Page 1

computer radio control system

EN

CZECH REPUBLIC

DC-16, DS-16, DS-14

ENFW 3.00

Page 2

computer radio control system

EN

1. Introduction ........................................................................................... 07

1.1 DC/DS .................................................................................................07

1.2 DS-14 ................................................................................................. 07

1.2.1 Activation method for software modules of JETI model 08

1.3 Features ............................................................................................. 09

1.4 Table of Contents ............................................................................. 10

1.5 Technical Support ........................................................................... 11

1.6 DC-16 Package Contents ............................................................... 11

1.7 DS-16 Package Contents ............................................................... 12

1.8 DS-14 Package Contents ............................................................... 12

2. System Specifications .......................................................................... 13

2.1 DC-16 ................................................................................................. 13

2.2 DS-16 ................................................................................................. 13

2.3 DS-14 ................................................................................................. 14

3. Description of Transmitter DC-16 ................................................... 15

3.1 Control Identification ................................................................... 15

3.2 Assembly Identification ................................................................ 16

3.3 Control Stick Assembly .................................................................. 17

3.3.1 Control Stick Length Adjustment ...................................... 17

3.3.2 Swivel Control Stick Adjustment ........................................ 17

3.3.3 Control Stick Tension Adjustment ..................................... 18

3.3.4 Ratchet Tension Adjustment .............................................. 18

3.3.5 Throttle stick travel adjustment ........................................ 19

3.3.6 Transmitter Mode Switch .................................................... 19

3.3.7 Transmitter Gimbals with Switch or Button Installation

.................................................................................................... 20

3.4 Swappable and Assignable Switches ........................................ 22

3.5 Digital Trims .................................................................................... 23

3.6 Transmitter Battery Pack ............................................................... 24

3.6.1 Charging ............................................................................... 24

3.6.2 Battery Replacement .......................................................... 24

3.7 PPM Output Connector .......................................................... 25

3.8 Handling ..................................................................................... 25

1

ver. 5.0 - 2014-04, FW ver. 3.0

Page 3

computer radio control system

EN

4. Description of Transmitter DS-16 .................................................... 26

4.1 Control Identification ................................................................... 26

4.2 Control Identification DS-14 ........................................................ 27

4.3 Assembly Identification ................................................................ 28

4.4 Control Stick Assembly .................................................................. 29

4.4.1 Control Stick Length Adjustment ...................................... 29

4.4.2 Swivel Control Stick Adjustment ........................................ 29

4.4.3 Control Stick Tension Adjustment ..................................... 30

4.4.4 Ratchet Tension Adjustment .............................................. 31

4.4.5 Throttle stick travel adjustment ....................................... 31

4.4.6 Transmitter Mode Switch .............................................. 33

4.4.7 Transmitter Gimbals with Switch or Button Installation

.................................................................................................... 34

4.5 Swappable and Assignable Switches ........................................ 37

4.5.1 Switch Removal Procedure ................................................. 38

4.5.2 Assembly Procedure ............................................................. 38

4.6 Digital Trims .................................................................................... 39

4.7 Transmitter Battery Pack ............................................................... 40

4.7.1 Charging ............................................................................... 40

4.7.2 Battery Replacement ........................................................... 40

4.8 PPM Output Connector ................................................................ 41

4.9 Handling .......................................................................................... 41

5. RF Transmitter Modules ..................................................................... 42

6. Transmitter Powering ON/OFF .......................................................... 43

6.1 Transmitter, Powering-ON ........................................................... 43

6.2 Transmitter Turning-OFF ............................................................... 43

6.3 Transmitter Restart ...................................................................... 43

7. Initial switching-on ............................................................................... 44

7.1 Main display ..................................................................................... 44

7.2 Navigation in the Menu ................................................................. 44

7.2.1 Browsing through the Menu ............................................... 46

7.2.2 Basic Menu Structure ........................................................ 46

7.3 Model Set-up Guide ....................................................................... 47

7.3.1 Airplane .................................................................................. 47

2

Page 4

computer radio control system

EN

7.3.2 Helicopter ................................................................................ 49

7.3.3 General .................................................................................... 51

7.3.4 Set up of Receiver Outputs .................................................. 53

8. Duplex Receivers .................................................................................... 55

8.1 Description ....................................................................................... 55

8.2 Installation ....................................................................................... 55

8.3 Binding .............................................................................................. 55

8.3.1 Standard pairing procedure .............................................. 55

8.3.2 A lt er na ti ve pa ir in g p ro ce du re th ro ug h t he

transmitter m enu .. .......................................... 56

8.4 Range test ......................................................................................... 56

8.5 Fail safe .............................................................................................. 56

8.6 Technical data receivers ................................................................. 58

8.6.1 Technical data receivers outside the U.S. ......................... 58

8.6.2 Technical data receivers for the U.S. ................................... 59

8.7 Using Device Explorer To Configure the Receiver ...................... 60

8.7.1 Support of remote commands for EX Bus devices ........... 63

8.8 RC-Switch ........................................................................................ 65

9. Main menu ............................................................................................... 67

9 .0 .1 Pa s sw ord pro te c t io n a ga in st a cc i de nt al

configuration changes .................................................................. 68

