1

INSTALLATION AND OPERATING INSTRUCTIONS

EuroJet

Eurojet Swimjet Instructions

www.agbudget.co.uk Luxury Swimming Pool Equipment at Budget Prices

16

GB

Preface

Your unit has been built in accordance with the latest state of the art, and is safe. However, the unit can be

dangerous if it is operated by persons who have not received the necessary training or instruction, or if it is used

improperly. Therefore, everyone entrusted with the task of installing the unit, setting it into operation, operating,

maintaining and repairing it, must read and understand the Operating Instructions and - especially - the Safety

Instructions. Before using the unit for the first time, you and/or your personnel should definitely receive instructions from the specialist consultant. If, contrary to expectations, technical defects occur in your unit, please

contact the customer service department or your dealer.

LIST OF CONTENTS PAGE

1 SAFETY INSTRUCTIONS ...................................................................................................................... 16-17

2 INST ALLING THE WALL NICHE IN CONCRETE SHUTTERED POOLS ..............................................18-19

3 FINAL ASSEMBLY INSTRUCIONS........................................................................................................ 20-21

4 OPERATION / INFORMATION FOR THE USER OF THE UNIT ............................................................. 23-27

4.1 BEFORE STARTING............................................................................................................................ 22

4.2 FIRST TIME OPERA TION.................................................................................................................... 22

4.3 STARTING THE UNIT .......................................................................................................................... 23

4.4 STRENGTH OF THE JET .................................................................................................................... 23

4.5 MASSAGE....................................................................................................................................... 23-24

4.6 SWIMMING AGAINST THE CURRENT ................................................................................................ 24

4.8 WINTERIZATION ................................................................................................................................. 24

4.8 AGAIN OPERATION ............................................................................................................................ 24

5 SERVICE...................................................................................................................................................... 24

6 FITTING INSTRUCTION FOR HANDGRIPS ...............................................................................................25

7 INFORMATION FOR THE ELECTRICIAN .............................................................................................. 26-27

1 SAFETY INSTRUCTIONS

1.1 Before Setting into Operation

Before installation and setting into operation, the Safety Instructions and the Operating Instructions

must be carefully read and observed. You must definitely comply with the requirements of the uwe

company and of the standards authorities.

1.2 Setting the Unit into Operation for the First Time

Before the unit is set into operation, the local safety regulations and the Saf ety Instructions must always be complied

with.

1.3 Sources of Danger

Warning!

The JETSTREAM system forces up to 700 litres of water per min ute into the pool through the nozzle. If all of

this enormous force is used for massage, it can cause injuries to muscles and to connectiv e tissue, as well as

internal injuries. Because of the reduced electrical resistance of the human body in swimming pools and the

resulting increased probability of the occurrence of dangerous currents in the body , increased safety requirements

are imposed on the electrical installation.

17

Therefore, you must definitely observe the following Safety Instructions:

The JETSTREAM has substantial power. Before massage, you must definitely reduce the

pressure.

Do not utilize full thrust against soft parts of the body.

Switch off pump before adjusting angle of nozzle.

For large-area massage, reduce the strength to half thrust.

In order to attach and detach the massage fitting switch off the pump.

T o massage a single part of the body , grip the massage hose firmly . When using the hose keep

a distance to those parts of the body that require massaging.

Do not approch the suction filter with long hair unless tied back.

Before putting the massage hose on or taking it off, switch off the pump.

For point massage, hold the nozzle of the massage hose firmly in your hand under water . Guide

the nozzle of the massage hose over the required places but at some distance from them.

Do not dive to the intake screen (if there is one) with long, unrestrained hair.

For requirements regarding the appropriate electrical installation, please see „Information for the Electrician“,

as per part 7. P arts of the equipment that contain electrically live parts must be inaccessible to persons using

the pool. Units and unit parts containing electrical components must be installed or fixed in such a wa y that they

cannot fall into the water . Units of enclosure class I must be permanently connected to permanently laid cables.

1.4 Proper Operation

All units are intended soleley for operation in co vered swimming pools and in open-air swimming pools with a

water temperature up to 35°C. The units are suitable for installing and operating in installations and rooms in

areas 1 and 2 as per EN-60335-2-41. The pump is normally installed in the walkw ay behind the pool wall, b ut it

must be ensured that the environment is dry and that the motor is protected by a suitably sized floor drain to

prevent flooding. The control panel should be installed either in a dry walkwa y or in an adjacent room, if possible

higher than the water lev el. Any kind of use other than the intended use is improper . The manuf acturer will not

accept liability for any damage or injury resulting from improper operation; the user alone must bear this risk.

