Operating Instructions and Parts Manual

Self-Feed Vertical Band Saw

Models: VSF-14-1 and VSF-14-3

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123

Ph.: 888-594-5866

Fax: 800-626-9676

www.wmhtoolgroup.com

Part No. 5518247

Revision A6 09/03

Copyright WMH Tool Group

This manual has been prepared for the owner and operator of a Model VSF-14 Self-Feed Vertical

Band Saw. Its purpose, aside from machine operation, is to promote safety using accepted

operating and maintenance procedures. To obtain maximum life and efficiency from your band

saw and to aid in using the machine safely, please read this manual thoroughly and follow

instructions carefully.

Warranty and Service

WMH Tool Group warrants every product it sells. If one of our tools needs service or repair, one

of our Authorized Repair Stations located throughout the United States can provide quick service

or information.

In most cases, a WMH Tool Group Repair Station can assist in authorizing repair work, obtaining

replacement parts, or perform routine or major maintenance repair on your JET product.

For the name of an Authorized Repair Station in your area, please call 1-888-594-5866, or visit

our web site at www.wmhtoolgroup.com

More Information

Remember, WMH Tool Group is consistently adding new products to the line. For complete, upto-date product information, check with your local WMH Tool Group distributor, or visit our web

site at www.wmhtoolgroup.com

.

WMH Tool Group Warranty

WMH Tool Group makes every effort to assure that its products meet high quality and durability

standards and warrants to the original retail consumer/purchaser of our products that each

product be free from defects in materials and workmanship as follows: 1 YEAR LIMITED

WARRANTY ON ALL PRODUCTS UNLESS SPECIFIED OTHERWISE, 6 MONTH LIMITED

WARRANTY ON THE MOTOR. This Warranty does not apply to defects due directly or indirectly

to misuse, abuse, negligence or accidents, normal wear-and-tear, repair or alterations outside our

facilities, or to a lack of maintenance.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED

ABOVE, BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND

FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG

THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL WMH TOOL GROUP BE LIABLE FOR DEATH, INJURIES TO PERSONS

OR PROPERTY, OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL

DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. Proof of purchase date and an

explanation of the complaint must accompany the merchandise. If our inspection discloses a

defect, we will either repair or replace the product at our discretion, or refund the purchase price if

we cannot readily and quickly provide a repair or replacement. We will return the 7repaired

product or replacement at WMH Tool Group’s expense, but if it is determined there is no defect,

or that the defect resulted from causes not within the scope of WMH Tool Group’s warranty, then

the user must bear the cost of storing and returning the product. This warranty gives you specific

legal rights; you may also have other rights, which vary from state to state.

WMH Tool Group sells through distributors only. Members of the WMH Tool Group reserve the

right to effect at any time, without prior notice, alterations to parts, fittings, and accessory

equipment, which they may deem necessary for any reason whatsoever.

2

Table of Contents

Warranty and Service .................................................................................................................................................. 2

More Information ..................................................................................................................................................... 2

WMH Tool Group Warranty .................................................................................................................................... 2

Table of Contents ......................................................................................................................................................... 3

Table of Figures ........................................................................................................................................................... 4

Warnings...................................................................................................................................................................... 5

How The VSF-14 Band Saw Operates........................................................................................................................ 7

Introduction .................................................................................................................................................................. 8

Specifications............................................................................................................................................................... 8

Model....................................................................................................................................................................... 8

VSF-14-1 ............................................................................................................................................................ 8

VSF-14-3 ............................................................................................................................................................ 8

Standard Features .................................................................................................................................................. 8

Standard Equipment ............................................................................................................................................... 8

Description ................................................................................................................................................................... 9

Installation.................................................................................................................................................................. 10

General ................................................................................................................................................................. 10

Machine Setup ...................................................................................................................................................... 10

Electrical Connections .......................................................................................................................................... 10

Cleaning ................................................................................................................................................................ 11

Operation ................................................................................................................................................................... 11

General ................................................................................................................................................................. 11

Controls................................................................................................................................................................. 11

Changing blade speeds: ....................................................................................................................................... 12

Blade Selection .......................................................................................................................................................... 12

Blade Removal and Installation ............................................................................................................................ 12

Blade Break-In Procedures................................................................................................................................... 13

Controlling the Cut ..................................................................................................................................................... 13

Hydraulic Feed Control ......................................................................................................................................... 13

Evaluating Cutting Efficiency ................................................................................................................................ 14

Setting the Vise for Angle Cuts ............................................................................................................................. 14

Setting the Vise for Square Cuts........................................................................................................................... 14

Work Setup ................................................................................................................................................................ 14

Setting the Blade Guide Bracket........................................................................................................................... 14

Starting the Saw.................................................................................................................................................... 15

Service and Maintenance .......................................................................................................................................... 16

Adjustments .......................................................................................................................................................... 16

Blade Tracking Adjustments ............................................................................................................................ 16

Blade Guide Bearing Adjustment ..................................................................................................................... 17

Cleaning ................................................................................................................................................................ 18

Lubrication............................................................................................................................................................. 18

Changing the Drive Motor V-Belt .......................................................................................................................... 18

Chip Brush and Chip Scraper Replacement......................................................................................................... 18

Blade Guide Bearing Replacement ...................................................................................................................... 19

Drive Motor Replacement ..................................................................................................................................... 19

Adjusting or Replacing the Counterbalance ......................................................................................................... 19

Replacing the Drive Wheel (Lower Wheel)........................................................................................................... 20

Replacing the Idler Wheel or Bearings (Upper Wheel)......................................................................................... 20

Troubleshooting ......................................................................................................................................................... 21

Replacement Parts .................................................................................................................................................... 23

Parts List for VSF-14 Saw Frame ......................................................................................................................... 25

Parts List for the VSF-14 Base ............................................................................................................................. 29

Parts List for the VSF-14 Gear Box Assembly...................................................................................................... 31

Parts List for the VSF-14 Bearing Shaft Assembly ............................................................................................... 32

Parts List for the VSF-14 Smooth Wheel Assembly ............................................................................................. 33

Parts List for the VSF-14 Idler Wheel Assembly .................................................................................................. 33

Electrical Schematics................................................................................................................................................. 34

115 Volts, Single Phase........................................................................................................................................ 34

230 Volts, Single Phase........................................................................................................................................ 34

230 Volts, Three Phase ........................................................................................................................................ 35

460 Volts, Three Phase ........................................................................................................................................ 35

3

Table of Figures

Figure 1: How the VSF-14 Band Saw Operates...............................................................................................7

Figure 2: Specifications....................................................................................................................................8

Figure 3: Component Descriptions and Locations ...........................................................................................9

Figure 4: Recommended Main Power Supply Wire Sizes..............................................................................11

Figure 5: Belt Speed/Position Relationship ....................................................................................................12

Figure 6: Blade Tracking Adjustment .............................................................................................................16

Figure 7: Guide Bearing Adjustment ..............................................................................................................17

Figure 8: Chip Brush and Chip Scraper Locations .........................................................................................18

Figure 9: Exploded View of the VSF-14 Saw Frame......................................................................................24

Figure 10: Exploded View of the VSF-14 Base ..............................................................................................28

Figure 11: Exploded View of the VSF-14 Gear Box Assembly.......................................................................31

Figure 12: Exploded View of the VSF-14 Bearing Shaft Assembly ................................................................32

Figure 13: Exploded View of the VSF-14 Smooth Wheel Assembly ..............................................................33

Figure 14: Exploded View of the VSF-14 Idler Wheel Assembly....................................................................33

Figure 15: Electrical Schematic for Single Phase Motor ................................................................................34

Figure 16: Electrical Schematic for Three Phase Motor.................................................................................35

4

Warnings

1. Read and understand the entire owners manual before attempting assembly or operation.

2. Read and understand warnings posted on the machine and in this manual. Failure to

comply with all of these warnings may cause serious injury.

3. Replace warning labels if they become obscured or removed.

4. This band saw is designed and intended for use by properly trained and experienced

personnel only. If you are not familiar with the proper and safe operation of a band saw,

do not use until proper training and knowledge have been obtained.

5. Do not use this band saw for other than its intended use. If used for other purposes,

WMH Tool Group disclaims any real or implied warranty and holds itself harmless from

any injury that may result from that use.

6. Always wear approved safety glasses/face shields while using this machine. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses.

7. Before operating this machine, remove tie, rings, watches, and other jewelry, and roll

sleeves up past the elbows. Remove all loose clothing and confine long hair. Non-slip

footwear is recommended. Do not wear gloves when operating the saw.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contain chemicals known to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well-ventilated area and work with approved

safety equipment, such as face or dust masks that are specifically designed to filter out

microscopic particles.

10. Do not operate this band saw while tired or under the influence of drugs, alcohol or any

medication.

11. Make certain the switch is in the OFF position before connecting the machine to the

power supply.

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the

power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and

adjusting wrenches are removed from the machine before turning it on.

15. Keep machine guards in place at all times when the machine is in use. If removed for

maintenance purposes, use extreme caution and replace the guards immediately.

