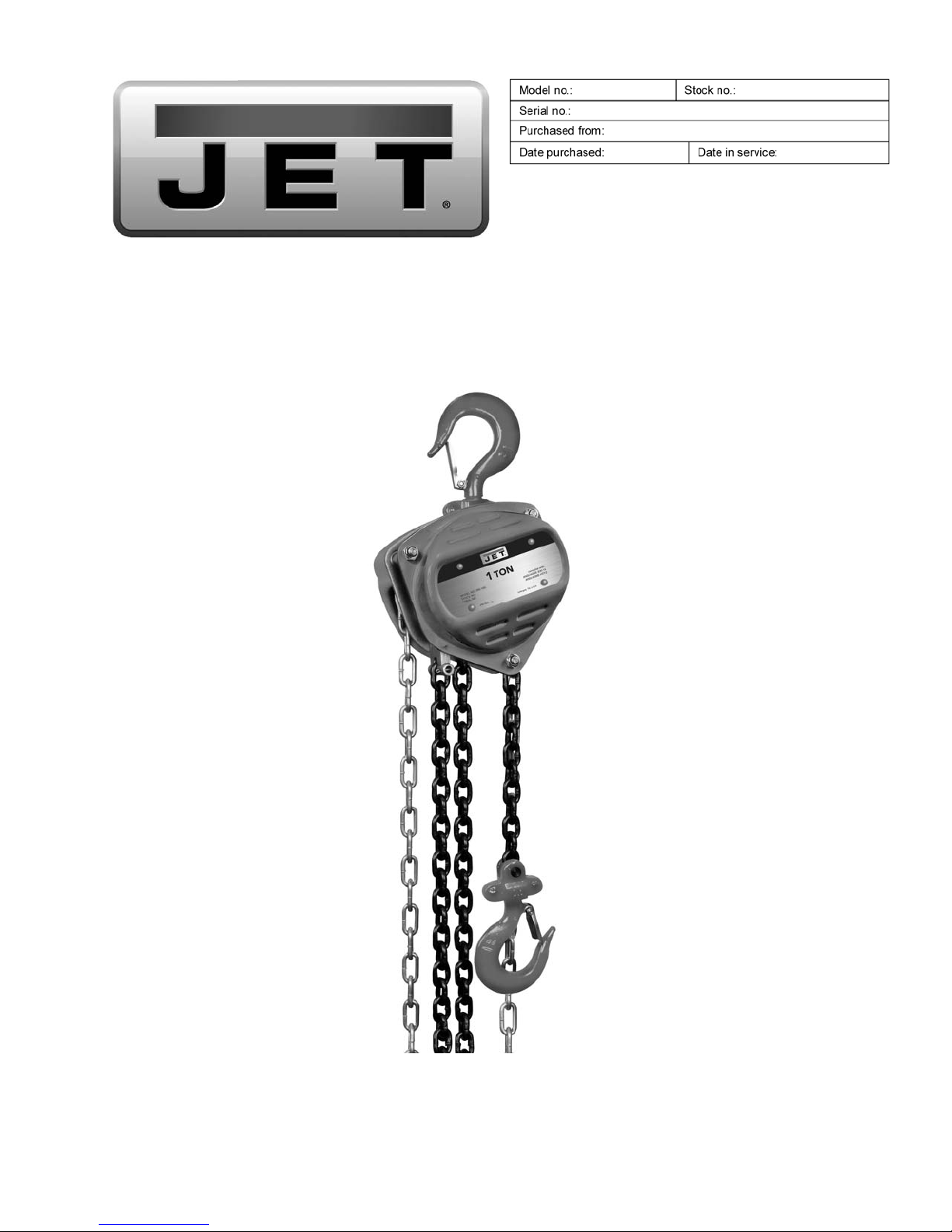

Jet S90 Series, S90-050, S90-100, S90-150, S90-200 Operating Instructions And Parts Manual

...Page 1

Operating Instructions and Parts Manual

S90 Series Hand Chain Hoists

For S90-100 serial no. 15070361H and higher

For S90-150 serial no. 15070389H and higher

For S90-300 serial no. 15070605H and higher

For S90-1000 serial no. 15070767H and higher

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-101900

Ph.: 800-274-6848 Revision C1 07/2018

www.jettools.com Copyright © 2018 JET

1-Ton model shown

Page 2

1.0 IMPORTANT SAFETY INSTRUCTIONS

WARNING – To reduce risk of injury:

1. Read and understand the entire owner’s

manual before attempting assembly or

operation.

2. Read and understand the warnings posted on

the tool and in this manual. Failure to comply

with all of these warnings may cause serious

injury and/or damage to property.

3. Replace the warning labels if they become

obscured or are missing.

4. Keep visitors a safe distance from the work

area. Keep children away.

5. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in

serious injury.

6. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

7. This chain hoist is designed and intended for

use by properly trained and experienced

personnel only. If you are not familiar with the

proper and safe operation of a chain hoist, do

not use until proper training and knowledge

have been obtained.

8. Do not use this chain hoist for other than its

intended use. If used for other purposes, JET

disclaims any real or implied warranty and

holds itself harmless from any injury that may

result from that use.

9. Do not use to lift people or loads over people.

10. Do not exceed the rated capacity of the chain

hoist.

11. Do not use more than hand power to pull the

hand chain.

12. Do not use the load chain as a sling; this may

cause damage to the chain.

13. Always inspect the chain hoist for damage

prior to use. If the chain hoist is damaged, do

not use until it has been repaired or replaced.

14. Do not use more than one chain hoist to lift or

move a load. If this is unavoidable, each chain

hoist must have the same capacity as the load

to be moved.

15. Never allow the load chain to “set” over sharp

edges. All lifts must be made with straight

chain that is free of obstacles.

16. If the hand chain is difficult to operate, then the

load exceeds the capacity of the chain hoist.

Select a chain hoist of larger capacity.

17. Do not use a chain hoist unless load is

centered between top and bottom hooks.

18. Always take time to study the job to be

performed and choose the safest method. Do

not place yourself or other people in an unsafe

position.

19. Stand to one side of the load being lifted and

make sure no one else is standing underneath

when lifting a load. Should a load slip, it will

descend at a high rate of speed and can cause

serious injuries to anyone standing directly

underneath.

20. Leave all internal maintenance to a qualified

JET Service Center.

21. Replace the chain with factory replacement

chain only. Do not use any other type of chain.

22. If welding near the hoist, do not allow the chain

or hook to be touched by a live electrode.

Prevent weld splatter upon the chain.

23. Never use the chain hoist if either hook is

stretched, deformed, or has a broken or

missing safety latch. Always replace the safety

latch and/or the hook before placing the chain

hoist back into service.

24. Understand and follow all procedures as set

forth in American National Standards titled

“Performance Standard for Hand Chain

Manually Operated Chain Hoists.” ANSI/ASME

HST-2; and “Overhead Hoists (Underhung),”

ANSI/ASME B30.16. These standards are

available through the American Society of

Mechanical Engineers, www.ASME.org

WARNING: This product can expose you to

chemicals including lead, which is known to the

State of California to cause cancer and birth

defects or other reproductive harm. For more

information go to http://www.p65warnings.ca.

gov.

Page 3

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly even

death.

2.0 Table of Contents

Section Page

1.0 IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................... 2

2.0 Table of Contents ........................................................................................................................................... 3

3.0 About this manual .......................................................................................................................................... 4

4.0 Specifications and Dimensions for S90 Series Chain Hoists ......................................................................... 5

5.0 Using the Chain Hoist .................................................................................................................................... 6

5.1 Prior to Operation ....................................................................................................................................... 6

5.2 Hooking the load ........................................................................................................................................ 6

5.3 Raising the Load ........................................................................................................................................ 7

6.0 Hand chain: Cutting and installing .................................................................................................................. 7

7.0 Load chain: Removing and installing ............................................................................................................. 8

7.1 Load chain inspection ................................................................................................................................. 8

7.2 Load chain removal (all models) ................................................................................................................ 8

7.3 Attaching load chain to load chain sprocket (all models) ........................................................................... 8

7.4

Completing load chain installation

7.5 Chain installation: 0.5T thru 2T .................................................................................................................. 9

7.6 Chain installation: 3T and 5T ...................................................................................................................... 9

7.7 Chain installation: 10T .............................................................................................................................. 10

8.0 Inspection and maintenance ........................................................................................................................ 11

9.0 Load and wear limits .................................................................................................................................... 12

9.1 Alloy steel chain ....................................................................................................................................... 12

9.2 Hooks (top and bottom) ............................................................................................................................ 12

9.3 Brake disc ................................................................................................................................................. 13

