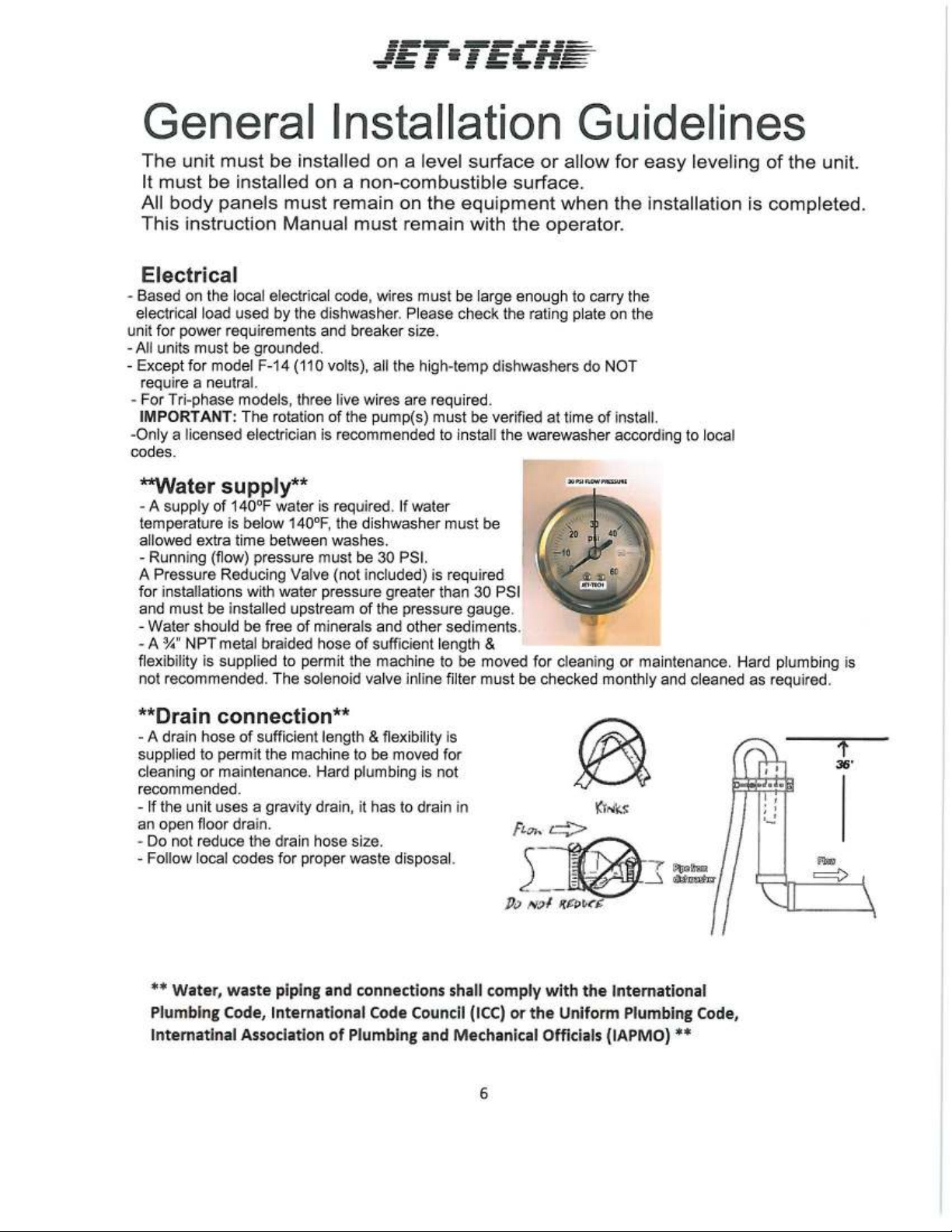

**WATER SUPPLY**

A 3/4” NPT coupling is required with 30 psi. dynamic pressure. A water

pressure regulator* may be required. The water pressure cannot be less

than 30 psi or exceed 30 psi. If the water pressure exceeds the prescribed

amount, you will get inconsistent washing temperature, premature failure and

thus may void the warranty.

Incoming water temperature must be 140º F (60º C). An easily accessible shutoff valve is recommended, making installation, service and maintenance easier.

A flexible fill hose is provided to make installation, servicing and

maintenance easier.

Make sure that the water is free from calcium and hard water

deposits. For these situations, an inline water cartridge system is

highly recommended. Build-up of calcium and lime deposits in the

washer may occur and servicing will be required on a more

frequent basis which will not be covered by the warranty.

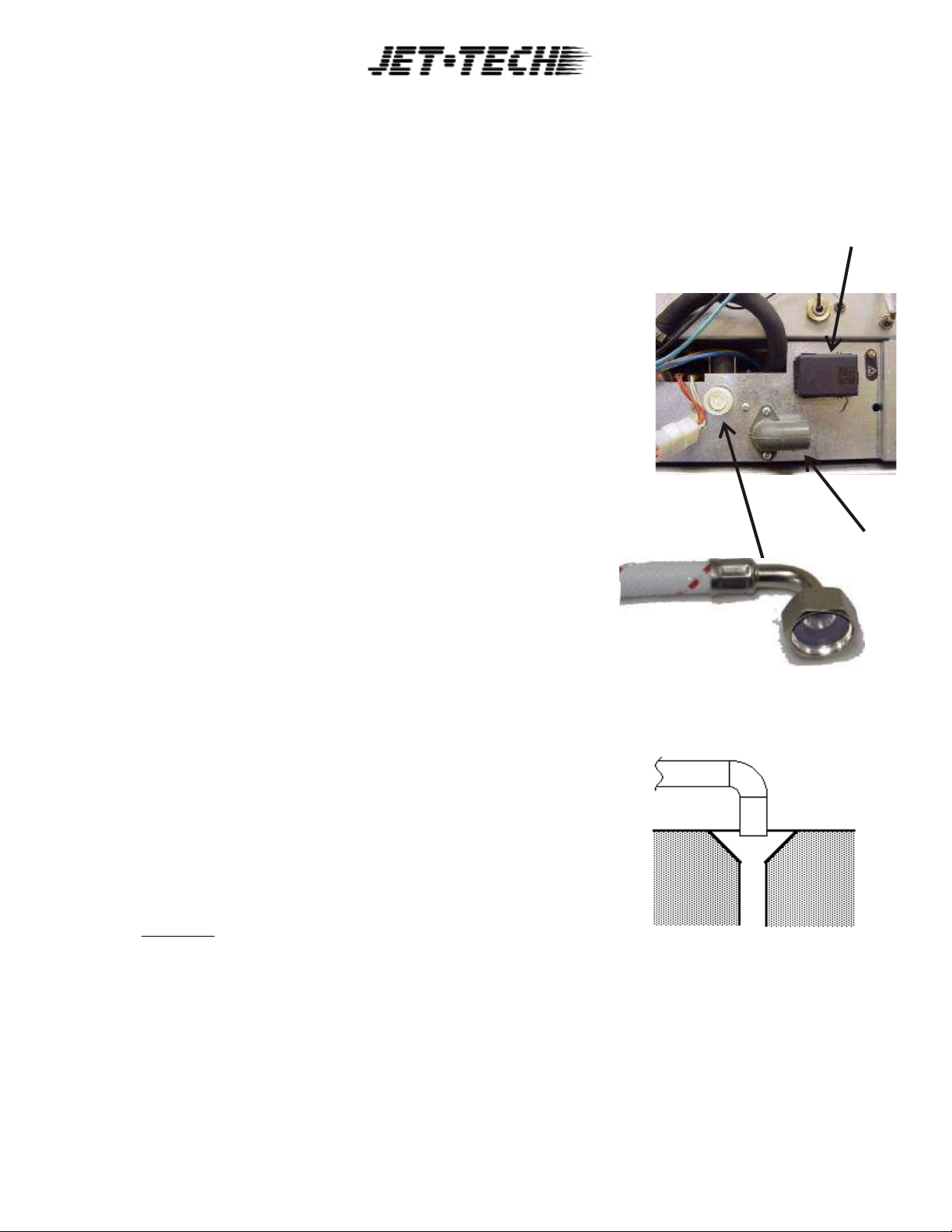

**DRAIN CONNECTION**

This washer has a gravity type drain. Since this unit is a “CounterType” installation, the flexible drain hose provided should be

connected to the drain outlet elbow at the rear of the unit behind the

rear access panel; and extended through the side opening directly

into a floor drain or

sink (see Figure )

All panels must be replaced on the unit when the

installation is completed.

