Page 1

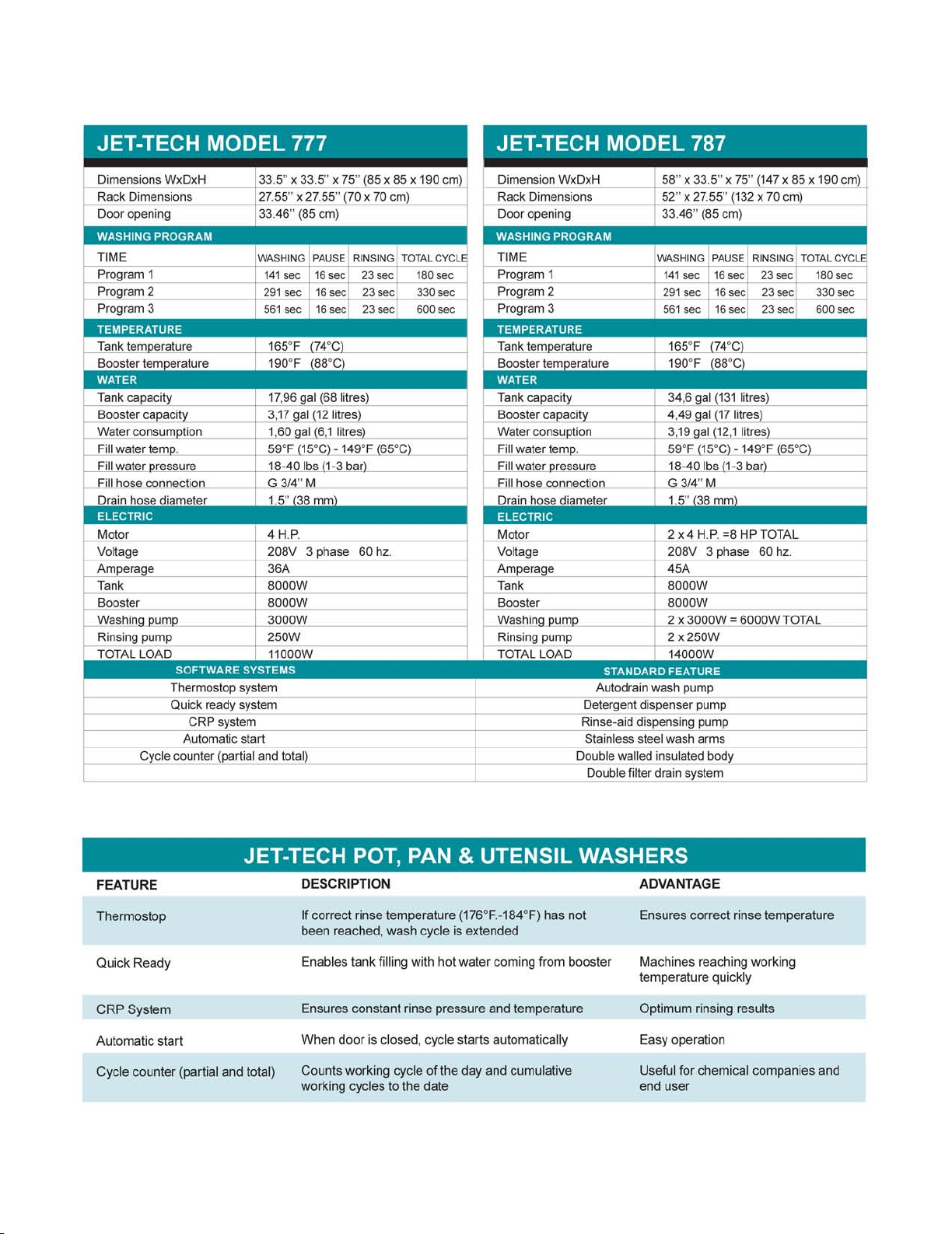

Page 2

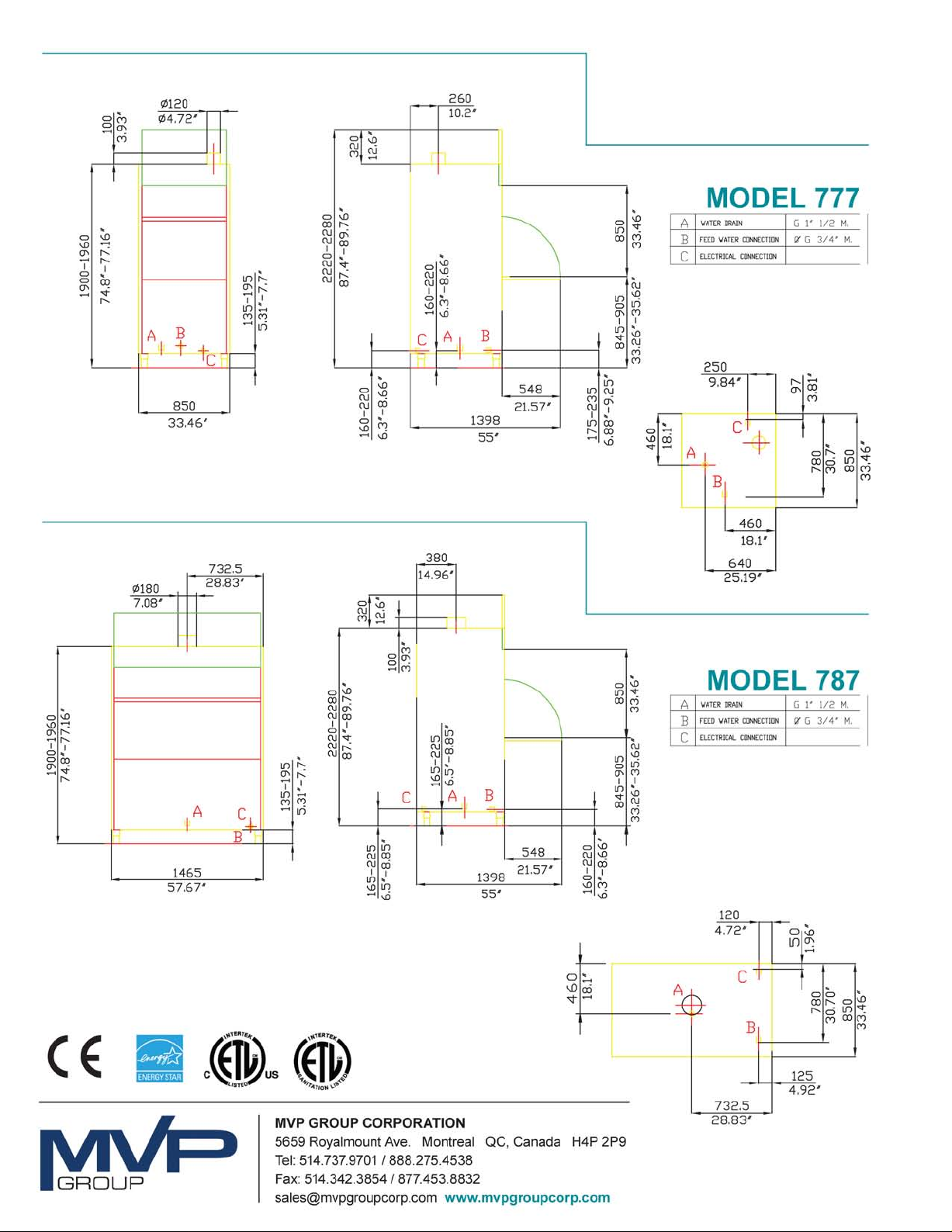

Page 3

Page 4

Page 5

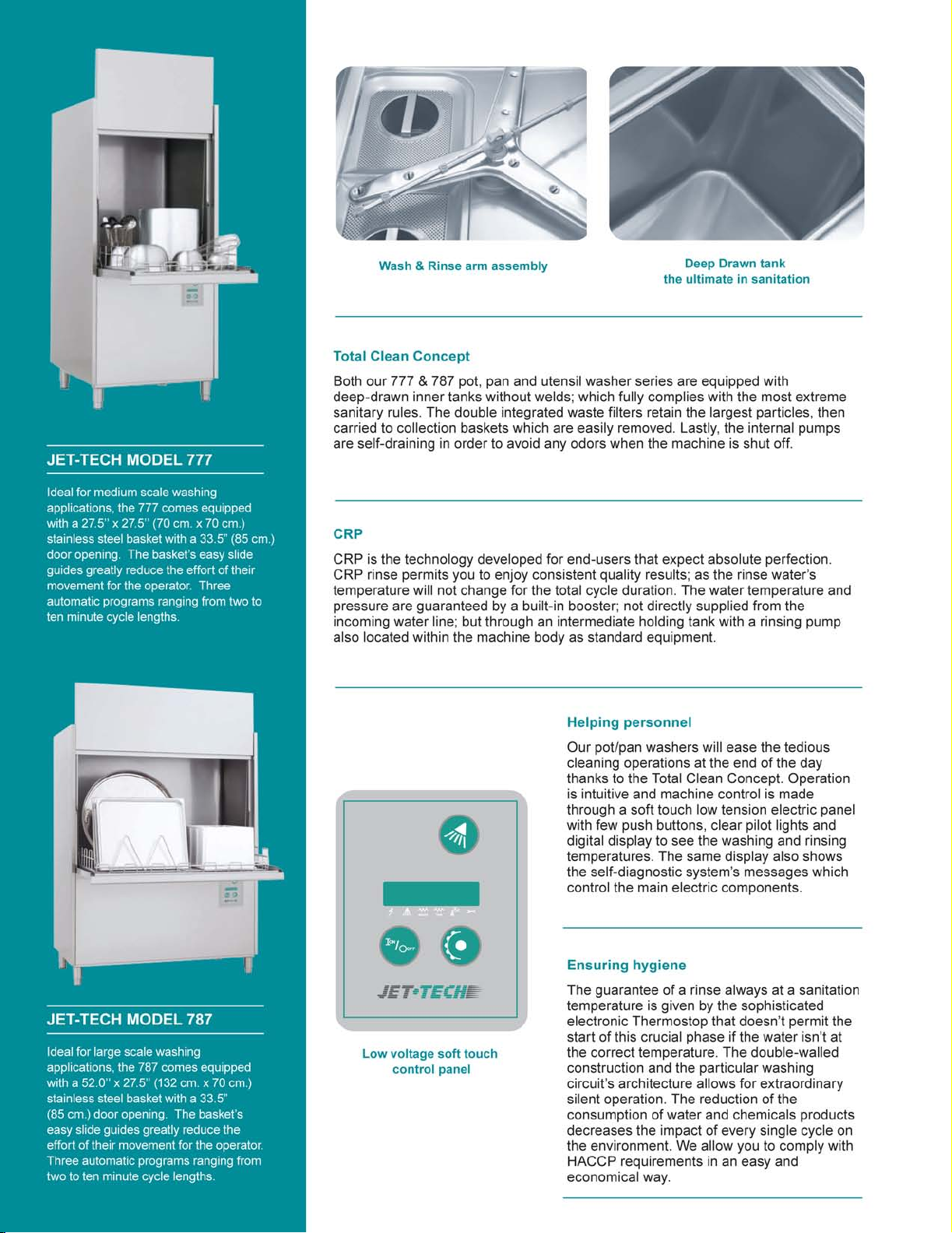

777 & 787

0WNER’S MANUAL

POT WASHER INSTALLATION AND MAINTENANCE

Page 6

POT, PAN & TRAY

WASHER MANUAL

INSTALLATION AND MAINTENANCE

FOR OPERATOR. DO NOT DISCARD

2

Page 7

“Creating endless

possibilities!”

We have included information to help troubleshoot

problems and facilitate resolving those problems.

General information pertaining to our hi-temp ware

washers will be covered in this

manual.

Specific

information on our current and older models is

available upon request, model by model.

If you find any discrepancy or can’t find certain

information, please contact us. We will be glad to be

of

assistance.

MVP GROUP CORPORATION

JET-TECH SYSTEMS

5659

Royalmount Avenue

Montreal, Quebec H4P

Tel.: 888 -275-4538 (888-ASK-4-JET); 514-737-9701

Fax:

877-453-8832;

E-mail: service@mvpgroupcorp.com

2P9

514-737-2792

3

Page 8

MANUFACTURERS LIMITED WARRANTY

MVP GROUP CORPORATION (Jet-Tech Systems) hereby warrants all new warewashers bearing

the name “JET-TECH” and installed within the continental United States of America or Canada to be

free from defects in material and workmanship, under normal and regular usage and operation, for a

period of one (1) year following the date of original installation (unless specified otherwise) but in

no event can exceed eighteen (18) months from the date of shipment from the factory.