10.0 Timing Marks for Gear Replacement ......................................................................................................... 13

11.0 Troubleshooting JET® Manual Chain Hoists .............................................................................................. 14

12.0 Replacement Parts ..................................................................................................................................... 15

12.1.1 S90 Chain Hoists – Exploded View ..................................................................................................... 15

12.1.2 S90-050 Chain Hoist (0.5 Ton) – Parts List ......................................................................................... 16

12.1.3 S90-100 Chain Hoist (1 Ton) – Parts List ............................................................................................ 18

12.1.4 S90-150 Chain Hoist (1.5 Ton) – Parts List ......................................................................................... 20

12.1.5 S90-200 Chain Hoist (2 Ton) – Parts List ............................................................................................ 22

12.1.6 S90-300 Chain Hoist (3 Ton) – Parts List ............................................................................................ 24

12.1.7 S90-500 Chain Hoist (5 Ton) – Parts List ............................................................................................ 26

12.1.8 S90-1000 Chain Hoist (10 Ton) – Parts List ........................................................................................ 28

13.0 Warranty and Service ................................................................................................................................. 30

............................................................................................................... 9

Page 4

3.0 About this manual

This manual is provided by JET covering the safe operation and maintenance procedures for a JET Series S90

Manual Chain Hoist. This manual contains instructions on installation, safety precautions, general operating

procedures, maintenance instructions and parts breakdown. Your hoist has been designed and constructed to

provide consistent, long-term operation if used in accordance with the instructions as set forth in this document.

If there are questions or comments, please contact your local supplier or JET. JET c an also be reached at our

web site: www.jettools.com.

Retain this manual for future reference. If the hoist transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual befor e attempting assembly

or operation! Failure to comply may ca use serious injury!

Register your product using the mail-in card provided, or register online:

http://www.jettools.com/us/en/service-and-support/product-registration/

The JET S90 hoists comply with OSHA, ANSI/ASME B30.16 and HST-2 standards.

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET, reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

4

Page 5

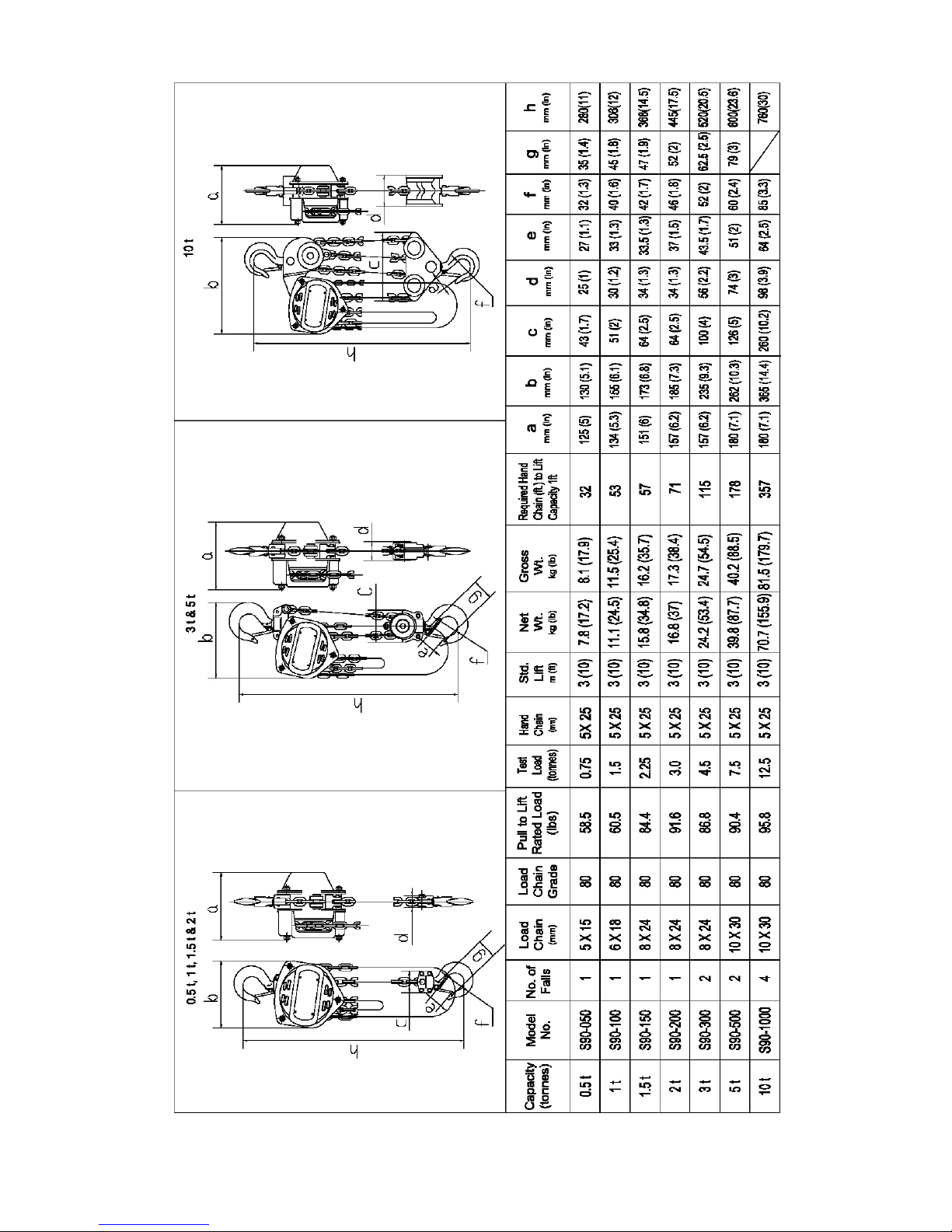

Gross weight includes shipping/packaging materials.

2

4.0 Specifications and Dimensions for S90 Series Chain Hoists

Table 1

Chain is available in various lengths. Specify required length when ordering.

1

5

Page 6

5.0 Using the Chain Hoist

5.1 Prior to Operation

1. Support f or the hoist may be hook, clevis pin,

trolley, or beam clamp. Whatever method of

suspension is chosen, the support

components must be rated equal to, or greater

than the capacity of the chain hoist.

2. If the chain hoist has not been used for an

extended period of time, check for proper

operation before putting into service.

3. The brake mechanism must be kept clean and

free from dirt, water, and oil. Never allow oil to

penetrate the brake mechanism. Always keep

your chain hoist clean and store in a clean, dry

location.

4. Although oiling the chain is not mandatory, a

light coat of 30W oil applied periodically to the

chain will create easier operation and prolong

the life of the chain.

5. Check the chain for damage and elongation.

Replace damaged chain before using the

chain hoist.

The load chain supplied with your JET chain hoist

is designed, manufactured, and tested for proper fit

and durability. Over a period of time, the chain may

need to be replaced. For your own safety, use

factory replacement chain only.

Use of other than factory

replacement chain may cause serious injury

and/or damage to the hoist.

