Page 1

OWNER’S MANUAL

TM

XACTA-LIFT

and FENCE Assembly

Instructions

For models XLIFT-K or XLIFT-I

Model XLIFT-K shown

P.O. BOX 1349 Phone: 253-351-6000

JET

WMH Tool Gr oup Auburn, W A 98071- 1349 Fax: 1-800-274-6840

www.wmht ool group.com e-mail j et@ wmhtoolgroup.com M-708124 1/03

Page 2

This manual has been prepared for the owner and operat ors of a JET XACTA- Lift. Its purpose, aside from proper

tool operation, is to promote safety through the use of accepted correct operating and maintenance procedures.

Complet ely read the safety and maint enanc e instructions before operating or servicing the tool. To obtain m aximum

life and efficiency from your XACTA-Lif t, and to aid i n usi ng the tool safely, read thi s manual thoroughl y and follow

all instructions carefully.

Warranty & Service

WM H Tool Group warrants every product it sells. I f one of our tools needs servic e or r epair, one of our Authorized

Repair Stations located throughout the United States can give you quick service.

In most cases, any one of these W M H Tool Group Repair Stations can authorize warranty r epair, assist you in

obtaining parts, or perform routine maint enanc e and major repair on your JET, Per formax, Powermatic or Wilton

tools.

For the nam e of an Authorized Repair Station in y our area, call 1- 800- 274- 6848.

More Information

WM H Tool Group is consistently adding new products to the line. For compl ete, up-to-date produc t infor mation,

check with your local WMH Tool G r oup distributor or visit wmhtoolgroup. c om.

Limited Warranty

WM H Tool Group (including JET, P er formax, Powermatic and W ilton brands) makes every ef fort to assure that its

products meet hi gh quality and durability standards and warrants to the original retail consumer/purchaser of our

products that each product be free from defects in materials and workmanship as follows: 1 YEAR LIMITED

WARRANTY ON ALL PRO DUCTS UNLESS SPECIFIED OTHERWISE. This warranty does not apply to defects

due directly or indir ec tly to misuse, abuse, negligence or ac c idents, normal wear-and-tear, repair or alterations

outside our facilities, or to a lack of maintenance.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE, FROM THE

DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREI N, ANY IMPLIED

WARRANTIES OR MERCHANTI B I LI TY AND F I TNESS ARE EXCLUDED. SO ME STATES DO NOT ALLOW

LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATIO N MAY NOT

APPLY TO YOU. WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS

OR PROPERTY, OR FOR INCIDENTAL, CO NTI NGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING

FROM THE USE O F OUR PRODUCTS. S OME STATES DO NOT ALLOW THE EXCLUSIO N OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIO N OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned f or examination, postage prepaid, to an

Authorized Repai r Station designated by our office. Proof of purchase date and an explanation of the complaint

must accompany the merchandi se. If our i nspect ion discloses a defect , WM H Tool Group will either repair or

replace the pr oduc t, or refund the purchase price if we cannot readil y and quickly provide a repair or replacement, if

you are willing to accept a refund. WMH Tool Group will return repaired product or repl acement at our expense, but

if it is determined there i s no defect, or t hat the defect r esul ted from causes not within the scope of our warranty,

then the user must bear the cost of stori ng and r eturning the product. This warranty gives you specif ic legal r ights;

you may al so have other rights, which vary from state to state.

WM H Tool Group sells through distributors only. WMH Tool Group reserves the right to effect at any time, without

prior notice, those alter ations to parts, fittings, and accessory equipment which they may deem necessary for any

reason whatsoever.

2

Page 3

WARNING

Disconnect the table saw from t he power source before attempting any assembly or adjustment . Failur e

to comply may cause serious injury!

Contents of t he XACT A LIFT

(XLIFT-K) shipping carton:

1 XACTA LIFT ( XLIFT-K)

1 Adjustment Handle

1 Phenolic Insert 1-1/2"

1 Insert Wrench

1 5/32 Hex Wrench

1 1/8 Hex Wrench

10 1/4-28 Socket Set Screws

1 Starti ng Pin

1 Aluminum Fence B r ac k et

2 Aluminum Fence E xtensions

2 MDF Sub Fences

1 Hardware Package

2 Fence Clamping Knobs

2 Guard Clamping Knobs

1 Assembly Instructions

1 War r anty Registration Card

Contents of XACTA LIFT

(XLIFT-I) shipping carton:

1 XACTA LIFT

1 Adjustment Handle

1 Insert Wrench

1 Phenolic Insert 1-1/2"

1 5/32 Hex Wrench

1 1/8 Hex Wrench

10 1/4-28 Socket Set Screws

1 Starti ng Pin

1 Assembly Instructions

1 War r anty Registration Card

Mounting your Router to the XACTA LIFT

1. Turn your XACTA LIFT upside down on the table.

With the 5/32 hex wrench supplied, remove t he

four 1/4- 20 x 1 flat head cap screws (Fig. 1) and

remove the aluminum car r iage plate.