16. Make sure the band saw is firmly secured to the floor before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and

perform its intended function – check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or replaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap material, oil and grease.

20. Keep visitors a safe distance from the work area. Keep children away.

21. Make your workshop kid proof with padlocks, master switches or by removing starter

keys.

22. Give your work undivided attention. Looking around, carrying on a conversation and

“horse-play” are careless acts that can result in serious injury.

5

Warnings (cont.)

23. Maintain a balanced stance at all times so that you do not fall or lean against the saw

blade or other moving parts.

24. Use the right tool. Don’t force a tool or attachment to do a job for which it was not

designed. The right tool will do the job better and safer at the rate for which it was

designed.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maintain tools with care. Keep tools sharp and clean for the best and safest performance.

Follow instructions for lubricating and changing accessories.

27. Make sure the work piece is securely attached or clamped to the table. Never use your

hand to hold the work piece.

28. Never brush away chips while the machine is running. Use the correct speed and feed for

the tool. Be sure that the tool is the correct one for your operation.

29. Never stand on a machine. Serious injury could occur if the machine tipped or if the saw

blade is unintentionally contacted.

30. Never leave the machine running unattended. Turn the power off and don’t leave the

machine until it comes to a complete stop.

Warnings for Sawing Systems

31. Always wear leather gloves when handling saw blades. The operator should not wear

gloves when operating the machine.

32. All doors should be closed, all panels replaced and other safety guards should be in

place prior to the machine being started or operated.

33. Be sure the blade is not in contact with the work piece when the motor is started. The

motor should be started and you should allow the saw to come up to full speed before

bringing the saw blade into contact with the work piece.

34. Do not allow the saw blade to rest against the work piece when the saw is not running.

35. Keep your hands away from the blade area.

36. The saw must be stopped and the electrical supply must be cut off before any blade

replacement or adjustment of blade support mechanism is done, or before any attempt is

made to change the drive belts or before any periodic service or maintenance is

performed on the saw.

37. Remove loose items and unnecessary work pieces from the area before starting the

machine.

38. Bring the adjustable saw guides and guards as close as possible to the work piece.

39. The work piece, or part being sawed, must be securely clamped before the saw blade

enters the work piece.

40. Remove cut off pieces carefully, keeping hands away from the saw blade.

41. The saw must be stopped and the electrical supply cut off or machine unplugged before

reaching into the cutting area.

- - SAVE THESE INSTRUCTIONS - -

6

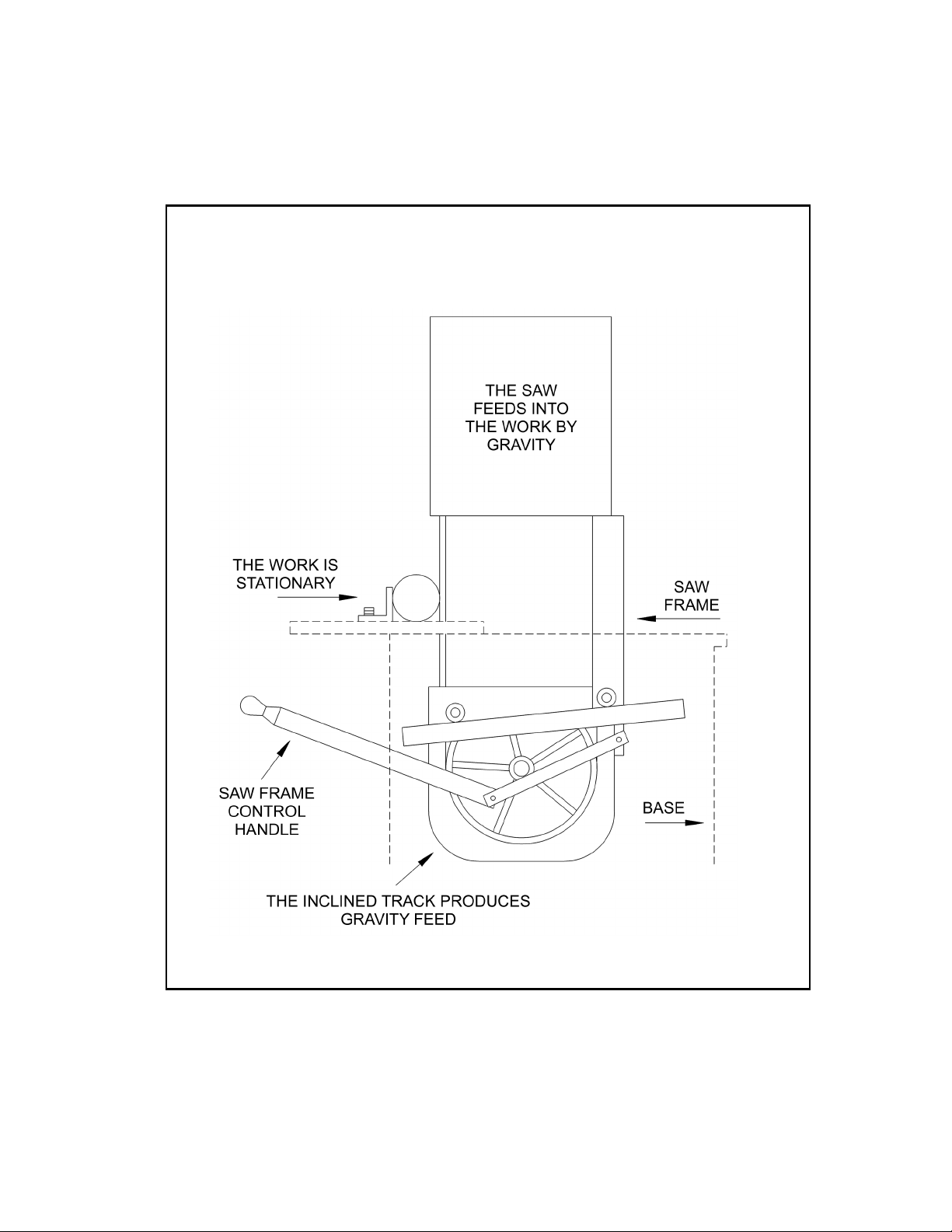

How The VSF-14 Band Saw Operates

Figure 1: How the VSF-14 Band Saw Operates

7

Introduction

This manual is provided by JET Equipment covering the safe operations and maintenance

procedures for Models VSF-14-1 and VSF-14-3. This manual contains instructions on installation,

safety precautions, general operating procedures, maintenance instructions and parts breakdown.

This machine has been designed and constructed to provide years of trouble free operation if used in

accordance to instructions set forth in this manual. If there are any questions or comments, please

contact either your local supplier or WMH Tool Group. WMH Tool Group can also be reached at our

web site: www.wmhtoolgroup.com.

Specifications

Model VSF-14-1 VSF-14-3

Blade Speeds (SFPM) 70, 140, 280, 580 70, 140, 280, 580

Height Capacity (max./in.) 14-1/2 14-1/2

Throat Capacity (max./in.) 8-1/2 8-1/2

Table Size (in.) 18-1/2 x 30-1/2 18-1/2 x 30-1/2

Table Height (in.) 30 30

Blade Wheel Diameter (in.) 14 14

Blade Length (approx./in.) 120 120

Blade Width (in.) 1/8 min. – 1 max. 1/8 min. – 1 max.

Floor Space Required (in.) 40L x 30-1/2W x 63H 40L x 30-1/2W x 63H

Motor

1HP, 1Ph,

115/230V, 60Hz

Net Weight (lbs.) 551 551

Figure 2: Specifications

Standard Features

• Welded frame and base of heavy gauge steel

• Swivel vise with scale for miter cuts

• Heavy duty precision ground cast iron table

• Four blade speeds (70, 140, 280, 580)

• Hydraulic feed control

• Counterweight for feed control

• Upper guide bar adjustment

• Guide rollers accept blade sizes: 1/8”, 1/4”, 3/8”, 1/2”, 5/8”, 3/4” and 1”