Proper operation also includes compliance with the operating, maintenance and repair conditions specified by

the manufacturer . Maintenance work, repair work and suchlike may only be perf ormed by authorised persons.

The units may only be used by persons who are familiar with them and who have been informed about the

dangers. The relevant regulations for the prevention of accidents and the other generally recognised rules

relating to safety and to occupational medicine must be complied with. If unauthorised modifications are made

on the units, the manufacturer will not accept liability f or an y resulting damage or injury.

1.5 Product Liability

The user’s attention is e xpressly dr awn to the f act that the unit ma y only be operated in the proper manner. If it

is operated in an improper manner, the user must bear sole responsibility. In such cases, therefore, the

manufacturer cannot accept any liability.

1.6 Procedure in an Emergency

Leave the water immediately, switch off the electrical supply to the unit by operating the main power switch or

circuit-breaker , and secure the unit to prevent it from being switched on again without authorisation.

1.7 Explanation of the Danger Symbols

Warning!

In these Operating Instructions, we have used this symbol to mark all texts which relate to

your safety. Please pass all safety instructions on to other users too.

In these Operating Instructions, we have used this symbol to mark all texts containing

instructions that are necessary for functional reasons. Please be sure to obey these instructions

in order to avoid damage to the unit.

18

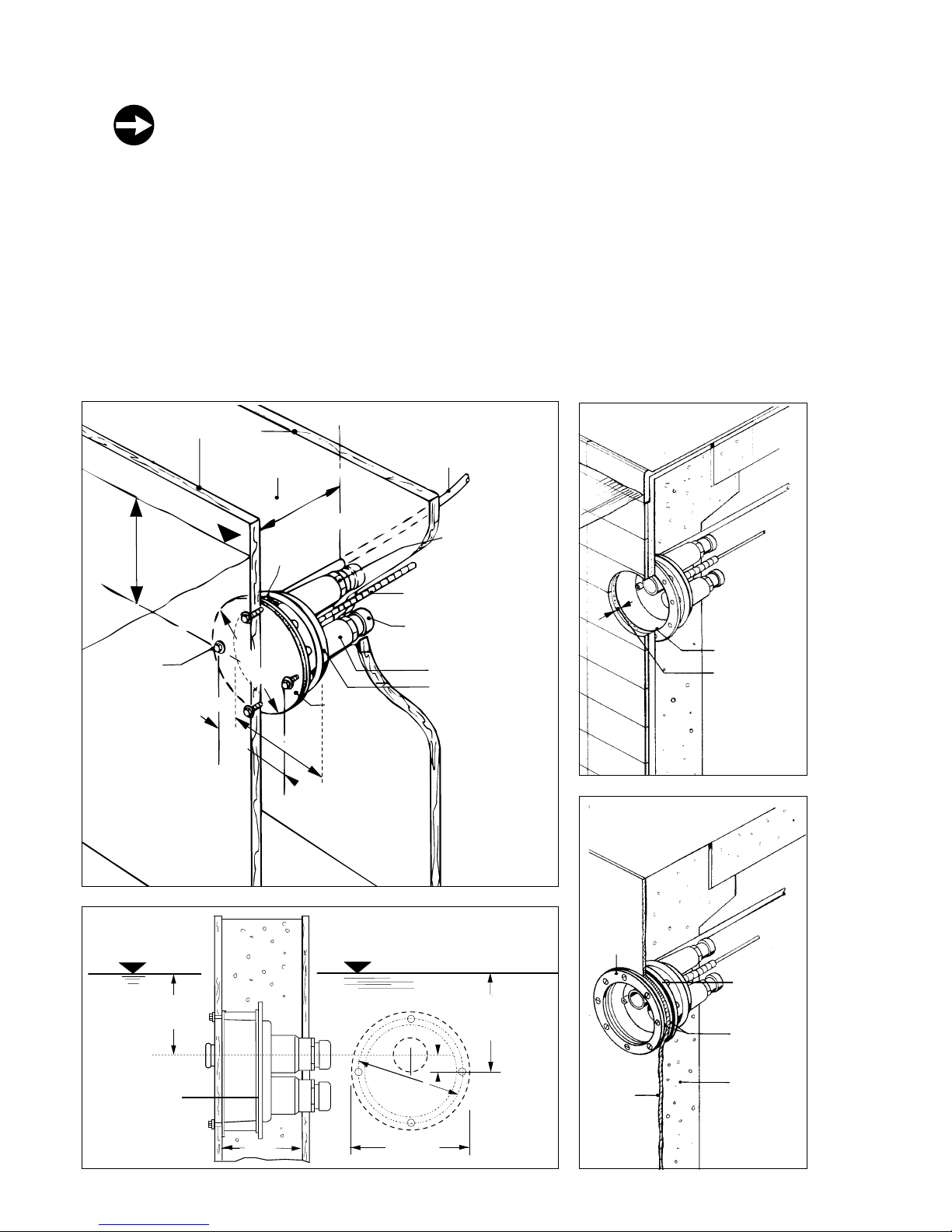

2 INSTALLING THE WALL NICHE IN CONCRETE SHUTTERED POOLS

Installation (fig. 1)

Position the wall niche ensuring that the read label “Oben” (top) is on top.

Viewed from inside the pool, the suction duct is on the v ertical middle axis above the center of the housing, the

pressure duct at the bottom on the right side.

The front of the wall niche must be set flush with the face of the wall concrete . In case of a liner/concrete pool,

the wall niche may project in order to compensate for the cement render of liner insulation thickness. It is

advisable to make provision for protecting tube by placing in protective conduit or through adjacent cable/

ventilation ducts.

• Tile plan (fig. 2)

Render and tile to inner edge of wall niche.

• Pools with plastic liner (fig.3)

Proceed as shown in fig. 3

shutterung

concrete

air inlet tube 4 m long

