OWNER'S MANUAL

JDP-17MF JET Drill Press

WMH TOOL GROUP

Consumer/Light Industrial Products Di vi sion

P.O. BOX 1349

Auburn, W A 98071- 1349

▪

Ph: 1-800-274-6848

E-mail : jet@wmhtoolgr oup.com

www.wmhtoolgroup.com M-354169 11/02

Copyright © WMH T ool Group

Fax: 1-800-274-6840

This m anual has been prepared for the owner and operators of a JDP-17MF Drill Press. Its purpose,

aside from machine operati on, is to promote saf ety through the use of accepted correct operating and

maint enance procedures. Compl etely read t he safety and m aintenance i nstructions before operat ing or

servi cing t he machi ne. T o obtain max imum lif e and eff ici ency from your JET Dr ill Press, and to aid in

using the machine safely , read this m anual thoroughly and foll ow inst r uc tions carefully.

Warranty & Service

The WMH Tool G r oup warrant s every product it sells. If one of our tool s needs service or repair, one of

our Authorized Repair Stat ions located thr oughout the United S tates can give you quick servic e.

In most cases, any one of these WMH Tool G r oup Repair Stations can authorize warrant y r epair, assist

you in obtai ning parts, or perform r outine maintenance and major repair on y our J E T, Performax, Wilt on,

or Powermatic tools.

For the nam e of an Authorized Repair Station in y our area, please call 1-800-274-6848, or visi t

www.wmhtoolgroup.com

More Information

Remember , the WMH Tool Group is consistently adding new products to the line. For c omplete, up-todate product i nform ation, check with your local WM H Tool Group distributor, or visit

www.wmhtoolgroup.com

WMH Tool Group Warranty

The WMH Tool G r oup ( includi ng P er form ax, Wil ton and Powermati c br ands) makes ever y effor t to

assure that its product s meet high qual ity and durability standards and warrants to the original r etail

consumer/purc haser of our products that each product be free from defects in mater ials and

workmanship as follow: 1 YEAR LIMI T E D WARRANTY ON ALL PRODUCTS UNLESS SPECIFIE D

OTHERWISE. This Warranty does not apply to defects due directly or indi r ec tly to misuse, abuse,

negligence or accidents, normal wear-and-tear, repair or alterati ons outsi de our facilities, or to a lack of

maintenance.

THE WMH TO O L GROUP LIMIT S ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

FROM THE DATE THE PRODUCT WAS PURCHASED AT RET A I L. EXCEPT AS STAT ED HEREIN,

ANY IMPLIED WARRANTIES OR MERCHANTI BILITY AND FITNESS ARE EXCLUDED. SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED W ARRANTY LASTS, SO

THE ABOVE LIMITATION MAY NOT APPLY TO YOU. T HE WMH TOOL GROUP SHALL IN NO

EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. S OME STATE S DO NOT ALLOW THE E XLUSI ON OR LIMIT A TION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an A uthorized Repai r S tation designat ed by our off ice. Proof of purc hase date and an

explanat ion of t he c omplai nt must accompany the mer c handise. If our inspection di scloses a defect, we

will either repair or replace the product, or refund the purchase price if we cannot readily and quickly

provide a repair or r eplacement , if y ou are willing to accept a refund. We will return repaired product or

replacement at WMH Tool Group’s expense, but if it is determined there is no def ect, or that the defect

resulted f rom causes not withi n the scope of WMH Tool Group’s warranty, then the user must bear the

cost of storing and returning the product. T his warranty gives you specif ic legal r ights; you m ay also

have ot her rights which vary f r om state to stat e.

The WMH Tool G r oup sel ls through distributors only. M embers of the WMH Tool Group reserve the

right to eff ec t at any time, without pr ior notic e, those alterat ions to parts, fittings, and accessory

equipment whi c h they may deem necessary for any reason whatsoever.

2

WARNING

Wear eye protection.

Always keep guards in place and in p roper operati ng condition. Do not operate the machine

without the guards for any reason.

Support workpiece adequately at all ti mes during operation; maintain control of work at all times.

This drill press is designed and intended for use by properly trained and experienced personn el

only. If you are not familiar with the proper and safe operation of a drill press, do not use until

proper training and knowledge has been obtained.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form a habi t of checking to see that keys and

adjusting wrenches are removed from the machi ne before turning it on.

• KEEP THE WORK AREA CLEAN. Cluttered areas and benches invite ac c idents.

• DON’T US E IN A DANGEROUS ENVIRONMENT. Don’t use power tools i n damp or wet locat ions,

or expose them to rain. K eep work area wel l light ed.

• KEEP CHILDREN AWAY. Al l v isitors should be kept a safe distance from the work area.

• MAKE THE WORKSHO P KIDPROOF wit h padlocks, master swatches, or by r emoving starter k ey s.

• DON’T FORCE THE M ACHINE. It will do the job better and safer at the rate f or whic h it was

designed.

• USE THE RIGHT TOOL. Don’t force a machine or at tachment to do a job for whi c h it was not

designed.

• USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good condit ion.

When usi ng an extension cord, be sure to use one heavy enough to carry the cur r ent your machine

will draw. An under sized cord will cause a drop in the line v oltage resulting in power loss and

overheating. The table following shows the correct siz e to use depending on the cord l ength and

nameplat e ampere rating. If in doubt, use the next heavier gauge. Remember, the small er the

gauge number, t he heavi er the cord.

Total Length of Cord in Feet

0-25 25-50

AWG

16 14

• WEAR PROPER APPAREL. Do not wear loose clothing, gl oves, neckties, rings, br ac elets, or other

jewelry which may get caught in moving part s. Nonsl ip footwear is recommended. W ear pr otective

hair covering t o c ontain long hair.