Standard Equipment

• Four foot pads

• Work light

• Chip tray

• Miter gauge

• Extension roller

• 5/8” Bi-metal blade

• Blade speed and pitch selector

• Conveniently located control panel

1HP, 3Ph,

230/460V, 60Hz

8

Description

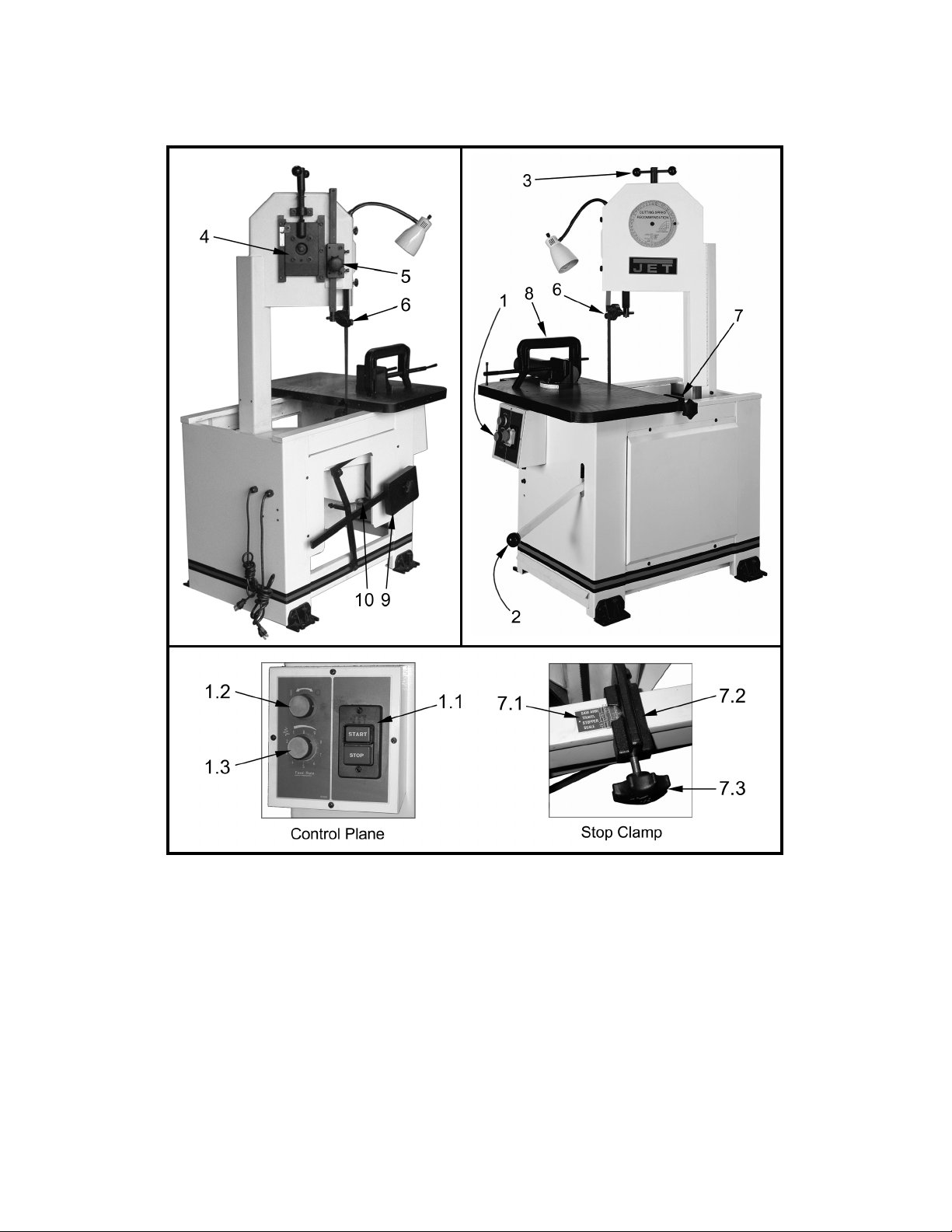

Figure 3: Component Descriptions and Locations

1. CONTROL PANEL – The operating controls for the band saw are located on the base at the

front of the machine.

1.1. ON/OFF SWITCH – Turns the machine on or off.

1.2. SAW FRAME RELEASE KNOB – Turning this knob counterclockwise unlocks the

release lever (Item 2).

1.3. FEED RATE ADJUST KNOB – Used to adjust the hydraulic feed control rate.

2. SAW FRAME RELEASE LEVER – Pull up on this lever to release the saw frame after

unlocking it (Ref Item 1.2) and push down to return the saw frame to its rearmost position.

3. BLADE TENSION HANDLE – Used to set the correct blade tension. Also used to remove and

install the saw blade.

9

4. UPPER BLADE WHEEL BLADE TRACKING ADJUSTMENT (See Blade Tracking

Adjustments) – If your saw should get out of adjustment and the blade runs off the wheel or

runs back against the lip, loosen the two bottom bolts on the upper wheel slide. Turn the set

screw in or out to make the blade run approximately 1/32” away from the lip on the back of

the wheel. Tighten the two upper wheel slide bolts. IMPORTANT:

If the blade is allowed to

run against the lip on the wheel it will wear the lip off.

5. GUIDE BAR LOCK – Used to lock the roll guides in position.

6. BLADE GUIDE – Should be adjusted so it clears your work by approximately 1/2”. This will

insure maximum blade rigidity.

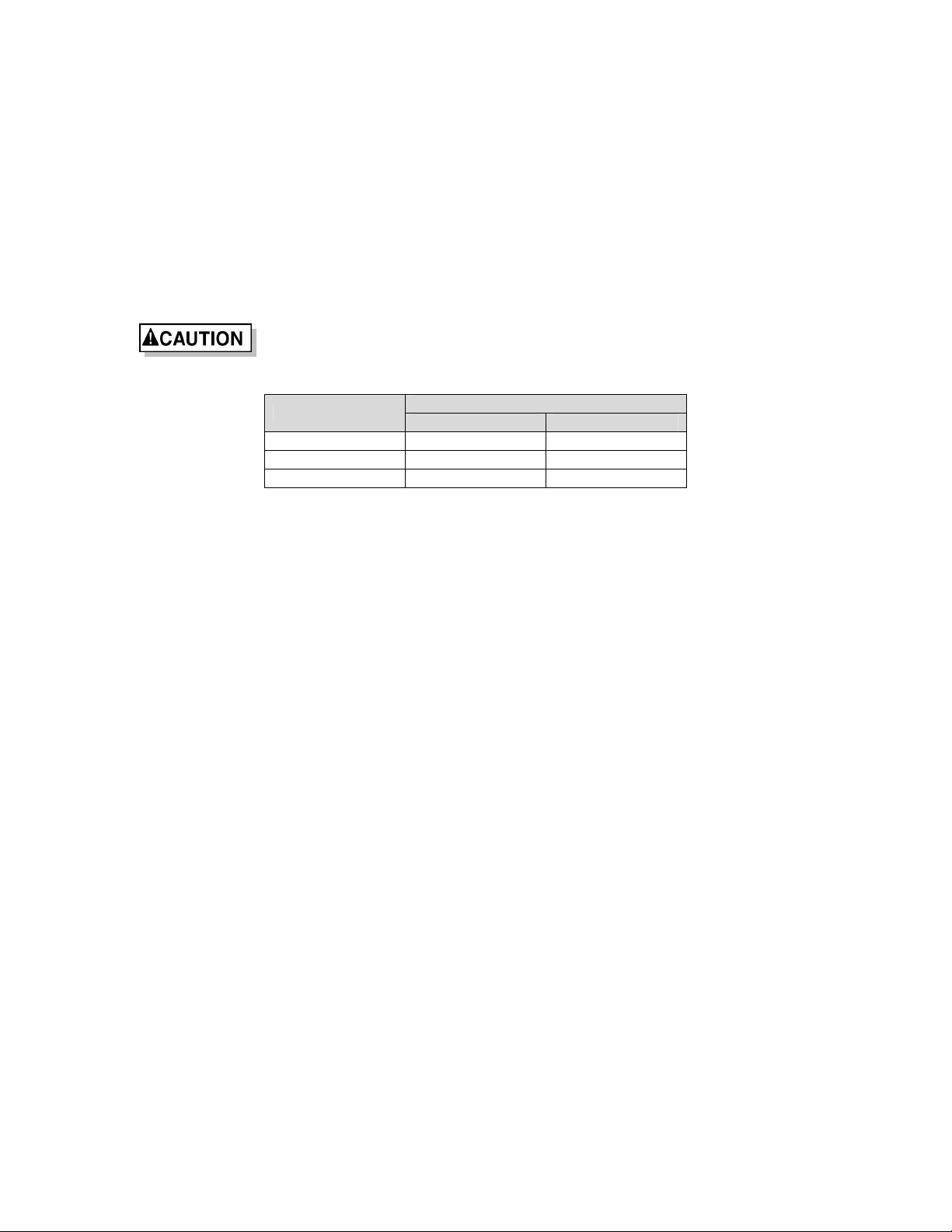

7. STOP CLAMP – Has two uses:

1) It can be set for the depth of cut;

2) If placed behind the frame, it will lock the frame in a

forward position for contour work.

7.1. Stop Clamp Scale – Shows the maximum depth of cut based on the size of blade you are

using.

7.2. Stop Clamp – Used with the Stop Clamp Scale (Figure 3 Item 7.1) to select the size of

the blade.

7.3. Lock Knob – To Lock the Stop Clamp.

8. C-CLAMP VISE – Used to hold stock in place during cutting. Graduations are provided to set

angle cuts.

9. COUNTERBALANCE WEIGHT – Used to maintain the blade pressure you desire.

10. HYDRAULIC CYLINDER – This should be adjusted to allow the frame to travel rapidly but not

free fall. This is a safety device and therefore should be kept properly adjusted.

Installation

General

• Do not install the machine in a damp, humid, dirty or badly illuminated environment.

Machine Setup

The band saw has been pre-adjusted at the factory and several test pieces have

been cut to verify cutting accuracy. Setup of the machine is limited to uncrating the

machine, securing it to the shop floor and connecting it to the electrical power source.

