Page 1

Operating Instructions and Parts Manual

XACTA Saw Deluxe

WALTER M EIE R (Manufa c turing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-708674

Ph.: 800-274-6848 Revision D 09/2013

www.waltermeier.com Copyright © 2013 Walter Meier (Manufacturi ng) Inc .

Page 2

Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local Walter Meier distributor, or visit waltermeier.com.

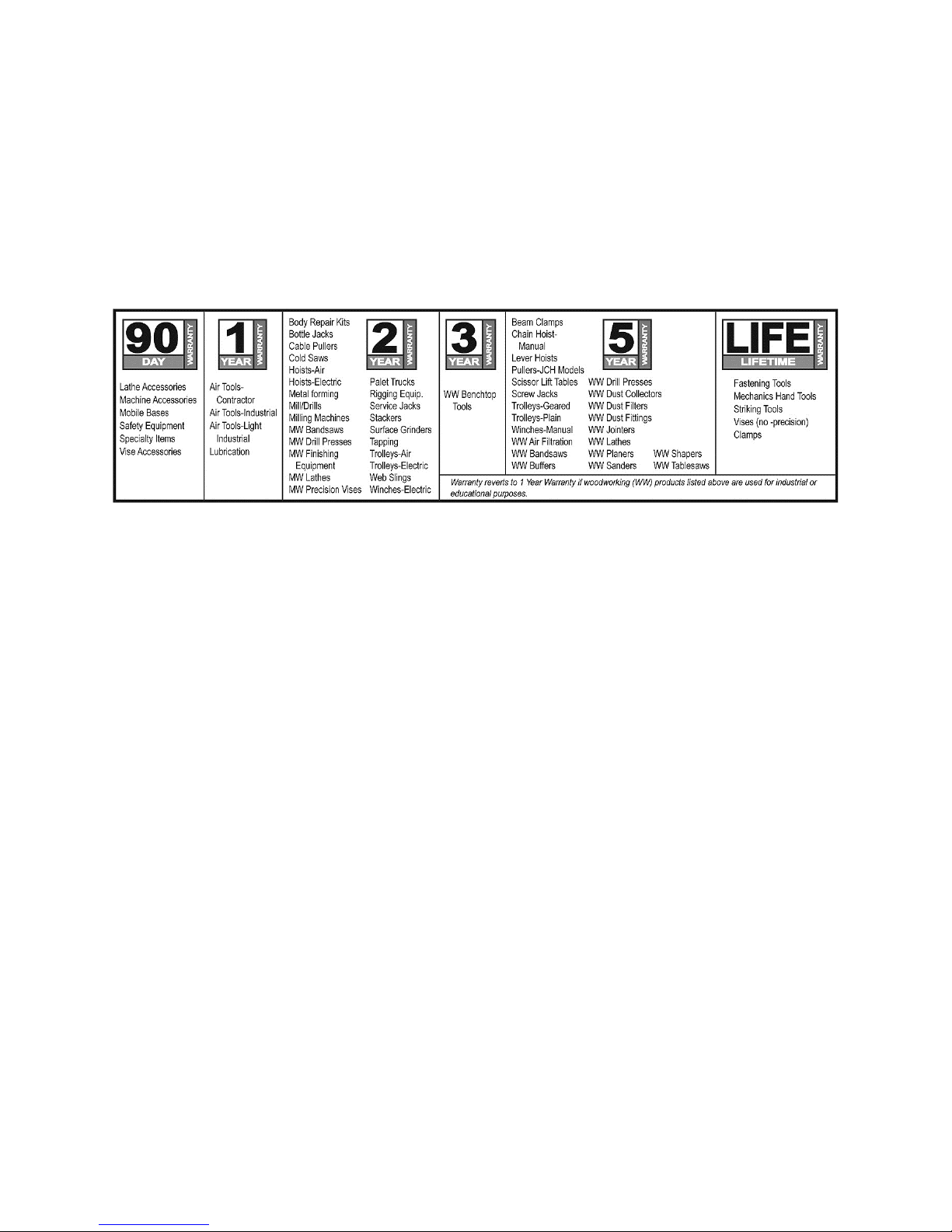

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS C OVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year W arranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE

LIMITED WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECI AL, OR CONSEQUENTIAL DAMAGES ARI SING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

® branded products are not sold in Canada by Walter Meier.

® t ools. For the name of an Authorized Service Center in

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Introduction ............................................................................................................................................. 6

Specifica tions ................................................................................................................ .......................... 6

Shipping Contents ................................................................................................................................... 7

Unpacking ............................................................................................................................................ 7

Cleaning .............................................................................................................................................. 7

Contents of the Shipping Container ...................................................................................................... 8

Assembly ................................................................................................................................................ 9

Motor Cover ......................................................................................................................................... 9

Handwheel Assembly ........................................................................................................................... 9

Miter Gauge and Fence Storage Hooks ................................................................................................ 9

Extens io n Wing .................................................................................................................................. 10

Blade Install ation/Replacement .......................................................................................................... 1 0

Riving Knife and Guard I nstallation ..................................................................................................... 11

Mounting Rail s & Ext ensi on Table ...................................................................................................... 12

Switch Installation .............................................................................................................................. 12

Electri c al Connec tions ........................................................................................................................... 12

Adjustments ................................................................................................................... ....................... 1 3

Handwheel Adjustments ..................................................................................................................... 13

Insert Adjustment ............................................................................................................................... 13

Miter Gauge ....................................................................................................................................... 13

Riving Knife Adjustment ..................................................................................................................... 14

Blade Alignment ................................................................................................................................. 15

Adjusting 45 and 90 Positive Stops .................................................................................................. 15

Changing the Belt .............................................................................................................................. 16

Maintenance .......................................................................................................................................... 17

Cleaning ............................................................................................................................................ 17

Lubrication ......................................................................................................................................... 17

Miscellaneous .................................................................................................................................... 17

Troubleshooting ..................................................................................................................................... 18

Optional Accessories ............................................................................................................................. 19

Parts ..................................................................................................................................................... 19

Ordering Replacement Parts .............................................................................................................. 19

Table & Cabinet Parts List .................................................................................................................. 2 0

Trunnion & Motor Parts List ................................................................................................................ 23

Trunnion & Motor Assembly Drawing.................................................................................................. 25

Blade Guard Part s and Assembly ....................................................................................................... 26

Wiring Diagrams .................................................................................................................................... 27

The specifications in this manual are given as general information and are not binding. Walter Meier

(Manufacturing) Inc., reserves the right to effect, at any time and without prior notice, changes or

alterati ons to par ts, fittings, and accessory equipment deemed necessary for any reason whatsoever.

3

Page 4

Warnings

1. Read and understand the ent ire owner's manual bef or e att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This table saw is desi gned and i nt ended f or use by properl y t rai ned and ex perienced per sonnel onl y.

If you are not familiar with the proper and safe operation of a table saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this table saw for ot her than its intended use. If used for other purpose s, Walter Meier

(Manufactur ing) Inc., di sclaims any real or implied warranty and hol ds itself harmless from any injury

that may result from that use.

6. Always wear approv ed safety glasses/fac e shields while using this table saw. Ev eryday eyeglasses

only have impact resi stant lenses; they are not safety glasses.

7. Before operating this table saw, remove tie, ri ngs, watches an d other jewelry, and roll sleeves up past

the elbows. Remove all loose clothing and c onfine long hair. Non-sli p footwear or anti-skid fl oor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during ext ended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

Lead from lead based paint.

Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

Arsenic and chromium from chemically treated lumber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machi ne while tired or under the influence of drugs, alcohol or any medication.

11. M ak e c er tain the machine is properl y grounded.

12. M ak e all machine adjustments or maintenance with the m ac hine unplugged from the power source. A

machine under repair should be RED TAGGED to show it must not be used until maintenance is

complete.

13. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

14. Keep safety guards in place at all times when the machi ne is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately after m aintenance is complete.

15. Check the ali gnment of t he riving knife, fenc e and miter slot t o the blade. A caution decal is i nstall ed

on each guard to remind t he oper ator of the dangers of improper machine operation.

16. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

17. P r ov ide for adequate space surroundi ng work ar ea and non-glare, ov er head lighting.

18. K eep the floor around the machi ne cl ean and free of scrap material, oil and grease.

4

Page 5

19. K eep v isitors a safe distance from the work area. Keep children away.

20. M ak e y our workshop child proof wit h padloc k s, m aster swit c hes or by r em ov ing safety keys.

21. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

22. Maintain a balanced stance at all times so that you do not fall or lean against the blade or other

moving part s. Do not over r eac h or use excessive force to perform any mac hine oper ation.

23. Use the ri ght t ool at the cor rect speed and feed r ate. Do not forc e a tool or attachment to do a job for

which it was not designed. T he ri ght tool will do the job better and safer.

24. Use recom mended accessories; improper accessories may be hazardous.

25. Maintai n tools with care. Keep blade sharp and cl ean for the best and saf est perf ormance. Follow

instructions for lubricating and changing accessories.

26. Check the saw blade for cracks or missing teeth. Do not use a cracked or dull blade or one with

missing teeth or im pr oper set. Make sure the blade is securely lock ed on the arbor .

27. Keep hand s cl ear of t he bl ade area. Do not reac h pa st t he blade t o cl ear par ts or scrap wit h the sa w

blade running. Never saw fr eehand. Avoid awkward o perations and hand p ositions where a sudden

slip coul d cause your hand to c ontact the blade.

28. Do not attempt to saw boards with l oose knots or with nails or other f oreign material, on its surfac e.

Do not attempt t o saw twisted, warped, bowed or “in wind” stock unless one edge has been joint ed for

guiding purposes prior to sawing.

29. Do not attempt to saw long or wide boards unsupported where spring or weight could cause the

board to shift posit ion.

30. Al ways use the riv i ng k nife, blade guard, push stic k and ot her saf ety dev ic es for all operat ions where

they can be used. On operati ons such as dadoing or mol di ng where the blade guar d cannot be used,

use feather boards, f ixtures and other safety devices and use ex treme caution. Reinstal l the riving

knife and blade guard im m ediately after completing the operation that required t heir r em ov al.

31. B e sure t he sa w blade r otates clockwise when viewed from the motor side (left si de) of t he machine.

32. Turn off the mac hine before cl eaning. Use a brush or compressed air to rem ov e c hips or debris — do

not use your hands.

33. Do not stand on the machine. Seri ous i njur y could occur if the machine tips ov er.

34. Never leave the mac hine r unning unattended. Turn the power off and do not leav e the mac hine until it

comes to a complete stop.

35. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiariz e you rself with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precauti ons are not heeded, it may result in serious injury or possibly

even death.

5

Page 6

Introduction

The JET XACTA® Saw Deluxe table saw you h av e purchased is a hi gh qual i ty machi ne t ool that will giv e

you years of superi or service. You will get maximum perf ormance and enj oyment from your new table

saw if you will take a few moments now to review the entire manual before beginning assembly and

operation.

This tabl e sa w, as well as all J E T products, are backed by a nationwide network of authoriz ed distributors

and/or servi ce centers. Pl ease contact your nearest di stributor should you requi re parts or serv ic e. Parts

are also available directly from Walter Meier (Manufacturing) Inc., by calling 1-800-274-6848.

Now that you have purc hased a table saw, it is a good time to consi der a dust collection system. See your

local JET dist ributor for the com plete line of dust collect ors and the f ull line of JET Dust Coll ector Hoses

and Accessories. Cu stomize your install ation and obtain maximum perf ormance with JET's dust hoods,

hoses, clamps, fi tt ings, and blast gates.

Assembling and fine tuning a table saw, fence and rail system, extension tables, etc. can be a time

consuming proj ect. It is best not to r u sh. The t able sa w does not c om e with a pl ug. Purchase a plug that

matches the 230V or 460V outlet that will be used. The table saw does not c ome with a blade so you may

want to purchase a variety of blades for different applications.

Specifications

Stock Number............................................................................................................ 708674 (3 HP, 1 P h)

........................................................................................................................ 708676 (5 HP, 1 Ph)

........................................................................................................................ 708680 (5 HP, 3 Ph)

Blade Diameter ..................................................................................................................................... 10”

Arbor Diameter .................................................................................................................................... 5/8”

Maximum Depth of Cut ........................................................................................................................... 3”

Maximum Thick ness at 45 Cut ........................................................................................................ 2-1/8”

Table in Front of Saw Bl ade at Maximum Cut ....................................................................................... 10 ”

Maximum Width of Dado.................................................................................................................. 13/1 6”

Maximum Diameter of Dado ................................................................................................................... 8”

Dust Port Diameter ................................................................................................................................. 4”

Dust Collecti on Minimum CFM required ............................................................................................... 350

Table Height ......................................................................................................................................... 34”

Table Size (with extension) .................................................................................................... 29"D x 42"W

Table Size (without extension) ............................................................................................... 29"D x 20”W

Arbor Speed .............................................................................................................................. 4300 RPM

Sound Rating:

(without blade) ................................................................................................................ 70 dB at 3 ft.

(with 10”x50T blade) ....................................................................................................... 85 dB at 3 ft.

Motor

SN 708674...................................................................................................... 3HP, 1Ph, 230V only

SN 708676..................................................................................................... 5 HP, 1Ph, 230V only

SN 708680................................................... 5HP, 3Ph, 230/460V, prewired 230V (see Note below)

Weight

Net ....................................................................................................................................... 330lbs.

Gross .................................................................................................................................... 407lbs.

Note: For 460V operati on, magnetic switch (Part No. JTA S 10- 23B ) m ust be pur c hased separately and

install ed. A qualified electrician is recommended.

The above specifications were current at the time this manual was published, but because of our policy of

continuous improvement, Walter M eier reserves the right to change specifications at any ti me and without

prior notic e, wit hout incurring obligati ons.

6

Page 7

Read and understand the entire contents of this manual before attempting

assembly or operat io n! Failure to comply may cause serious inju ry.

Shipping Contents

Unpacking

Remove box and wood crati ng completely from

around saw. Check f or shipping damage. Report

any damage imm ediately to your di stributor and

shipping agent. Do not discard any shipping

material until the Table Saw is assembled and

running properly.

Compare the c ontent s of y our cont ainer wit h t he

parts lists i n the next two pages to m ake sure all

parts are intac t. Missing part s, if any, shoul d be

reported to your di stributor. Read the instruct ion

manual thoroughly for assembly, maintenance

and safety instruc tions.

1. Unbolt the saw fr om the skid.

2. Carefully sl ide the saw from the pall et onto

the floor.

Do not con nect the tablesaw

to the power source until all assembly has

been completed! Failure to comply may

cause serious inj ury!

