Page 1

JET TECH TECHNICAL MANUAL

737E VER1.02

2015/12

1

Page 2

Contacts

Technical Support 1-888-275-4538

Robert Marsolais Service Manager 225 robert@mvpgroupcorp.com

Alan Gallagher Service Consultant 214 alan@mvpgroupcorp.com

Jonathan Menard Service Consultant 230 jonathan@mvpgroupcorp.com

Richard M. Hiller Special Projects Manager 211 richard@mvpgroupcorp.com

service @mvpgroupcorp.com

Tools

Some of the tools you will need

to repair and service the 737e.

Volt Meter

Temperature meter

Allen Keys (Metric)

Phillips screw driver

Nut drivers (Metric)

Wrenchs (Metric)

(inches)

2

US Metric

(mm)

1/8 3.18

5/32 3.97

4

3/16 4.76

5

13/64 5.16

7/32 5.56

15/64 6.05

6

1/4 6.35

17/64 6.75

7

9/32 7.14

5/16 7.94

8

11/32 8.73

9

3/8 9.53

10

11

7/16 11.11

15/32 11.91

12

1/2 12.7

13

17/32 13.49

14

Page 3

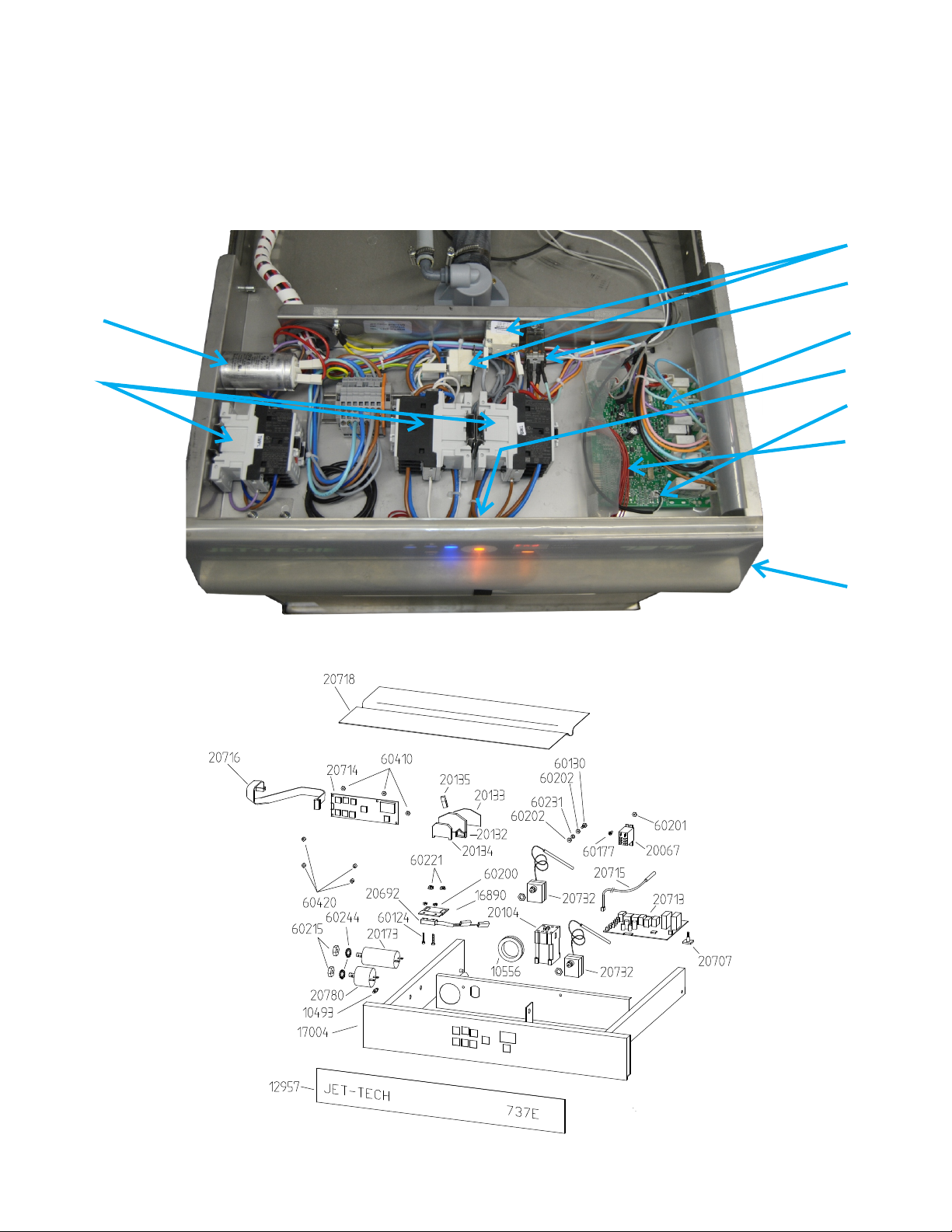