1. Remove the saw from the shipping skid; discard any hold-down devices.

2. Place the saw on the shop floor. This machine must be installed on a firm, level

surface. Make sure it is mounted securely to the floor using mounting anchors

secured through the holes in the base. In addition, adjust the level of the

worktable by adjusting the four feet pads.

3. If the saw will be used to cut long pieces of stock, allow plenty of room for the

length of the stock.

Electrical Connections

A qualified electrician should make the electrical connections

following all local and state codes.

The machine uses high voltage electrical power that poses a

significant risk of serious injury or death if proper precautions

are not observed. Make sure the machine is properly

grounded.

Connect the machine to the electrical power branch circuit. Observe the following

guidelines when connecting the saw to the power source.

1. Make sure the saw is disconnected from the electrical power branch circuit (trip

the required circuit breakers or remove the required fuses).

10

following table is recommended.

Cleaning

• All unpainted surfaces of the machine are treated with a rust preventative. Clean all

Operation

General

• Always wear approved safety glasses when using this machine. Before operating the

• Never use the machine if it is missing any guards or other safety devices.

• Maintain a balanced stance at all times so that you do not fall or lean against the saw

• Never leave the machine running. Always make sure it has come to a complete stop

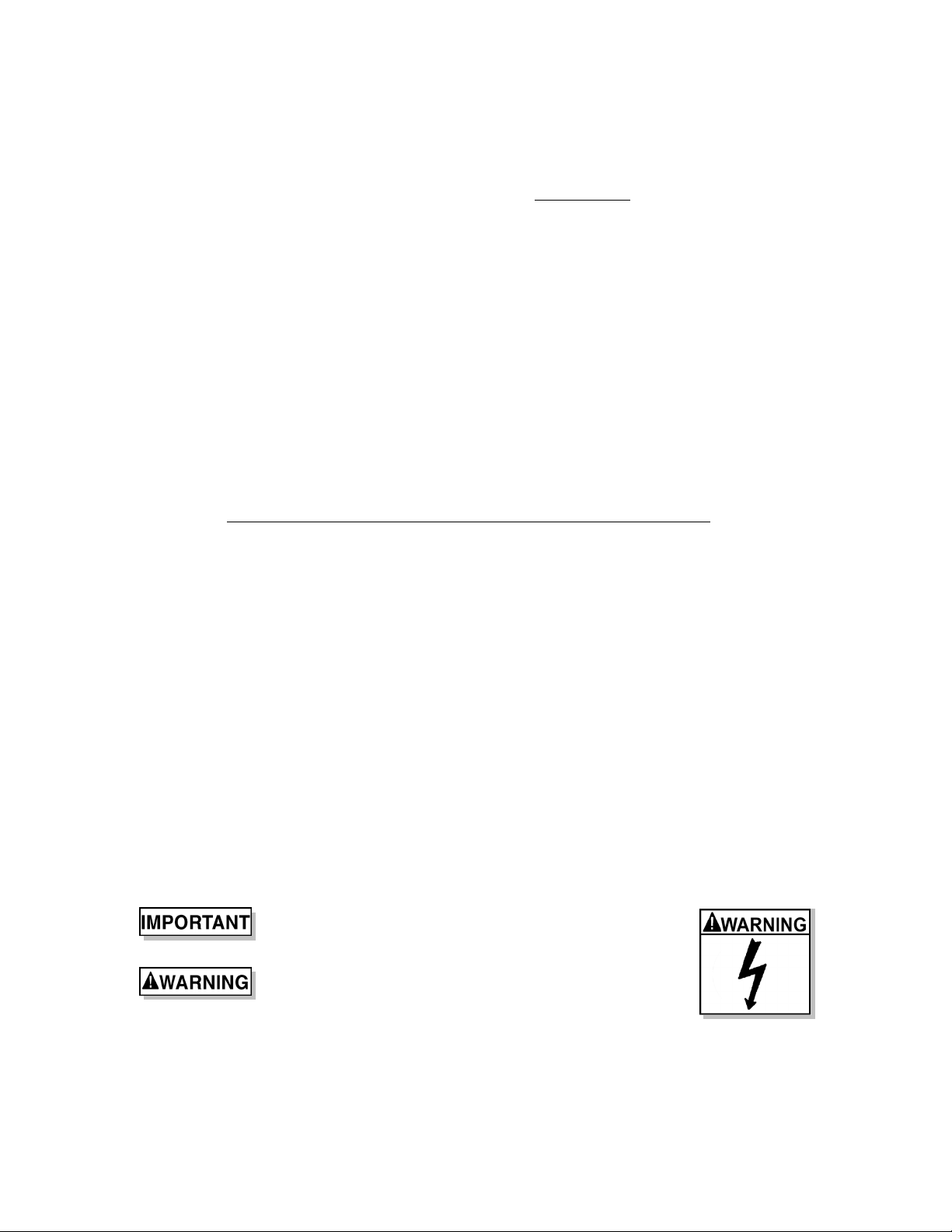

Controls

• ON / OFF Switch (Figure 3 Item 1.1). Located on the right side of the control panel.

• Feed Control Knob (Figure 3 Item 1.3). Located on the left side of the control panel.

• Blade Speeds (Figure 5). The band saw has four blade speeds. The different speeds

2. Place a warning placard or tag on the service panel to prevent accidental

electrical shock.

3. When installing the motor power cord into a receptacle, make sure the plug is

compatible with the receptacle.

4. When using hard-wired connections, connect the wires as shown in the wiring

diagram.

5. Install the fuses or reset the breakers.

6. Check the operation of the saw.

For circuits that are a long distance from the electrical service box, the wire size

must be increased in order to deliver ample voltage to the motor. To minimize

power losses and to prevent motor overheating and burnout, the use of wire

sizes for branch circuits or electrical extension cords according to the

Conductor Length

AWG (American Wire Gauge) Number

120 Volt Lines 240 Volt Lines

0 – 50 Feet No. 14 No. 14

50 – 100 Feet No. 12 No. 14

Over 100 Feet No. 8 No. 12

Figure 4: Recommended Main Power Supply Wire Sizes

rust protected surfaces with a mild solvent. Do not use paint thinner, lacquer thinner,

gasoline or mineral spirits; these will damage painted surfaces.

machine, remove tie, rings, watches and other jewelry, and roll sleeves up past the

elbows. Remove all loose clothing and confine long hair. Non-slip footwear is

recommended. Do not wear gloves when operating the saw.

blade or other moving parts.

before leaving the machine.

Press this switch to start or stop the machine.

The knob is the hydraulic cylinder feed control valve. It is used to set the amount of

force that is applied to the saw blade. The feed rate is proportional to the opening of

the valve. Increasing the valve opening (counterclockwise) increases the feed rate;

decreasing the valve opening (clockwise) reduces the feed rate.

are obtained by changing the position of the motor drive V-belt on step pulleys.

Change blade speeds as follows. Caution: Change speeds only when the machine is

not running.

11

Changing blade speeds:

1. Disconnect the electrical power from the band saw branch circuit to prevent

accidental motor start-up.

2. Place the saw frame in the rearmost position by pushing down on the saw

frame release lever (Figure 3 Item 2) and lock it by turning the saw frame

release knob (Figure 3 Item 1.2) clockwise.

3. Remove the panel on the base to expose the V-belt and pulleys.

4. Lift the motor to loosen the belt.

5. Select the speed using the placard on the saw head. Put the V-belt in the

pulley grooves of the pulley for the desired speed (Refer to Figure 5 for belt

locations and the speeds available).

6. Lower the motor to tighten the V-belt.

Figure 5: Belt Speed/Position Relationship

Blade Selection

The band saw is delivered with a saw blade that is adequate for a variety of jobs on a

variety of common materials. Refer to Figure 5 for the speeds recommended for various

materials. These speeds, while appropriate for many common cutting needs, do not

encompass the wide variety of special blade configurations (tooth pitch and set) and

Blade Removal and Installation

special alloys for cutting unusual or exotic materials.

A coarse blade could be used for a solid steel bar, but a finer tooth blade would be used

on a thin-wall steel tube. In general, the blade choice is determined by the thickness of

the material; the thinner the materials; the finer the tooth pitch.

A minimum of three teeth should be on the work piece at all times for proper cutting. The

blade and work piece can be damaged if the teeth are so far apart that they straddle the

work piece.

For very high production cutting of special materials, or to hard-to-cut materials such as

stainless steel, tool steel or titanium, you can ask your industrial distributor for more

specific blade recommendations. The supplier that provides the work piece material

should be able to provide you with very specific instructions regarding the best blade (and

coolant or cutting fluid, if needed) for the material or shape supplied.

Use leather gloves when changing the saw blade to protect your hands from

cuts and scratches. Use protective eye wear that meets ANSI SPECIFICATION

Z87.1.

Disconnect the band saw from its electrical power source.

12

1. To remove the blade, place the saw frame in the rearmost position by pushing down

on the saw frame release lever (Figure 3 Item 2) and lock it by turning the saw frame

release knob (Figure 3 Item 1.2) clockwise.