label

“top”

presure duct

prodective sleeve for

pneumatic tube for wall

thickness up to 50 cm

special nipple do

not remove

suction duct

wall niche

shuttering

screw

M8 x 50 plasitic

24

23,7 - 38,7

(optimal 28,7)

Ø 28,9

Ø 31

25,6

water level

cut into

edge of yellow

protective cover

and remove

before rendering

1

2

3

Ø 31

20-35

(opt. 25)

Ø 25,6

24

23,7 - 38,7

(optimal 28,7)

3,7

water level

water level

metal frame

render and tile

to inner edge

max thickness

render and

tile 5 cm

one rubber

gasket to

front and

back of

liner

liner

concrete

gasket

clamping

frame

19

Installing the wall niche in steel, aluminium and polyester pools

Installing the wall niche in deck level pools with overflow channel

Ø 31

Ø 25,6

23,7 - 38,7

(optimal 28,7)

3,7

20-35

(opt. 25)

24

~13,5

~8

~42

~35

Ø 31

20-35

(opt. 25)

Ø 25,6

3,7

24,0

Ø 23,5

8

x

4

5

°

=

3

6

0

°

45°

Ø 0,9

dimensions in cm

dimensions in cm

water level water level

nozzle center line

clamping frame

air inlet tube for air

suction end part to be

installed 5 - 10 cm

above water level

pool wall

sunk screw

M 8 x 35

use clamping

frame for cutting

and drilling

label

top

gasket

concrete max.

wall niche

suction duct

protective

sleeve for

pneumatic tube

water level water level

air inlet tube for air

suction end part to be

installed 5 - 10 cm

above water level

suction duct

protective sleeve

for pneumatic tube

nozzle center

line

wall niche

gasket

shuttering

use drilling template

for drills in the

shuttering

air inlet

label „top“

20

3 FINAL ASSEMBLY INSTRUCIONS

INSTRUCIONS FOR AUTHORIZED PERSONS ONLY

Before installation

The safety instructions must be read carefully before installation. You must definitely fulfil the requir ements stated

by the uwe company and by the standars authorities. If the instructions are not observed, the installation engineer

shall bear the sole responsibility. The manufacturer shall thus be absolved of any liability .

Installing the nozzle assembly (fig.1)

1. Unscrew gland nut (10) and remove blank plastic washer. Leave rubber sealing washer (13) in housing.

2. Thread free end of the 10 m length of PVC pneumatic tube (12) through the gland aperture from within the pool.

3. On the pneumatic switch assembly (3) is a short length of pneumatic tube (12). Thread this through the gland

nut (10) and fix it to end of the tube connector (11) showing inside the pool. Tighten gland nut (10).

