Page 1

.lET

EQUIPMENT & TOOLS

OPERATOR'S MANUAL

TG-400 TOUCH-UP SPRAY GUN

~

"

~

Stock No. M-228174

.lET EGUIIIIMENT a TOOLS, INC.

A W"H. Waller Meier Holding Company

PO. BOX1477 / 1901 JEFFERSON AVENUE

TACOMA, WASHINGTON 98401-1477

[206] 572-5000

FAX1-206-383-8705

J

"

Revised 6/92

Page 2

-

Important Information

-

1 YEAR

LIMITEDWARRANTY

JEToffersa one year

warrantyon all products

.

REPLACEMEN:riPARTS.

Replacementpartsfor this tool are available directly from JET Equipment& Tools.

To place anorder call 1-800-274-6844. Pleasehave the following informationready:

1. Visa, MasterCardor DiscoverCard number

2. Expirationdate

3. Part numberlistedwithin this manual

4. Shipping address other than a Post Office box

REPLACEMENTPARTS.WARRANTY.

JET Equipment & Tools makes every effortto assurethatparts meet high quality and dura-

bility standards andwarrants to the originalretailconsumer/purchaserof our partsthat each

such part(s)be free from defects in materialsand workmanshipfor a periodof thirty (30)

days from the date of purchase.

~ROOF OF PURCHASE.. .

Please retain yourdated sales receiptas proofof purchase tovalidate the warranty period.

LIMITED TOOL AND EQUIPMENT WARRANTY.'

JET makes every effort to assure that its products meet high quality and durability standards and warrants to the

original retail consumer/purchaser of our products that each product be free from defects in materials and

workmanship as follows: 1 YEAR LIMITED WARRANTY ON ALL JET PRODUCTS. Warranty does not apply to

defects due directly or indirectly to misuse, abuse, negligence or accidents, repairs or alterations outside our

facilities or to a lack of maintenance. JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED

ABOVE FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN,

ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED. SOME STATES DO

NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION

MAY NOT APPLY TO YOU. JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS

OR PROPERTY OR FOR INCIDENTAL, CONTINGENT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING

FROM THE USE OF OUR PRODUCTS, SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY

NOT APPLY TO YOU. To take advantage of this warranty, the product or part must be returned for examination,

postage prepaid, to an authorized service station designated by our Tacoma office. Proof of purchase date and

an explanation of the complaint must accompany the merchandise. If our inspection discloses a defect, JET will

either repair or replace the product or refund the purchase price, if we cannot readily and quickly provide a repair

or replacement, if you are willing to accept such refund. JET will return repaired product or replacement at JET's

expense, but if it is determined there is no defect, or that the defect resulted from causes not within the scope of

JET's warranty, then the user must bear the cost of storing and returning the product. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state.

JETEquipment&Tools,P.O.Box1477,Tacoma,WA98401-1477:(206)572-5000.