• ALWAYS USE SAFETY GLASSES. Also use face or dust masks if t he c utting operation is dusty.

Ever y day eyeglasses only hav e impact r esi stant lenses; they are not safety glasses.

• DON’T OVERREACH. Keep proper footing and bal anc e at all times.

• MAINTAIN T OOLS WITH CARE. Keep tools sharp and clean for best and safest perfor mance.

Follow i nstr uc tions for lubricating and changing accessories.

• ALWAYS DISCONNECT THE MACHINE FRO M THE POWER SOURCE BEFORE SE RV ICING.

• REDUCE THE RISK OF UNINTENTIONAL START ING. Make sure the switc h is in the of f position

before pl ugging in.

3

• USE RECOMMENDED ACCESSORIES. The use of acc essories and attachments not

recommended by JET may cause hazards or risk of injury to persons.

• NEVER STAND ON A MACHINE. Serious injury could occur if the m ac hine is tipped.

• CHECK DAMAGED PARTS. Before further use of the machine, a guard or other part that is

damaged should be carefull y c hec k ed to determine that i t will operate properly and perform its

intended function - c hec k for alignment of moving parts, binding of moving parts, breakage of par ts,

mounti ng, and any other condi tions that may affect its operation. A guar d or other part that is

damaged should be properly repaired or replaced.

• NEVER LEAVE THE MACHINE RUNNING UNATTENDED. TURN POWER OFF. Don’t leave the

machine until it comes to a c omplete stop.

• SOME DUST CREATED by power sanding, sawing, gr inding, drilling and other construct ion activities

contains chemicals known to cause cancer, birth defects or other repr oduc tive harm. S ome

examples of these chemicals are:

• Lead from lead based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from c hemically-treated lumber .

• Your risk from those exposures vari es, depending on how often you do t his type of work. To reduce

your exposure to these chemicals: work in a well venti lated area, and work with appr oved saf ety

equipment , such as those dust masks that are specifical ly designed to filter out microscopic part icles

• DO NOT oper ate tool whil e under the influence of dr ugs, alcohol or any medicat ion.

• DO NOT drill pieces of material that are too small to be safely supported.

• WHEN drilling a large workpiece, prov ide additional support at t able height.

• ADDITIONAL INFORMATION regarding the safe and proper oper ation of this product is available

from the National Safet y Counc il, 1121 Spr ing Lake Drive, Itasca, IL 60143-3201, in the Accident

Prev ention Manual for Industrial Operat ions and also in the saf ety Data Sheets provided by t he NS C.

Please also refer to the American National Standards I nstitute ANSI 01.1 Safet y Requirement s for

Woodworking Machinery and the U.S. Depart ment of Labor OSHA 1910.213 Regulations.

• SAVE THESE INSTRUCTIONS refer to them often and use them to instruct others.