9.1 Model ................................................................................................. 69

9.1.1 Model Selection ..................................................................... 69

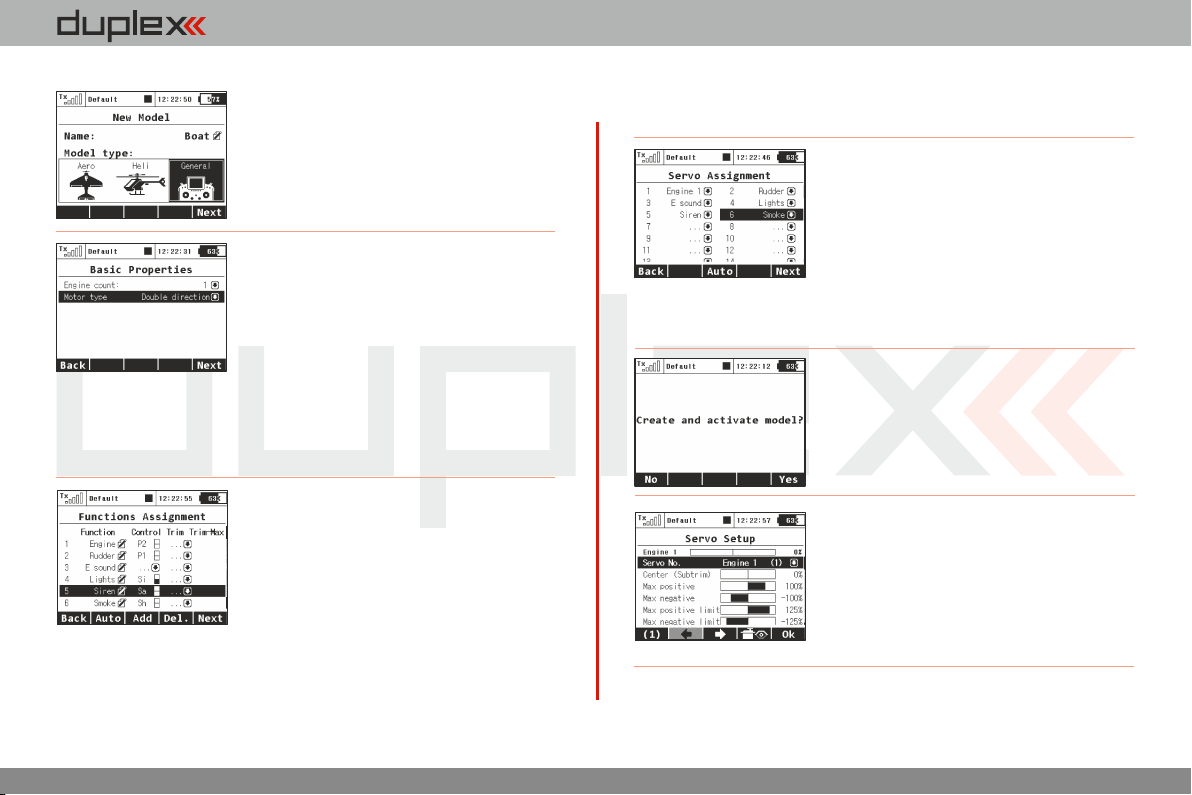

9.1.2 New Model .............................................................................. 70

9.1.3 Basic configuration- AIRPLANE ......................................... 71

9.1.4 Basic Configuration - HELICOPTER .................................... 72

9.1.5 Swash mix ............................................................................... 74

9.1.6 Basic Configuration-GENERAL ........................................... 74

9.1.7 Assignment of functions ...................................................... 75

9.1.8 Servo Assignment ................................................................. 76

9.1.9 Servo Setup ............................................................................. 77

9.1.10 Servo balancer ................................................................... 78

9.2 Fine Tuning ....................................................................................... 80

9.2.1 Flight Modes ......................................................................... 80

3

Page 5

computer radio control system

EN

9.2.2 Digital trim .............................................................................. 83

9.2.3 Flight Mode Trims .................................................................. 85

9.2.4 Dual Rate/Exponential ........................................................ 86

9.2.5 Programmable Function Curves ....................................... 88

9.2.6 Aileron Differential ................................................................ 90

9.2.7 Ailevator Function ............................................................... 90

9.2.8 V-Tail Mix ................................................................................. 91

9.2.9 Delta/Elevon Mix ................................................................... 92

9.2.10 Butterfly Mix ......................................................................... 92

9.2.11 Free Mixes ............................................................................. 94

9.2.12 Governor/Gyro ..................................................................... 97

9.2.13 Throttle Limiter .................................................................... 98

9.2.14 Snap Roll .............................................................................. 98

9.3 Advanced Properties .................................................................... 100

9.3.1 Other Model Options .......................................................... 100

9.3.2 Sticks / Switches Setup ..................................................... 101

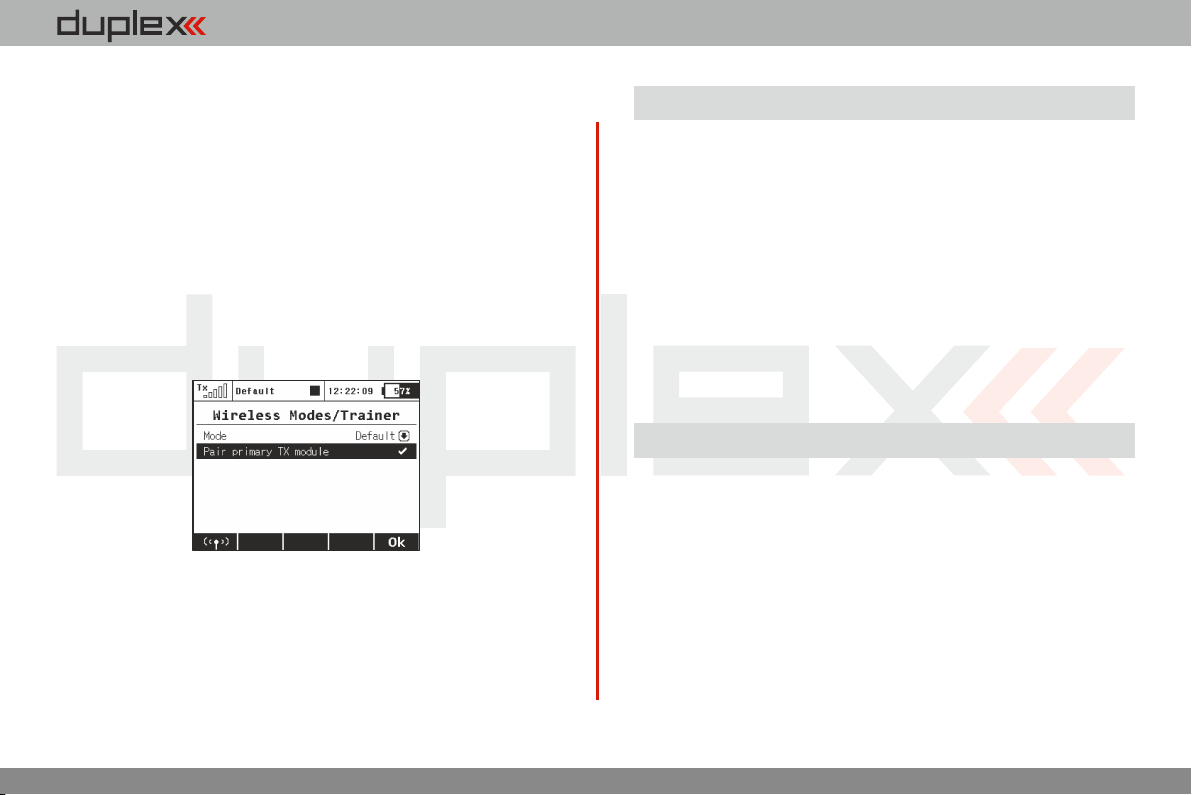

9.3.3 Wireless Modes/Trainer .................................................... 102

9.3.4 Logical Switches ................................................................. 107

9.3.5 Sounds on Event (Sound Assignments) .......................... 109

9.3.6 Sequencer ............................................................................. 110

9.3.7 Accelerometer (DS only) ................................................... 111

9.3.8 Telemetry Controls .............................................................. 112

9.3.9 Sound of Proportional Controls ....................................... 113

9.4 Timers/Sensors .............................................................................. 115

9.4.1 Timer ...................................................................................... 115

9.4.2 Alarms ................................................................................... 117

9.4.3 Vario ....................................................................................... 118

9.4.4 Voice Output ........................................................................ 119

9.4.5 Sensors/Logging Setup .................................................... 120

9.4.6 Displayed Telemetry ........................................................... 121

9.4.7 Main Screen ......................................................................... 124

9.5 Applications ................................................................................... 125

9.5.1 Data Analyzer ...................................................................... 125

9.5.2 Audio Player ........................................................................ 126

9.5.3 JETIBOX ................................................................................. 126

9.5.4 Games ................................................................................... 127

4

Page 6

computer radio control system

EN

9.6 System ............................................................................................ 127

9.6.1 Configuration ..................................................................... 127

9.6.2 Servo & Range Test ............................................................. 129

9.6.3 View Inputs ........................................................................... 130

9.6.4 Receiver Output (Servo Monitor) .................................... 131

9.6.5 System sound ....................................................................... 131

9.6.6 Sound Volume ..................................................................... 132

9.6.7 Installed Modules ............................................................... 132

9.6.8 Limitations in copying models between transmitters . 133

9.6.9 USB ......................................................................................... 133

9.6.10 Info ....................................................................................... 133

9.7 Throttle Lock .................................................................................. 135

9.8 Select Input control ..................................................................... 135

9.9 Trim Menu ..................................................................................... 139

9.10 How Transmitter Output Functions are Processed .............. 139

10. Transmitter to PC Connection ....................................................... 140

10.1 Memory & System Files ............................................................. 140

10.2 Update Firmware ....................................................................... 140

10.3 Sounds, Alarms & Acoustic Updates ....................................... 140

10.4 System Backup ............................................................................ 141

10.5 PC Joystick ..................................................................................... 141

10.6 Telemetry Data Logging ............................................................. 141

10.7 Copying models between the transmitters ............................. 141

11. Battery Safety Handling Rules ........................................................ 142

11.1 Transmitter Battery Pack .......................................................... 142

11.2 General Safety Rules ..................................................................... 142

11.3 Flight Safety Check ..................................................................... 143

11.4 Application ..................................................................................... 143

11.5 FCC /IC Information ....................................................................... 143

12. Model Menu – Airplane/Sailplane .............................................. 145

12.1 Butterfly Mix (Crow Mix) .............................................................. 145

12.2 Aileron Differential ....................................................................... 145

12.3 Ailevator ....................................................................................... 146

5

Page 7

computer radio control system

EN

12.4 V-Tail Mix ..................................................................................... 146

12.5 Delta/Elevon Mix .......................................................................... 147

12.6 Spoilers to Elevator Mix ............................................................. 147

12.7 Ailerons to Rudder Mix ................................................................ 148

12.8 Rudder to Ailerons Mix ................................................................. 149

12.9 Butterfly (Crow) Mix ..................................................................... 150

12.10 Rudder to Elevator Mix ............................................................. 151

12.11 Aileron to Flap Mix ..................................................................... 152

12.12 Aileron to Flap Mix (Brake Variation) ................................... 153

12.13 Elevator to Flap Mix ................................................................... 153

12.14 Flaps Mix – Camber Control .................................................... 154

12.15 Throttle Cut (Kill Switch) ........................................................... 155

12.16 Throttle Idle ................................................................................. 155

13. Accessories for Transmitters ........................................................... 156

13.1 Tray for DC-16 ................................................................................ 156

13.2 Stick Ends for DC/DS ............................................................... 156

13.3 Replacement switches ................................................................ 156

13.4 Straps for DC/DS .................................................................... 157

13.5 Charging ......................................................................................... 157

13.6 Other .............................................................................................. 157

13.7 O v e r v i e w o f t h e D S - 1 4 e x p a n s i on m o d u l e s

(transmitter e qu ip me nt comparison)............ 1 58

6

Page 8

computer radio control system

EN

1 Introduction

1.1 DC/DS

The DC/DS transmitters were developed and produced with the

cooperation of professional and world champion pilots. These

transmitters were created with the goals of maximum utility, simple

handling, maximum durability and the ultimate reliability of their

mechanical parts. The metal case, with its chemically resistant

outside surface treatment, provides maximum protection for the

interior components. The straightforward case shape makes

servicing easy. The metal, quad ball bearing equipped, stick gimbals

with their magnetic Hall sensors are another revolutionary design

concept used to make the DC/DS among the world’s most advanced

R/C systems.

Purposefully placed at the top of the transmitter, the 3.8“ backlit LCD

display with its wide viewing angle offers nearly perfect visibility in

just about any lighting condition. Thanks to its high resolution

display and use of a relatively large number of graphic images it was

possible to create a simple and intuitive setup procedure for

displaying telemetric data.

The DUPLEX EX family of products have been equipped with an

improved telemetric data transfer system which can be viewed on

the LCD transmitter display or saved for later analysis on a PC. The

transmitter allows the setup of audible notifications (optionally

created by the user), which can be related to actual telemetric values

or to sound alarms or signals which have been assigned to

conditions of various control elements.

1.2 DS-14

The DS-14 hand-held transmitter expands the range of model

transmitters equipped with the JETI Duplex system, this new design

is based on the high-end model DS-16. Unlike the DS-16, the DS-14

offers a unique concept of individual feature setup based upon the

requirements of each customer. The transmitter is available in a basic

configuration that will meet the needs of most users for most model

types. For individual setting of the transmitter there is a configurator

available at swshop.jetimodel.com. After the simple registration of

your transmitter it is possible to select additional features based

upon your individual demands. For example, if you fly only

helicopter models, select such features as "Throttle Limiter" or

"Gyro Settings" but you will probably not need to increase the

number of flight modes. These are more suitable for controlling

glider models.

The DS-14 features newly designed gimbal sticks. We managed to

keep all the characteristics of the full metal sticks used in the DS-16,

mainly thanks to high-quality materials and Hall sensors inside the

sticks which are fully supported by high quality ball bearings.

As a result, the DS-14 becomes a powerful tool with the possibility to

individually select many features at a very attractive price.

7

1.1.

Page 9

computer radio control system

EN

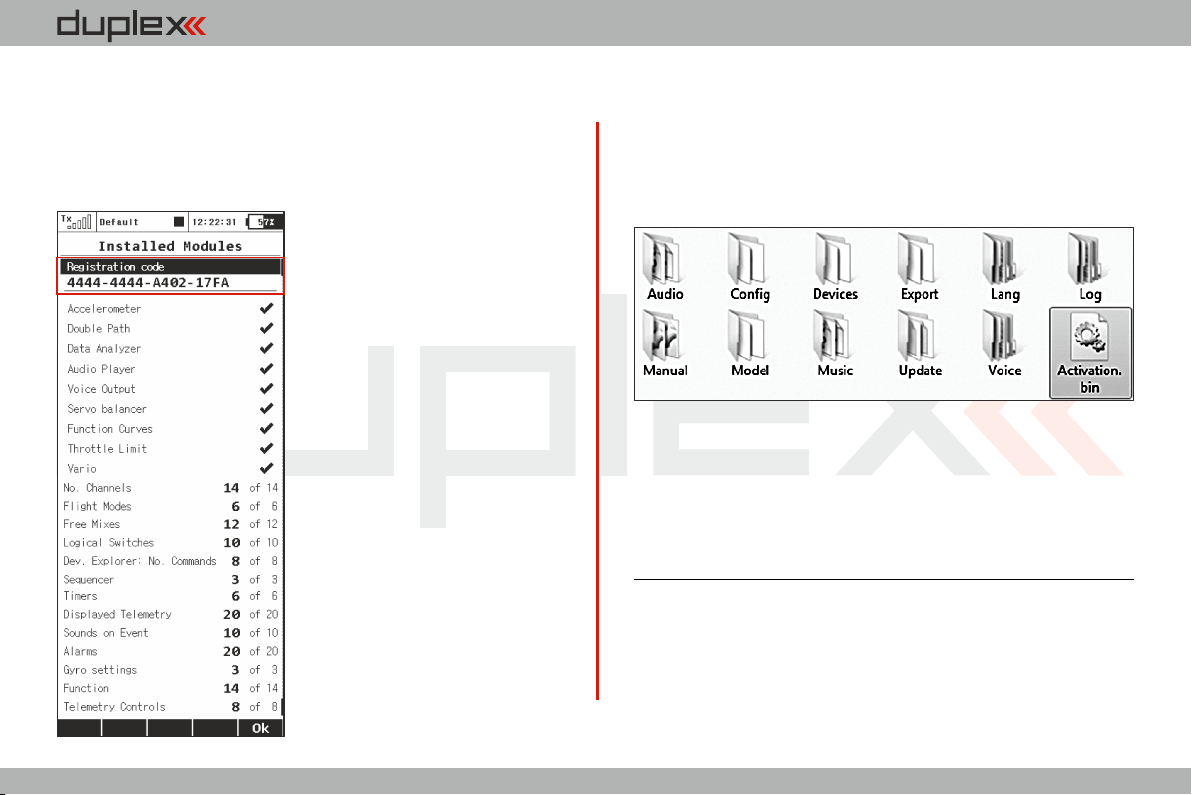

1.2.1 Activation method for software modules of JETI model

1. Make sure you have the most current firmware version in your

transmitter.

2. Register onswshop.jetimodel.com.

3. After clicking on the „Register

new product“ button you will be

redirected to a form where you

enter a product type (DS-14),

followed by the „serial number”

(SN: xxxxxxxxx) (to be found on the

back of the transmitter behind the

screen) and then enter the „16

digit registration code” (xxxxxxxx-xxxx-xxxx) (see the menu

„System -> Installed Modules”

highlighted by the frame). After

registering your transmitter, you

can select individual function

modules that you want to activate.

4. Mark selected modules and

proceed to checkout.

5. Then you will be asked to pay

the rel ev ant amount. After

p a y m e n t , a u n i q u e

nontra ns ferable file named

“A c t i va t i o n. b i n” w i l l b e

generated. It will then be sent to your e-mail.

6. Connect the DS-14 to your computer and enable USB mode.

7. Copy the “Activation.bin” file to the transmitter SD card into the

root folder. The contents of the transmitter SD card can then look like

this:

8. Disconnect the transmitter from the computer (Do not forget to

confirm the safe hardware removal). Then confirm in your

transmitter that you want to update and restart it.

If the activation is successful, an informative table with a list of

modules appears immediately after switching on. Then it is

possible to operate the transmitter as usual.

8

1.1.

Page 10

computer radio control system

EN

1.3 Features

Duplex 2.4GHz – the DC/DS transmitters feature the Duplex 2.4GHz,

frequency hopping, digital, data stream system originally developed

by JETI model in the Czech Republic. This system has been reliably

used for many years.

Built-in Telemetry – from the start, the DC/DS transmitters were

designed and built with many attractive features and include the full

integration of all Duplex telemetry sensors.

Transmitters - these designs emphasize use comfort, state-of-theart appearance and use premium quality materials.

Precise Gimbals – the transmitter gimbals are equipped with Hall

sensors and ball bearings for precision movement with an almost

unlimited lifespan.

LCD Display – oversized 3.8“ backlit LCD display with 320x240

resolution which is highly visable under any light conditions.

Li-Ion Battery – provides a proven and reliable energy source with a

high capacity (3200mAh) and a long service life.

Easy Charging – simply connect the wall power supply to the

transmitter. The DC/DS may also be charged through their USB to PC

interface.The charging progress is shown on the DC/DS display.

Integrated Antenna – the antennas are located behind fully

integrated covers in both the DC-16 and DS-14/16 cases for

protection against mechanical damage.

Large Memory – 4GB memory space for storing models, sounds, and

telemetry data.

USB Connector – convenient connection to your PC. Fast firmware &

sound upgrades, telemetry data downloads.

Fast Navigation – 3D wheel-style interface combined with function

keys allow for speedy navigation within the DC/DS menu.

Digital Trims – fully programmable trims and a revolutionary

automatic trimming function.

Swappable and Assignable Switches – all of the switches on the

DC/DS transmitters (2- or 3-position) can be easily moved and

assigned to create a custom configuration that works best for your

application.

Programming – the logical and intuitive transmitter firmware is

designed to be simple to use. Just follow the step-by-step screens.

The creation of a new model can be accomplished with just a few

easy steps.

Sounds/Alarms – the DC/DS transmitters are equipped with audible

alarms and also allows the use of user-recordable alarms and sounds

to keep you fully informed while also keeping distractions to a

minimum. "

Depends on equipment - The specific function is available if the

corresponding module is activated. The DC-16 and DS-16

transmitters in their basic version have all the modules activated on

maximum possible values. With the DS-14 transmitter it is possible

to take advantage of the system that enables purchasing of the

9

1.1.

Page 11

computer radio control system

EN

extended functions from swshop.jetimodel.com.

1.4 Table of Contents

To make navigation faster, the DC/DS transmitter Instruction Manual

has been divided into 5 basic groups:

1 . Introduction and product support.

2. Basic description and mechanical adjustments.

3. First time switch-on. Basic helicopter and airplane set up.

4. Advanced programming. Detailed descriptions.

5. PC upgrade/upload, safety information, and special mixes.

Important parts of the instructions are separated from the text and

highlighted according to importance.

Advice Note Warning

Advanced modelers may want to begin with group 3 where you will

get all of the basic information for model setup. This is the quickest

way to understand the basic ideas of the DC/DS transmitter

programming and with this basic information you can begin to

create your own model. More advanced programming functions are

found in group 4. This is where you can find detailed descriptions of

all of the DC/DS functions. The last section provides detailed

description of firmware upgrades, downloads, and special mixes.

10

1.1.

Page 12

computer radio control system

EN

1.5 Technical Support

If you feel uncertain about how to set up particular transmitter

functions, do not hesitate to take advantage of our technical

support:

1. Web Site

Either the JETI model (manufacturer) or your local distributor’s web

sites offer a wide range of support for the DC/DS transmitters. You will

find advice, tips or frequently asked questions (FAQ) which, in most

cases, contain the answers to your questions.

2. Distributor, Manufacturer

You may also find support at your local hobby shop, distributor, or

directly with the manufacturer JETI model s.r.o.

3. Service and Warranty Coverage

JETI model CZ exclusively warranties that the products purchased will be

free from defects in materials and workmanship for a period of 24 months

from the date of purchase by the customer. This warranty covers only

those products purchased from an authorized JETI model CZ distributor

or dealer. Third party transactions are not covered by this warranty. Proof

of purchase is required for warranty claims. Repair or replacement

decisions are at the sole discretion of JETI model CZ or an authorized

service provider. This warranty does not cover cosmetic damage or

damage due to an accident, misuse, abuse, negligence, commercial or

research use, or modification of or to any part of the product. This

warranty does not cover damage due to improper installation, operation,

maintenance, or attempted repair by anyone other than JETI model CZ or

an authorized service provider.

JETI model CZ reserves the right to change or modify this warranty

without notice and disclaims all other warranties, expressed or implied.

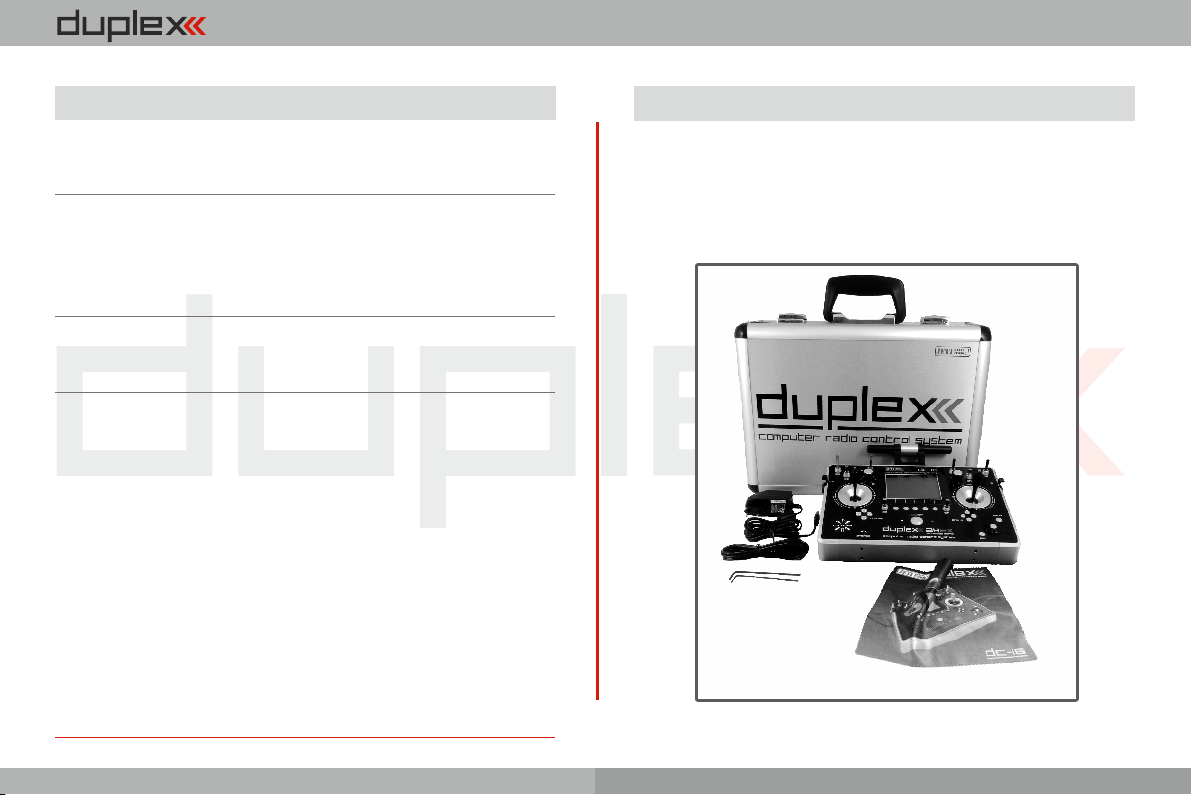

1.6 DC-16 Package Contents

1. 2. 3. JETI DC-16 Transmitter, Wall Power Supply, JETI DC-16

Transmitter Aluminum Case, USB PC Cable, Installation Hex Key 4. 5.

