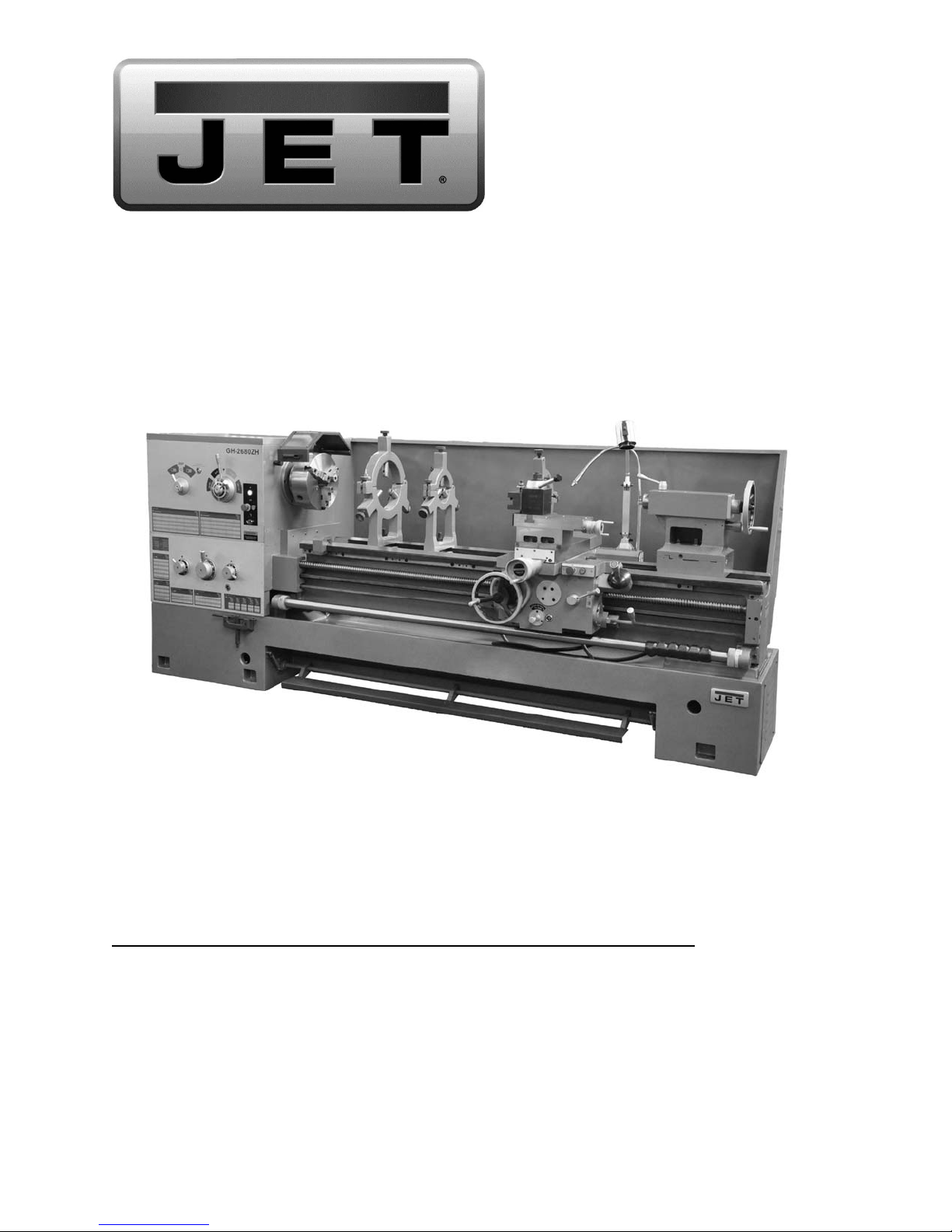

Page 1

Operation and Maintenance Instructi ons

ZH Series Large Bore Lathes

Models GH-2680ZH; GH-26120ZH

For ZH-Series Lathes Parts List and Electrical Diagrams, see document M-321860-1

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-321860

Ph.: 800-274-6848 Revision C3 08/2018

www.jettools.com Copyright © 2017 JET

Model GH-2680ZH shown

Page 2

1.0 IMPORTANT SAFETY

INSTRUCTIONS

1. Read and understand the entire owner’s manual

before attempting assembly or operation .

2. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply with all of these warnings may cause

serious injury.

3. Replace the warning labels if they become

obscured or removed.

4. This lathe is designed and intended for use by

properly trained and experienced personnel

only. If you are not familiar with the proper and

safe operation of a lathe, do not use until proper

training and knowledge have been obtained.

5. Do not use this lathe for other than its intended

use. If used for other purposes, JET disclaims

any real or implied warranty and holds itself

harmless from any injury that may result from

that use.

6. Always wear approved safety glasses/face

shields while using this lathe. Everyday

eyeglasses only have impact resistant lenses;

they are not safety glasses.

7. Before operating this lathe, remove tie, rings,

watches and other jewelry, and roll sleeves up

past the elbows. Remove all loose clo thing and

confine long hair. Non-slip footwear or anti-skid

floor strips are recommended. Do not wear

gloves.

8. Wear ear protectors (plugs or muffs) during

extended periods of operation.

9. Do not operate this machine while tired or under

the influence of drugs, alcohol or any

medication.

10. Make certain the switch is in the OFF position

before connecting the machine to the power

supply.

11. Make certain the machine is properly grounded.

12. Make all machine adjustments or maintenance

with the machine unplugged from the power

source.

13. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and adjusting

wrenches are removed from the machine before

turning it on.

14. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately after

maintenance is complete.

15. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it

will operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may

affect its operation. A guard or other part that is

damaged should be properly repaired or

replaced.

16. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

17. Keep the floor around the machine clean and

free of scrap material, oil and grease.

18. Keep visitors a safe distance from the work

area. Keep children away.

19. Make your workshop child proof with padlocks,

master switches or by removing starter keys.

20. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in serious

injury.

21. Maintain a balanced stance at all times so that

you do not fall or lean against moving parts. Do

not overreach or use excessive force to perform

any machine operation. Never force the cutting

action.

22. Maintain a balanced stance at all times so that

you do not fall or lean against moving parts. Do

not overreach or use excessive force to perform

any machine operation. Never force the cutting

action.

23. Use the right tool at the correct speed and feed

rate. Do not force a tool or attachment to do a

job for which it was not designed. The right tool

will do the job better and more safely.

24. Use recommended accessories; improper

accessories may be hazardous.

25. Maintain tools with care. Keep cutting tools

sharp and clean for the best and safest

performance. Follow instructions for lubricating

and changing accessories.

26. Do not attempt to adjust or remove tools during

operation.

27. Never stop a rotating chuck or workpiece with

your hands.

28. Choose a low spindle speed when working

unbalanced workpieces, and for threading and

tapping operations.

29. Do not exceed the maximum speed of the

workholding device.

30. Do not exceed the clamping capacity of the

chuck.

2

Page 3

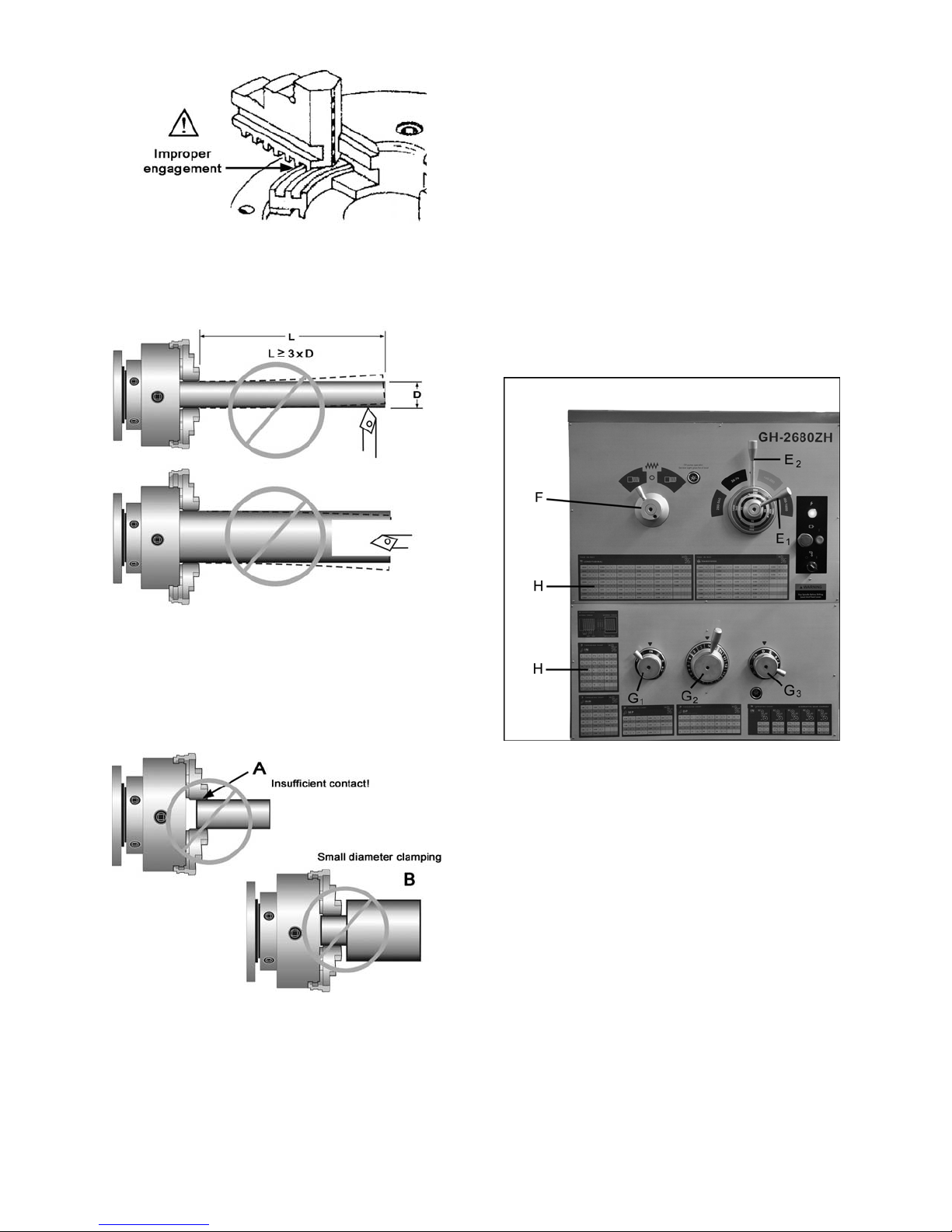

31. Workpieces longer than 3 times the chucking

diameter must be supported by the tailstock or a

steady rest.

32. Avoid small chuck diameters with large turning

diameters.

33. Avoid short chucking lengths and small

chucking contact.

34. Turn off the machine and disconnect from power

before cleaning. Use a brush to remove

shavings or debris — do not use your hands.

35. Do not stand on the machine. Serious injury

could occur if the machine tips over.

36. Never leave the machine running unattended.

Turn the power off and do not leave the

machine until moving parts come to a complete

stop.

37. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

38. Do not operate the lathe in flammable or

explosive environments. Do not use in a damp

environment or expose to rain.

WARNING: This product can expose you to

chemicals including lead and cadmium which

are known to the State of California to cause

cancer, and phthalates which are known to the

State of California to cause birth defects or other

reproductive harm. For more information go to

http://www.p65warnings. ca.gov.

WARNING: Some dust, fumes and gases

created by power sanding, sawing, grinding,

drilling, welding and other construction activities

contain chemicals known to the State of California

to cause cancer and birth defects or other

reproductive harm. Some examples of these

chemicals are:

• lead from lead based paint

• crystalline silica from bricks, cement and other

masonry products

• arsenic and chromium from chemically treated

lumber

Your risk of exposure varies, depending on how

often you do this type of work. To reduce your

exposure to these chemicals, work in a wellventilated area and work with approved safety

equipment, such as dust masks that are

specifically designed to filter out microscopic

particles. For more information go to

http://www.p65warnings.ca.gov/ and http://www.

p65warnings.ca.gov/wood.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly even

death.

3

Page 4

2.0 Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Covered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of these machines in the processing of metal, plastics, or other materials may void the warranty. The exceptions

are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846.Please note that you will be asked to provide proof

of initial purchase when calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

4

Page 5

3.0 Table of Contents

1.0 IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................... 2

2.0 Warranty and Service ..................................................................................................................................... 4

3.0 Table of Contents ........................................................................................................................................... 5

4.0 Specifications ................................................................................................................................................. 6

5.0 Dimensions and mounting hole centers ......................................................................................................... 8

6.0 General description and nomenclature .......................................................................................................... 9

7.0 Unpacking .................................................................................................................................................... 11

7.1 Contents of the Shipping Container ......................................................................................................... 11

8.0 Installation .................................................................................................................................................... 12

8.1 Leveling the lathe ..................................................................................................................................... 12

8.2 Completing installation ............................................................................................................................. 12

8.3 Chuck Preparation .................................................................................................................................... 13

8.4 Break-In Period ........................................................................................................................................ 13

9.0 Maintenance/Lubrication

9.1 Coolant Preparation ................................................................................................................................. 16

10.0 Electrical Connections ................................................................................................................................ 16

10.1 Conversion to 460 Volt Operation

11.0 Basic Controls ............................................................................................................................................ 18

12.0 Operation ................................................................................................................................................... 20

12.1 Tool Setup .............................................................................................................................................. 21

12.2 Spindle Speed ........................................................................................................................................ 21

12.3 Feed and Thread Selection .................................................................................................................... 21

12.4 Thread Cutting ........................................................................................................................................ 22

13.0 Adjustments ............................................................................................................................................... 22

13.1 Chuck Jaw Reversal ............................................................................................................................... 22

13.2 Gib Adjustments ..................................................................................................................................... 22

13.3 Tailstock Adjustments ............................................................................................................................ 23

13.4 Gap Section ............................................................................................................................................ 23

13.5 Belt Adjustment and R eplacement

13.6 Brake Strap ............................................................................................................................................ 24

13.7 Friction Clutch Adjustment ..................................................................................................................... 24

13.8 Aligning Tailstock to Headstock ............................................................................................................. 25

13.9 Spindle Bearings .................................................................................................................................... 25

13.10 Speed Control ...................................................................................................................................... 25

13.11 Lead Screw .......................................................................................................................................... 26

13.12 Apron Feed Clutch ............................................................................................................................... 26

13.13 Tool Post .............................................................................................................................................. 26

13.14 Cross Slide Nut Adjustment ................................................................................................................. 27

13.15 Shear Pin Replacement ....................................................................................................................... 27

13.16 Steady Rest Adjustment ....................................................................................................................... 27

13.17 Follow Rest Adjustment ........................................................................................................................ 28

14.0 Troubleshooting the ZH Series Lathes ....................................................................................................... 29

15.0 Lubrication Schedule and General Maintenance ....................................................................................... 30

16.0 Reference Tables ....................................................................................................................................... 31

16.1Inch Lead And Feed ................................................................................................................................. 31

16.2Special Inch Lead And Feed .................................................................................................................... 32

16.3 Speed Selection Lever Positions ............................................................................................................ 33

17.0 Electrical – 230 volt to 460 volt Conversion ............................................................................................... 33

18.0 Change Gear Diagram ............................................................................................................................... 34

............................................................................................................................... 14

............................................................................................................ 17

............................................................................................................ 24