This warranty is valid ONLY for the original owner of the “Jet-Tech” unit and is not transferrable.

If a defect in material(s) or workmanship is detected or found to exist within the above stated

period, MVP Group Corp., at its sole discretion, shall either repair or replace any original

equipment manufacturers part which has proven to fail within the machine, providing that the

equipment has not been altered or tampered with in any manner, has been installed correctly as

per the owner’s manual and maintained and operated in complete accordance with this manual.

The labor cost to repair or replace any part proven to be defective, as per above clause(s), shall be

covered by MVP Group Corp., within the continental United States of America or Canada provided

that prior authorization for this labor was approved by MVP Group Corp., the service work was

performed by an authorized MVP Group Corp., service agency and that this agency installed an

original and genuine Jet-Tech part in the machine. Any repair work performed by a non-authorized

service depot remains the sole responsibility of the user and MVP Group Corp., will not be held

responsible. The installation of any generic part will not be valid and therefore voids this

warranty. All authorized labor coverage shall be limited to regular hourly rates only. Any

supplemental hourly rates or charges, such as weekends, holidays or emergency premiums remain

the responsibility of the user.

MVP Group Corp., (Jet-Tech) hereby states that warranty travel time shall be limited to and

without exception, a round-trip total of two (2) hours OR mileage up to a maximum of one hundred

(100) miles (160 KM) round-trip. Any charges exceeding those stated herein must have prior

authorization by the factory or will be at the customer’s expense.

Exceptions to above warranty are: (A) Damages resulting from shipping, handling or abuse. (B)

Incorrect installation and/or connections. (C) Adjustments or calibration of any parts. (D) Faults due

to lack of regular maintenance or cleaning of any internal part(s). (E) Replacement of any wearable

items such as peristaltic squeeze tubing or gaskets. (F) Excessive lime, mineral, alkali or hard

water conditions (In excess of 6 grain) and (G) Poor results due to use of an incorrect type of

detergent or rinse additive (for non-commercial type applications or products containing chlorine)

and excessive or inadequate water temperature(s) or pressure conditions or incorrect use.

MVP GROUP CORPORATION STATES THAT THERE ARE NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, THAT ARE NOT SET FORTH HEREIN, MVP GROUP

CORPORATION SHALL ASSUME NO OTHER RESPONSIBILITY, EITHER DIRECT OR NON DIRECT OR BE LIABLE FOR ANY OTHER OR ADDITIONAL LOSS OR DAMAGE WHETHER

BEING DIRECT OR CONSEQUENTIAL, AS A RESULT OF ITS EQUIPMENT.

Warranty: One year parts & labor (Continental USA and Canada).

The manufacturer reserves the rights to alter design and specifications without notice.