DO NOT

automatically when the power is turned ON.

* - not supplied

** SEE PAGE 6 FOR FURTHER IMPORTANT DETAILS**

manually fill wash tank with water. The dishwasher will fill

7

W

ater

inlet connection

Electrical

Drain

outlet

Page 8

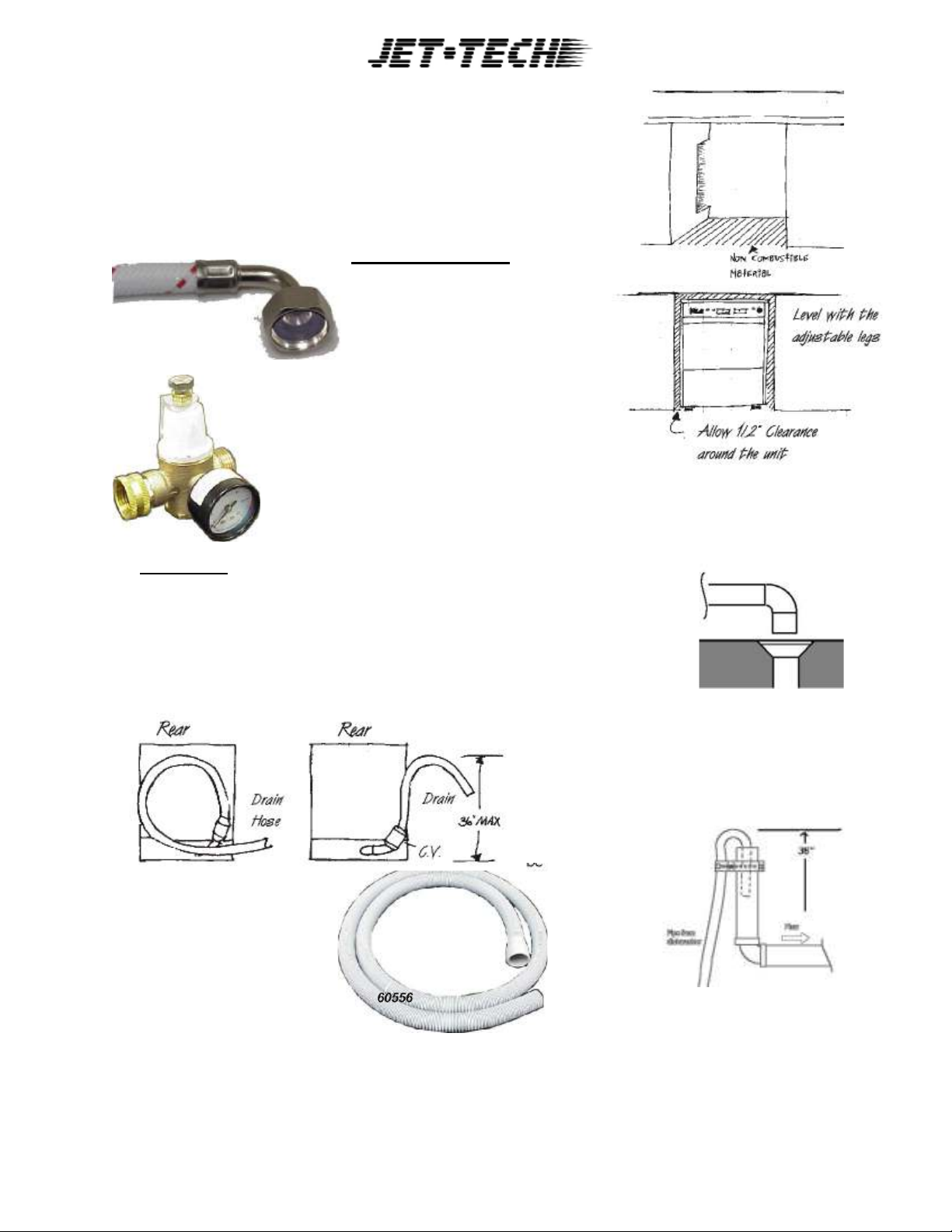

Connecting your new F-16DP

This glasswasher must be installed on a level, rigid, nonflammable

surface. Ensure that the machine is level by installing the feet

(shipped in the wash tank of the machine) and adjusting the leveling.

Be sure to provide adequate space for water, drain and electrical

connections.

**WATER SUPPLY**

A 3/4”NPT fitting is required with 30 psi. dynamic pressure. A water

pressure regulator* may be required. The water pressure cannot be less

than 30 psi or exceed 30 psi. If the water pressure exceeds the

prescribed amount, you will get inconsistent washing temperature,

premature failure and thus may void the warranty.

Incoming water temperature must be 140ºF (60ºC). An easily

accessible shut-off valve is recommended, making installation, service and

maintenance easier. A flexible fill hose is provided to make installation, servicing

and maintenance easier.

Make sure that the water is free from calcium and hard water deposits. For these

situations, an inline water cartridge system is highly recommended. Build-up of

calcium and lime deposits in the washer may occur and servicing will be required

on a more frequent basis which will not be covered by the warranty.

**DRAIN**

·

F-16 DP: This glasswasher is equipped with an automatic drain

pump that will pump the drain water to a maximum height of 36" (0.9

meter). Drain pump equipped machines have a white button on the

control panel beside the green power button.

1" ID flexible drain hose is provided to facilitate maintenance and servicing of the

machine. It is important not to reduce the size of this hose. A 1" check-valve* may be

required. .

ELECTRICAL

A 208-240 volt, 60 Hz, Single Phase circuit is required for this unit. Check the

rating plate on the machine for amp draw. In spite of the fact that the rating

plate shows 208 volts, the unit is designed function properly on 208 volts to

240 volts.

The terminal block is located at the back of the machine. Open the plastic

cover, pass the cable through the cable strain relief and connect the wires to

the L1, L2 & Ground. There should be sufficient cable length to permit the

machine to be pulled out for service. DO NOT turn on the power to the

machine until the water supply & drain lines have been connected. DO NOT

manually fill wash tank. It will fill automatically.

IMPORTANT NOTE

Reasonable access to and around the machine for service must be provided.

Disconnecting of hard plumbing or removal of counter tops or cabinets, etc., for

servicing is not covered by warranty.

* - not supplied

All panels must be replaced on the unit when the installation is completed.