5

Page 6

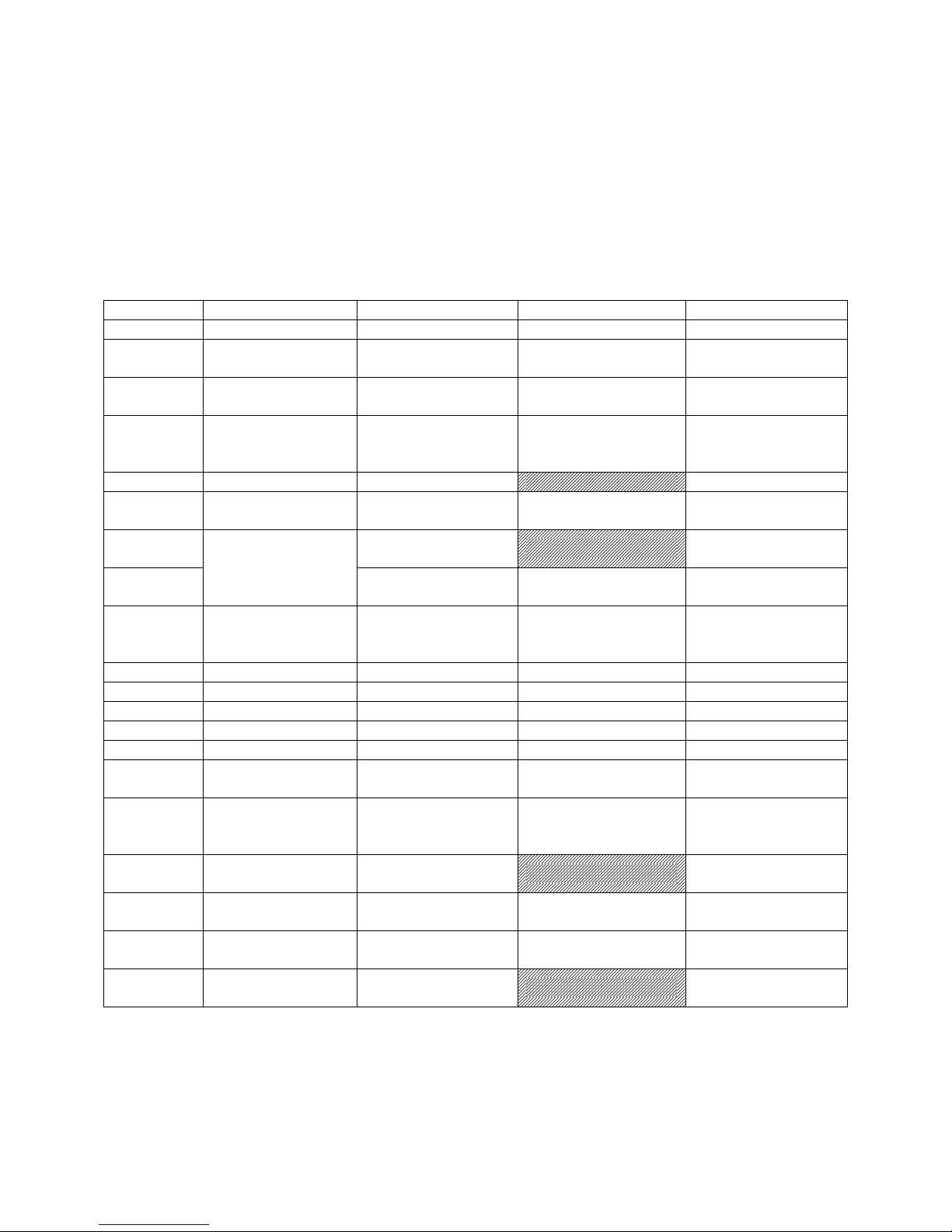

4.0 Specifications

Model Number................................................................................ GH-2680ZH ......................................... GH-26120ZH

Stock Number ....................................................................................... 321860 .................................................. 321890

General Capacities:

Maximum Swing over Bed ......................................................... 26” (660mm) ......................................... 26” (660mm)

Maximum Swing over Cross Slide ....................................... 16-1/2” (420mm) ................................... 16-1/2” (420mm)

Maximum Swing Through Gap .................................................. 34” (870mm) ......................................... 34” (870mm)

Length of Gap ........................................................................ 7-7/8” (200mm) .................................... 7-7/8” (200 mm)

Distance between Centers ...................................................... 80” (2030mm) ..................................... 120” (3050mm)

Width of Bed .............................................................................. 16” (405mm) ......................................... 16” (405mm)

Motors and Electrical:

Main Motor.............................................................................TEFC Induction ..................................... TEFC Induction

Horsepower ....................................................................... 10 HP (7.5kW) ...................................... 10 HP (7.5kW)

Phase ............................................................................................... 3 PH ...................................................... 3 PH

Voltage ............................................................ 230/460V (prewired 230V) .................... 230/460V (prewired 230V)

Full Load Amps ........................................................................ 25.4/12.7A .............................................25.4/12.7A

Cycle ............................................................................................... 60 Hz .................................................... 60 Hz

Feed Motor ...................................................................................... Induction ............................................... Induction

Horsepower ................................................................................... 1/2 HP ................................................... 1/2 HP

Phase ............................................................................................... 3 PH ...................................................... 3 PH

Voltage ............................................................ 230/460V (prewired 230V) .................... 230/460V (prewired 230V)

Full Load Amps ........................................................................ 2.85/1.65A .............................................2.85/1.65A

Cycle ............................................................................................... 60 Hz .................................................... 60 Hz

Coolant Pump Motor ........................................................................ Induction ............................................... Induction

Horsepower ................................................................................... 1/8 HP ................................................... 1/8 HP

Phase ............................................................................................... 3 PH ...................................................... 3 PH

Voltage ............................................................ 230/460V (prewired 230V) .................... 230/460V (prewired 230V)

Full Load Amps ........................................................................ 0.54/0.27A .............................................0.54/0.27A

Cycle ............................................................................................... 60 Hz .................................................... 60 Hz

Power Transmission ..................................................................... v-belt (x 4) ............................................. v-belt (x 4)

Controls circuit ............................................................................... 110V A.C. ..............................................110V A.C.

Lamp circuit ..................................................................................... 24V A.C. ...............................................24V A.C.

Indicators circuit ............................................................................. 110V A.C. ............................................. 110V A.C.

Headstock and Spindle:

Spindle Bore .......................................................................... 4-1/8” (105mm) ..................................... 4-1/8” (105mm)

Spindle Mount.......................................................................... D1-8 Camlock ....................................... D1-8 Camlock

Spindle Taper with Sleeve ....................................... 113mm Dia. 1:20 / MT-5 ....................... 113mm Dia. 1:20 / MT-5

Number of Spindle Speeds ........................................................................ 12 .......................................................... 12

Range of Spindle Speeds .....................................................36 to 1600 RPM .................................... 36 to 1600 RPM

Distance Floor to Spindle Center (approx.) .............................................. 46” ......................................................... 46”

3-Jaw Scroll Chuck:

Load Capacity........................................................................ 661 lb (300 kg) ...................................... 661 lb (300 kg)

Inside Diameter ............................................................ 5-11/16” (145mm) ................................ 5-11/16” (145 mm)

Carriage:

Maximum Compound Rest Travel ........................................ 5-1/2” (140 mm) .................................... 5-1/2” (140 mm)

Maximum Compound Rest Swivel ................................................ +/- 90 deg. .............................................

Maximum Cross Slide Travel ............................................ 14-1/16” (358 mm) ................................ 14-1/16” (358 mm)

Maximum Carriage Travel ....................................................... 65” (1650mm) .............................. 106-1/4” (2700 mm)

+/- 90 deg.

6

Page 7

GH-2680ZH GH-26120ZH

Gearbox:

Number of Longitudinal Feeds................................................................... 51 .......................................................... 51

Range of Longitudinal Feeds ..... 0.0020 – 0.094 in./rev. (0.051-2.39mm/rev) ............ 0.0020 – 0.094 (0.051-2.39mm)

Number of Cross Feeds ............................................................................ 40 .......................................................... 40

Range of Cross Feeds ............... 0.0010 – 0.040 in/rev. (0.027-1.02mm/rev) .............. 0.0010 – 0.40 (0.027-1.02mm)

Number of Inch Threads ............................................................................ 48 .......................................................... 48

Range of Inch Threads .................................................................. 30-2 T.P.I. .............................................. 30-2 T.P.I

Number of Metric Threads ......................................................................... 22 .......................................................... 22

Range of Metric Threads ................................................................. 1-14 mm ................................................ 1-14 mm

Number of Diametral Threads ................................................................... 24 .......................................................... 24

Range of Diametral Threads........................................................... 56-4 D.P. ............................................... 56-4 D.P.

Number of Modular Threads ...................................................................... 18 .......................................................... 18

Range of Modular Threads .............................................................. 0.5-7mm ................................................ 0.5-7mm

Leadscrew Pitch ...................................................................... 1/2” (12.7mm) ....................................... 1/2” (12.7mm)

Tailstock:

Tailstock Spindle Travel ............................................................. 6” (150mm) ........................................... 6” (150mm)

Tailstock Taper ...................................................................................... MT-5 ..................................................... MT-5

Maximum Tailstock Cross Displacement ............................. +/- 0.40” (10mm) ................................... +/- 0.40” (10mm)

Other:

Small Steady Rest Capacity ......................................... 3/4” – 5” (20-125mm) ............................ 3/4” – 5” (20-125mm)

Large Steady Rest Capacity ....................................... 4” – 9.5” (100-240mm) .......................... 4” – 9.5” (100-240mm)

Follow Rest Capacity .................................................... 3/4” – 4” (20-100mm) ............................ 3/4” – 4” (20-100mm)

Coolant tank capacity ............................................................... 3.4 gal. (13L) ......................................... 7.1 gal. (27L)

Overall Dimensions .............................. 137-13/16”L x 53-1/8”W x 58-1/16”H .... 177-5/32”L x 48-1/32”W x 58-1/16”H

(3500 x 1350 x 1475 mm) (4500 x 1220 x 1475 mm)

Approximate Net Weight .................................................. 7932 lbs. (3595 kg) ................................ 8010 lbs . (3630k g)

1

Values are emission levels, not necessarily to be seen as safe operating levels. Since workplace conditions vary,

this information is only intended to allow the user to make a better estimation of the hazards involved.

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

7

Page 8

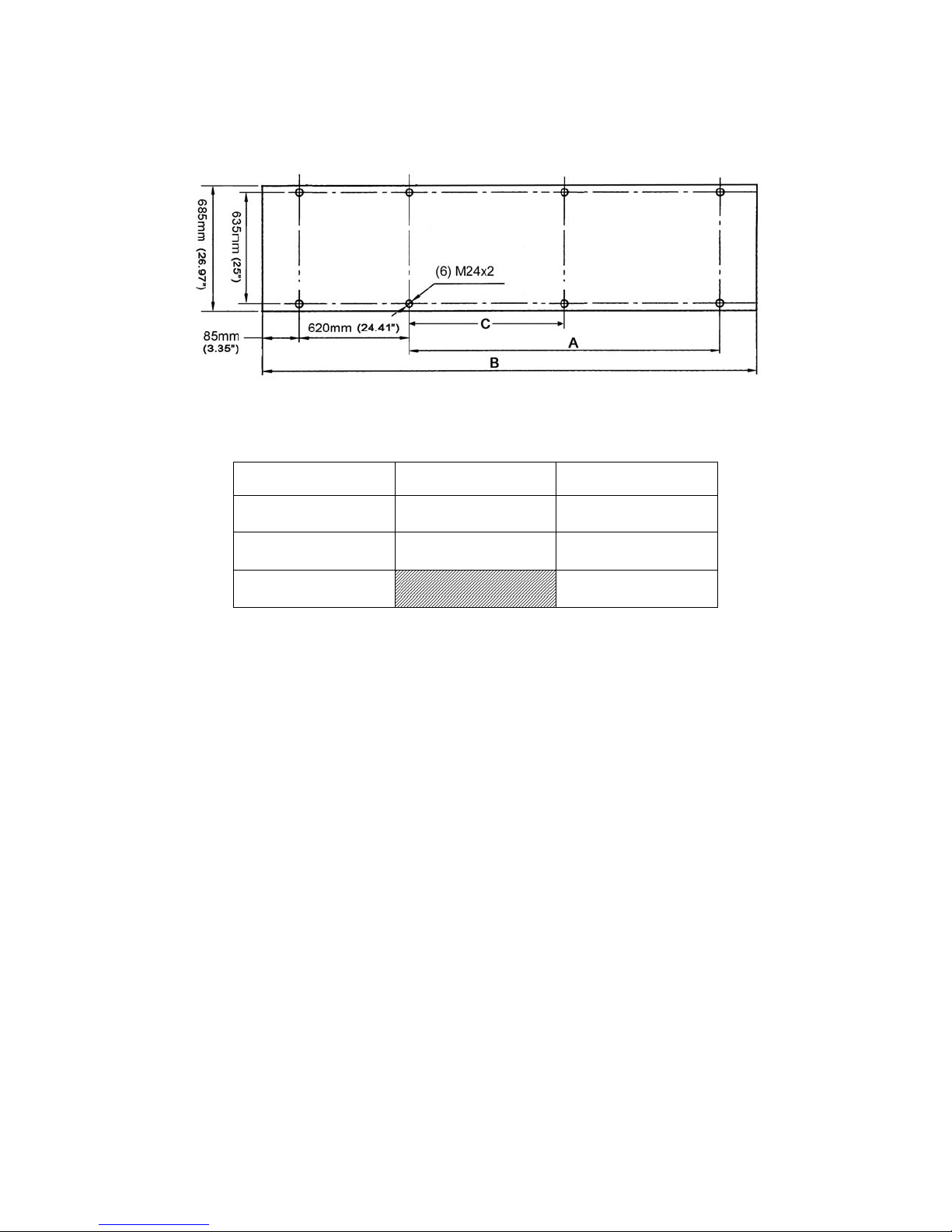

5.0 Dimensions and mounting hole center s

Figure 1

Lathe Size

A 2560mm(100.8 in.) 3565mm(140.4 in.)

80 inch

(GH-2680ZH)

120 inch

(GH-26120ZH)

B 3500mm(137.60 in. ) 4500mm (177.2 in.)

C 1721.5mm (67.8 in)