2. Remove the master r ing from the carriage plate, by

fir st removing the six 1/4-20 x 3/4 flat head

machine scr ews that secure t he c lamping br ac k ets

to the aluminum c ar r iage plate (F ig. 2).

3. Remove the sub-base and screws that attach the

sub-base to your router. NOTE: If your sub-base

cannot be removed, just remove the screws that

will be used to attach your router to the mounting

ring.

4. Lay the master r ing on a flat surface with t he

countersunk holes and the engraving facing

upwards and with the engraved "T" to the top

and the engraved "B" to t he bottom.

Tools requir ed to mount your router to the

XACTA LIFT ( XLIFT-K), or XACT A LIFT

(XLIFT-I):

1 Screwdriver

Tools requir ed for adjustment:

1 7/16" Open End Wrench

3

Page 4

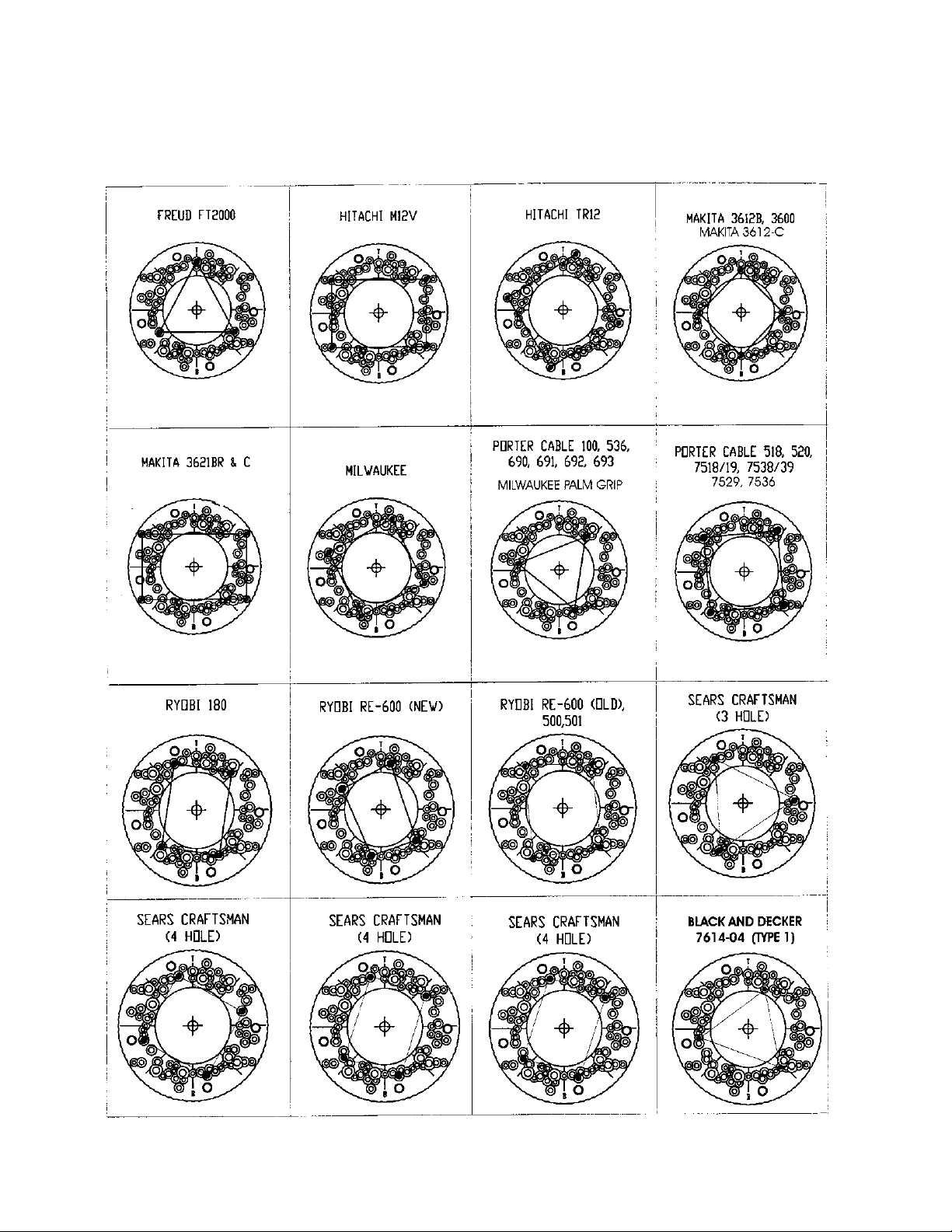

5. Pages 13-14 show a series of drawings of the

master ring with the holes shaded solid to match

may differ ent routers. Locate your r outer and then

locate the pr oper holes in the m aster r ing using the

drawing as an aid. With a felt tip marker or penc il,

mark a line on the mounting plate for each hole

that you will be using for your router.

6. With the holes marked on the master r ing, place

the mounting plate on the base of your router and

rotate it to line up the correct holes i n your router.

Don't worry about handl e location at this point as

that can be set when the m ounting plate is reattached to t he aluminum carriage plate.

7. The master r ing is 1/4" thi ck and may prevent your

screws that come with your r outer from engaging

your router sufficiently. If this is the case, source

longer f lat head screws from y our local hardware or

automotive par ts supplier. With t he screws you

removed from your router (or the longer screws

which you acquired) attach the mounting plate to

your router (Fig. 3). Lightly secure the screws at

first to ensure that the master ring will locate in the

center of y our router, and then t ighten securely.

8. You must now re-att ac h the mounting r ing to the

aluminum carriage plate. Wit h the carriage plate

upside down in front of you, slide the master r ing

with router at tached into plac e to engage the

recess of the carr iage plate (Fig. 4).