* - not supplied

** SEE PAGE 6 FOR FURTHER IMPORTANT DETAILS**

W

ater

8

In

L1

L2

W

ater

out

Page 9

Connecting your new F-18, F18DP

This dishwasher must be installed on a level, rigid, nonflammable

surface. Ensure that the machine is level by installing the feet

(shipped in the wash tank of the machine) and adjusting the leveling.

Be sure to provide adequate space for water, drain and electrical

connections.

**WATER SUPPLY**

A 3/4” NPT fitting is required with 30

psi. dynamic pressure. A water pressure

regulator* may be required. The water

flow pressure cannot be less than 30 psi

or exceed 30 psi. If the water pressure

exceeds the prescribed amount, you will

get inconsistent washing temperature,

premature failure and thus may void the warranty.

Incoming water temperature must be 140º F (60º

C). An easily accessible shut-off valve is

recommended, making installation, service and

maintenance easier.

A flexible drain hose is provided to make installation, servicing and maintenance

easier. Make sure that the water is free from calcium and hard water deposits. For

these situations, an inline water cartridge system is highly recommended. Build-up of

calcium and lime deposits in the washer may occur and servicing will be required on a

**DRAIN**

·

F-18: This dishwasher has a gravity drain. Maximum height of the floor drain

should not exceed 6" (15cm). A 1.5" ID flexible drain hose is supplied to

facilitate maintenance and servicing of the machine.

·

F-18 DP: This dishwasher is equipped with an automatic drain pump that will

pump the drain water to a maximum height of 36" (0.9 meter). A 1" ID flexible

drain hose is supplied to facilitate maintenance and servicing of the machine. It

is important not to reduce the size of this hose. A 1" check-valve*

more frequent basis which will not be covered by the warranty.

may be required on

drain pump equipped models. Drain pump

equipped machines have a white button on

the control panel beside the green power

button. Conversion from gravity to “DP” is

not possible in the field.

Gravity Drain

* - not supplied

** SEE PAGE 6 FOR FURTHER IMPORTANT DETAILS**

P

umped Drain

9

Page 10

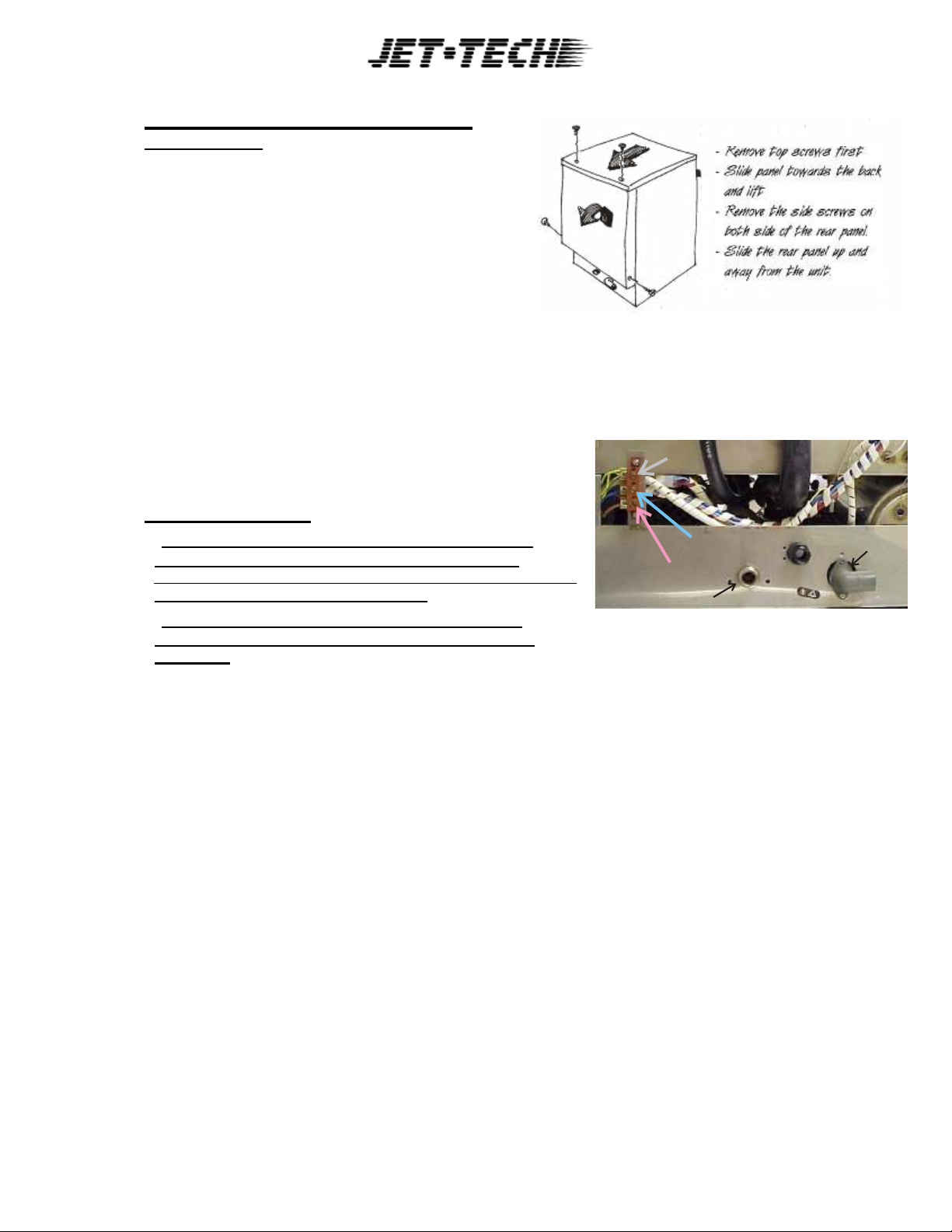

Installation F-18 , continued

ELECTRICAL

A 208-240 volt, 60 Hz, Single Phase circuit is required

for this unit. Check the rating plate on the front of the

machine for the amp draw. In spite of the fact that the

rating plate shows 220 volts, the unit is designed

function properly on 208 volts to 240 volts.

The top & back panels must be removed for the

electrical hook -up. The top panel is secured by two

Phillips head screws. Once the screws are removed,

the panel should be slid to the back and lifted. The

back panel is also held by two screws. Remove them,

pull the bottom away from the machine and lift the

panel.

The terminal block is located inside the back cover. Pass the cable through the cable strain relief and

connect the wires to the terminals L1 (brown wire), L2 (blue wire) & Ground (yellow & green wire). Replace

the top & back panels being careful not to pinch or kink any

wires or hoses. There should be sufficient cable length to

permit the machine to be pulled out for service.

IMPORTANT NOTE

Reasonable access to and around the machine for

service must be provided. Disconnecting of hard

plumbing or removal of counter tops or cabinets, etc., for

servicing is not covered by warranty.

DO NOT fill dishwasher manually with water. The

dishwasher will fill automatically when the power is

turned on.

G

L1

L2

W

ater

In

All panels must be replaced on the unit when the installation is completed.

* - not supplied

10

W

ater

Out

Page 11

Connecting your new F-20

This dishwasher must be installed on a level, rigid, nonflammable surface. Ensure that the

machine is level by installing the feet (shipped in the wash tank of the machine) and adjusting the

leveling. Be sure to provide adequate space for water, drain and electrical connections.

**WATER SUPPLY:**

A 3/4” NPT fitting is required with 30 psi. dynamic pressure. A water

pressure regulator* may be required. The water pressure cannot be less

than 30 psi or exceed 30 psi. If the water pressure exceeds the prescribed

amount, you will get inconsistent washing temperature, premature parts

failure and thus may void the warranty.