Set (1,5mm; 2mm), Cleaning Cloth, Instruction Manuals 6.

3

2

4

5

11

1

6

1. 2.

Page 13

computer radio control system

EN

1.7 DS-16 Package Contents

1. 2. 3. JETI DS-16 Transmitter, Wall Power Supply, JETI DS-16

Transmitter Aluminum Case, USB PC Cable, Installation Hex 4. 5.

Key Set (1,5mm; 2mm), Cleaning Cloth, Instruction Manuals 6.

3

1

2

5

4

6

1.8 DS-14 Package Contents

1. 2. 3. 4. JETI DS-14 Transmitter, Wall Power Supply, USB PC Cable,

Installation Hex Key Set (1,5mm; 2mm), Instruction Manuals.

2

3

4

1

1

12

2.2.

Page 14

computer radio control system

Frequency

2.4GHz

Dimensions

WxLxH

(with Antenna)

180x270x40 mm

7.1x10.6x1.6",

(230x270x40mm)

(9.1x10.6x1.6")

Weight

1.5kg (53 oz)

Number of Channels

16

Number of control directions

using all Sticks/Switches/Knobs

Up to 20

Resolution

4096 steps

Battery

Li-on 3200mAh 3.6V

Operating Time

Up to 11 hours

Internal Memory

microSD 4GB

Telemetry

Yes

PC Connection

USB mini

Graphic Display

3.8" - 320x240px

Operational Temperature

-10 up to 60 °C

(14 up to140°F)

Frequency

2.4GHz

Dimensions

WxLxH

(with Display)

194x172x40 mm

7.7x6.8x1.6"

(194x233x40 mm)

(7.7x9.2x1.6")

Weight

1.25kg (44 oz)

Number of Channels

16

Number of control directions

using all Sticks/Switches/Knobs

Up to 18

Resolution

4096 steps

Battery

Li-on 3200mAh 3.6V

Operating Time

Up to 11 hours

Internal Memory

microSD 4GB

Telemetry

Yes

PC Connection

USB mini

Graphic Display

3.8" - 320x240px

Operational Temperature

-10 up to 60 °C

(14 up to 140°F)

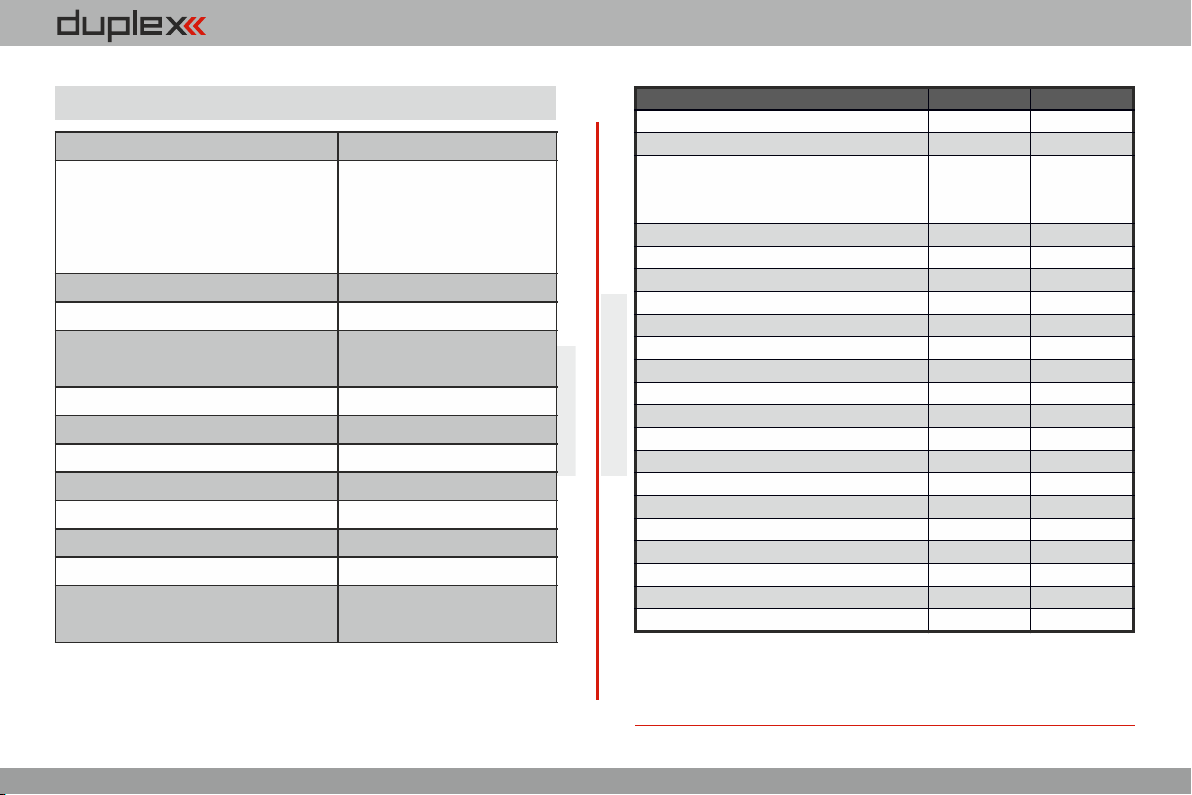

2 System Specifications

2.1 DC-16 2.2 DS-16

EN

13

2.2.

Page 15

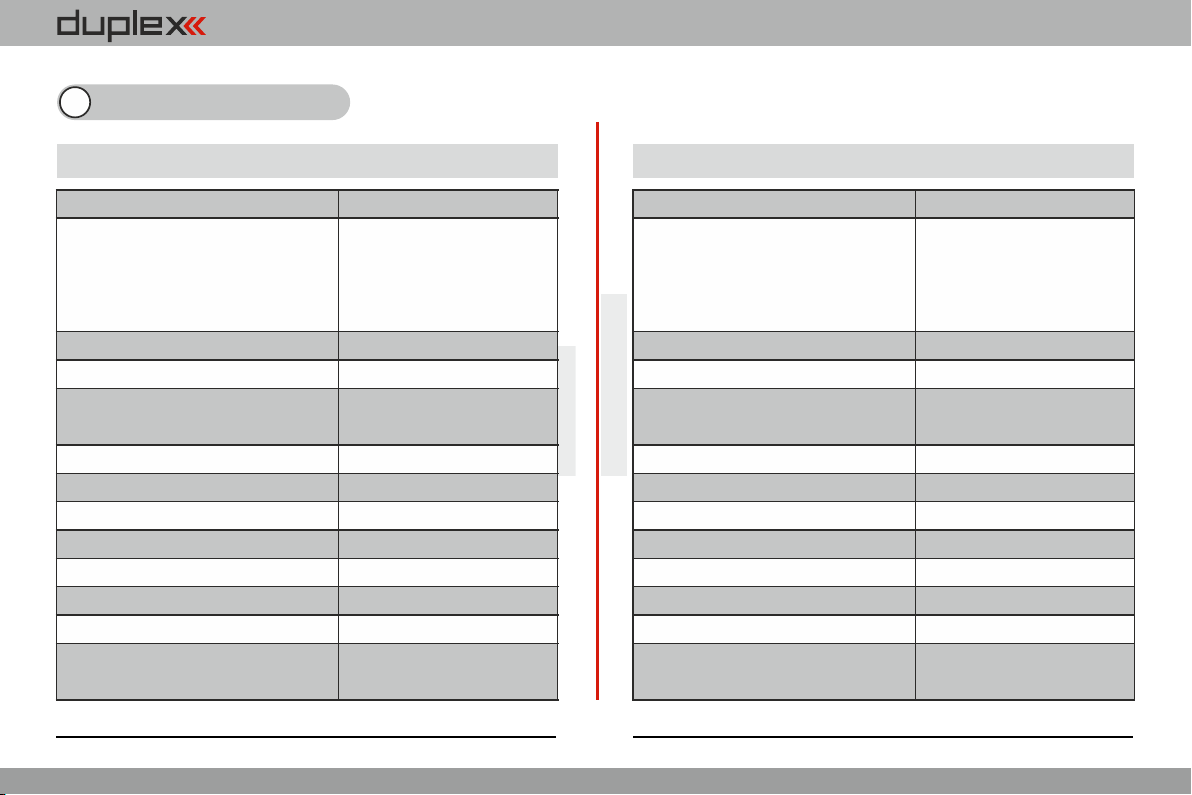

2.3 DS-14

Frequency

2.4GHz

Dimensions

WxLxH

(with Display)

194x172x40 mm

7.7x6.8x1.6"

(194x233x40 mm)

(7.7x9.2x1.6")

Weight

1.25kg (44 oz)

Number of Channels

Up to 14

Number of control directions

using all Sticks/Switches/Knobs

Up to 18

Resolution

4096 steps

Battery

Li-on 3200mAh 3.6V

Operating Time

Up to 11 hours

Internal Memory

microSD 4GB

Telemetry

Yes

PC Connection

USB mini

Graphic Display

3.8" - 320x240px

Operational Temperature

-10 up to 60 °C

(14 up to140°F)

Software modules

Basic

Extended

Number of channels

8

14

Accelerometer

m

l

Secondary transmitter module in

*)

Trainer/Student or „Double Path“

function

m

l

Number of flight modes

3

6

Free mixes

5

12

Telemetry analysis via graphs

m

l

Audio player

m

l

Logical switches

0

10

Number of control commands

0

8

Sequencer

0

3

Timers

3

6

Number of telemetry items on the LCD

10

20

Sounds on events

5

10

Alarms

10

20

Voice output

m

l

Gyro setting function

1

3

Servo balancer

m

l

Function curves

m

l

Telemetry controls

0

5

Throttle limiter

m

l

Vario

m

l

computer radio control system

EN

*) Double Path mode allows the operation of two separately paired receivers in a model. Even if this

module is not activated, both transmitter modules communicate with the receiver for the best possible

connection quality and safety.

m - The module is not included in the basic version

l - This function is available after purchasing the module

14

2.2.