At this point, take note of the handle location and

on/off switch to ensure they are in the best locat ion

for use. You can rotate the router at this point t o

have it in the best possibl e location for use. Once

satisfied with the router location, place one of the

clamping brackets int o the correct l oc ation and

feed one of the 1/4-20 x 3/4" flat head screws from

under the aluminum car r iage plate and thread into

the clamping bracket. Repeat this step f or the other

five cl amping bracket s.

9. Once the brackets are in place, securely tight en the

six 1/4-20 x 3/4" screws.

4

Page 5

10. Using the 1/4-20 x 1" fl at head screws (removed in

step 1), re-i nstall the carriage to the XACTA LIFT

(Fig. 5). NOTE: Use the socket head cap screws as

locati ng pins for easier installation of the car r iage.

Your router should now be installed onto the XACTA

LIFT.

NOTE: It is unlikely that your router will not fit one of the

hole patterns on the master ring. However, if it will not

match, new holes will have to be drilled. Proceed as

follows:

1. Remove the master r ing from the carriage plate

(see step #2 above) and place it engraved side

down.

2. Center your rout er ' s sub-base onto the master

ring, and rotate the sub-base until there is

minimal interferenc e with any of the pr e- dr illed

holes in the ring.

3. Clamp t he sub-base to the master ring and use

the sub-base holes as a template to drill the

holes into the master ring. Use a bi t slightly

larger than y our sub-base screws.

4. Remove the clamps and fli p the master ri ng over

so the engraved side with the "T" and " B " is now

face up.

5. Countersink the holes to suit the router ' s flat

head screws. (NOTE: If the router y ou are

mounti ng does not have flat head screws holding

the sub-base, then source f lat head screws that

match at a local suppli er .)

6. Continue the assembly process according to t he

instructions under "Mounting Your Router..."

LEVELING THE XACTA LIFT

Included wit h y our XACT A LIFT are ten 1/4-28 set screws

and 1/8 hex wrench. These set screws can be used to

level your XACTA LI FT to the table; thread the set

screws into the ten tapped holes in your LIFT from above

using the 1/8 hex wrench pr ovided (Fig. 6).