Incoming water temperature must be 140º F (60º C). An easily accessible

shut-off valve is recommended, making installation, service and

maintenance easier. A flexible drain hose is provided to make installation,

servicing and maintenance easier.

Make sure that the water is free from calcium and hard water deposits. For these situations, an online water cartridge system is highly recommended. Build-up of calcium and lime deposits in the

washer may occur and servicing will be required on a more frequent basis which will not be

covered by the warranty.

**DRAIN:**

This dishwasher has a gravity drain. Maximum height of the floor drain should not exceed

20" (50cm). A 1.5" ID flexible drain hose is recommended to facilitate maintenance and

servicing of the machine.

ELECTRICAL:

A 208-240 volt, 60 Hz, Single Phase circuit is required for this unit. Check the rating plate on the

machine for amp draw. In spite of the fact that the rating plate shows 208 volts, the unit is designed

function properly on 208 volts to 240 volts.

The top & back panels must be removed for the electrical hook

-up. The top panel is secured by Phillips head screws. Once the

screws removed, the panel should be slid to the back and lifted.

The back panel is also held by Phillips head screws. Remove

them, pull the bottom away from the machine and lift the panel.

The terminal block is located at the top of the machine and can

be accessed by removing the top and back panel. Pass the

cable through the cable strain relief at the back and connect

the wires to the terminals L1 (brown wire), L2 (blue wire) &

Ground (yellow & green wire). There should be sufficient cable

length to permit the machine to be pulled out for service.

DO NOT

manually fill wash tank with water. The dishwasher will fill automatically when the power is turned ON.

IMPORTANT NOTE

Reasonable access to and around the machine for service must be provided.

Disconnecting of hard plumbing or removal of counter tops or cabinets, etc., for servicing

is not covered by warranty.

All panels must be replaced on the unit when the installation is completed.

* - not supplied

** SEE PAGE 6 FOR FURTHER IMPORTANT DETAILS**

11

Page 12

Connecting your new F-22

This dishwasher must be installed on a level, rigid, nonflammable surface. Ensure that the

machine is level by installing the feet (shipped in the wash tank of the machine) and adjusting the

leveling. Be sure to provide adequate space for water,

drain and electrical connections.

**WATER SUPPLY:**

A 3/4” NPT fitting is required with 30 psi. dynamic

pressure. A water pressure regulator* may be

required. The water flow pressure cannot be less than

30 psi or exceed 30 psi. If the water pressure exceeds

prescribed amount, you will get inconsistent

the

washing temperature, premature parts failure and

thus may void the warranty.

Incoming water temperature must be 140º F (60º C). An easily accessible shut-off valve is

recommended, making installation, service and maintenance easier.

A flexible drain hose is provided to make installation, servicing and

maintenance easier.

Make sure that the water is free from calcium and hard water deposits. For

these situations, an inline water cartridge system is highly recommended.

Build-up of calcium and lime deposits in the washer may occur and servicing

will be required on a more frequent basis which will not be covered by the

warranty.

**DRAIN:**

This dishwasher has a gravity drain. Maximum height of the drain should not exceed 20" (50cm).

A 1.5" ID flexible drain hose* is recommended to facilitate maintenance and servicing of the

machine.

ELECTRICAL:

A 208-240 volt, 60 Hz, Single Phase or Three Phase circuit is required for this unit.

Check the rating plate on the machine for amp draw and phase. In spite of the fact

that the rating plate shows 208 volts, the unit is designed function properly from 208

to 240 volts.

volts

The terminal block is located in the control box on the side of the unit. The

faceplate of the control panel pulls out, exposing the terminal block, after the

screws are removed. Pass the cable through the cable strain relief at the back and

connect the wires to the terminals L1 (brown wire), L2 (blue wire), L3 (black wire) &

Ground (yellow & green wire). There should be sufficient cable length to permit the

machine to be pulled out for service.

DO NOT

manually fill wash tank with water. The dishwasher will fill automatically when the power is turned ON.

IMPORTANT NOTE

Reasonable access to and around the machine for service must be provided.

Disconnecting of hard plumbing or removal of counter tops or cabinets, etc., for servicing

is not covered by warranty.

All panels must be on the unit when the installation is finished.

* - not supplied

** SEE PAGE 6 FOR FURTHER IMPORTANT DETAILS*

12

Page 13

F

-22 Dish Table configuration

The F-22 is

design to

received

standard

size dish-

tabling

Below

configurations

with the F

If the soiled

the right

side), the

adjusted down to allocate room

for the sink.

If

you

installation, change the brack

that

to the

.

you

can see the

-22.

(sink) section is on

side

(control

control

need to do a

guides

left

the trays from the front

side

different

that can be done

panel

panel can be

corner

et

.

13

Page 14

Connecting your new 727

This dishwasher must be installed on a level, rigid, nonflammable surface. Ensure that the

machine is level by installing the feet (shipped in the wash tank of the machine) and adjusting the

leveling. Be sure to provide adequate space for water, drain and electrical connections.

**WATER SUPPLY**

A 3/4” NPT fitting is required with 30 psi. dynamic pressure. A

water pressure regulator* may be required. The water flow

pressure cannot be less than 30 psi or exceed 30 psi. If the water

pressure exceeds the prescribed amount, you will get inconsistent

washing temperature, premature failure and thus may void the

warranty. Incoming water temperature must be 140º F (60º C). An

easily accessible shut-off valve is recommended, making

installation, service and maintenance easier. This type hose is

standard for most warewashing machines. Fittings should be

available from your

Flexible hoses must be used to make installation, servicing and

maintenance easier.

Make sure that the water is free from calcium and hard water deposits. For these situations, an online water cartridge system is highly recommended. Build-up of calcium and lime deposits in the

washer may occur and servicing will be required on a more frequent basis which will not be

covered by the warranty.

**DRAIN**

This dishwasher is equipped with an automatic drain pump that will pump the drain water to a

maximum height of 36" (0.9 meter). A 1" ID flexible drain hose is recommended to facilitate

maintenance and servicing of the machine. It is important not to reduce the size of this hose.

There should be sufficient hose length to permit the

machine to be pulled out for service.

local hardware or plumbing supply house.

Electrical

Water In

ELECTRICAL

A 208-240 volt, 60 Hz, Single Phase circuit is required for

this unit. Check the rating plate on the machine for amp

draw. Despite of the fact that the rating plate shows 208

volts, the unit is designed function properly on 208 volts

to 240 volts.

The terminal block is located at the back of the unit.

Open the cover and connect the wires to the terminals

L1 , L2 & Ground. There should be sufficient cable length to permit the machine to be pulled out

for service. DO NOT TURN ON THE POWER TO THE MACHINE UNTIL THE WATER SUPPLY &

DRAIN LINES HAVE BEEN CONNECTED.

IMPORTANT NOTE

Reasonable access to and around the machine for service must be provided. Disconnecting of

hard plumbing or removal of counter tops or cabinets, etc., for servicing is not covered by warranty.

* - not supplied

All panels must be on the unit when the installation is finished.

** SEE PAGE 6 FOR FURTHER IMPORTANT DETAILS**

14

Water Out

Page 15

Connecting your new 737

This dishwasher must be installed on a level, rigid, nonflammable surface.

Ensure that the machine is level by installing the feet (shipped in the wash

tank of the machine) and adjusting the leveling. Be sure to provide

adequate space for water, drain and electrical connections.