The Table Saw should be pl aced i n an area wit h

a sturdy level floor, good ventilation and

sufficient lighting. Leave enough space around

the machine f or mounting extension wings and

rail assemblies, and loading and off-loading

stock and general maintenance work.

Cleaning

Exposed metal surfaces, such as the table top

and extension wings, have been given a

protectiv e coating at the f actory. T his should be

removed with a soft cloth moistened with

kerosene. Do not use acetone, gasoline, or

lacquer thinner for this purpose. Do not use

solvents on plastic parts, and do not use an

abrasive pad because it may scratch the

surfaces.

7

Page 8

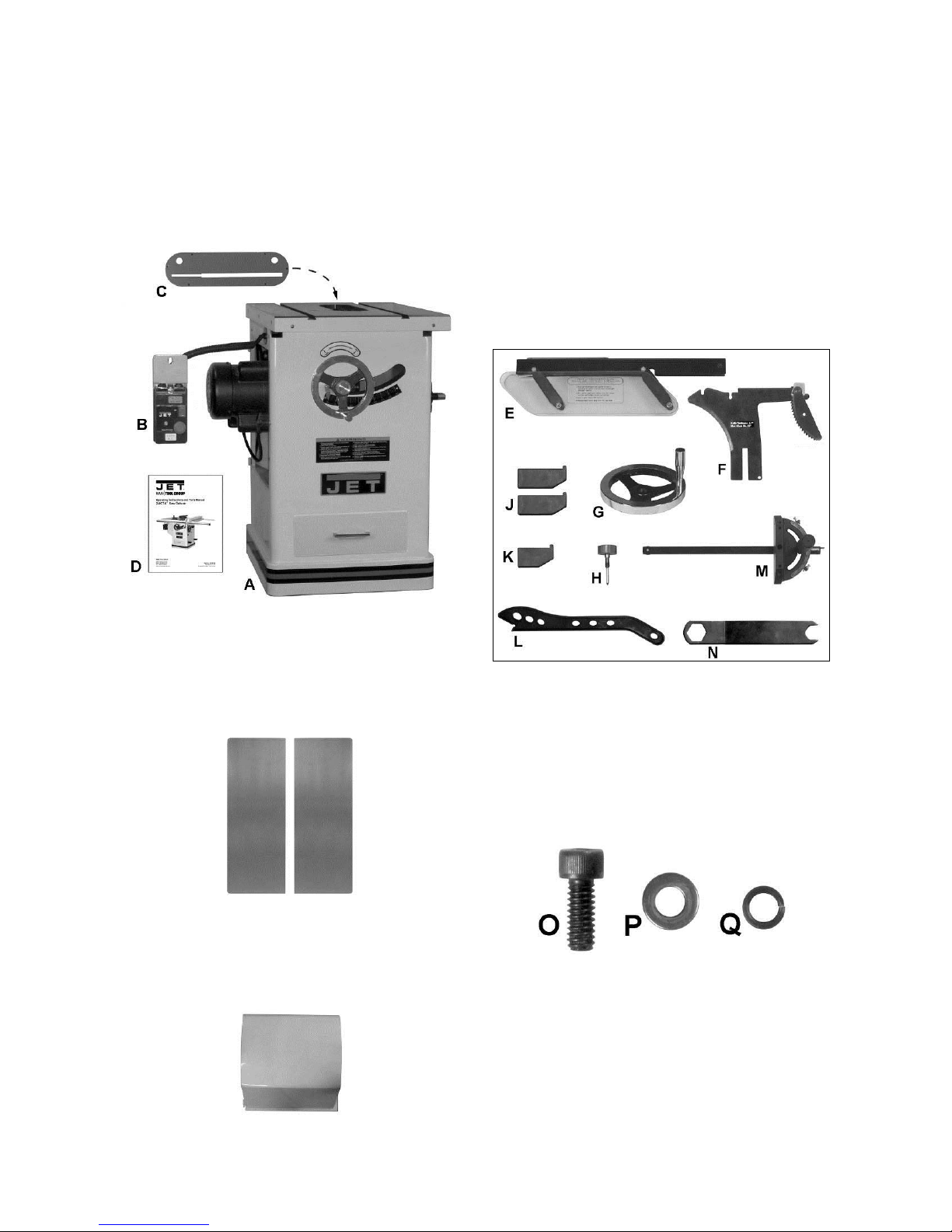

Contents of the Shipping Containe

r

Main Saw Container

1 Table Saw (A)

1 Switch (B)

1 Table Insert (C)

1 Owner's Manual (D)

1 Warranty Car d (not shown)

Small Box

The small box consists of the following items:

1 Blade Guard Assembl y (E)

1 Riving Knife and Pawl A ssembly (F)

1 Handwheel and Swivel Handle (G)

1 Lock Knob (H)

2 Large Hook (J)

1 Small Hook (K)

1 Push Stick (L)

1 Miter Gauge Assembly ( M)

1 27mm Arbor Wrench (N)

Main Saw Container

Extension Tables

Two extension tables are packaged in individual

boxes.

Extension Tables

Side Cover Box

1 Side Cover

Contents of Side Cover B ox

Contents of the Sm all B ox

Hardware

6 1/4 x 5/8 Socket Head Cap Screw (O)

6 1/4 Flat Washer (P)

6 1/4 Lock Washer (Q)

Contents of Hardw ar e B ag

8

Page 9

Assembly

Moto r Cover

Referring to Fi gur es 1 and 2:

Tools: 17mm Wrench, 12mm Wrench

1. Remove shipping bracket (A) securing the

motor (C) to table.

2. After the shipping bracket has been removed,

install the screw (B) back into the motor

support bracket . The upper screws wil l be used

to later to hold the extension wing in place.

3. Remove shipping bracket (D) holding switch

assembly (E) to table. Do not discard the

bracket (D); it will be used to install the switch.

4. Remove the remaining hex cap screw, lock

washer, and flat washer (F and Fig. 5) in the

table edge.

5. Install motor cover (G) by aligni ng the pins (H)

on the cover with brackets on the cabinet.

6. Fasten cover by pulling out the latch (J),

closing the door , and releasing the latch.

Figure 1

Handwheel Assembly

Referring to Fi gur e 3:

Hardware: (2) Handle & Handwheel (C),

(2) Lock Knob (D), (2) Shaft Key (A)

Tools: 3mm hex wrench

The f ront handwheel (E) is instal led at the factory.

Install the side handwheel (C) as follows:

1. Line up the key (A) (taped to shaft) on the

shaft (B) with the key way in the handwheel (C)

and slide the handwheel ont o the shaft.

2. Tighten the set screw on the handwheel hub

(3mm hex wrench) securely to hold in place.

3. Install the center lock knob (D) by inserting into

center hole in the shaft and threading in a

clockwise dir ec tion.

4. Install the remaining handwheel assembly (E)

in the same manner.

Miter Gauge and Fence Storage Hooks

Referring to Fi gur e 3:

Hardware: (1) Small Hook (F) , (2) Large Hook (K),

(6) 1/4” Flat Washers (J), (6) 1/4" Lock Washers

(H), (6) 1/4 x 5/8 Socket Head Cap Screws (G)

Tools: 5mm hex wrench

Mount the small hook (F) and two large hooks (K)

to the side of the saw cabinet with six eac h

socket head cap screws (G), 1/4" lock washers (H)

and 1/4" flat washers (J). Tighten with hex wrench.