2. Remove the panel on the base to expose the lower blade wheel.

3. Open the panel on the saw head to expose the upper blade wheel.

4. Remove the blade safety guard.

5. Turn the blade tension handle (Figure 3 Item 3) counterclockwise until the blade

hangs loose.

6. Use leather gloves to prevent cuts and scratches. Pull the blade off the drive wheels

and out of the blade guides. Store the removed blade carefully before proceeding.

7. To install the blade, slide the new blade into the blade guides.

8. Place the blade over the bottom wheel.

9. Place the blade over the top wheel. The teeth must point down toward the table.

10. Push the blade so it is seated against the shoulders of the wheels.

11. Turn the blade tension handle clockwise enough to hold the blade firmly in place.

12. Reconnect the saw to its electrical power source.

13. Turn the machine on to allow the blade to position itself. Check and adjust the

tracking of the blade. Refer to Blade Tracking Adjustments in this manual.

14. Turn the blade tension handle clockwise to finish tightening the blade. Do not overtighten the blade; tighten it just enough so it does not slip while cutting.

15. Install the wheel guards and blade covers.

The most common causes of your band saw not cutting straight are:

1. Blade tension is set to low.

2. The blade is either dull or worn on one side.

3. The blade is upside down. The teeth must point down toward the

Blade Break-In Procedures

New blades are very sharp and, therefore, have a tooth geometry that is easily damaged

if a careful break-in procedure is not followed. Consult the blade manufacturer’s literature

for break-in of specific blades on specific materials. However, the following procedure will

be adequate for break-in of JET-supplied blades on lower alloy ferrous materials.

1. Clamp a section of round stock in the vise. The stock should be two inches or larger

in diameter.

2. Operate the saw at low speed. Start the cut with a very light feed rate.

3. When the saw has completed about 1/3 of the cut, increase the feed rate slightly and

allow the saw to complete the cut.

4. Keep the feed rate at the same setting and begin a second cut on the same or similar

work piece.

5. When the saw has completed about 1/3 of the cut, increase the feed rate while

watching the chip formation until cutting is at its most efficient rate (refer to Evaluating

Cutting Efficiency in this manual). Allow the saw to complete the cut.

6. The blade is now considered ready for use.

Controlling the Cut

Hydraulic Feed Control

The weight of the saw frame provides the force needed to cut through the work piece.

The saw has a hydraulic cylinder that controls the feed rate.

The hydraulic feed control circuit consists of a single-acting hydraulic cylinder and a flowcontrol valve. The feed control cylinder resists motion in the forward direction to control

table.

13

the feed rate. The control cylinder offers no resistance when the saw frame is moved

backward. A knob on the control panel controls the rate at which the saw frame moves

forward. The control knob (needle valve) controls the rate at which the hydraulic fluid is

released from the hydraulic cylinder. When the needle valve is closed, the cylinder is

locked. With the needle valve slightly open, the cylinder permits slow, or light, force.

Opening the needle valve further increases the feed rate and applies more force to the

saw blade and the work piece.

The needle valve is adjusted until the saw is operating efficiently. The efficiency of

operation is usually evaluated by observing chip formation. (Refer to Evaluating Cutting

Efficiency for more information on cutting efficiency.

Evaluating Cutting Efficiency

Is the blade cutting efficiently? The best way to determine this is to observe the chips

formed by the cutting blade.

• If the chip formation is powdery, then the feed is much to light, or the blade is dull.

• If the chips formed are curled, but colored – blue or straw colored from heat generated

during the cut – then the feed rate is to high.

• If the chips are slightly curled and are not colored by heat – the blade is sufficiently sharp

and is cutting at its most efficient rate.

Setting the Vise for Angle Cuts

The vise can be adjusted through a 45

o

arc. Adjust as follows:

1. Loosen the hex head bolt and remove the taper pin on the vise.

2. Rotate the vise to the desired angle. For accurate cuts, use a variable protractor

to set the position of the jaw; align one side of the protractor with one side of the

blade.

3. Re-install the taper pin and tighten the hex head bolt on the vise.

Setting the Vise for Square Cuts

The procedure for setting the vise for square cuts is identical to setting for angle cuts (see

Setting the Vise for Angle Cuts) except that a machinist’s square is used to position the

vise.

Work Setup

1. Move the saw frame to its rearmost position by pushing down on the saw frame

release lever (Figure 3 Item 2) and lock it in place by turning the saw frame release

knob (Figure 3 Item 1.2) clockwise.

2. Turn the c-clamp handle counterclockwise enough to fit the stock.

3. Place the work piece on the worktable. For long work pieces, provide support at the

other end. If necessary, provide additional downward clamping to hold the work piece

securely on the worktable.

Setting the Blade Guide Bracket

4. Clamp the work piece in the vise by rotating the c-clamp handle clockwise.

Do not allow the blade to rest against the work piece when the saw is not

cutting.

The band saw has an adjustable blade guide bracket. The blade guide bracket allows

you to set the blade guide for varying heights of work pieces.

To make accurate cuts and prolong blade life, the blade guide bracket should be set one

inch above the piece to be cut. Adjust the bar position as follows:

14

1. Place the work piece in the vise and clamp tightly.

2. Loosen the locking knob on the back of the guide bracket (Figure 3 Item 5).

3. Slide the guide bracket to the desired position.

4. Tighten the locking knob to secure the guide bracket.

Starting the Saw

1. Make sure that the saw frame is in the rearmost position and turn the saw frame

release knob (Figure 3 Item 1.2) to the OFF (clockwise) position.

2. Clamp the work piece in the vise. (Refer to Figure 6 for examples of how different

shaped work pieces are clamped in the vise).

3. Be sure that the blade is not in contact with the work piece when the motor is started.

4. Start the motor and allow the saw to come up to speed.

5. Turn the feed rate knob clockwise all the way. This closes the hydraulic valve and

stops the feed rate.

6. Turn the saw frame release knob counterclockwise to the ON position.

7. Pull up on the saw frame release lever (Figure 3 Item 2) to release the saw frame.

8. Slowly let the saw feed into the work piece by turning the feed rate control knob

(Figure 3 Item 1.3) counterclockwise until the proper feed rate is reached (See

Evaluating Cutting Efficiency).

9. Do not force the cut. Let the weight of the saw provide the cutting force.

10. At the end of the cut, push down on the saw frame release lever to move the saw

frame back to the rearmost position and turn the saw frame release knob clockwise

to lock it.

Never operate the saw without the blade covers in place.

Make sure the blade is not in contact with the work piece when the motor is

started. Do not force the saw through the work piece.

15

Service and Maintenance

Adjustments

The efficient operation of the band saw is dependent upon the condition of the saw blade.

If the performance of the saw begins to deteriorate, the first item that you should check is

the blade.

If a new blade does not restore the machine’s cutting accuracy and quality, refer to the

troubleshooting guide (or the blade manufacturer’s guide) for conditions to consider and

adjustments that can be made to increase the life of the blade.

To change the blade, refer to the blade changing procedures in the Blade Selection

section of this manual.

Blade Tracking Adjustments

Blade tracking has been tested at the

factory. Adjustment is rarely required

when the blade is used properly and if

the blade is correctly welded. (Refer to

Figure 7 for location of blade tracking

adjustment setscrew).

1. Place the saw frame in its

rearmost position by pushing

down on the saw frame release

lever (Figure 3 Item 2) and lock

it in place by turning the saw

frame release knob (Figure 3

Item 1.2) clockwise.

2. Make sure the blade is properly

tensioned.

NOTE: Keep proper tension on

the blade at all times using the

blade tension adjustment.

3. Loosen the two bottom bolts

(Figure 6, Item B) on the wheel

slide.

While performing the following

steps, keep the blade from

rubbing excessively on the

shoulder of the wheel.

Excessive rubbing will

damage the wheel and/or the

blade.

4. Start the saw. Turn the setscrew

to tilt the idler wheel until the

blade is touching the shoulder

of the idler wheel.

5. Turn the setscrew (Figure 6,

Item A) so the blade starts to

move away from the shoulder of

the wheel; then immediately

turn the setscrew in the other

direction so the blade stops;

then moves slowly towards the

shoulder.

Figure 6: Blade Tracking Adjustment

16

Keep your fingers clear of the blade and wheel to avoid injury.

6. Turn the setscrew to stop the motion of the blade on the wheel as it gets closer to

the wheel shoulder. Put a six-inch length of paper between the blade and the

wheel. The paper should not be cut as it passes between the wheel shoulder and

the blade.

7. Turn the setscrew a small amount. Repeat the insertion of the paper between the

wheel shoulder and the blade until the paper is cut in two pieces.

NOTE: You may have to repeat the check with the paper several times before the

blade and the shoulder cut the paper into two pieces. Do not hurry the

adjustment. Patience and accuracy here will pay off with better, more accurate,

quieter cutting and much longer machine and blade life.

8. When the paper is cut, turn the setscrew slightly in the counterclockwise direction.

This assures that the blade is not touching the shoulder of the wheel.