5

Page 6

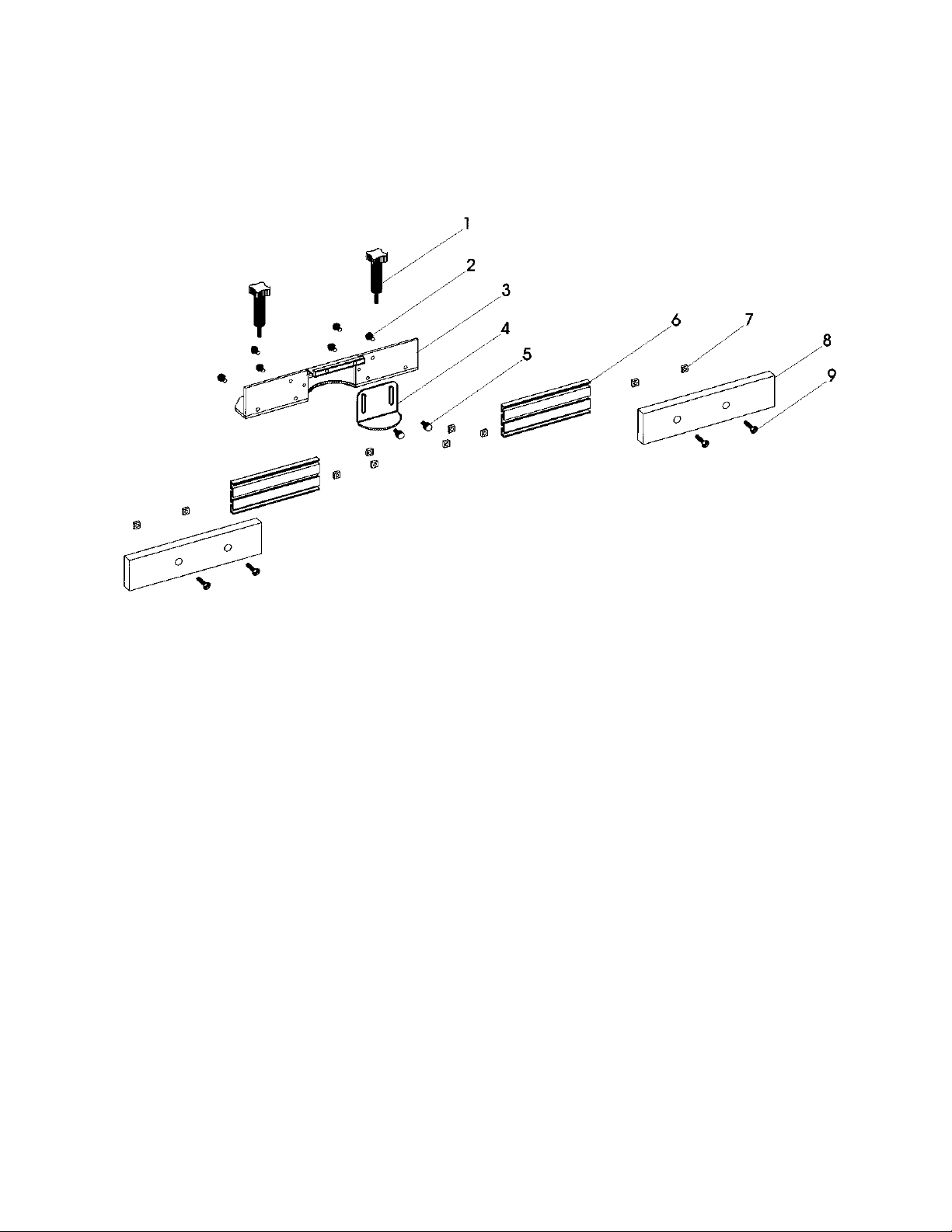

MOUNTING THE DELUXE FENCE

ASSEMBLY

1. Take the three button head Phillips screws and put

one through each hole on t he vertical side of the

aluminum f enc e support ( Fig. 7). There are three

holes on each side of the fence support; do one

side at a time. Start the square nuts on each screw.

Do not tight en, leave loose for i nstallati on.

2. Take one fenc e extension assembly and install

onto the f enc e support (Fig. 8). The holes are

staggered for easy installation.

3. Slide assembly along the fence support until it

stops at the fence guard bridge (Fi g. 9). Securel y

fasten the screws.

4. Take the remaining thr ee button head Phillips

screw and perform steps 1, 2 and 3 on the other

side of the fence support.

5. Slide t he MDF Subfences and the square nut s

attached into the T-Sl ots of the f enc e extension

(Fig. 10).

6

Page 7

NOTE: T he MDF Subfences can be mounted either

on the left or right but the screws should be closest

to the center of the fence once installed (Fig. 11) .