Table 1

8

Page 9

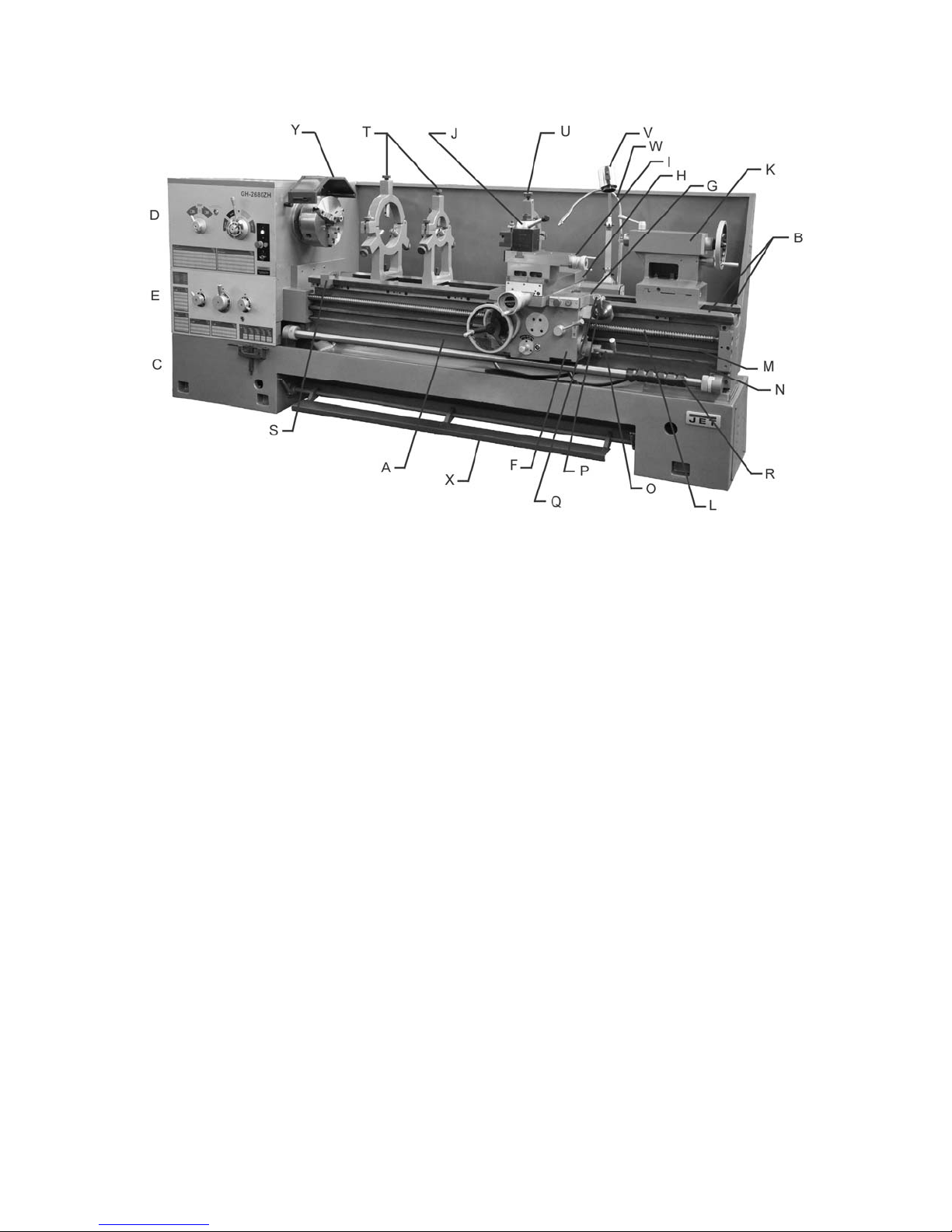

6.0 General description and nomenclature

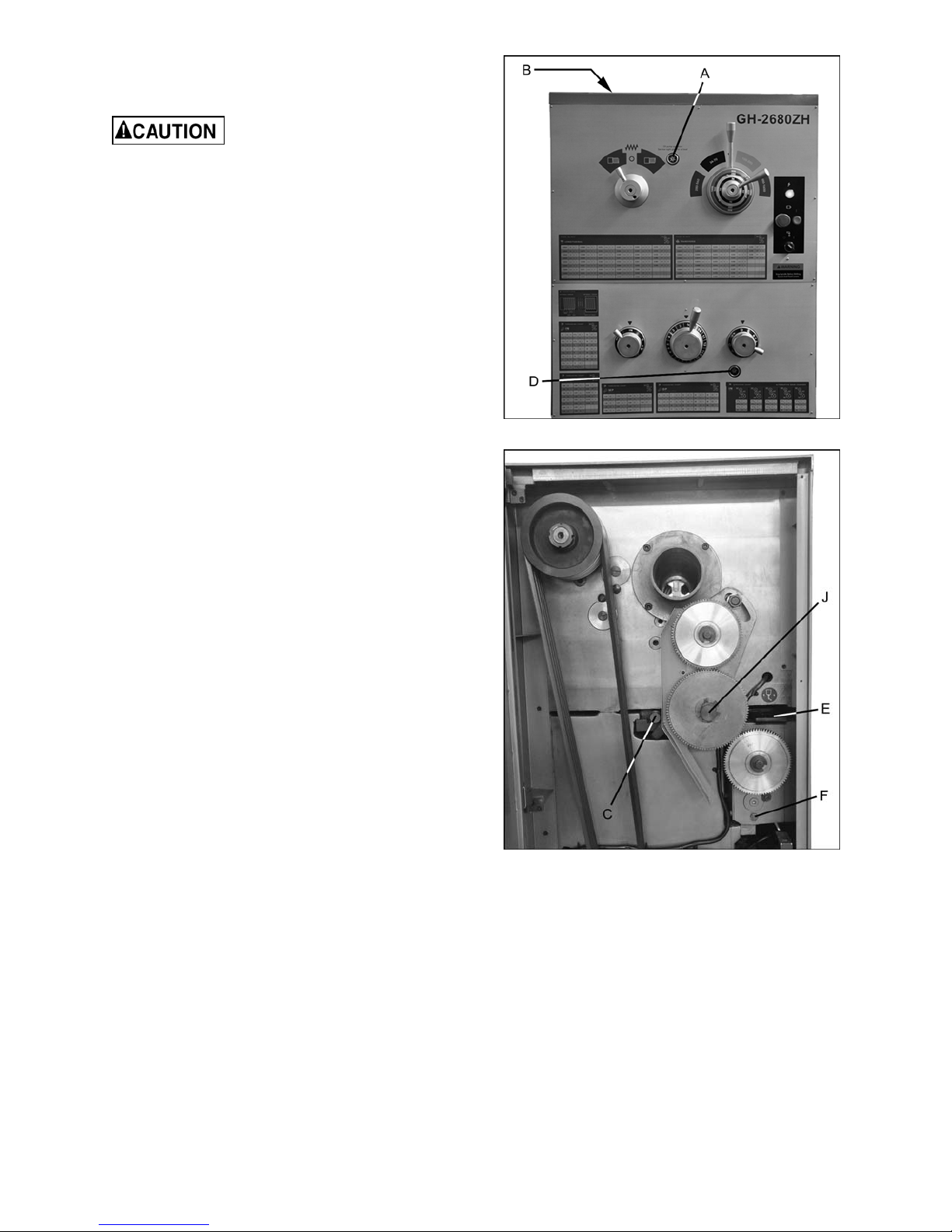

Figure 2 – General Description (GH-2680ZH shown)

The ZH series lathe operates on a centralized gear

system. The motor power is transferred through

four v-belts to a shaft, which in turn transmits the

energy through a multi-disc friction clutch and

various gear pairs, to the spindle. The clutch also

controls the spindle’s direction of rotation. Through

clutch disengagement, the operator can stop the

spindle without turning off the motor, which will

prolong the life of the motor.

Bed and Stand

Feed Gearbox

The gearbox (E) is made from high quality cast iron

and is mounted to the left side of the machine bed.

This lathe adopts a three-axle sliding common gear

mechanism, together with thread selection change

mechanism, and doubling mechanism, which

enable it to cut a comprehensive range of metric,

modular and diametral pitch threads, thus

eliminating the need for gear changes except

where special threading is required.

The lathe bed (A) is made of cast iron with low

vibration and high rigidity. Two precision-ground vslideways (B), reinforced by supersonic fre-quency

hardening, offer precision guidance for the

carriage. The main drive motor is mounted in the

stand (C) below the gearbox.

(The GH-26120ZH model has three stands: left,

center, and right).

Headstock

The headstock (D) is cast from high grade, low

vibration cast iron. In the head, the spindle is

supported at three points; by a cylindrical roller

bearing at the front and a tapered roller bearing

and ball bearing. See section 11.0for detailed

explanation of controls. The electrical box is

mounted to the rear of the headstock.

Carriage

The carriage assembly is composed of the Apron,

the Saddle, the Cross Slide, the Compound Rest,

and the four-way Tool Post.

Apron (F).Quick travel of the Apron for

positioning is accomplished by means of a bedmounted rack and pinion, operated manually by

the handwheel on the front of the apron, or

automatically by the feed direction handle (P),

which has a rapid traverse (Q).

Saddle (G). The saddle is made from high

quality cast iron and rides along the v-ways.

Cross Slide (H). The cross-slide is mounted on

the saddle and used for cross feed operations.It

moves on a dovetailed slidewhich can be

adjusted for play by means of the gibs.

9

Page 10

Compound Rest. The compound rest (I), which

is T-slotted and mounted on the cross slide, can

be rotated 360°, allowing tapers to be turned.

The compound rest travels on dovetailed ways,

with adjustable gibs.

Quick Change Tool Post. The tool post (J) is a

turret design, mounted to the compound rest. It

holds up to one tool.

Tailstock

The tailstock (K) slides on a v-way and can be

locked at any location by a clamping lever. The

tailstock has a heavy duty quill with a No. 5 Morse

Taper and etched graduation scale. The tailstock

can be offset for taper cutting, and bearings can be

adjusted for drag along the ways.

Leadscrew and Feed Rod

The leadscrew (L) and feed rod (M) are mounted

on the front of the machine bed. They are

connected to the gearbox at the left and are

supported by bearings on both ends.

The leadscrew is used only for threading functions.

This maintains its accuracy and prolonged service

life.

Spindle Direction Control Axle(N)

Spindle rotation can be reversed by simply moving

the control lever (O) mounted at the right of the

carriage. (Allow spindle to come to a stop before

reversing.)

Steady Rest

The ZH series lathes are provided with small and

large steady rests (T). A steady rest serves as a

support for shafts on the free tailstock end. The

steady rest is mounted on the bedway and secured

from below with a bolt, nut and locking plate.

Follow Rest

The traveling follow rest (U) is mounted to the

saddle, and thus follows the movement of the

turning tool. Only two fingers are required as the

place of the third is taken by the turning tool. The

follow rest is used for turning operations on long,

slender work pieces. It prevents the work piece

from flexing under the pressure of the cutting tool.

Work Lamp

Adjustable halogen lamp (V) with independent

on/off switch.

Coolant Nozzle(W)

Fully adjustable gooseneck; flow is regulated

through a valve lever at its base.

Foot Brake(X)

Activates a braking strap at the motor for

emergency stopping of all lathe functions.

Chuck Guard (Y)

Travel Stops

Six stops (R)can be moved to any position along

the travel setting rod, and are secured in place

using socket head screws. The convex surface of

the stop contacts a limit switch on the underside of

the apron. The travel setting rod can be rotated on

an eccentric into six positions to modulate the

contact between stops and limit switch.

A carriage stop (S) is also provided for manual

carriage operation.

10

Page 11

1 Tool Box, containing the following:

7.0 Unpacking

Open shipping container and check for shipping

damage. Report any damage immediately to your

distributor and shipping agent. Do not discard any

shipping material until the Latheis set up and

running properly.

Compare the contents of your container with the

following parts list to make sure all parts are intact.

Missing parts, if any, should be reported to your

distributor. Read the instruction manual thoroughly

for set up, maintenance and safety instructions.

7.1 Contents of the Shipping Container

(Refer to Figure 3)

1 Lathe

2 Steady Rests (mounted on Lathe)

1 Follow Rest (mounted on Lathe)

1 Three Jaw Scroll Chuck, 12-25/32” (mounted

on Lathe) – A

1 Drive Plate – B

4 Tool Holder – C

1 Face Plate, 24-25/32” (with 6 dogs) – D

1 Round Nut Spanner, 170-210 mm – E

4 Change Gears – 63T, 69T, 78T, 90T – F

1 Morse Reduction Sleeve – G

1 Live Center, MT-5 – H

1 Dead Center, MT-5 – I

2 Drive Pins – J

1 Cam Wrench – K

1 Chuck Wrench – L

2 Hex Socket Head Cap Screw – M

1 Gap Bridge Pin Driver – N

1 Drift Key – O

1 Round Nut Spanner (45-52 mm) – P

1 Hex Key Set (2, 3, 4, 6,8,10,12 mm) – Q

6 Leveling Bolts with Hex Nuts – R

(qty. 8 for GH-26120ZH)

6 Leveling Pads – S

(qty. 8 for GH-26120ZH)

1 Flat Blade Screwdriver – T

1 Cross Point Screwdriver – U

2 Open End Wrenches (17/19,19/22) – V

1 White Touch-up Paint Can – W

1 Oil Gun – X

1 Operating Instructions Manual

1 Parts List Manual

1 Warranty Card

1 Test Record

1 Packing List

NOTE: Optional accessories are available for JET Lathes, such as Taper Attachm ent, Collet Closer and

Digital Read Out. Contact your dealer or JET for more information.

ZH Series Lathes – Contents of Shipping Container

Figure 3

11

Page 12

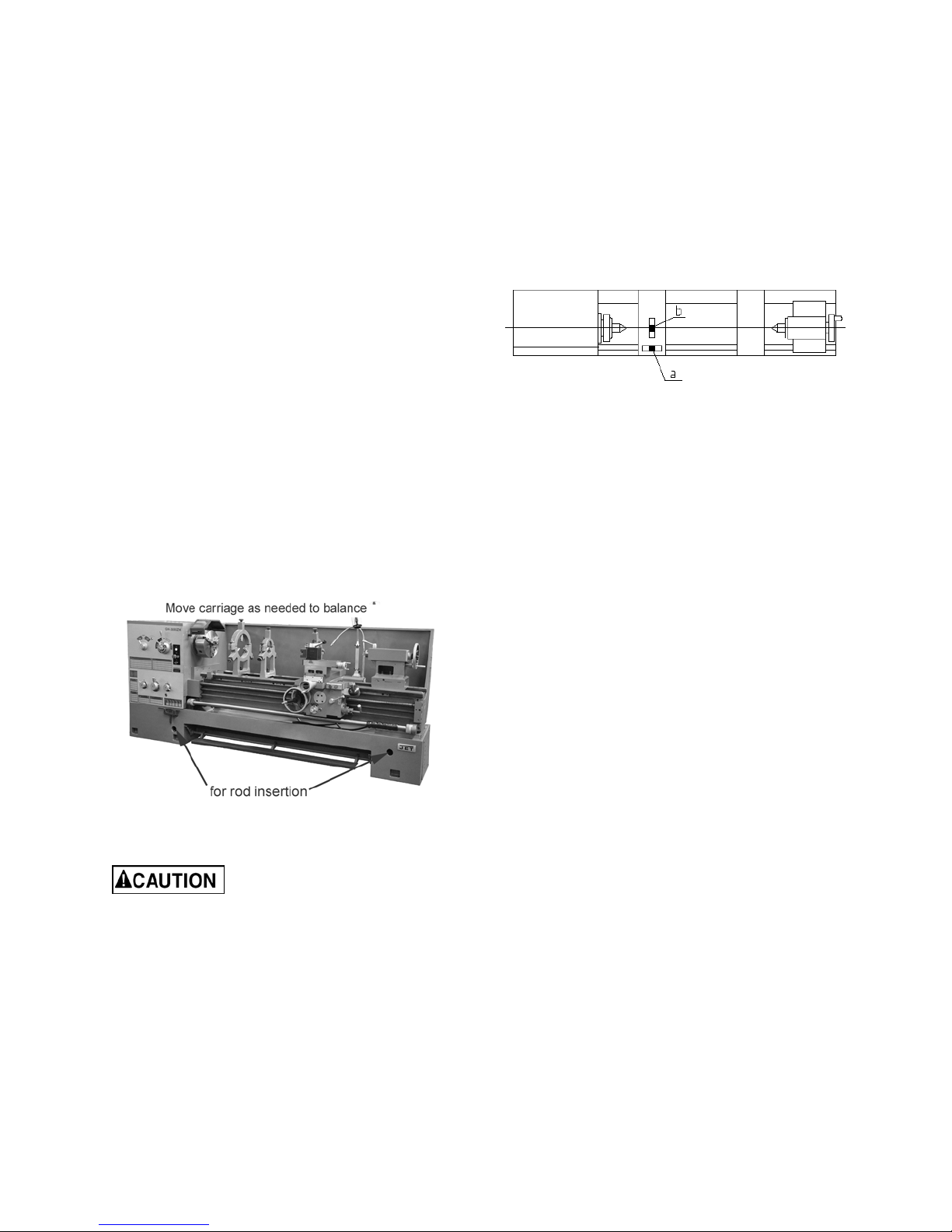

8.0 Installation

1. Finish removing all crate material from around

lathe.

2. Unbolt lathe from shipping pallet.

3. Choose a location for the lathe that is dry and

has sufficient illumination.

4. Allow enough room to service the lathe on all

four sides, and to load and off-load work

pieces. In addition, if bar work is to be

performed, allow enough space for stock to

extend out the headstock end. If used in

production operations, leave enough space for

stacking unfinished and finished parts.

5. The foundation must be solid to support the

weight of the machine and prevent vibration,

preferably a solid concrete floor.

6. The lathe’s center of weight is near the

headstock. Before lifting, move the tailstock

and the carriage (release carriage lock, section

11.0) to the right end of the bed and lock them.

7. Sling the lathe using steel rods or pipes of

sufficient strength inserted through the holes in

the stand (see Figure 4). Do not lift lathe by

the spindle. With properly rated lifting

equipment, slowly raise the lathe off the

shipping pallet.

8.1 Leveling the lathe

It is imperative that the lathe be on a level plane;

that is, where headstock and tailstock center points

remain aligned throughout the tailstock travel, with

the bed ways absent of twist and thus parallel to

the operational center line.

A lathe which is not properly leveled will be

inaccurate, producing tapered cuts. Also, the

center point of the tailstock will vary as it is

positioned along the bed, thus requiring constant

readjustment of the set of the tailstock.

Figure 5 – Leveling

9. Use a machinist’s precision level on the bed

ways both front to back and side to side, as

shown in Figure 5. Take the reading in one

direction every 10 inches. Make sure the ways

are clean and free of any debris before placing

a level upon them.

10. Deviation over bed length(see Figure 5):

(a) Maximum 0.02/1000mm

(b) Maximum 0.04/1000mm

11. Tighten foot screw nuts evenly to avoid

distortion.

12. Leveling should be inspected occasionally,

and especially if the accuracy of the lathe

beings to diminish.

Figure 4 – Lifting preparation

Confirm that all suspension

equipment is properly rated and in good

condition for lifting the lathe. Do not allow

anyone beneath or near the load w hile lifting.

