Page 1

Operating Instructions and Parts Manual

JHS Series Hydraulic Stackers

Models JHS-1100 and JHS-2200

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60124 Part No. M-140520

Ph.: 800-274-6848 Revision B 1/07

www.wmhtoolgroup.com Copyright © WMH Tool Group

Model JHS-2200 s hown

Page 2

WARRANTY AND SERVICE

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of

these WMH Tool Group Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check

with your local WMH Tool Group distributor, or visit jettools.com.

WARRANTY

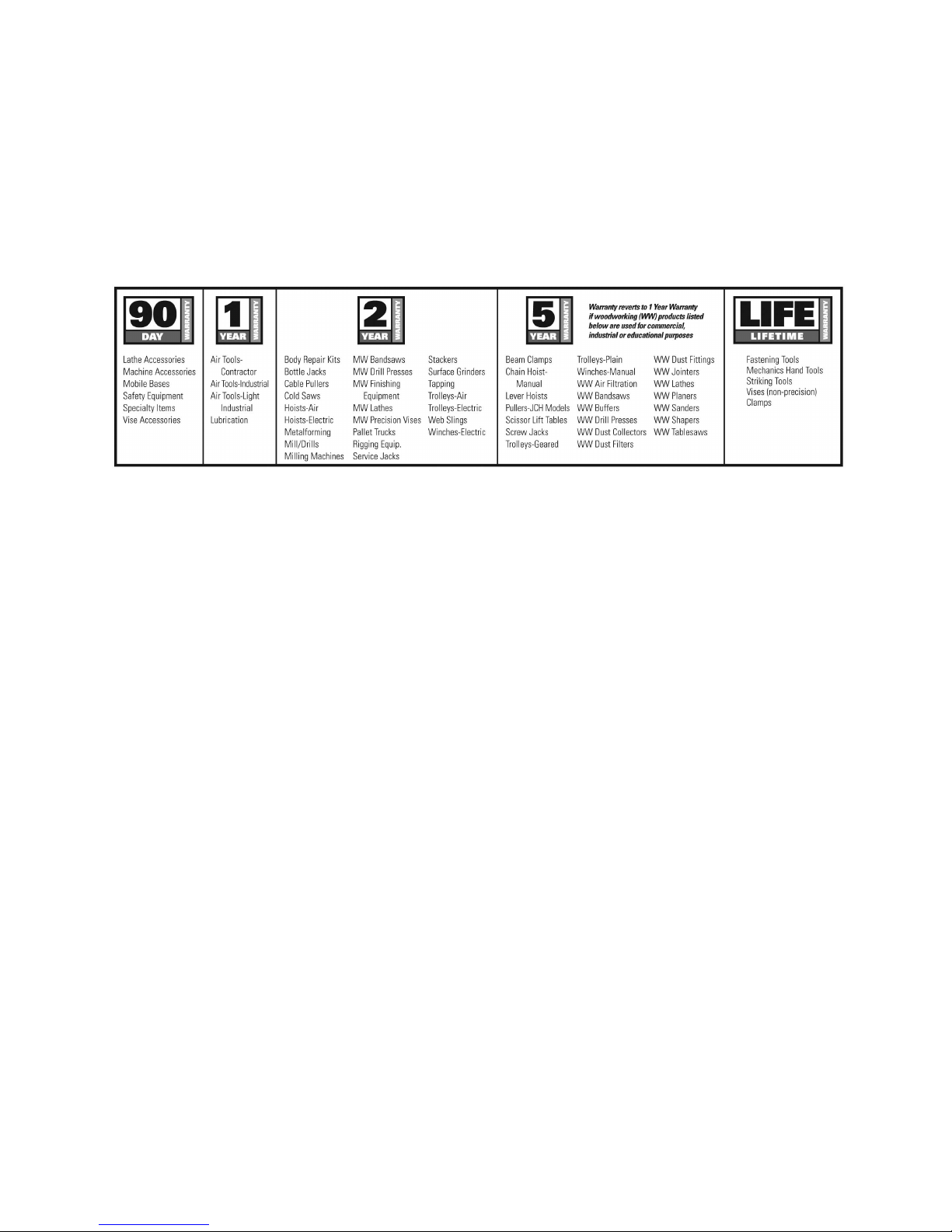

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR

EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND

FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY,

OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE

OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information

and are not binding. Members of WMH Tool Group reserve the right to effect at any time, without prior notice, those

alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

® branded products are not sold in Canada by WMH Tool Group.

JET

® tools. For the name of an Authorized Service Center in

2

Page 3

• Read and understand all warnings and operating instructions before attempting to use the winch

stacker.