The sub-fence is adjusted by loosening the two flat

head Phillips screws on the front of each MDF

board. Once loosened, slide the board to the

desired opening. S ec ur ely tighten the flat head

Phillips screws.

6. Mount the adjustable fence guard to the bridge on

the fence support wi th the two fence guard knobs

(Fig. 12).

7. Mount the assembl ed fence to the main plate of the

XACTA LIFT wi th one fence knob i n eac h of the

threaded holes in the top corners of t he plate (Fi g.

13).

8. The v ac uum attachment is sized to acc ept

standard 2-1/4" vacuum hose or a dust collector

adaptor JET Part #JW1000 (see your local J E T

dealer f or adaptors). To install hose on the vacuum

attachm ent, press nozzle down slightly on the

flexible ar ms and piv ot inward (Fig. 14) .

7

Page 8

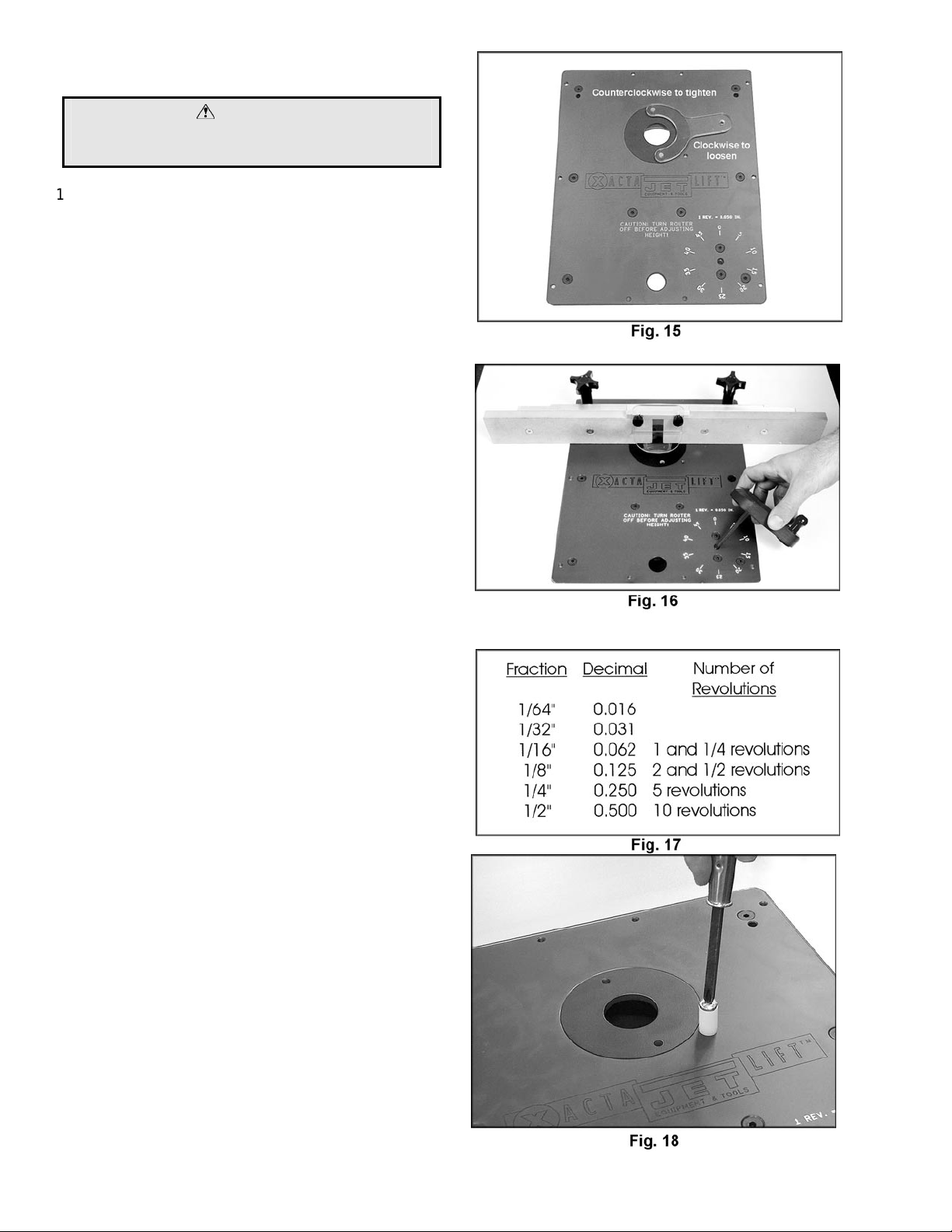

USING YOUR XACTA LIFT

CAUTION

Always turn router off and disconnect router from

power source before m ak ing any height adj ustment.