8. The lathe can be placed upon the cast iron

leveling pads under each foot hole, and

adjusted using the adjusting bolts with hex

nuts. Or, it may be secured to the floor

usingboltsplaced head-down in the concrete,

and using shims where needed to level the

machine.

8.2 Completing installation

13. Exposed metal surfaces have been coated

with a rust protectant. Remove this using a soft

rag and mild commercial solvent or kerosene.

Do not use paint thinner, gasoline, or lacquer

thinner, as these will damage painted

surfaces. Cover all cleaned surfaces with a

light film of ISO68/SAE-20W machine oil, such

as Mobil DTE Oil Heavy Medium.

14. Open the end gear cover. Clean all

components of the end gear assembly and

coat all gears with a heavy, non-slinging

grease. Close the end gear cover. (Note: A

limit switch prevents the lathe from operating

when the end gear cover is open.)

Page 13

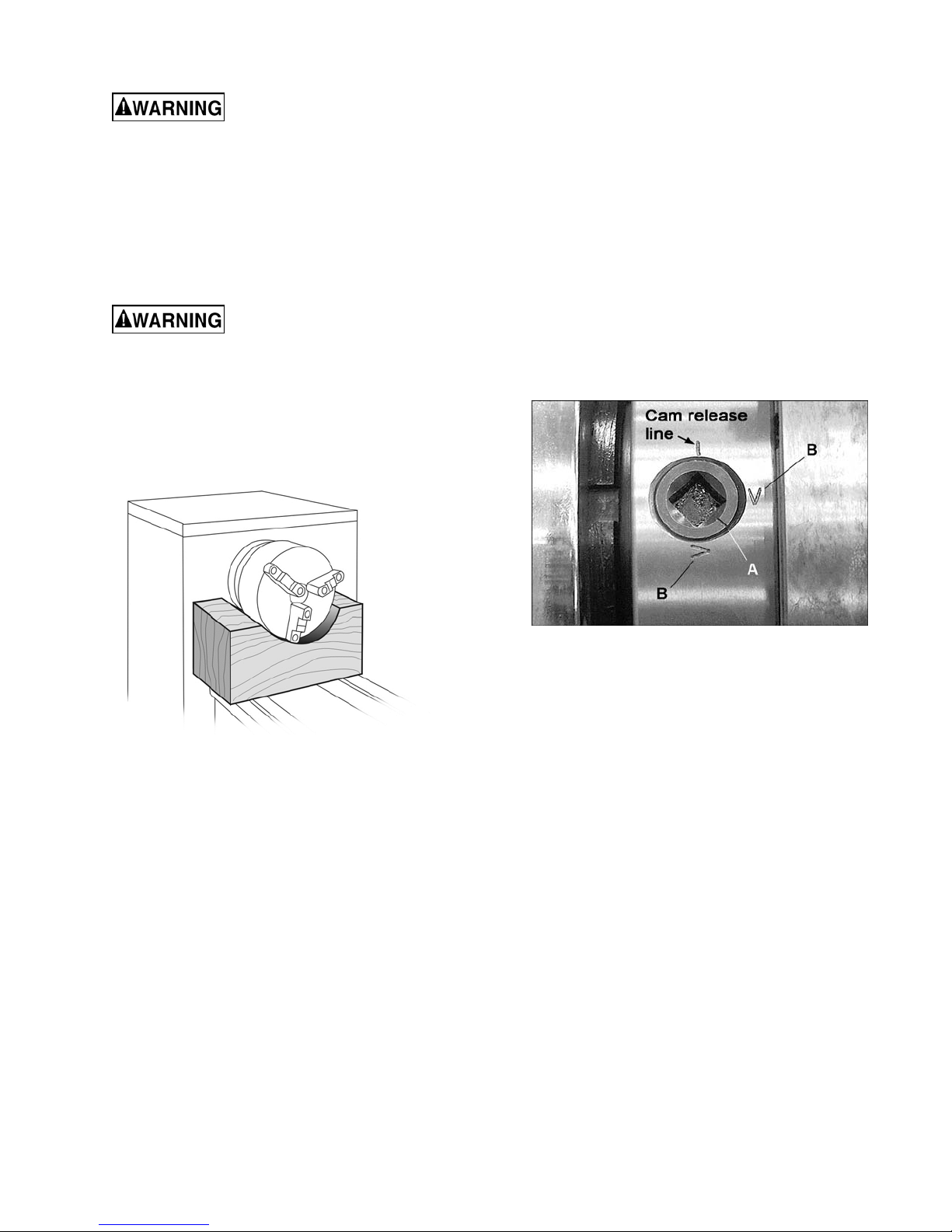

8.3 Chuck Preparation

Read and understand all

directions for chuck preparation. Failure to

comply may cause serious injury and/or

damage to the lathe.

The three-jaw scroll chuck is shipped pre-installed

on the lathe. It can be used for clamping cylindrical,

triangular and hexagonal stock, and has reversible

jaws.

Note: An optional 4-jaw chuck is available (part no.

ZH-2504). See your dealer to order.

Use an assistant or hoist to

help remove a chuck.

Before removing a chuck, place a flat piece of thick

plywood across the bedways under the chuck to

prevent damage to the bedways should the chuck

fall from your hands. Alternatively, many users

make a wood chuck cradle that sits atop the ways

and accepts the specific diameter of chuck. Figure

6 shows an example.

5. Lift the chuck up to the spindle nose and press

onto the spindle. Tighten in place by turning

the camlocks 1/4 turn clockwise. The index

mark (A, Figure 7) on the camlock should be

between the two indicator arrows (B) when

tight, as shown in Figure 7.

• If the index mark (A) is not between the two

arrows, i.e. the cam turns beyond the

indicator arrows, then remove the chuck

and turn the camlock stud IN one full turn.

• If a camlock will not engage, remove the

chuck and turn the camlock stud OUT one

full turn.

6. Make sure chuck is secure on the spindle with

the camlocks correctly engaged.

Figure 6 – Chuck cradle (not included)

To remove a chuck from the spindle:

1. Support the chuck while turning six camlocks

1/4-turn counterclockwise, using the chuck

wrench from the tool box. See Figure 7.

2. Carefully remove the chuck from the spindle

and place on a firm work surface. If the spindle

seems stuck, use a mallet at various points on

the back side to help free it from the spindle.

3. Inspect the camlock studs. Make sure they

have not become cracked or broken during

transit. Clean all parts thoroughly with solvent.

Also clean the spindle and camlocks.

4. Cover all chuck jaws and the scroll inside the

chuck with #2 lithium tube grease. Cover the

spindle, camlocks, and chuck body with a light

film of 20W oil.

Figure 7 – Camlocks

8.4 Break-In Period

Do not run the lathe above 560 RPM for the first six

hours of operation, to allow gears and bearings to

adapt and run smoothly.

13

Page 14

9.0

Maintenance/Lubrication

Lathe must be serviced at all

lubrication points and all reservoirs filled to

operating level before the lathe is put into

service. Failure to comply may cause serious

damage to the lathe.

The ZH series lathe is shipped with oil in the

reservoirs. Coolant is not included.

Use clean lubricants and check levels often,

including before each working shift. To ensure

proper lubrication, oil levels should not be less than

the center of the oil sight glass. Try not to overfill,

as this may cause leakage.

A chart is supplied in section 15.0 for quick

reference to all lubrication points.

Unless specified otherwise, the lubrication points

require a non-detergent, ISO 68, SAE 20W oil. The

recommended brand for this lathe is Mobil DTE

Oil Heavy Medium.

1. Headstock – Oil must be up to indicator mark

in oil sight glass at the rear of the headstock.

[NOTE: The sight glass on the front of the

headstock (A, Figure 8) verifies operation of

the oil pump, the one at rear of headstock (not

shown) indicates oil level]. Top off with SAE

20W oil. Fill by removing the rubber mat and

unscrewing the plug (B) on top of the

headstock.

2. To drain the headstock, remove the nut on the

drain pipe (C, figure 9). Drain oil completely

and clean out all metal shavings, then rinse

the casting case with kerosene. During the

breaking-in process for the lathe, the first oil

change should be after 10 days; the second

after 20 days. Then change the oil in the

headstock every three months.

®

Figure 8 – Headstock lubrication

Figure 9 – Lubrication points

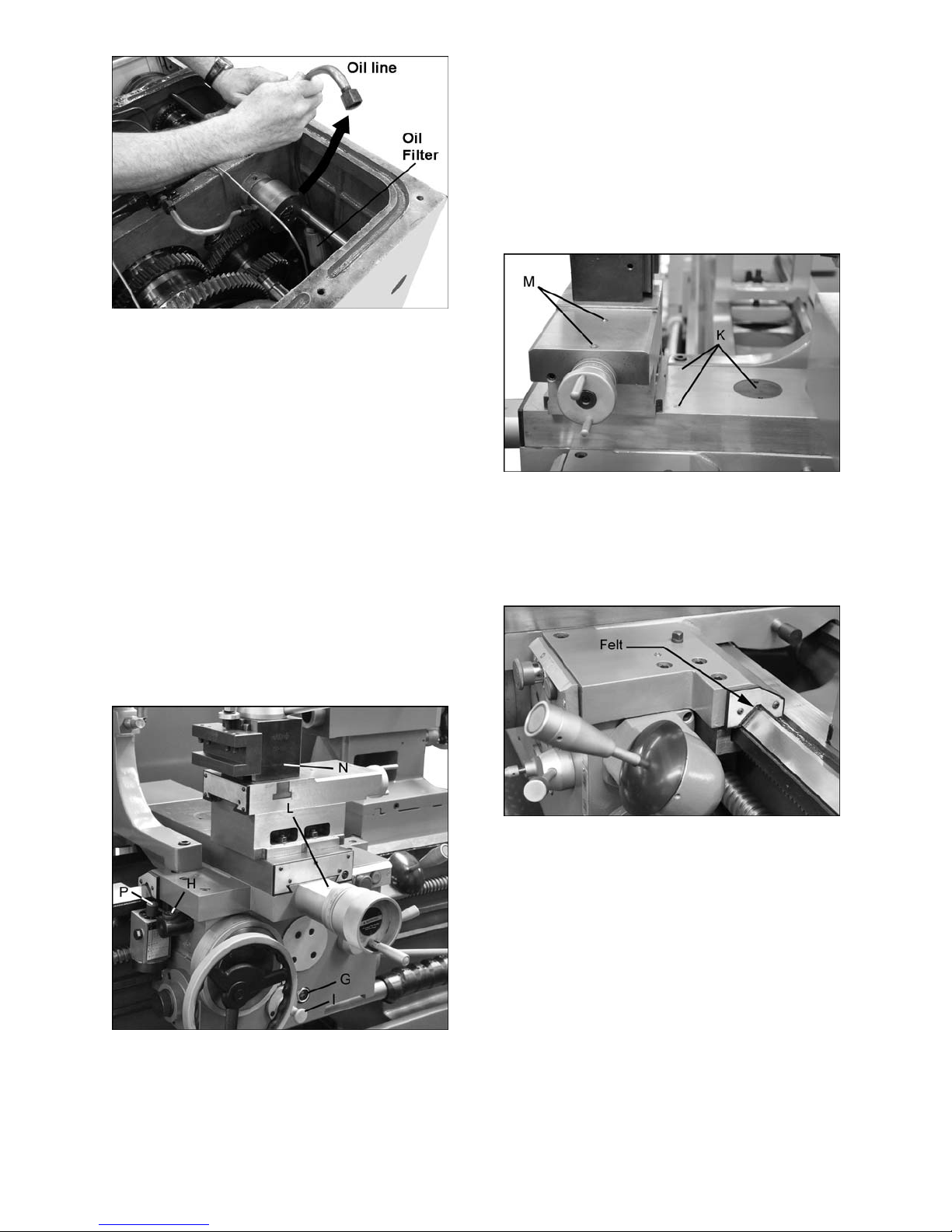

3. Oil Filter – The filter should be cleaned once a

month. To access, open the top cover on the

headstock, unscrew the nut on the oil line, and

pull up the oil line to bring the filter up. See

Figure 10. Use a brush to clean.

14

Page 15

Figure 10 – Oil filter access

4. Change Gear Axle – Periodically remove end

plug (J, Figure 9) and press #2 lithium grease

into the axle to lubricate the gear axle and

sleeve. Coat all gears with non-slinging

grease.

5. Gearbox – Oil must be up to indicator mark in

oil sight glass (D, Figure 8). Top off with SAE

20W oil. To add oil to the gearbox, pour it into

the pan (E, Figure 9). To drain, remove drain

plug (F, Figure 9). Drain oil completely and

refill after the first three months of operation.

Then change oil in the gearbox every six

months.

6. Apron – Oil must be between indicator marks

in the oil sight glass (G, Figure 11). Top off

with SAE 20W oil. Unscrew oil plug (H, Figure

11) to fill. To drain, remove drain plug on the

underside of apron. Drain oil completely and

refill after the first three months of operation.

Then, change oil in the apron annually.

through various oil lines to lubricate the ways

below the saddle. Perform this several times

daily.

8. Threading Dial – Frequently lubricate via one

ball oiler (P, Figure 11) on top of the dial with

SAE 20W oil.

9. Cross Slide – Daily lubricate one ball oiler on

the handwheel housing (L, Figure 11)and three

ball oilers on the platform (K, Figure 12), with

SAE 20W oil.

Figure 12 – Lubrication points

10. Saddle – The anti-dust felt o n both ends of the

v-guide ways (Figure 13) should be cleaned

weekly with kerosene. If the felt becomes

damaged, replace it.

Figure 11 – Lubrication points

7. One-shot Lube System:Pull knob (I, Figure 11)

and hold for several seconds to allow oil to fill

the pump from the apron reservoir. Then

release the knob which will push the oil

Figure 13 – Anti-dust felt

11. Compound Rest – Daily lubricate two ball

oilers (M, Figure 12) on top of compound rest

with SAE 20W oil.

12. Tool Post – Regularly clean dirt and coolant

from around the tool post to maintain its repositioning accuracy(N, Figure 11).

13. Leadscrew, Feed Rod, and Direction

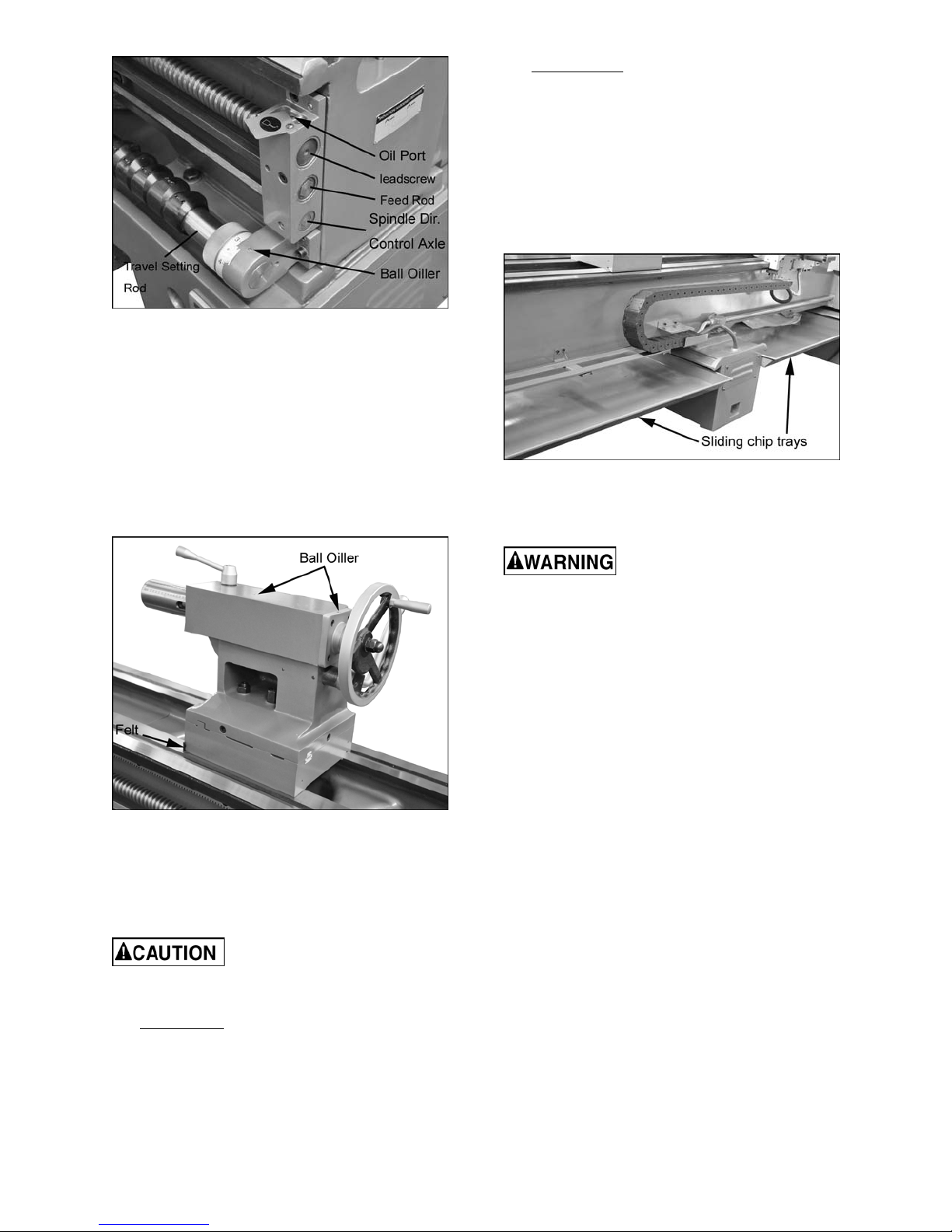

Control Axle – Slide the cover on the right

side bracket (Figure 14) to expose the oil port

and fill with SAE 20W oil daily. The oil is

distributed to all three elements by a woolen

line.