1/4 x 5/8

Figure 2

Figure 3

9

Page 10

Extension Wing

Referring to Fi gur es 4 and 5:

Hardware: (6) 7/16”x1-1/2” Hex Cap Bolts, (6) 7/ 16”

Lock Washers, (6) 7/16” Flat Washers & (2)

Extension Wings

Tools: 17mm Wrench, Straight Edge

1. Attach the left extension wing (A) to the

table (B) with three each hex cap screws (E),

lock washers (F) and flat was her s (G). Snug so

the extension wing can still be manually

adjusted but do not tighten.

2. Adjust the extension wing horizontally so the

front edge is flush with the front edge of the

saw table (C). T hen, using the str aightedge as

reference, adjust vertically so the tops of the

extension wing and saw table ar e flush.

3. Tighten the three extension wing mounting

screws.

4. Remove the mounting hardware (Fig. 5) from

the table on the right side; then attach the right

extension wing in the same manner.

Figure 4

Blade Installation/Replacement

Use care when working with or

around sharp saw blad e to preven t inju ry!

To install or replac e a blade ( r efer to Figure 6):

Tools: 27mm Wrench

1. Disconnect machine from power source.

2. Raise the blade height all the way up and set

the blade tilt to 0º (refer to Handwheel

Adjustments on page 14).

3. Remove the table insert.

4. Rotate the arbor to li ne up the slot (C) with the

arbor lock (D).

5. Press the arbor lock (D) in the di recti on shown

by the arrow to engage it i nto the slot (C) in the

arbor. At the same time remove the arbor

nut (A), loosening with a 27mm wrench if

necessary.

6. Remove the collar (B).

7. Instal l the bl ade, making sure the c utting t eeth

at the top of the blade poi nt toward the f ront of

the saw. If unsure, refer to Figure 8 for the

proper blade orientation.

8. Replace the collar (B) and arbor nut (A).

9. Engage the arbor lock (D) and ti ghten the nut

(A) with a 27mm wrench.

10. Lower the blade below the table.

Figure 5

Figure 6

10

Page 11

Riving Knife and Guard Installation

Description

Referring to Fi gur e 7:

The complete riving knife and guard assembly is

shown in A. Before installing onto the sa w, t he anti-

kickback pawl (E) must be separated from the

riving knife (H) as follows:

1. Press and hold the quick-release butt on (D) on

the base of the anti-kickback pawl (E) and lift

the pawl to remove from the riving knife (H).

Inst a lla tion

Referring to Fi gur e 8:

2. Set the saw blade to the 90 degree position

and raise it all the way (refer to Handwheel

Adjustments on page 13).

3. Remove the table insert (J).

4. Located inside the table and accessible

through the insert opening (Figure 8 inset),

place the quick-release clamp lock handle (K)

in the unlock position.

5. The floating clamp block (L) is spring loaded

and will move away (O) from the fixed

block (M), leav ing a gap.

6. Insert the bottom of the riv ing k nif e (N1, N2) all

the way int o the gap bet ween t he clamp b lock s

(L, M); then lock the handle (K).

7. Replace the insert (J) back on the table. The

saw blade and riving knife should protrude

through the slot in the insert.

Figure 7

Referring bac k to Figure 7:

8. Attach the anti-kickback pawl (E) by pressing

and holding the quick-release button (D) and

inserting the lock pin of the pawl into the

appropriate sl ot (F) on the riving knife.

9. In similar manner attach the guard (C) by

pressing and holding the quick-release button

(B) and inserting t he lock pin of the guard into

the appropriate slot (G) on the riving knife.

You should feel a snap as each piece locks in

position. Attempt to lift as a test to make sure that

they are securely loc k ed in plac e.

Adjustment

The clamping bloc ks (L, M, Fig. 8) are adjusted at

the factor y and no further adj ustment of the blade

guard and riving knife assembly should be

necessary. However, proper alignment is very

important. Before operating the table saw, read

Riving Knife Adjus tment (p.14) to v erify and follow

the adjustment pr oc edur e if necessary .

Figure 8

11

Page 12

Mounting Rails & Extension Table

Electrical Connections

With the extension wings properly aligned, the

rail and fence assembl y can now be mount ed to

the saw. Refer to the XACTA

Fence II

Commercial 30/50 Owner's Manual (Part No.

M-708950Z) for mounting instructions for the

rails, fence and optional wooden extension

table.

Switch Installation

Referring to Fi gur e 9:

Hardware: Switch Brace

Tools: 8mm hex wrench , 8mm wren c h

1. Remove the hex nut from the flat head

screw that secures the left extension table to

the front rail (B).

2. Place switch assembly bracket (A) behind

the front rail (B) and just inside the front

edge of the left ext ens ion wing.

3. Replace t he hex nut, securing the f ront rail,

extension t able and switch assem bly. Handtighten only at t his tim e.

4. Loosen the hex cap screw (C) and slide the

open tab of the switch brace (E) onto the

screw (C) and washer (D). Hand-tighten only

at this time.

5. Remove the nut and star washer (F) from

the screw at t he bottom of t he switch plat e

on the back of the switch assembly.

6. Fasten the switch brace to the switch

bracket assembly with the star washer and

nut.

7. Align the switch and tighten all hardware.

A qualified electrician must

complete all electrical connections! Failure

to comply may result in serious injury!

The machine must be

properly grounded while in use to protect the

operator from electric shock! Failure to

comply may result in serious injury!

If a plug i s provided with your m achine, do not

modify the plug. If it will not fit your electrical

receptacle, hav e a qualifi ed elect rician install the

proper connections to meet all electric al codes.

XACTA

Saw Deluxe table saws with stock

numbers 708674 and 708676 are r ated at 230V

only. Saws with stock number 708680 ar e r ated

at 230/460V, and come from the factory

prewired 230V.

To switch from 230V to 460V (machines with

stock number 708680 only):

1. Disconnect the machine from the power

source, (unplug).

2. Open the saw cabinet door.

3. Remove the cover from the motor junction

box.

4. Change wires following the diagram on the

inside of the cover .

5. Replace the cover and close the cabinet

door.

6. Replace the magnetic on- off switch with par t

#JTAS10-23B (available through your

authorized JET distributor or by calling

Walter Meier (Manufacturing) Inc., at the

number on the cover) .

Figure 9

Confirm power at the site is the same as the saw

before making any electrical connections.

Review the electrical schematics on page 27-27.

The on and off switch is th ermally protect ed. If

the saw motor is overloaded, or a momentary

interruption of electrical current is sensed, the

saw will shut off. Allow a few minutes for the

saw to cool do wn and reset by pushing the off

button.

Using extension cords can cause a loss in

power to your m achine. It i s best if the saw is

plugged directly into an outlet on a dedicated

circuit.

12

Page 13

Adjustments

Handwheel Adjustments

Referring to Fi gur e 10:

The front handwheel (B) controls the raising and

lowering of t he blade ( blade height).

The side handwheel ( D) control s the blade t ilt. The

blade can be adjusted for a tilt between 90º

(vertical or a set ti ng of 0º on t he scale) and 45º l eft

tilt (D).

Blade height

1. Loosen the lock knob (A) on the front

handwheel (B).

2. Turn the handwheel (B) clock wise to raise and

countercl oc k wise to lower the blade.

3. Tighten the lock knob (A).

Blade tilt adjustment

1. Loosen the lock knob (C) on the side

handwheel (D).

2. Turn the handwheel (D) counterclockwise to

adjust the saw blade do wn to 45º left tilt. Turn

clockwise to adj ust the saw blade to m aximum

of 90º.