Top of 737e

20732

20067

20173

20104

20713

20714

20715

20716

20718

3

Page 4

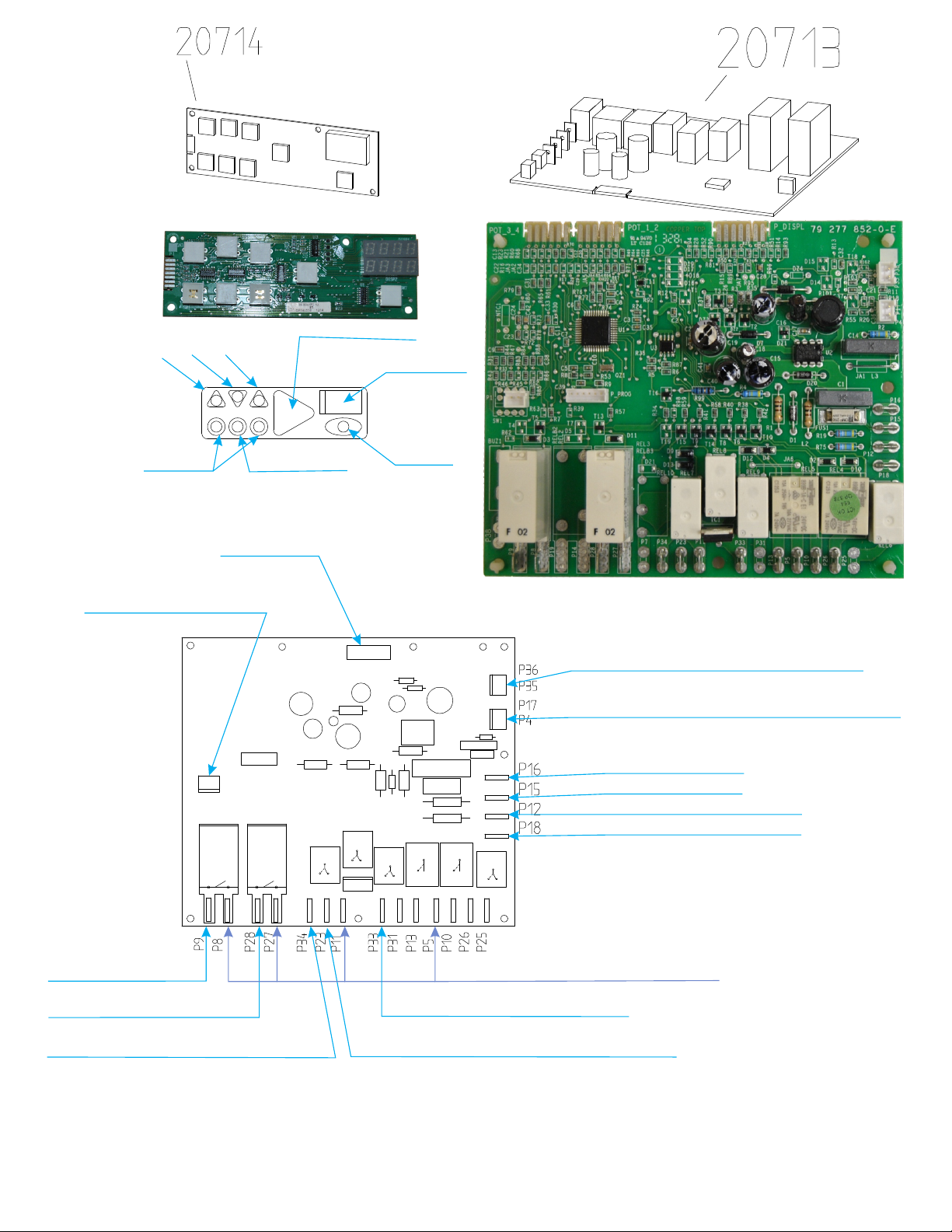

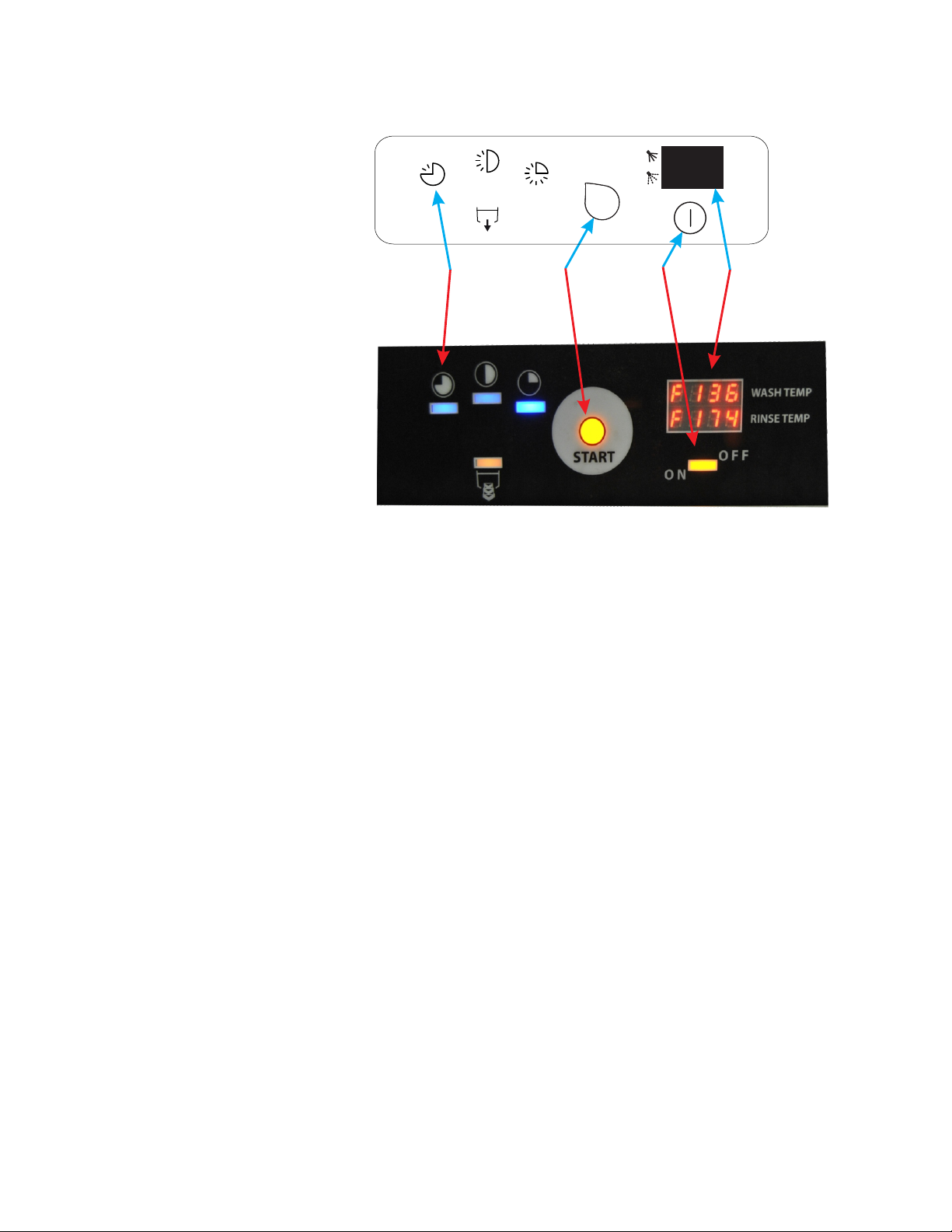

Wash Cycles

4m 3m 2m

Cycle Start

Display

Unused

Touch-Pad

Final Rinse Probe

Drain

ON/OFF

temperature probe Wash Tank

Temperature probe rinse booster

Power line L1

Power line L2

Door switch signal

Water level signal

Booster Heat

Wash Heat

Incoming Water (chemicals)