15

Page 16

Figure 14 – Lubrication points

14. Travel Setting Rod – Periodically insert SAE

20W oil into the ball oiler on each end of the

rod (Figure 9).

15. Tailstock – Daily lubricate two ball oilers

(Figure 15) on top of tailstock with SAE 20W

oil.

The anti-dust felt beneath the tailstock that

runs along the ways should be cleaned weekly

with kerosene. If the felts become damaged,

replace them.

GH-26120ZH: Pour coolant (approx. four

gallons) into one of the chip trays (Figure 16).

Or, slide out one of the chip trays and pour

directly into the side trough on the center

stand.

2. After machine has been connected to power,

turn on coolant pump and check to see that

coolant is cycling properly. Flow is controlled

by the tap at the base of the nozzle.

3. Reinstall access cover or chip tray.

Figure 16 – GH-26120ZH chip trays

10.0 Electrical Connections

Figure 15 – Tailstock lubrication

16. V-Belts – Regularly check and adjust the

tightness of the v-belts to prolong their service

life. See section 13.5.

9.1 Coolant Preparation

Follow local regulations and/or

coolant manufacturer’s recomme nd-dations for

use, care and disposal.

1. GH-2680ZH: Remove access cover on the

tailstock end of the lathe stand. Make sure

coolant pump has not shifted during transport.

Pour four gallons (approximate) of coolant mix

into the reservoir.

Electrical connections must be

made by a qualified electrician in compliance

with all relevant codes. This machine must be

properly grounded while in use to help protect

the operator from electrical shock and possible

fatal injury.

The main motor is rated for 230/460V and comes

from the factory prewired at 230V. Confirm that

power available at the lathe’s location is the same

rating as the lathe.

A minimum 10-gauge wire should be used for

incoming power leads.

IMPORTANT: The lathe must be wired properly

and phased correctly. The spindle must rotate

counterclockwise (as viewed from the tailstock

end) while the feed rod must rotate clockwise (as

viewed from the tailstock end). If the motor runs

and the lathe operates, but the rapid traverse does

not function, this signals that the machine has been

incorrectly phased. If this occurs, disconnect lathe

from power source and switch any two of the three

power leads (not the green ground wire).

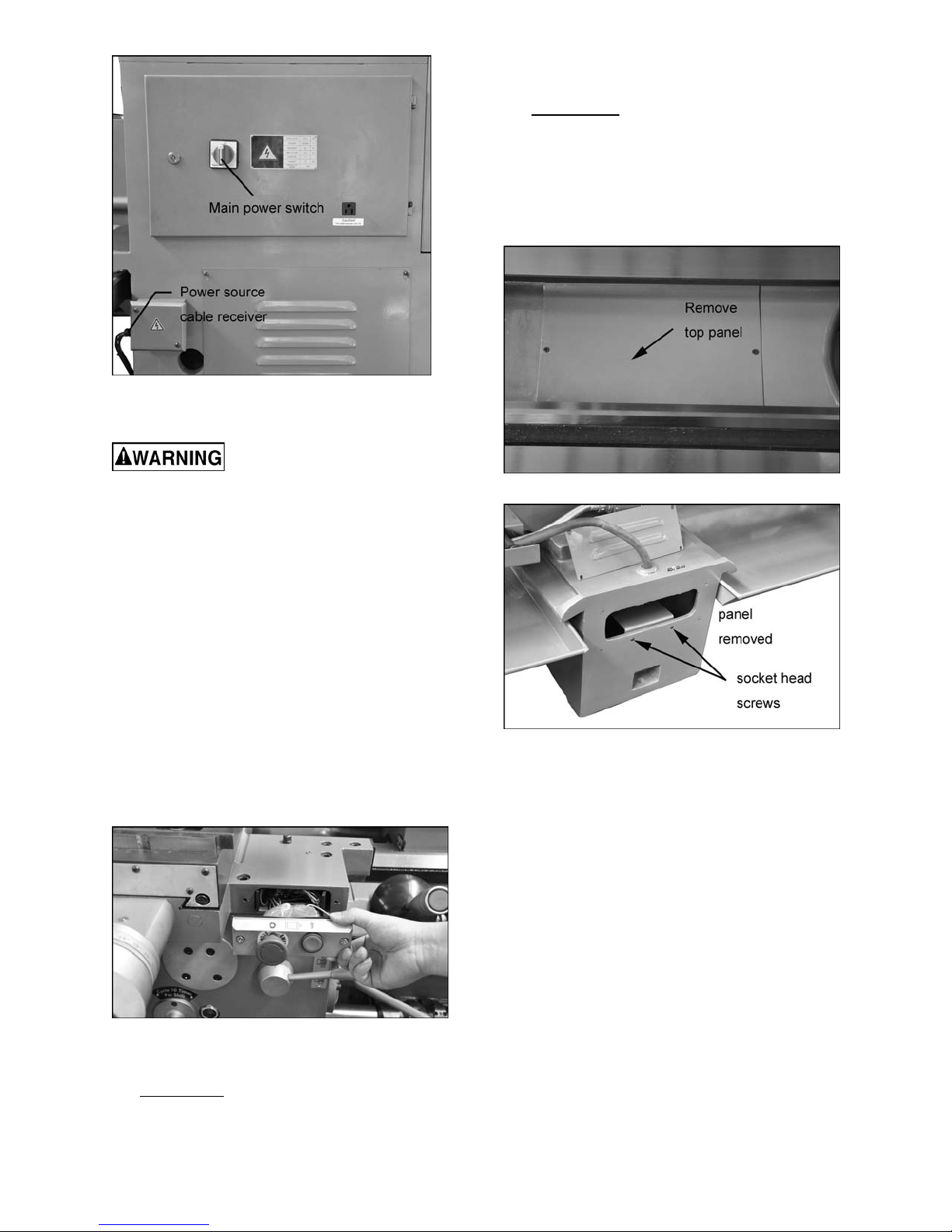

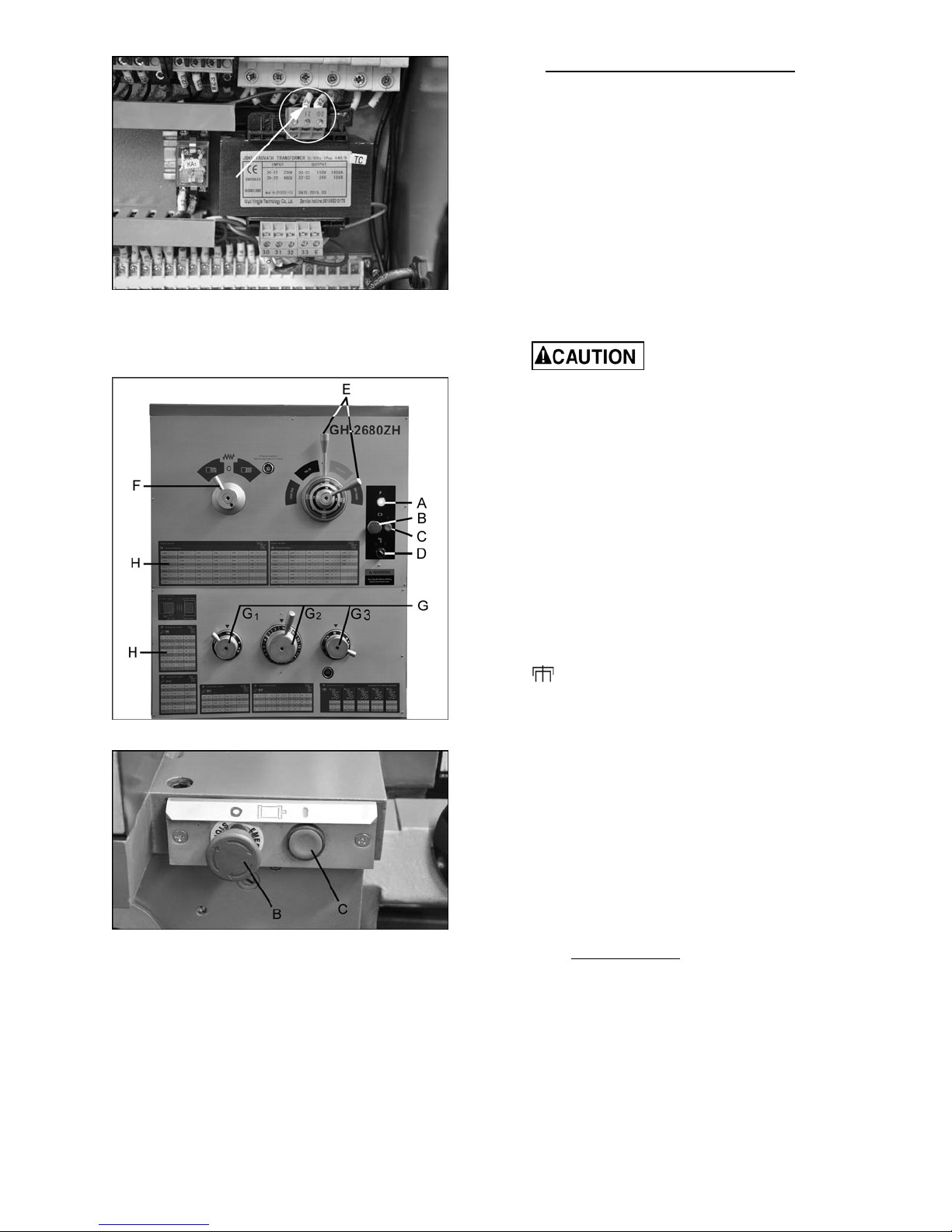

Main Power Switch (Figure 17).

Power Source Cable Receiver (Figure 17).

Make sure the lathe is properly grounded.

16

Page 17

Figure 17 – Power input

10.1

Conversion to 460 Volt Operation

pump junction box according to diagram on the

junction box cover.

GH-26120ZH:

1) Remove top panel inside the bed (Figure

19).

2) Remove rear panel on center stand then

remove the two socket head screws

(Figure 20) that secure the plate on which

the coolant pump is mounted.

Disconnect machine from

power source. Failure to do so may cause

serious or fatal injury.

Wiring diagrams are located at the relevant areas

on the machine; each diagram is also provided in

section 17.0. Should discrepancies exist, the

diagrams on the machine take precedence.

There are four steps involved in converting to 460

volt power:

1. Main Motor: Open lower panel at rear of lathe

beneath the gearbox, and change the wires in

the junction box on the main motor, according

to the diagram on the junction box cover.

2. Rapid Feed Motor: Remove the control panel

on the saddle (Figure 18) to rewire the rapid

feed motor. Change the leads according to the

wiring diagram in sect. 17.0.It is not

necessary to pull out the rapid feed motor

for voltage conversion.

Figure 18 – Rapid feed motor wire access

3. Coolant Pump:

Figure 19 –Coolant pump access (GH-26120ZH)

Figure 20 – Coolant pump access (GH-26120ZH)

3) Tilt the plate until you can reach the

coolant pump junction box through the top

opening in the bed. Follow the diagram on

the coolant pump to change the leads.

4) Properly orient the pump, and secure the

plate with the two screws.

5) Close both covers.

4. Transformer: Open electrical box on rear of

machine on the headstock side. Switch wire

from 230V terminal to 460V terminal as

outlined on the transformer label. See Figure

21.

Voltage conversion is now complete. Close the

electrical box before operating the lathe.

GH-2680ZH:Open access panel on the base

at the tailstock end. Change wires in coolant

17

Page 18

Figure 21 – Transformer rewiring

NOTE: Lathe will still have power. Twist

button clockwise to reset.

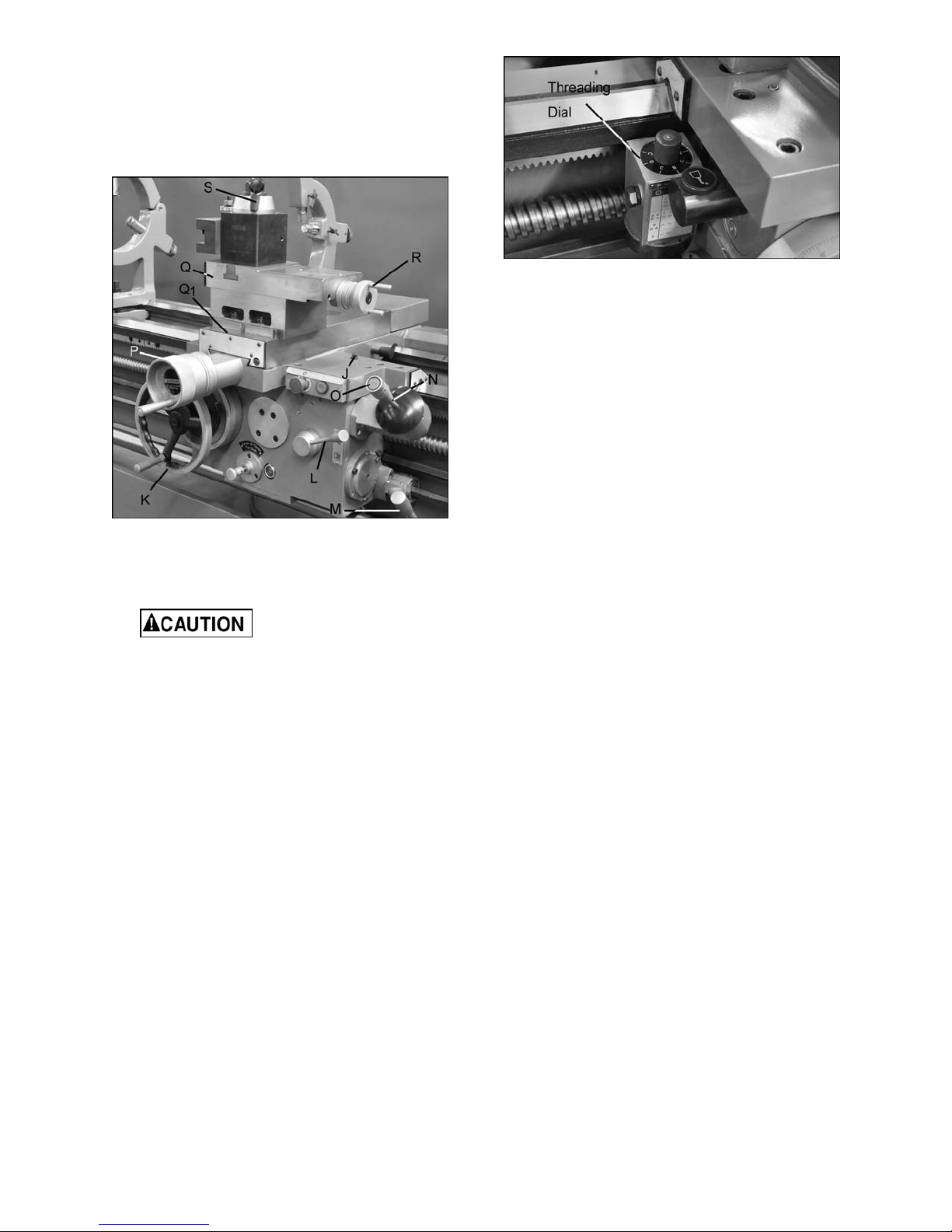

• ON Button (C, Figure 22 and 23). Ac tivates

motor.