Page 16

computer radio control system

EN

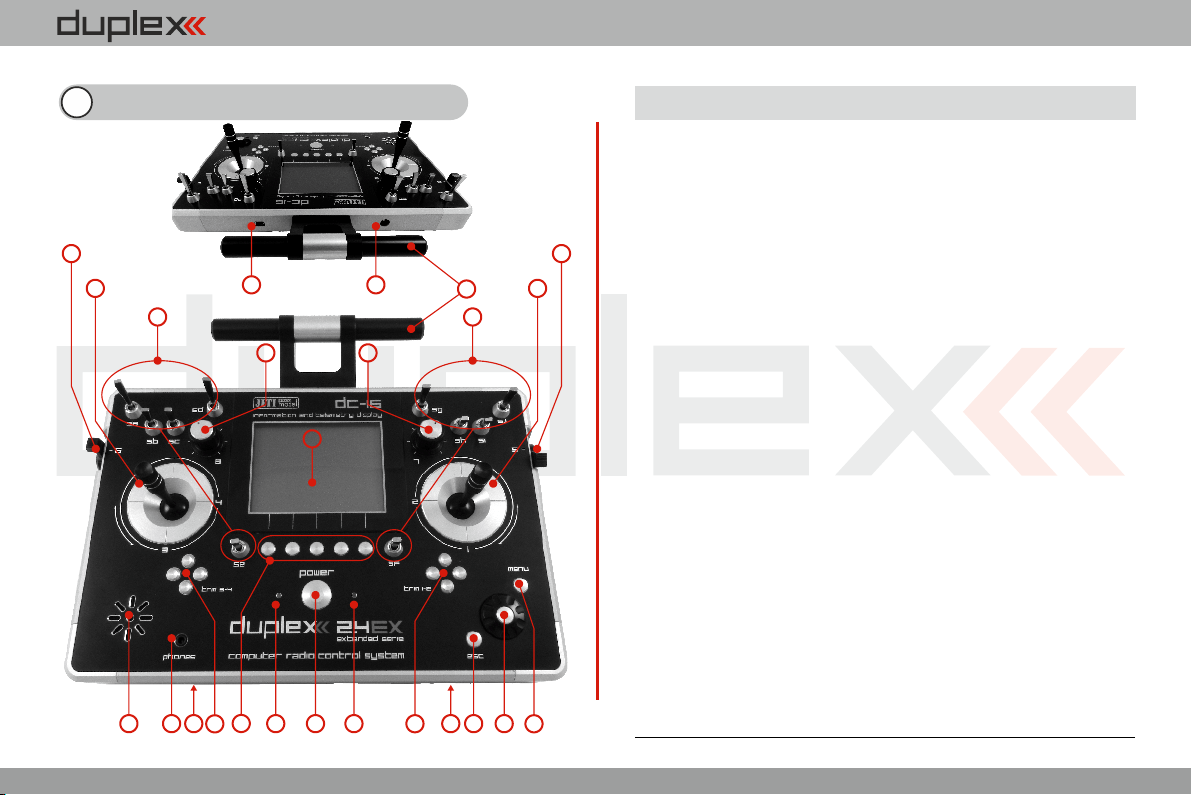

3 Description of Transmitter DC-16

2

3

1921

18

10

4

22 22

11

12

17

89

2020

5

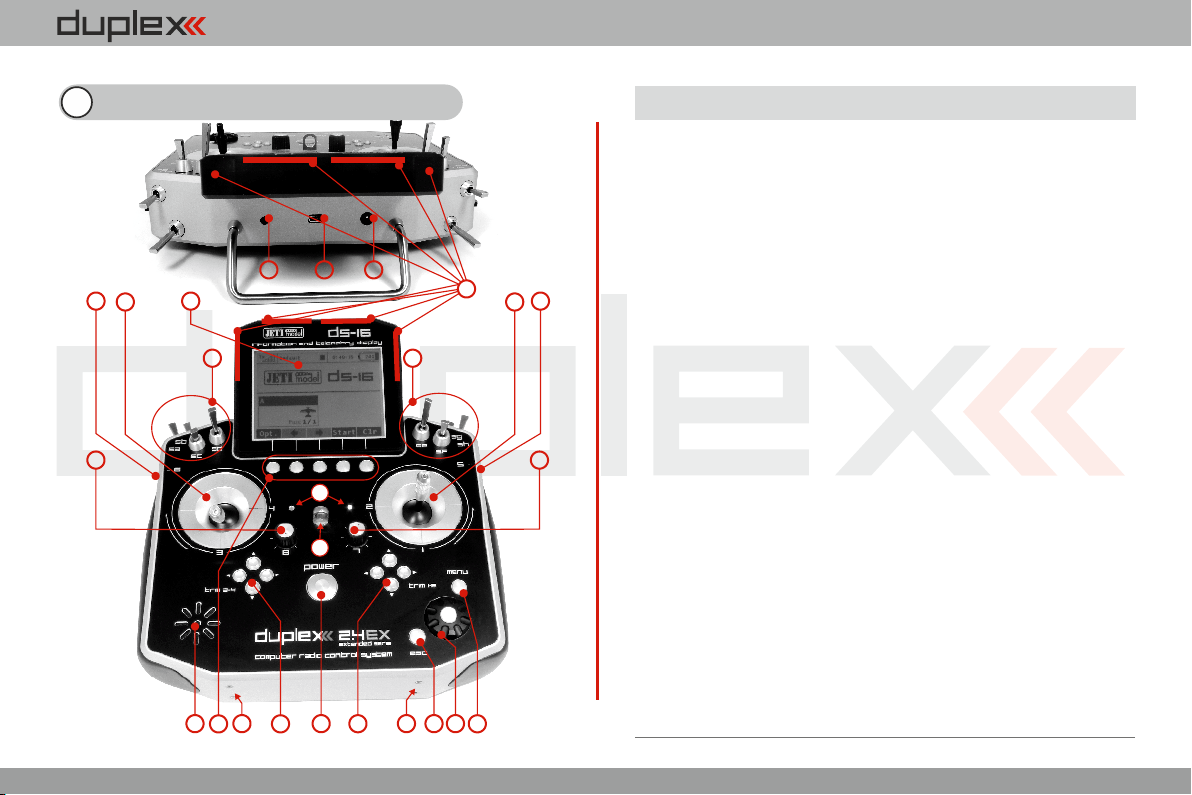

3.1. Control Identification

1. Right Stick 1, 2 – the DC-16 Transmitter Supports Modes 1-4, see Control

Sticks -> mode change

2. Left Stick 3, 4 the DC-16 Transmitter Supports Modes 1-4, see Control

Sticks -> mode change

67

16

3

15

1

14

13

3. Swappable and Assignable Switches: Sa, Sb, Sc, Sd, Se, Sf, Sg, Sh, Si, Sj

4. Digital Trims for the Left Stick T3, T4

5. Digital Trims for the Right Stick T1, T2

6. Right Side Control Lever 5

7. Left Side Control Lever 6

8. Rotary Control Knob 7

9. Rotary Control Knob 8

10. LCD Display

11. Function Buttons F1 – F5

12. Transmitter On/Off Power Switch

13. 3D Control Selector

14. Menu Button

15. ESC Button

16. Antenna/ Transmitter Handle

17. Charge Jack

18. USB PC Interface

19. Earphone Jack

20. ON/OFF & Charging LED Indicators

21. Speaker

22. Transmitter Neck Strap Bracket Installation Holes

15

2.2.

Page 17

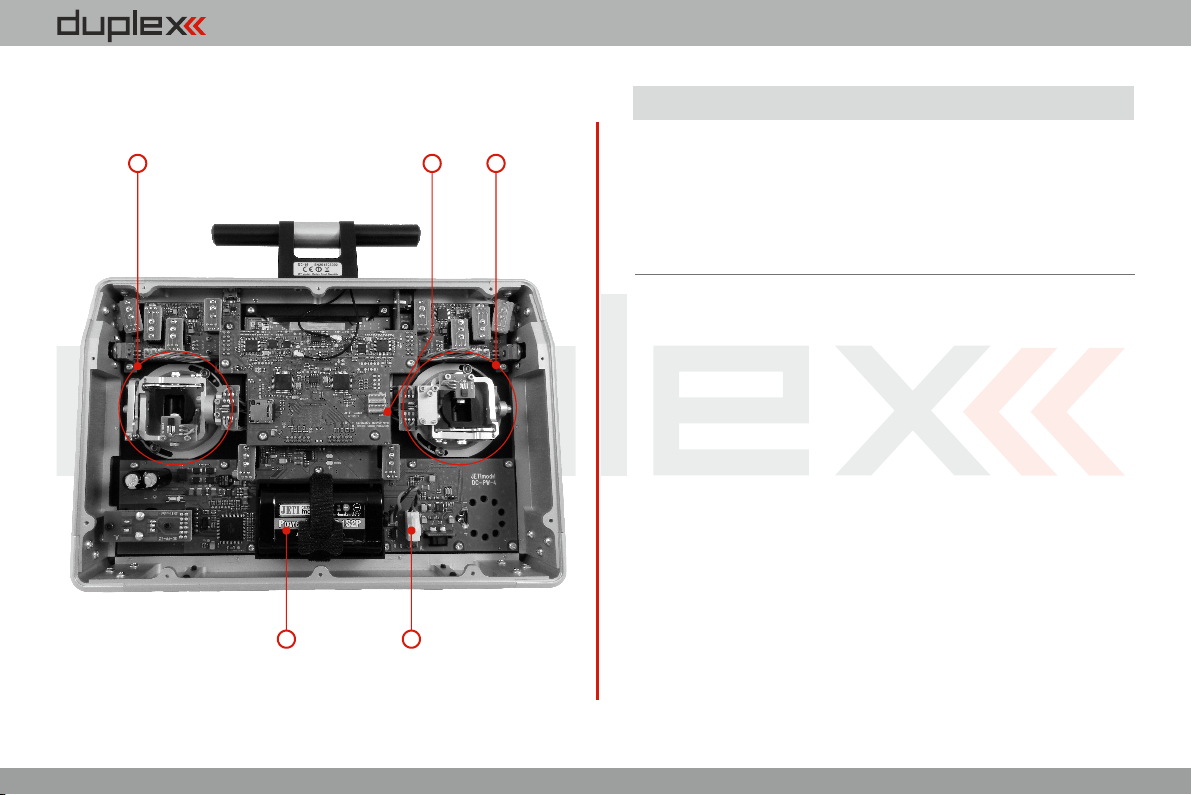

computer radio control system

3.2. Assembly Identification

EN

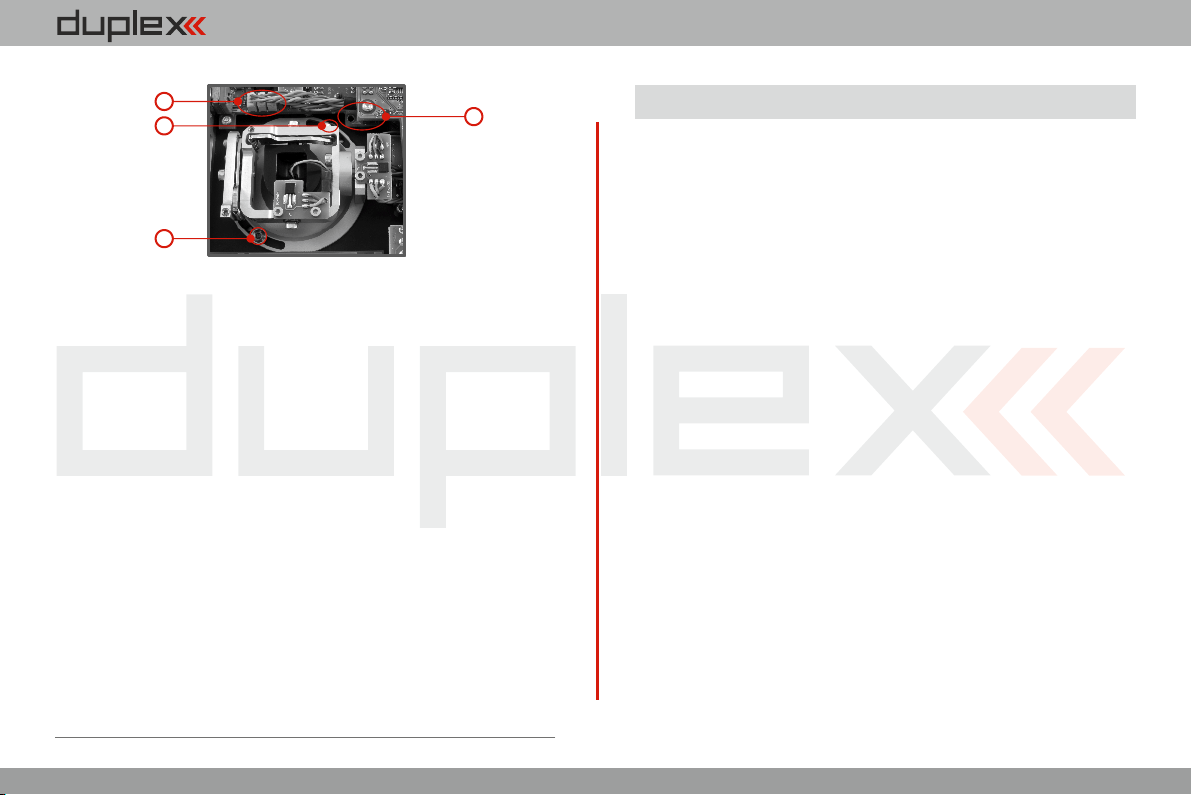

25 2627

24

23

23. Battery Connector

24. Transmitter Battery Pack

25. PPM Output Connector

26. Left Gimbal Assembly

27. Right Gimbal Assembly

16

2.2.

Page 18

computer radio control system

EN

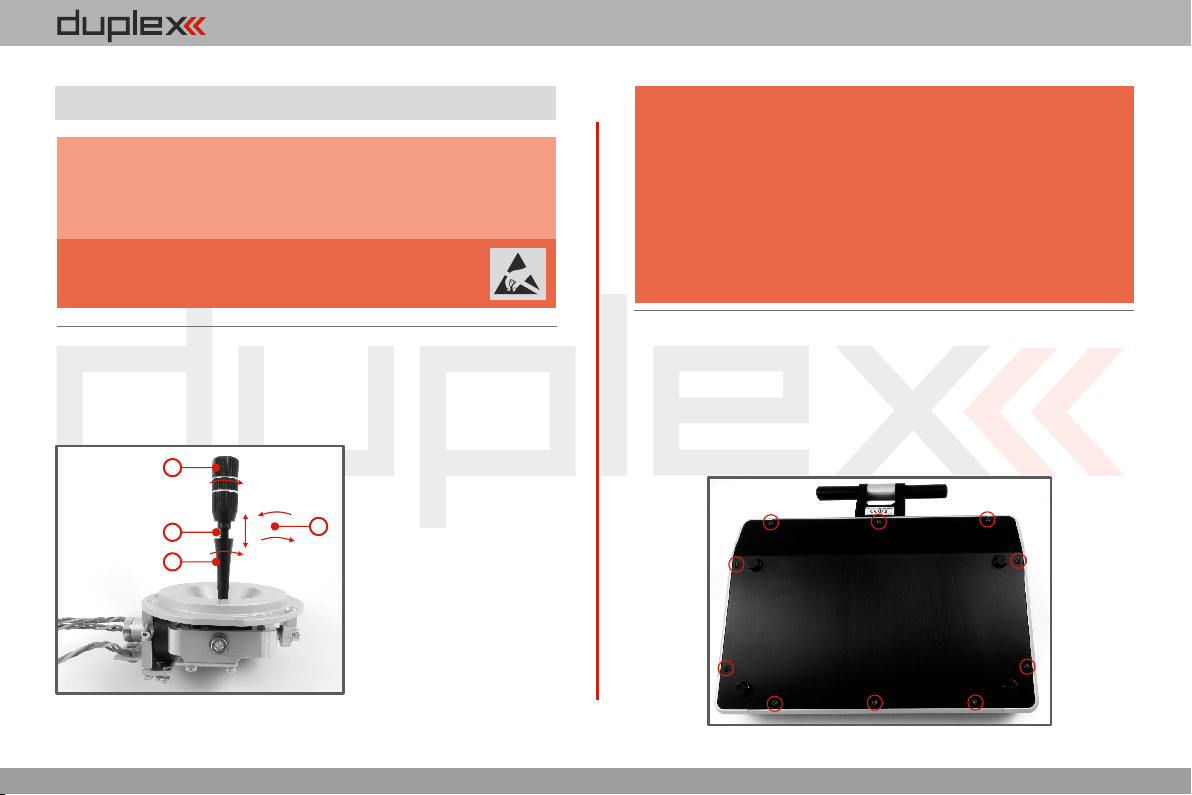

3.3 Control Stick Assembly

Note:

Warning:

3.3.1 Control Stick Length Adjustment

The stick length is adjustable to suit your flying style. The stick end

separates into two parts.

When handling with back cover removed always

switch off the transmitter and disconnect the

battery (unplug the connector). Also do not connect

the charging adapter or the USB cable.

Restrict your contact with the printed circuit

boards to a minimum. You can damage your

radio by electrostatic discharge!

1. Hold the top part of the

st i ck e nd f irml y a nd

1

2

3

u n s c r e w ( t u r n i t

counterclockwise).

2. Turn the stick end

clockwise to shorten or

4

c o un te r cl oc k wi se t o

lengthen the overall stick

length.

3. Adjust the lower part

to support the top part of

the stick end.

4. F i na lly s ec ure b y

tightening both parts to

each other.

Warning:

If you have installed optional sticks with switch or button ends,

make sure that while adjusting the stick length you observe the

wires that pass through the stick shaft and through the gimbal

opening in order to prevent damaging the connecting cables.

The safest method is to remove the small set-screw from the

side of the stick housing to allow the switch or knob internals to

remain stationary while you rotate the stick housing for height

adjustment.. (See 4.3.6)

3.3.2 Swivel Control Stick Adjustment

In order to customize the feel of your radio you may adjust the angle

of the stick control assemblies.