9. Shut off the saw.

10. Tighten the two bottom bolts on the upper wheel slide (Figure 6, Item B).

Blade Guide Bearing Adjustment

Proper adjustment of the blade guide bearings is critical to efficient operation of the band

saw. The blade guide bearings are adjusted at the factory. They should rarely require

adjustment. When adjustment is required, readjust immediately. Failure to maintain

proper blade adjustment may cause serious blade damage or inaccurate cuts.

It is always better to try a new blade when cutting performance is poor. If performance

remains poor after changing the blade, make the necessary adjustments.

If a new blade does not correct the problem, check the blade guides for proper spacing.

For most efficient operation and maximum accuracy, provide 0.001” clearance between

the blade and the guide bearings. The bearings will still turn freely with this clearance. If

the clearance is incorrect, the blade may track off the drive wheel.

Disconnect the band saw from its electrical power source.

Check the blade to make sure the welded section is the same thickness as the

rest of the blade. If the blade is thicker at the weld, the guide bearings may be

damaged.

If required, adjust the guide bearings as follows:

1. The upper and lower blade guides are adjusted the same way.

2. Loosen the blade guide setscrews with an Allen wrench.

3. Position the bearing by turning

the eccentric shafts. Set the

clearance to approximately

0.001”. (See Figure 7).

4. Tighten the blade guide

setscrews with the Allen

wrench.

5. Use the same procedure to

adjust the other blade guide

bearing.

6. When the adjustment is correct,

the guide bearings should

rotate freely with slight pressure

of the finger (blade stopped).

Figure 7: Guide Bearing Adjustment

17

Cleaning

1. Clean off any oil and grease on the machine surfaces.

2. After cleaning, coat the machined surfaces of the band saw with medium

consistency machine oil. Reapply the oil coating at least every six months.

3. Clean up accumulated saw cuttings after use. Make sure the lead screw and the

rapid nut are kept free from saw cuttings and other material that would cause

damage.

Lubrication

Lubricate the following components at the recommended intervals using the lubricants

specified:

1. Ball bearings: the bearings are lubricated and sealed – periodic lubrication is not

required.

2. Blade guide bearing: the bearings are lubricated and sealed – periodic lubrication

is not required.

3. Upper wheel bushing: six to eight drops of oil each week.

4. Pivot points, shafts and bearing areas: six to eight drops of oil each week.

Changing the Drive Motor V-Belt

Disconnect the band saw from its electrical power source.

1. Move the saw frame to its rearmost position and by pushing down on the saw

frame release lever (Figure 3 Item 2) and lock it in place by turning the saw frame

release knob (Figure 3 Item 1.2) clockwise.

2. Remove the panel on the base to expose the belt and pulleys.

3. Pivot the motor upwards to loosen the belt.

4. Remove the worn belt.

5. Put the replacement belt in the pulley position for the speed you require. (Refer to

Figure 5 for belt locations and the speeds available).

6. Tighten the belt by pivoting the motor downward.

7. Replace the panel and unlock the saw frame.

Chip Brush and Chip Scraper Replacement

The purpose of

the chip brush and

chip scraper is to

remove chips from

the saw teeth, the

saw blade and the

lower blade wheel

so an excessive

amount of chips

doesn’t get into

the wheel guard

section of the saw.

Figure 8: Chip Brush and Chip Scraper Locations

With extended

use, this brush

and/or scraper will

become worn and

will require replacement.

18

Disconnect the band saw from its electrical power source.

1. Remove the two screws and washers holding the brush or scraper on.

2. Remove the worn brush or scraper.

3. Install the replacement brush or scraper.

4. Install the two screws and washers.

5. Adjust the brackets, if necessary, so that the brush makes slight contact with the

lower blade wheel and the scraper is as close as possible to the saw blade

without touching it.

Blade Guide Bearing Replacement

Disconnect the band saw from its electrical power source.

1. Remove the saw blade. (Refer to Blade Removal and Installation).

2. Remove the bearing locking screw

3. Remove the damaged bearing and bushing.

4. Separate the damaged bearing from the bushing.

5. Install the replacement bearing on the bushing.

6. Install the bearing locking screw.

7. Install the saw blade. (Refer to Blade Removal and Installation).

8. Adjust the bearing clearance. (Refer to Blade Guide Bearing Adjustment).

Drive Motor Replacement

Disconnect the band saw from its electrical power source.

1. Remove the drive motor V-belt. (Refer to Changing the Drive Motor V-Belt).

2. Loosen the setscrew that holds the motor pulley to the shaft and remove the

pulley.

3. Open the motor junction box and disconnect the power cord wires from their

terminals.

4. Remove the nuts, washers and bolts that secure the motor to the mounting plate.

5. Installation of the motor is the reverse of the above steps. (Refer to Changing the

Drive Motor V-Belt and the electrical schematics at the end of this manual).

Adjusting or Replacing the Counterbalance

The counterbalance is located on the base of the saw. It is used to adjust the amount of

force the saw puts on the work piece when the hydraulic control cylinder is open.

Disconnect the band saw from its electrical power source.

1. Lock the saw frame in its rearmost position by pushing down on the saw frame

release lever (Figure 3 Item 2) and lock it in place by turning the saw frame

release knob (Figure 3 Item 1.2) clockwise.

2. Turn the handle on the counterweight counterclockwise to loosen it (Figure 3

Item 9).

3. Slide the counterweight along the bar to the proper location.

4. Turn the handle on the counterweight clockwise to tighten it (Figure 3 Item 9).

19

Replacing the Drive Wheel (Lower Wheel)

Disconnect the band saw from its electrical power source.

1. Remove the saw blade. (Refer to Blade Removal and Installation).

2. Loosen the setscrew in the wheel hub.

3. Pull the wheel from the speed reducer shaft.

4. Examine the drive edge and shoulder of the wheel for damage. Replace the

wheel if it’s damaged.

5. Install the wheel.

6. Tighten the setscrew in the wheel hub.

7. Install the saw blade. (Refer to Blade Removal and Installation).

Replacing the Idler Wheel or Bearings (Upper Wheel)

Disconnect the band saw from its electrical power source.

1. Remove the saw blade. (Refer to Blade Removal and Installation).

2. Remove the retaining ring and shim from the shaft.

3. Remove the wheel and the bronze bearing.

4. Examine the drive edge and shoulder of the wheel for damage. Replace the

wheel if it’s damaged.

5. Install the bearing and the wheel.

6. Install the retaining ring and shim on the shaft.

7. Install the saw blade. (Refer to Blade Removal and Installation).

20

Troubleshooting

Problem Probable Cause Suggested Remedy

Excessive Blade

Breakage

1. Material is loose in the

vise.

2. Incorrect speed or feed.

3. Blade pitch is too coarse

for the material.

4. Incorrect blade tension.

5. Saw blade is in contact

with the work piece before

the saw is started.

6. Blade rubs on the wheel

flange.

7. Misaligned blade guides.

8. Cracking at the weld.

Premature Blade

Dulling

1. Blade pitch is too coarse.

2. Blade speed is too high.

3. Inadequate feed pressure.

4. Hard spots in the work

piece.

5. Scale on/in the work piece.

6. Work hardening of material

(especially stainless steel).

7. Insufficient blade tension.

8. Operating the saw without

pressure on the work

piece.

Blade Is Twisting 1. Blade is binding in the cut.

2. Blade tension is too high.

1. Clamp work securely.

2. Check the Machinist’s

Handbook for the

speed/feed appropriate for

the material being cut.

3. Check the Machinist’s

Handbook for the

recommended blade type.

4. Adjust the blade tension

just to the point where the

blade does not slip on the

wheel. (Refer to Figure 3

Item 3).

5. Start the motor before

placing the saw blade

against the work piece.

6. Adjust the blade tracking.

(See Blade Tracking

Adjustment).

7. Adjust the blade guides.

(See Blade Guide Bearing

Adjustment).

8. Use a longer annealing

cycle.

1. Use a finer tooth blade.

2. Use a lower blade speed.

(See Figure 5).

3. Decrease the feed

pressure. (See Figure 3

Item 1.3).

4. Increase the feed pressure

(hard spots). (See Figure 3

Item 1.3).

5. Reduce the blade speed

and increase the feed

pressure (scale). (See

Figure 3 Item 1.3 and

Figure 5).

6. Increase the feed pressure.

(See Figure 3 Item 1.3).

7. Increase the tension to the

proper level. (See Figure 3

Item 3).

8. Do not run the blade in/on

the material at idle.

1. Decrease the feed

pressure. (See Figure 3

Item 1.3).

2. Decrease the tension on

the blade. (See Figure 3

Item 3).

21

Troubleshooting

Problem Probable Cause Suggested Remedy

Unusual Wear On

Side/Back Of Blade

Bad Cuts (Crooked) 1. Work piece is not square

Bad Cuts (Rough) 1. Blade speed is too high for

1. Blade guides are worn.

2. Blade guide bearings are

not adjusted.

3. Blade guide bearing

bracket is loose.

with the blade.

2. Feed pressure is too high.

3. Guide bearings are not

adjusted properly.

4. Inadequate blade tension.

5. Span between the two

blade guides is too wide.

6. Dull blade.

7. Incorrect blade speed.

8. Blade guide assembly is

loose.