• Coolant On-Off Switch (D, Figure 22).

Activates coolant pump.

2. Speed Selection Levers (E, Figure 22):

Located on front of headstock. Move levers left

or right to desired spindle speed, according to

accompanying chart on the dial.

3. Feed Direction Lever (F, Figure 22): Located

on front of headstock. Moving the lever

changes direction of feed. Center position is

neutral.

11.0 Basic Controls

Figure 22 – Headstock Controls

Figure 23 – Alternate controls

1. Control Panel: Located on front of headstock.

An abbreviated control panel is also mounted

to front of carriage.

• Power Indicator Light (A, Figure 22).

Illuminates whenever lathe is receiving

power.

• Emergency Stop Button (B, Figure 22 and

23). Shuts down all machine functions.

Do not move feed directio n

lever while machine is running.

4. Thread Pitch and Feed Selector Levers (G,

Figure 22): Located on front of headstock, are

used conjunctively to set up for threading or

feeding, according to the accompanying chart

(H).

Lever G

is used to control/change between

1

the different thread styles, and is also used for

altering the feed setting.

The symbols on the dial are identified as

follows:

mm = metric threads

IN = inch threads

MP = module pitch

DP = diametral pitch

= when this position is selected, the

input shaft of the gearbox is directly

connected to the lead screw, and will

bypass the gearbox.

This function is available for cutting special

thread forms or nonstandard thread forms,

which are not covered by the standard

gearbox drive train set-up.

Note: Control dial G

must be set to position

3

○ for this operation.

Example: The current standard set of gears

installed with the machine are 82, 97, and

81. This will give a thread pitch equal to

0.506” (12.857mm).

Calculating pitch:

P=(82/97) x (97/81) = 0.6061” (12.857mm)

2

Nonstandard threads are attained by

changing gears in the gear train, based on

this calculation.

Lever G

selects the pitch of the thread and the

2

feed/revolution.

Lever G

doubles the thread pitch or

3

feeddependent on the following positions:

18

Page 19

I/II/III/IV = The leadscrew is used to cut

thread forms.

A/B/C/D = The feed rodis used to control

the feed/revolution.

The ratios between them are:

I: II: III: IV: = A:B:C:D = 1:2:4:8

Figure 24 – Carriage controls and settings

5. Carriage Lock (J, Figure 24): Located on top

right of carriage. Turn clockwise to lock,

counterclockwise to unlock.

Carriage lock must be

loose before moving carri age or damage to

lathe may occur.

6. Carriage Handwheel (K, Figure 24): Located

on the apron. Rotate handwheel clockwise to

move carriage assembly toward tailstock

(right). Rotate the wheel counterclockwise to

move carriage assembly toward headstock

(left). A scale is mounted to the ring, graduated

in 0.05 inch increments, and can be calibrated

by loosening the thumb screw lock and

rotating the ring as needed. Always re-tighten

ring before using the feed.

7. Half Nut Lever (L, Figure 24): Located on

front of apron assembly. Engages the

leadscrew for threading operations.

8. Threading Dial (Figure 25):Indicates the point

on the leadscrew where the half nut can be reengaged to continue inch threading.

Figure 25

9. Spindle Direction Control Lever (M, Figure

24). Move lever to the right so that its tab

clears the notch, then down for forward spindle

rotation, or up for reverse spindle rotation.

Allow spindle to come to a stop before

changing directions.

Position lever in neutral position (tab in notch)

before shutting off the lathe.

10. Feed Direction Lever (N, Fi gure 24): Left and

right moves the carriage in the corresponding

directions (longitudinal feed); up and down

moves the cross slide (cross feed).

11. Rapid Traverse Button (O, Figure 24). Push

for rapid movement in the direction set by the

feed direction lever. Rapid longitudinal

movement disengages the carriage

handwheel. However, the cross slide

handwheel should be disengaged (pull it

out) before using rapid feed.

IMPORTANT:The rapid traverse button is not

used for actual feeding of the tool, only for

initial positioning. Also, be aware that

engaging the rapid traverse will override

automatic feed.

12. Cross Slide Handwheel (P, Figure 24):

Located above apron assembly. Clockwise

rotation moves cross slide toward rear of

machine. The accompanying scale is

graduated in 0.002 inch increments. Before

using rapid feed, disengage this handle by

pulling it outward.

13. Compound Rest (Q, Figure 24): Located on

top of the cross slide and can be rotated 360°

by loosening four nuts (two in front, two in

back). There are calibrations in degrees (Q1,

Figure 24) to assist in placement of the

compound rest to the desired angle.

14. Compound Rest Handle (R, Figure 24):

Rotate clockwise or counterclockwise to

position. The accompanying scale on the collar

is graduated in 0.001 inch increments.

15. Tool Post Clamping Lever (S, Figure 24):

Rotate counterclockwise to loosen and

clockwise to tighten. Always use minimum of

two clamping screws to secure a cutting tool.

19

Page 20

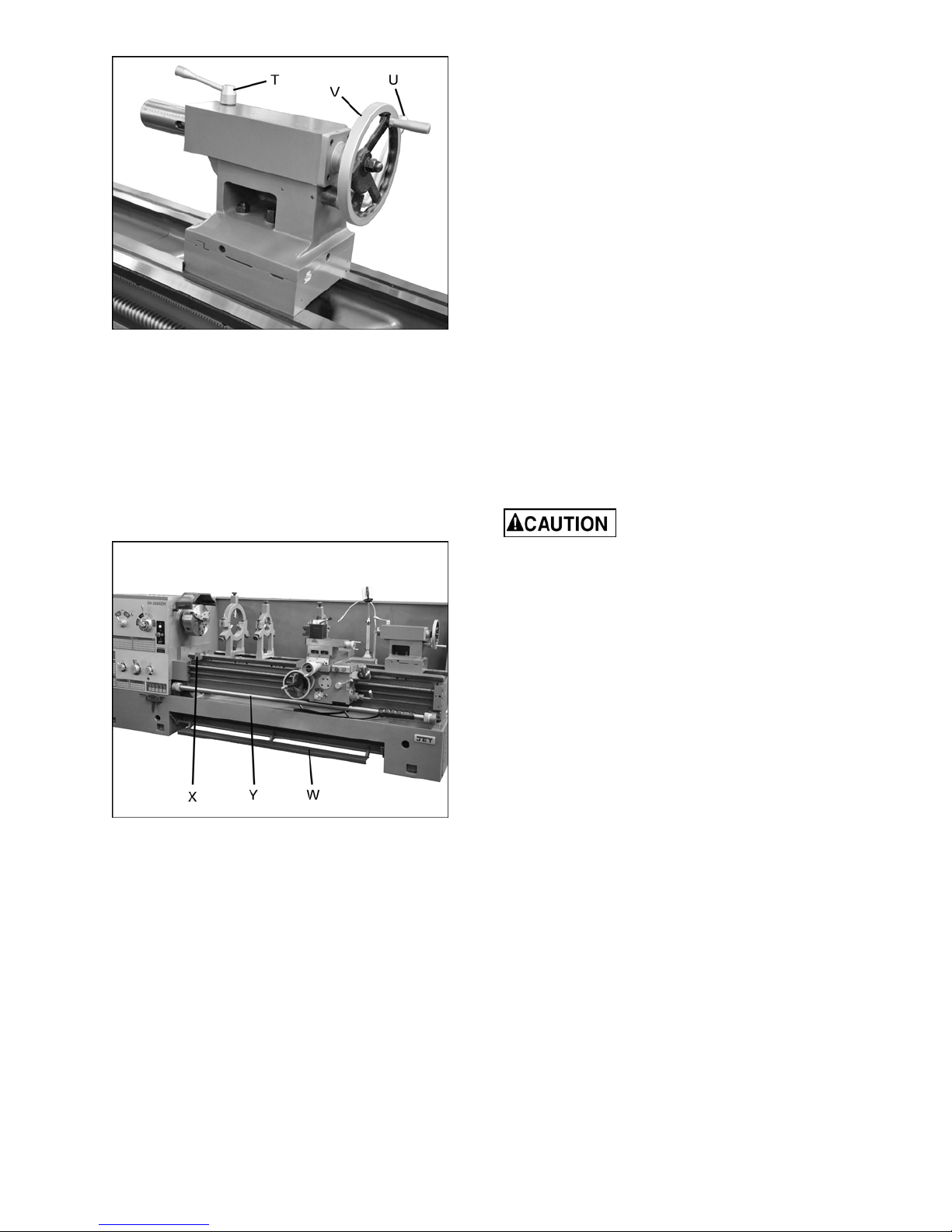

21. Travel Setting Rod ( Y, Figure 27): Up to six

pre-set configurations are possible for

repetitive operations, without having to reposition the stops each time. Use the knurled

knob at the right end of the rod to set the rod

at one of six positions shown on the dial. Then

move the desired number of eccentric stops

into position for that particular operation and

tighten them securely to the rod with the

screws beneath them. When the apron trip

lever contacts a stop, the clutch will

disengage.

12.0 Operation

Figure 26 – Tailstock controls

16. Tailstock Quill Clamping Lever (T, Figure

26): Rotate clockwise to lock the sleeve.

Rotate counterclockwise to unlock.

17. Tailstock Clamping Le ver (U, Figure 26): Lift

up to lock. Push down to unlock.

18. Tailstock Quill Traverse Handwheel (V,

Figure 26): Rotate clockwise to advance the

quill and counterclockwise to retract it. Fully

retract it to eject a center or drill chuck.

Figure 27 – Other controls

19. Foot Brake (W, Figure 27): For emergency

shutdown of all lathe functions. The connecting

rod mechanism is in the bed stand, and

activates a brake strap at the main motor.

(Caution: Lathe still has power.)

The foot brake is not intended for normal

stopping of the lathe. Overuse can result in

hastened wear of brake parts.

20. Manual Carriage Stop (X, Figure 27): Can be

used during manual feed operation to limit

carriage travel. NOTE: It is not intended to

stop the carriage during automatic feed. The

carriage stop can be repositioned along the

bed by loosening the two screws underneath

the stop.

The operator should consult shop manuals such as

“Machinery’s Handbook” for cutting speeds and

feeds appropriate to specific workpieces. Correct

feed depends upon the material to be cut, cutting

operation, tool type, chucking rigidity, depth of cut,

and desired surface quality.

IMPORTANT: Allow a break-in period for the new

lathe so that gears and bearings can adapt; do not

run the lathe above 560 RPM for the first six hours

of operation.

The following points must be

observed when operating the lathe:

• Never turn any handles or levers when the

spindle is at high speed.

• Change spindle speed only after the spindle

stops.

• Change feed rate only when the spindle is at

low speed or is stopped.

• Never exceed the maximum speed limitation of

the work holding device.

• Before starting the spindle, always verify that

the oil pump is working (there should be oil in

the sight glass on the front of the headstock).

• Before starting spindle, check that each handle

or lever is at correct position to ensure normal

engagement of the gears. The spindle

direction control lever should be at neutral

position.

• If the brake becomes ineffective, turn off the

machine and adjust the brake immediately.

Never reverse the friction clutch for braking.

• W hen operating spindle direction control lever,

always turn it to correct position; never use

“pre-position” for cutting at a reduced speed.

• Jaw teeth and scroll must be fully engaged, to

prevent the jaws from breaking and being

thrown from the chuck (see Figure 28).

20

Page 21

Figure 28 – Insufficient jaw tooth engagement

• Avoid long workpiece extensions, as parts may

bend or fly off (see figure 29). Use rests or the

tailstock for support.

the point of the tailstock center as a gauge and

shims under the tool to obtain the correct center

height.

Use a minimum of two clamping screws to secure

each tool.

12.2 Spindle Speed

Twelve speeds are available by placing the first

speed lever (E

and placing second lever (E

matches the color for the range you desire. These

selections are identified on the lever hub, as well

as in Table 6, section 16.3.

You may need to turn the chuck by hand to assist

engagement of the gears.

Never change speed while spindle is turning.

, Figure 31) in one of four positions,

1

) in a position that

2

Figure 29 – Improper setups

• Avoid short clamping contact (Figure 30, A) or

clamping on a minor part diameter (Figure 30,

B). Face-locate the workpiece for added

support.

Figure 30 – Improper setups

12.1 Tool Setup

The cutting angle is correct when the cutting edge

is in line with the center axis of the workpiece. Use

Figure 31

12.3 Feed and Thread Selection

To obtain various feed settings and thread pitches,

the four levers (F,G

1,G2,G3

1. Refer to the Feed and Thread Charton the

front of the headstock (H, Figure 31). The

chart is also shown in section 16.10 of this

manual.

2. Any gear changes should be made in

accordance with the chart.

3. Move levers (G

appropriate position according to the Feed and

Thread Chart.

TIP: When selecting feed/speed correlations,

remember the general principal that high speeds

complement fine feeding, and low speeds are

better for coarse feeding.

21

) are used conjunctively.

1,G2,G3

, Figure 31) to the

Page 22

12.4 Thread Cutting

Threading is performed in multiple passes, with an

initial cutting depth of about 0.2 mm, and

decreasing depth in succeeding cuts. It is

recommended that test cuts be made on scrap

material and the results checked before proceeding

with regular material.

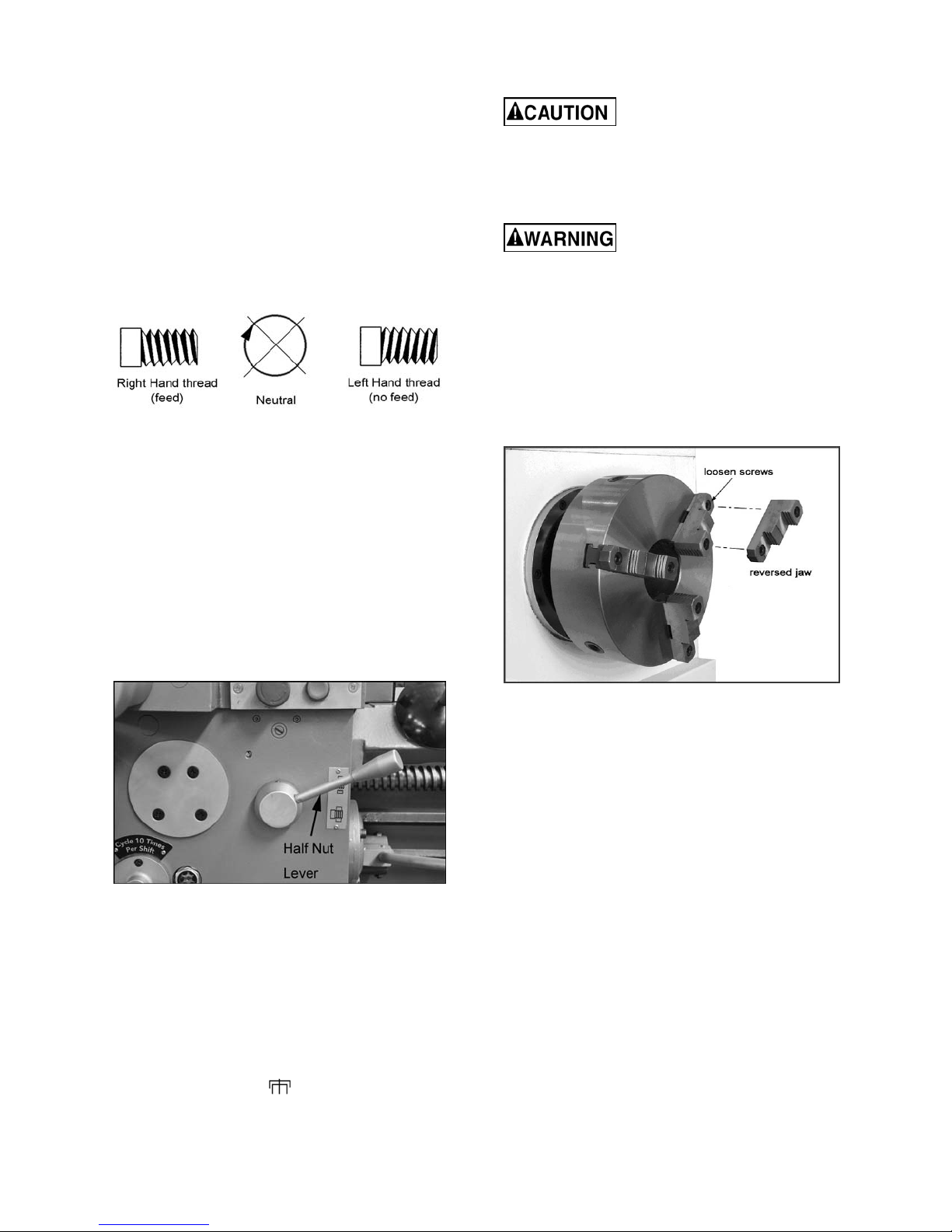

1. Move thread selection lever (F, Figure 31) to

desired direction, for right-hand or left-hand

threads. NOTE: The overrunning clutch in the

apron will prevent the tool post from feeding

for left-hand threads. It will only feed when

right-hand threads are being cut.