Page 3

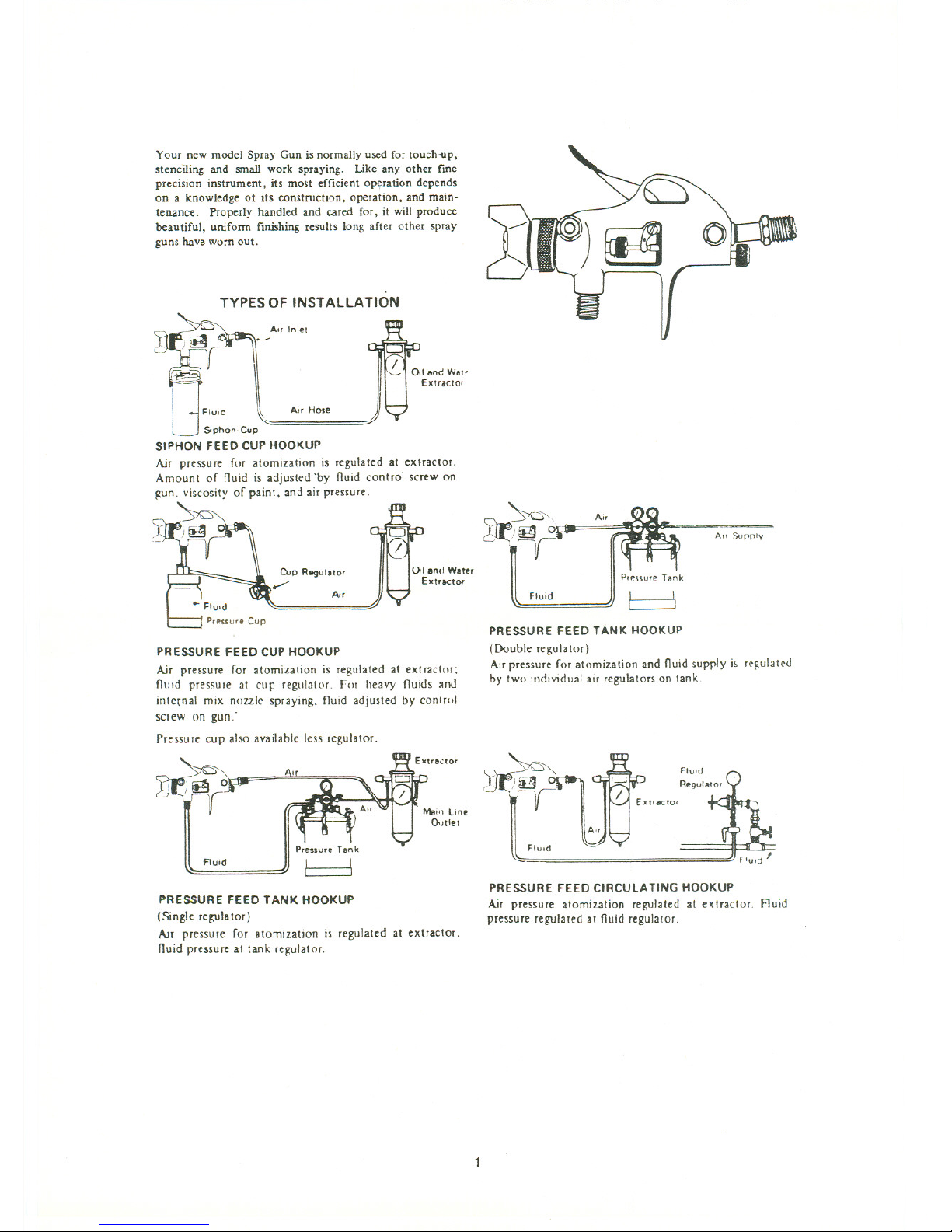

Your new model Spray Gun is normally used for touch-ilp,

stenciling and small work spraying. Like any other fine

precision instrument, its most efficient operation depends

on a knowledge of its construction, operation, and main-

tenance. Properly handled and cared for, it will produce

beautiful, uniform finishing results long after other spray

guns have worn out.

TYPESOF INSTALLATION

)

.

1~~ _A"',,',,

d:f~~

l

f1"",,~.

l_j SiphonCup

SIPHON FEED CUP HOOKUP

Ot! and W.,'

E.tractor

Oil and Water

E .tractor

Air

Prl'ssure Cup

PRESSURE FEED CUP HOOKUP

Air pressure for atomization is regulated at extractor;

fluid pressure at cup regulator. For heavy fluids and

internal mix nozzle spraying. fluid adjusted by control

screw on gun'-

Pressure cup also available less regulator.

FluId

PRESSURE FEED TANK HOOKUP

(Single regula tor)

Air pressure for atomization is regulated at extractor.

fluid pressure at tank regulator.

A.. Sor>r>ly

Pr.ssure Tank

FluId

PRESSURE FEED TANK HOOKUP

(Double regulator)

Air pressure for atomization and fluid supply is

by two individual air regulators on tank

rcgulatcJ

~~

nr;~r.

Fluid

FluId'

PRESSURE FEED CIRCULATING HOOKUP

Air pressure atomization regulated at extractor. Fluid

pressure regulated at fluid regulator.