Power Line L2

Wash

Drainage

4

Page 5

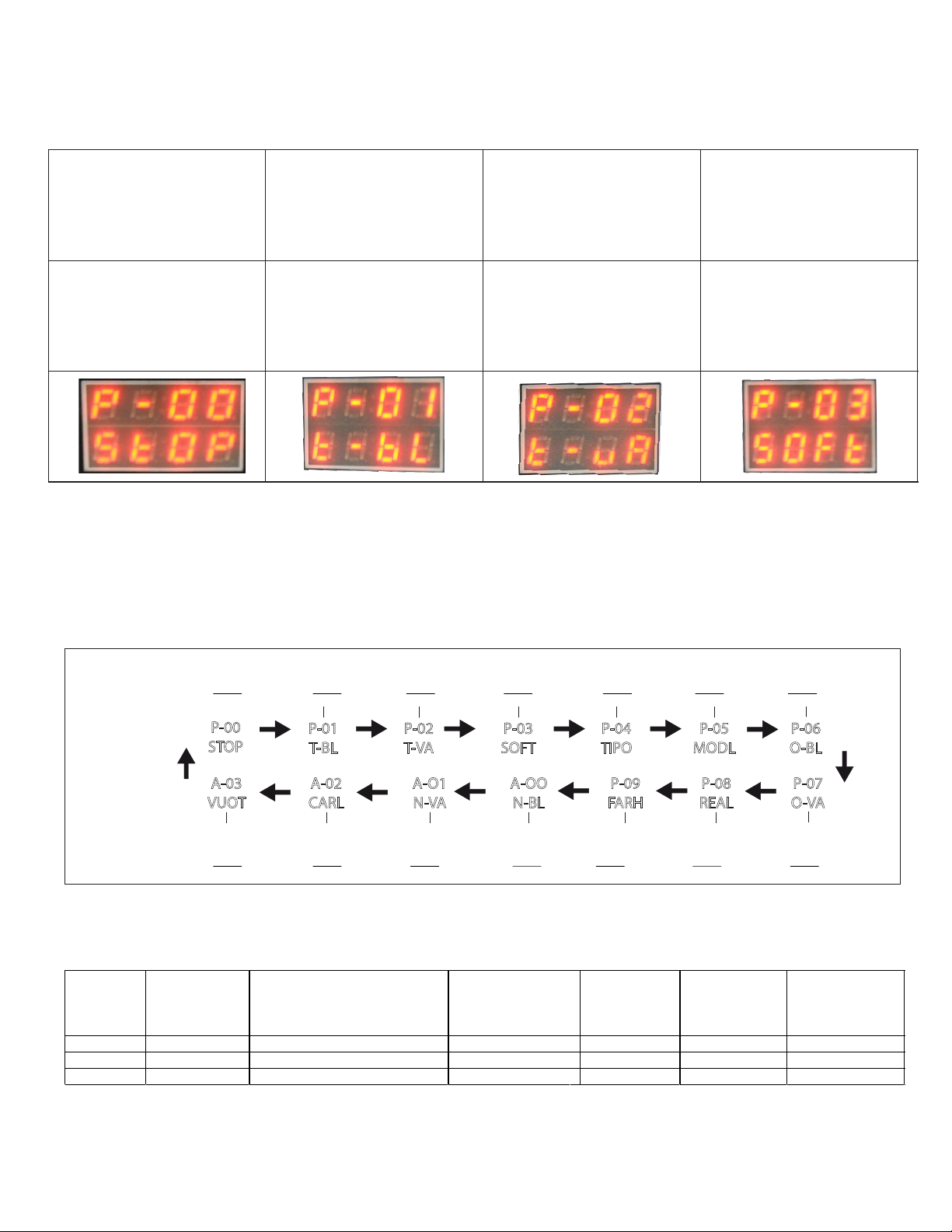

ELECTRONIC BOARD PROGRAMMING

START

C

B

A

D

MENU ACCESS

Level 1

Level 1 access will allow you to change the first 4 settings.

1 TURN THE MACHINE ON AND OFF BY PRESSING BUTTON A.

(IF THE MACHINE IS ALREADY ON, TURN IT OFF BY PRESSING BUTTON A)

2 PRESS BUTTON B SEVEN (7) TIMES WITHIN (10) SECONDS FROM TURNING OFF

MACHINE.

3 PRESS AND KEEP PRESSING BUTTON C ONCE QUICKLY.

“P-00 STOP” WILL BE ON THE DISPLAY.

MODIFY PARAMETERS

1 SELECT A PARAMETER BY SCROLLING THROUGH THE MENU WITH BUTTON B.

2 PRESS BUTTON C TO ENTER INTO THE PARAMETER MODIFICATION.

3 PRESS BUTTON B TO MODIFY THE PARAMETER WITH AVAILABLE OPTIONS

AND BUTTON C TO CONFIRM THE MODIFICATION.

ONCE YOU CONFIRM THE MODIFICATION, YOU RETURN TO POINT 1 WITH THE OPTION TO

SELECT ANOTHER PARAMETER BY SCROLLING THROUGH THE MENU WITH BUTTON B.