Figure 10

3. After selecting the position, tighten the lock

knob (C).

Insert Adjustment

Adjust the setscrews in the insert with a 2.5mm hex

wrench (Figure 11) to ensure that the insert is

stable and fl ush with the table top.

Miter Gauge

Referring to Fi gur e 12:

1. Operate miter gauge by loosening the lock

knob (A) and turni ng the miter body (B) to the

desired angle. To move gauge beyond index

stops of 45 and 90, flip down the stop (C).

2. Adjust index stops by turning one of three

adjustment screws (D).

Note: Always make test cuts. Do not rely solely on

miter gauge indi cator m arks. T here are holes i n the

miter gauge body that will allow you to mount a

wooden extension fence.

Figure 11

Figure 12

13

Page 14

Riving Knife Adjustment

Lateral alignment

The saw blade and riv ing knife must be in line as

close as possible with each other (lateral

alignment) for the prevention of kickback. Upon

initial blade guard and riving knife installation no

further adj ustment should be necessary. Ali gnment

should be checked an d adjusted, if r equired, after

each blade change.

Check the alignment as follows:

1. Remove the blade guard and pawl (C, E,

Fig. 7).

2. Place a straightedge (A, Fig. 13) on the table

so it rests against the blade (B, Fig 13) and

riving knife (C, Fig. 13). Rotate the blade so the

top of the blade tooth touches the straightedge.

The saw blade and rivi ng k nife must be in line.

If adjustm ent is requi r ed:

3. Remove the table insert.

4. Loosen the lock handle (A, Fig. 14) and

remove the riving knife, making a note as to

which direction the riving knife needs to be

moved to align it wit h the saw blade.

5. Using a 3mm hex wrench, make adjustments

to any of the four set screws (D, Fig. 15)

accessible through openings located in the

corners of the floating clamp block (E, Fig. 15).

6. If necessary, repeat the above procedure.

Figure 13

Figure 14

Figure 15

14

Page 15

Blade Alignment

Tools: 8mm hex wrench, combination square,

marker

Blade alignment with the table is adjusted at the

factory. Aft er a period of use, or, after moving the

saw to another location, the blade may no longer

be aligned wit h the t able.

To check and align the blade ( r efer to Figure 16):

1. Disconnect the saw fr om the power source.

2. Raise the blade guard up a way fr om the blade.

3. Choose a tooth on the far side of the blade

(towards the rear) and position the tooth

slightly above the table insert. Mark the tooth

with a marker. Measure the distance from the

side of the bl ade to the ri ght T-slot edge using

a combination square. Make sure to measure

between the teet h not on t he toot h (Figur e 16) .

4. Rotate the blade toward the front so that the

marked tooth i s just above the insert. M easure

the distance from the side of the blade to the

right T-slot edge. The two measurements

should be the same.

Figure 16

5. If they are not the same, loosen four hex

socket cap screws (A, Fig. 17) that hold the

table to the base. T wo are shown in Fi gur e 17.

6. Make the needed adjustm ents and tighten the

four hex socket cap screws firmly.

7. Check the alignment once again after

tightening har dware.

Adjusting 45 and 90 Positive Stops

The stops hav e been adjusted at the fact ory. After

a period of use, or, after moving the saw to another

location, the stops may no longer be set properly.

To check and adjust the stops:

Tools: 12mm wrench, combination square

1. Disconnect saw f r om power source.

2. Raise the saw blade to its maximum height

using the handwheel.

3. Set the blade at 90 degrees to the table by

turning the blade tilting handwheel clockwise

as far as it will go.

Figure 17

4. Place a combination square on the table

against the blade and check to see that the

blade is at a 90 angl e to the tabl e, Figure 18.

Make sure square is not touching a blade

tooth.

Figure 18

15

Page 16

5. If blade is not at 90 degrees, open the motor

cover door, loosen lock nut (A, Fig. 19) and

turn adjusting stop screw (B, Fig. 19) on the

front trunnion in, or out. The adjusting stop

screw should stop against the front trunnion

bracket when the blade is 90 to the table.

6. Tighten the lock nut (A, Fig. 19).

7. Set the blade at 45 degrees to the table by

turning the blade tilting handwheel counterclockwise as far as it will go. Place a

combination square on the table against the

blade. Make sure square is not touching a

blade tooth.

8. If the blade is not 45 degrees, remove the

raising and lowering handle. Loosen lock nut

(A, Fig. 19) and turn adjusting stop screw

(B, Fig. 19) on t he front t r unnion in, or out. The

adjusting stop screw should stop against the

front tr unnion bracket when the blade i s 45 to

the table.

9. Check the acc uracy of the poi nter (C, Fig. 20)

on the angle scale and adjust, if necessary.

Assembly and adjustment of the saw are now

complete. Make sure all fasteners are ti ght. The

saw may now be placed into operation.

Changing the Belt

Figure 19

Figure 20

Make all machine adjustments

or maintenance with the machine unplugged

from the power source. Failure to comply may

cause serious inj ury!

Referring to Fi gur e 21:

1. Disconnect the machine from the power

source, unplug.

2. Lower the blade to its l owest point.

3. Loosen two hex cap bolt s (A).

4. Take the tension off of the belt (B) by lif ting up

on the motor.

5. Remove the belt from the arbor and motor

pulleys.

6. Replace and ten sion the belt. The weight of the

motor should appl y enough tension to the bel t.

Tighten the hex cap bolts (A).

7. Check the belt tension after the saw has been

used for a few hours. Adj ust as necessary .

Figure 21

16

Page 17

Maintenance

Always disconnect power to the machine before performing maintenance. Failure

to do this may result in serious personal injury.

Cleaning

Note: The following maintenance schedule

assumes the saw is being used every day.

Daily:

Wipe down the table surface and grooves

with a rust prev entive.

Cl ean pitch and resin from the saw blade.

Weekly:

Table surface must be kept clean and free of

rust for best results. Apply a coat of paste

wax to the surface to facilitate this. An

alternativ e is to apply white t alcum powder,

rubbed in vigorously once a week with a

blackboard eraser; this will fill casting pores

and form a moisture barrier. This method

provides a tabl e top that is sli ck and allows

rust rings to be easily wiped from the

surface. Important also is the fact that

talcum powder will not stain wood or mar

finishes as wax pick up does.

Cl ean m otor housing with compressed air.

Wipe down the fence rails with a dry silicon

lubricant.

Periodic:

Lubrication

Grease the tilting worm gear, raising worm

gear, castor system worm gear and the

trunnion areas with a good grade nonhardening grease.

Check all adjustments after lubr icating.

Miscellaneous

Routinely chec k condi tion of the following items:

Mounting bolts

Power switch

Saw blade

Blade guard assembly

Keep the inside of the c abinet and trunnion

area clean.

Check for excessive play in the tilting and

raising mechani sm and in the saw arbor and

re-adjust as requir ed.

Check for belt tension and wear. Readjust or

replace belt as required.