9. Blade guide bearing

assembly is loose.

10. Blade track is too far away

from the wheel flanges.

11. Guide bearing is worn.

the feed pressure.

2. Blade teeth are too coarse.

1. Replace the blade guides.

(See Setting the Blade

Guide Bracket).

2. Adjust the blade guide

bearings. (See Blade

Guide Bearing

Adjustment).

3. Tighten the blade guidebearing bracket. (See

Blade Guide Bearing

Adjustment).

1. Adjust the vise so that it is

square with the blade.

(Always clamp the work

piece tightly in the vise).

2. Lower the feed pressure.

(See Figure 3 Item 1.3).

3. Adjust the guide bearing

clearance to 0.001” (0.002”

maximum). (See Blade

Guide Bearing

Adjustment).

4. Gradually increase the

blade tension. (See Figure

3 Item 3).

5. Move the blade guide

bracket closer to the work

piece. (See Setting the

Blade Guide Bracket).

6. Replace the blade. (See

Blade Removal and

Installation).

7. Check the blade speed.

(See Figure 5).

8. Tighten the blade guide

assembly. (See Setting the

Blade Guide Bracket).

9. Tighten the blade guide

bearing assembly. (See

Blade Guide Bearing

Adjustment).

10. Adjust the blade tracking.

(See Blade Tracking

Adjustment).

11. Replace the worn bearing.

(See Blade Guide Bearing

Replacement).

1. Reduce the blade speed

(See Figure 5).

2. Replace the blade with a

finer tooth blade.

22

Replacement Parts

This section provides exploded view illustrations that show the replacement parts for the

Models VSF-14-1 and VSF-14-3 Self-Feed Vertical Band Saw. Also provided are parts

listings that provide part numbers and descriptions. The item numbers shown in the

exploded views match the item numbers in the parts listing.

Order replacement parts from:

Identify the replacement part by the part number shown in the parts listing. Be sure to

include the model number and serial number of your machine when ordering replacement

parts to assure that you will receive the correct part.

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123

Ph.: 888-594-5866

Fax: 800-626-9676

www.wmhtoolgroup.com

23

24

Figure 9: Exploded View of the VSF-14 Saw Frame

Parts List for VSF-14 Saw Frame

Item Part No. Description Size Qty.

1 5519711 Blade Tension Knob 2

2 5519712 Blade Tension Handle 1

3 5519718 Flat Washer 5/8” x 40 x T3 2

4 5519713 Spring 1

5 5519714 Screw Rod 1

6 5519715 Bracket 1

7 TS-0680042 Flat Washer 3/8” x 23 x T2 2

8 TS-0209051 Socket Head Cap Screw 3/8-16 x 1-1/2” 2

9 5519716 Blade Wheel Slide Race 2

10 TS-0720091 Lock Washer 3/8” 6

11 TS-0209031 Socket Head Cap Screw 3/8-16 x 3/4” 6

12 5519717 Drive Shaft Holder 1

13 5519718 Flat Washer 5/8” x 40 x T3 1

14 TS-0561072 Hex Nut, Full 5/8-18 1

15 TS-0561072 Hex Nut, Full 5/8-18 1

16 5519719 Blade Wheel Slide 1

17 TS-0680042 Flat Washer 3/8” 4

18 TS-0209091 Socket Head Cap Screw 3/8-16 x 2” 4

19 TS-0060051 Hex Cap Screw 3/8-16 x 1” 1

20 TS-0813021 Flat Slotted Machine Screw 1/4-20 x 3/8” 1

21 TS-0680021 Flat Washer 1/4” 1

22 5519720 Tension Indicator 1

23 5519721 Rivet 2 x 8 2

24 5519722 Tension Label 1

25 5519723 Upper Blade Guide Handle 3/8” x 1” 1

26 5519724 Spring Pin 6 x 50 2

27 5519725 Upper Blade Guide Bracket 1

28 TS-0209091 Socket Head Cap Screw 3/8-16 x 2” 2

29 TS-0680042 Flat Washer 3/8” 2

30 TS-0207011 Socket Head Cap Screw 1/4-20 x 3/8” 1

31 5519726 Upper Blade Guide Slide 1

32 TS-0050021 Hex Cap Screw 1/4-20 x 5/8” 1

33 5519727 Spring Pin 6 x 25 1

34 5519728 Blade Guide Shaft 1

35 TS-0208011 Socket Head Cap Screw 5/16-18 x 3/8” 1

36 5519729 Upper Shaft 1

37 TS-0208021 Socket Head Cap Screw 5/16-18 x 1/2” 2

38 5519730 Blade Guide Mtg. Bracket 2

39* 5519731 Bearing Shaft Assembly 4

40 5519733 Blade Guide Knob 1/4” x 5/8” 1

41 5519734 Saw Blade Safety Cover 1

42 5519735 Special Washer 3

43 5519736 Eccentric Shaft 1

44* 5519737 Smooth Wheel Assembly 1

45 TS-0680061 Flat Washer 1/2” 1

46 TS-0070031 Hex Cap Screw 1/2-13 x 1-1/2” 1

47 TS-0090061 Hex Cap Screw 3/8-16 x 1-1/4” 2

48 TS-0570032 Hex Nut, Full 3/8-24 2

49 5519740 Saw Frame 1

50 5519741 Gearbox Pulley 1

51 5519742 Key 5 x 5 x 40 1

52* 5519743 Gear Box Assembly 1

53

5519766 V-Belt

3V-320 1

25

Parts List for VSF-14 Saw Frame

Item Part No. Description Size Qty.

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69*

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

5519767 Drive Motor Pulley

TS-148201 Hex Cap Screw

5519768 Motor

5521706 Motor

5519769 Key

TS-0570032 Hex Nut, Full

TS-0720091 Lock Washer

5519770 Motor Mounting Bracket

TS-0060051 Hex Cap Screw

TS-0570032 Hex Nut, Full

TS-0680042 Flat Washer

5519771 Motor Mounting Bracket

TS-0209051 Socket Head Cap Screw

TS-0720091 Lock Washer

TS-0060051 Hex Cap Screw

5519772 Eccentric Bolt

5519773 Smooth Wheel Assembly

5519775 Flat Washer

5519776 Counter Balance Bracket

TS-0680021 Flat Washer

TS-0207021 Socket Head Cap Screw

TS-0680041 Flat Washer

TS-0060071 Hex Cap Screw

TS-0070041 Hex Cap Screw

TS-0720111 Lock Washer

5519777 Eccentric Bracket

5519778 Eccentric Bolt

TS-0561051 Hex Nut, Full

TS-0680061 Flat Washer

5519779 Brush Mounting Bracket

5519780 Brush

TS-0813032 Slotted Round Head Screw

TS-0680021 Flat Washer

TS-0813032 Slotted Round Head Screw

5519781 Shaft Bolt

TS-0680042 Flat Washer

5519782 Handle Lever

TS-0209061 Socket Head Cap Screw

TS-0680042 Flat Washer

5519783 Spring Pin

TS-0720091 Lock Washer

TS-0209081 Socket Head Cap Screw

TS-0051021 Hex Cap Screw

5519784 Lower Blade Guide Bracket

5519785 Lower Blade Guide Shaft

5519786 Chip Scraper

TS-0680021 Flat Washer

TS-0813032 Slotted Round Head Screw

5519787 Drive Wheel

5519788 Plastic Pad

5519789 Flat Washer

TS-0060051 Hex Cap Screw

5519790 Saw Blade

5519791 Bolt

1

M6 x 10 2

1HP, 1 Phase 1

1HP, 3 Phase 1

5 x 5 x 40L 1

3/8-24 2

3/8” 2

1

3/8-16 x 1” 2

3/8-24 2

3/8” 4

1

3/8-16 x 1” 2

3/8” 2

3/8-16 x 1” 2

1

2

1/4” 1

1

1/4” 1

1/4-20 x 1/2” 1

3/8” 2

3/8-16 x 1-1/2” 1

1/2-13 x 1-3/4” 1

1/2” 1

1

1

1/2-13 2

1/2” 2

1

1

1/4-20 x 1/2” 2

1/4” 2

1/4-20 x 1/2” 2

1

3/8” 1

1

3/8-16 x 1-1/4” 1

3/8” 2

6 x 20 2

3/8” 2

3/8-16 x 1-3/4” 2

5/16-18 x 5/8” 1

1

1

1

1/4” 2

1/4-20 x 1/2” 2

1

2

10.5 x 40 x 5 1

3/8-16 x 1” 1

5/8”T x 19 x 0.9 x 3048L 1

1

26

Parts List for VSF-14 Saw Frame

Item Part No. Description Size Qty.