4

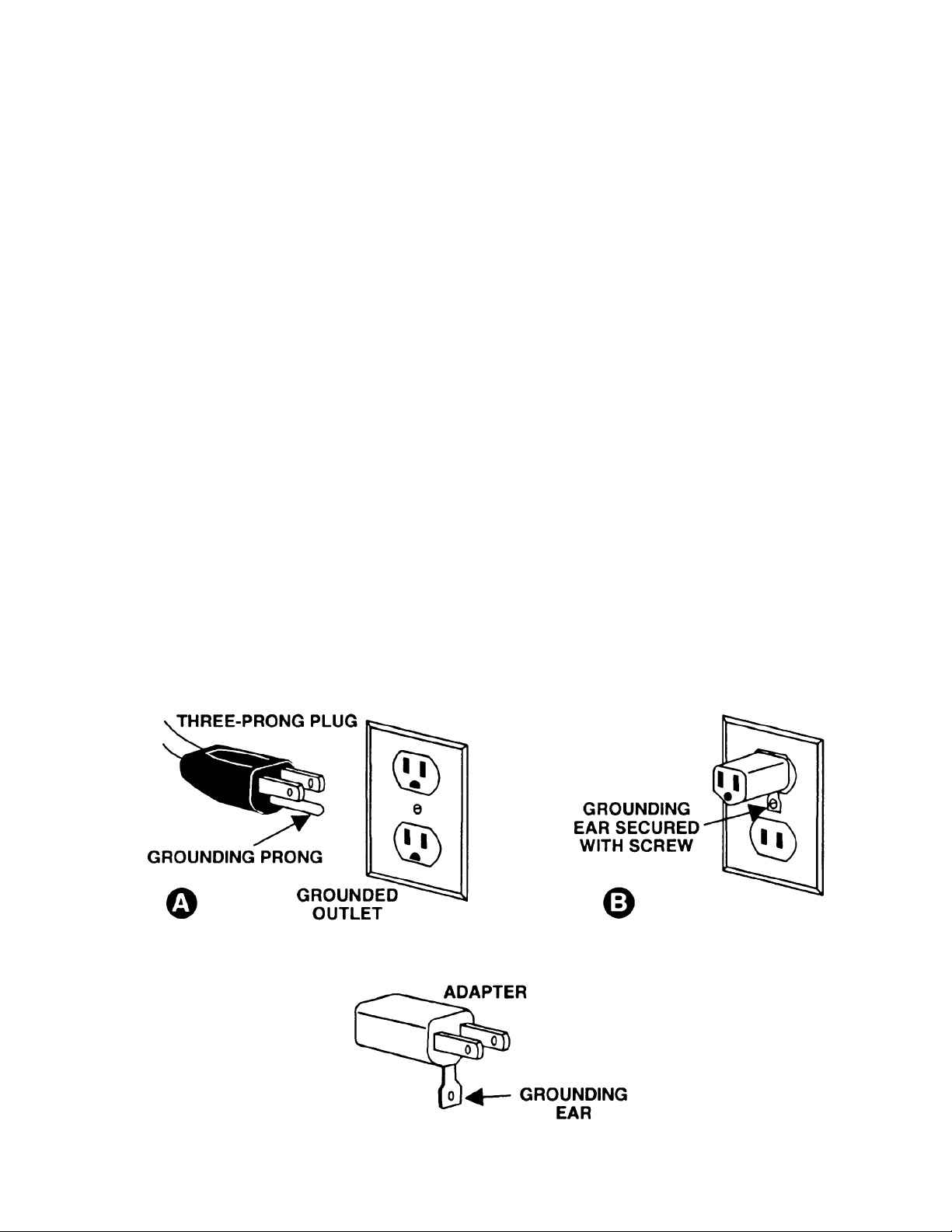

Grounding Instructions

Caution: This tool must be grounded while in use to protect the operator from electric shock.

In the event of a malfunction or br eak down, grounding provides a path of least resistance for electr ic

current to r educ e the risk of electri c shock. This tool is equipped with an elec tric cord having an

equipment -grounding conductor and a gr ounding plug. T he plug must be pl ugged into a mat ching outlet

that is properly installed and grounded in accor danc e with all local codes and ordinanc es.

Do not modi fy the plug provided. If it will not fit the outlet, have the proper outlet installed by a quali fied

electrician.

Improper connection of the equipment-grounding c onduc tor can result in a risk of electri c shock. The

conductor, with insulati on havi ng an outer surface t hat is green with or without yellow stri pes, is the

equipment -grounding conductor . If r epair or replac ement of the electric cord or pl ug is necessary, do not

connect the equi pment-grounding conductor to a live term inal.

Check with a qualifi ed electri c ian or serv ice personnel if the groundi ng instructi ons are not c ompletely

understood, or if in doubt as to whether the tool i s properly grounded. Use only three wire ext ensi on

cords that have three-prong grounding plugs and three-pole receptacl es that accept the t ool’s plug.

Repair or replace a damaged or worn cord immediately.

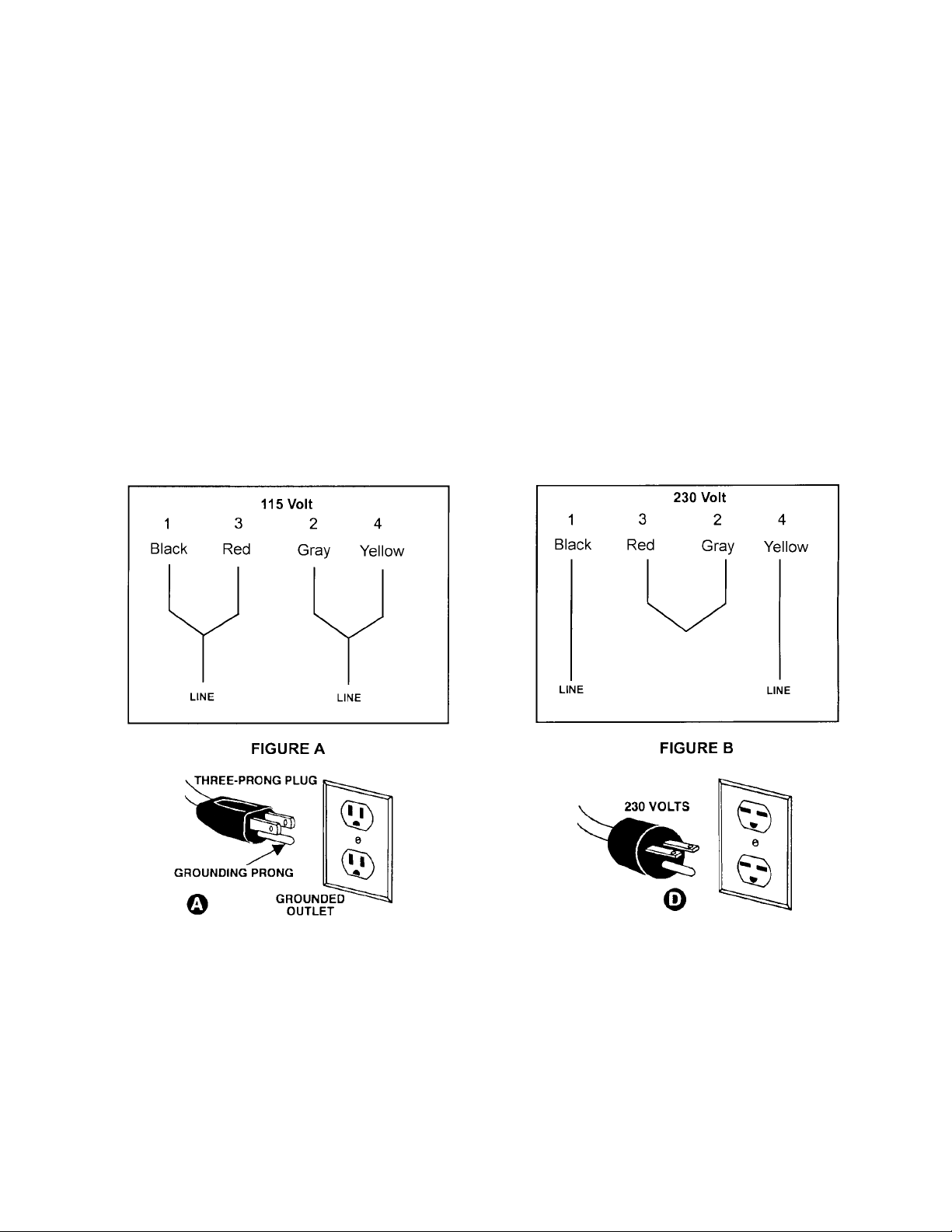

115 Volt Operation

As received from the factory, your drill press is ready to run at 115 v olt operation. This drill press, when

wired for 115 volt, is int ended for use on a circ uit that has an outlet and a plug that looks li k e the one

illustrated in (A). A temporary adapter, which look s like the adapter as illustrated in (B), may be used to

connect thi s plug to a two-pole recept acle, as shown in (B) if a properly gr ounded outlet i s not avai lable.