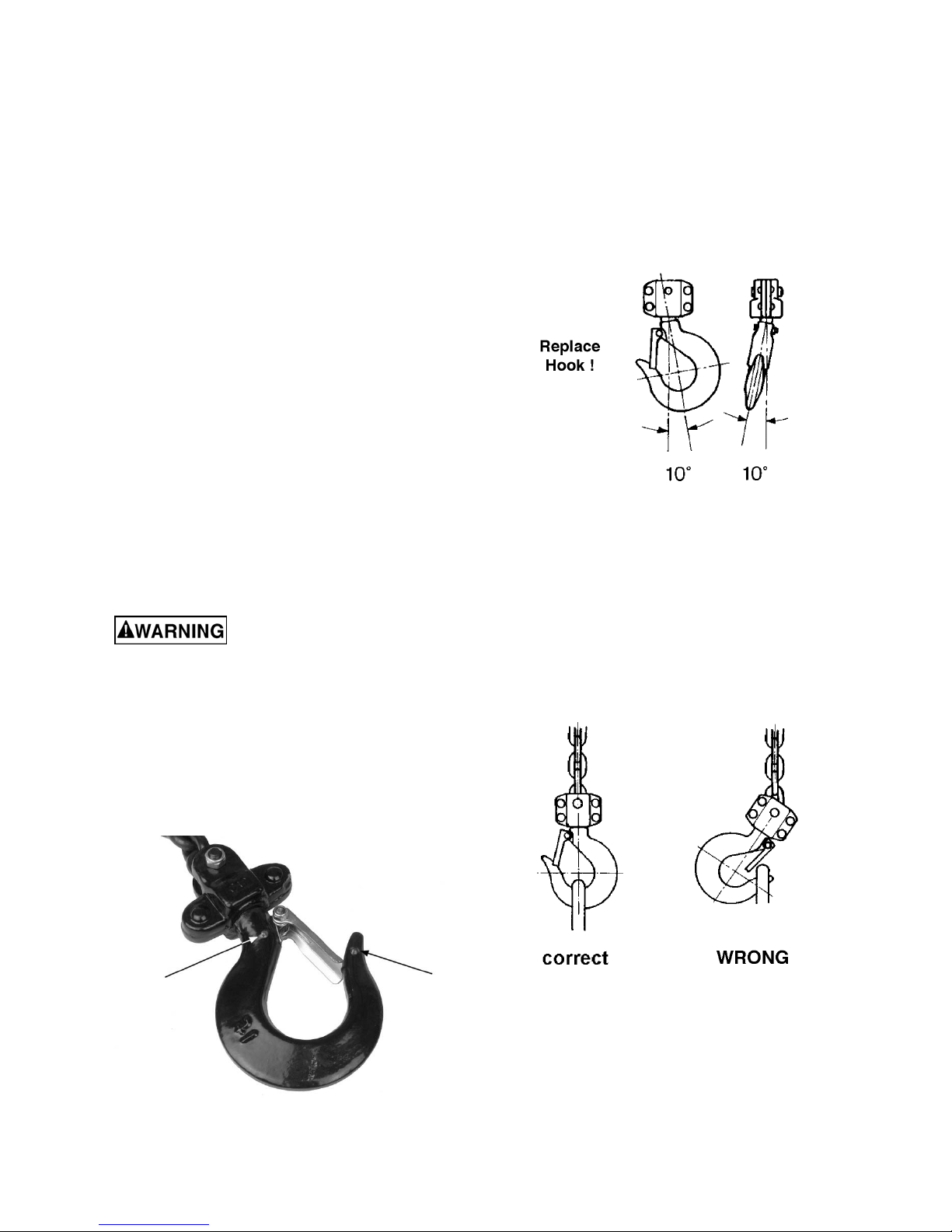

6. The top and bottom hooks on your JET c hain

hoist are designed to open to warn of an

overload. Both top and bottom hooks (1/2T to

5T models) have indicator points cast into the

hook. See Figure 1. The measurement

between indicator points must fall below the

limit shown in section 9.2, Table 3. If it

exceeds the limit, the hook must be replaced.

7. It is important to c heck top and bottom hooks

for proper opening. If the safety latch no longer

contacts the hook opening, replace the hook.

Never side load the top or bottom hook;

this practice is dangerous and could lead

to serious injury.

8. If the vertical angle at the neck of the bottom

or top hook reaches 10°, replace the hook (see

Figure 2).

Figure 2

5.2 Hooking the load

1. Secure the upper hook.

2. Place the bottom hook securely into the object

to be lifted.

3. Place ropes or chain in the center of the

bottom hook, making sure the safety latch is

secure. Never load the hook in front of the

safety latch. See Figure 3.

Figure 1

Figure 3

4. Avoid lifting one load with two hoists. If this is

unavoidable, apply equal weight to both hoists

and use hoists with the proper lift capacity.

Capacity of each hoist must be equal to the

total load to be lifted.

6

Page 7

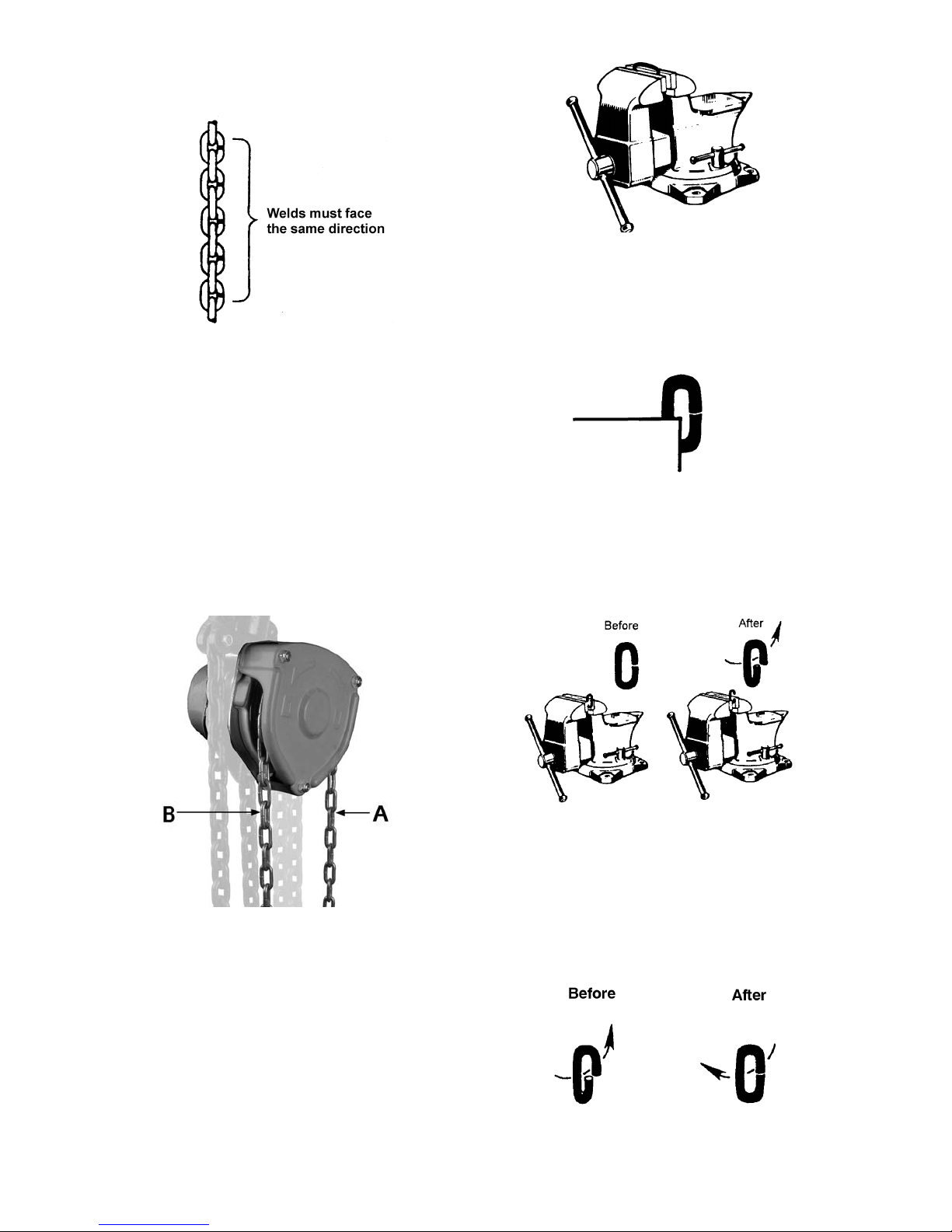

5. Check that the chain is not twisted at the

bottom hook. All welds should face the same

direction (Figure 4).

Figure 4

6. For hoists with two or more falls of chain, make

sure the bottom hook is not capsized (turned

over). This may cause the chain to twist.

5.3 Raising the Load

Figure 6

2. Using a hack saw, cut through upper part of

link at the weld.

3. Loosen the link, reposition link vertically at

edge of vise with the level of the cut above the

vise jaw (Figure 7).

To raise load, pull right side of hand chain (A,

Figure 5) so that wheel turns clockwise.

To lower load, pull left side of hand chain (B,

Figure 5) so that wheel turns counterclockwise.

Important: Make sure hoist has an adequate

length of load chain to raise or lower the load in a

safe manner. Do not attempt to lower hoist beyond

its limit.

Figure 5

6.0 Hand chain: Cutting

Figure 7

4. Tighten vise jaw.

5. Using an adjustable wrench, twist the link

horizontally from front to back. (Figure 8)

Open just far enough to insert (or remove) a

second chain link.

Figure 8

Note: Chain length is now ready to lengthen or

shorten.

6. Insert (or remove) the second end link at the

opening in the first end link.

7. Using an adjustable wrench, twist the link

horizontally until the link is in the original

closed position. See Figure 9.

and installing

To cut hand chain in order to lengthen or shorten:

1. Insert one link lengthwise into a vise (Figure

6). Be sure that the side opposite the weld lies

completely below surface of vise jaw (about

1/3 of a link). This prevents nicking or cutting

the lower part of the link.

Figure 9

7

Page 8

Do not push the link inward

from the curved ends. This will distort the li nk.

Check that the link is closed and free of twist.

8. If installing entire new chain, insert end of

hand chain into groove at top of hand chain

wheel (see Figure 11). Rotate handwheel and

pull chain through.