**WATER SUPPLY**

A 3/4” NPT fitting is required with 30 psi. dynamic pressure. A water

pressure regulator* may be required. The water flow pressure cannot be

less

than 30 psi or exceed 30 psi. If the water pressure exceeds the prescribed amount, you will get inconsistent

washing temperature, premature failure and thus may void the warranty.

Incoming water temperature must be 140º F (60º C). An easily accessible shut-off valve is recommended,

making installation, service and maintenance easier. This type hose is standard for most warewashing

machines. Fittings should be available from your local hardware or plumbing supply house.

Flexible hoses must be used to make installation, servicing and maintenance easier.

Ensure that the water is free from calcium and hard water deposits. For these situations, an inline water

cartridge system is highly recommended. Build-up of calcium and lime deposits in the washer may occur and

servicing will be required on a more frequent basis which will not be covered by the warranty.

**DRAIN**

This dishwasher is equipped with an automatic drain pump that will pump the drain

water to a maximum height of 36" (0.9 meter). A 1" ID flexible drain hose is

recommended to facilitate maintenance and servicing of the machine. It is important

not to reduce the size of this hose. A 1" check-valve* may be required.

ELECTRICAL

A 208-240 volt, 60 Hz, Single Phase circuit is required for this unit. Check the

rating plate on the machine for amp draw. In spite of the fact that the rating plate

shows 208 volts, the unit is designed function properly on 208 volts to 240 volts.

There should be sufficient cable length to permit the machine to be pulled out for

service.

The top & back panels must be removed for the electrical hook -up. The top panel

is secured by Phillips head screws. Once the screws removed, the panel should be

slid to the back and lifted. The back panel is held by 6 screws. Remove them,

pull the top away from the machine and lift the panel.

The terminal block is located at the back of the machine.

Pass the cable through the cable strain relief at the back and

connect the wires to the terminals L1 (brown wire), L2 (blue

wire) & Ground (yellow & green wire). There should be

sufficient cable length to permit the machine to be pulled out

for service. DO NOT TURN ON THE POWER TO THE

MACHINE UNTIL THE WATER SUPPLY & DRAIN LINES

HAVE BEEN CONNECTED.

IMPORTANT NOTE

Reasonable access to and around the machine for service

must be provided. Disconnecting of hard plumbing or

removal of counter tops or cabinets, etc., for servicing is not

covered by warranty.

* - not supplied

All panels must be on the unit when the installation is finished.

** SEE PAGE 6 FOR FURTHER IMPORTANT DETAILS**

G

W

ater

Out

W

L2

ater

L1

In

15

Page 16

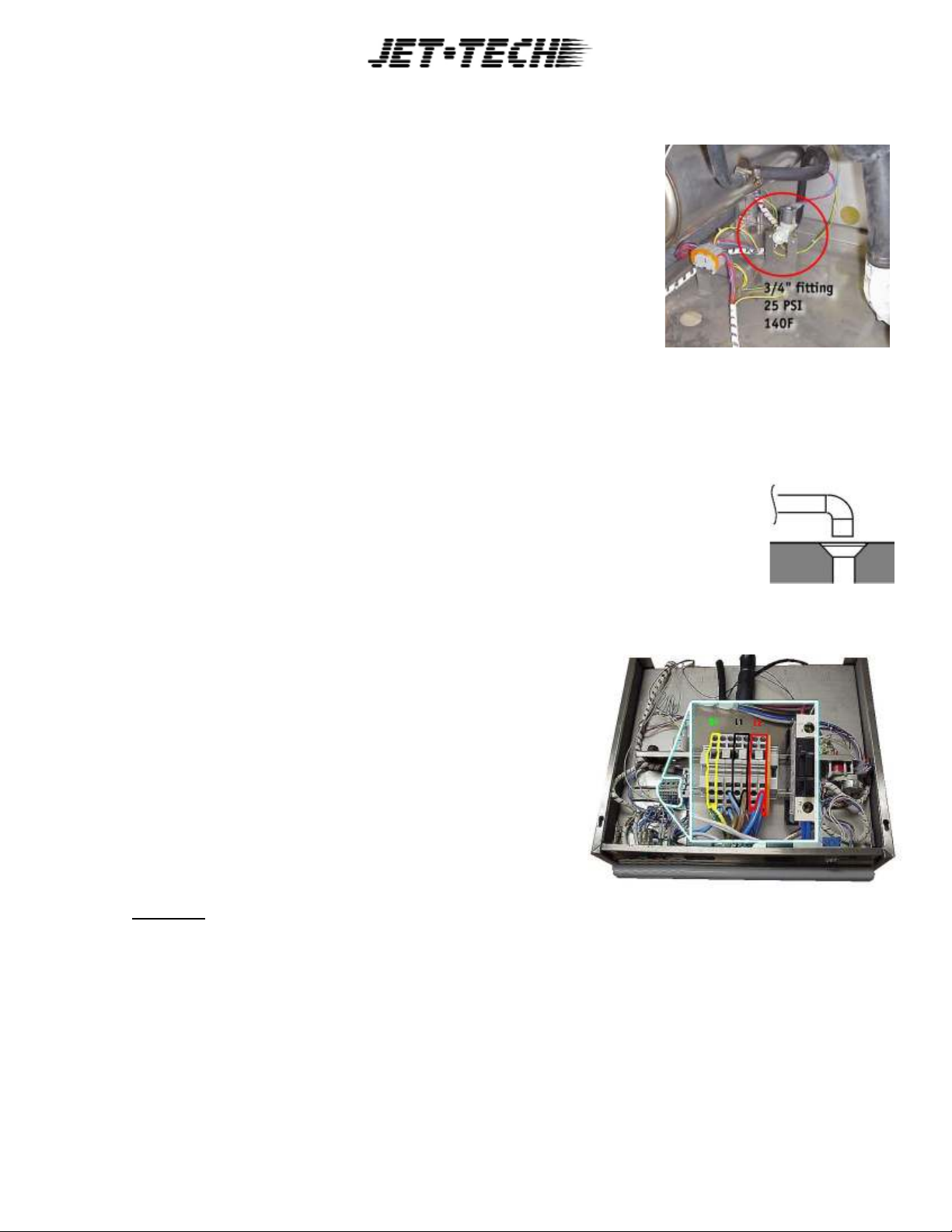

Connecting your new 747

This dishwasher must be installed on a level, rigid, nonflammable surface. Ensure that the

machine is level by installing the feet (shipped in the wash tank of the machine) and adjusting the

leveling. Be sure to provide adequate space for water, drain and electrical connections.

**WATER SUPPLY**:

A 3/4” NPT fitting is required with 30 psi. dynamic pressure. A water pressure regulator* may be

required. The water flow pressure cannot be less than 30 psi or exceed 30 psi. If the water pressure

exceeds the prescribed amount, you will get inconsistent washing temperature, premature parts

failure and thus may void the warranty.

Incoming water temperature must be 140º F (60º C). An easily accessible shut-off

valve is recommended, making installation, service and maintenance easier. This

type hose is standard for most warewashing machines. Fittings should be available

from your local hardware or plumbing supply house.

Flexible hoses must be used to make installation, servicing and maintenance

easier.

Make sure that the water is free from calcium and hard

water deposits. For these situations, an inline water

cartridge system is highly recommended. Build-up of calcium and lime

deposits in the washer may occur and servicing will be required on a more

frequent basis which will not be covered by the warranty.

**DRAIN**:

This dishwasher has a gravity drain. Maximum height of the drain should

not exceed 20" (50cm). A 1.5" ID flexible drain hose is recommended to

facilitate maintenance and servicing of the machine.