The tempor ary adapter should only be used unt il a properl y grounded outlet can be installed by a

qualified elec trici an. This adapter is not applicable in Canada. The green colored rigid ear, lug, or

tab, extending f r om the adapter, must be connected to a permanent gr ound such as a properly grounded

outlet box, as shown in (B).

5

230 Volt Operation

If 230V, single phase operati on is desired, the following instructions must be fol lowed:

1. Disconnect the machine f rom the power source.

2. This JET drill press is supplied with f our motor leads that are connected for 115V operat ion, as

shown in Figure A. Rec onnec t these four motor leads for 230V operati on, as shown in Figure B.

3. The 115V attachment plug (A) , supplied with t he dr ill press, must be replaced with a UL/CSA listed

plug suitable for 230V operation (D). Contact your l oc al Authoriz ed JET Service Cent er or qualif ied

electrician for proper procedures to install t he plug. The drill press must comply with all local and

national c odes after the 230 volt plug is installed.

4. The drill press with a 230 volt plug should only be connected to an out let having the sam e

confi gur ation (D). No adapter is available or should be used with the 230 volt plug.

Important: In all c ases (115 or 230 volt s), make certain the receptac le in question is properly grounded.

If you ar e not sure, hav e a r egistered elect r ician check the receptacl e.

6

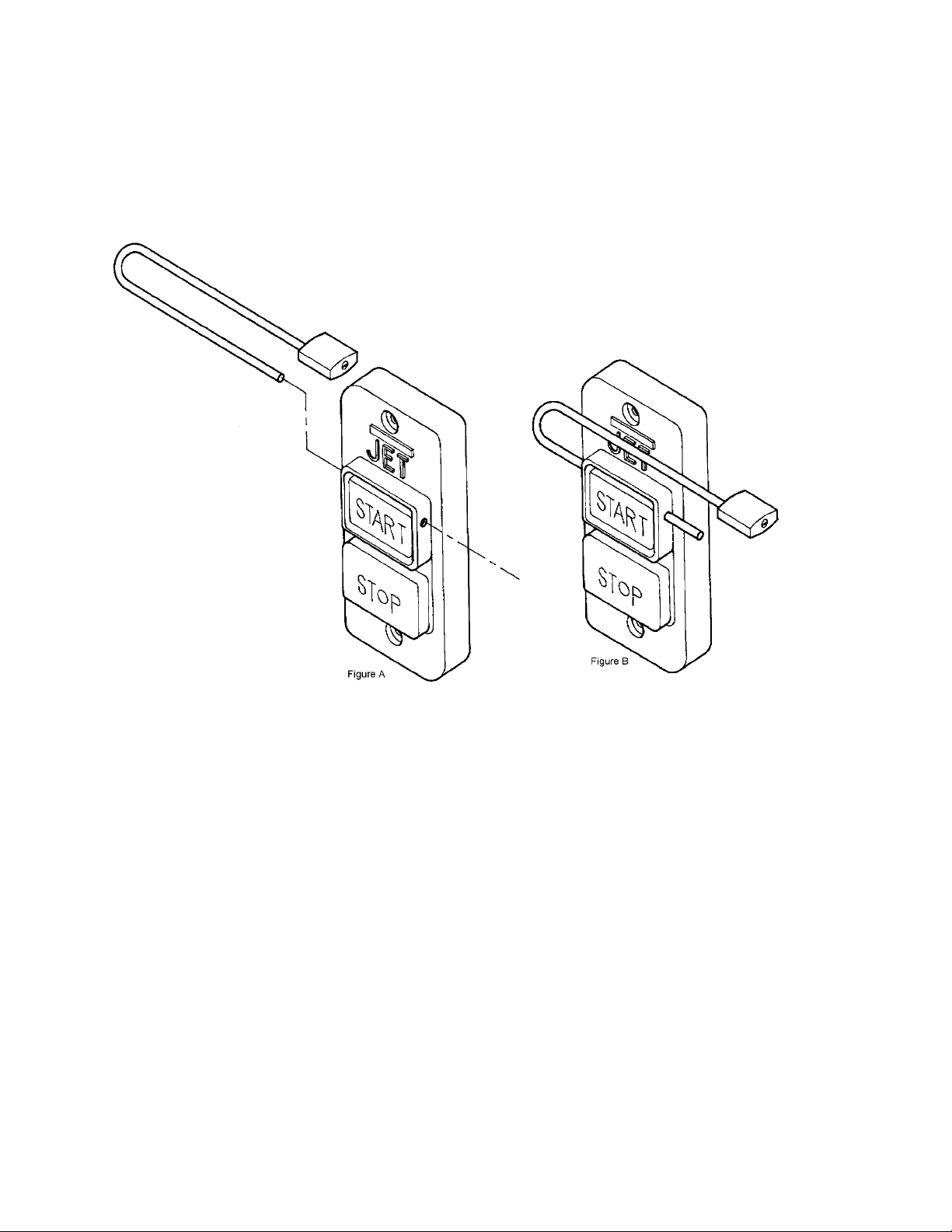

On-Off Switch Padlock

Model No . BP-1, Sto ck No. 709736

To safeguard your machine from unaut hor ized operati on and to avoid accidental starting by y oung

children, the use of a padl oc k is highly rec ommended. J E T model B P - 1 is avai lable from your local

authorized JET distri butor or by calling JET E quipment & Tools at 800-274-6848.