5

Page 6

P-00

STOP

P-01

T-BL

P-02

T-VA

P-03

SOFT

Thermostop

0= not active

1=active

default:0

Temperature boiler

Min 60C 140F

Max 95C 200F

Default 85C 185F

Temperature Tank

Set to 70C 160F

Default 60C 140F

Soft start

0= not active

1= active

default: 1 ,set to 0

THERMOSTOP

0 = not active

1 = active

∗DEFAULT 0=NOT ACTIVE

TEMPERATURE BOILER

Min 60°C

Max 95°C

∗DEFAULT 85°C

TEMPERATURE TANK

Min 40°C

Max 65°C

∗DEFAULT 60°C

SOFT START

0 = not active

1 = active

∗DEFAULT 1=ACTIVE

TYPE MACHINE

Min 1

Max 2

∗DEFAULT SEE CHART

MODEL MACHINE

Min 1

Max 27

∗DEFAULT SEE CHART

OFFSET TEMPERATURE BOILER

Min - 20°C

Max +20°C

∗DEFAULT 0°C

AVAILABLE PARAMETERS

P04

(DISPLAY)

2 8

4 31 70 + 120 + 180 + 240

MAX DRAIN TANK

Min 1 min

Max 20 min

∗DEFAULT 2 min

DON’T MODIFY

P05

(DISPLAY)

MAX LOADING TANK

Min 1 min

Max 20 min

∗DEFAULT 10 min

DON’T MODIFY

MODEL

727E / 737E

757E

MAX HEATING TANK

Min 1 min

Max 60 min

∗DEFAULT 45 min

DON’T MODIFY

120 + 180 + 240 sec

CYCLE

6

MAX HEATING BOILER

Min 5 min

Max 60 min

∗DEFAULT 30 min

DON’T MODIFY

sec

TEMPERATURE UNITS

FAR = FAHRENHEIT

CEL = CELSIUS

∗DEFAULT CEL=CELSIUS

REAL TEMPERATURE

0 = FILTERED

1 = REAL

∗DEFAULT 0 = FILTERED

DON’T MODIFY

OFFSET TEMPERATURE TANK

Min - 20°C

Max +20°C

∗DEFAULT 0°C

DON’T MODIFY

DRAIN PUMP

YES

Page 7

Level 2

P-04

TIPO

P-05

MODL

P-06

O-BL

P-07

O-VA

TYPE OF MACHINE

SET AT 2

MODEL OF MACHINE

SET AT 8

OFFSET

TEMPERATURE BOILER

! DO NOT CHANGE

SET AT 0

OFFSET

TEMPERATURE TANK

! DO NOT CHANGE

SET AT 0

PP-0

P-01

P-02

P-03

P-08

REAL

P-09

FARH

A-00

N-BL

A-01

N-VA

REAL TEMPERATURE

0= FILTERED

1= ACTUAL

DEFAULT=0

TEMPERATURE UNIT

0=CELSIUS

1= FAHRENHEIT

SET TO 1

MAX HEATING TIME

FOR BOILER

MIN 5 MIN

MAX 60 MIN

DEFAULT 30 MIN

MAX HEATING TIME

FOR TANK

MIN 1 MIN

MAX 60 MIN

DEFAULT 45MIN

Level 2 access will allow you to change all 14 settings.

1 TURN THE MACHINE ON AND OFF BY PRESSING BUTTON A.

(IF THE MACHINE IS ALREADY ON, TURN IT OFF BY PRESSING BUTTON A)

2 PRESS BUTTON B SEVEN (7) TIMES WITHIN (10) SECONDS

FROM TURNING OFF MACHINE.

3 PRESS AND KEEP PRESSING BUTTON C FOR THREE (3) SECONDS

UNTIL P-00 STOP IS ON THE DISPLAY.

7

Page 8

A-02

CARL

A-03

VUOT

MAX FILL TIME

MIN 1 MIN

MAX 20 MIN

DEFAULT 10 MIN

MAX DRAIN TIME

MIN 1 MIN

MAX 20 MIN

DEFAULT 2 MIN

ntcb

E-01

Booster temperature probe faulty or not connected properly

ntcu

E-02

Tank temperature probe faulty or not connected properly

FILL

E-03

Water fill not completed within allocated time (10 min)

Obstruction in water line, or faulty solenoid valve.

t bo

E-04

Booster temperature limit setpoint reached (+14C/ 57F)

t UA

E-05

Tank temperature limit setpoint reached (+14C/57F)

drA

E-06

Drain problem; Drainage not completed on maximum set time.

Bad drain pump, obstruction in drain line or pump.

bnot

E-07

Maximum booster heating time reached (15min)

unot

E-08

maximum tank heating time reached (30 min)

SErulCE

E-09

Memory error or electronic board damaged

Error Codes

8

Page 9

-PSd--1

-PLd--1

88:88

empty

-r r-

0143

Drain pump test

door closed

d--0 = door open

Wash pump test

door closed

N/A

SALT

OPEN

-rb-

0078

empty

88:88

-rL-

0046

N/A

Booster heater test

temperature in Celsius

Wash Tank Heater test

Temperature in Celsius

-ECd--1

-ERd--1

-Erd--1

-Ebd--1

P-10

door closed

P-13

door closed

P-25

door closed

Solenoid valve

(chemical pumps) test

door closed

Level 3

Level 3 access will allow you test different components.