4. Insert 5 disks from white plastic disk (9) on the ground of the jet-casing (15). After that insert seal (8) and one

of the clamping disk (7) inside. Then put down the nozzle (6) and the clamping disk (5). The clamping disk (5)

is fortified on the nozzle with 4 screws (4). If the nozzle wouldn’t be steered into se v eral directions y ou ha ve to

put out 1 of the plastic disk (9)

5. The face plate (2) will be attract with the 2 Screws (1) easily.

Installing the pump, suction and pressure hoses with PVC-fittings

If the pump is to be installed on a console/mounting bracket, supplied as an optional extra, it should be fitted to

the pool wall beforehand with concrete wall fixings. The pump should be secured with anti-vibration mountings.

Alternatively, the pump should be secured with appropriate fixings on a concrete plinth. Stick the suction - and

pressure hose with „TANGIT “into the transition joint of the wallfitting. After the splicing, the ball-valves should be

open and closed like picture 4.

Important: be careful if you stuck together suction - and pressure hose corr ectly . (Arrow on the

ball-valves signed on Picture 4).

Do not forget to insert the gasket between hose nipple and pump nipple.

Tighten the pump base with fixing bolts or anti-vibration mountings.

Important note:

The pump is normally installed in the walkway behind the pool wall.

The installation evironment must be dry and must be protected by a suitably sized floor drain

to prevent flooding.

Installing the air inlet fittings (fig.5

Insert the non return valve into the end of the air inlet tube. Fix the clip (17 to the pool wall in such a way that the

opening of the air inlet fitting (16 is at least 5 cm above the maximum water level of the pool. Push the tube over

the straight connector of the valve. Secure the tube with the pipe clamp.

Note:

The purpose of the non return valve is to absorb back pressure generated by use of the massage

attachments, and to prevent water spraying out of the air inlet fitting. The valve will only function

properly as long as no hair/debris or lime deposit accumulates within it.

Therefore the valve has to be fixed above water level.

Shorten the air inlet tube if it is longer as necessary . The shorter the tube, the lesser the resistance and the higher

the volume of air flow.

21

5

16

18

19

5

10

13

15

4

7

6

8

9

11

12

14

17

1 2 3

4

Mounting the control panel

The control panel must not be installed in a chamber . It should be accommodated either in a dry walkway behind

the pool wall or in an adjacent room. The connection must be effected carefully in accor dance with EN 60335-2-

41. Connection to the power supply is effected by means of a 5 x 2,5 mm² (3N PE 400V) cable or a 4 x 2,5 mm² (3

PE 230 V) cable. Both a power switch, with which the unit can be isolated from the power supply on all poles, and

an earth leakage circuit breaker (R.C.C.B.) should be provided in this cable (see: “Information for the Electrician”).

Plug the 10 m length of the PVC tube coming from the wall niche, onto the free nipple of the “T” connector (19

outside the control panel (18.

22

JetStream EuroJet

Installation in concrete pools

4 OPERATION / INFORMATION FOR THE USER OF THE UNIT

4.1 Before starting

Safety precautions and operating instructions must be carefully read and observed before setting up and

operating.

4.2. First time operation

Before operating, local saf ety requirements must be met and safety precautions must be observed.

Before operating the unit for the first time, rotate the pump by hand several times at the

ventillating fan in the direction shown.

Do not set a defective unit into operation.

Display the Safety Instructions in a clearly visible manner.

Keep the Operating Instructions available.

The water temperature must not exceed 35°C.

dimensions in cm

34

Ø 43,0

18

24

20 - 35

(optimal 25)

58

50

82

22

15,6

25,5

6

approx 5-10 cm

above waterlevel

water level

23

4.3 Starting the unit

Before swivelling the nozzle, switch off the pump.

When you press the pneumatic button (1), this s witches the unit ON or OFF. When using a separate waterproof

switch for remote control the unit can also be oper ated from outside the pool. The nozzle (6) can be swivelled in

any direction within a cone of about 30°.

Before swivelling the nozzle, you must definitely switch the unit off.

4.4 Strength of the jet

The JETSTREAM has considerable energy, ther efor e r educe the setting!

The strength of the jet is reduced by turning the nozzle head (3) clockwise. Note that a small flow will always

occur thus preventing damage to the pump.