To lock out an on-off switch:

1. Open the padlock. See Fig. A.

2. Insert through holes i n the start button. S ee Fig. B

3. Close the padlock.

4. Place the key in a safe place.

7

Specifications: JDP-17MF

Stock Number................................................................................................................................354169

Swing.............................................................................................................................................16-1/2”

Type..................................................................................................................................................Floor

Drilling Capacity ..................................................................................................................................5/8”

Chuck Size..........................................................................................................................................5/8”

Spindle Travel..................................................................................................................................4-3/8”

Spindle Distance to Base......................................................................................................................49”

Spindle Distance to Table (max.)....................................................................................................29-1/8”

Table Size Di ameter.......................................................................................................................13-3/4”

Table Tilt....................................................................................................................................+ or - 45°

Spindle T aper ....................................................................................................................................MT-2

Column Diameter .............................................................................................................................3-1/8”

Number of Spindle S peeds....................................................................................................................16

Range of Spi ndle Speeds ................................................................................................. 200-3,630 RPM

Overall Height...................................................................................................................................... 66”

Base Size........................................................................................................................12-1/2” x 19-5/8”

Motor......................................................................................................................................3/4HP, 1 Ph

...........................................................................................................................115/230V, prewired 115V

Net Weight (approx.) ...................................................................................................................... 189 lb.

Shipping Wei ght (approx. ) .............................................................................................................. 200 lb.

Table of Contents Page

Warranty .................................................................................................................................................2

Warnings ....................................................................................................................... .......................3-4

Grounding Instructions.............................................................................................................................5

115V Operati on .......................................................................................................................................5

230V Operati on .......................................................................................................................................6

On-Off Switch Padl ock ............................................................................................................................7

Specifications..........................................................................................................................................8

Table of Contents....................................................................................................................................8

Contents of Shipping Container...............................................................................................................9

Tools Supplied for Assembly ...................................................................................................................9

Tools Required for Assembly...................................................................................................................9

Before Assembly .....................................................................................................................................9

Assembly..........................................................................................................................................10-11

Removing the Chuck and A r bor.............................................................................................................11

Adjusting the Depth Stop.......................................................................................................................12

Changing Spindle Speeds......................................................................................................................12

Speed and Pulley Char t.........................................................................................................................13

Return Spring Adjustment ......................................................................................................................14

Table Tilt Adjustm ent.............................................................................................................................14

Basic Operation.....................................................................................................................................15

Lubrication.............................................................................................................................................15

Troubleshooting.....................................................................................................................................16

Part’s Breakdown...................................................................................................................................17

Part’s List..........................................................................................................................................18-20

Wiring Diagram .....................................................................................................................................21

The specifications in this manual are given as general informati on and are not binding. WMH TOOL

GROUP r eserv es the ri ght t o eff ect, at any t i m e and without pri or not ic e, changes or al ter ati ons to part s,

fittings, and accessory equi pment deem ed nec essary for any reason whatsoever.

8

Contents of the Shipping Container

1. Head Assembly

1. Table

1. Column and Brack et Assembly

1. Base

1. Owner’s Manual

1. Warranty Registration Card

1. Chuck and Chuck Key

3. Downfeed Handle

1. Table Bracket Lock Handle

1. Table Bracket Raising Handle

4. M10 x 40 Hex Cap Bolts

1. Arbor

1. Drift Key

Tools Supplied for Assembly

1. 3mm Hex W r enc h

1. 5mm Hex W r enc h

Tools Required for Assembly

1. 17mm Box Wrench or a 6”-8” Adjustable

Wrench

WARNING!

Read and understand all assembly

instructions before attempting assembly!

Failure t o comply may cau se serious in jury!

Before Assembly

1. Remove the contents from the shipping

container.

2. Compare the contents of the shipping

container wit h the list f ound above. Report

any shortages or damage to your JET

distributor.

3. Clean all rust protected surfaces with

kerosene or a light solvent. Do not use

lacquer thinner, paint thinner, or gasoline.

These will damage pl astic components and

painted surf aces.

9

Assembly

1. Place the base (A, Fig. 1) on a l evel floor.

2. With a 17mm wrench attach the column

assembly (B, Fig. 1) to the base (A, Fig. 1)

with four M 10 x 40 hex cap bol ts (C, Fi g. 1).

Tighten firmly.

3. Thread lock handle (D, F ig. 2) i nto the t able

bracket (E, Fig. 2).

4. Loosen the set screw (F, Fig. 3) on the

raising handle (G, Fig. 3) with a 3mm hex

wrench.

5. Slide the handle onto the table bracket

shaft.

6. Turn the handle until the set screw is

opposite the flat section on the shaft, and

tighten t he set scr ew to secure t he handle.

7. Insert the table (H, Fig. 3) into the table

bracket.

8. Tighten the t able lock handle (I, Fig. 3).

10

9. With the aid of a second person, carefully

lif t the head ont o the col umn top. Caution:

The head assembly is heavy! Use care

when lifting onto the column!

10. Rotate head assem bly unti l sides of the bel t

cover are parallel with the sides of the base.

11. Tighten two set screws (A, Fig. 4) with a

5mm wrench until they ar e snug.

12. Install three down feed handles (B, Fig. 4)

into the down f eed hub (C, Fig. 4) .