17

Page 18

Troubleshooting

Trouble Possible Cause Solution

Saw stops or will

not start

Overload tripped

Saw unplugged from wall or m otor

Fuse blown or circuit breaker tripped

Cord damaged

Allow motor to cool and reset by

pushing off switch

Check all plug connections

Replace fuse or reset circuit breaker

Replace cord

Does not make

accurate 45 or

90 cuts

Material binds

blade when

ripping

Saw makes

unsatisfactory

cuts

Blade does not

come up to

speed

Saw vibrates

excessively

Stops not adjusted cor r ec tly

Angle pointer not set accurately

Miter gauge out of adj ustm ent

Fence not ali gned with blade

Warped wood

Excessive feed rate

Splitter not ali gned with blade

Dull blade

Blade mounted backwards

Gum or pitch on blade

Incorrect blade for cut

Gum or pitch on table

Extension cord too light or too long

Low shop voltage

Motor not wired for correct voltage

Stand on uneven fl oor

Damaged saw blade

Bad V-belts

Bent pulley

Improper motor mounting

Loose hardware

Check blade with square and adjust

stops

Check blade with square and adjust

pointer

Adjust miter gauge

Check and adjust fenc e

Select another piece of wood

Reduce feed rate

Align splitter with blade

Sharpen or replac e blade

Turn blade around

Remove blade and clean

Change blade to corr ec t t y pe

Clean table

Replace with adequat e si z e c or d

Contact your loc al elec tric company

Refer to motor junction box

Reposition on flat, level surface

Replace saw blade

Replace V-belts

Replace pulley

Check and adjust mot or

Tighten har dware

Rip fence binds

on guide rails

Material kicked

back from blade

Blade does not

raise or tilt freely

Guide rails or ext ensi on wing not installed

correctly

Guide of rip fenc e not adjusted properly

Rip fence out of alignm ent

Splitter not ali gned with blade

Feeding stock without rip fence

Splitter not in plac e

Dull blade

Letting go of material before it is past

blade

Anti-kick bac k plates dull

Sawdust and debris in raising and tilting

mechanisms

Re-assemble guide rails, refer to fence

manual

Adjust guides, refer to fence manual

Align rip fenc e with miter slot

Align splitter with blade

Install and use rip fence

Install and use splitter (with guard)

Replace blade

Push material all the way past blade

before releasi ng work

Replace or sharpen anti-kick back

plates

Clean and re-grease

18

Page 19

Optional Accessories

Stock No Description

708295 Tenoning Jig

for 10” saws only:

708097 Dado Insert

708118 Universal Mobile Base

Parts

Ordering Replacement Parts

Replacement par ts are li sted on the f ollowing page s. To order parts or reac h our servi ce depar tm ent, call

1-800-274-6848, Monday through Friday (see our website for business hours, www.waltermeier.com).

Having the Model Number and Serial Number of your mac hine available when you cal l will allow us to

serve you quickly and accurately.

19

Page 20

Table & Cabinet Parts List

Index No. Part No. Description Size Qty

1 ............... JTAS10-1 .................Lock Knob ............................................................................................. 1

2 ............... JTAS10-2 .................Miter Gauge Body.................................................................................. 1

3 ............... TS-1540031 .............Hex Nut ..............................................................M5 .............................. 3

4 ............... JTAS10-4 .................Pointer................................................................................................... 1

5 ............... JTAS10-5 .................Stop Link ............................................................................................... 1

6 ............... TS-1521011 .............Socket Set Screw ...............................................M4x4 .......................... 1

7 ............... JTAS10-7 .................Special Pin .........................................................M3x6 .......................... 1

8 ............... TS-2205201 .............Hex Cap Scre w ..................................................M5x20 ........................ 3

9 ............... JTAS10-9 .................Guide Bar .............................................................................................. 1

10 ............. JTAS10-10 ...............Guide Washer ....................................................................................... 1

11 ............. JTAS10-11 ...............Flat Head Screw .................................................M6x8 .......................... 1

................. JTAS10-M G .............Miter Gauge Assembly (#1-11) .............................................................. 1

12 ............. TS-0267041 .............Socket Set Screw ...............................................1/4 -20x3/8 .................. 6

13 ............. JTAS10L-13N ..........Tab le In sert ........................................................................................... 1

13A .......... 708097 ....................Dado Insert - ( Optional Accessory) ........................................................ 1

14 ............. JTAS10L-14WN .......Table ..................................................................................................... 1

15 ............. JTAS10L-15WN .......Extension Wing ..................................................................................... 2

18 ............. TS-0061051 .............Hex Cap Sc re w ..................................................7/16-14x1-1/2 ............. 6

19 ............. TS-0720101 .............Lock Washer ......................................................7/16 ............................ 6

20 ............. TS-0680051 .............Flat Washer ........................................................7/16 .......................... 10

22 ............. JTAS10-22W ...........Switch Plate .......................................................................................... 1

23 ............. JTAS10-23 ...............Magnetic Switch .................................................3HP, 230V, 1 Ph ......... 1

................. JTAS10-2 3A ............Magnetic Switch .................................................5HP, 230V, 3 Ph ......... 1

................. JTAS10-2 3B ............Magnetic Switch .................................................5HP, 460V, 3 Ph ......... 1

................. JTAS12-2 3 ...............Magnetic Switch * ..............................................5HP, 1 Ph, 230V ......... 1

24 ............. TS-081C052 ............Pan Head Screw ................................................#10-24x3/4 ................. 1

26 ............. JTAS10-26 ...............Strain Relief Bushing ..........................................708674, PG-11 ........... 2

................. JTAS10-26A ............Strain Relief Bushing ..........................................708676, PG13.5 ......... 2

................. JTAS10-26B ............Strain Relief Bushing ..........................................708680, MG25A-16B .. 2

27 ............. JTAS10-27 ...............Strain Relief Bushing ..........................................708674, 6N3-4............ 2

................. JTAS10-27A ............Strain Relief Bushing ..........................................708676, 7N-2.............. 2

................. JTAS10-27B ............Strain Relief Bushing ..........................................708680, 8R3 ............... 2

28 ............. JTAS10-28 ...............Tap Screw ..........................................................M5x10 ...................... 10

29 ............. JTAS10-29 ...............Cord Plate ..........................................................708674, 14x16............ 1

................. JTAS10-2 9A ............Cord Plate ..........................................................708676, 15x17............ 1

................. JTAS10-2 9B ............Cord Plate ..........................................................708680, 17x21............ 1

30 ............. JTAS10L-30N ..........Identification Plate ................................................................................. 1

31 ............. JTAS10DX-31 ..........Power Cord (switch to motor,3HP 1PH 230V) .....14AWGx3C,SJT,300V 1

................. JTAS10DX-31A........Power Cord (switch to motor,5HP 1PH 230V) .....12AWGx3C,SJT,300V 1

................. JTAS10DX-31B........Power Cord (switch to motor,5HP 3PH 230/460V)14AWGx4C,ST,600V. 1

32 ............. JTAS10DX-32 ..........Power Cord (3HP 1PH 230V) .............................14AWGx3C,SJT,300V 1

................. JTAS10DX-32A........Power Cord (5HP 1PH 230V) .............................12AWGx3C,SJT,300V 1

................. JTAS10DX-32B........Power Cord (5HP 3PH 230/460V) .......................14AWGx4C,ST,600V .. 1

33 ............. JTAS10-33 ...............Power Cord Sleeve (708674) ..............................Ø19 ............................ 1

................. JTAS10-33A ............Power Cord Sleeve (708676,708680) .................Ø22 ............................ 1

34 ............. JTAS10L-34 .............Tilt Scal e ............................................................................................... 1

35 ............. JTAS10-35 ...............Warning Label ....................................................................................... 1

36 ............. JTAS10-36 ...............JET Label .............................................................................................. 1

38 ............. JTAS10L-38WN .......Cabinet.................................................................................................. 1

39 ............. TS-1482101 .............Hex Cap Sc re w ..................................................M6x50 ........................ 1