4.5 Massage

Before massage, you must definitely reduce the jet pressur e.

Do not utilize full thrust against soft parts of the body

For large-area massage, reduce the strength to half thrust

In order to attach and detach the massage fitting switch off the pump

For point massage, hold the nozzle of the massage hose firmly in your hand under water . Guide

the nozzle of the massage hose over the required places but at some distance from them.

• Massage hose

When you wish to put the massage hose on or take it off, you must first switch off the JETSTREAM equipment.

Put the massage hose onto the nozzle (2) and secure it with the aid of the movab le ring. To take the massage

hose off, hold the hose with one hand, and with the other hand release the mov ab le ring by mo ving it to w ards

the hose. You can now pull the hose off the nozzle.

• Spot massage

For specific massage of particular parts of the body and muscles, use the massage hose with the little nozzle.

When doing so, hold the nozzle of the hose firmly in your hand under water, and guide the nozzle over the

required place but at some distance from it. The shorter the distance between the nozzle and the part of the

body that is to be massaged, the stronger the massage pressure.

nozzle head (2)

pneumatic button

nozzle (3)

24

• Back massage

Massaging the back by means of the massage hose without the assistance of another person is v ery difficult.

Therefore, use the special nozzle for back massage; you attach this to the jet nozzle in the same way as you

attach the massage hose. P osition y ourself with your bac k to the nozzle. The shorter the distance between the

nozzle and your back, the stronger the massage.

• Before massage, y ou m ust definitely reduce the jet pressure.

• Surface massage

Reduce the jet to half strength. Simply position yourself directly in front of the nozzle. The broad pressure-jet

powerfully massages your skin, the tissue beneath it, and your muscles. This promotes the circulation of the

blood, loosens you up and relax es you.

4.6 Swimming against the Current

Select maximum flow and the jet direction so that the layer of water just under the surface is made to flow

strongly, without excessive eff ervescence being visible on the water surface.

4.7 Winterization

If the unit is installed in a pool where there is a danger of frost, the water level has to be reduced to the lo w est

point of the front plate. Close the v alve on the suction side, then unscre w the discharging screw at the underside of the pump.

Do not screw the discharging screw in again after having emptied the pump.

4.8 Again- operation

Before putting into operation again, screw in the dischar ging screw , open valves and fill the pool. Before switching

on, rotate the pump by hand several times at the ventillating fan in the direction shown.

5 SERVICE

Operate the unit only in perfect condition. Take care to have it regularly checked and seviced.

When repairing or bringing into operation again, ensure that tampering has not occured.

The unit is only to be serviced by authorized persons. Do not conduct any work which might

have impair on the safety of the unit. Only buy original spares from your dealer or uwe.

25

6 FITTING INSTRUCTIONS FOR HANDGRIPS

Mounting:

1. Fix upper end cap to pool wall as shown.

2. Pull down lower cap to staighten rope.

3. Drill holes for lower cap and screw into position.

Fitting in concrete shuttered pools

Fitting in steel, aluminium or poly ester pools

800

58

105

45

ca. 736

JETSTREAM

45

58

Ø 7

36

Ø 8

50

nozzle

hand grips are identical

and can be interchanged

broken screw

are only needed

for prefab. pools

prefab. pools:

mark the two

additional drills

dimensions in mm

end cap

gasket

wall plug

fixing screw

end cap

pool wall

gasket

back plate

clamping

plate

gasket

screw M 6x40

screw M 6x25

26

7 INFORMATION FOR THE ELECTRICIAN

7.1 Notes about connection of the pool pumps JETSTREAM COCO 2,5 kW and COCO 3,5 kW

(version without illumination) for threephase 3 N ~ 400 V 50 Hz

This affects your safety!

Therefore, perform all work carefully in accordance with the regulations EN-60335-2-41. You

must definitely observe the safety instructions and the requirements stated by the standards

authorities.

All work on the pool pump may be performed only by firms having authorisation from the uwe company , or

by trained electrical experts. The EN regulations and the relevant accident prevention r egulations must be

observed in all work where voltage is present.

Important notes!

1 Connection to the indoor wiring

For the connection of the 400 V 3N A C 50 Hz (three-phase) electrical supply to the control panel and motor, a

conductor cross-section of at least 5 x 2.5 mm² CU is necessary (pay attention to the length of the cable). An

all-pole isolating switch with 3 mm contact must be pro vided in the mains cable .