13. Raise table to approximately seven inches

below spindle assem bly, and lock t he table

in place.

14. P lace a piece of scrap wood on the table.

15. T horoughly cl ean spindle, arbor, and chuck.

Important: These three pieces must be

free of any rust protection, or lubricant. If

they are not cl ean, the arbor and chuck will

fail to seat in t he spi ndle.

16. P lace arbor int o the chuck.

17. Twist the chuc k to retract the chuck j aws if

they are exposed.

18. Place arbor and chuck assembly into the

spindle.

19. Turn t he ar bor and chuck assembl y unti l the

tang on the arbor engages the slot at the

end of the spindle.

20. Lower the down feed handle so that the

chuck m eets the scrap wood. Pressure on

the down feed handle once t he chuc k m eets

the scrap wood seats the arbor and chuck

into the spindle, See Figure. 5.

Removing the Chuck and Arbor

1. Unplug machine from the power source.

2. Raise the table unt il it is about seven inchs

below the chuck.

3. Place a piece of scrap wood on the table,

and lower quill using the down feed handle.

4. Rotate spindle to align the key hole in the

spindle with the key hole in the quill.

5. Insert the drift key (D, Fig. 6) into the

aligned slot s and tap l i ghtl y. The chuc k and

arbor assembly should fall from the spindle.

11

Adjusting the Depth Stop

To drill m ultiple holes at the same preset depth,

use the depth stop:

1. Use a penci l to mark the depth the bit will

drill into the workpiece (A, Fig. 7).

2. With the drill bit in the chuck, lower down

feed handle t o advance bit to y our m ark, see

Figure 7.

3. With y our ot her hand, advance the lock nuts

(B, Fig. 7) on the depth stop rod until they

are snug to the seat (C, F ig. 7).

4. The drill bit will now advance to this point.

5. To release, advance the nuts counter-

clockwise to t he top of the dept h stop.

Changing Spindle Speeds

A spindle speed and bel t arrangem ent chart are

found on the i nside of the belt cov er (D, F ig. 8) .

Refer to this chart whenever changing speeds.

To change spindle speeds:

1. Unplug the machine from the power

source.

2. Loosen two bar knobs (E, Fig. 8) found on

each side of t he head assem bly.

3. Rotate the tension adjuster (F, Fig. 8) to

bring t he motor base as close to the head as

possible.

4. Change the belts location according the

speed chart and the speed you desire.

5. Rotate the tension adjuster (F. Fig. 8) to

tension the belts.

6. Ti ghten two bar knobs (E, Fig. 8). Belt s are

properly tensioned when finger and thumb

pressure midway between the two pulleys

causes approximately ½” deflection.

12

Speed & Pulley Chart

13

Return Spring Adjustment

The retur n spring is adjusted at t he factory and

should not need further adjustment. If

adjustment is deemed necessary:

1. Unplug the machine from the power

source.

2. Loosen two jam nuts (A, Fig. 9). Do not

remove.

3. Firmly hold the c oil spring cover (B , Fig. 9).

4. Pull out the cover and rotate until the pin (C,

Fig. 9) on the return spring plate engages

the next not ch i n t he coi l spri ng cover. Turn

the cov er cl oc kwise to decrease tensi on and

counter-clockwise to increase tensi on.

5. Tighten two jam nuts (A, Fig. 9). Do not

over-tighten. Nuts should not contact the

housing when tight. T he j am nuts should be

tightened against eachother.

Work Light

Install a light bulb, no larger than 60 watts into

the socket accessed from beneath the head.

The light bulb is control led by the rocker switch

(D, Fig. 9).

Table Tilt Adjustment

CAUTION!

Remove the ali gnment pin first an d then

loosen t he hex cap bo lt. Failure to comp ly

may cause the tab le assembly to sep arat e

from the column and fall.

To tilt the table:

1. Turn nut (D, Fig. 11) clockwise to pull out

the alignment pin ( E , Fig. 11) .

2. Loosen hex cap bol t ( F, Fi g. 11) , and t il t the

table to t he desired angle.

3. Tighten the hex cap bolt ( F, Fig. 11).

4. The alignment pin only works at 90° and

must be reinserted when the table is

returned to 90°.

14

Basic Operation

• Always use a bac k-up piece of scrap wood

to cover the table. This protects both the

table and the drill bit.

• Place m aterial to be drilled i n such as way

as to com e int o contact with the lef t side of

the column. This prevents the material from

spinning.

WARNING!

If the work piece is n ot large enough to

come into contact wi t h the column, use a

clamp or drill press vise that is securely

fastened to the table!

Failure t o comply may cau se serious in jury!

• Feed the bit into the material with only

enough force to allow the drill bit to work.

Feeding too slowly may cause burning of

the workpiece. Feeding too quickly may

cause the motor to stop and/ or the drill bit to

break.

• Generall y speaking, t he smaller the drill bit,

the greater the RPM required. Wood

requires higher speeds than m etal. Metal is

usually drilled at sl ower speeds.

• In dusty environments, frequently blow out

any dust that accumulates insi de the motor.

Lubrication

Periodic ally lubricat e the gear and the rack, t he

table elevation mechanism, the splines

(grooves) in the spindle, and the teeth of the

quill with a #2 tube grease.

15

Trouble Probable Cause Remedy

Drill press will not start.

Drill press does not come up

to speed.

Drill Press vibrates

excessively.

Noisy Operat ion.

Workpiece Burn s.

Drill bit wanders.

Wood splinters on the

underside.

Drill bit binds in workpiece.

Excessive drill bit runout, or

wobble.

Quill returns too slow, or too

fast.