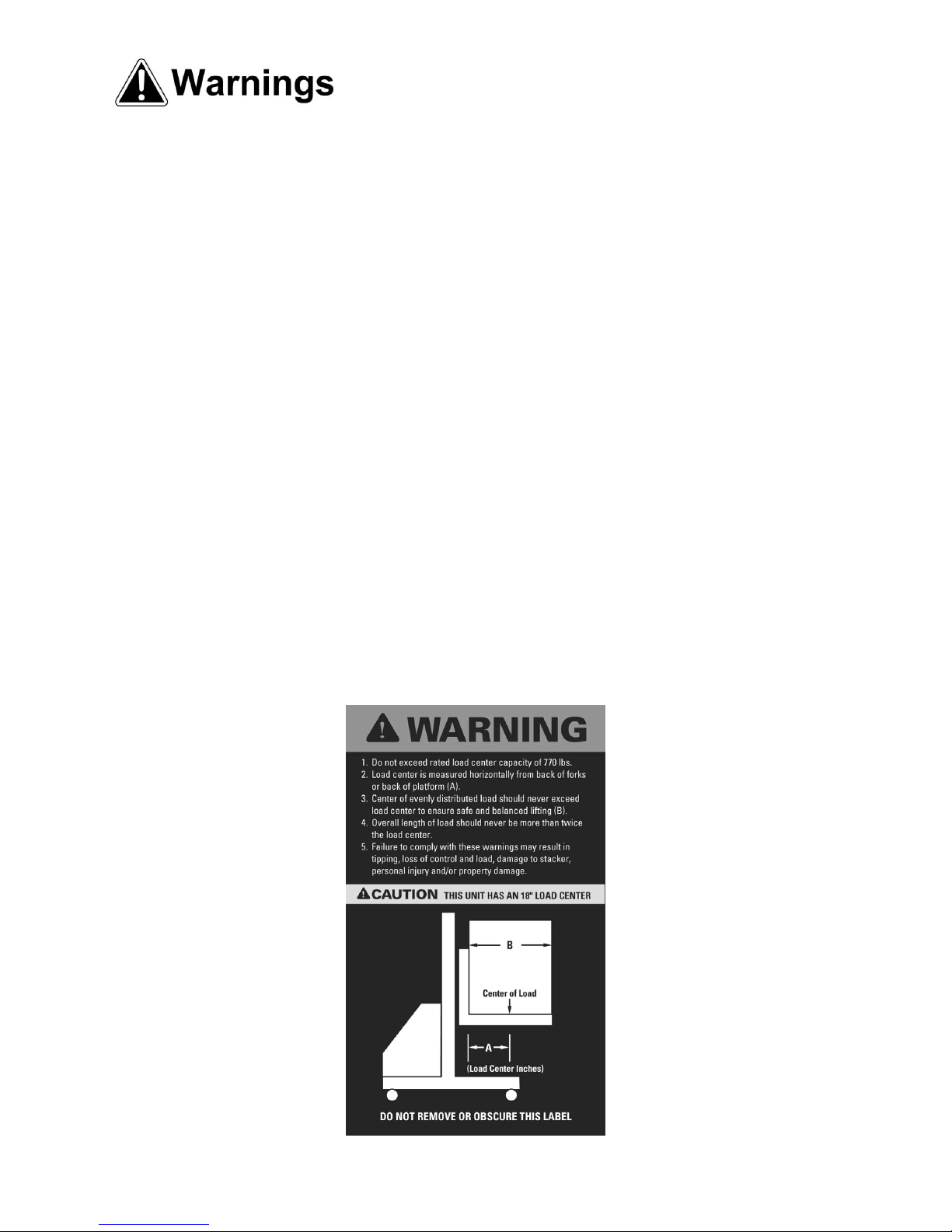

• Do not exceed rated load or load center capacity. Excessive load can cause tipping or loss of control.

• Do not exceed load center capacity of stacker. Load center is measured horizontally from back of forks

or platform. Overall length of load must never be more than twice the load center capacity.

• Do not allow anyone to sit or ride on fork, or enter area beneath forks.

• Center of evenly distributed load should never exceed load center to ensure safe and balanced lifting.

• Always keep fingers, hands and feet clear of forks and mast when lifting or lowering load.

• Always center, stabilize, and secure load before raising forks or moving the stacker.

• Do not allow more than half of load to extend beyond load center of stacker.

• Always keep load close to mast.

• Do not transport load in the raised position.

• Use on level, smooth, finished floors only.

• Do not use on uneven or sloping floors.

• Always allow load to descend in a controlled, cautious manner.

• Always use genuine factory replacement parts only.

• Failure to comply with all of these warnings may result in tipping, loss of control and load, damage to

hydraulic stacker, personal injury and/or property damage.