9. Re-weld the link at the cut.

10. Grind off excess on weld so that it is smooth.

Do not operate the hois t with a

twisted, kinked or damaged load chain. Do not

splice the load chain. Check the chain for

excessive wear or stretch. Failure to comply

may cause serious injury.

7.0 Load chain: Removing

and installing

7.1 Load chain inspection

Over time, the load chain will wear or elongate.

This can cause damage to the hoist, breakage, or

non-engagement of the load sheave.

Do not operate the hois t with a

twisted, kinked or damaged load chain. Do not

splice load chain. Check the chain for

excessive wear or stretch. Failure to comply

may cause serious injury.

To inspect the load chain for wear:

1. Test the hois t under load in both the lifting and

lowering directions, observing the operation of

chain and sprockets. Chain should feed

smoothly into and away from the sprockets.

2. If the chain binds, jumps, or is noisy, make

sure it is clean and properly lubricated. If the

trouble persists, inspect the chain and mating

parts for wear, distortion, or other damage.

3. Clean the chain before inspection. Examine for

gouges, nicks, weld splatter, corrosion, and

distorted links. Slacken the chain and move

adjacent links to one side, looking for wear at

the contact points. If you see wear or suspect

stretching, measure the chain as explained in

section 10.1. If chain matches or exceeds the

limit shown in Table 2, replace the load chain

before using the hoist.

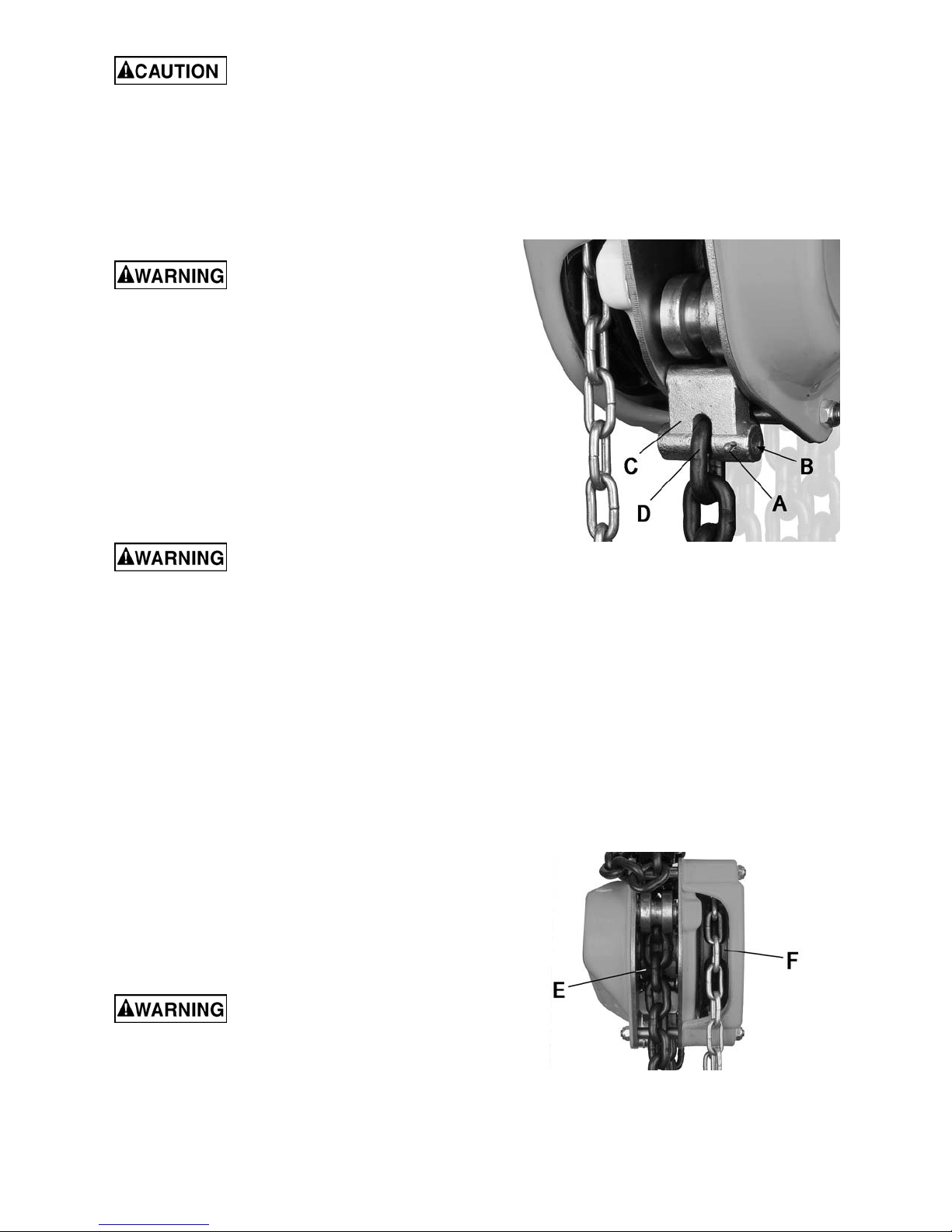

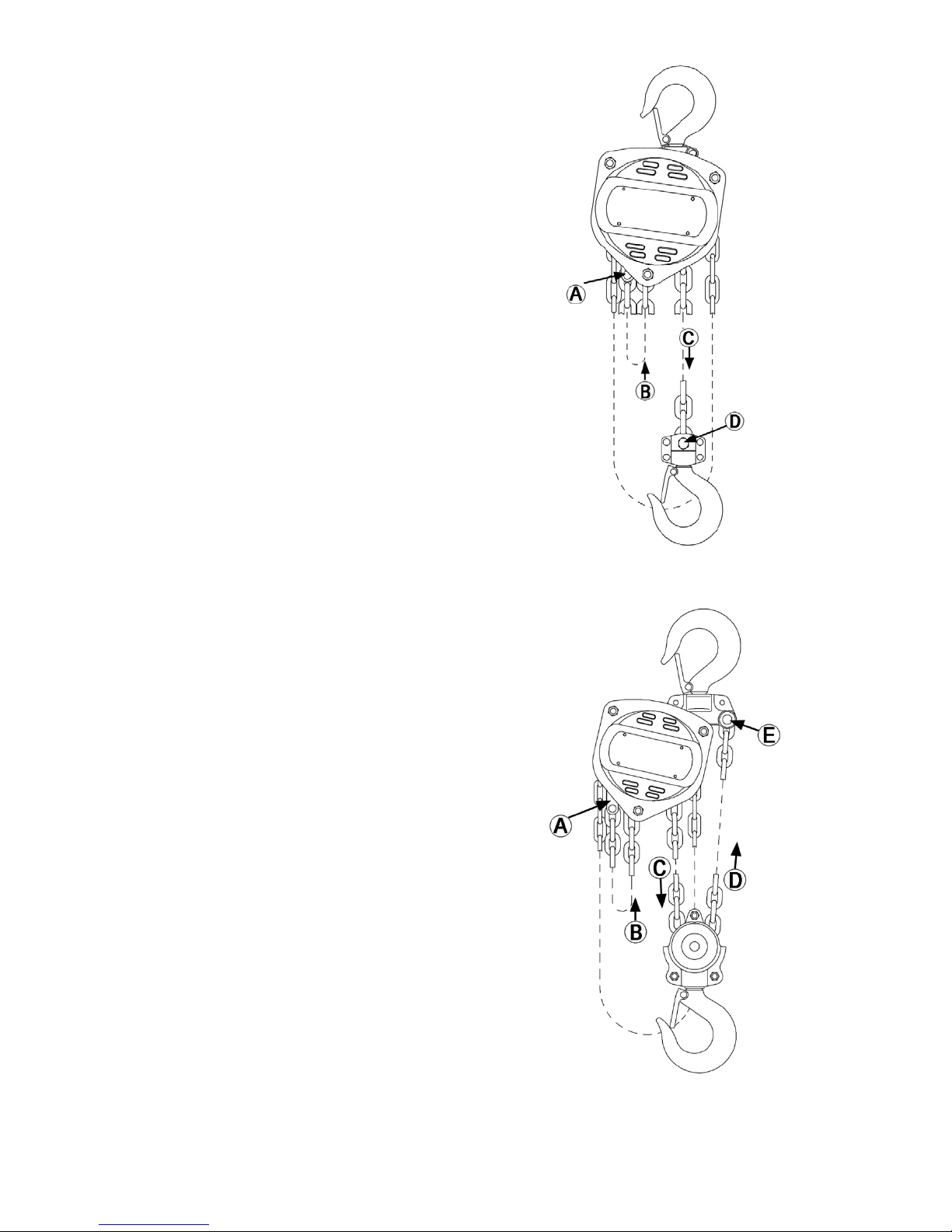

7.2 Load chain removal (all models)

Remove old load chain as follows while referring to

Figure 10:

1. Remove split pin (A) and pin stopper (B) on

the chain anchor C), allowing the end of the

load chain to fall free.