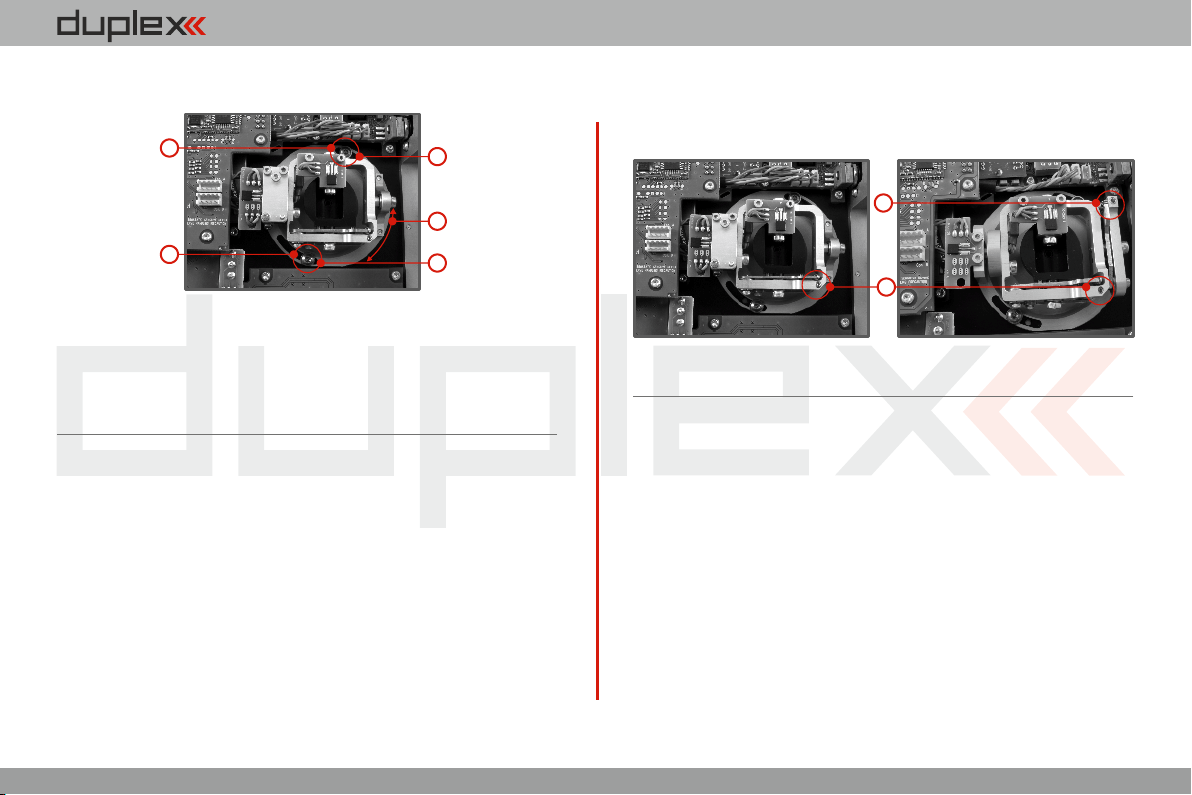

1. switch off the transmitter and remove the 10 screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack connector.

17

2.2.

Page 19

computer radio control system

EN

2. Loosen both machine screws securing the control stick

assembly.

2

2

3. Adjust (rotate) to desired position.

4. Securely tighten both machine screws securing the control stick

assembly.

5. Reconnect transmitter battery pack and reinstall radio back

cover and cover screws.

4

3

4

3.3.3 Control Stick Tension Adjustment

The stick gimbal tension is fully adjustable for each axis. This allows

you to fully customize your radio‘s control feel. Simply adjust each

gimbal‘s spring to your desired tension.

1. Switch off the transmitter and remove the 10 screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack

connector.

2. Use indicated machine adjustment screws to change the

desired spring tension.

By turning the screw anticlockwise, you will loosen spring

tension. As a result the moving resistance of the control stick will

decrease. By turning the screw clockwise, you will tighten

spring tension. As a result the moving resistance of the control

stick will increase.

2

2

3. Reconnect transmitter battery pack and reinstall radio back

cover and cover screws.

3.3.4 Ratchet Tension Adjustment

Do you prefer smooth throttle feel or ratchet throttle feel? You can

adjust the DC-16 transmitter either way you like allowing you to fully

customize your radio‘s handling. Each tension is set by a different

machine screw.

1. Switch off the transmitter and remove the 10 screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack

connector.

2. For ratchet tension adjustment use the machine screw “A”.

Turn slowly (anticlockwise) until you achieve the desired

ratchet tension. For smooth tension adjustment, use the

achine screw “B”. Turn slowly (clockwise) until you achieve

18

2.2.

Page 20

computer radio control system

EN

2

2

the desired smooth tension.

3. Reconnect transmitter battery pack and reinstall radio back

cover and cover screws.

AB

3.3.5 Throttle stick travel adjustment

The throttle stick travel is adjustable to suit your flying style.

1. Switch off the transmitter and remove the 8 screws that secure the

radio back cover. Next, remove the radio back cover. Be sure to

disconnect the transmitter battery pack connector.

2. Use indicated machine adjustment screws to limit the throttle

stick travel. By turning the screw clockwise, you will shorten the

throttle stick travel.

3. Reconnect transmitter battery pack and reinstall radio back cover

and cover screws.

After making a limit the throttle stick travel you must re-calibrate the

transmitter stick in the software menu, see sec tion 9.6.3

–Calibration of Proportional Controls.

3.3.6 Transmitter Mode Switch

The DC-16 transmitter allows you to switch between Mode 1, 2, 3

and 4 stick configurations with just few simple steps. In order to do

some of these, the stick control assemblies will need to be swapped.

1. Switch off the transmitter and remove the 10 screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack

connector.

2. Disconnect the control stick assembly wires from the Tx board.

(3 wires X, Y, S)

Y

X

3

3. Remove the stick assembly connecting wires from their holders.

19

S

2

4

4

2.2.

Page 21

computer radio control system

It may be necessary to remove the screws securing the RF circuit

board to release the wire group.

4. Remove both machine installation screws for each of the

control stick assemblies.

6

5

5. Carefully remove both control stick assemblies. Gently pull in

your direction (toward the transmitter back side).

6. Swap both stick unit assemblies and install them back into

correct positions.

Y

X

9

7. Reinstall and secure the machine screws for each of the control

stick assemblies.

S

8

7

7

EN

Note:

After making a mode switch you must re-calibrate the

transmitter stick assemblies and setup the correct mode

in the software menu, see section 9.6.1 – Configuration.

The switch between Modes 1 to 3 or Modes 2 to 4 are

done with the software only (NO manual stick change is

necessary).

3.3.7 Transmitter Gimbals with Switch or Button

Installation

If you want to operate the DC-16 transmitter using the optional stick

end switch or button functions, you must purchase one or more of

these separately:

• Stick with 2-position switch

• Stick with 3-position switch

• Stick with push-button

• Stick with potenciometer

Advice:

For installation of the optional gimbal stick ends with

switches/buttons we recommend that you send your

transmitter to one of the factory authorized service

centers or to your authorized dealer.

1. Switch off the transmitter and remove the 10 screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack

connector.

20

2.2.

Page 22

computer radio control system

9

Y

X

3

S

2

4

8

10

EN

4

2. Disconnect the control stick assembly wires from the Tx board.

(3 wires )X, Y, S

3. Remove the stick assembly connecting wires from their holders.

4. Remove both machine installation screws for each of the

control stick assemblies.

5. Carefully remove both control stick assemblies. Gently pull in

your direction (toward the transmitter back side). This upgrade

will be done outside of the transmitter case.

7

6

6. Unscrew the upper part of the stick assembly (anticlockwise).

7. Insert the connecting wires through the hollow opening of the

transmitter stick.

11

8. Adjust length of the stick to suit your flying style. (See 4.3)

Note:

After installation of the optional stick ends with switch or

button make sure that while adjusting the stick length you

observe the wires that pass through the stick shaft and

through the gimbal opening in order to prevent damaging

the connecting cables. The safest method is to remove the

small set-screw from the side of the stick housing to allow

the switch or knob internals to remain stationary while you

rotate the stick housing for height adjustment.

9. Pass the switch wires through the same gimbal opening as the

hall sensor cable (through the center of the gimbal assembly).

10. Next insert wire ends through the opening of the printed circuit

board and solder them to the matching soldering points in such

a way that the same color wires lay on the top of each other.

11. Carefully move transmitter sticks to their full outside positions

in order to make sure that you have sufficient wire length and, if

needed, adjust accordingly. The connecting cables for

all moving parts of the unit should have sufficient length in

order not to be exposed to any mechanical damage and any

bending stresses.

21

2.2.

Page 23

computer radio control system

EN

14

13

13

12. Install stick unit assembly back to correct position.

13. Install and secure the machine screws for the control stick

assembly.

14. Connect control stick assembly wires to the Tx board connector

(3 wires ). Pay close attention to the wire lengths. Connect X, Y, S

the longest wire as the first one from the outside of the

transmitter (3 connectors ).X, Y, S

15. Secure the stick assembly wires into their holders.

16. Reconnect transmitter battery pack and reinstall radio back

cover and cover screws.

Installation and Configuration of Gimbals Switches

After the switch has been installed into the stick assembly you have

to re-configure and enable it in the transmitter software before it will

function properly. This can be done in the transmitter menu „Main

menu->Advanced setup->Sticks/ switches setup“, see section

9.3.2.

S

XY

15

3.4 Swappable and Assignable Switches

One of the most important features of a JETI transmitter is the switch

function assignment flexibility. The DC-16 transmitter automatically

detects the type of switch and assigns the selected function. The

following switch types are available:

• 2-position short or long switch

• 2-position spring-loaded long switch

• 3-position short or long switch

You may either swap the existing switches around or take advantage

of the optional accessories and create your own custom

configuration.

Factory Switch Configurations for the DC-16 Transmitter

Sa - 2- position spring-loaded long switch

Sb - 3- position short switch

Sc - 2- position short switch

Sd - 2- position long switch

Se - 3- position short switch

Sf - 3- position short switch

Sg - 3- position long switch

Sh - 2- position short switch

Si - 2- position short switch

Sj - 3- position long switch

22

2.2.

Page 24

computer radio control system

EN

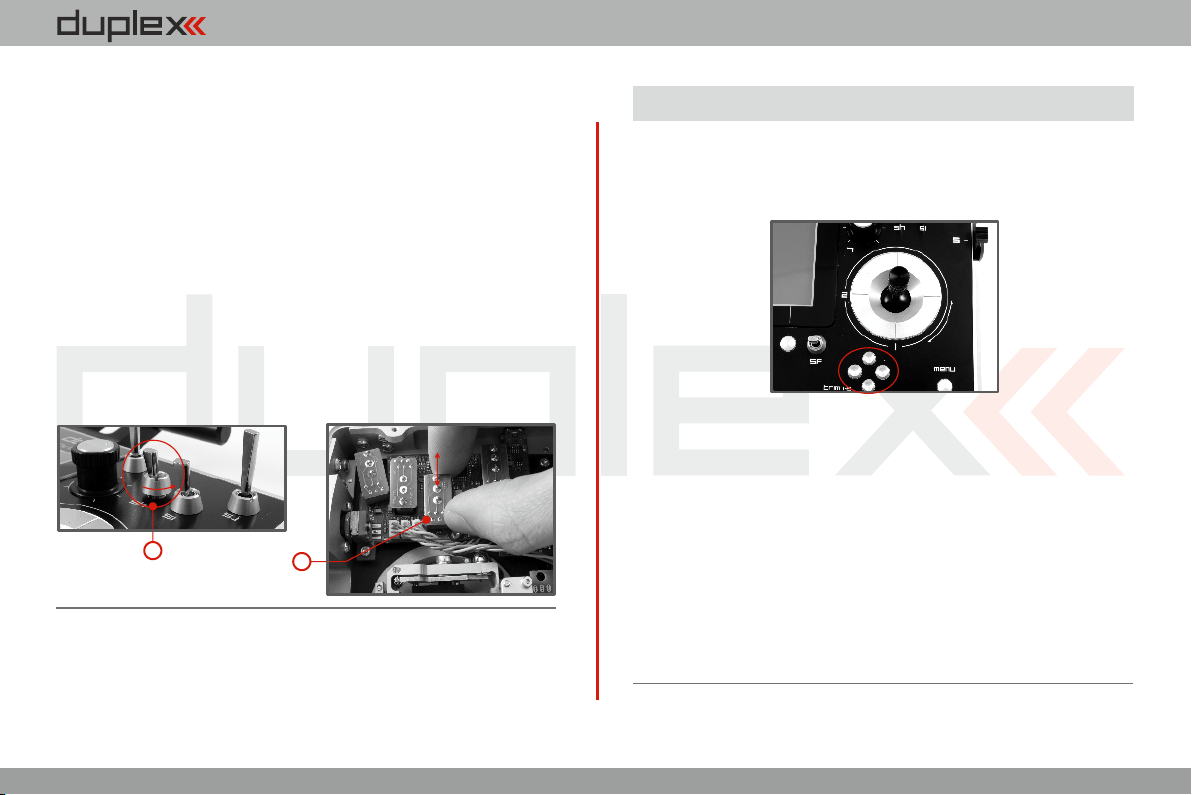

Switch Exchange:

1. Switch off the transmitter and remove the 10 screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack

connector.

2. With the specialized wrench (not included) carefully loosen and

remove the switch installation nut.

3. Carefully hold the switch by its printed circuit board assembly

and slowly pull it out. Use this method to also remove and

exchange all of the other switches. After re-assembling and

turning on your transmitter the software will sound a warning

reminding you that you have executed a change. Always re inspect all assigned functions of the switches before

attempting to fly.

2

3

3.5 Digital Trims

Transmitter gimbals are used for controlling the basic flight

functions like throttle, roll(aileron), pitch(elevator), and yaw(rudder).

Immediately under the transmitter gimbal sticks you can see four

push-buttons which are the programmable, digital trim buttons.

The digital trims are used for fine trimming of the flying model. When

the transmitter is turned off, the trim values are stored in memory

and are recalled when the system is turned back on.

Every model has its own trim setup. Also all flight modes may be

configured to use different trim configurations. By pressing one of

the buttons, the screen will automatically change to display the

graphic position of that trim. The transmitter trims feature an

acoustic step and centre beep alarm.

In the „Digital trim“ menu it‘s possible to enable a special

function used as automatic trimming. Digital trim steps and trim

range setting is explained in „Main menu->Fine tuning/flight

modes->Digital trim“

23

2.2.

Page 25

computer radio control system

EN

3.6 Transmitter Battery Pack

The DC-16 transmitter is powered by a Li-Ion type battery pack and

comes equipped with its own built-in advanced battery

management and charging circuit. In switched-on position, the

transmitter LCD display shows the status and condition of the

battery pack. The Li-Ion battery is factory installed.

3.6.1 Charging

The DC-16 transmitter can be charged with the included wall power

supply or through the built-in USB port.

For fast charging use the included wall power supply. Charging time

is around 3 hours. During the charging process the transmitter can

be in switched-on or off position. The charging status is clearly

shown by lit red and green LEDs. If the transmitter is switched on

during the charging process you can see the charging progress

directly on the LCD display.

Transmitter Charging:

1. Plug in the included power supply to a wall outlet.

2. Plug the main charging connector into the transmitter. If the

green LED goes out, the transmitter is not fully charged. The

red LED indicates the battery charging status.

• Discharged battery – red LED is slow blinking, the green LED

is OFF

Close to full charge – red LED is permanently ON, the green •

LED is OFF

Fully charged battery – the red and green LEDs are ON•

3.6.2 Battery Replacement

Should you decide to replace the transmitter battery, please follow

these steps:

1. Switch off the transmitter and remove the 10 screws that

secure the radio back cover. Next, remove the radio back cover.