Page 4

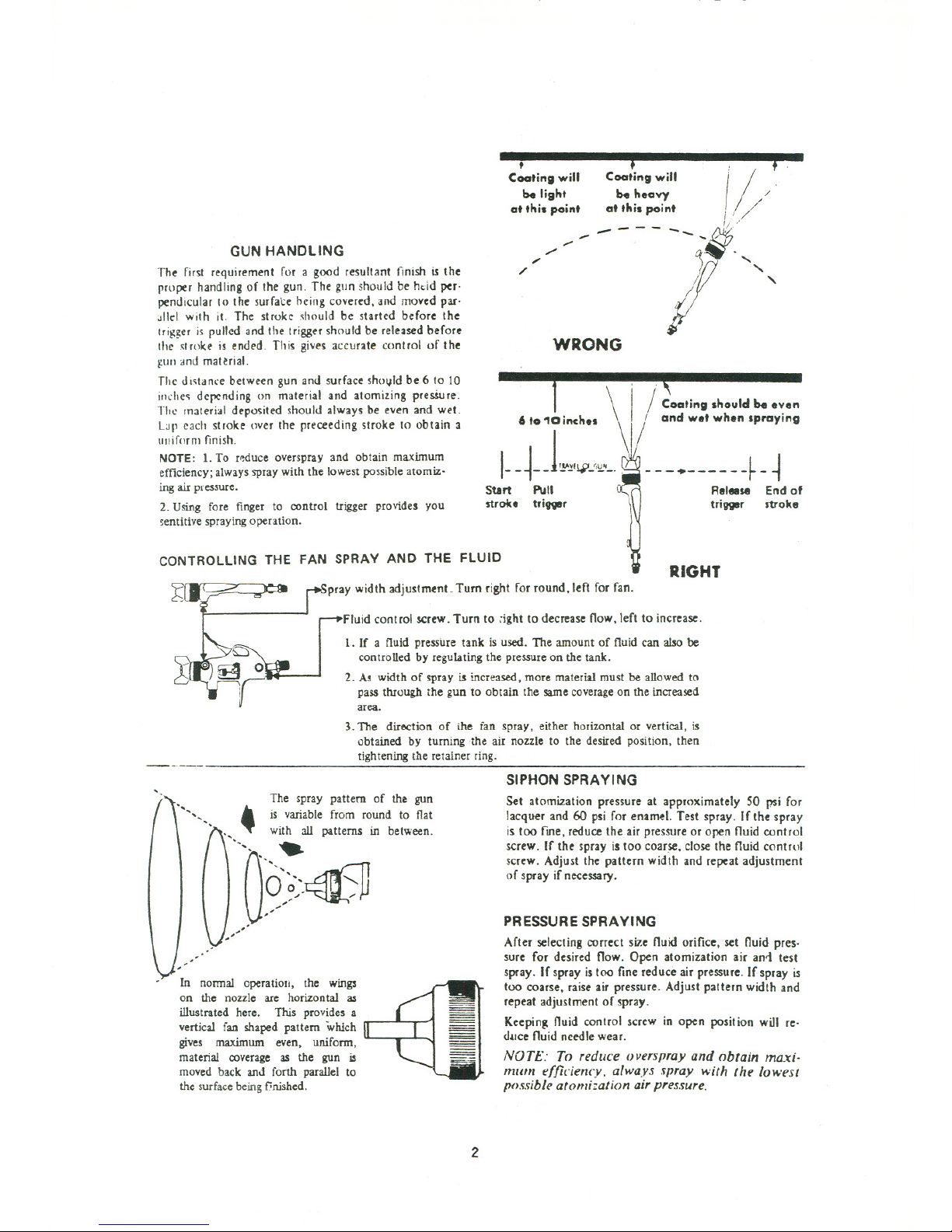

GUN HANDLING

Th~ first requirement for a good resultant finish is the

proper handling of the gun. The gun should be hdd per-

pendicular to the surfate heing covered, and moved par-

allel with it. The stroke should be started before the

Irigger is pulled and the trigger should be released before

the st roke is ended. This gives accurate control of the

gun and material.

The distance between gun and surface shovld be 6 to 10

inches depending on material and atomizing presSure.

TII\: material deposited should always be even and wet.

Lap each stroke over the preceeding stroke to obtain 3

uniform finish.

NOTE: 1. To rp-duce overspray and obtain maximum

efficiency; always spray with the lowest possible atomiz-

ing air pressure.

2. Using fore finger to control trigger provides you

sentitive spraying operation.

CONTROLLING THE FAN SPRAY AND THE FLUID

-

.

Coetting will

be light

at this point

,

Coetting will

be heavy

at this point

I

'

!

/""

. /

1///

!/ .'

....

/'

./

"

/'

----

"-

"-

"

WRONG

1 " \

\

I

/Coating should be even

",'0;Mh.. \! a.d wolwho. ,;..

1- _~__L,IV~C'_

~

' - - --~ - ~

Start Pull Release End of

stroke tri1Xl8r \ trigger stroke

pray width adjustment- Turn right for round, left for fan.

RIGHT

Fluid cont rol screw-Turn to ;jght to decreaseflow, left to increase.

1. If a fluid pressure tank is used. The amount of fluid can also be

controlled by regulating the pressure on the tank.

2. As width of spray is increased, more material must be allowed to

pass through the gun to obtain the same coverageon the increased

area.

3. The direction of the ian spray. either horizontal or vertical, is

obtained by turning the air nozzle to the desired position, then

tightening the retainer ring.

'.

SIPHON SPRAYING

"'"

"

The spray pattern of the gun

. is variable from round to flat

. ~ with all patterns in between.