4

Page 9

TABLE OF CONTENTS

CREATING ENDLESS POSSIBILITIES........................................................................3

WARRANTY…………………………………………………………………………………….4

Table of Contents……………………………………………………………………………..4

Section 1 Introduction…………………………………………………………………………………….6

Section 2 POT WASHER HANDLING AND TRANSPORT .......................................................... 7

2.1 Transport and packing ........................................................................................................ 7

2.2 Handling .............................................................................................................................. 7

Section 3 DANGER ZONES AND SAFETY MECHANISMS ........................................................ 7

3.1 Danger of burns: ................................................................................................................. 7

3.2 Hazardous electric current: ................................................................................................. 7

3.3 Safety devices: .................................................................................................................... 7

Section 4 INSTALLATION ............................................................................................................ 8

4.1 Removal from packing and positioning: ............................................................................. 8

4.2 Electrical connections: ....................................................................................................... 8

4.3 Plumbing connections: ........................................................................................................ 9

4.4 Drain connections:

4.5 Controls and Adjustments: .................................................................................................. 9

4.6 Activating the detergent and rinse aid chemical pumps...................................................... 10

4.7

Calibrating

4.8

Calibrating the

the rinse aid pump ........................................................................................... 11

4.9 Important Notes: .................................................................................................................

Section 5 POT WASHER USE .................................................................................................... 14

Auxiliary connections for external roof vents or chemical pumps………………………………13

5.1 Pot Washer Use: ............................................................................................................. 14

5.2 Setting up the pot washer for use: .................................................................................... 14

Automatic machine loading: ............................................................................................. 14

5.4 Wash start. ........................................................................................................................ 14

5.5 Drain cycle. ....................................................................................................................... 15

5.6 Temperature and cycle number display. ........................................................................... 16

5.7 Machine use precautions : ................................................................................................ 16

5.8 Operations to be performed at the end of the work cycle ................................................ 16

Section 6 MAINTENANCE .......................................................................................................... 17

6.1 General provisions: ........................................................................................................... 17

6.2 Periodic Maintenance………………………………………………........................................ 14

6.3 Do’s and Don’ts with the pot washer................................................................................ 17

6.4 Self-diagnosis.................................................................................................................... 18

Section 7 DISMANTLING ............................................................................................................ 18

5

……………

............................................................................................... 9

detergent pump: ........................................................................................ 12

13

Page 10

Section

1 INTROD UCTION

This manual provides important information about installation,

washer. It is important that you read it carefully.

Proper installation and regular maintenance will ensure you years of reliable operation and perfect washing results of

your pot washer.

Please consult

contained in this manual may cancel the warranty. We recommend you retain this manual for future reference.

with JET-TECH

for any need for service. Please keep in mind that non-compliance with the instructions

We remind you that the warranty does not cover:

Damage caused by transport. If this should occur, the customer must note the damage on the carrier’s bill of lading,

immediately upon receipt of the unit.

Damage caused by incorrect installation. It is therefore compulsory that installation and testing be performed by

qualified and skilled personnel.

Damage caused by any use other than that for which the machine has been manufactured.

Damage caused by non-compliance of the provided instructions.

The installer must:

Check for proper electrical circuit and circuit breaker of sufficient capacity carry the load as indicated on the rating

plate.

Make sure that circuit breaker is

Test the machine and make sure there is no malfunction.

Inform and train the personnel in charge of operating the machine about its use and the hazards it generates.

Agree with the user on a periodic check of the machine according to how much the machine is used.

well identified

TERMINOLOGY

The terms “main switch”, “on-off valve” and “drain line” are used in this manual with the following meanings:

.

operation

and maintenance of the pot/pan & utensil

Main switch:

On-off valve:

Drain line:

The pot washer must be on a dedicated electrical circuit.

The circuit must be protected with a circuit breaker with thermal magnetic tripping mechanism able to completely

cut off the power supply from the pot washer.

An

on-off gate or ball valve able to quickly and completely turn off the water supply.

It must be installed

and must be easily accessible.

It must supply only the pot washer.

It must have a suitable size for draining double the flow rate indicated in the table.

in close proximity to

the pot washer

6

Page 11

SECTIO N 2 POT WASHER HANDLING AND TRANSPORT

2.1 Transport and packing

The pot washer must be transported using suitable means.

The appliance must be packed in a cardboard box on a wooden pallet.

2.2 Handling

The lift points are indicated on the packing box. The

pot washer must be handled using a

jack

. Do not sling the pot washer with ropes.

fork

lift

or pallet

SECTIO N 3 DANGER ZONES AND SAFETY MEC HANISMS

Identification of the danger zones and relevant type of hazard and general description of the safety measures.

3.1 Danger of burns:

On the booster and rinsing circuits during machine installation and maintenance.

3.2 Hazardous electric current:

On the main electrical control panel.

On washing, rinsing and chemical pumps.

On electric elements.

Protection of the pot washer's hazardous parts

The panels are the protection that limits access to the internal components.

The panels are fixed with screws.

Residual risks

Do not open the hood or door of the pot washer before the washing cycle has ended.

Do not introduce bare hands in the washing tank.

Do not remove the machine panels before disconnecting the power supply.

3.3 Safety devices:

Magnetic micro switch

Device that interrupts filling, washing and rinsing operations when the hood or door is opened.

Thermal overload protec tion element

The wash pumps are incorporated with an automatic reset thermal switch which cuts off the motor’s electric

power supply in case of irregular operation.