2. Disconnect the transmitter battery connector.

3. Loosen the battery fastening strap and remove the battery.

3

If the transmitter battery has been disconnected for

Note:

longer than 1 minute, the time, and date will be deleted.

Warning:

24

DC-16 transmitters should only be operated only

with original or manufacturer approved battery

packs. The use of other battery packs will void the

warranty.

2

2.2.

Page 26

computer radio control system

EN

3.7 PPM Input/Output Connector

The PPM output is accessible via connector labeled „B“. This

connector features the non-stabilized battery voltage output in the

range of 3.2V - 4.2V (max. 1A) which can be used as power supply for

the connected HF module as well as for the PPM signal output. The

transmitter output functions are in the form of a standard PPM

signal.

3

4

2

1

1. PPM input (3V logics)

2. Positive (+) pin

3. Negative (-) pin

4. PPM signal output (3V logics, configurable in „System

->Configuration”)

3.8 Handling

The DC-16 transmitter can be comfortably carried by holding it for

the antenna cover/handle as shown on the picture.

Warning:

Before each flying session, and especially with a new

model, it’s important to perform a range check.

If you are operating a mo del with a DC- 16

transmitter do not shield and avoid contact of the

transmitter antenna with your body.

This might increase likelihood of range problem.

25

2.2.

Page 27

computer radio control system

EN

4 Description of Transmitter DS

17

18

19

7

2

8

10

3

20

23

21 22 22

11

4

5

12

4.1 Control Identification DS-16

1. Right Stick 1, 2 – the DS-16 Transmitter Supports Modes 1-4, see Control

Sticks -> mode change

2. Left Stick 3, 4 the DS-16 Transmitter Supports Modes 1-4, see Control

Sticks -> mode change

3. Swappable and Assignable Switches: Sa, Sb, Sc, Sd, Se, Sf, Sg, Sh

4. Digital Trims for the Left Stick T3, T4

16

3

15

14

13

6

1

9

5. Digital Trims for the Right Stick T1, T2

6. Right Side Control Lever 5

7. Left Side Control Lever 6

8. Rotary Control Knob 7

9. Rotary Control Knob 8

10. LCD Display

11. Function Buttons F1 – F5

12. Transmitter On/Off Power Switch

13. 3D Control Selector

14. Menu Button

15. ESC Button

16. Shows the Antenna but NOT the handle.

Add the handle and assign it a number and pointer in the photo.

17. Charge Jack

18. USB PC Interface

19. Earphone Jack

20. ON/OFF & Charging LED Indicators

21. Speaker

22. Transmitter Neck Strap Bracket Installation Holes

23. Neckstrap Hook

26

2.2.

Page 28

computer radio control system

EN

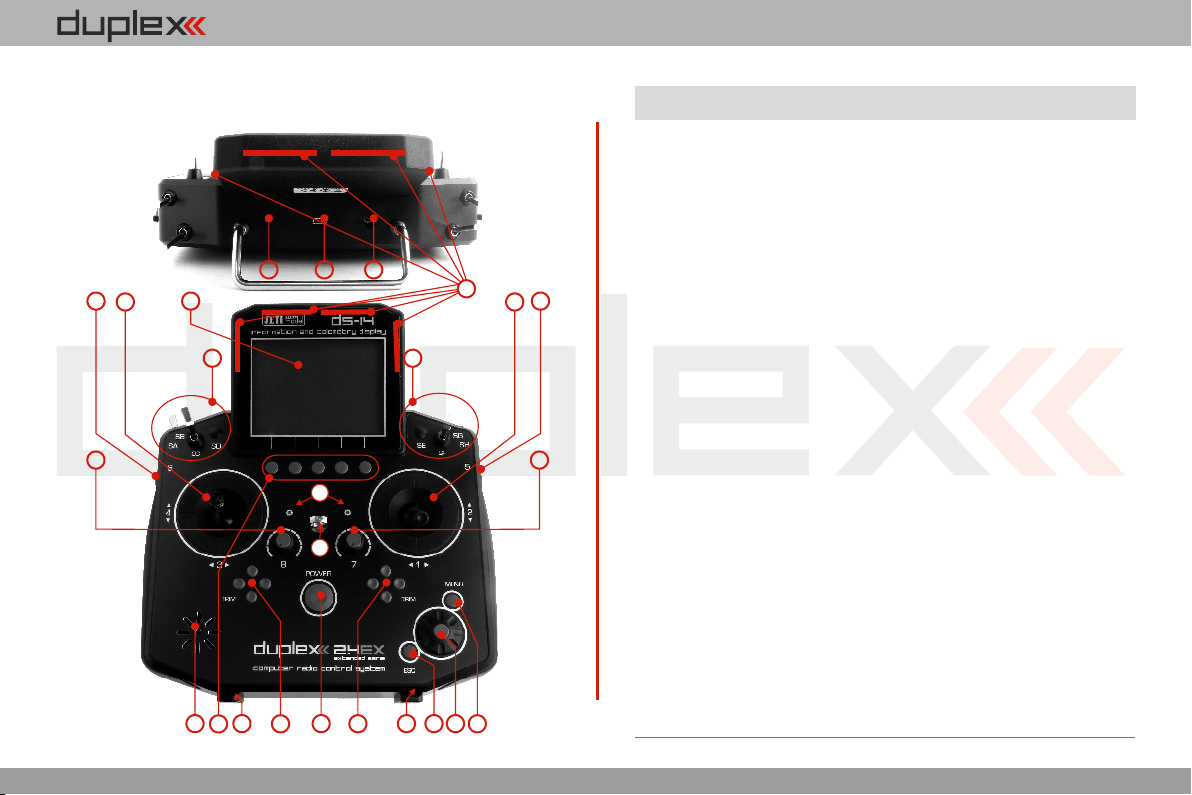

4.2 Control Identification DS-14

1. Right Stick 1, 2 – the DS-14 Transmitter Supports Modes 1-4, see Control

Sticks -> mode change

2. Left Stick 3, 4 the DS-14 Transmitter Supports Modes 1-4, see Control

Sticks -> mode change

3. Swappable and Assignable Switches: Sa, Sb, Sc, Sf, Sg, Sh

4. Digital Trims for the Left Stick T3, T4

19

7

2

8

10

3

20

23

21 22 22

11

4

5

12

16

3

15

14

13

6

1

9

17

18

5. Digital Trims for the Right Stick T1, T2

6. Right Side Control Lever 5

7. Left Side Control Lever 6

8. Rotary Control Knob 7

9. Rotary Control Knob 8

10. LCD Display

11. Function Buttons F1 – F5

12. Transmitter On/Off Power Switch

13. 3D Control Selector

14. Menu Button

15. ESC Button

16. Shows the Antenna but NOT the handle.

Add the handle and assign it a number and pointer in the photo.

17. Charge Jack

18. USB PC Interface

19. Earphone Jack

20. ON/OFF & Charging LED Indicators

21. Speaker

22. Transmitter Neck Strap Bracket Installation Holes

23. Neckstrap Hook

27

2.2.

Page 29

computer radio control system

EN

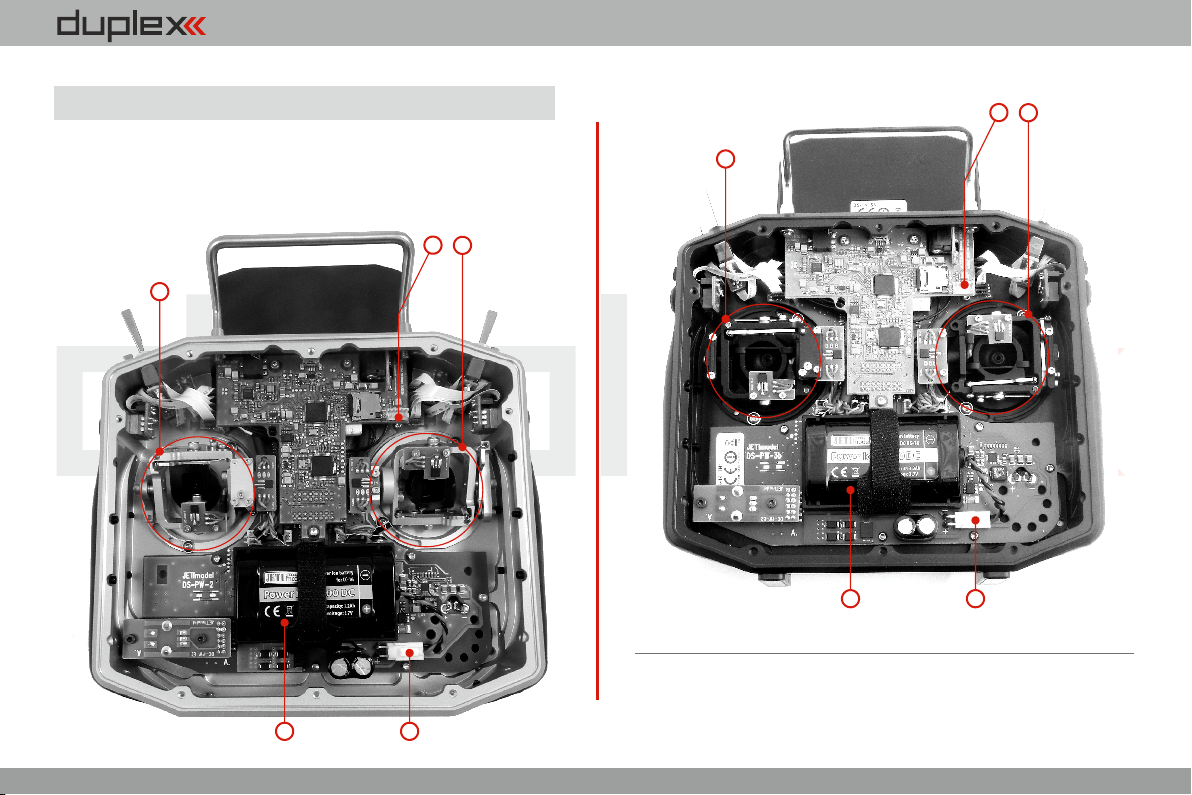

4.3 Assembly Identification

23. Battery Connector

24. Transmitter Battery Pack

25. PPM Output Connector

26. Left Gimbal Assembly

27. Right Gimbal Assembly

DS-16

26

DS-14

26

25

27

24

25

27

23

24

23

28

2.2.

Page 30

computer radio control system

EN

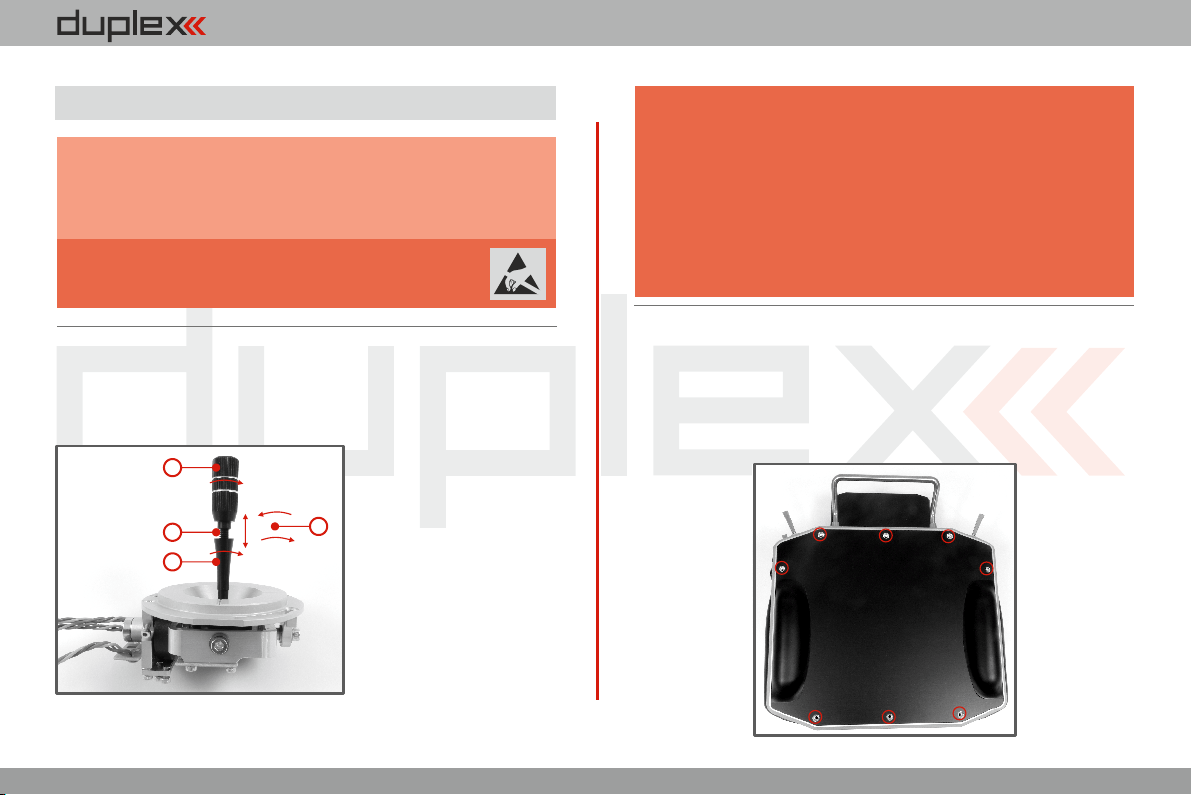

4.4 Control Stick Assembly

Note:

Warning:

4.4.1 Control Stick Length Adjustment

The stick length is adjustable to suit your flying style. The stick end

separates into two parts.

When handling with back cover removed always

switch off the transmitter and disconnect the

battery (unplug the connector). Also do not connect

the charging adapter or the USB cable.

Restrict your contact with the printed circuit

boards to a minimum. You can damage your

radio by electrostatic discharge!

1. Hold the top part of the

st i ck e nd f irml y a nd

1

2

3

u n s c r e w ( t u r n i t

anticlockwise).

2. Turn the stick end

clockwise to shorten or

4

c o un te r cl oc k wi se t o

lengthen the overall stick

length.

3. Adjust the lower part

to support the top part of

the stick end.

4. F i na lly s ec ure b y

tightening both parts to

each other.

Warning:

If you have installed optional sticks with switch or

button ends; make sure that while adjusting the stick

length you observe the wires that pass through the

stick shaft and through the gimbal opening in order

to prevent damaging the connecting cables. The

safest method is to remove the small set-screw from

the side of the stick housing to allow the switch or

knob internals to remain stationary while you rotate

the stick housing for height adjustment.. (See 4.3.6)

4.4.2 Swivel Control Stick Adjustment

In order to customize the feel of your radio you may adjust the angle

of the stick control assemblies.

1. Switch off the transmitter and remove the 8 screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack connector.

29

2.2.