ELECTRICAL:

A 208-240 volt, 60 Hz, Single Phase or Three Phase circuit is

required for this unit. Check the rating plate on the machine for

amp draw. Pump rotation must be verified on 3 phase units at time

of install. In spite of the fact that the rating plate shows 208 volts, the

unit is designed function properly from 208 volts to 240 volts.

The bottom cover (under the controls) is snapped in to position and

should be removed. The terminal block is located in the base of the

unit, on the left side.

Pass the cable through the cable strain relief at the back and connect

the wires to the terminals L1 (brown wire), L2 (blue wire), L3 (black wire)

& Ground (yellow & green wire). There should be sufficient cable length

to permit the machine to be pulled out for service.

DO NOT manually fill wash tank with water. The dishwasher will fill

automatically when the power is turned ON.

IMPORTANT NOTE

Reasonable access to and around the machine for service must be provided.

Disconnecting of hard plumbing or removal of counter tops or cabinets, etc., for servicing

is not covered by warranty.

Verify rotation of the pumps for three phase unit.

All panels must be replaced on the unit when the installation is completed.

* - not supplied

** SEE PAGE 6 FOR FURTHER IMPORTANT DETAILS**

16

Page 17

Connecting your new 767

This dishwasher must be installed on a level, rigid, nonflammable surface. Ensure that the

machine is level by installing the feet (shipped in the wash tank of the machine) and adjusting the

leveling. Be sure to provide adequate space for water, drain and electrical connections.

**WATER SUPPLY:**

A 3/4” NPT fitting is required with 30 psi. dynamic pressure. A water pressure regulator* may be

required. The water flow pressure cannot be less than 30 psi or exceed 30 psi. If the water pressure

exceeds the prescribed amount, you will get inconsistent washing temperature, premature parts

failure and thus may void the warranty.

Incoming water temperature must be 140º F (60º C).

A flexible drain hose is provided to make installation, servicing and maintenance easier.

Make sure that the water is free from calcium and hard water deposits. For these situations, an online water cartridge system is highly recommended. Build-up of calcium and lime deposits in the

washer may occur and servicing will be required on a more frequent basis which will not be

covered by the warranty.

**DRAIN**:

This dishwasher has a gravity drain. Maximum height of the drain should not exceed 20" (50cm).

A 1.5" ID flexible drain hose is provided to facilitate maintenance and servicing of the

machine.

ELECTRICAL:

A 208-240 volt, 60 Hz, Single Phase or Three Phase circuit is required for this unit. Check the

rating plate on the machine for amp draw and phase. Pump rotation must be verified on 3 phase units

at time of install. In spite of the fact that the rating plate shows 208 volts, the unit is designed

function properly from 208 volts to 240 volts.

The terminal block is located under the control panel, inside the machine. Pass the cable through

the cable strain relief at the back and connect the wires to the terminals L1 (brown wire), L2 (blue

wire), L3 (black wire) & Ground (yellow & green wire). There should be sufficient cable length to

permit the machine to be pulled out for service.

DO NOT

automatically when the power is turned ON.

IMPORTANT NOTE

Reasonable access to and around the machine for service must be provided.

Disconnecting of hard plumbing or removal of counter tops or cabinets, etc., for servicing

is not covered by warranty.

Verification of the pump rotation is very important!

All panels must be on the unit when the installation is finished.

* - not supplied

** SEE PAGE 6 FOR FURTHER IMPORTANT DETAILS**

manually fill wash tank with water. The dishwasher will fill

17

Page 18

RINSE ADDITIVE

BLUE TUBE

DETERGENT

RED TUBE

F-18DP

CHEMICAL PUMPS

Models 727, 737, 747, 767, F-14, F-16DP, F-18, F-18DP, F-20 & F-22 are supplied with

factory installed liquid detergent and rinse additive pumps to automatically dispense during

each wash & rinse cycle. Before accessing the bottom section of the dishwasher, make sure

that the power is turned off at the

source (breaker panel).

The bottom panel can only be

removed with a flat tool like a screwdriver. Insert the screw-driver in the

gap between the front panel and the

side panel. Pry open towards you.

Do this on both sides.

The red & blue hoses connected to the pumps must be routed out of the

bottom of the dishwasher. The red tube is for detergent and the blue tube is for

rinse additive. The containers can be either to the right or left of the

dishwasher. Perforating the stainless panel is not recommended.

The two chemical pumps are factory adjusted to accommodate most installations.

There is a mark on the pump indicating this setting.

It is recommended that only qualified personnel alter these settings.

UNDER NO CIRCUMSTANCES should the detergent pump be

turned off.

18

Page 19

19

RINSE PRESSURE

20-30 PSI

RINSE FLOW INDICATOR

DETERGENT FLOW INDICATOR

F-18DP

VISUAL CHEMICAL DELIVERY VERIFICATION

The peristaltic chemical pumps are located in the base of the dishwasher. They

feature a transparent cylinder (1) to visually see if fluid is passing through the

pumps. The pumps are automatically energized during the “initial fill” (when

turning on the dishwasher) and “rinse cycle” (after the wash cycle). During this

time, the flow indicator (2) will move between the “Min Flow” position and the

“Max Flow” position (3) in the cylinder. It is normal for the pumps to cycle on and

off.

If the flow indicator (2) does not move during the fill or rinse, no fluid is

circulating through the pump. It is recommended not to use the dishwasher until

this condition is resolved.

TROUBLESHOOTING

30 PSI

1. Ensure that there is sufficient chemical in the container and that the tube is not kinked.

The filter on the end of the tube must reach to the bottom of the container. If the filter or

tube is blocked, remove and soak in warm water to dislodge the obstruction.

2. There may be air in the pump. To “Prime” the pumps (remove the air), turn off and drain

the dishwasher. Replace the stand pipe, close the door and turn on the dishwasher. The

pumps will be activated as the machine fills. The Flow Indicators (2) should start to move

by the time the machine has filled. If not, repeat the drain and fill.

3. The Squeeze Tube (flexible tube inside the pump) is worn or perforated. This part is a

normal wear and tear item that must be replaced periodically (when pump performance

diminishes). Call for Service.

4. The pump does not operate - the roller in the middle of the pump does not turn during the

fill or rinse. Call for Service.

For any other request on set-up and installation, please contact us toll free at 1 888 275 4538

extension 611 or (514) 737-9701 (International)

IMPORTANT: Remember to always use caution and protective gear whenever you are

manipulating chemicals. They can burn the skin. Follow the manufacturer’s instructions carefully.

Page 20

1

8

F-18DP

CONTROL P

ANELS

7

ON

OFF

2

5

4

P

7

3

6

6

5

1

4

3

6

7

1 Green Power Button Switch

2 Power ON Indicator Light

3 Rinse Temperature Gauge

4 Wash Temperature Gauge

1

2

5

3 4

5 “READY” Indicator Light

6 Cycle Start Button

7 Cycle Indicator Light

8 White Drain Pump Button

20

Page 21

BASIC STEPS TO START

Begin with an empty dishwasher. The wash tank should be empty.

Make sure the filter screens and the overflow pipe are in place.

Close the door.

Push the square green button. The dishwasher will take about two minutes

to fill and 20 minutes to heat the water. The booster (rinse) will heat up first

and then the wash tank will heat up.

When the dishwasher is ready, the ready light will come on. This indicates

that the dishwasher has reached optimum temperature.

You can now start washing.

Fill the basket. Only one basket can be used at a time.