2. Pull the hand chain (Figure 5) until load chain

is completely removed from gear assembly.

Figure 10

7.3 Attaching load chain to load

chain sprocket (all models)

Install new load chain onto load chain sprocket as

follows, referring to Figure 11:

1. Position the load chain sprocket (E) by rotating

hand chain wheel (F) so that the wide and

narrow grooves show.

2. Insert the load chain into the sprocket grooves

so that chain will wind up and back over the

sprocket. Welds must face away from the

sprocket.

3. Rotate hand chain wheel so that load chain

falls six to eight inches at back of sprocket.

Do not add to the load chain.

Replace entire chain. Failure to comply may

cause serious injury.

Figure 11

8

Page 9

Referring back to Figure 10:

4. Insert one end of chain link (D) into chain

anchor (C).

5. Insert pin stopper (B) through chain anchor (C)

and chain link (D) and secure with split pin (A).

Continue with section 8.4, proceeding to the

section that applies to your hoist.

7.4

Completing load chain installation

The following procedure assumes that the load

chain has been attac hed to the chain anchor and

fed through the load chain sprocket as described in

the previous section. This procedure will complete

the load chain and bottom hook installation.

7.5 Chain installation: 0.5T thru 2T

Referring to Figure 12:

1. Remove lock nut and bolt (D) from lower hook.

2. Insert the last chain link (C) into lower hook

slot.

3. Re-insert bolt through lower hook slot and

chain link.

4. Install lock nut onto bolt and tighten.

Figure 12

(1/2 through 2-ton hoists)

7.6 Chain installation: 3T and 5T

Referring to Figure 13:

1. After installing the load chain into load chain

sprocket (B), run the remaining chain through

your hand to remove any twist. The last link of

the chain must be in the same direction as the

first. If not, cut off the last link.

2. Insert the last link into pulley of lower hook (C).

3. Pull load chain through and up from unders ide

of pulley (C,D).

4. Remove lock nut and chain anchor pin in

upper hook slot (E).

5. Insert the last link into upper hook slot.

6. Check that load chain is not twisted.

7. Reinstall chain anchor pin through upper hook

slot and last chain link, and secure with the

lock nut.

Figure 13

(3-ton and 5-ton hoists)

9

Page 10

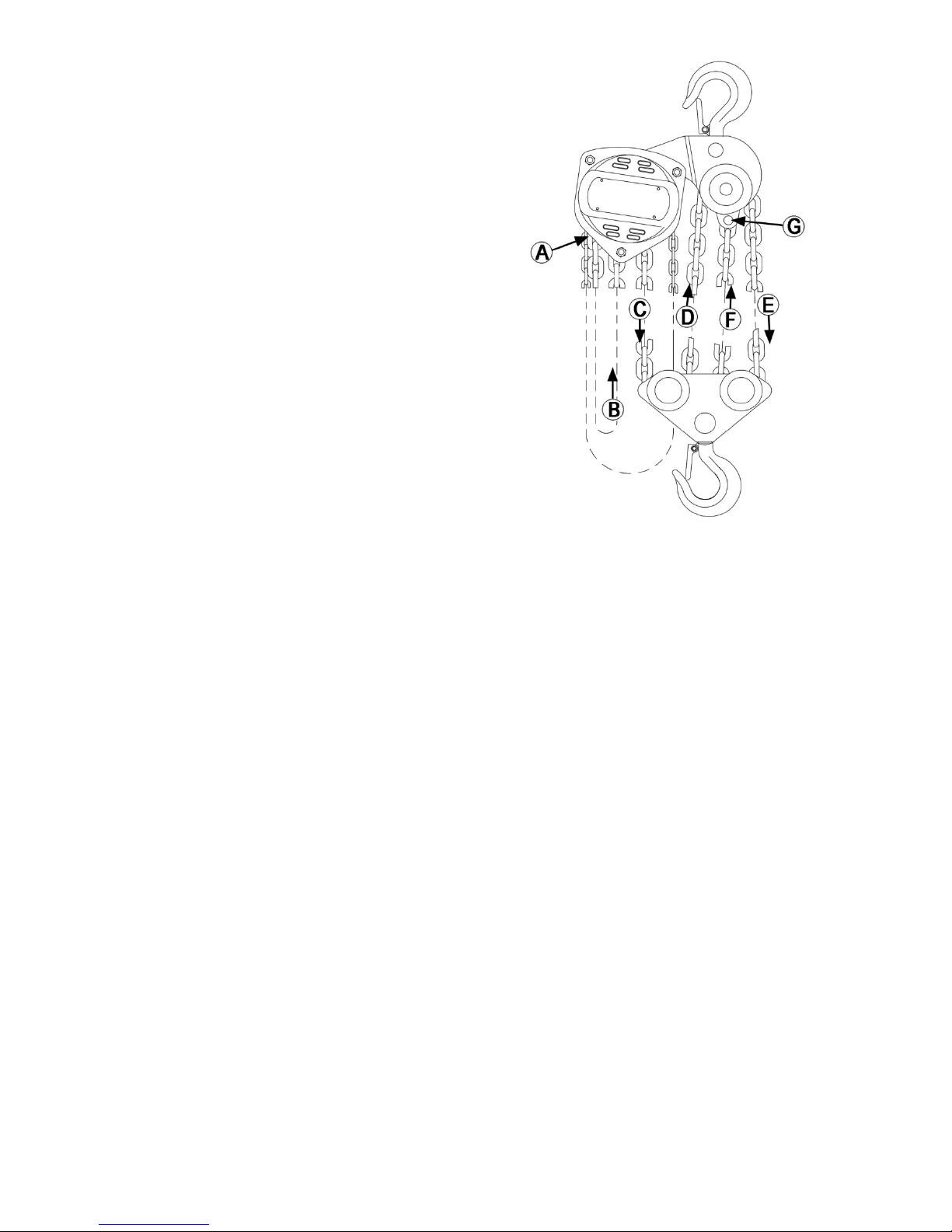

7.7 Chain installation: 10T

Referring to Figure 14:

1. After installing load chain into load chain

sprocket (B), run the remaining chain through

your hand to remove any twist. The last link of

the chain must be in the same direction as the

first. If not, cut off the last link.

2. Insert the last link into the left pulley of the

lower hook (C).

3. Pull the load chain through and up from

underside of the pulley (C, D).

4. Insert the last link into the pulley of the upper

hook (D), moving the chain up, around, and

then down (E). Check that the load chain is not

twisted and welds face away from the pulley.

5. To prevent the chain from free-wheeling, insert

a screwdriver securely into a link at the base of

the upper pulley (left side).

6. Insert the last link into the right pulley of the

lower hook (E).

7. Pull the load chain through and up from the

underside of the pulley (E, F).

8. Remove the lock nut and chain anchor pin in

upper hook slot (G).

9. Insert the last link into the upper hook slot.

10. Check that load chain is not twisted.

11. Reinstall chain anchor pin through upper hook

slot and last chain link, and secure with lock

nut.

12. Remove screwdriver from link at base of upper

pulley.

Figure 14

(10-ton hoists)

10

Page 11

8.0 Inspection and maintenance

Read and follow ANSI Inspection and Maintenance Instructions. Know the meaning of Frequent Inspection,

Periodic Inspection, Normal Service, Heavy Service, and Severe Service. It is the customer’s responsibility to

understand and follow all ANSI and JET inspection and maintenance instructions.

All repairs and adjustments are to be per formed b y tr ained an d exper ience d per sonnel

using procedures that are approved for the hoist system being serviced.

All safety related deficiencies discovered in the inspection are to be correc ted before

the hoist is placed back into service.

Check for internal damage whenever external damage has occurred. Failure to comply

may cause serious injury.

1. Clean hoist after each use and oil lightly.

2. Do not drop or drag the hoist.

3. Store the hoist in a clean and dry environment.

4. Chain oiling is not mandatory but will increase the life of the chain.

5. Leave all repairs and adjustments of internal parts to qualified repair personnel.

6. Inspect the load chain and the lower hook after lifting a maximum weight load.

7. This hoist uses special alloy hoisting chain and does not interchange with any other manufacturer. All

replacement chain must be purchased from your JET distributor or from JET directly by calling 800-274-

6848.