40 ............. TS-0680021 .............Flat Washe r ........................................................1/4 .............................. 2

41 ............. JTAS10-41 ...............Spring.................................................................................................... 1

42 ............. JTAS10-42 ...............Foam Strip............................................................................................. 1

43 ............. JTAS10L-43WN .......Motor Cover .......................................................................................... 1

44 ............. TS-1540021 .............Nylon Insert Lock Nut .........................................M6 .............................. 1

45 ............. JTAS10-45 ...............Handle................................................................................................... 1

20

Page 21

47 ............. TS-0210011 .............Socket Head Cap Screw .....................................7/16-1 4x3/4 ................ 4

48 ............. TS-0680011 .............Flat Washer ........................................................3/16 ............................ 2

49 ............. JTAS10L-49WN .......Lower Panel .......................................................................................... 1

50 ............. JTAS10L-50N ..........Dust Hose Adapter ................................................................................ 1

51 ............. JTAS10-52W ...........Switch Brace Kit ** ................................................................................ 1

52 ............. TS-081C062 ............Screw .................................................................#10-24x1 .................... 1

53 ............. TS-0560071 .............Hex Nut ..............................................................#10-24 ........................ 1

54 ............. TS-0733031 .............Star Washer .......................................................# 10 ............................. 1

55 ............. JTAS10L-55 .............Hook ..................................................................................................... 2

56 ............. TS-0680021 .............Flat Washe r ........................................................1/4 .............................. 6

57 ............. TS-0720071 .............Lock Washer ......................................................1/4 .............................. 6

58 ............. TS-0207031 .............Socket Head Cap Screw .....................................1/4-20 x5/8 .................. 6

59 ............. JTAS10L-59 .............Hook ..................................................................................................... 1

60 ............. TS-0561011 .............Hex Nut ..............................................................1/4-20 ......................... 6

61 ............. JTAS10L-61 .............Electr ical Box......................................................................................... 1

62 ............. JTAS10L-62 .............Draw e r .................................................................................................. 1

63 ............. JTAS10L-63 .............Handle................................................................................................... 1

64 ............. TS-1550031 .............Flat Washe r ........................................................M5 .............................. 2

65 ............. TS-0720051 .............Lock Washer ......................................................#10 ............................. 2

66 ............. TS-081C032 ............Pan Head Screw ................................................#10-24x1/2 ................. 2

* 10” saws with 5HP, 1Ph motor uses these parts.

** Switch Brace kit c ontains bracket, screw, nut, star washer, and 8m m hex wrench.

21

Page 22

1

)(

6

2

)(

3

3

4

)

3(8

9

10

11

12

13

13A

(optional)

5

6

14

)(

428

15

18

7

(

)

2

)

(

6

)

19(6

20 (6)

61

49

28(2)

45

44

42

43

40

41

40

63

39

29

30

34

36

64(2)

65(2)

66(2)

60(6)

62

35

38

55(2)

20 (4)

47

56(6)

(

4

)

28(4)

50

59

58(6)

57(6)

22

Page 23

Trunnion & Motor Parts List

Index No. Part No. Description Size Qty

101 ........... JTAS10L-101 ...........Arbor Nut ............................................................................................... 1

102 ........... JTAS10-102 .............Arbor Flange ......................................................................................... 1

104 ........... JTAS10L-104N ........Arbor with Flange .................................................................................. 1

105 ........... JTAS10-105 .............Key ....................................................................M5x44 ........................ 2

106 ........... BB-6203ZZ ..............Ball Bearing ........................................................6203ZZ....................... 2

107 ........... JTAS10-107 .............Wave Washer ........................................................................................ 4

108 ........... JTAS10-108 .............Rear Bearing Load Spacer .................................................................... 2

108-1 ........ JTAS10DX-108 ........Front Bearing Load Spacer .................................................................... 1

109 ........... TS-0267041 .............Socket Set Screw ...............................................1/4-20x3/8 ................ 10

110 ........... JTAS10-110N ..........Arbor Pulley ........................................................................................... 1

111 ........... TS-0209081 .............Socket Head Cap Screw .....................................3/8-16x1-3/4 ............... 1

112 ........... JTAS10DX-112 ........Key.....................................................................1/4x1/4 x45.................. 1

113 ........... TS-0720091 .............Lock Was h e r ......................................................3/8 ............................ 10

114 ........... JTAS10DX-114 ........Arbor Bracket ........................................................................................ 1

115 ........... JTAS10-115 .............Spanner Nut .......................................................................................... 1

116 ........... JTAS10L-116 ...........Nut .....................................................................5/8 .............................. 1

117 ........... JTAS10-117 .............Spring Pin...........................................................M6x50 ........................ 1

118 ........... JTAS10-118 .............Key.....................................................................1/4x1/4 x2-5/16............ 1

119 ........... TS-0680051 .............Flat Washer ........................................................7/16 ............................ 2

120 ........... TS-0091031 .............Hex Cap Scr e w ..................................................7/16- 1 4 x1 ................... 2

121 ........... JTAS10DX-121 ........Shaft ..................................................................................................... 1

122 ........... JTAS10-122 .............Motor Bracket ........................................................................................ 1

123 ........... JTAS10-123 .............Pin......................................................................................................... 1

124 ........... JTAS10-124 .............Spring Clip............................................................................................. 2

125 ........... JTAS10L-125N ........Poly V-Belt .........................................................260J ........................... 1

126 ........... JTAS10DX-126 ........Motor Mounting Bracket ......................................................................... 1

127 ........... JTAS10-127N

128 ........... TS-0680031 .............Flat Washer ........................................................5/16 .......................... 10

129 ........... TS-0720081 .............Lock Was h e r ......................................................5/16 ............................ 9

130 ........... TS-0081031 .............Hex Cap Scr e w ..................................................5/16- 1 8 x3/4 ................ 4

131 ........... JTAS10DX-131N .....Motor ..................................................................3HP, 1Ph, 230V only .. 1

................. JTAS10D X-131C .....Motor ..................................................................5HP, 1Ph, 230V only .. 1

................. JTAS10D X-131A ......Motor ..................................................................5HP, 3Ph, 230/460V ... 1

................. JTAS10D X-131CS ...Centrifugal Switch Assembly (not shown) .............................................. 1

................. JTAS10-131D ..........Fan Cover (not shown) .......................................................................... 1

................. JTAS10-131F ...........Motor Fan (not shown) ........................................................................... 1

................. C-600125 .................Start Capacitor (not shown) ................................3HP, 1Ph motor .......... 1

................. C-040250 .................Run Capacitor (not shown) .................................3HP, 1Ph motor .......... 1

................. JTAS10-1315B ........Start Capacitor (not shown) ................................5HP, 1Ph motor .......... 1

................. JTAS10-1315A ........Run Capacitor (not shown) .................................5HP, 1Ph motor .......... 1

132 ........... TS-0209071 .............Socket Head Cap Screw .....................................3/8-16x1-1/2 ............... 6

133 ........... JTAS10DX-133 ........Rear Trunnion Bracket ........................................................................... 1

134 ........... TS-0561031 .............Hex Nut ..............................................................3/8-16 ......................... 5

135 ........... TS-0209051 .............Socket Head Cap Screw .....................................3/8-16x1 ..................... 4

136 ........... JTAS10-136 .............Spring Pin...........................................................M8x25 ........................ 4

137 ........... TS-0561081 .............Hex Nut ..............................................................3/4-10 ......................... 1