2 Safety precautions

To prevent shock-hazard voltage, the unit must be made safe by protective grounding as per EN-60335-2-41

and by installing a 30 mA earth leakage circuit breaker (R.C.C .B.). Furthermore, the motor must be connected

as per EN-60335-2-41 to the potential equalisation system.

3 Fusing

For 400 V: 16 A slo w-b low fuses, or 16 A automatic circuit-breakers. Pay attention to cable length and voltage

drop.

For 230 V: 16 A slo w-b low fuses, or 16 A automatic circuit-breakers. Pay attention to cable length and voltage

drop.

4 Po wer consumption

The maximum power consumption of the pump units at a nominal v oltage of 400 V 3N AC 50 Hz is as

follows:

COCO 2,5 kW bzw. 3,5 kW

BAMBO2, BAMBO, VIVA, LIBRA 3-5, LIDO, LIDO2 3,5 kW

EuroJet 1,7 kW bzw. 3,2 kW (1N PE ~ 230 V 50 Hz)

5 Motor protection

The necessary switching and safety elements are accommodated in the control panel, and so there is no need

for any additional motor protection. Please check whether the overcurrent relay is adjusted to suit the rated

current of the motor.

6 Direction of rotation

Please check the direction of rotation. To do this, observe the direction-of-rotation arrow on the pump. To check

the direction of rotation in the dry-running state, switch the pump on for 2 - 3 seconds only, in order to prevent

damage to the rotating mechanical seal. If the direction of rotation is wrong, the flow speed is much lower, and

furthermore the drive motor takes a higher current, and so the ov ercurrent rela y might respond. If the direction

of rotation is wrong, two phase-wires of the mains cable should be interchanged by an electrical e xpert.

Installing the control panel

Install the control panel in a dry environment, on an internal wall and higher than the water level if possible. Open

the control panel by means of the key supplied. Lead the wires into the control panel through the glands, and

connect the wires in accordance with the wiring diagram. Tighten the glands.