8. Check and inspect the brake system frequently.

9. Annually, the hoist should be disassembled, inspected, and cleaned by trained and experienced personnel

only. Contact a JET authorized service center by calling your dealer or visiting our web site at jettools.com.

10. After servicing, test the hoist with no load, then test the hoist with a load.

11

Page 12

9.0 Load and wear limits

9.1 Alloy steel chain

Carefully inspect entire load chain. As illustrated in

Figure 15, measure five consecutive links with

calipers to measure the length. Check every three

feet and especially where excessive wear is

indicated. Any load chain that shows noticeable

deformation or heat influence must be replaced

with a new one. Never extend load chain by

welding a second piece to the original.

9.2 Hooks (top and bottom)

See Figure 16.

Replace hook when “A” measurement is equal to

or greater than the “A” Limit in the table below.

Never heat treat the hook or attach anything to the

hook by welding.

A

B

Figure 16

Figure 15

Capacity

0.5 ton 75 77.3

1 ton 90 92.6

1.5 ton 120 123.4

2 ton 120 123.4

3 ton 120 123.4

5 ton 150 154.3

10 ton 150 154.3

5 Links Normal

(mm)

Table 2

5 Links Limit

Replace if:

Load

Capacity

0.5 ton 1 1.36" 1.44" – –

1 ton 1 1.77” 1.88" – –

1.5 ton 1 1.86" 1.97" – –

2 ton 1 2.05” 2.17” – –

3 ton 2 2.45” 2.60” – –

5 ton 2 3.06” 3.24” – –

10 ton 4 – – 2.52” 2.67”

chain

column

“A”

Norm

Table 3

“A”

Limit

“B”

Norm

“B”

Limit

12

Page 13

9.3 Brake disc

Replacement limits for brake disc.

Figure 17

Load

Capacity

0.5 ton 1 39 22 2.5 2

1 ton 1 60 30.5 2 1.5

1.5 ton 1 68 35.5 2 1.5

2 ton 1 68 35.5 2 1.5

3 ton 2 68 35.5 2 1.5

5 ton 2 85 45.5 2.5 2

10 ton 4 85 45.5 2.5 2

Table 4

d = inner diameter

D = outer diameter

tn = normal measurement

tv = replacement limit

chain

column

D

(mm)

d

(mm)

tn

(mm)

tv

(mm)

10.0 Timing Marks for Gear Replacement

If the gears on the S90 hoist need replacement or removal for any reason, make sure they are re-installed

correctly. Figure 18 shows the proper orientation of the timing marks when meshing the gears.

Figure 18

13

Page 14

11.0 Troubleshooting JET® Manual Chain Hoists

Symptom Possible Cause Correction1

Hoist will not move in

either direction.

Hoist will not lift load, or

lifts with great difficulty.

Hoist will not lower load,

or lowers with great

difficulty.

Load drifts downward

while suspended.

Load chain jumps, or

makes excessive noise.

Hand chain wheel is jammed, worn, or

damaged.

Inspect and clean hand chain and hand

chain wheel. Replace if worn or damaged.

Hand chain slips over wheel. Check hand chain wheel for damage or

worn cogs. Replace if needed.

Load sheave or load chain is jammed. Inspect and clean. Check for chain link

deformation. Replace elements if needed.

Oil load chain for optimal performance.

Load gear/spur gears jammed due to

obstruction or damage.

Inspect, clean, and re-grease gears.

Replace if worn or damaged.

Bearing failure. Contact JET service center for disassembly

and replacement of bearings.

Load too heavy for hoist. Use a hoist with proper capacity for load.

(models with overload protection2):

Slip clutch overload protection has

been triggered due to excess load

capacity.

Disengage overload to reset hoist (see

instruction manual). Only lift loads within

hoist capacity. Inspect hoist elements for

damage after overload has occurred.

Load chain is binding. Inspect and clean load chain, load sheave,

and stripper. Make sure chain is not

twisted. Oil chain for optimal performance.

Replace elements if deformation or other

damage is found.

Load sheave is jammed. Inspect and clean. Replace load sheave if

damaged or excessively worn.

Ratchet disc teeth, pawls or pawl

Inspect elements and replace if needed.

springs worn or damaged.

Bearing failure. Contact JET service center for disassembly

and replacement of bearings.

Load chain is binding due to

obstruction, damage or wear.

Inspect and clean load chain and load

sheave. Keep load chain lightly oiled.

Replace chain if damaged or worn.

Brake/ratchet disc not releasing due

to obstruction or damage.

Inspect and clean ratchet and pawl

assemblies.

Load beyond capacity of hoist. Use properly rated hoist for load.

Ratchet disc teeth, pawls or pawl

Inspect elements and replace if needed.

springs worn or damaged.

Brake disc(s) worn or dirty. Inspect brake disc(s) for wear or damage.

Consult thickness tolerances in manual,

replace if needed.

Load chain is dirty or dry. Inspect and clean load chain and load

sheave. Oil chain for optimum performance.

Load chain kinked or twisted. Remove twists in chain.

Load chain is worn or deformed, or

otherwise damaged.

Chain catching in load sheave. Inspect and clean chain and sheave. Check

Hook latch not closing. Latch is bent or broken. Replace latch.

Hook is deformed preventing proper

latch operation.

1

Some corrections may need to be performed by a JET authorized service center.

2

Identified by “WO” in model number.

Replace chain (use JET-authorized chain

only).

for chain deformations.

Replace hook assembly.

14

Page 15

12.0 Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach ou r service department, call 1800-274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Having the Model Number and Serial

Number of your machine available when you call will allow us to serve you quickly and accurately.

Non-proprietary parts, such as fasteners, can be found at local hardware stores, or may be ordered from JET.

Some parts are shown for reference only, and may not be available individually.

12.1.1 S90 Chain Hoists – Exploded View

15

Page 16

12.1.2 S90-050 Chain Hoist (0.5 Ton) – Parts List

Index No Part No Description Size Qty

1 ................ S90-050-1G ............... Top Hook Assembly................................................. ...................................... 1

.................. .................................. Top Hook ................................................................. ...................................... 1

.................. .................................. Safety Latch ............................................................. ...................................... 1

.................. .................................. Double Spring .......................................................... ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M4x20 ........................... 1

.................. .................................. Lock Nut................................................................... M4 ................................. 1

.................. .................................. Top Hook Holder...................................................... ...................................... 1

.................. .................................. Rivet......................................................................... 5x20mm ........................ 2

2 ................ S90-050-2 ................. Safety Latch Assembly ............................................ ...................................... 2

.................. .................................. Safety Latch ............................................................. ...................................... 2

.................. .................................. Double Spring .......................................................... ...................................... 2

.................. .................................. Socket Head Cap Screw ......................................... M4x20 ........................... 2

.................. .................................. Lock Nut................................................................... M4 ................................. 2

3 ................ S90-050-3 ................. Top Hook Shaft ........................................................ ..................................... 1

4 ................ S90-050-4G ............... Bottom Hook Assembly ........................................... ...................................... 1

.................. .................................. Bottom Hook ............................................................ ...................................... 1

.................. .................................. Safety Latch ............................................................. ...................................... 1

.................. .................................. Double Spring .......................................................... ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M4x20 ........................... 1

.................. .................................. Lock Nut................................................................... M4 ................................. 1

.................. .................................. Bottom Hook Holder ................................................ ...................................... 1

.................. .................................. Rivet......................................................................... 5x20mm ........................ 2

5 ................ L100-50-6 .................. Bottom Hook Shaft and Lock Nut ............................ M6 ................................. 1

6 ................ 187721 ...................... Load Chain – specify length .................................... 5x15mm ........................ 1

7 ................ L100-25-27G ............. Acorn Nut with Lock Washer ................................... M6 ................................. 6

8 ................ L100-50-28 ................ Rivet......................................................................... 3x5mm .......................... 4

9 ................ LM000033 ................. Name Plate .............................................................. ...................................... 1

10 .............. S90-050-10G ............. Gear Cover Assembly.............................................. ...................................... 1

.................. .................................. Gear Cover .............................................................. ...................................... 1

.................. .................................. Bushing .................................................................... ...................................... 2

11 .............. S90-050-11 ............... Drive Shaft ............................................................... ...................................... 1

12 .............. S90-050-12 ............... Spur Gear Assembly................................................ ...................................... 2

.................. .................................. Spur Gear ................................................................ ...................................... 2

.................. .................................. Pinion Gear .............................................................. ...................................... 2

13 .............. L100-50-47 ................ Snap Ring ................................................................ 18mm ............................ 1

14 .............. S90-050-14 ............... Load Gear ................................................................ ...... ................................ 1

15 .............. S90-050-15 ............... Gear Side Plate Assembly ....................................... ................ ...................... 1