1 TURN THE MACHINE ON AND OFF BY PRESSING BUTTON A.

(IF THE MACHINE IS ALREADY ON, TURN IT OFF BY PRESSING BUTTON A)

2 PRESS BUTTON C SEVEN (7) TIMES WITHIN (10) SECONDS

FROM TURNING OFF MACHINE.

9

Page 10

10

Page 11

11

Page 12

12

Page 13

13

Page 14

Part Number Description

10342 CONNECTOR DIAMETER 6,5

10349 CONNECTOR

10421 SMALL SQUARE

10422 NUT

10425 NUT

10433 NUT

10435 NUT

10441 SPRING F.BULB PROBE THERMOSTAT

10471 SPRING

10472 SPRING

10479 BUFFER

10493 PIVOT

10502 ADJUSTABLE FOOT

10534 TUBE

10552 PLATE

10556 FAIR LEAD

10598 SQUARE

10609 SPACER

11351 BUSH

11510 TUBE

11543 CONNECTOR

11586 TUBE POMPE VIDANGE 1000-1201

11994 ROD FILTER

11998 NUT

12007 SUPPORT

12008 SUPPORT

12017 PIVOT

12019 PLATE

12020 NUT

12021 CONNECTOR

12022 LID WITH FILTER

12024 CONNECTOR

12025 TUBE

12027 CONNECTOR

12028 NUT

12030 TUBE

12035 TUBE

12037 TUBE

12038 FILTER

12039 FILTER

12048 PIVOT

12049 DOOR HOOK

12050 DOOR CATCH

12051 BUSH

12052 SPRING

12053 PLATE

12054 DOOR CATCH BODY

12055 SCREW

12060 ANTI-VIBRATION

12074 HUB

12076 MANIFOLD

12128 FILTER

12129 DISK

12760 TRANSPARENT FILM 110X150

12957 FILM 737 E JET-TECH

15006 PIVOT

15030 KIT SUPERIOR SUPPORT ARM

15031 KIT INFERIOR SUPPORT ARM

15061 CONNECTOR

15086 GAS SPRING

15088 WASH/RINSE ARM 50-1200

15089 WASH/RINSE ARM

15093 ANTI REFLUX DEVICE X-33

15103 CONNECTOR PROBE TEMPERAT.NSF

15105 PLUG DOOR MICROSWITCH

16029 TUBE F.PRES.SWITCH CF 50 2001

16039 BUFFER FOR FLASK EPDM

16045 TUBE 3/4-3/4 TRAY 600X400

16048 MANOMETER

16053 RUBBER-CARRIER 1/4 GAS

16057 BOYLER 737 BULKHEAD NSF

16073 PLUG NYLON TFT 26X1,5

16074 NUT NYLON 3/4 BLACK RO/3-4 N

16345 SQUARE F.PRESSURE SWITCH 2001

16366 FLASK DET.PUMP DS 400

16666 AIR TRAP STAINLESS STEEL

16679 RUBBER-CARRIER PG13 1/2-18/1"

16754 PIVOT FOR GAS SPRING

16890 SQUARE MAGNET.SWITCH AT 50

16905 RIGHT BASKET GUIDE AT 50

16906 LEFT BASKET GUIDE AT 50

16913 DOOR AT 50

16914 BASEMENT AT 50

16915 RIGHT GUIDE AT 50

16916 LEFT GUIDE AT 50

16919 REAR PANEL AT 50

16920 TOP AT 50

16930 FLASK FOR VALVE NSF

17004 PANEL TS 58 OMEGA ELECTRONICS

17024 TANK AT 50

17025 RIGHT LAT.PANEL AT 50

17026 LEFT LAT.PANEL AT 50

17027 PANEL JET-TECH 737 NSF

17056 FLASK MANOMETER 737 NSF

20017 FIXING CABLE ST 16

20050 FAIR LEAD WITH DIAPHRAGM DG 29

20067 RELAY 12A 230V

20079 BOYLER HEATING ELEM.230V 4000W

20088 TANK HEATING ELEM.230V 2800W

20104 CONTACTOR 220/230V 50/60HZ

20132 TERMINAL

20133 PLATE 249-116

20134 TERMINAL 281-313

20135 STAPLE

20173 CAPACITOR 16

20192 PRESSURE SWITCH

20332 SPIRAL

20336 CLIP

20337 CLIP NYLON

20532 TERMINAL BLOCK CF 50 400V

20552 CONNECTOR AUT.D.DOS.(5X7)

20569 SOLENOID VALVE 1A 240V 60HZ UL

20582 TERMINAL FV110

PARTS LIST

14

Page 15

20589 FILTER FOR AUT.DET.DOSER 5X7

20692 MAGNETIC SWITCH E5121VDA0196

20693 MAGNET M302NCBCNC42

20707 SUPPORT FOR ELECTRONIC CARD

20713 ELECTRONIC CARD POWER

20714 ELECTR.CARD CONTROL AND VIEW

20715 PROBE TEMPERATURE 2 MT ELECTR.

20716 CONNECT.CABLE EL.CARD 7+7 40CM

20718 MYLARD PROTECTION THICKN.0,10

20728 AUTOMATIC DET.DOSER GN202 NSF

20729 AUTOMATIC DET.DOSER GN82B NSF

20732 SAFETY THERMOSTAT 124° WYF 2MT