3

Page 4

Table of Contents

Table of Contents.................................................................................................................................... 4

Specifications .......................................................................................................................................... 4

Introduction .............................................................................................................................................4

Stacker Safety Precautions......................................................................................................................5

Assembly & Adjustment...........................................................................................................................5

Operation................................................................................................................................................ 5

Troubleshooting....................................................................................................................................... 6

Replacement Parts.................................................................................................................................. 6

HS-1100 Mast Assembly ...................................................................................................................... 7

Parts List: JHS-1100 Mast Assembly................................................................................................... 8

JHS-2200 Mast Assembly .................................................................................................................. 10

Parts List: JHS-2200 Mast Assembly................................................................................................. 11

JHS-1100 and JHS-2200 Pump Assembly .........................................................................................13

Parts List: JHS-1100 and JHS-2200 Pump Assembly ........................................................................ 14

Specifications

Model Number.............................................................JHS-1100.............................................. JHS-2200

Stock Number..................................................................140520...................................................140521

Load Capacity (lbs).............................................................1,100..................................................... 2,200

Pallet Capacity (L x W in)................................................. 48 x 40...................................................48 x 40

Load Center (in) ......................................................................20.......................................................... 20

Maximum Lifting Height (in) .....................................................59.......................................................... 59

Minimum Fork Height (in).....................................................2-3/4...................................................... 2-3/4

Turning Radius (degrees/in)............................................ 360 / 50................................................. 360 / 50

Handle Force Req'd at Capacity (lbs).......................................31.......................................................... 62

Handle Strokes to Reach Maximum

Height (no load/max. load) ........................................... 45 / 75.................................................... 45 /75

Fork Dimensions (L x W x H in)...................41-3/4 x 4-3/8 x 2-3/8............................. 41-3/4 x 5-1/4 x 2-1/4

Overall Fork Width Min/Max (in)..................................11 / 27-1/2............................................. 11 / 27-1/2

Outrigger Size (W x H in)......................................... 2-3/8 x 2-3/8................................................ 4 x 3-1/2

Outrigger Inside Width Min/Max (in) ......................34-1/4 / 50-1/2....................................... 34-1/4 / 50-1/2

Outrigger Outside Width Min/Max (in) ...................38-7/8 / 55-5/8............................................. 42 / 58-3/4

Load Wheel Size (OD x W in) .............................. 5 x 3-1/4 Nylon.......................................5 x 3-1/4 Nylon

Caster Size (OD x W in)...............................7 x 2 Poly/Aluminum.............................. 7 x 2 Poly/Aluminum

Overall Dimensions (L x W x H in) ......................62 x 38-7/8 x 78...........................................62 x 42 x 78

Net Weight (lbs).....................................................................396........................................................ 548

Shipping Weight (lbs).............................................................416........................................................ 568

The above specifications were current at the time this manual was published, but because of our policy of

continuous improvement, WMH Tool Group reserves the right to change specifications at any time and

without prior notice, without incurring obligations.

Introduction

Congratulations on your purchase of a JET Hydraulic Stacker.

Your hydraulic stacker is designed to prevent lifting injuries by providing a stable, mobile lifting device for

moderate to heavy loads. It is ideal for use in confined areas or narrow aisles.

Your hydraulic stacker is simple and easy to operate with your choice of a hydraulic operated foot pedal

or pallet truck style handle for additional leverage. Durable smooth rolling nylon load wheels and large

diameter swivel casters make the hydraulic stacker easy to maneuver. Caster brakes are standard to

prevent movement. It features a hydraulic pump with automatic overload protection, heavy-duty welded

steel frame, durable powder coat finish, and with regular maintenance will provide years of dependable

service.

An optional steel platform is available to convert your hydraulic stacker to a mobile work station.

4

Page 5

Stacker Safety Precautions

1. Read and understand manual completely

before operation.

2. Do not exceed rated load center or weight

capacity. Load center is measured

horizontally from the back of forks.

JHS-1100; #18 for JHS-2200). Align holes in

legs with holes in mast to enable legs to be

equal distance from mast. Legs should slide

into tube openings easily without force.

7. Fasten legs with four hex cap screws, four

lock washers and four flat washers (#26 thru

28 for JHS-1100; #25 thru 27 for JHS-2200).

Tighten hex nuts firmly.

3. To ensure safe and balanced lifting, center

of balanced load should not be positioned

past the load center.

4. Never allow anyone to sit or ride on fork, or

to remain beneath fork.

5. Always center, balance and secure load

before raising or moving stacker.

6. Do not transport loads in the raised position.

7. Use only on smooth finished floors; do not

use on sloping floors.