27

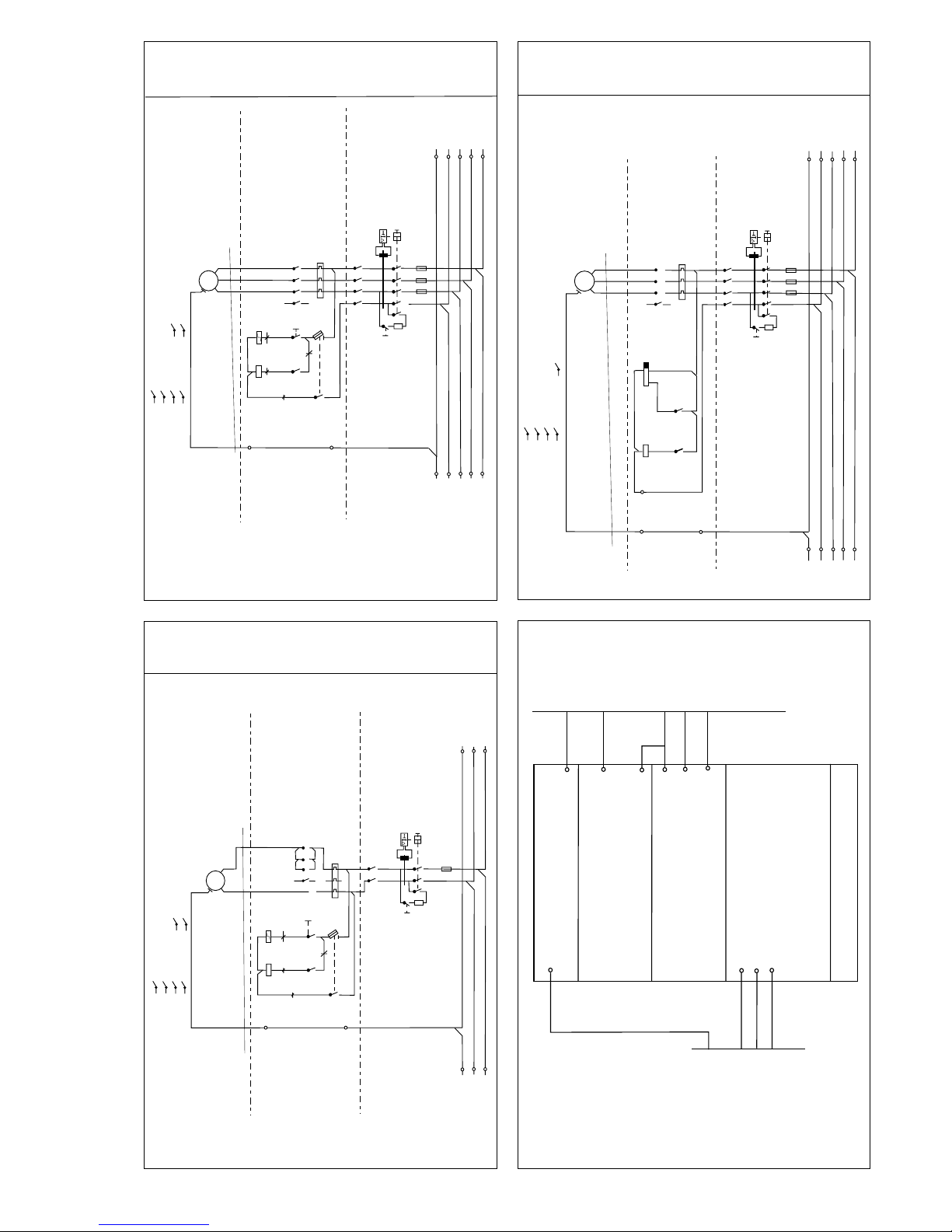

Wiring diagramm for JETSTREAM EuroJet, BAMBO2, BAMBO, COCO

(versions without illumination), JUNO, LIBRA 3-5, LIDO, LIDO 2, VIVA

with pneumatic switch 3N ~ PE 400 V

Wiring diagramm for JETSTREAM, EuroJet, BAMBO2, BAMBO, COCO

(versions without illumination), JUNO, LIBRA 3-5, LIDO, LIDO 2,

VIVA with pneumatic switch and time relay 3N ~ PE 400 V

Wiring diagramm for JETSTREAM, EuroJet, BAMBO2, BAMBO,

COCO (versions without illumination), JUNO, LIBRA 3-5, LIDO, LIDO

2, VIVA with pneumatic switch and token box 3N ~ PE 400 V

Pump control panel build

PE

M1

3~

M

K1

42146

BN

A2 A2

BU

N

N

1

2

1

3

S1

2 2.3

4 2.4

6 2.4

14 2.4

1- 1-

3-

5-

13-

2 2.5

PE

PE

L1

L2

L3

N

PE

L1

L2

L3

N

PE

4A

30mA

F1

16A

53

4

1

531

26

4

2

6

5317

4

2

86

F2

S1

531

426

531

13

F3

1

2

F4

RD

RD

K2

A1

K2

213

A1

1- 2 .5

4x2,5mmý

K1

PE

M1

3~

M

K1

3.5

42146

2-60 min.

A2

A2

A1

N

1

18

S2

2 3.2

4 3.3

6 3.3

14 3.3

15 1-

3-

5-

13-

18 3.5

PE

PE

L1

L2L3N

PE

L1

L2

L3

N

PE

30mA

F1

16A

53

4

1

5

3

1

26

426

5317

4286

F2

S1

531

426

531

13

F3

3

RD

K1

A1

K2

B1

2

1

3

15

K2

3.4

4x2,5mmý

control panel

2.3

4.3

6.3

14.4

1- 1-

3-

5-

13-

2.5

30mA

42

F2

PE

M1

~

M

K1

4

2

14

6

BN

A2 A2

A1

BU

N

N

1

2

1

3

S1

4x2,5mmý

PE

PE

L1NPE

L1

N

PE

4A

F1

16A

1

31

2

42

S1

531

426

531

13

F3

1

2

F4

RD

RD

K2

A1

K2

K1

2

1

1- 2.5

31

cut the general electric connection

before opening the electric control box.

N

1

3 5 1 3 5 13 A1

PE N

L1

L2 L3

246642N14A2

Electric cable 380 V 3N~PE

Ground

Circuit breaker

Circuit

breaker

diving

Main

contactor

Remote control

Towards engine

Pump build

Pump control panel build

pneumatic

switch

pneumatic

switch

pneumatic

switch

Loading...

Loading...