Figure 32

2. Set speed levers (E

speed. Use the lowest speed possible when

threading.

3. Select desired thread using thread pitch

levers (G

with the charts on the headstock. These charts

are also included in section 16.10 of this

manual.

4. Engage the half nut (Figure 33). The half nut

must be engaged during the entire threading

process when doing metric, diametral, and

modular threading.

1,G2,G3

, Figure 31) in conjunction

Figure 31) to desired

1,E2,

13.0 Adjustments

Adjustments to the lathe,

especially those involving alignments of

bearings, spindle, leadscrew, clutch, etc.,

should only be performed by qualified

personnel, as improper alignments can dama ge

the machine and/or create a safety hazard.

Turn off main switch and press

emergency stop button before making

adjustments to the lathe.

13.1 Chuck Jaw Reversal

The three jaws on the scroll chuck are reversible,

to hold stock with larger diameters. See Figure 34.

Loosen the two screws with the provided hex key,

remove the jaw, and rotate it 180-degrees. Reinstall the jaw, and tighten each screw in

increments until fully tightened.

Figure 34 – Chuck jaw reversal

Figure 33

5. W hen tool reaches end of cut, disengage and

back out the tool to clear the workpiece.

6. Reverse direction to allow cutting tool to return

to its starting point.

7. Repeat the process until desired result is

obtained.

NOTE: When a special thread must be cut that is

not found on the chart, move thread change control

lever (G

to IV, then reset the change gears.

, Figure 31) to position, and lever (G3)

1

13.2 Gib Adjustments

After a period of time, some of the moving

components may need adjustment for play due to

wear.Do not overtighten gib screws as this can

hasten wear to components.

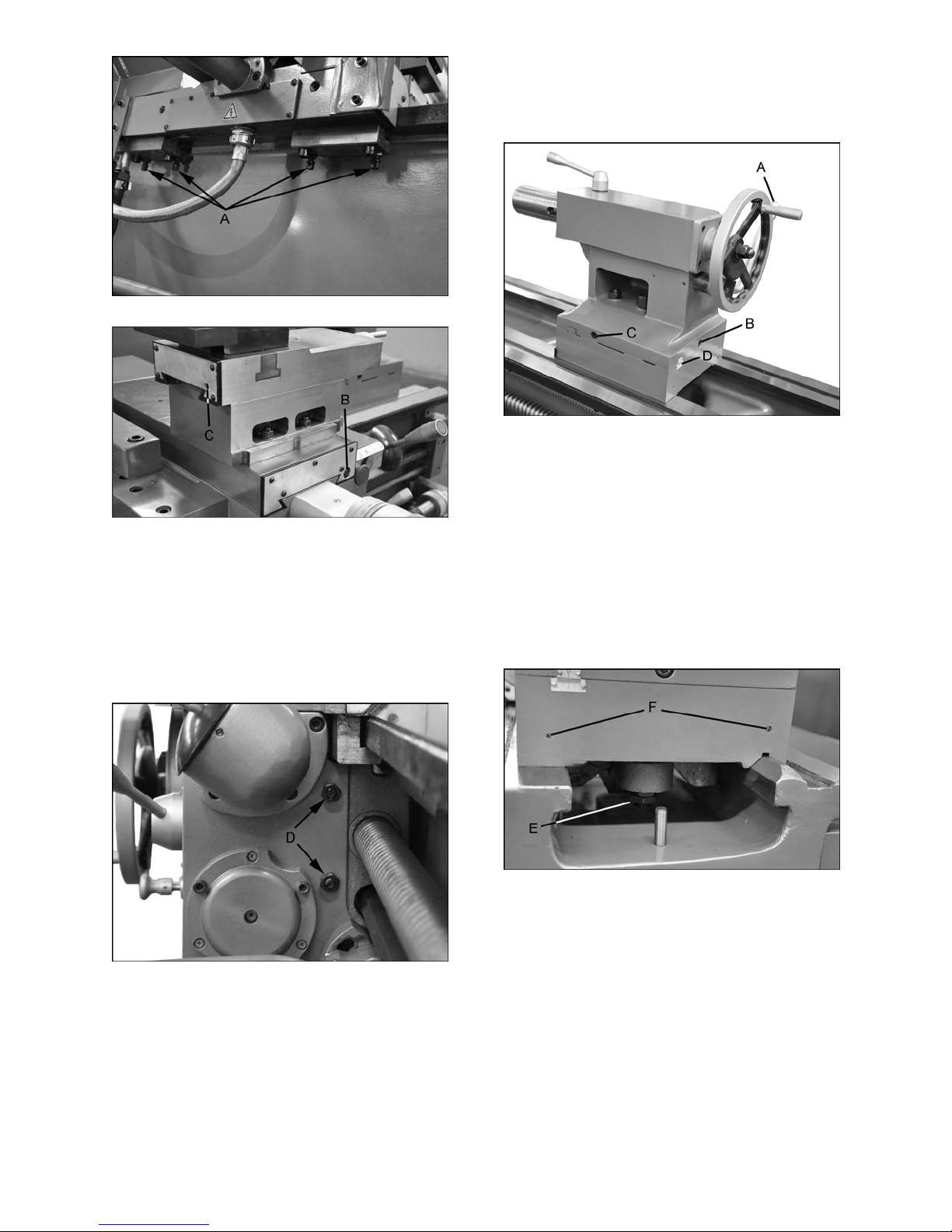

Saddle – Turn screws (A, Figure 35) on either side

of the saddle at the rear to adjust drag on the

saddle.

Cross Slide – Gib screws are located at front and

rear of slide opposite to one another (B, Figure 36).

To adjust drag, loosen rear gib screw one turn, and

tighten front gib screw a quarter turn. Rotate the

handwheel to check the play. Repeat as needed

until slide moves freely without play. Gently tighten

rear gib screw.

22

Page 23

Figure 35– Saddle sliding plate adjustment

Figure 36 – Gib adjustments, slide and rest

Compound Rest – Gib screws are located at front

and rear of the compound rest (C, Figure 36). To

adjust, use the same method as for the Cross

Slide.

Half Nut – Gib screws are located on the right side

of the apron (D, Figure 37). Loosen the jam nuts

and rotate the screws clockwise until any backlash

is corrected. Then retighten nuts.

3. Alternately loosen and tighten front and rear

screws (C). (only front screw shown.)

The scale (D) on the end of the tailstock indicates

amount of offset, and helps when re-centering.

Figure 38 – Tailstock adjustments

If the clamping force needs to be adjusted, use the

hex nut (E, Figure 39).

When the clamping lever is released, the tailstock

“floats” upward approximately 0.05 to 0.15mm from

the bed ways through four elastically supported

bearings, which allows easy sliding of the tailstock.

The float amount of these bearings can be

adjusted by turning the set screws (F, Figure 39) at

either end. IMPORTANT: This is a sensitive

adjustment. Always clamp the tailstock to the bed

before turning these set screws, to ensure rigidity

and prevent the bearings from crashing.

Figure 37 – Half Nut gib adjustment

13.3 Tailstock Adjustments

The tailstock can be offset to cut shallow tapers up

to 5° angle. See Figure 38.

1. Loosen tailstock in position by lowering locking

handle (A).

2. Loosen socket head cap screw (B).

Figure 39 – Tailstock bearing adjustment

13.4 Gap Section

1. To remove the gap section (A, Figure 40),

remove four socket head bolts (B) and two

socket bolts at the ends of the rails (C).

2. Remove the two tapered alignment pins (D) by

placing the provided gap bridge pin driver (E)

over them and threading the screw (E

into them, until the pins are loosened enough

to be pulled out.

3. Remove the gap section.

23

) down

1

Page 24

Figure 40 – Gap section

To reinstall the gap section:

4. Clean the bottom and the ends of the gap

section thoroughly.

5. Set gap section in place and align the ends.

6. Insert the tapered pins into their holes through

the gap and into the lathe bed.

7. Reinstall the six bolts (B/C), and tighten

alternately until all are snug. Make sure gap

remains aligned with the ways while tightening

the screws.

13.5

Belt Adjustment and Replacement

The belts should be inspected periodically. New

belts have a tendency to stretch slightly after a

short period of use; and prolonged use will require

that they be tightened to compensate for normal

wear.

NOTE:If a worn, cracked or frayed belt needs

replacing, replace all three as a matched set.

To adjust or replace belts:

1. Disconnect machine from power source.

2. Open end gea r cove r, re mov e lower rea r cover

and lower side cover. This will expose the

motor and v-belts.

3. Loosen upper hex nut (A, Figure 41). Place

scrap piece of wood under motor to act as

lever. Lift motor up and block temporarily.

4. Remove belts. Install new belts onto pulleys.

5. Lift up on motor and remove temporary

blocking.

6. Tension belts by loosening lower nut (B,

Figure 41) and tightening down upper nut (A,

Figure 41) until light finger pressure causes

approximately 3/4” deflection on each belt.

7. Install covers and connect lathe to the power

source.

Figure 41 – Belt and brake strap adjustment

13.6 Brake Strap

After the clutch is disengaged, the main drive can

be stopped by the brake. If the spindle does not

stop rapidly, the brake strap may need adjustment.

Use the two adjusting nuts (Figure 41) to tighten

the strap. Do not overtighten the strap, which can

cause it to distort.

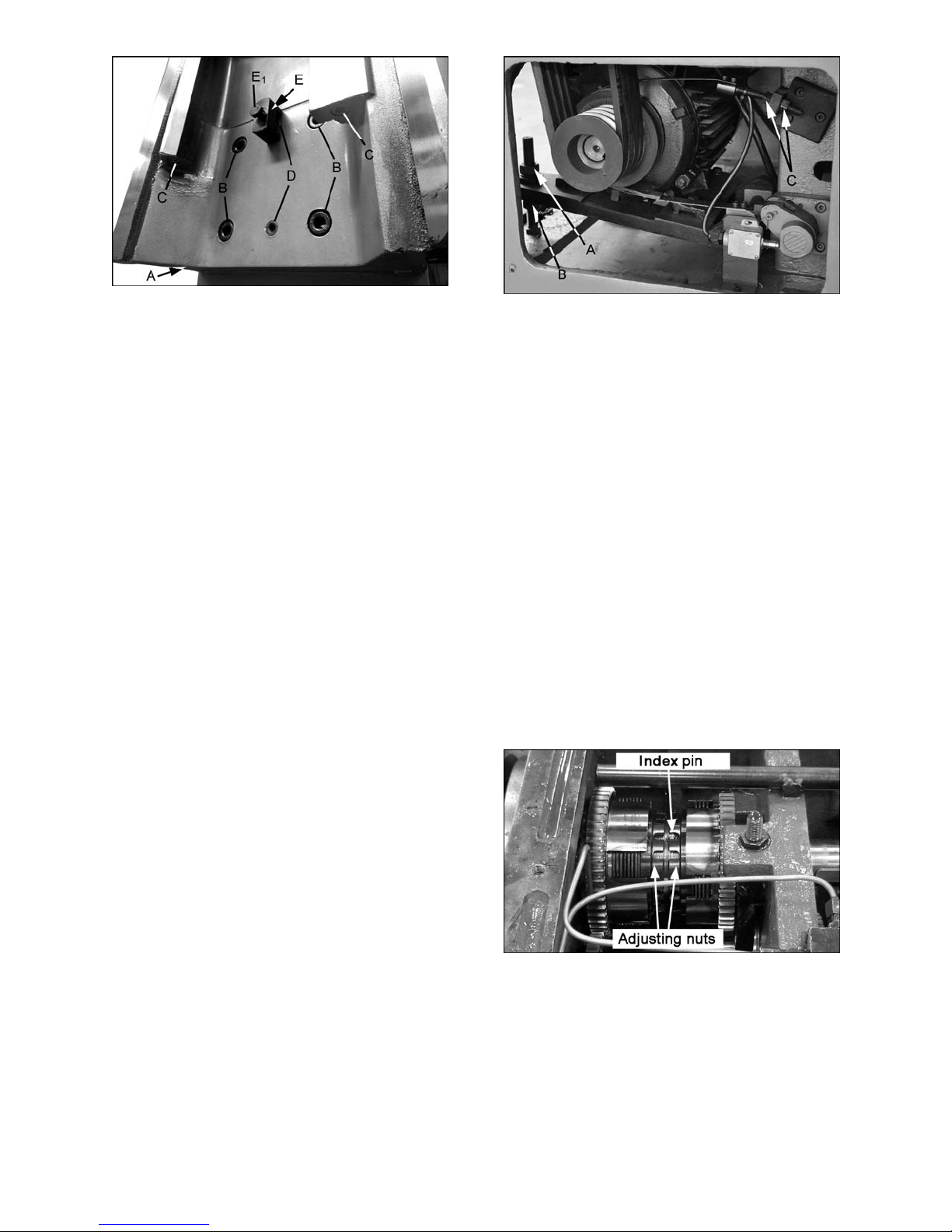

13.7 Friction Clutch Adjustment

The lathe operates on a centralized gear drive. The

power of the main motor is transfe rred through vbelts to an axle, then through a multi-disc friction

clutch and various gear pairs to the spindle. The

spindle’s forward and reverse motion is controlled

by the clutch; it also provides an overload

protection.

The clutch must be in proper adjustment to ensure

normal working of the spindle. If the clutch is too

loose, its efficiency is reduced and it may slip or

cause heat build-up; if too tight, it becomes difficult

to operate the spindle direction control lever and

the clutch will not properly engage.

Figure 42 – Spindle Clutch Adjustment

24

Page 25

Figure 43 – Spindle Clutch Adjustment

1. Make sure the lathe is OFF at the master

switch.

2. Remove the top cover of the headstock.

3. Determine the appropriate clutch.

4. Use a screwdriver to push in the index pin

(Figures 42 and 43). The pin is spring loaded.

5. Rotate the adjusting nut to the next index

position, which will be indicated by a “click.”

NOTE: The clutch reacts quickly; adjust clutch

nut by one division only. You must feel and

hear the clutch engagement – a clicking

sound. If clutch adjustment is too tight, it will

not engage.

If the spindle does not stop in the OFF

position, the forward/reverse clutch adjustment

is out of balance. (The spindle follows the

direction with the tighter clutch adjustment).

6. Reinstall headstock cover, and test the clutch

function.

NOTE: Never reverse the friction clutch for braking.