.................. .................................. Gear Side Plate ....................................................... ...................................... 1

.................. .................................. Bearing Race ........................................................... ...................................... 1

.................. .................................. Bushing .................................................................... ...................................... 2

16 .............. S90-050-16 ............... Stripper .................................................................... ...................................... 1

17 .............. L100-50-32 ................ Guide Roller ............................................................. ...................................... 2

18 .............. S90-050-18 ............... Roller Set (Right and Lef t) ....................................... ø3x5mm ...................... 56

19 .............. S90-050-19 ............... Load Sheave ........................................................... ...................................... 1

20 .............. S90-050-20 ............... Wheel Side Plate Assembly..................................... ...................................... 1

.................. .................................. Stay Bolt .................................................................. ...................................... 3

.................. .................................. Pawl Pin ................................................................... ...................................... 2

.................. .................................. Bearing Race ........................................................... ...................................... 1

21 .............. S90-050-21 ............... Disc Hub .................................................................. ...................................... 1

22 .............. S90-050-22 ............... Brake Disc ............................................................... ...................................... 2

23 .............. S90-050-23 ............... Ratchet Disc ............................................................ ...................................... 1

24 .............. S90-050-24 ............... Pawl Spring.............................................................. ...................................... 2

25 .............. S90-050-25 ............... Pawl ......................................................................... ...................................... 2

26 .............. S90-050-26 ............... Snap Ring ................................................................ 6mm .............................. 2

27 .............. S90-050-27G ............. Brake Cover ............................................................. ...................................... 1

28 .............. S90-050-28 ............... Hand Chain – specify length .................................... 5x25mm ........................ 1

29 .............. S90-050-29 ............... Hand Chain Wheel .................................................. ...................................... 1

30 .............. S90-050-30 ............... Pinion Nut ................................................................ M8 ................................. 1

31 .............. L100-50-4 .................. Split Pin.................................................................... 2x20mm ........................ 1

16

Page 17

Index No Part No Description Size Qty

32 .............. S90-050-32G ............. Hand Wheel Cover .................................................. ...................................... 1

33 .............. L100-50-34 ................ Chain Anchor Plate .................................................. ...................................... 1

34 .............. S90-050-34 ............... Split Pin.................................................................... 1.6x15mm ..................... 1

35 .............. L100-50-35 ................ Chain Anchor Pin ..................................................... ...................................... 1

.................. L100-WT ................... Warning Tag (not shown) ........................................ ...................................... 1

Note: When ordering replacement chains (index #6 and 28), specify length.

17

Page 18

12.1.3 S90-100 Chain Hoist (1 Ton) – Parts List

Index No Part No Description Size Qty

1 ................ S90-100-1G ............... Top Hook Assembly................................................. ...................................... 1

.................. .................................. Top Hook ................................................................. ...................................... 1

.................. .................................. Safety Latch ............................................................. ...................................... 1

.................. .................................. Double Spring .......................................................... ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M4x20 ........................... 1

.................. .................................. Lock Nut................................................................... M4 ................................. 1

.................. .................................. Top Hook Holder...................................................... ...................................... 1

.................. .................................. Rivet......................................................................... 6x20mm ........................ 2

2 ................ S90-100-2 ................. Safety Latch Assembly ............................................ ...................................... 2

.................. .................................. Safety Latch ............................................................. ...................................... 2

.................. .................................. Double Spring .......................................................... ...................................... 2

.................. .................................. Socket Head Cap Screw ......................................... M4x20 ........................... 2

.................. .................................. Lock Nut................................................................... M4 ................................. 2

3 ................ S90-100-3 ................. Top Hook Shaft ........................................................ ...................................... 1

4 ................ S90-100-4G ............... Bottom Hook Assembly ........................................... ...................................... 1

.................. .................................. Bottom Hook ............................................................ ...................................... 1

.................. .................................. Safety Latch ............................................................. ...................................... 1

.................. .................................. Double Spring .......................................................... ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M4x20 ........................... 1

.................. .................................. Lock Nut................................................................... M4 ................................. 1

.................. .................................. Bottom Hook Holder ................................................ ...................................... 1

.................. .................................. Rivet......................................................................... 5x20mm ........................ 2

5 ................ S90-100-5 ................. Bottom Hook Shaft and Lock Nut ............................ M6 ................................. 1

6 ................ JLP75A-44 ................ Load Chain – specify length .................................... 6x18mm ........................ 1

7 ................ L100-50-27G ............. Acorn Nut with Lock Washer ................................... M8 ................................. 6

8 ................ L100-100-28 .............. Rivet......................................................................... 3x5mm .......................... 4

9 ................ LM000034 ................. Name Plate .............................................................. ...................................... 1

10 .............. S90-100-10G ............. Gear Cover Assembly.............................................. ...................................... 1

.................. .................................. Gear Cover .............................................................. ...................................... 1

.................. .................................. Bushing .................................................................... ...................................... 2

11 .............. S90-100-11 ............... Drive Shaft ............................................................... ...................................... 1

12 .............. S90-100-12 ............... Spur Gear Assembly................................................ ...................................... 2

.................. .................................. Spur Gear ................................................................ ...................................... 2

.................. .................................. Pinion Gear .............................................................. ...................................... 2

13 .............. L100-50-47 ................ Snap Ring ................................................................ 22mm ............................ 1

14 .............. S90-100-14 ............... Load Gear ................................................................ ...... ................................ 1

15 .............. S90-100-15 ............... Gear Side Plate Assembly ....................................... ................ ...................... 1

.................. .................................. Gear Side Plate ....................................................... ...................................... 1

.................. .................................. Bearing Race ........................................................... ...................................... 1

.................. .................................. Bushing .................................................................... ...................................... 2

16 .............. JLP75A-31 ................ Stripper .................................................................... ...................................... 1

17 .............. S90-100-17 ............... Guide Roller ............................................................. ...................................... 2

18 .............. JLP75A-29 ................ Roller Set (Right and Left) ....................................... ø3x6mm ...................... 74

19 .............. S90-100-19 ............... Load Sheave ........................................................... ...................................... 1

20 .............. S90-100-20 ............... Wheel Side Plate Assembly..................................... ...................................... 1

.................. .................................. Stay Bolt .................................................................. ...................................... 3

.................. .................................. Pawl Pin ................................................................... ...................................... 2

.................. .................................. Bearing Race ........................................................... ...................................... 1

21 .............. S90-100-21 ............... Disc Hub .................................................................. ...................................... 1

22 .............. S90-100-22 ............... Brake Disc ............................................................... ...................................... 2

23 .............. S90-100-23 ............... Ratchet Disc ............................................................ ...................................... 1

24 .............. S90-100-24 ............... Pawl Spring.............................................................. ...................................... 2

25 .............. S90-100-25 ............... Pawl ......................................................................... ...................................... 2

26 .............. S90-100-26 ............... Snap Ring ................................................................ 7mm .............................. 2

27 .............. S90-100-27G ............. Brake Cover ............................................................. ...................................... 1

28 .............. S90-050-28 ............... Hand Chain – specify length .................................... 5x25mm ........................ 1

29 .............. S90-100-29 ............... Hand Chain Wheel .................................................. ...................................... 1

30 .............. S90-100-30 ............... Pinion Nut ................................................................ M10 ............................... 1

31 .............. JLP150A-03 .............. Split Pin.................................................................... 2.5x25mm ..................... 1

18

Page 19

Index No Part No Description Size Qty

32 .............. S90-100-32G ............. Hand Wheel Cover .................................................. ...................................... 1

33 .............. S90-100-33 ............... Chain Anchor Plate .................................................. ...................................... 1

34 .............. L100-50-4 .................. Split Pin.................................................................... 2x20mm ........................ 1

35 .............. S90-100-35 ............... Chain Anchor Pin ..................................................... ...................................... 1

.................. L100-WT ................... Warning Tag (not shown) ........................................ ...................................... 1

Note: When ordering replacement chains (index #6 and 28), specify length.