Page 31

computer radio control system

EN

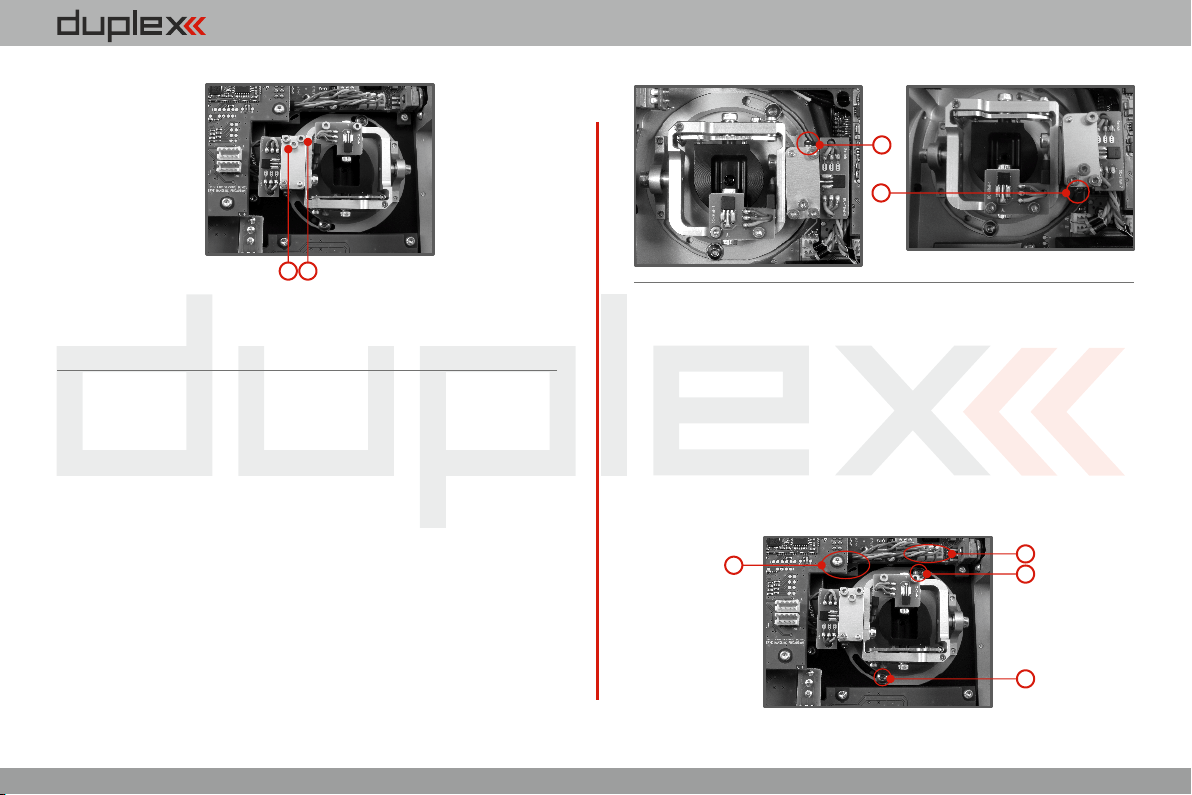

2. Loosen both machine screws securing the control stick

assembly.

2

4

3

DS-16DS-16DS-16 DS-14DS-14DS-14

4

2

3. Adjust (rotate) to desired position.

4. Securely tighten both machine screws securing the control stick

assembly.

5. Reconnect transmitter battery pack and reinstall radio back

cover and cover screws.

4.4.3 Control Stick Tension Adjustment

The stick gimbal tension is fully adjustable for each axis. This allows

you to fully customize your radio‘s control feel. Simply adjust each

gimbal‘s spring to your desired tension.

1. Switch off the transmitter and remove the 8 screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack

connector.

2. Use indicated machine adjustment screws to change the

desired spring tension.

By turning the screw anticlockwise, you will loosen spring

tension. As a result the moving resistance of the control stick will

decrease. By turning the screw clockwise, you will tighten

spring tension. As a result the moving resistance of the control

stick will increase.

2

2

DS-16DS-16DS-16

2

2

DS-14DS-14DS-14

3. Reconnect transmitter battery pack and reinstall radio back

cover and cover screws.

30

DS-16DS-16DS-16

DS-14DS-14DS-14

2.2.

Page 32

computer radio control system

EN

4.4.4 Ratchet Tension Adjustment

Do you prefer smooth throttle feel or ratchet throttle feel? You can

adjust the DS-16 transmitter either way you like allowing you to fully

customize your radio‘s handling. Each tension is set by a different

machine screw.

1. Switch off the transmitter and remove the 8 screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack

connector.

2. For ratchet tension adjustment use the machine screw “A”. Turn

slowly (anticlockwise) until you achieve the desired ratchet

tension. For smooth tension adjustment, use the machine screw

“B”. Turn slowly (clockwise) until you achieve the desired

smooth tension.

DS-16DS-16DS-16

AB

3. Reconnect transmitter battery pack and reinstall radio back

cover and cover screws.

DS-14DS-14DS-14

AB

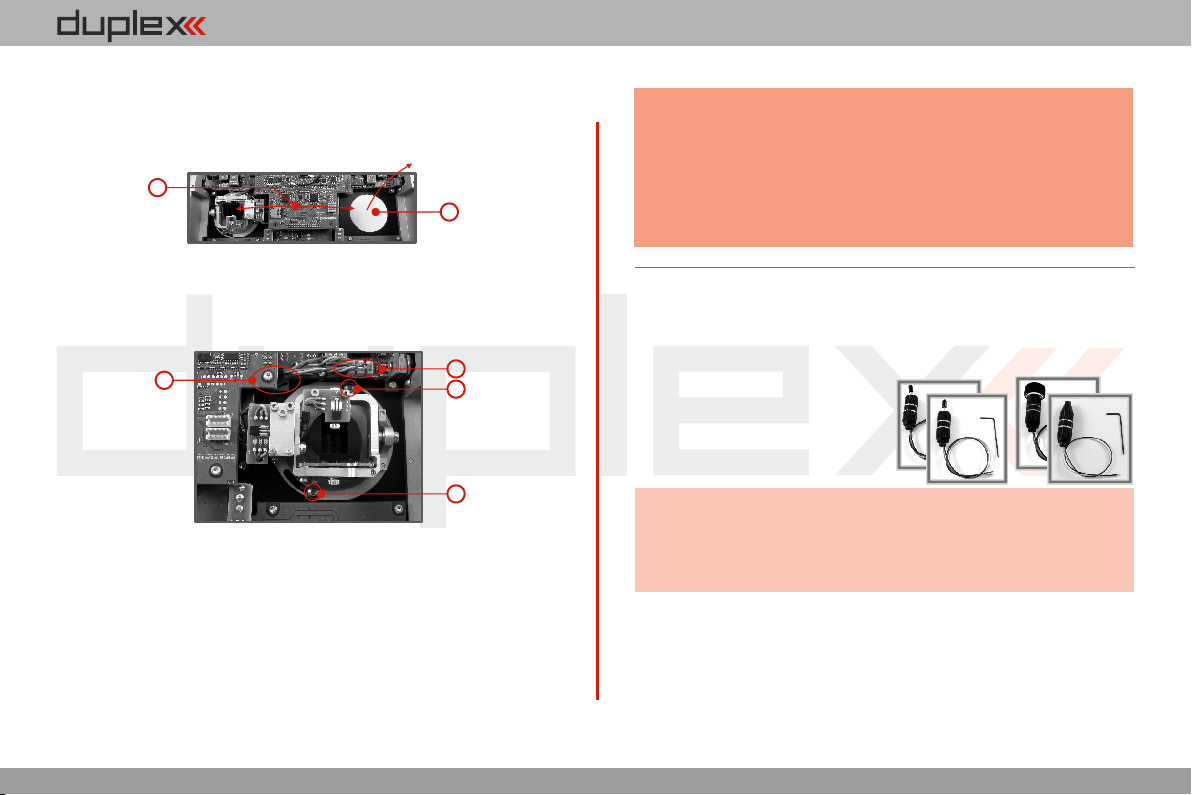

4.4.5 Throttle stick travel adjustment

The throttle stick travel is adjustable to suit your flying style.

1. Switch off the transmitter and remove the 8 screws that secure the

radio back cover. Next, remove the radio back cover. Be sure to

disconnect the transmitter battery pack connector.

2. Use indicated machine adjustment screws to limit the throttle

stick travel. By turning the screw clockwise, you will shorten the

throttle stick travel.

3. Reconnect transmitter battery pack and reinstall radio back cover

and cover screws.

2

DS-16DS-16DS-16

DS-16DS-16DS-16

DS-14DS-14DS-14

2

DS-14DS-14DS-14

31

2.2.

Page 33

computer radio control system

After making a limit change to the throttle stick travel you must recalibrate the transmitter stick in the software menu, see section

9.6.3 –Calibration of Proportional Controls.

EN

32

2.2.

Page 34

computer radio control system

EN

4.4.6 Transmitter Mode Switch

The DS-16 transmitter allows you to switch between Mode 1, 2,

3 and 4 stick configurations with just few simple steps. In order to do

some of these, the stick control assemblies will need to be swapped.

1. Switch off the transmitter and remove the screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack.

2. Release and pull out the screws of the upper printed circuit

board (the "T" plate).

3. Remove the "T" circuit board by grasping the plate by its edges

near where the bottom fastener goes. Gently lift the board to

disconnect its connectors from the board below. Once

disconnected, tilt the board upward toward the display so that

it is out of the way.

2

3

4. Disconnect the control stick assembly wires from the Tx board.

(3 wires ).X, Y , S

5. Remove the stick assembly connecting wires from their holders

on the main board.

6. Remove both machine installation screws for each of the

control stick assemblies.

7. Carefully remove both installation machine screws. Gently lift

in your direction (toward the transmitter back side).

8. Swap both stick assembly units an install them back into their

correct positions.

8

7

5

4

YYY

SSS

XXX

XXX

YYY

SSS SSS

YYY

XXX

6

33

2.2.

Page 35

computer radio control system

EN

9. Reinstall and secure the machine screws for each of the control

stick assemblies.

10. Connect the control stick assembly wires to the Tx board

connector (3 wires . The orientation of the wires is X, Y , S)

labeled on the board.

11. Secure the stick assembly wires into their holders.

12. Mount the "T" plate back into place. First insert the connectors

of the "T" printed circuit board into the body of transmitter and

then carefully insert the "T" plate into its connectors on the

main board. Be careful while handling the wires underneath the

"T" plate to avoid any resistance when installing the "T" plate. If

the wires cause any resistance or if the wires are pinched or

stressed in any way, please re-route the wires and try the "T"

board installation again.

13. Reinstall the "T" plate mounting screws.

14. Reconnect transmitter battery pack and reinstall radio back

cover and cover screws.

Note:

After making a mode switch you must re-calibrate the

transmitter stick assemblies and setup the correct mode

in the software menu, see section 9.6.1 – Configuration.

The switch between Modes 1 to 3 or Modes 2 to 4 are

done with the software only (NO manual stick change is

necessary).

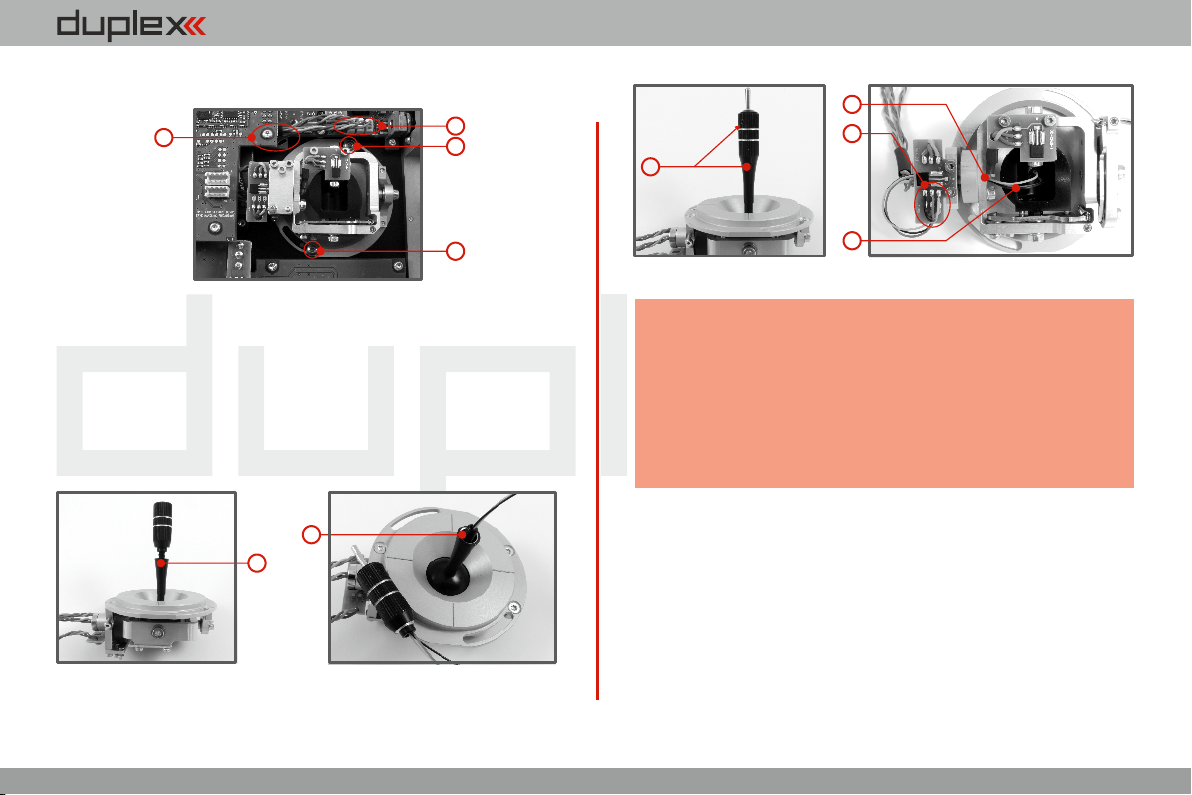

4.4.7 Transmitter Gimbals with Switch or Button

Installation

If you want to operate the DS-16 transmitter using the optional stick

end switch or button functions, you must purchase one or more of

these separately:

• Stick with 2-position switch

• Stick with 3-position switch

• Stick with push-button

• Stick with potenciometer

Advice:

1. Switch off the transmitter and remove the 8 screws that secure

the radio back cover. Next, remove the radio back cover. Be sure

to disconnect the transmitter battery pack connector .

2. Release and pull out the screws of the upper printed circuit

board (the "T" plate).

3. Remove the "T" circuit board by grasping the plate by its edges

near where the bottom fastener goes. Gently lift the board to

disconnect its connectors from the board below. Once

disconnected, tilt the board upward toward the display so that

it is out of the way.

4. Disconnect the control stick assembly wires from the Tx board.

(3 wires ).X, Y, S

5. Remove the stick assembly connecting wires from their holders

on the main board.

34

For installation of the optional gimbal stick ends with

switches/buttons we recommend that you send your

transmitter to one of the factory authorized service

centers or to your authorized dealer.

2.2.

Page 36

computer radio control system

EN

6. Remove both installation machine screws for each of the

2

control stick assemblies.

7. Carefully remove both control stick assemblies. Gently lift in

your direction (toward the transmitter back side).