107*

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

206

207

5519792 Idler Wheel Assembly

5519795 Idler Wheel Shaft

5519796 Work Light

5519797 Door Handle

TS-0680021 Flat Washer

TS-0570032 Hex Nut, Full

TS-0680042 Flat Washer

TS-0207011 Socket Head Cap Screw

TS-0680021 Flat Washer

5519798 Speed Indicator Dial

5519799 Flat Washer

5519800 Pad

5519801 Dial Knob

5519802 Dial Scale

5519803 Dial Base

TS-0813021 Slotted Flat Head Screw

TS-0680021 Flat Washer

5519804 Idler Wheel Cover

TS-0680021 Flat Washer

TS-0561011 Hex Nut, Full

5521710 Hex Cap Screw

5521711 Overload

1

1

1

1/4” 2

1/4” 2

3/8-24 2

3/8” 2

1/4-20 x 3/8” 1

1/4” 1

1

1

1

1

1

1

1/4-20 x 3/8” 5

1/4” 5

1

1/4” 1

1/4-20 1

1/8” x 3/8” 4

16A (1PH Only) 1

* = See Separate Parts List

27

28

Figure 10: Exploded View of the VSF-14 Base

Parts List for the VSF-14 Base

Item Part No. Description Size Qty.

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

5519805 C-clamp Vise

5519806 C-clamp Knob

5519807 C-clamp Handle

5519808 Lead screw

5519809 Spring

5519810 Ball

5519811 Shaft

5519812 Pivot Pin

5519813 Vise Base

5519814 Vise Bracket

TS-0208061 Socket Head Cap Screw

5519815 Degree Gauge

5519816 Rivet

TS-0209071 Hex Cap Screw

TS-0720091 Lock Washer

TS-0680041 Flat Washer

5519819 Saw Table

5519820 Stock Roller Mtg. Bracket

TS-0720081 Lock Washer

TS-0051051 Hex Cap Screw

5519821 Stock Roller

5519822 Stock Roller Mtg. Bracket

TS-0680061 Flat Washer

5519823 Return Lever

5519824 Plastic Handle

TS-0680042 Flat Washer

TS-0570032 Hex Nut, Full

5519825 Control Box

5519826 Control Panel Cover

5519827 Control Panel Label

JMD18-056A Power ON/OFF Switch

5519829 Hydraulic ON/OFF Knob

5519830 Feed Rate Adjust Knob

5519831 Slotted Round Head Screw

TS-0813051 Slotted Flat Head Screw

5519833 Chip Collector Drawer

TS-0209031 Socket Head Cap Screw

TS-0680042 Flat Washer

TS-0070071 Hex Cap Screw

TS-0680061 Washer

TS-0561051 Hex Nut, Full

5519836 Stop Pad

5519837 Stop Bracket

5519838 Stop Bracket Knob

TS-0680021 Flat Washer

TS-0813051 Slotted Flat Head Screw

5519841 Right Side Panel

5519842 Position Label

5519843 Spring Pin

TS-0680042 Flat Washer

TS-0720091 Lock Washer

TS-0060051 Hex Cap Screw

TS-0570032 Hex Nut, Full

TS-0680042 Flat Washer

1

2

1

1

1

OD = 5mm 1

1

1

1

1

5/16-18 x 1 2

1

2 x 8 3

3/8-16 x 1-1/2” 1

3/8” 1

3/8” 1

1

1

5/16” 4

5/16-18 x 1” 4

1

1

1/2” 2

1

1

3/8” 2

3/8-24 1

1

1

1

120/220/440V 3 Phase 1

1

1

3/16” x 1/2” 4

1/4-20 x 5/8” 4

1

3/8-16 x 3/4” 2

3/8” 2

1/2-13 x 2-1/2” 1

1/2” 2

1/2-13 1

1

1

3/8” x 2” 1

1/4” 4

1/4-20- x 5/8” 4

1

1

6 x 45 2

3/8” 8

3/8” 1

3/8-16 x 1” 4

3/8-24 1

3/8” 4

29

Parts List for the VSF-14 Base

Item Part No. Description Size Qty.

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

196-1

197

198

199

200

201

202

203

204

205

208

TS-0070071 Hex Cap Screw

TS-0561051 Hex Nut, Full

TS-0680042 Flat Washer

TS-0570032 Hex Nut, Full

5519845 Weight Mounting Bracket

TS-0208041 Socket Head Cap Screw

5519846 Pivot Shaft

TS-0209091 Socket Head Cap Screw

5519847 Coupler

5519848 Weight Knob

5519849 Counterbalance Weight

5519850 Saw Base

5519851 Connector

5519852 Connector Mounting Nut

5519853 Control Box

5521707 Worklight Power Cable

5519854 Power Cable with Plug

5519855 Left Side Panel

TS-0680021 Flat Washer

TS-081F032 Phillips Pan Head Screw

5519857 Hydraulic Cylinder Assy.

TS-0561031 Hex Nut, Full

5519858 Cylinder Lower Support

TS-0060091 Hex Cap Screw

5521798 Leg

5521709 Socket Head Cap Screw

5521716 Taper Pin

1/2-13 x 2-1/2” 4

1/2-13 4

3/8” 1

3/8-24 1

1

5/16-18 x 3/4” 1

1

3/8-16 x 2” 1

1

3/8-16 x 2” 1

1

1

PG13.5 2

5

1

115V Only 1

115V Only 1

1

1/4” 4

1/4-20 x 1/2” 4

1

3/8-16 1

1

3/8-16 x 2-1/2” 1

4

3/8-16 x 1” 8

1

* = See Separate Parts List

30

Figure 11: Exploded View of the VSF-14 Gear Box Assembly

Parts List for the VSF-14 Gear Box Assembly

Item Part Number Description Size Qty.

52-1 5519744 Gear Box 1

52-2 BB6204Z Bearing 6204Z 2

52-3 5519745 Oil Seal TC20 x 32 x 7B 1

52-4 5519746 O-Retainer Ring ID45.7 x 2.62W 2

52-5 5519747 Gearbox Drive Shaft Cover 1

52-6 TS-0720071 Lock Washer 1/4” 4

52-7 TS-0207041 Socket Head Cap Screw 1/4-20 x 3/4” 4

52-8 5519748 Oil Level Gauge OD = 26mm 1

52-9 5519749 Oil Plug PT1/4” 1

52-10 5519750 Worm Shaft 1

52-11 5519751 O-Retainer Ring ID113.97 x 2.62W 1

52-12 5519752 O-Retainer Ring ID61.6 x 2.62W 1

52-13 5519753 End Seal Cover 1

52-14 TS-0720071 Lock Washer 1/4” 4

52-15 TS-0207041 Socket Head Cap Screw 1/4-20 x 3/4” 4

52-16

52-17

52-18

52-19

52-20

52-21

52-22

5519754 Ventilation Bolt

5519755 Bearing

5519756 Transmission Gear

5519757 Key

5519758 Bushing

5519759 C-Retainer Ring

BB6206Z Bearing

5/8”-18UNF 1

6205Z 1

1

8 x 7 x 28 1

1

S30 1

6206Z 1

31

Parts List for the VSF-14 Gear Box Assembly

Item Part Number Description Size Qty.

52-23

52-24

52-25

52-26

52-27

52-28

52-29

52-30

52-31

52-32

5519760 Oil Seal

5519761 Main Oil Seal Cover

5519762 Key

5519763 Socket Head Cap Screw

TS-0207041 Socket Head Cap Screw

5519764 Main Shaft Cover

5519765 Main Shaft

TS-0090061 Hex Cap Screw

TS-0720091 Lock Washer

TS-0570032 Hex Nut, Full

TC38 x 52 x 7B 1

1

8 x 7 x 30 1

3/16” x 1/2” 3

1/4-20 x 3/4” 3

1

1

3/8-16 x 1-1/4” 3

3/8” 3

3/8 –24 3

32

Figure 12: Exploded View of the VSF-14 Bearing Shaft Assembly

Parts List for the VSF-14 Bearing Shaft Assembly

Item Part Number Description Size Qty.

39-1 5521712 Ball Bearing 627-2Z 8

39-2 5521713 Blade Wheel 4

39-3 5521714 E Retaining Ring E7 4

39-4 5519732 Bearing Shaft 4

39-5 5521715 C Retaining Ring 4

Figure 13: Exploded View of the VSF-14 Smooth Wheel Assembly

Parts List for the VSF-14 Smooth Wheel Assembly

Item Part Number Description Size Qty.

44-1 5519738 Smooth Wheel 1

44-2 5519739 Bearing 2

69-1

69-2

5519774 Smooth Wheel

BB6201Z Bearing

2

6201Z 4

Figure 14: Exploded View of the VSF-14 Idler Wheel

Parts List for the VSF-14 Idler Wheel Assembly

Item Part Number Description Size Qty.

107-1

107-2

107-3

5519793 Idler Wheel

BB6205ZZ Bearing

5519794 C-Retainer Ring

1

6205ZZ 2

2

33

(115 Volts, Single Phase)

115 Volts, Single Phase

(230 Volts, Single Phase)

230 Volts, Single Phase

Electrical Schematics

34

Figure 15: Electrical Schematics for Single Phase Motor

(230 Volts, Three Phase)

230 Volts, Three Phase

(460 Volts, Three Phase)

460 Volts, Three Phase

Figure16: Electrical Schematics for Three-Phase Motor

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123

Ph.: 847-851-1000

Fax: 800-626-9676

www.wmhtoolgroup.com

Copyright WMH Tool Group

Loading...

Loading...