8. Always keep hands and feet clear of fork

when lifting or lowering load.

9. Pull pump release lever slowly to allow load

to descend in a controlled manner.

10. Failure to comply with the above warnings

may result in tipping, loss of control,

personal injury and/or property damage.

Assembly & Adjustment

1. Remove all packing material from the

stacker.

Do not exceed rated load and

load center capacities. Excessive load can

cause tipping or loss of control. Use on

finished, smooth and level floors only; do

not use on slopes.

Operation

1. Insert both forks evenly and completely

under the load. Load must be distributed

equally on both forks and centered toward

the mast. Do not allow more than half the

load to extend beyond load center. Do not

lift load with fork tips only and do not lift

unstable or loose load.

2. Press the foot pedal or push the pump

handle downwards to raise the forks by one

stroke. Continue to pump the pedal, or

handle, until desired height is reached. Do

not exceed maximum lifting height.

3. To lower the forks, pull the pump release

lever on the handle slowly to allow the load

to lower in a cautious and controlled

manner.

2. To assemble forks, unscrew socket head flat

screw (#4 page 7, for JHS-1100; #5 page 10

for JHS-2200). Tap fork shaft out (#5 for

JHS-1100; #6 for JHS-2200). Forks to be

assembled must come from the same crate

as the mast.

3. Align holes in forks (#1) with holes in

carriage (#3 for JHS-1100; #4 for JHS-2200)

and tap fork shaft through carriage and fork

holes.

4. Be sure assembled forks are even and

parallel. Reinstall socket head flat screw in

carriage to hold fork shaft in place.

5. To assemble outrigger legs, check to be

sure legs to be assembled come from the

same crate as the mast.

6. Insert outrigger legs (#29 & #31 for JHS1100; #24A and #24B for JHS-2200) into

tube openings in bottom of mast (#25 for

4. To move stacker with load, lower forks

carefully. Use both hands with a firm grip to

push and steer the stacker on level, smooth

finished floors only. Keep all people clear

from stacker while lifting, lowering and

moving load.

CAUTION: When not in use, do not allow heavy

loads to remain on the forks for an extended

period of time. Always lower forks when not in

use.

For optimum performance, the drive chain (#35

on model JHS-1100, #37 on model JHS-2200)

should be lubricated with chain oil regularly.

5

Page 6

Troubleshooting

Trouble Probable Cause Remedy

Fork will not lift to

maximum height.

Forks will not rise.

Forks can not be

lowered.

Hydraulic oil level is low. Fill with hydraulic oil.

Oil level is low, or oil is too viscous. Fill with oil, or change oil.

Oil has impurities. Change oil.

Hex nut (#71 on JHS-1100, #62 on

JHS-2200) is too high, keeping the

pumping valve open.

Air in hydraulic pump.

The lifting piston is deformed,

resulting from overloading.

The fork was kept in high position for

extended time resulting in rusting and

jamming of the exposed piston rod.

Adjustment nut (#71 on JHS-1100,

#62 on JHS-2200) not in correct

position.

Adjust hex nut properly.

Release air from the system by

pulling pump release handle, then

pumping handle up and down several

times.

Replace the piston.

Keep fork in lowest position when not

in use. Keep piston well lubricated.

Adjust nut properly.

Fork frame and roller sprocket are

jammed.

Sealing parts worn or damaged. Replace parts.

Hydraulic fluid leak.

Some parts cracked or worn. Replace parts.

Release valve unable to close

properly due to impurities in hydraulic

oil.

Hydraulic system cracked or bored. Inspect and replace the waste parts.

The forks descend

without the release

valve working.

Air in the oil.

Seal parts worn or damaged in

hydraulic pump.

Adjustment nut (#71 on JHS-1100,

#62 on JHS-2200) is not in correct

position.

Replacement Parts

Correct jam; replace bearing if

necessary.

Replace with new oil.

Release air from oil by pulling pump

release handle, then pumping handle

up and down several times.

Replace worn or damaged parts.

Adjust nut properly.

Replacement parts are listed on the following pages. To order parts or reach our service department, call

1-800-274-6848 between 7:30 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you call will allow us to serve you quickly and

accurately.