"'" ......

~s~~~-.~

,'''

.

In normal operation, the wings

on the nozzle are horizontal as

lius trated here. This provides a

vertical fan shaped pattern which

gives maximum even, uniform,

material coverage as the gun is

moved back and forth parallel to

the surface being finished.

Set atomization pressure at approximately 50 psi for

lacquer and 60 psi for enamel. Test spray. If the spray

istoo fme,reducetheairpressureoropenfluid control

screw. If the spray is too coarse, closethe fluid control

screw. Adjust the pattern width and repeat adjustment

of spray if necessary.

PRESSURE SPRAYING

Afterselectingcorrectsizefluidorifice,set fluidpres-

sure for desired flow. Open atomization air an.J test

spray. If spray istoo fine reduce air pressure. If spray is

too coarse,raiseair pressure.Adjustpatternwidth and

repeat adjustment of spray.

Keeping fluid control screw in open position will re-

duce fluid needle wear.

NOTE: To reduce overspray and obtain maxi-

mllm efficienc:v. always spray with the lowest

possible atomization air pres.sure.

2

Page 5

FAUL TV SPRAV (and how to correct them)

A faulty spray is caused by imporper cleaning or dried material around the

fluid nozzle tip or in the air nozzle. Soak these parts in a solvent that will

soften the dried material and remove with a brush or cloth. Never use

metal instruments to clean the air or fluid nozzles. These parts are care-

fully m~chined and any damage to them will cause a faulty spray. if

either the air nozzle or fluid nozzle is damaged, the part must be replaced

before a perfect spray can be obtained.

PATTERN

~

SPITTING

CAUSE

CORRECTION

Dried material in side.

port" A" restricts passage

of air. Greater flow of air

from cleaner side-port

uB" forces fan pattern in

direct ion of clogged side.

A

ff<~

U

'

I<'

.

J,~/)/))/. .

"l~

Dissolve materia! in side-polts with

thinn;r. tilen blow ~un clean. Do not

poke into openin~s with metal instru.

ments.

B

Dried material around

the outside of the fluid

nozzle tip at position

uC" restricts the passage

of atomizing air at one

point through the center

opening of air nonle and

results in pattern shown.

This pattern can also be

caused by loose air no7.-

zle.

fj

~

....

'-d

Remove air nozzle and Wipe off iluid

lip, using rag wet with thiuner. Ti~ht-

en air nozzle.

A split spray or one that is

heavy on each end of a fan

pattern and weak in the mid-

dle is usually caused by (I)

too high an atomizal1on air

pressure, or (2) by attempting

to get too wide a spray with

thin mat-erial,

Reducing air pressure will correct

cause (I). To correct cause (2), open

material control to full position by

turning to left. At the sametime, turn

spray width adjustment to righl. This

will reduce width of spraybut willcor.

rect split spray pattern,

(I) Dried out packingarol;nd

material needle valvepermits

air to get into fluid p2Ssage.

way. This results in spitting,

(2) Dirt between fluid nonle

seat :md body or !ooselyin-

stalled fluid nozzlewill make

gun spit.

(3) A loose or defective swiv-

el nut on siphon cup or ma-

teria) hose can cause spitting.

To correct cause (I)

back up knurled nut

(E), place two drops

of machine oil on

packing, replace nut

and lighten with fing.

ers only. In aggra-

vated cases, replace

packing,

To correct cause (2), remove fluid noz-

zle (F), clean back of nozzle and no7..

zle seat in gun body using rag wet with

thinner, replace nozzle and draw up

tightly against body.

To correct cause (3), tighten or re-

place swivel nut.

.

~

3

Page 6

.JET

EQUIPMENT & TOOLS

TG-400

Touch Up Gun

517

PART#

DESCRIPTION

OTY

PART# DESCRIPTION

OTY

501 STEM

1

543

SPRING

502 BODY

1

544

SCREW

503 PACKING 1

545 VALVENUT

504 RING 1 549 SPRING

505 SPRING 1 551 TRIGGER

506 RING

1 556

CAP

507 PIN

1 557

AIRCONNECTION

508 CONNECTION 1 5232 AIRNOZZLE

509 TRIGGERSCREW 1 5237 NEEDLEASSEMBLY

514 FLUIDNOZZLE

1

5240 STEMASSEMBLY

517 BODY 1 5241

SIDEPORTCONTROLASSY

530 PACKING

4 700

CUp*

537 LOCK NUT 1 701

CUPCOVER*

538 REARLOCKNUT

1

702

GASKET*

* NOTSHOWNON DIAGRAM

RPK-400 Repair Kit: Contains part # 503, 509, 530, 543

RBK-400 Rebuild Kit: Contains part # 544, 549, 551, 5240, 5237

7/94

4

Page 7

General Maintenance

SPRAY GUN

I. Immerse only the front end of the gun until solvent

just covers the fluid connection.