20741 PROBE NTC 1/4 2MT CONNECTOR

20769 NUT SEKO F.6MM 0000061001

20779 SHRINK TUBING D.6,4

20780 FILTER UL

21616 U BOLT AUT.PERIST.DOSER JET-T.

21700 LOOM 737 E NSF

30049 DISH BASKET 50X50

30105 UNIVERSAL BASKET 50X50

40226 MOTOR PUMP

40293 DRAIN PUMP 60HZ

60003 GASKET

60004 WASHER TEFLON 15X10X3

60007 WASHER TEFLON 15X10X9

60009 GASKET 52X42X6

60010 O RING

60012 GASKET

60050 O RING

60074 O RING

60075 O RING

60076 O RING

60081 CLIP

60082 CLIP

60083 CLIP

60084 CLIP

60089 CLIP

60093 CLAMP

60102 SCREW

60103 SCREW

60109 SCREW

60124 SCREW 3MAX30

60130 SCREW

60131 SCREW 5MAX10

60132 SCREW

60135 SCREW

60137 SCREW

60145 SCREW 6MA X 8

60163 SCREW

60166 SCREW

60177 SCREW 4MAX10

60179 SCREW

60187 SCREW 4MAX10

60191 SCREW 6MAX12

60194 SCREW 4MAX30

60200 NUT

60201 NUT

60202 NUT

60208 NUT

60210 NUT 8MA

60212 NUT

60215 NUT

60221 NUT DIN 6923 5MA

60222 NUT DIN 6923 5MA INOX

60231 WASHER

60234 WASHER

60242 WASHER

60244 WASHER

60250 RING

60410 PLASTIC NUT M3

60420 SPACER NYLON 7X4X6

60540 HOSE POLYAMIDE 5X7 MM

60552 RED HOSE 5X7 X-32/X-33

60553 BLUE HOSE 5X7 X-32/X-33

60556 TUBE FOR DRAIN PUMP

60565 HOSE

60596 BAG

60626 PANEL

60655 PACKAGE F 18/737 JET-TECH

60657 PEDESTAL F 18/737 JET-TECH

60659 EXPANTED 85X10X10X3

60675 EXPANTED 87X42X3 K20

15

Page 16

MANUFACTURERS LIMITED WARRANTY

Jet Tech Systems Corporation (Jet Tech) hereby warrants all new warewashers

bearing the name JET TECH and installed within the continental United States of

America or Canada to be free from defects in material or workmanship, under normal

and regular usage and operation, for a period of one (1) year following the date

of original installation, (unless specified otherwise) but in no event can exceed

eighteen (18) months from the date of shipment from the factory.

If a defect in material(s) or workmanship is detected; or found to exist within

the stated period above, Jet Tech, at its sole discretion, shall either repair or

replace any original equipment manufacturers part which has proven to fail within

the machine; providing that the equipment has not been altered or tampered with in

any manner, has been installed correctly as per the owners manual, and maintained

and operated in complete accordance with this manual.

The labor cost to repair or replace any part proven to be defective, as per above

clause(s), shall be covered by Jet Tech Systems, within the continental United

States of America or Canada; provided that: prior authorization for this labor

was approved by Jet-Tech Systems, the service work was performed by an authorized

Jet Tech service agency; and that this agency installed an original and genuine

Jet Tech part in the machine. Any repair work performed by a non-authorized

service depot remains the sole responsibility of the user, and Jet Tech Systems

will not be held responsible. The installation of any generic part will not be

valid; and therefore voids this warranty. All authorized labor coverage shall be

limited to regular hourly rates only. Any supplemental hourly rates or charges,

such as weekends or emergency premiums remain the responsibility of the user.