Figure 44 – Tailstock/Headstock alignment

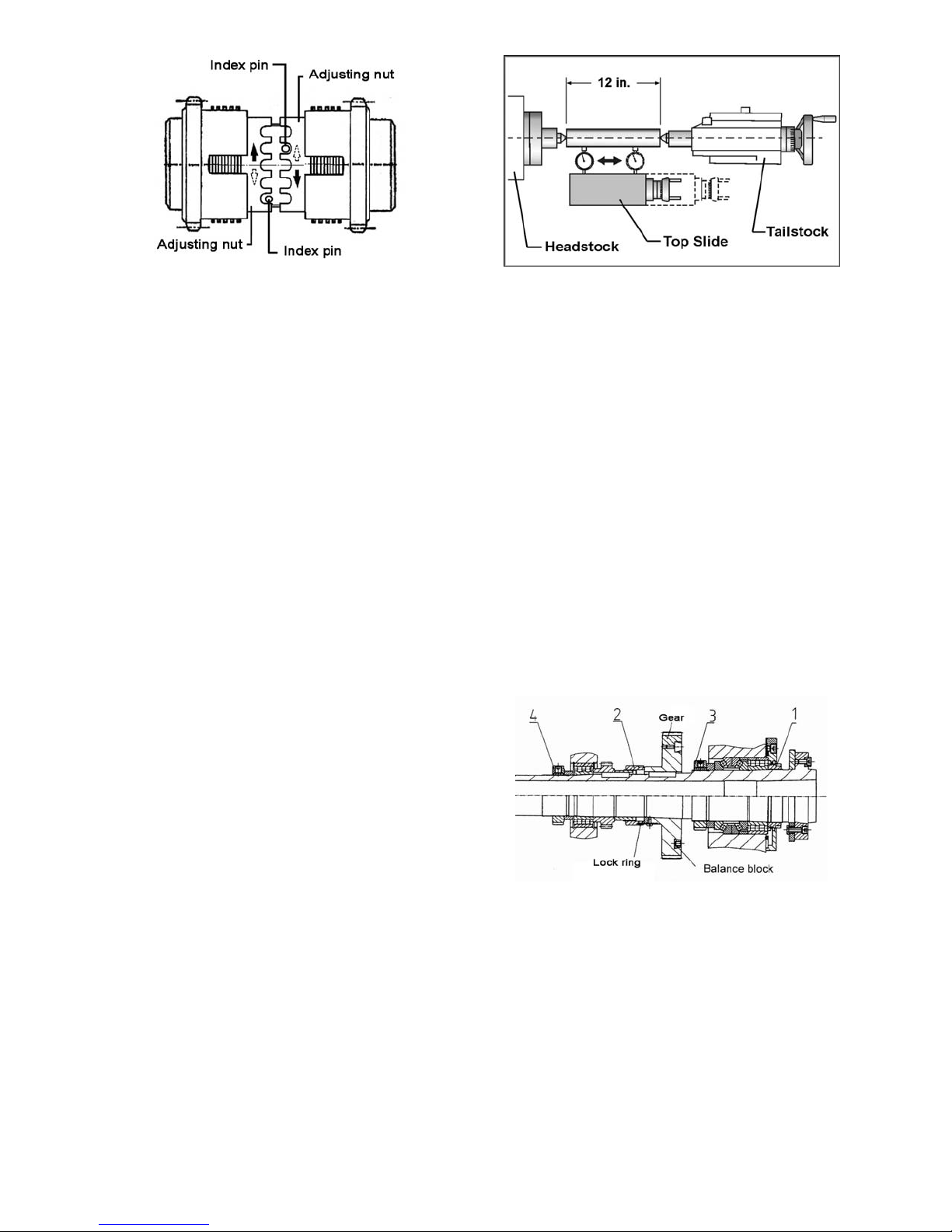

13.9 Spindle Bearings

The spindle system is supported by three bearings,

with the rear bearing serving as an auxiliary

support.

Any play of the spindle bearings has been adjusted

out by the manufacturer, so that radial and axial

run-out of the spindle is within tolerances. If play

develops in the future, adjust the bearings as

follows (see Figure 45):

1. Loosen nut (1). Then loosen lock ring and

loosen nut (2).

2. Adjust the play of front and middle bearings

using nuts (3) and (4).

3. After adjustment, tighten the nuts one by one.

4. Run the machine without load for at least two

hours, at highest speed. The temperature rise

should not exceed 70 degrees Celsius

(158°F). Otherwise, the machine must be

adjusted again.

13.8 Aligning Tailstock to Headstock

Headstock and Tailstock have been aligned at the

factory and should not require attention. If future

adjustment should ever be needed, proceed as

follows. (Make sure that twist in the lathe bed is not

contributing to the problem – refer tosection

8.1,Leveling the Lathe.)

1. Fit a 12” ground, center-drilled, steel bar

between centers of the headstock and tailstock

(Figure 44).

2. Fit a dial indicator to the top s lide and traverse

the center line of the bar. If it indicates a taper,

adjustment is needed.

3. Align the tailstock using the off-set screws at

front and back (see C, Figure 38) until the

tailstock is aligned.

Figure 45 – Spindle bearing adjustment

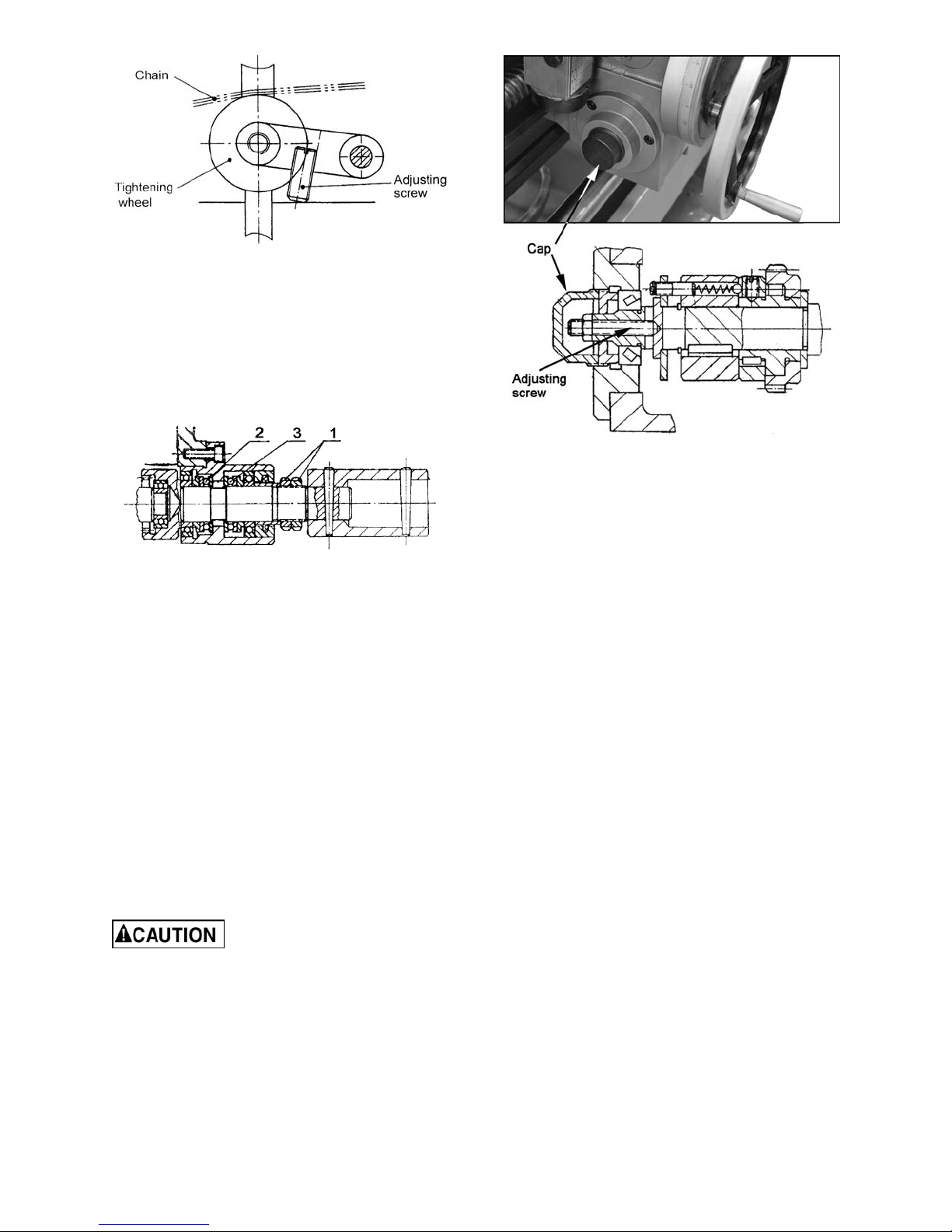

13.10 Speed Control

If the chain on the speed control mechanism of the

main drive becomes elongated and loose, the

position of the speed control dial may become

inaccurate.

Open the top cover of the headstock. Tighten the

chain using the adjusting screw (Figure 46).

25

Page 26

Figure 46 – Speed control chain adjustment

13.11 Lead Screw

To ensure the pitch accuracy in cutting threads,

any axial run-out of the lead screw must be

eliminated. See Figure 47. This is achieved by

adjusting the thrust bearings (2 and 3) using the

nut (1).

Figure 47 – Lead screw runout adjustment

13.12 Apron Feed Clutch

The feed transmission begins with the feed rod to

the apron, through feed clutch to worm, through the

gear drives, to longitudinal or cross movement.

The worm axle is equipped with an overstep clutch

to provide rapid feed for the carriage. When the

rapid feed motor drives the worm axle, it oversteps

the feed rod in one direction.

The carriage (longitudinal feed) handwheel is

automatically disengaged when the carriage is in

rapid feed or longitudinal automatic feed. When the

feed movements stop, the handwheel will

reengage.

If the cutting force will not reach rated maximum

value, remove the cap and adjust the clutch using

the adjusting screw (see Figure 48).

Figure 48 – Feed clutch adjustment

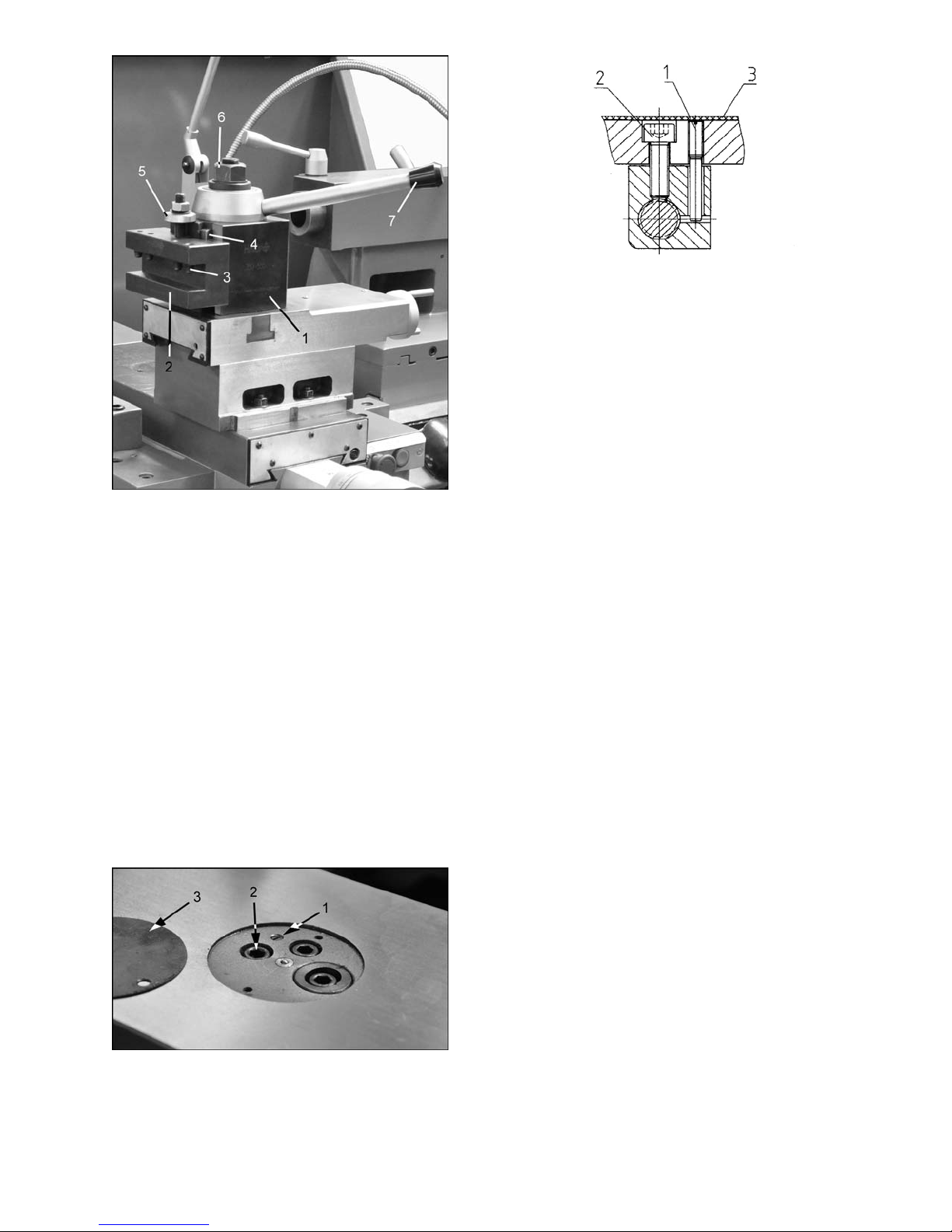

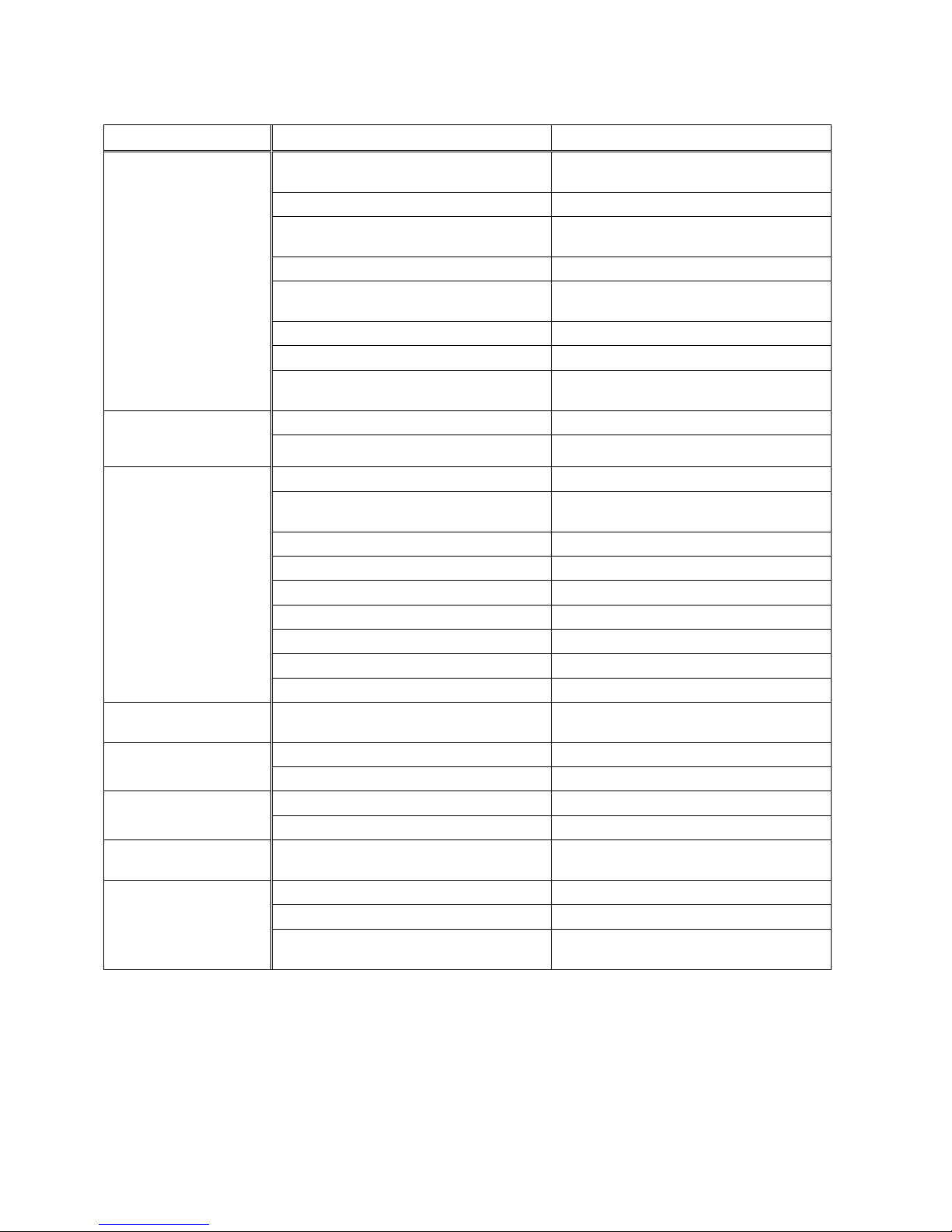

13.13 Tool Post

Tool holder (2) is positioned to the tool post body

(1) through a dovetail groove and its center height

can be adjusted by sliding the dovetail along the

groove and turning screw (5).

The tool holder can be fixed by turning lever (7)

and the middle bolt will drive the wedge block (4)

downward for clamping the tool holder.

The whole tool post can be fixed by the top nut (6).

Tool shank can be fixed to the tool holder by its

screw (3) (see Figure 49).

Do not over tighten the feed

clutch. Over tightening may nullify the

protective feature and can damage the lathe.