6

Page 7

JHS-1100 Mast Assembly

7

Page 8

Parts List: JHS-1100 Mast Assembly

Index No. Part No. Description Size Qty

1............... JHS1100-1...............Fork....................................................................................................... 2

1A ............ 140522 ....................Optional Steel Platform.......................................28-1/4" x 41-1/2"......... 1

2............... JHS1100-2...............Adjusting Screw..................................................................................... 2

3............... JHS1100-3...............Mounting Plate ...................................................................................... 1

4............... JHS1100-4...............Dog Point Socket Set Screw...............................M6 x 25 ...................... 1

5............... JHS1100-5...............Fork Shaft.............................................................................................. 1

6............... JHS1100-6...............Guide Roller .......................................................................................... 4

7............... JHS1100-7...............Bushing..............................................................10 x 8 x 8 ................... 4

8............... JHS1100-8...............Guide Roller Axle...................................................................................4

9............... BB-6005ZZ ..............Ball Bearing........................................................6005ZZ....................... 4

10............. JHS1100-10.............Snap Ring ..........................................................Ø 25 ........................... 6

11............. JHS1100-11.............Snap Ring ..........................................................Ø 47 ........................... 6

12............. JHS1100-12.............Rolling Axle Cover................................................................................. 4

13............. JHS1100-13A ..........Rubber Grip Handle............................................................................... 2

14............. TS-1551041.............Lock Washer ......................................................M6............................ 16

15............. TS-1503021.............Socket Head Cap Screw.....................................M6 x 10 .................... 16

17............. JHS1100-17.............Snap Ring ..........................................................Ø 20 ........................... 8

18............. JHS1100-18.............Dust Cap............................................................................................... 4

19............. BB-6204ZZ ..............Ball Bearing........................................................6204ZZ....................... 8

20............. JHS1100-20.............Front Wheel........................................................................................... 2

21............. JHS1100-21.............Front Wheel Axle ................................................................................... 2

22............. JHS1100-22.............Bar ........................................................................................................ 1

23............. TS-1504031.............Socket Head Cap Screw.....................................M8 x 16 ...................... 2

24............. TS-1551061.............Lock Washer ......................................................M8.............................. 4

25............. JHS1100-25.............Mast ...................................................................................................... 1

26............. TS-1540081.............Hex Nut..............................................................M12............................ 4

27............. TS-1551081.............Lock Washer ......................................................M12............................ 4

28............. TS-1492101.............Hex Cap Screw ..................................................M12 x 100 .................. 4

29............. JHS1100-29.............Left Outrigger Leg.................................................................................. 1

30............. JHS1100-30.............Steel Fence........................................................................................... 1

31............. JHS1100-31.............Right Outrigger Leg ............................................................................... 1

32............. TS-1550031.............Flat Washer........................................................M5.............................. 6

33............. TS-1551031.............Lock Washer ......................................................M5.............................. 6

34............. TS-1533032.............Phillips Pan Head Machine Screw ......................M5 x 10 ...................... 6

35............. JHS1100-35.............Chain .................................................................12A-1 x 58.................. 2

36............. JHS1100-36.............Link Pin ................................................................................................. 2

37............. JHS1100-37.............Split Pin..............................................................Ø 2 x 16...................... 4

38............. JHS1100-38.............Link Pin ................................................................................................. 2

39............. TS-2310181.............Hex Nut..............................................................M18............................ 4

40............. JHS1100-40.............Split Pin..............................................................Ø 4 x 30...................... 2

41............. JHS1100-41.............Link Pin ................................................................................................. 2

42............. JHS1100-42.............Foot Pedal............................................................................................. 1

43............. JHS1100-43.............Spring Pin...........................................................Ø 8 x 30...................... 2

44............. JHS1100-44.............Spring Pin...........................................................Ø 3 x 30...................... 2

45............. JHS1100-45.............Roller Pin .............................................................................................. 1

46............. JHS1100-46.............Bushing..............................................................17 x 15 x 15................ 1

47............. JHS1100-47.............Roller .................................................................................................... 1

48............. JHS1100-48.............Snap Ring ..........................................................Ø 12 ........................... 3

49............. JHS1100-49.............Bushing..............................................................18 x 16 x 8.................. 6

50............. JHS1100-50.............Foot Lever............................................................................................. 1

51............. JHS1100-51.............Roller Axle............................................................................................. 1

52............. JHS1100-52.............Spring Pin...........................................................Ø 4 x 22...................... 2

53............. JHS1100-53.............Roller .................................................................................................... 1

54............. JHS1100-54.............Lever..................................................................................................... 1

55............. JHS1100-55.............Spring Pin...........................................................Ø 6 x 32...................... 1

56............. JHS1100-56.............Handle................................................................................................... 1

8

Page 9

57............. JHS1100-57.............Blocking Spring ..................................................................................... 1

58............. JHS1100-58.............Spring Pin...........................................................Ø 4 x 30...................... 2

59............. JHS1100-59.............Chain Wheel.......................................................................................... 2

60............. JHS1100-60.............Chain Wheel Bracket ............................................................................. 1

61............. JHS1100-61.............Spring Pin...........................................................Ø 8 x 50...................... 1

