Page 1

MODEL 777

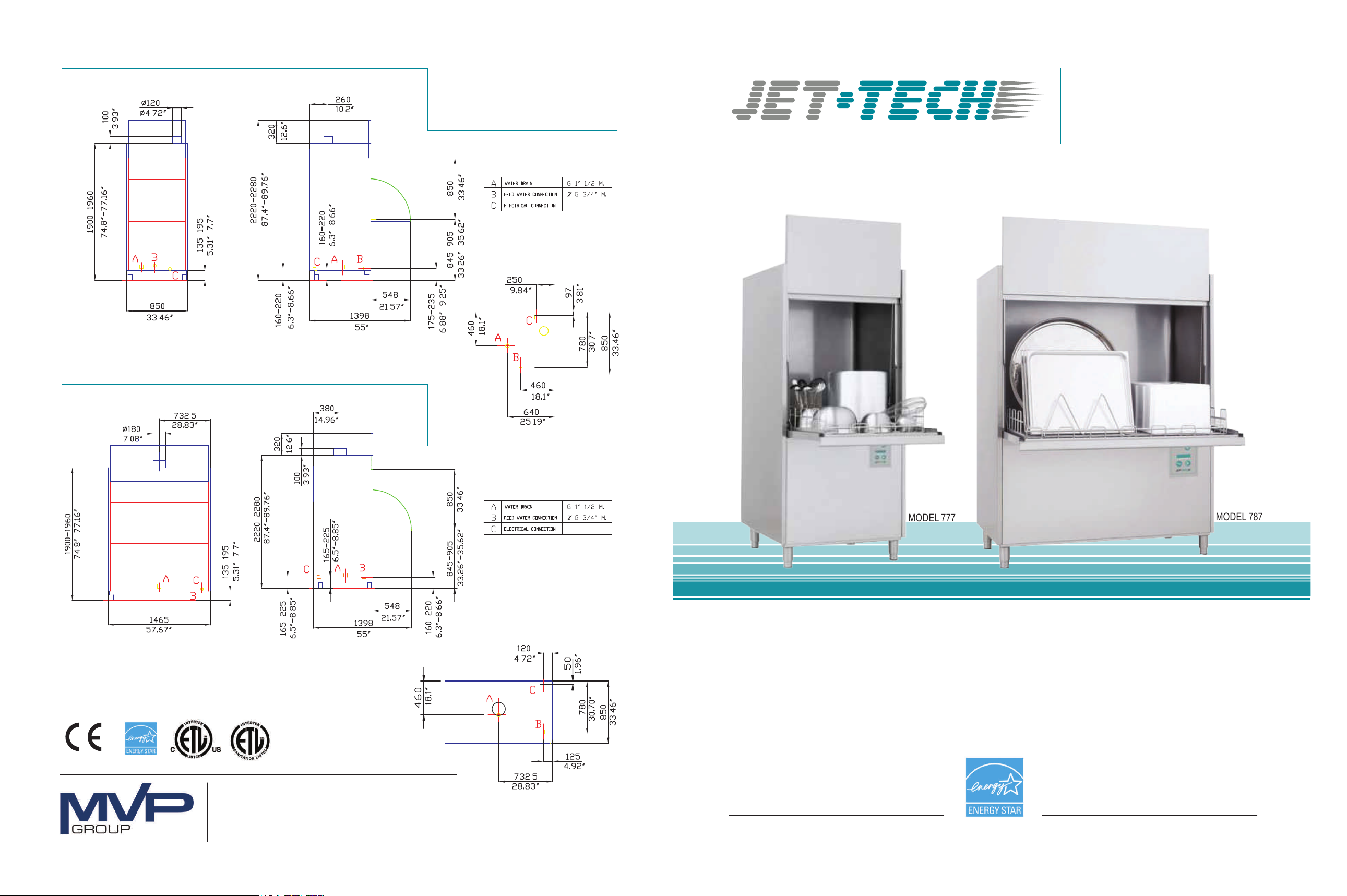

777 & 787

POT/PAN & UTENSIL WASHERS

with built-in booster

WARRANTY: 1 year parts and labor. Certain conditions apply. See owner’s manual for details.