Safety thermostat

In case of a thermostat malfunction, a secondary safety contact thermostat with manual reset comes into

operation and interrupts power to the elements.

7

Page 12

SECTI ON 4 INSTALLATION

4.1 Removal from packing and positioning:

Make sure that the pot washer is in perfect condition. In case of damage, you must immediately contact the

freight forwarder. In case of doubt concerning the pot washer condition,

have

the unit

The installation must be performed exclusively by qualified technicians, according to the JET-TECH’s

instructions.

Move the pot washer where you wish to install it and remove the packing.

checked by an authorized service centre before being put into use.

This pot washer is designed for fixed connections only.

Position the pot washer on a flat surface.

Install electrical, water and drain lines in the washing area according to the instructions provided on the

machine's technical data sheet. Further details are indicated in the paragraphs relative to plumbing and

electrical connections.

Before connecting the pot washer to the water and electrical supply, please consult the data plate on the pot

washer. All services on site must be in compliance with the pot washer requirements.

The floor must be measured taking the overall weight of the machine into consideration. It must also be

perfectly flat.

NOTE: to connect the pot washer to work tops, couple the supports on the edges of the tank and fix them using the

screws provided. The connection can be either on the front or side.

4.2 Electrical connections :

“The pot washer shall be installed in accordance with local codes, or in the absence of local codes, installed

in accordance with the applicable requirements in the National Electrical Code, NFPA 70, Canadian

Electrical Code (CEC), Part 1, CSA C22.1, and Standard for Ventilation Control and Fire Protection of

Commercial Cooking Operations, NFPA 96”

When connecting the pot washer to the power supply, refer to the wiring diagram and the data plate of the

pot washer.

Make sure that the voltage and frequency of the power supply correspond to those on the plate indicating the

technical

Install a “main switch” (not provided) on the electrical line that supplies the pot washer in compliance with the

requirements of the local electrical standards.

The incoming power cable from the main switch (not provided) will be connected to the terminal

block located inside the machine.

The power cable must be rated for at least

The power cable must be copper conductors only.

Before

Before

label near the terminal block)

An effective ground connection in conformity with the prevention standards is

equipment.

On the three-phase models, check for correct rotation of the wash pump.

characteristics located on the right side of the machine.

165°F (

the

supply connections check minimum supply conductor amp capacity (see label near the terminal block).

the

supply connections check maximum rating of supply overcurrent- protective

75°C).

device

required

for operator

8

(see

safety

and

Page 13

Note

minimum washing temperature

158 °F (70°C)

minimum rinsing temperature

190 °F (88°C)

minimum wash time

320 sec.

minimum rinse time

23

sec.

Filling hose

26.4 mm (3/4")

Max. incoming water temperature

140 °F (60 °C)

Min. incoming water pressure

14.5psi (100 kPa)

Max. incoming water pressure

50 psi (345 kPa)

Water hardness (recommended)

6 grains

Water flow rate

5.3 gpm (20 l/min.

)

: If repairs on the electric circuit must be performed, disconnect from the mains and apply a tag on the switch indicating

repairs are in progress.

4.3 Plumbing connections:

To connect the pot washer to the water network make sure that:

There is a “gate valve” that is able to interrupt the water supply when necessary or in case of repair.

A supply pipe has adequate capacity for each appliance in order to avoid any load or pressure drops.

A pressure reducer complete with by-pass has been installed upstream, if the static pressure is greater than

345 kPa (50 psi).

Then connect the filling solenoid valve to the water supply tap using the hose provided.

4.4 Drain Connection:

The wash tank empties by gravity, so the drain needs to be situated below the base

of the machine.

The drain pipe needs to be connected to a drain- trap built into the floor.

The table below indicates the requirements and default settings of the pot washer:

4.5 Adjustment and controls:

To display the temperatures and cycle number.

Warning, only for machines without rinse aid and detergent dispensers :

“This machine must be operated with an automatic detergent pump and, if applicable, an automatic

rinse additive pump, including a visual means to verify that detergents and rinse are delivered or a

visual or audible alarm to signal if detergents and rinse are not available for delivery to the respective

washing and rinsing systems. Please see instructions for electrical and plumbing connections located in

this manual.”

By keeping the C button pressed for approximately 4 seconds, the instant temperature of the booster and of the

tank, as well as the number of daily cycles and of the machine's life cycles, can be displayed.

9

Page 14

4.6 Calibrating the detergent and rinse aid pumps

The chemical pumps are set in the "OFF" position at the factory. Once the machine is installed, it is

necessary to activate and calibrate the detergent and rinse aid measuring devices by following these

instructions:

Turn off the machine, lift the hood or open the door and keep the C and D button s pressed for 5 seconds.

The following will then appear:

Display the following by using the C button:

Confirm the entry to the main menu mode using the D button

Then scroll the various menu items using the A button until the following appears:

“detergent pump”

Now it is possible to enable the measuring device by keeping button D pressed

:

The word off switches to on. Keep it on until it is apparent that the detergent delivery pipe has become filled.

Again pressing the button go to the wordin g “rinse aid pump”.

Fill the rinse aid measuring device pipes following the same instructions provided for the detergent

measuring device.