62............. TS-1503051.............Socket Head Cap Screw.....................................M6 x 20 ...................... 1

63............. JHS1100-63.............Shaft ..................................................................................................... 1

64A .......... JHS1100-64A ..........Large Handle Pin................................................................................... 1

64B .......... JHS1100-64B ..........Small Handle Pin................................................................................... 1

65............. JHS1100-65.............Roller .................................................................................................... 1

66............. JHS1100-66.............Shaft ..................................................................................................... 1

67............. TS-1490061.............Hex Cap Screw ..................................................M8 x 35 ...................... 2

68............. TS-1540061.............Hex Nut..............................................................M8.............................. 2

69............. JHS1100-69.............Spring.................................................................................................... 1

70............. JHS1100-70.............Release Rod ......................................................................................... 1

70A .......... JHS1100-70A ..........Chain .................................................................05B-1 x 15.................. 1

71............. JHS1100-71.............V-Nut..................................................................M6.............................. 1

72............. JHS1100-72.............Wheel Cover .........................................................................................2

73............. JHS1100-73.............Snap Ring ..........................................................Ø 52 ........................... 2

74............. BB-7205AC..............Ball Bearing........................................................7205AC ...................... 2

75............. JHS1100-75.............Foot Brake.............................................................................................2

76............. JHS1100-76.............Stop Lug................................................................................................ 2

77............. TS-1550061.............Flat Washer........................................................M8.............................. 2

78............. JHS1100-78.............V-Nut..................................................................M8.............................. 2

79............. JHS1100-79.............Hex Head Bolt ....................................................M10 x 25 .................... 4

80............. TS-1551071.............Lock Washer ......................................................M10............................ 4

81............. TS-1550071.............Flat Washer........................................................M10............................ 4

82............. JHS1100-82.............Dust Cap............................................................................................... 4

83............. JHS1100-83.............Wheel Axle ............................................................................................ 2

84............. BB-6205ZZ ..............Ball Bearing........................................................6205ZZ....................... 4

85............. JHS1100-85.............Wheel.................................................................180 x 25 x 50.............. 2

85A .......... JHS1100-85A ..........Hydraulic Pump Assembly..................................................................... 1

................. PT2748J-JET...........JET Logo Label ..................................................................................... 2

................. JHS1100-ID .............ID & Warning Label ............................................................................... 1

................. JWS-FW ..................Fork Warning Label ............................................................................... 2

................. JWS-LCW................Load Center Warning Label ................................................................... 1

9

Page 10

JHS-2200 Mast Assembly

10

Page 11

Parts List: JHS-2200 Mast Assembly

Index No. Part No. Description Size Qty

1............... JHS2200-1...............Fork....................................................................................................... 2

2............... 140523 ....................Optional Steel Platform.......................................28-1/4" x 41-1/2"......... 1

3............... JHS1100-2...............Adjusting Screw..................................................................................... 2

4............... JHS2200-4...............Mounting Plate ...................................................................................... 1

5............... JHS1100-4...............Dog Point Socket Set Screw...............................M6 x 25 ...................... 1

6............... JHS2200-6...............Fork Shaft.............................................................................................. 1

7............... JHS1100-6...............Guide Roller .......................................................................................... 4

8............... JHS1100-7...............Bushing..............................................................10 x 8 x 8 ................... 4

9............... JHS1100-8...............Guide Roller Axle...................................................................................4

10............. BB-6206ZZ ..............Ball Bearing........................................................6206ZZ....................... 4

11............. JHS2200-11.............Rolling Axle Cover................................................................................. 4

12............. JHS1100-13A ..........Rubber Grip Handle............................................................................... 2

13............. TS-1551041.............Lock Washer ......................................................M6............................ 16

14............. TS-1503021.............Socket Head Cap Screw.....................................M6 x 10 .................... 16

15............. TS-1551061.............Lock Washer ......................................................M8.............................. 4

16............. TS-1515011.............Socket Head Cap Screw.....................................M8 x 16 ...................... 2

17............. JHS2200-17.............Bar ........................................................................................................ 1

18............. JHS2200-18.............Mast ...................................................................................................... 1

19............. JHS1100-17.............Snap Ring ..........................................................Ø 20 ........................... 8

20............. JHS2200-20.............Front Wheel Axle ................................................................................... 2

21............. JHS1100-18.............Dust Cap............................................................................................... 4

22............. BB-6204ZZ ..............Ball Bearing........................................................6204ZZ....................... 8

23............. JHS1100-20.............Front Wheel........................................................................................... 2

24A .......... JHS2200-24A ..........Left Outrigger Leg.................................................................................. 1

24B .......... JHS2200-24B ..........Right Outrigger Leg ............................................................................... 1