Chuck, or arbor do not stay in

place.

Troubleshooting

1. Drill press unplugged from

wall, or motor.

2. Fuse blown, or circuit

breaker tripped.

3. Cord damaged.

4. Starting capacitor bad.

1. Extension cor d too light or

too long.

2. Low current.

1. Stand on uneven surface.

2. Bad belt(s).

1. Incorrect belt tension.

2. Dry spindle.

3. Loose spindle pulley.

4. Loose motor pulley.

1. Incorrect Speed.

2. Chips not clearing from hole

or bit.

3. Dull drill bit.

4. Feeding too slow.

1. Bit sharpened incor r ec tly.

2. Bent drill bit.

3. Bit, or chuck not instal led

properly.

1. No backing board used.

1. Workpiece pinching the bit.

2. Excessive feed rat e.

3. Chuck jaws not tight.

4. Improper belt tension.

1. Bent drill bit.

2. Worn spindle bearings.

3. Bit, or chuck not properly

installed.

1. Spring has im pr oper tension.

1. Dirt, grease, etc on arbor,

chuck, or spindle.

1. Check all plug connections.

2. Replace fuse, or reset circui t

breaker.

3. Replace cord.

4. Replace starti ng c apac itor.

1. Replace with adequate siz e

and length cord.

2. Contact a quali fied

electrician.

1. Adjust stand so that it rests

evenly on the f loor.

2. Replace belts.

1. Adjust belt tension. See

“Changing Spi ndle Speeds”,

page 12.

2. Lubricate spindle. See

“Lubricat ion” page 15.

3. Check tightness of r etaining

nut on pulley , and tighten if

necessary.

4. Tighten set screws in pulleys.

1. Change to appropriate

speed, see speed and pulley

chart, page 13.

2. Retract drill bit f requently to

remove chips.

3. Resharpen, or replace drill

bit.

4. Increase feed rat e.

1. Resharpen bit correct ly.

2. Replace drill bit.

3. Reinstall the chuck, or bi t

properly.

1. Place a scrap board

underneath the workpiec e to

prevent splintering.

1. Support or clamp workpiece.

2. Decrease feed rate.

3. Tighten chuck jaws.

4. Increase belt tensi on, see

page 12.

1. Replace drill bit.

2. Replace spindle bearings.

3. Reinstall the bit, or c huc k

properly.

1. Adjust “Return Spr ing

Tension,” page 14.

1. Clean all mating surfaces

thoroughly with a cleaner

degreaser.

16

Parts Breakdown for JDP-17MF

17

Par t s List for J ET JDP-17MF Drill Press

Index Part

No. No. Description Size Qty.

1..........10600111..................... Base.................................................................. ...................................1

2A........12909001A1................. Column and Holder Assy. .................................. ...................................1

3.......... TS-1525021 ................. Set Screw.......................................................... M10x12......................1

5.......... TS-1491061 ................. Hex Cap Bolt..................................................... M10x40 ......................4

6..........10700605A1................. Bracket.............................................................. ...................................1

7..........10600702..................... Pinion Gear....................................................... ...................................1

8..........10600802..................... Gear Shaft......................................................... ...................................1

9..........10600902..................... Worm Pinion ..................................................... ...................................1

10........10601002..................... Crank Handle..................................................... ................................... 1

11........TS-1523031.................Set Screw.......................................................... M6x10........................1

12........10901203A1................. Table Bracket Assy............................................ ...................................1

13........TS-0071011.................Hex Cap Bolt..................................................... 5/8”x1-1/2”..................1

14........10601401..................... Locator Pin........................................................ ...................................1

15........TS-0561011.................Hex Nut............................................................. 1/4"-20........................1

16........10601601..................... Angle Scale....................................................... ...................................1

17........10601702..................... Centering Scale................................................. ...................................1

18........2658MZDU36............... Drive Screw....................................................... ...................................4

19........10601901..................... Column Lock Handle ......................................... ...................................1

20........10602001..................... Table Lock Handle............................................. ...................................1

21........10702112..................... Table................................................................. ...................................1

22........10602205..................... Rack.................................................................. ...................................1

23........10702307A1................. Rack Ring.......................................................... ...................................1

24........TS-1523031.................Set Screw.......................................................... M6x10........................1

25........10902515A1................. Head.................................................................. ...................................1

26........TS-1525021.................Set Screw.......................................................... M10x 12 ......................2

27........10602702..................... Lamp Socket..................................................... ................................... 1

28........2669BZDA37 ...............Pan Head Screw................................................ M6x8..........................2

29........10902905..................... Handle S hift er .................................................... ...................................1

30........10603002A1................. Cam .................................................................. ...................................1

31........TS-1490021.................Hex Cap Bolt..................................................... M8x16........................1

32........10703211..................... Slide Bar (right)................................................. ...................................1

33........10903302..................... Slide Bar Bolt .................................................... ...................................2

34........10703414..................... Motor Base........................................................ 75x125.......................1

35........TS-0720111.................Lock Washer ..................................................... ½”...............................2

36........TS-1540071.................Hex Nut............................................................. M12............................2

37........ ....................................Handle Body (re:17373839) ............................... ...................................1

38........17373839..................... Feed Shaft Assy (#37,38, 39) ............................. ...................................1

39........ ....................................Spring Pi n (re: 17373839).................................. ...................................1

43A......10604303A1................. Handle Bar A ssy................................................ ...................................3

45........10661801..................... Shaft Collar ....................................................... ...................................1

46........10904618..................... Scale................................................................. ...................................1

48........2658MZDU36............... Drive Screw....................................................... ...................................2

49A......10604902A2................. Coil Spring and Cover ....................................... ...................................1

51........10905116..................... Spring Seat........................................................ ...................................1

52........10905203..................... Plate.................................................................. ...................................1

53........TS-0561052.................Hex Nut............................................................. 1/2"-20UNF.................1

54........10605403..................... Quill Set Screw.................................................. ...................................1

55........TS-1540071.................Hex Nut............................................................. M10............................1

56........10905612..................... Quill................................................................... ...................................1

57........10705703..................... Rubber Washer ................................................. ...................................1

58........10905829..................... Spindle.............................................................. ...................................1

59........BB-6205ZZ ..................Ball Bearing....................................................... ...................................1

18

Index Part

No. No. Description Size Qty.