Jet Tech Systems Corp. (Jet Tech) hereby states that: warranty travel time shall

be limited to, and without exception, a round-trip total of two (2) hours OR

mileage up to a maximum of one hundred (100) miles round-trip. Any charges

exceeding those stated herein must have prior authorization by the factory.

Exceptions to above warranty are: (A) Damages resulting from shipping, handling

or abuse. (B) Incorrect installation and/or connections. (C) Adjustments or

calibration of any parts. (D) Faults due to lack of regular maintenance or

cleaning of any internal part(s). (E) Replacement of any wearable items such as:

glasswasher curtains, or peristaltic squeeze tubing or gaskets. (F) Excessive

lime, mineral, alkali or hard water conditions and (G) Poor results due to: use of

an incorrect type of detergent (for non-commercial type applications), and

excessive or inadequate water temperature(s) or pressure conditions.

JET TECH SYSTEMS CORPORATION STATES THAT THERE ARE NO OTHER WARRANTIES, EXPRESSED

OR IMPLIED, THAT ARE NOT SET FORTH HEREIN, JET TECH SYSTEMS CORPORATION SHALL

ASSUME NO OTHER RESPONSIBILITY, EITHER DIRECT OR NON-DIRECT, OR BE LIABLE FOR ANY

OTHER OR ADDITIONAL LOSS OR DAMAGE WHETHER BEING DIRECT OR CONSEQUENTIAL, AS A

RESULT OF ITS EQUIPMENT.

16

Page 17

SERVICE CALL REGULATIONS

JET TECH ware washers are warranted as specified in the MANUFACTURERS LIMITED

WARRANTY.

Upon receiving the demand for repairs on a unit, we will create a work order or

Warranty Authorization which will have all the pertinent information. We will

send this form to you as a purchase order for service. We ask that you respect the

times allocated on the form. Should more time is required to complete a service

call, call us and ask for more time. Without proper authorization, your claim for

payment will be delayed.

We will pay for:

1. Labor to replace a defective part, as per the attached Allocated Times Schedule.

2. Travel time, as specified in the MANUFACTURERS LIMITED WARRANTY.

3. JET TECH original replacement parts supplied from service company inventory

We will NOT pay for:

Unauthorized labor charges.

Unauthorized travel charges.

Waiting time. Call for an appointment, if required.

More than one man on a service call.

Travel time exceeding the MANUFACTURERS LIMITED WARRANTY.

More than one service call for the same problem.

Adjustment or calibrations, as specified in the MANUFACTURERS LIMITED WARRANTY.

Replacement of small items (pilot light, screens, jets).

Cleaning or regular maintenance.

Overtime or weekends charges (time and a half, or more)

Problems due to improper installation.

Problems due inadequate or improper use of the equipment.

Problems due to improper water supply temperature or inadequate/excessive water pressure.

Problems due to inadequate/excessive electric supply.

Disconnecting of hard plumbing or removal of counter tops, etc.

We are here to help you with diagnostic or service problems.

Call us toll free at 1-888-275-4538, extension 611 for assistance. After office hours assistance

is also available by dialing the extension 411 or *411. Our email is service@mvpgroupcorp.com.

All paperwork related to warranty work can be sent by email to warranty@mvpgroupcorp.com .

Other contact information is available at www.mvpgroupcorp.com .

Our standard procedure is to invoice all parts shipped at $0 for WARRANTY REPAIRS regardless what

the amount shows on the work order. All defective parts should be kept for 90 days. After this

period, the parts can be discarded.

YOUR INVOICE MUST INCLUDE THE FOLLOWING INFORMATION:

1. Warranty Repair Authorization Number.

2. Model and serial numbers.

3. Problem reported.

4. Detailed description all charges including dates, hours worked and work done.

5. Reason for part failure.

6. Indicate the general state of the equipment, cleanliness and if abuse is apparent.

We expect that your work is warranted by your company for at least 90 days.

17

Page 18

COVER PAGE

2 CONTACT

3 TOP OF DISHWASHER

4 ELECTRONICS

5 PROGRAMMING

6 PROGRAMMING (CONT)

7 PROGRAMMING (CONT)

8 PROGRAMMING (CONT)

8 ERROR CODES

9 LEVEL 3, TESTING

10 EXPLODED VIEW

11 EXPLODED VIEW (CONT)

12 EXPLODED VIEW (CONT)

13 EXPLODED VIEW (CONT)

14 PARTS LIST

15 PARTS LIST (CONT)

16 WARRANTY

17 WARRANTY REGULATION

18 LAST PAGE

18

Loading...

Loading...