25............. TS-154010...............Hex Nut..............................................................M16............................ 4

26............. TS-155110...............Lock Washer ......................................................M16............................ 4

27............. JHS2200-27.............Hex Head Bolt ....................................................M16 x 150 ..................4

28............. TS-1550031.............Flat Washer........................................................M5.............................. 6

29............. TS-1551031.............Lock Washer ......................................................M5.............................. 6

30............. TS-1533032.............Phillips Pan Head Machine Screw ......................M5 x 10 ...................... 6

31............. JHS2200-31.............Steel Fence........................................................................................... 1

32............. JHS1100-36.............Link Pin ................................................................................................. 2

33............. JHS1100-37.............Split Pin..............................................................Ø 2 x 16...................... 4

34............. TS-2310181.............Hex Nut..............................................................M18............................ 4

35............. JHS1100-40.............Split Pin..............................................................Ø 4 x 30...................... 2

36............. JHS1100-41.............Link Pin ................................................................................................. 2

37............. JHS1100-35.............Chain .................................................................12A-1 x 58.................. 2

38............. JHS1100-59.............Chain Wheel.......................................................................................... 2

39............. JHS1100-11.............Snap Ring ..........................................................Ø 47 ........................... 2

40............. JHS1100-60.............Chain Wheel Bracket ............................................................................. 1

41............. JHS1100-61.............Spring Pin...........................................................Ø 8 x 50...................... 1

42............. TS-1503051.............Socket Head Cap Screw.....................................M6 x 20 ...................... 1

43............. TS-1490061.............Hex Cap Screw ..................................................M8 x 35 ...................... 2

44............. TS-1540061.............Hex Nut..............................................................M8.............................. 2

45............. JHS1100-85A ..........Hydraulic Pump Assembly..................................................................... 1

46............. JHS1100-42.............Foot Pedal............................................................................................. 1

47............. JHS1100-43.............Spring Pin...........................................................Ø 8 x 30...................... 2

48............. JHS1100-45.............Roller Pin .............................................................................................. 1

49............. JHS1100-46.............Bushing..............................................................17 x 15 x 15................ 1

50............. JHS1100-47.............Roller .................................................................................................... 1

51............. JHS1100-51.............Roller Axle............................................................................................. 1

52............. JHS1100-49.............Bushing..............................................................18 x 16 x 8.................. 6

53............. JHS1100-50.............Foot Lever............................................................................................. 1

54............. JHS1100-48.............Snap Ring ..........................................................Ø 12 ........................... 3

55............. JHS1100-52.............Spring Pin...........................................................Ø 4 x 22...................... 2

11

Page 12

56............. JHS1100-53.............Roller .................................................................................................... 1

57............. JHS1100-54.............Lever..................................................................................................... 1

58............. JHS1100-55.............Spring Pin...........................................................Ø 6 x 32...................... 1

59............. JHS1100-70.............Release Rod ......................................................................................... 1

60............. JHS1100-70A ..........Chain .................................................................05B-1 x 15.................. 1

61............. JHS2200-61.............Anchor Bolt............................................................................................1

62............. JHS1100-71.............V-Nut..................................................................M6.............................. 1

63............. JHS1100-56.............Handle................................................................................................... 1

64............. JHS1100-57.............Blocking Spring ..................................................................................... 1

65............. JHS1100-58.............Spring Pin...........................................................Ø 4 x 30...................... 2

66............. JHS1100-44.............Spring Pin...........................................................Ø 3 x 30...................... 2

67A .......... JHS1100-64A ..........Large Handle Pin................................................................................... 1

67B .......... JHS1100-64B ..........Small Handle Pin................................................................................... 1

68............. JHS1100-38.............Link Pin ................................................................................................. 2

69............. BB-7205AC..............Ball Bearing........................................................7205AC ...................... 2

70............. JHS1100-10.............Snap Ring ..........................................................Ø 25 ........................... 2

71............. JHS1100-72.............Wheel Cover .........................................................................................2

72............. JHS1100-75.............Foot Brake.............................................................................................2

73............. JHS1100-76.............Stop Lug................................................................................................ 2

74............. TS-1550061.............Flat Washer........................................................M8.............................. 2

75............. JHS1100-78.............V-Nut..................................................................M8.............................. 2

76............. JHS1100-79.............Hex Head Bolt ....................................................M10 x 25 .................... 4

77............. TS-1551071.............Lock Washer ......................................................M10............................ 4

78............. TS-1550071.............Flat Washer........................................................M10............................ 4

79............. JHS1100-82.............Dust Cap............................................................................................... 4

80............. JHS1100-83.............Wheel Axle ............................................................................................ 2

81............. BB-6205ZZ ..............Ball Bearing........................................................6205ZZ....................... 4