61........BB-6203Z..................... Ball Bearing....................................................... ...................................1

62........10606201..................... Washer.............................................................. ...................................1

63........10606301..................... Lock Nut............................................................ ...................................1

64........10606401..................... Spindle Nut........................................................ ...................................1

65........10706508A1................. Driving Sleeve................................................... ...................................1

66........BB-6205Z..................... Ball Bearing....................................................... ...................................2

67........10706705..................... Collar................................................................. ...................................1

68........10706802..................... Retaining Ring................................................... ...................................2

69........10606904..................... Pulley Set Nut.................................................... ...................................1

70........10607018..................... Spindle Pulley.................................................... ...................................1

71........561766......................... Arbor.................................................................MT2xJT2....................1

72A......561708......................... Chuck................................................................ ...................................1

73........10607303..................... Wedge............................................................... ...................................1

74........8907522151.................Motor................................................................. ...................................1

............ 82061041.....................Motor Fan (not shown)....................................... ...................................1

............ 89075161.....................Motor Fan Cover (not shown) ............................ ...................................1

............ 299155BA04 ................ Centrifugal Switch (not shown)........................... ...................................1

............ 2992A55A14 ................ Capacitor ( not shown) ........................................ ...................................1

75........2808B530C3................Motor Cable....................................................... ...................................1

76........TS-1490041.................Hex Cap Bolt..................................................... M8x25........................4

77........TS-0680031.................Flat Washer....................................................... 5/16”...........................8

78........TS-1540061.................Hex Nut............................................................. M8..............................4

79........10607970A1................. Motor Pulley ...................................................... ...................................1

80........2571NNC109 ............... Parallel Key....................................................... ...................................1

81........TS-1524011.................Set Screw.......................................................... M8x8..........................1

83........12201501..................... Wire Clip ........................................................... ...................................3

84........TS-1533042.................Pan Head S c rew................................................ M5x12 ........................3

85........2807AB08D4................Power Cable...................................................... ...................................1

87........DC1200-44................... On-Off Switch.................................................... ...................................1

88........10608813..................... Switch Box ........................................................ ...................................1

89........TS-1533052.................Pan Head S c rew................................................ M5x16 ........................2

90........10909012A1................. Pulley Cover Assy ............................................. ...................................1

92........2638BZDA40 ...............Round Head Screw............................................ M6x16 ........................4

95........10609510..................... Center Pulley..................................................... ...................................1

96........BB-6202Z..................... Ball Bearing....................................................... ...................................2

98........10609801..................... Center Pulley Shaft............................................ ...................................1

99........VB-A25........................V-Belt ................................................................ A25.............................1

101......TS-0680021.................Flat Washer....................................................... 1/4".............................4

106......TS-0561052.................Hex Nut............................................................. 1/2"-20UNF.................1

112......10611201..................... Chuck Key Holder.............................................. ...................................1

113......2668BBDA40 ............... Pan Head Screw ................................................ M6-1.0x16 ..................1

119......VB-A25........................V-Bel t ................................................................ A25.............................1

128......2653MBDE15............... Tapping Scr ew................................................... ...................................2

131......CK-16.......................... Chuck Key......................................................... ...................................1

137......10308846..................... Switch Cover..................................................... ...................................1

138......TS-1533042.................Pan Head Screw................................................ M5x12........................2

139......2852D55723................. Bulb Switch........................................................ ...................................1

140......10714001..................... Motor Bar (left).................................................. ...................................1

149......2536MBE616 ............... Spring Pin.......................................................... ...................................2

150......10916904..................... I.D. Label........................................................... ...................................1

162......10216210..................... Warning Label................................................... ...................................1

163......2658MZDU36............... Drive Screw....................................................... ...................................4

165......10616519..................... Speed Chart ...................................................... ...................................1

19

Index Part

No. No. Description Size Qty.

169......11316904..................... Nameplate......................................................... ...................................1

601......TS-1533032.................Pan Head Machine Screw.................................. M5x10........................1

602......2504MBC005...............Tooth Washer.................................................... ...................................1

607......TS-0720101.................Lock Washer .....................................................7/16”...........................2

610......TS-1503081.................Socket Head Cap Sc rew.................................... M6x35........................2

611......10661102..................... Seat................................................................... ...................................1

612......TS-1540081.................Hex Nut............................................................. M12............................1

613......10661301..................... Scale Bolt.......................................................... ...................................1

614......13005701..................... Nut .................................................................... ...................................2

615......13005601..................... Washer.............................................................. ...................................1

616......TS-1504051.................Hex Socket Cap Screw...................................... M8x25 ........................1

617......10761701..................... Set Ring ............................................................ ...................................1

618......10604505..................... Round Nut ......................................................... ...................................1

700......TS-152704...................Hex Wrench......................................................3MM...........................1

701......TS-152706...................Hex Wrench......................................................5MM...........................1

801......28065558U4................. Bulb Wire .......................................................... ...................................2

903......2801CBHA01...............Cable Protection................................................ ...................................2

20

21

Loading...

Loading...