9

8

3

8. Unscrew the upper part of the stick assembly (anticlockwise).

9. Insert the connecting wires through the hollow opening of the

transmitter stick.

7

5

10

4

XXX

YYY

SSS SSS

YYY

XXX

11

12

13

10. Adjust length of the stick to suit your flying style. (See 4.3)

YYY

SSS

XXX

6

Note:

After installation of the optional stick ends with switch or

button, make sure that while adjusting the stick length

35

2.2.

Page 37

computer radio control system

EN

you observe the wires that pass through the stick shaft and

through the gimbal opening in order to prevent damaging

the connecting cables. The safest method is to remove the

small set-screw from the side of the stick housing to allow

the switch or knob internals to remain stationary while

you rotate the stick housing for height adjustment.

11. Pass the switch wires through the same gimbal opening as the

hall sensor cable (through the center of the gimbal assembly).

12. Next insert wire ends through the opening of the printed circuit

board and solder them to the matching soldering points in such

a way that the same color wires lay on the top of each other.

13. Carefully move transmitter sticks to their full outside positions

in order to make sure that you have sufficient wire length and, if

needed, adjust accordingly. The connecting cables for

all moving parts of the unit should have sufficient length in

order not to be exposed to any mechanical damage and any

bending stresses.

14. Install the stick unit assembly back into its correct position.

15. Install and secure the machine screws for the control stick

assembly.

15

17

16

YYY

SSS

XXX

15

16. Connect the control stick assembly wires to the Tx board

connector (3 wires ). Pay close attention to the wire X, Y, S

lengths. Connect the longest wire as the first one from the

outside of the transmitter (3 connectors ).X, Y, S

17. Secure the stick assembly wires into their holders.

18. Mount the "T" plate back into place. First insert the connectors

of the "T" printed circuit board into the body of transmitter and

then carefully insert the "T" plate into its connectors on the

main board. Be careful while handling the wires underneath the

"T" plate to avoid any resistance when installing the "T" plate. If

the wires cause any resistance or if the wires are pinched or

stressed in any way, please re-route the wires and try the "T"

board installation again.

19. Reinstall the "T" plate mounting screws.

20. Reconnect transmitter battery pack and reinstall radio back

cover and cover screws.

Installation and Configuration of Gimbals Switches

After the switch has been installed into the stick assembly you have

to re-configure and enable it in the transmitter software before it will

function properly. This can be done in the transmitter menu „Main

menu->Advanced setup->Sticks/ switches setup“, see section

9.3.2.

36

2.2.

Page 38

computer radio control system

EN

Warning:

You should keep the wire placement as shown in the

picture. The wires must be placed as far as possible

from th e magnetic element Please avoid a).

permanent contact of the wire with magnetic the

element. It could be damaged isolating of the wires.

a)

a)

Proper arrangement

of the display flat,

flexible cable.

a)

a)

a)

4.5 Swappable and Assignable Switches

One of the most important features of a JETI transmitter is the switch

function assignment flexibility. The DS-16 transmitter automatically

detects the type of switch and assigns the selected function. The

following switch types are available:

• 2-position short or long switch

• 2-position spring-loaded long switch

• 3-position short or long switch

• 2-position locking switch

• potenciometer

You may either swap the existing switches around or take advantage

of the optional accessories and create your own custom

configuration.

Factory Switch Configuration for the DS-16 Transmitter

Sa - 3 - position short switch

Sb - 2 - position long switch

Sc - 2 - position short switch

Sd - 2 - position long switch

Se - 3 - position long switch

Sf - 2 - position short switch

Sg - 2 - position spring-loaded long switch

Sh - 2 - position short switch

Factory Switch Configuration for the DS-14 Transmitter

Sa - 3 - position short switch

Sb - 3 - position long switch

Sc - 2 - position short switch

Sf - 3 - position short switch

Sg - 2 - position spring-loaded long switch

Sh - 2 - position short switch

37

2.2.

Page 39

computer radio control system

EN

4.5.1 Switch Removal Procedure

1. Switch off the transmitter and remove the 8 screws that secure

the radio back cover. Next, remove the radio back cover.

Be sure to disconnect the transmitter battery pack

connector.

2. With the specialized wrench (not included) carefully loosen and

remove the switch installation nut.

2 2

3. Hold the switch from the back side of the transmitter and pull it

towards you, so that the switch is released from the body of

transmitter.

3

4. Disconnect the flat flexible cable from its connector on the

main board.

The flat flexible cables that link the main printed circuit board

with the switches are oriented as shown in the picture The (4a).

wire is always color coded on one side of both ends The (4b).

markings must be oriented as shown below.

4a

4b

4b

4.5.2 Assembly Procedure

1. Insert the flat flexible cable to the switch connector of the

switch. See the orientation above.

2. Push the switch onto its spot in the transmitter housing.

3. Tighten the switch installation nut from the front of the

transmitter. Use the specialized wrench (not included).

4. Connect the flat flexible cable to the main printed circuit board

of the transmitter. See the orientation above.

The cable has to be inserted to the connector that matches the

position on the front panel where the switch is installed.

5. Reconnect transmitter battery pack and reinstall radio back

cover and cover screws.

38

2.2.

Page 40

computer radio control system

EN

After you turn on the transmitter for the first time after any switches

have been modified, you will notice that the configuration for a

selected model no longer matches.

Note:

When replacing the switch it is also necessary to Sa

remove the switches and from the transmitter Sb Sc

body.

When replacing the switch it is also necessary to Sc

remove the switch from the transmitter body.Sb

When replacing the switch it is also necessary to Sh

remove the switches and from the transmitter Sg Sf

body.

When replacing the switch it is also necessary to Sf

remove the switch from the transmitter body.Sg

4.6 Digital Trims

Transmitter gimbals are used for controlling the basic flight

functions like throttle, roll(aileron), pitch(elevator), and yaw(rudder).

Immediately under the transmitter gimbal sticks you can see four

push-buttons which are the programmable, digital trim buttons.

The digital trims are used for fine trimming of the flying model. When

the transmitter is turned off, the trim values are stored in memory

and are recalled when the system is turned back on.

Every model has its own trim setup. Also all flight modes may be

configured to use different trim configurations. By pressing one of

the buttons, the screen will automatically change to display the

graphic position of that trim. The transmitter trims feature an

acoustic step and centre beep alarm.

In the „Digital trim“ menu it‘s possible to enable a special

function used as automatic trimming. Digital trim steps and trim

range setting is explained in „Main menu->Fine tuning/flight

modes->Digital trim“

39

2.2.

Page 41

computer radio control system

EN

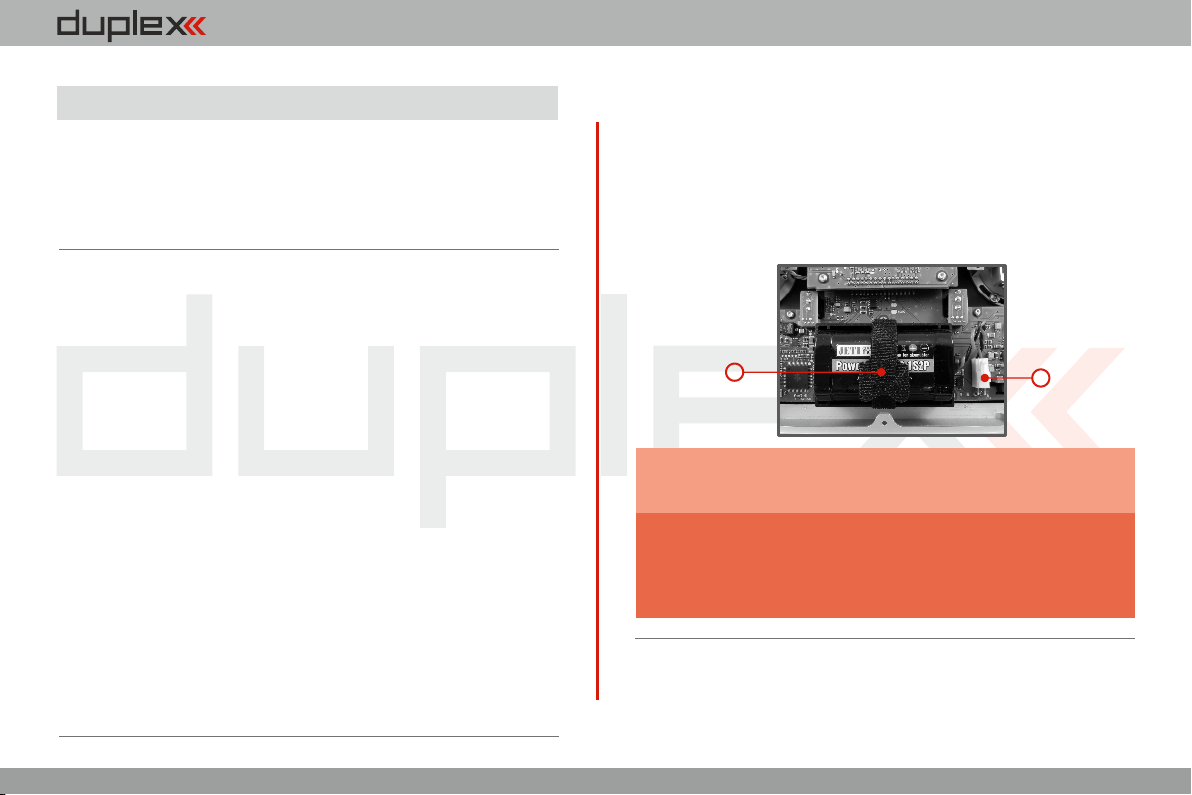

4.7 Transmitter Battery Pack

The DS-16 transmitter is powered by a Li-Ion type battery pack and

comes equipped with its own built-in advanced battery

management and charging circuit. In switched-on position, the

transmitter LCD display shows the status and condition of the

battery pack. The Li-Ion battery is factory installed.

4.7.1 Charging

The DS-16 transmitter can be charged with the included wall power

supply or through the built-in USB port.

For fast charging use the included wall power supply. Charging time

is around 3 hours. During the charging process the transmitter can

be in switched-on or off position. The charging status is clearly

shown by lit red and green LEDs. If the transmitter is switched on

during the charging process you can see the charging progress

directly on the LCD display.

Transmitter Charging:

1. Plug-in the included power supply to a wall outlet.

2. Plug the main charging connector into the transmitter. If the

green LED goes out, the transmitter is not fully charged. The

red LED indicates the battery charging status.

• Discharged battery – red LED is slow blinking, the green LED

is OFF

Close to full charge – red LED is permanently ON, the green •

LED is OFF

Fully charged battery – the red and green LEDs are ON•

4.7.2 Battery Replacement

Should you decide to replace the transmitter battery, please follow

these steps:

1. Switch off the transmitter and remove the 8 screws that

secure the radio back cover. Next, remove the radio back cover.

2. Disconnect the transmitter battery connector.

3. Loosen the battery fastening strap and remove the battery.

3

If the transmitter battery has been disconnected for

Note:

longer than 1 minute, the time and date will be deleted.

Warning:

40

DS-16 transmitters should only be operated only

with original or manufacturer approved battery

packs. The use of other battery packs will void the

warranty.

2

2.2.

Page 42

computer radio control system

EN

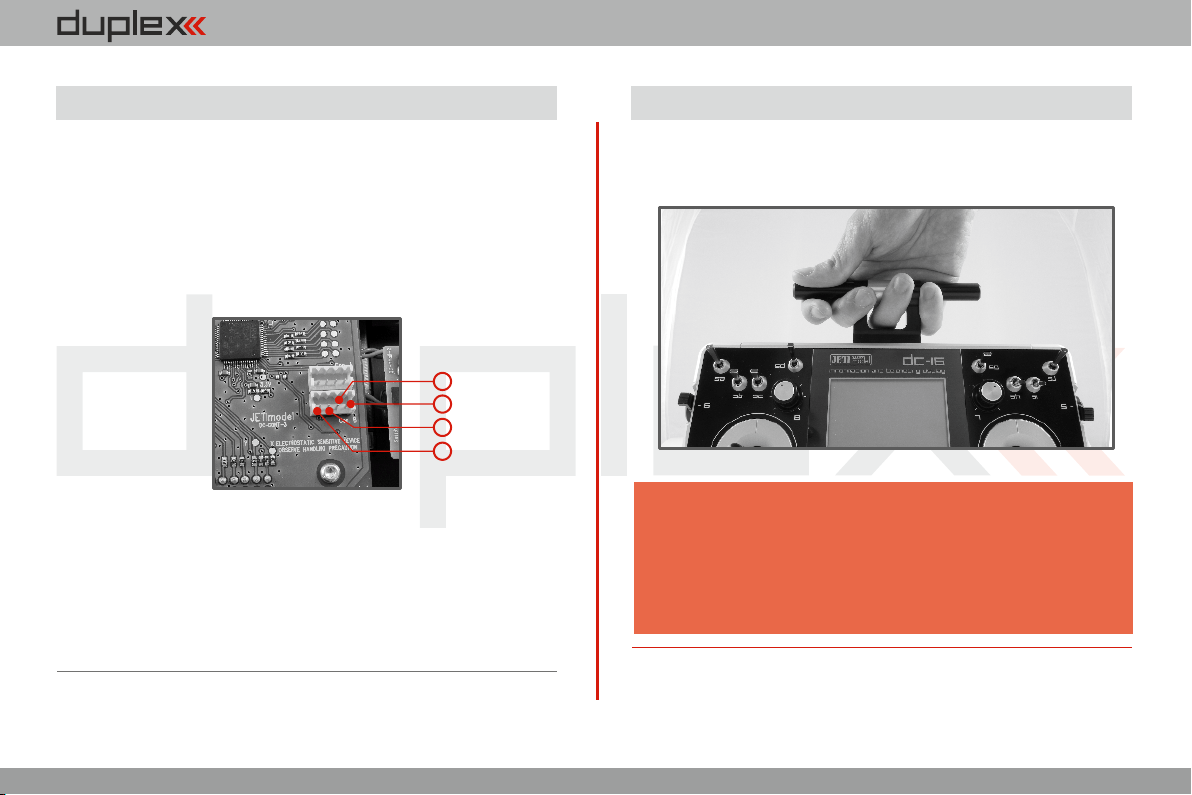

4.8 PPM Input/Output Connector

The PPM output is accessible via connector labeled „B“. This

connector features the non-stabilized battery voltage output in the

range of 3.2V - 4.2V (max. 1A) which can be used as power supply for

the connected HF module as well as for the PPM signal output. The

transmitter output functions are in the form of a standard PPM

signal.

3

4

2

1

1. PPM input (3V logics)

2. Positive (+) pin

3. Negative (-) pin

4. PPM signal output (3V logics, configurable in

„System->Configuration”)

4.9 Handling

The DS-16 is equipped with a metal handle for practical

manipulation as shown in the picture.

The transmitter antenna locations are shown in the picture below.

Warning:

Before each flying session, and especially with a

new model, it's important to perform a range

check. If you are operating a model with a DS-16

transmitter do not shield and avoid contact of the

transmitter antennas (see Photo)with your body.