Slide it in to the dishwasher.

Close the door and press the round black button. The dishwasher will start

washing for a few minutes. When the wash pump stops, the rinse is about to

start. Verify that the Rinse Pressure Gauge (P.6) is showing 20-30 PSI and

that the Chemical Flow Indicators (P.19) are moving. The rinse continues for

approximately 20 seconds.

When the cycle light (near the start button) goes off, open the door and

remove the tray to let air dry.

If you are ready for another wash, slide a basket in the dishwasher, close the

door & press the Cycle Start Button. If not, just close the door to retain the

heat in the dishwasher and conserve energy.

You should drain the dishwasher at least once a day or when the water is soiled.

The dishwasher should be turned off, drained, cleaned and left empty at night.

To drain the dishwasher, follow these simple steps;

Turn OFF the power.

Pull out the overflow tube (CAUTION: water may be hot)

Press the white drain button (if so equipped) until all the water is gone. Be

careful not to let any debris go down the drain as it may block the pump.

21

Page 22

OPERATION

Before operating the machine, ensure that the electrical power, water supply and drain connections

have been made as per the installation instructions.

Ensure that the overflow pipe is correctly set in its place (inside the wash tank). The overflow pipe

should never be forced into its position. For the first use of the day, the wash tank should not have

any water.

Familiarize yourself with the gauges, buttons and indicator lights on the

control panel.

Check chemical levels. The containers should have sufficient quantities

of Detergent (for wash) and Rinse Additive (drying agent).

Press the Square Green Power Button (1).The Power Indicator Light

will illuminate (as well as the Digital Temperature Gauges , if so equipped).

If the wash tank is empty, the machine will start to fill. Always keep the door

closed during this time. When the machine has filled to its required water

level, the elements will then raise the rinse and wash

water temperatures automatically.

It will take approximately 15-20

minutes in order to obtain the

optimum temperatures (185°F in the

booster and 160°F in the wash tank).

The Ready Indicator Light (5) will

illuminate to indicate that the machine

is ready for its first load.

Fill the basket with dishware and

trays then push the basket into the

machine.

Overflow

Stand pipe

It is more economical to wash

when the basket is fully loaded. It is

also important not to overload the

basket. Water should always be

able to spray freely around the

dishware and trays.

Overflow

Press the round black Cycle Start

Button (6) to start the wash cycle.

On the model 767, set the selector to 2, 4 or 6 minute wash.

Closing the hood on Models F-22, 747 & 767 will automatically start the cycle. The Cycle Indicator

Light (7) will illuminate. The cycle starts and consists of a wash (up to 6 minutes), a brief pause and

then a rinse (from 18 to 25 seconds). Another basket can be filled while the first one is being

washed. The Cycle Indicator Light (7) will extinguish to signal the end of the cycle. It is important to

remove the basket from the machine while they are hot to let the dishes air dry. They will not dry if

left in the machine.

Heater

Water Level

Air Trap

!Do Not Touch

Wash arm

Wash pump

Filter

22

Page 23

IMPORTANT NOTES:

-The

models F-22, 747 and 767

to initiate the wash cycle. Once the unit has filled up with water and the

temperatures have reached their maximums, slide the basket in and close the door.

Closing the door will start the wash cycle. At the end of the cycle, after the cycle

light has switched off, open the door and remove the basket. The cycle light will

come on at that point for a few seconds to reset the timer for the next wash.

- JET-TECH high temperature warewashers do not dump water and fill after every

cycle. The wash water is refreshed during every cycle by the hot

rinse water. Only excess water is expelled from the machine via the overflow

pipe. If the wash water becomes soiled, it is recommended turn off and drain the

dishwasher, clean

all debris from the filters and wash tank and turn on the dishwasher to

fill with fresh water

- Some models are equipped with an automatic drain pump (White button on the

front control panel) that will evacuate excess water. Please see the section

on: DRAIN PUMP OPERATION.

- During the rinse cycle, verify that Rinse Pressure is 30 PSI and that

the Chemical Flow Indicators are moving.

- IMPORTANT: If the dishwasher will not be used for two (2) or more hours, it should

be drained and turned off. The dishwasher should never be left in the “ON” position

and unattended.

differ from the under-counter units in the way

23

Page 24

Jet-Tech F-

BASIC STEPS TO O

18

D

P

PERATE

185 F

Make sure dishwasher is empty (no water)

and the

debris.

filters & wash tank

are clean of

Close the door and press the power

button. Wait

attain optimum washing temperatures.

20 minutes for the water to

165 F

3

Pre-rinse dishes and/or glasses and cups. Load rack in the dishwasher and

close the door. Only one rack at a

time.

2

4

5

Press the Start button.

Wash cycle is 3 minutes

.

Wait for the green light to turn off

before taking the tray out

Take tray out to let dishes air dry

.

6

.

24

Page 25

F-

22

BASIC STEPS TO O

At the start of each day,

ensure dishwasher is empty (no water)

and that the wash tank is clean (no debris)

Pre-rinse dishes, glasses and cups

.

PERATE

1

3

160 F

Close the door,

press the Power B

Wait for the water to obtain

optimum washing temperature

Load rack in the dishwasher

and close the door. Only one rack at a

time.

utton to ON.

.

2

185 F

4

5 6

Close the door to start the wash cycle

.

Wait for the green light to turn OFF

before removing the rack

Repeat from step

3 for more trays.

.

25

Page 26

DRAIN PUMP OPERATION

Models 727, 737, F-16DP and F-18DP are factory built with drain pumps. A square white button

on the control panel beside the green power button also evidences this feature. All other models

have a gravity drain.

Drain pump equipped models will pump the waste water to a maximum height of 36” (0.9 meter). A

1” ID flexible hose of sufficient length is provided to facilitate maintenance and servicing of the

machine. It is important not to reduce the size of this hose. A 1” check valve* may be required. There

should be sufficient hose length to permit the machine to be pulled out for service. Drainage time

should not exceed 1 minute.

The drain pump activates automatically during a rinse cycle and functions when the water fill valve

is open: during the fill and rinse cycles. This allows the removal of excess water entering the unit.

To manually drain the wash tank, you must:

1. -Turn off the machine (square green button on control panel).

2. -Open the door, remove the basket, and remove the overflow pipe (also known as stand pipe).

3. -Press and hold the white button on the control panel, which will activate the drain pump.

Release the button when the water has been discharged.

The most common causes of drain pump failure are:

-Debris was flushed down the drain and blocked the impeller in the pump. Removing the impeller

cover and clearing the obstruction generally restores normal pump function.

-The drain hose, at the back of the unit, is restricted.

IMPORTANT! Pump failure caused by debris blockage is NOT covered by the warranty.

Push and Hold

* - not supplied

26

Page 27

27

Page 28

PROBLEM ANALYSIS

INDEX

1. Constantly fills

2. Dishwasher makes a high

pitch noise when washing

3. Dishwasher overflow

4. Does not operate/start

5. Does not wash properly

6. Filling is too long. Exceeds 3

minutes.

7. Filling is too short (under 1

minute)

>The water level system may have

an air leak.

>>verify the water level system

from the pressure switch to the tube

down to the air trap. Replace the

defective parts as required.

>The air trap may have dirt in it.

>>Clean the air trap.

2. Dishwasher makes a high

8. Machine takes too long to pitch noise when washing

empty. Time exceed 2 minutes.