10

Page 15

4.7 Adjusting the amount of rinse aid

The quantity of rinse aid can be adjusted by determining the measuring device on/off time.

Follow these instructions:

Turn off the machine, lift the hood or open the door and keep the C and D buttons pressed for 5 seconds.

The following will then appear:

Display the following by using the C button:

Confirm the entry to the main menu mode using the D button

Then scroll the various menu items using the A button

until the following appears:

“rinse aid” with the on time expressed in seconds specified.

The on time can be modified by acting on the following buttons:

The measuring device operation is disabled when the value 0 is set.

11

Page 16

The set time will be automatically saved. To exit this mode just keep the A button pressed until the machine-off dashes are

displayed.

We recommend you set the most appropriate value according to the manufacturer’s recommended dose.

Perform a few test washes to complete the adjustment stage.

4.8 Detergent measuring device adjustment:

The quantity of detergent can be adjusted by determining the measuring device on/off time.

Follow these instructions:

Turn off the machine, open the door and keep the C and D buttons pressed for 5 seconds.

The following will then appear:

Display the following by using the C button:

Confirm the entry to the main menu mode using the D button

Then scroll the various menu items using the A button until the following appears:

“detergent” with the on time expressed in seconds specified.

12

Page 17

The on time can be modified by acting on the following bu ttons:

The set time will be au tomatically saved. To exit this mode just keep the C button pressed until the machine- off

dashes are displayed.

We recommend you set the most appropriate value according to the manufacturer’s recommended dose.

Perform a few test washes to complete the adjustment stage.

CAUTION: This menu features items whose setting must not be modified. If some parameters are modified

accidentally, just set the KEY 10 to reset to the default values.

4.9 IMPORTANT NOTES:

We recommend you carefully follow the instructions below in order to maintain the pot washer in perfect and safe

operational conditions:

Use the appliance only for the purpose it has been designed for.

Any other use is considered improper and dangerous.

Use the appropriate basket for the product being washed. A general purpose open basket for large items &

bakery tray basket are supplied with the machine.

During Transport or delivery, do not leave the machine

DO NOT bypass the safety devices of the machine (micro switches, thermostats) envisaged by the manufacturer.

DO NOT operate the machine if it is not connected correctly and all safety devices are not operating.

Have any repair performed only at the manufacturer’s premises or at authorized service centers; only genuine

spare parts must be used.

Failure to follow these instructions may jeopardize safety of the machine.

Do not leave the machine on if not in use.

We recommend you do not use steel brushes or sponges, acid products and corrosive substances to clean

stainless steel.

The overflow tube must be installed in the wash tank before turning on the pot washer for use.

Before

draining

Never move any magnetic objects close to the machine as it could start, even with the

open. Never use the door as a support surface.

Do not wash the machine using direct jets of water.

Always close the water supply when the machine is not being used (see Section 4.3).

Never open the machine hood quickly if it has not finished the cycle.

Never immerse bare hands in the washing solutions.

Never remove the machine panels if the upstream electricity supply has not been previously disconnected.

The machine must not be used by untrained personnel.

Never use the machine without protections.

Do not use the machine to wash objects of shapes, types and sizes that are not compatible with those declared

by the manufacturer.

Turn off the machine immediately using the main switch if you notice any water leaks coming from the machine.

Auxiliary connections for external roof vents or chemical pumps

To connect your own external devices to this machine, you may use the

and/or safety contactor. This signal must only be used to activate the coil on an auxiliary relay 208V (not supplied). A

step down transformer may be required (not supplied). Do not use internal power from the pot washer to power your

devices. Please contact MVP Group if additional information is required.

MVP Group is not responsible for any external devices connected to the pot washer or any malfunction of the pot

washer caused by an improperly installed external device.

the machine, always turn it off.

outside,

exposed to

SIGNAL

the elements.

door

from the wash pump contactor

13

Page 18

SECTIO N 5 POT WASHER USE

A : turning the machine on

B : display

C : temperature display / cycle selection

E: machine on lamp

F: automatic start signaling lamp

G: booster heating indicator lamp

H : tank heating indicator lamp

I : machine water loading indicator lamp.

L : machine “safe mode” lamp

Open the wall-mounted water valve

Switch on the wall-mounted line switch

Place the overflow and washing filters in their envisaged positions

Checks :

Before using the pot washer the following checks must be performed:

The water level inside the tank must be 10 mm (3/8”) from the edge of the overflow.

The washing and rinsing arms must rotate freely, moved by the water pressure.

The washing and rinsing temperatures must correspond to the temperatures indicated in the table.

The dispenser must pick up the correct quantity of agent at each washing cycle. At the end of the washing cycle, the

perfectly cleaned glassware will dry immediately due to evaporation when the basket is removed from the machine.

5.3 Automatic machine loading :

5.1 POT WASHER USE :

5.2 Setting up the pot washer for use:

Turn on the machine using the A button.

The machine starts loading, the E lamp indicates that the machine is on,

whereas the I lamp indicates that the loading cycle is in progress.

After loading, the machine automatically starts to heat first for the booster, then for the tank.

14

Page 19

When the pot washer emits a

the machine is ready for use.

“beep”

and the D button lights up green,

Open the door, introduce a basket of kitchenware to be washed, then select the washing program by pressing the C button

repeatedly. The selected program can be viewed on the display.