MVP GROUP CORPORATION

5659 Royalmount Ave. Montreal QC, Canada H4P 2P9

Tel: 514.737.9701 / 888.275.4538

Fax: 514.342.3854 / 877.453.8832

sales@mvpgroupcorp.com www.mvpgroupcorp.com

MODEL 787

Oct. 2016

MODEL 777

MODEL 787

THE ABSOLUTE HIGHEST INNOVATION IN WARE WASHING

How to wash and sanitize in a quick, efficient, economic way

and fully comply with today’s strict hygienic and sanitation

requirements? This is the request of all chefs and bakers

today; who in their every-day activity are using baking trays,

pots, pans, utensils, baskets, etc. which come into

contact with food. Jet-Tech provides you an answer

to this question with our Series 777 & 787

cutting-edge technology warewash equipment.

Whether you operate a bakery, hotel, supermarket, school,

meat department, hospital, or laboratory, these highly

productive washers will ensure a perfect kitchen ware

hygiene; with their specially designed star-shaped wash

arms to effectively ensure total coverage and

contr i b u t e to an im pe c cable c le a n l i ne s s .

Special baskets and accessories permit the washing

of every kind of wares, that is how our T otal Clean

Concept will make your life a whole lot easier!

2016-10

Page 2

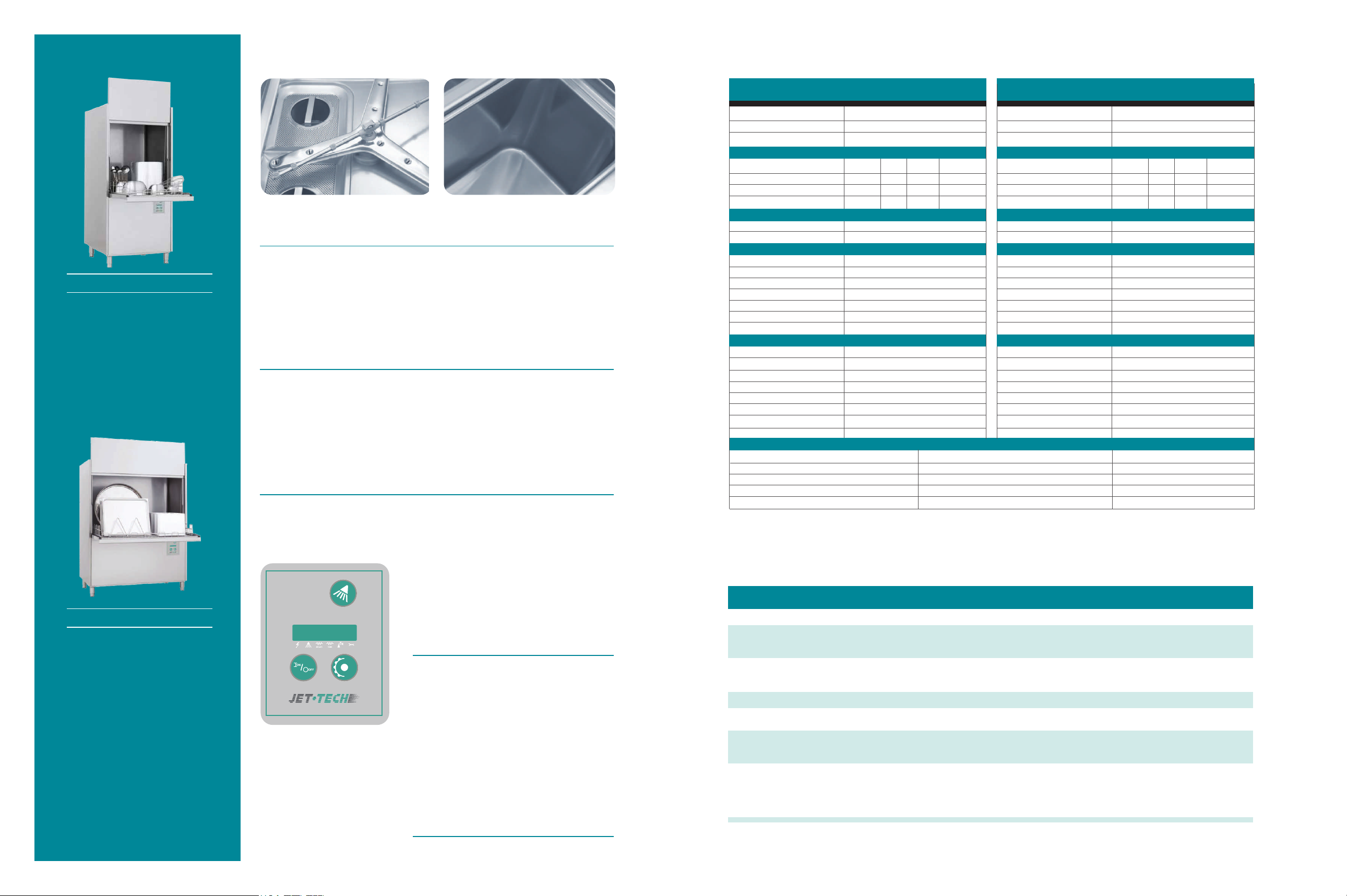

JET-TECH MODEL 777 JET-TECH MODEL 787

JET-TECH MODEL 777

Ideal for medium scale washing

applications, the 777 comes equipped

with a 27.5’’ x 27.5’’ (70 cm. x 70 cm.)

stainless steel basket with a 33.5” (85 cm.)

door opening. The basket’s easy slide

guides greatly reduce the effort of their

movement for the operator. Three

automatic programs ranging up to

ten minute cycle lengths.

JET-TECH MODEL 787

Ideal for large scale washing

applications, the 787 comes equipped

with a 52.0’’ x 27.5’’ (132 cm. x 70 cm.)

stainless steel basket with a 33.5”

(85 cm.) door opening. The basket’s

easy slide guides greatly reduce the

effort of their movement for the operator.

The 787 is very capable of washing

large numbers of wares to allow the

greatest flexibility of usage.

Incorporating our exclusive half-load

function; activating only one of two

pumps saving valuable energy during