9. Pilot lamps do not illuminate >The wash tank may have too

10. Spots on glasses much detergent.

11. The wash pump does not >>Too much soap may cause the

operate consistently during a pump to make a high pitch noise.

wash cycle Reduce the detergent amount; and

12. Wash cycle is too short ensure it is of the non-foaming type

used. The mechanical seals may be

PROBLEM

worn. Replace as required.

>CHECK

>>ACTION

1. Constantly fills

>Dishwasher has inactive/not been

drained in a long time (more than

three hours).

>>Switch dishwasher OFF. Pull

over-flow and drain unit completely.

Once drained, clean wash tank and

filters. Put all parts back in. Close

door, switch it ON, and let fill.

>Is overflow tube(stand-pipe)

properly positioned in wash tank?

>>Check for cracks or burrs at

bottom of overflow tube.

>The air pressure switch may be

faulty.

>>Replace switch.

3. Dishwasher overflow

>Drain outlet hose may be blocked.

>>Un-clog or reposition hose or

replace the drain hose.

>Drain pump may be blocked or

defective not allowing proper

drainage of machine.

>>Un-clog or replace drain pump,

as required.

>Incoming water pressure may be

incorrect.

>> If the water pressure is too high

(above 30 psi), you must install a

pressure regulator.

>Regular dishwashing soap may

have been used or has

contaminated the dishwasher

accidentally, causing an excessive

amount of sudsing.

>>Drain the tank, remove as much

28

Page 29

suds as possible. Leave overflow >>Verify all connections.

out, close the door and put power

on. Let unit run for 2 to 4 minutes. >Verify that power is going to the

Turn off unit, put overflow back in, machine.

close the door and refill unit. Try >>Verify the breaker or fuses. Verify

washing. If reoccurs try from the electrical connections to the

beginning again. machine.

>The solenoid valve may have dirt

in it or may be defective.

>>Clean the filter or replace as

required.

4. Does not operate or start

5. Does not wash properly

>Are the scrap screens clean?

>>Clean the scrap screens & filters.

Don't forget the wash pump screen.

>The door micro switch may be >Are the wash/rinse arm jets

defective. clogged?

>>Adjust switch. Some of the parts >>Clean the jets/nozzles. Be

may have to be replaced. careful not to lose the o-rings.

>The momentary relay may be >Detergent system may be

defective or disconnected. defective.

>>All wires must well in place. If so >>Peristaltic hose(s) may have to

replace it. be replaced. The detergent filter in

the container may be clogged or

>The power switch may be worn. Replace. Check the detergent

unplugged or defective. line for deposits. Clean the line if

>>Verify connections and replace necessary.

as required.

>The pressure switch may be faulty. is completed.

>>Adjust switch. Replace as >>Pre-rinse the dishes properly

required. before they are placed into the dish

>The solenoid valve may have dirt

in it or may be defective. >Drain outlet hose may be blocked.

>>Clean filter or replace as Drain pump may be blocked or

required. defective, and is not allowing proper

>The timer may be defective. >>Un-clog, reposition hose or

>>Replace. change drain hose. Un-clog or

>The washing cycle button may be

defective. >Incoming water pressure may be

>>Replace. either too low or too high will result

>The wiring may have a break or >>If the pressure is too low (under

short to ground. 20 psi), check that the valve is fully

>Dishes appear dirty after the cycle

racks.

drainage of machine.

replace drain pump, as required.

in poor rinsing.

29

Page 30

>>Clean the air trap.

opened. If it is, the customer may

need to install a pressure-booster

pump to increase the water pressure.

If the water pressure is too high

(above 30psi), you must install a

pressure regulator.

>Is the wash water clean?

>>Drain the tank, rinse and refill.

>Is the water level in the wash tank

correct?

>>Water level should be just under

the opening of the overflow pipe. Too

little water will cause the wash pump

to draw air. Too much water will keep

the arm from spinning properly and

may cause water to come out the

door. Both cases reduce the

performance of the dishwasher.

>Small specs remain on glasses

after rinsing.

>Have the incoming water analysed.

May need a filtering system.

>The air pressure switch may be

faulty.

>>Replace Pressure switch

>The air trap may have dirt in it.

>The detergent used is of poor

quality.

>>Replace with a better quality

commercial brand or increase

dosage.

>The solenoid valve may have dirt in

it or may be defective.

>>Clean filter or replace as required.

>Wash pump may be clogged or

defective.

>>Open face plate of wash pump for

inspection. Clean wash pump or

replace it if necessary.

6. Filling is too long. Exceeds 3

minutes.

>Incoming water pressure may be

incorrect.

>>If the pressure is too low (under

20 psi), check that the faucet is fully

opened. If it is, the customer may

need to install a pressure-booster

pump to increase the water pressure.

>The stand-pipe may be set

incorrectly.

>>Remove the stand-pipe and check

the seat for dirt.

>The air pressure switch may be

faulty.

>>Adjust or replace as required.

>The air trap may have dirt in it.

>>Clean the air trap.

>The solenoid valve may have dirt in

it or may be defective.

>>Clean filter or replace as required.

7. Filling is too short (under 1

minute)

>The air pressure switch may be

faulty.

>>Adjust or replace as required.

>Incoming water pressure is

probably too high (above 30PSI

flow).

>>Install a water

Pressure Reducing Valve.

>The air trap may have dirt in it.

>>Clean the air trap.

30

Page 31

8. Machine takes too long to

drain. Time exceed 2 minutes.

Should be less than 1 minute.

>Drain outlet hose may be blocked

or kinked.

Drain pump may be blocked or

defective not allowing proper

drainage of machine.

>>Un-clog or reposition hose or

replace the drain hose. Un-clog or

replace drain pump, as required.

>The overflow pipe may be

clogged.

>>Clean out any residue.

9. Pilot lamps do not illuminate

>Pilot lamps may be faulty.

>>Check connections. Replace as

required.

>The power switch may be

unplugged or defective.

>>Verify and replace as required.

>>Verify the breaker.

>>Verify electrical connections

behind the machine

10. Spots on glasses

>Rinse aid pump may need to be

primed or adjusted.

>>Prime or adjust. Replace as

required.

>The rinse agent may be of an

inferior quality.

>>Replace with a quality commercial

brand.

11. The wash pump does not

operate consistently during a

wash cycle

>Machine may not be leveled.

>>Level the dishwasher.

>The air pressure switch may be

faulty.

>>Adjust or replace as required.

>The air trap may have dirt in it.

>>Clean the air trap.

>Water level in wash tank is too low.

>>Adjust pressure switch or replace

as required. Water level should be

level with the stand-pipe opening.

12. Wash cycle is too short

>The timer may be defective.

>>Replace.

IMPORTANT NOTES

Locate and clearly identify the water

shut-off valve that supplies the

dishwasher and the fuse box or

breaker switches.

Only qualified and/or licensed

technician can repair this piece of

equipment. Removing panels exposes

wires and live current. The breaker

should be switched off or fuses

removed before servicing or removing

panels. The water supply must also

the

be

turned off.

Don’t expose yourself injury.

Call Jet-Tech for service or support.

31

Page 32

BLANK PAGE

Page 33

Do you have any questions?

Do you need service?

Phone:

888-275-4538 toll free

(514) 737-9701

Fax:

877-453 8832 toll free

(514) 737-2792

Email: service@jet-tech.com

MODEL:________________

SERIAL:________________

DATE INSTALLED:_______

SERVICE:

33

Page 34

OWNER’S MANUAL

DISHWASHER INSTALLATION,

OPERATION

AND MAINTENANCE

FOR OPERATOR. DO NOT DISCARD

010

Loading...

Loading...