5.4 Wash start.

PW1 = Short washing program

PW2 = Intermediate washing program

PW3 = Intensive washing program

Close the door and press the D button to start the cycle. The button will light up blue for the entire duration of the

cycle; the machine will start the first cycle.

During the washing stage, the tank water temperature will be displayed first, then the rinsing

Note:

We recommend you disconnect the automatic start at the end of the work cycle by keeping the D button pressed until the

F lamp switches off, then close the hood or door; the machine will restart only by pressing the D button again

temperature; at the end of the cycle a “beep” will be heard and the display will show the word End.

If the F lamp is on, it means that the next washing cycles will start automatically when the hood or the

door is closed.

.

5.5 Drain cycle.

Open the door, remove the upper filters and all food residue, then remove the overflow.

15

Page 20

5.6 Temperature and cycle number display.

By keeping the C button pressed for approximately 4 seconds, the instant temperature of the booster and of the

tank, as well as the number of daily cycles and of the machine's life cycles, can be displayed.

5.7 Machine use precautions:

Use industrial-type detergent, possibly without foam.

Do not introduce bare hands into the washing water. Arrange cups and glasses upside down inside the baskets.

Arrange the dishes in the appropriate basket on the support pins, with the internal surface positioned upward.

Arrange silverware and teaspoons with the handles positioned downward.

Do not place silverware and stainless steel knives in the same basket. This could make the silverware darken and

could corrode the steel.

Use the suitable basket for all types of crystalware (dishes, glasses, cups, silverware, etc.). To reduce the

consumption of detergent and electricity, wash only when the baskets are full, but be careful not to overload them.

We recommend you make a preliminary wash. The wash quality can be notably improved if any food residue, lemon

peel, toothpicks, olive stones, etc., which could partially obstruct the pump filter and affect the wash efficiency, are

removed before washing.

5.8 Operations to be performed at the end of the work cycle

Perform the drain/cleaning cycle of the machine.

Turn off the machine.

Lift the cover and remove the cleaned dishes.

Drain the water from the tank by lifting the overflow.

Switch off the main switch of the machine.

Remove the filter and clean it thoroughly.

Clean and rinse the inside of the kitchenware thoroughly. Remove any residual grime with a cloth or a soft brush and

a mild detergent. Rinse. Do not allow food residue to accumulate on the bottom of the tank.

Leave the machine cover open to let the inside dry out.

Always make sure that all washing and rinsing nozzles are free from lime or solid residue.

NOTE:

Do

not wash the appliance with direct or high-pressure jets since any infiltrations in the electrical components

may jeopardize correct operation of the equipment and the single safety devices, with risk of the warranty being revoked.

16

Page 21

SECTIO N 6 DAILY MAINT ENANCE

6.1 General provisions:

Although the machine has been designed to require minimum maintenance, the following rules must be followed

m

aintain the machine in proper operating conditions.

Keep the pot washer clean and in good condition.

If the water hardness is over 70 ppm, a water softener may be required. If a water hardness is not installed,

periodic descaling may be required including the booster tank. Consult your chemical supplier.

Use protective gloves

Always

turn off and drain

when

cleaning the pot washer. Hot water or chemicals may cause skin irritation.

the pot washer before cleaning.

6.2 PERIODIC MAINTENANCE

to

To make the following operations easier, the basket support frame can be removed from its position.

Remove the upper and lower rinsing arms by unscrewing the relevant connections.

Unscrew and clean all the nozzles, then remount them.

Remove the upper and lower washing arms by unscrewing the rinsing pin, then clean and rinse them.

Remove the washing pump filter, then clean and rinse it.

Clean the washing tank thoroughly.

Leave the hood or door open for all the time it is not used.

Lime deposits build up on the internal surfaces of the booster, pipes, etc. due to the magnesium and calcium salts in the

water. The lime and these deposits may jeopardize correct operation of the appliance; it is therefore necessary

to have the lime removed periodically by an expert.

If the appliance is not used for a prolonged time, lubricate the steel surfaces using liquid paraffin.

Have the booster and washing pump drained completely by an expert so as to prevent ice formation.

If the machine is not working correctly or in case of failure, contact an authorized service centre.

6.3 DOS AND DON’TS WITH THE POT WASHER

MAKE SURE that the water hardness is correct.

MAKE SURE that the dishes have been pre-cleaned.

MAKE SURE that only the detergents recommended by a chemistry expert are used.

MAKE SURE that the machine is cleaned thoroughly, rinse it and let it dry (leaving the doors open) at the end of the day.

MAKE SURE that the lime removal program recommended by a chemistry expert is followed.

MAKE SURE that only products especially formulated for stainless steel are used.

DO NOT exceed with the detergent, sanitizer, rinsing or anti-lime agent concentrations recommended by the

manufacturer of those chemical substances.

DO NOT use steel wool to clean the items to be washed or the pot washer surface.

DO NOT let foreign bodies, especially metal contaminants, enter the machine.

DO NOT use the pot washer without filters.

NOTE: failure to follow the use, care and maintenance instructions may void the warranty.

17

Page 22

Error code

Message displayed description

ER 02

TANK WATER DRAIN

FAILED

The alarm is displayed when the drain motor pump cannot drain the

tank correctly. For example, the overflow was not removed or the

main drainage is clogged.