138 ........... JTAS10-138 .............Fiber Washe r ......................................................................................... 4

139 ........... JTAS10DX-139 ........Rear Trunnion ...................................................................................... 1

140 ........... JTAS10-140 .............Rear Bushing......................................................................................... 2

140-1 ........ JTAS10DX-140 ........Front Bushing ........................................................................................ 1

141 ........... JTAS10DX-141 ........Yoke ...................................................................................................... 1

142 ........... TS-0270011 .............Socket Set Screw ...............................................5/16-18x1/4 ................ 4

143 ........... JTAS10-143

144 ........... JTAS10DX-144 ........Shaft ..................................................................................................... 1

145 ........... JTAS10-145 .............Spring Pin...........................................................M5x30 ........................ 2

146 ........... JTAS10-146 .............Worm (Left thread) ................................................................................ 2

146-1 ........ JTAS10DX-146 ........Worm (Right thread) .............................................................................. 1

147 ........... JTAS10-147 .............Lock Pin ................................................................................................ 4

148 ........... JTAS10-148 .............Key.....................................................................M5x35 ........................ 2

..........Motor Pulley .......................................................................................... 1

.............Collar .................................................................................................... 2

23

Page 24

Trunnion & Motor Parts List

Index No. Part No. Description Size Qty

149 ........... TS-0208041 .............Socket Head Cap Screw .....................................5/16-18 x3/4” ............... 4

150 ........... JTAS10L-150N ........Dust Deflector........................................................................................ 1

151 ........... JTAS10L-151N ........Hose Clamp .......................................................................................... 2

152 ........... JTAS10DX-152 ........Front Trunnion ....................................................................................... 1

................. JTAS10D X-TA .........Trunnion Assembly (#113, 135, 136, #139 t hr ough #141 and # 152) ...... 1

153 ........... TS-0051021 .............Hex Cap Scr e w ..................................................5/16- 1 8 x5/8 ................ 2

154 ........... TS-0561021 .............Hex Nut ..............................................................5/16-18 ....................... 2

155 ........... JTAS10-155A ..........Lock Knob ............................................................................................. 2

156 ........... JTAS10-156 .............Fiber Washe r ......................................................................................... 2

157 ........... TS-0208061 .............Socket Head Cap Screw .....................................5/16-18 x1 ................... 2

158 ........... JTAS10DX-158 ........Front Trunnion Bracket .......................................................................... 1

159 ........... JTAS10-159 .............Hand Wheel Handle .............................................................................. 2

160 ........... JTAS10-160 .............Hand Wheel .......................................................................................... 2

161 ........... JTAS10-161 .............Shield Plate ........................................................................................... 1

162 ........... TS-0813022 .............Round Head Screw ............................................1/4-2 0x3/8 .................. 1

163 ........... JTAS10-163 .............Pointer................................................................................................... 1

164 ........... JTAS10-164 .............Pointer Bracket ...................................................................................... 1

165 ........... TS-081C102 ............Pan Head Screw ................................................#10-24x2 .................... 2

166 ........... JTAS10DX-166 ........Guide Block ........................................................................................... 1

167 ........... TS-0680041 .............Flat Washe r ........................................................3/8 .............................. 1

169 ........... JTAS10DX-169 ........Tilt Shaft ................................................................................................ 1

170 ........... JTAS10L-170 ...........Wrench.................................................................................................. 1

171 ........... JTAS10L-171 ...........Hose ..................................................................700mm ....................... 1

172 ........... JTAS10L-172 ...........Plate ...................................................................................................... 1

173 ........... TS-0208041 .............Socket Head Cap Screw .....................................5/16-18 x3/4 ................ 3

174 ........... JTAS10L-174

175 ........... TS-0680011 .............Flat Washer ........................................................3/16 ............................ 3

176 ........... TS-0720051 .............Lock Was h e r ......................................................#10 ............................. 3

177 ........... JTAS10L-177 ...........Hex Cap Bolt ......................................................#10-24x3/8 ................. 3

178 ........... JTAS10L-178 ...........Special Screw........................................................................................ 1

179 ........... JTAS10L-179A ........Arbor Lock Insert Assembly (#179-1through #179-5) ............................. 1

179-1 ........ JTAS10L-179-1 ........Arbor Lock Insert ................................................Ø8 .............................. 1

179-2 ........ JTAS10L-179-2 ........Spring.................................................................................................... 1

179-3 ........ JTAS10L-179-3 ........Insert Bracket ........................................................................................ 1

179-4 ........ TS-1502051 .............Socket Head Cap Screw .....................................M5 x 20 ...................... 2

179-5 ........ TS-1521041 .............Socket Set Screw ...............................................M4 x 10 ...................... 1

180 ........... JTAS10L-180 ...........Spring.................................................................................................... 1

181 ........... TS-0640071 .............Nylon Insert Lock Nut .........................................1/4-20 ......................... 3

182 ........... JTAS10L-182N ........Spacer ................................................................................................... 2

183 ........... JTAS10L-183 ...........Guide Bracket........................................................................................ 1

184 ........... TS-0245051 .............Flat Head Socket Screw .....................................1/4-20x1 ..................... 2

185 ........... JTAS10L-185 ...........Special Screw........................................................................................ 1

186 ........... JTAS10L-186 ...........Extension Support Plate ........................................................................ 1

187 ........... TS-1541021 .............Nylon Insert Lock Nut .........................................M6 .............................. 1

188 ........... JTAS10L-188 ...........Plate ...................................................................................................... 1

189 ........... JTAS10L-189A ........Riving Knife Extension Plate .................................................................. 1

190 ........... TS-1513021 .............Flat Head Socket Screw .....................................M5x12 ........................ 2

191 ........... JTAS10L-191 ...........Clamping Block ..................................................................................... 1

192 ........... JTAS10L-192 ...........Spring.................................................................................................... 1

193 ........... JTAS10L-193 ...........Clamping Block ..................................................................................... 1

194 ........... TS-1514031 .............Flat Head Socket Screw .....................................M6X20........................ 2

195 ........... JTAS10L-195 ...........Locking Handle ...................................................................................... 1

196 ........... TS-1541031 .............Nylon Insert Lock Nut .........................................M8 .............................. 1

197 ........... JTAS10L-197 ...........Spring Shim Ring................................................................................... 1

198 ........... JTAS10L-198 ...........C-Ring ................................................................S52 ............................ 1

...........Chip Plate.............................................................................................. 1

24

Page 25

Trunnion & Motor Assembly Drawing

25

Page 26

Blade Guard Parts and Assembly

Index No. Part No. Description Size Qty

1 ............... JTAS10L-301 ...........Riving Knife .......................................................................................... 1

................. JTAS10D X-BGA ......Blade Guard Assembly (Index #2 thru #16, #21, #22) ............................ 1

2 ............... PM2000-302 ............Bushing ................................................................................................. 2

3 ............... JTAS10L-303 ...........Blade Guard Body ................................................................................. 1

4 ............... JTAS10L-304 ...........Blade Guard Si de Shi eld........................................................................ 2

5 ............... PM2000-305 ............Linking P late .......................................................................................... 4

6 ............... TS-1550041 .............Flat Washer ........................................................M6 .............................. 8

7 ............... TS-1514021 .............Flat Head Socket Screw .....................................M6x16 ........................ 8

8 ............... PM2000-308 ............Front Shield ........................................................................................... 1

9 ............... PM2000-309 ............Bushing ................................................................................................. 1