slower periods. Three automatic

programs ranging up to ten

minute cycle lengths.

Wash & Rinse Arm Assembly

Deep drawn tank

The ultimate in Sanitation

Total Clean Concept

Both our 777 & 787 pot, pan and utensil washer series are equipped with

deep-drawn inner tanks without welds; which fully complies with the most extreme

sanitary rules. The double integrated waste filters retain the largest particles, then

carried to collection baskets which are easily removed. Lastly, the internal pumps

are self-draining in order to avoid any odors when the machine is shut off.

CRP

CRP is the technology developed for end-users that expect absolute perfection.

The CRP rinse permits you to enjoy the consistent quality results obtained; as the

rinse water’s temperature will not change for the total cycle duration. The water

capacity and pressure are guaranteed by a built-in booster; not directly supplied

from the incoming water line; but through an intermediate holding tank with a rinsing

pump also located within the machine body as standard equipment.

Helping personnel

Our pot/pan washers will ease the tedious

cleaning operations at the end of the day

thanks to the Total Clean Concept. Operation

is intuitive and machine control is made

through a soft touch low tension electric panel

with few push buttons, clear pilot lights and

digital display to see the washing and rinsing

temperatures. The same display also shows

the self-diagnostic system’s messages which

control the main electric components.

Ensuring hygiene

The guarantee of a rinse always at a sanitation

temperature is given by the sophisticated

electronic Thermostop that doesn’t permit the

start of this crucial phase if the water isn’t at

Low voltage soft touch

control panel

the correct temperature. The double-walled

construction and the particular washing

circuit’s architecture allows for extraordinary

silent operation. The reduction of the

consuption of water and chemicals products

decreases the impact of every single cycle on

the environment. We allow you to comply with

HACCP requirements in an easy and

economical way.