2. Use a bristle brush and solvent to wash off accumu-

lated paint.

3. Do not submerge tHeentire spray gun in solvent be-

cause:

a. the lubricant in the leather packings wiJldissolve

and the packings willdry out.

b. the lubricant at wear surfaces willdissolvecausing

harder operation and faster wear.

c. residue from dirty solvent may clvg the narrow air

passagesin the gun.

4. Wipedown the outside of the gun with solventdamp-

ened rag.

S. Lubricate gun daily. Usealight machine oilon:

a. fluid needle packing.

b. air valvepacking.

c. side port control packing.

d. triggerpivot point.

Coat the fluid control springwith vaseline.

6. Caution: Neveruse lubricanIScontaining silicone. This

material may cause finish defects.

PRECAUTIONARY NOTE

All parts on a spray gun should be screwed in hand tight

at first; this will avoid the possibility of cross threading

the parts. If the parts can not be turned by hand easily,

make sure you have the correct parIs. unscrew, realign,

and try again. NEVER use undue force in mating parts.

AIR NOZZLE, FLUID Po!OZZLE,NEEDLE ASSEMBLY

I. All nozzles and needles are precision made. They

sh<)uld be handled with care.

2. Except as described in S., do not make my alterations

in the gun. To do so could cause finishing difficulties.

3. To clean nozzles, soak them in solvent to dissolve any

dried material, then blow them clean with air.

4. Do not probe any of the holes in the noules with

metal instruments. If probing is necessary, use only a

tool that is softer than brass.

S. Adjust the fluid needle valve so that when gun is

triggered, air-flow occurs before f1'Jid-flow.

POINTERS ON CLEANING

WHEN USED WITH A CUP

A compatible solvent should be siphoned through gun by

inserting tube from siphon cup in an open container of sol-

vent. Trigger gun intermittently to thoroughly flush' pas-

sageways and internal parts.

WHENUSEDWITHPRESSURE CUP

Shut off the air supply to the Pressure Tank and release the

pressure in the tank. Hold a piece of cloth over the gun

nozzle and pull the trigger, the air willback up through the

fluid nozzle and force the fluid out of the hose and into the

tank. Remove paint from tank, clean tank and put enough

compatible solvent into the tank to clean the hose and gun

thoroughly. Spray this through the gun triggering the gun

intermittently until it is clean, then blowout the fluid hose

to dry it and remove all traces of materials by attaching it

to the air line.

5

Page 8

AIR SUPPLY

1/111111111111/1111/111111/1/'::'f /'::.11/1/1//'!.-I.!!1/1/1 ~

Pitch pipe bock toward air Nellvlr

.

Compressor unit

PIPE SIZE. 1.0. line"'"

I

InUl IIdr.ln It

..eh low point

\

011and water

I.trador .

"

Drain

r 25 FEETORMORE .,

Oillltd WI- EatrKto, 8houldt. It II., 25 ft. f,om ml eomp.-or. F.rth., jf poIIibli.

The oil Ind _tel' e.trlC1or should not be mounted on

or nllr the lir compressor.

The temperatureofairisgreatlyincreasedduringcom.

pression. }.j the air cools down to room temperature, in

the air line. on its way to the spray 2'Jn, the moisture

contained in it condenses.Thus, for maximumeffective.

ness, the oil and water extractor should be mounted at

some point in the air supply system where the tempera.

ture of thc compressed air in the line is likely to be

lowest.

Ail lines must be properly drained

Pitch all air lines back towards the compressor so that

condensed moisture will flow back into the air receiver

where it can be drained ofi. EachlowSoint in an air line

actsasa water.trap.Suchpointsshoul befittedwithan

easily accessibledrain. See diagramahove.

6

Air Flow

CFM

'0

.,..,"

""

,,""

20

%0" "''' "''' "'''

30

""

%0"

,"

,"

..

O ," ," ," ,"

50 ," ," ,"

,"

10

''' '''

"4"

l'l,"

Air Consumption

Fuild Nozzle

CFM

Pat

Compres$or

Air

Orifice Size

at 8"

Required

Connection

30 psi 50 psi

<p1.8MM

2.8

4.0 8"

1 H.P.

W' NPS(M)

(0.75 W)

Loading...

Loading...