1. Depending on the size of the router bit you are

using it may be desirable to use an i nsert ring to

reduce the size of the opening. To install the insert

ring place the insert int o the opening of t he main

plate, t hen wi th the insert wrench turn

counterclockwise to tighten (then remove the insert

wrench). See Fi g. 15.

2. With the router bit installed, place t he adjustment

handle into ac cess port in the main plate (Fig. 16).

3. Bring the bit flush to the table top.

4. To raise your router, turn the adjustment handl e

clockwise; t o lower turn the adjustment handle

counterclockwise. Keep in mind that one complete

revolution of the adjustm ent handle equals 0.050"

or 1/20". See Fig. 17.

5. Make the desired height adjustment. W hen y our

adjustment is complet e, remove the adjustabl e

handle.

6. A starting pin is prov ided to assist in cert ain

freehand operat ions when the fence is not used.

Thread the pin into the router plate with a

screwdriver (Fig. 18).

8

Page 9

MODIFICATION FOR HEIGHT

ADJUSTMENT TENSION

WARNING

Disconnet router from power source!

The height adjustment tensi on is set at the factory;

however, if you find the tension is too loose and the

router's height adjustment moves when routing, then

modification is as follows:

1. Turn your XACTA LIFT upside down on a table

(Fig. 19).

2. With a 7/16 open end wrench, l oosen the 1/4-20

hex nut (F ig. 20). Then bac k out the antibacklash set scew with the 5/32 hex wrench.

3. Rotate the brass tensioning collar so it tightens

against the rubber washer (Fig. 21). NOTE : A

drop of oi l on the rubber washer eases the

rotation of the brass ring agai nst the washer.

4. Make certain when you have f inished tightening

the coll ar that one of the slots on the coll ar is

centered to the c arriage nut. T his ensures that

the anti-backlash screw will tighten into the slot

of the brass tensioning collar. See Fig. 21.

5. Tighten t he 1/4-20 hex nut (that you loosened in

step 2).

9

Page 10

PARTS LIST

XACTA LIFT DELUXE FENCE ASSEMBLY

Index Part

No. No. Description Size Qty.

1 ......... XLIFT-M0026................Fence Clamping Knobs...................... ................................................ 2

2 ......... XLIFT-E0040................Button Head Screw............................1/4-20 x 1/2"............................ 6

3 ......... XLIFT-E0032................Aluminum Fence Bracket...................2-1/2" x 2-1/2" x 3/16" x 14"..... 1

4 ......... XLIFT-M0039................ Fence Guard ...................................... 1/8 Polycarbonate.................... 1

5 ......... XLIFT-M0028................ Guard Clamping Knob........................ ................................................ 2

6 ......... XLIFT-E0030................Aluminum Fence Extension................7/16" x 2-1/2" x 7"....................2

7 ......... XLIFT-F0028................ Square Nut......................................... 1/4-20.................................... 10

8 ......... XLIFT-M0040................ MDF Sub Fences...............................3/4" x 2-1/2" x 10-3/4" .............. 2

9 ......... XLIFT-F0017 ................ Fl at Head Screws............................... 1/4-20 x 1"............................... 4

The specifications i n this manual ar e given as general information and are not binding. JET , WM H Tool Group

reserves the r ight to ef fect, at any time and wit hout prior noti ce, changes or alterat ions to parts,

fittings, and accessory equipment deemed necessary for any reason whatsoever.

10

Page 11

PARTS BREAKDOWN

JET XACTA LIFT

11

Page 12

PARTS LIST

JET XACTA LIFT

Index Part

No. No. Description Size Qty.