82............. JHS1100-85.............Wheel.................................................................180 x 20 x 60.............. 2

83............. JHS1100-44.............Spring Pin...........................................................Ø 3 x 30...................... 2

84............. JHS1100-63.............Shaft ..................................................................................................... 1

85............. JHS1100-69.............Spring.................................................................................................... 1

86............. JHS1100-65.............Roller .................................................................................................... 1

87............. JHS1100-66.............Shaft ..................................................................................................... 1

................. PT2748J-JET...........JET Logo Label ..................................................................................... 2

................. JHS2200-ID .............ID/Warning Label................................................................................... 1

................. JWS-FW ..................Fork Warning Label ............................................................................... 2

................. JWS-LCW................Load Center Warning Label ................................................................... 1

12

Page 13

JHS-1100 and JHS-2200 Pump Assembly

13

Page 14

Parts List: JHS-1100 and JHS-2200 Pump Assembly

Index No. Part No. Description Size Qty

................. JHS1100-85A ..........Hydraulic Pump Assembly (includes the following)

43............. JHS1100-43.............Spring Pin...........................................................Ø 8 x 30...................... 1

86............. JHS1100-86.............Bolt........................................................................................................ 1

87............. JHS1100-87.............Spring Cap............................................................................................ 1

88............. JHS1100-88.............Spring.................................................................................................... 1

89............. JHS1100-89.............Dust Seal *.........................................................20 x 28 x 6.................. 1

90............. JHS1100-90.............U-Ring * .............................................................20 x 28 x 5..................1

91............. JHS1100-91.............Pump .................................................................................................... 1

92............. JHS1100-92.............Plunger Piston....................................................................................... 1

93............. SB-4MM...................Steel Ball............................................................Ø 4 ............................. 2

94............. JHS1100-94.............Spring.................................................................................................... 1

95............. JHS1100-95.............Adjusting Screw..................................................................................... 1

96............. JHS1100-96.............Spring.................................................................................................... 1

97............. JHS1100-97.............Adjusting Screw..................................................................................... 1

98............. JHS1100-98.............Back-Up Ring *...................................................................................... 1

99............. JHS1100-99.............U-Ring * .............................................................18 x 25 x 5..................1

100........... JHS1100-100...........Release Plug......................................................................................... 1

101........... JHS1100-101...........Washer..................................................................................................1

102........... JHS1100-102...........Spring.................................................................................................... 1

103........... JHS1100-103...........Spring Base........................................................................................... 1

104........... SB-6MM...................Steel Ball............................................................Ø 6 ............................. 2

105........... JHS1100-105...........Pin......................................................................3 x 13.8 ...................... 1

106........... JHS1100-106...........Release Plug......................................................................................... 1

107........... JHS1100-107...........O-Ring *.............................................................13.2 x 2.65 ................. 2

108........... JHS1100-108...........Back-Up Ring *...................................................................................... 1

109........... JHS1100-109...........Washer..................................................................................................1

110........... JHS1100-110...........Washer..................................................................................................1

111........... JHS1100-111...........Dust Seal ...........................................................32 x 40 x 5.5............... 1

112........... JHS1100-112...........Cover .................................................................................................... 1

113........... JHS1100-113...........O-Ring *.............................................................63 x 3.55 .................... 1

114........... JHS1100-114...........O-Ring *.............................................................31.5 x 3.55 ................. 1

115........... JHS1100-115...........U-Ring * .............................................................32 x 40 x 5.5............... 1

116........... JHS1100-116...........Ram Piston............................................................................................ 1

117........... JHS1100-117...........Oil Plug ................................................................................................. 1

118........... JHS1100-118...........Pump Body............................................................................................ 1

119........... SB-6.5MM................Steel Ball............................................................Ø 6.5 .......................... 1

120........... JHS1100-120...........Spring Base........................................................................................... 1

121........... JHS1100-121...........Spring.................................................................................................... 1

122........... JHS1100-122...........Adjusting Screw..................................................................................... 1

123........... JHS1100-123...........Relief Plug............................................................................................. 1

124........... JHS1100-124...........Spring.................................................................................................... 1

125........... JHS1100-125...........O-Ring *.............................................................4.87 x 1.6 ................... 2

126........... JHS1100-126...........Nozzle................................................................................................... 1

127........... JHS1100-127...........Cam ...................................................................................................... 1

................. JHS1100-RK............Pump Repair Kit (includes parts marked with *)...................................... 1

14

Page 15

15

Page 16

WMH Tool Group

2420 Vantage Drive

Elgin, Illinois 60124

Phone: 800-274-6848

www.wmhtoolgroup.com

16

Loading...

Loading...