ER 03

BOOSTER HEATING FAILED

Problem in the booster elements. When this message is

displayed, the booster heating and Thermostop are automatically

ER 04

LOADING FAILURE

The alarm is displayed when the machine does not load water

properly.

ER 05

TANK PROBE OPEN

This alarm means that the tank temperature sensor is not working

properly.

ER 06

TANK PROBE SHORT-

CIRCUIT

This alarm means that the tank temperature sensor is not working

properly.

ER 07

BOOSTER PROBE OPEN

This alarm means that the booster temperature sensor is not

working properly.

ER 08

BOOSTER PROBE

SHORT*

This alarm means that the booster temperature sensor is not

working properly.

ER 09

BOOSTER LOADING

FAILURE

The alarm is displayed when the booster does not load

water properly.

HIR

BOOSTER

TEMPERATURE

The alarm is displayed when the booster temperature is too high.

HIW

TANK TEMPERATURE TOO

HIGH

The alarm is displayed when the tank temperature is too high.

SA FE

This alarm is displayed when any safety temperature thermostat

has intervened.

WNC

REPLACE TANK WATER

This message is displayed when the wash water has not been

replaced for 1 working day.

A drain cycle is required.

ER 23

TANK HEATING FAILED

Problem in the tank elements. When this message is displayed, the

tank heating and Thermostop are automatically disabled.

6.4 Self-diagnosis

The machine is able to recognize various alarm or malfunction situations. Every malfunction is signaled by messages generated on the

display; the L lamp lights up and the machine runs in "safe mode", i.e. with limited functions.

SECTIO N 7 DISMANTLING

Machine dismantling

There are no materials on our machines that require special disposal procedures.

18

19

Page 23

Page 24

20

Page 25

21

Page 26

MVP GROUP CORPORATION

JET-TECH SYSTEMS

5659

Royalmount Avenue

Montreal, Quebec H4P

Tel.: 888 -275-4538 (888-ASK-4-JET); 514-737-9701

Fax:

877-453-8832;

E-mail: service@mvpgroupcorp.com

2P9

514-737-2792

Page 27

JET - TECH

777

(208V - 3PH - 60Hz)

Page 28

INDICE – INDEXINDICE – INDEX

INDICE – INDEX

INDICE – INDEXINDICE – INDEX

Tav. 1 – Carrozzeria

Tav. 2 – Impianto elettrico

Tav. 3 – Componenti in vasca

Tav. 4 – Gr. Lavaggio

Tav. 5 –Alimentazione

Tav.6 – lance lavaggio – Risciacquo

Tav.7 – Pompa lavaggio

Tav.8 – Pompa di risciacquo

Tav. 1 – Machine Body

Tav. 2 – Electrical system

Tav. 3 – Supply

Tav. 4 – Tank components

Tav. 5 – Washing

Tav. 6 – Wash arms – Rinse

Tav. 7 – Wash pump

Tav. 8 – Wash pump

Page 29

42680

41038

TA.01

42324

42670

80987

42144

42042

4108701 (dx)

4108801 (sx)

42045

41059

42035

41247

41095

4109301

4113501

CVI173

927006

42036

42118

42122

4114501

42123

42110

Page 30

TA.02

H.228048

228004

(4A)

H.228047

80875

(4A)

80350

80351

DEI4

DEI395

80351

929115

220011

80972

215030

80873

(100mA)

80874

(2A)

80990

75888

461021

231014

BOILER

TA N K

80928

80934

Page 31

468151

SPP4

121075

121075

423010

TA.03

143005

460201

42092

472061

42089

209022

DISPENSER)

(DETERGENT

209024

(RINSE-AID

DISPENSER)

468200

H.775601

467002

472061

42092

42165

80988

42181

(8kw)

80840

42185

Page 32

42054

TA.04

4205901

929161

42315

926056

929174UL

929161

4206301

929164

929165

929164

Page 33

TA.05

143010

143173

41525

429050

437078

437025

468165

429036

41059

41167

143010

DEV1

RAT35

130162

80539T

80538

224021

143005

929171

80530

926189

80840 (8kw)

456002

467002

Page 34

41064CP

42053

TA.06

4205901

926252

929196

926132

42211

42211

456060

42209

80380

80371

42208

42208

80373

456060

80374

80365

8037480373

926132

80365

42209

80371

80380

929196

41064CP

41064

926252

42053

41185

4206301

Page 35

929188

TA.07

929189

929190

2275U4662

41992

929179

929191

929180

929174UL

Page 36

TA.08

41900

ZFCI121DX

41901

41904

41903

41902

130162

Page 37

QO+ FO: M AIN SW ITCH END FUSES BY

CUS TOMER

H01

A02

A02

1

CN1

1 2

PF1

5

23456

CN2

4

1

2

3

7

1

234

CN6

1

234

CN3

PF3

PF2

CN9

CN10

CN7

CN4

3

6

4

5

2

CN8

1

CN5

1

4

5

6

7

8

2

3

Page 38

CN4

CN8

2

3

8

1

456

7

CN5

CN10

CN9

CN3

234

1

2

3

2

345

1

4

1

5

6

CN7

PF2

PF3

CN6

234

CN2

23456

7

1

1

Page 39

Loading...

Loading...