1 ......... XLIFT-F0001 ................ Fl at Head Cap Screw ..............................1/4 x 3/4............................ 20

2 ......... XLIFT-P0003-1.............Aluminum Main Plate..............................14-3/4 x 11-3/4 x 1/4........... 1

3 ......... XLIFT-S0001-1.............Steel Side Supports ................................1/2 x 1/2 x 13-1/4................2

4 ......... XLIFT-E0001-1.............Aluminum Shaft Mounting B lock .............1 x 1-1/2 x 10.1 ................... 1

5 ......... XLIFT-F0002 ................ Socket Head Cap Screw .........................1-1/4 x 7/8...........................4

6 ......... XLIFT-M0001................ Steel Drive Pulley Spindle....................... ........................................... 1

7 ......... XLIFT-M0006................ Bronze Flange Bearing ............................3/4 x 7/8 x 3/4.....................1

8 ......... XLIFT-E0001-2.............Drive Pulley Mounting Bl ock ...................1 x 1-1/2 x 2........................ 1

9 ......... XLIFT-M0011................ Rubber T iming B elt.................................130 XL x 3/8........................ 1

10 ....... XLIFT-M0005................Drive Pulley (Delrin)................................20 XL x 3/8..........................1

11 ....... XLIFT-M0009................Bronze Sleeve Bearing...........................3/4 x 7/8 x 3/4..................... 4

12 ....... XLIFT-F0005................Flat Head Cap Screw..............................1/4 x 1................................. 4

13 ....... XLIFT-E0001-3.............Aluminum Bearing Mounts......................1 x 1-1/2 x 4........................ 2

14 ....... XLIFT-S0002-1.............Steel Carriage Nut...................................3/4 x 1 x 1-1/2..................... 1

15 ....... XLIFT-F0003................Nylon Insert Lock Nut..............................1/2-20................................. 1

16 ....... XLIFT-E0002-1.............Aluminum Carriage Bracket ....................3/8 x 3 x 8-1/2..................... 1

17 ....... XLIFT-F0006................Half Dog Pt. Set Screw (Anti-Backlash)...1/4-20 x 1............................1

18 ....... XLIFT-M0012................Rubber W asher.......................................1/2 x 1-1/16 x .093.............. 1

19 ....... XLIFT-M0003................Brass Anti-Backlash Nut..........................1 x .450 x 1/2-20................. 1

20 ....... XLIFT-M0004................Threaded Pulley (Delrin) .........................20 XL w/ 1/2-20................... 1

21 ....... XLIFT-F0004................Socket Head Cap S c r ew .........................1/4 x 1................................. 4

22 ....... XLIFT-S0001-2.............Carriage Mounting Block.........................1/2 x 1/2 x 3 Steel............... 2

23 ....... XLIFT-E0002-2.............Aluminum Carriage Gusset .....................3/8 x 2-1/2 x 3..................... 2

24 ....... XLIFT-P0002................Aluminum Carriage Plate........................7.9 x 8-1/2 x 3/16................ 1

25 ....... XLIFT-M0007................Bronze Thrust Washer............................9/16 x 1-1/4 x 1/16 thk ........ 1

26 ....... XLIFT-M0042................Carriage Lead Screw............................... ........................................... 1

27 ....... XLIFT-M0008................Bronze Flange Bearing............................1/2 x 5/8 x 3/4 Lg................ 1

28 ....... XLIFT-M0017-1............Phenolic Insert Ring................................1-1/2 hole opening .............. 1

29 ....... XLIFT-M0016-1............Insert Wrench ......................................... ........................................... 1

30 ....... XLIFT-M0018................Lift Handle (Arbor on)............................... ........................................... 1

31 ....... XLIFT-M0015................Hex Key..................................................1/4 ...................................... 1

32 ....... XLIFT-F0007................Socket Head Cap S c r ew .........................1/4 x 1-1/4...........................1

33 ....... XLIFT-M0041-1............Phenolic Lif t Handle Knob.......................1/4" Cored Hol e................... 1

34 ....... XLIFT-P0009................Master Ring............................................. ........................................... 1

35 ....... XLIFT-P0011................Master Ring Clamp ................................. ........................................... 6

36 ....... XLIFT-F0008................Oval Point Socket Set Screw..................1/4-28 x 1/4....................... 10

37 ....... XLIFT-P0012................Starter Pin............................................... ........................................... 1

12

Page 13

ROUTER HOLE PATTERNS

The following is a series of hole patterns f or varous routers as noted i n S tep 5 of "Mounting Your Router." Loc ate the

name and correc t model number of your r outer and then locate the holes in the m ast er r ing. With a f elt tip marker or

pencil mark a li ne on the mounting plate for eac h hole you will be using for your router.

13

Page 14

ROUTER HOLE PATTERNS (continued)

14

Loading...

Loading...