Dimension WxDxH

Rack Dimensions

Door opening

WASHING PROGRAM WASHING PROGRAM

TIME

Program 1

Program 2

Program 3

TEMPERATURE

Tank temperature

Booster temperature

WATER

Tank capacity

Booster capacity

Water consuption

Fill water temp.

Fill water pressure

Fill hose connection

Drain hose diameter

ELECTRIC

Motor

Voltage

Amperage

Tank

Booster

Washing pump

Rinsing pump

TOTAL LOAD

SOFT WARE SYSTEMS STANDARD

Thermostop system

Quick ready system

CRP system

Automatic start

Cycle counter (partial and total)

33.5’’ x 33.5’’ x 75’’ (85 x 85 x 190 cm)

27.55’’ x 27.55’’ (70 x 70 cm)

33.46’’ (85 cm)

WASHING PAUSE RINSING TOTAL CYCLE

141 sec 16 sec 23 sec 180 sec

291 sec 16 sec 23 sec 330 sec

561 sec 16 sec 23 sec 600 sec

165°F (74°C)

190°F (88°C)

17,96 gal (68 litres)

3,17 gal (12 litres)

1,60 gal (6,1 litres)

59°F (15°C) - 149°F (65°C)

18-40 lbs (1-3 bar)

G 3/4’’ M

1.5’’ (38 mm)

4 H.P.

208V 3 phase 60 hz.

36A

8000W

8000W

3000W

250W

11250W

Stainless steel wash arms

Double walled insulated body

Double filter drain system

Autodrain wash pump

Dimension WxDxH

Rack Dimensions

Door opening

TIME

Program 1

Program 2

Program 3

TEMPERATURE

Tank temperature

Booster temperature

WATER

Tank capacity

Booster capacity

Water consuption

Fill water temp.

Fill water pressure

Fill hose connection

Drain hose diameter

ELECTRIC

Motor

Voltage

Amperage

Tank

Booster

Washing pump

Rinsing pump

TOTAL LOAD

JET-TECH POT, PAN & UTENSIL WASHERS

FEATURE

Thermostop

Quick Ready

CRP System

Automatic start

Cycle counter (partial and total)

Half load function (787)

DESCRIPTION

If correct rinse temperature (176°F.-184°F) has not

been reached, wash cycle is extended

Enables tank filling with hot water coming from booster

Ensures constant rinse pressure and temperature

When door is closed, cycle starts automatically

Counts working cycle of the day and cumulative

working cycles to the date

It is possible to use half machine (only model 787)

having two separate washing and rinsing systems.

Machine will indicate that right hand side only is

working

58’’ x 33.5’’ x 75’’ (147 x 85 x 190 cm)

52’’ x 27.55’’ (132 x 70 cm)

33.46’’ (85 cm)

WASHING PAUSE RINSING TOTAL CYCLE

141 sec 16 sec 23 sec 180 sec

291 sec 16 sec 23 sec 330 sec

561 sec 16 sec 23 sec 600 sec

165°F (74°C)

190°F (88°C)

34,6 gal (131 litres)

4,49 gal (17 litres)

3,19 gal (12,1 litres)

59°F (15°C) - 149°F (65°C)

18-40 lbs (1-3 bar)

G 3/4’’ M

1.5’’ (38 mm)

2 x 4 H.P. =8 HP TOTAL

208V 3 phase 60 hz.

45A

8000W

8000 W

2 x 3000W = 6000W TOTAL

2 x 250W

14250W

OPTIONAL EQUIPMENT

Detergent dispenser

Low level detergent sensor

Rinse-aid dispensing pump

Low level rinse sensor

ADVANTAGE

Ensures correct rinse temperature

Machines reaches faster working

temperature

Optimum rinsing results

Easy operation

Useful for chemical companies and

end user

Avoids unnecessary operating costs

in case of low output requirements

Loading...

Loading...