19

Page 20

12.1.4 S90-150 Chain Hoist (1.5 Ton) – Parts List

Index No Part No Description Size Qty

1 ................ S90-150-1G ............... Top Hook Assembly................................................. ...................................... 1

.................. .................................. Top Hook ................................................................. ...................................... 1

.................. .................................. Safety Latch ............................................................. ...................................... 1

.................. .................................. Double Spring .......................................................... ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M4x25 ........................... 1

.................. .................................. Lock Nut................................................................... M4 ................................. 1

.................. .................................. Top Hook Holder...................................................... ...................................... 1

.................. .................................. Rivet......................................................................... 6x24mm ........................ 2

2 ................ JLP150A-63 .............. Safety Latch Assembly ............................................ ...................................... 2

.................. .................................. Safety Latch ............................................................. ...................................... 2

.................. .................................. Double Spring .......................................................... ...................................... 2

.................. .................................. Socket Head Cap Screw ......................................... M4x25 ........................... 2

.................. .................................. Lock Nut................................................................... M4 ................................. 2

3 ................ S90-150-3 ................. Top Hook Shaft ........................................................ ...................................... 1

4 ................ S90-150-4G ............... Bottom Hook Assembly ........................................... ...................................... 1

.................. .................................. Bottom Hook ............................................................ ...................................... 1

.................. .................................. Safety Latch ............................................................. ...................................... 1

.................. .................................. Double Spring .......................................................... ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M4x25 ........................... 1

.................. .................................. Lock Nut................................................................... M4 ................................. 1

.................. .................................. Bottom Hook Holder ................................................ ...................................... 1

.................. .................................. Rivet......................................................................... 6x20mm ........................ 2

5 ................ S90-150-5 ................. Bottom Hook Shaft and Lock Nut ............................ M8 ................................. 1

6 ................ JLP150A-44 .............. Load Chain – specify length .................................... 8x24mm ........................ 1

7 ................ L100-50-27G ............. Acorn Nut with Lock Washer ................................... M8 ................................. 6

8 ................ L100-100-28 .............. Rivet......................................................................... 3x5mm .......................... 4

9 ................ LM000035 ................. Name Plate .............................................................. ...................................... 1

10 .............. S90-150-10G ............. Gear Cover Assembly.............................................. ...................................... 1

.................. .................................. Gear Cover .............................................................. ...................................... 1

.................. .................................. Bushing .................................................................... ...................................... 2

11 .............. S90-150-11 ............... Drive Shaft ............................................................... ...................................... 2

12 .............. S90-150-12A ............. Spur Gear Assembly................................................ ...................................... 2

.................. .................................. Spur Gear ................................................................ ...................................... 2

.................. .................................. Pinion Gear .............................................................. ...................................... 2

13 .............. L100-300-47 .............. Snap Ring ................................................................ 28mm ............................ 1

14 .............. S90-150-14 ............... Load Gear ................................................................ ...... ................................ 1

15 .............. S90-150-15A ............. Gear Side Plate Assembly ....................................... ...................................... 1

.................. .................................. Gear Side Plate ....................................................... ...................................... 1

.................. .................................. Bearing Race ........................................................... ...................................... 1

.................. .................................. Bushing .................................................................... ...................................... 2

16 .............. JLP150A-31 .............. Stripper .................................................................... ...................................... 1

17 .............. S90-150-17 ............... Guide Roller ............................................................. ...................................... 2

18 .............. S90-150-18 ............... Roller Set (Right and Lef t) ....................................... ø4x6mm ...................... 60

19 .............. S90-150-19 ............... Load Sheave ........................................................... ...................................... 1

20 .............. S90-150-20 ............... Wheel Side Plate Assembly..................................... ...................................... 1

.................. .................................. Stay Bolt .................................................................. ...................................... 3

.................. .................................. Pawl Pin ................................................................... ...................................... 2

.................. .................................. Bearing Race ........................................................... ...................................... 1

21 .............. S90-150-21 ............... Disc Hub .................................................................. ...................................... 1

22 .............. S90-150-22 ............... Brake Disc ............................................................... ......

23 .............. S90-150-23 ............... Ratchet Disc ............................................................ ...................................... 1

24 .............. S90-150-24 ............... Pawl Spring.............................................................. ...................................... 2

25 .............. S90-150-25 ............... Pawl ......................................................................... ...................................... 2

26 .............. S90-150-26 ............... Snap Ring ................................................................ 8mm .............................. 2

27 .............. S90-150-27G ............. Brake Cover ............................................................. ...................................... 1

28 .............. S90-050-28 ............... Hand Chain – specify length .................................... 5x25mm ........................ 1

29 .............. S90-150-29 ............... Hand Chain Wheel .................................................. ...................................... 1

30 .............. S90-150-30 ............... Pinion Nut ................................................................ M12 ............................... 1

31 .............. S90-150-31 ............... Split Pin.................................................................... 3x25 mm ........................ 1

................................ 2

20

Page 21

Index No Part No Description Size Qty

32 .............. S90-150-32G ............. Hand Wheel Cover .................................................. ...................................... 1

33 .............. S90-150-33 ............... Chain Anchor Plate .................................................. ...................................... 1

34 .............. S90-150-34 ............... Split Pin.................................................................... 2.5x23mm ..................... 1

35 .............. S90-150-35 ............... Chain Anchor Pin ..................................................... ...................................... 1

.................. L100-WT ................... Warning Tag (not shown) ........................................ ...................................... 1

Note: When ordering replacement chains (index #6 and 28), specify length.

21

Page 22

12.1.5 S90-200 Chain Hoist (2 Ton) – Parts List

Index No Part No Description Size Qty

1 ................ S90-200-1G ............... Top Hook Assembly................................................. ...................................... 1

.................. .................................. Top Hook ................................................................. ...................................... 1

.................. .................................. Safety Latch ............................................................. ...................................... 1

.................. .................................. Double Spring .......................................................... ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M5x30 ........................... 1

.................. .................................. Lock Nut................................................................... M5 ................................. 1

.................. .................................. Top Hook Holder...................................................... ...................................... 1

.................. .................................. Rivet......................................................................... 6x20mm ........................ 2

2 ................ S90-200-2 ................. Safety Latch Assembly ............................................ ...................................... 2

.................. .................................. Safety Latch ............................................................. ...................................... 2

.................. .................................. Double Spring .......................................................... ...................................... 2

.................. .................................. Socket Head Cap Screw ......................................... M5x30 ........................... 2

.................. .................................. Lock Nut................................................................... M5 ................................. 2

3 ................ S90-200-3 ................. Top Hook Shaft ........................................................ ...................................... 1

4 ................ S90-200-4G ............... Bottom Hook Assembly ........................................... ...................................... 1

.................. .................................. Bottom Hook ............................................................ ...................................... 1

.................. .................................. Safety Latch ............................................................. ...................................... 1

.................. .................................. Double Spring .......................................................... ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M5x30 ........................... 1

.................. .................................. Lock Nut................................................................... M5 ................................. 1

.................. .................................. Bottom Hook Holder ................................................ ...................................... 1

.................. .................................. Rivet......................................................................... 6x20mm ........................ 2

5 ................ S90-200-5 ................. Bottom Hook Shaft and Lock Nut ............................ M8 ................................. 1

6 ................ JLP150A-44 .............. Load Chain – specify length .................................... 8x24mm ........................ 1

7 ................ JLP150A-40G ............ Acorn Nut with Lock Washer ................................... M8 ................................. 6

8 ................ L100-100-28 .............. Rivet......................................................................... 3x5mm .......................... 4

9 ................ LM000036 ................. Name Plate S90-200 ............................................... ...................................... 1

10 .............. S90-200-10G ............. Gear Cover Assembly.............................................. ...................................... 1

.................. .................................. Gear Cover .............................................................. ...................................... 1

.................. .................................. Bushing .................................................................... ...................................... 2

11 .............. S90-200-11 ............... Drive Shaft ............................................................... ...................................... 1

12 .............. S90-200-12A ............. Spur Gear Assembly................................................ ...................................... 2

.................. .................................. Spur Gear ................................................................ ...................................... 2

.................. .................................. Pinion Gear .............................................................. ...................................... 2

13 .............. S90-150-13 ............... Snap Ring ................................................................ 28mm ............................ 1

14 .............. S90-200-14 ............... Load Gear ................................................................ ...... ................................ 1

15 .............. S90-200-15A ............. Gear Side Plate Assembly ....................................... ...................................... 1

.................. .................................. Gear Side Plate ....................................................... ...................................... 1

.................. .................................. Bearing Race ........................................................... ...................................... 1

.................. .................................. Bushing .................................................................... ...................................... 2

16 .............. JLP150A-31 .............. Stripper .................................................................... ...................................... 1

17 .............. S90-200-17 ............... Guide Roller ............................................................. ...................................... 2

18 .............. S90-150-18 ............... Roller Set (Right and Lef t) ....................................... ø4x6mm ...................... 60

19 .............. S90-200-19 ............... Load Sheave ........................................................... ...................................... 1

20 .............. S90-200-20 ............... Wheel Side Plate Assembly..................................... ...................................... 1

.................. .................................. Stay Bolt .................................................................. ...................................... 3

.................. .................................. Pawl Pin ................................................................... ...................................... 2

.................. .................................. Bearing Race ........................................................... ...................................... 1

21 .............. S90-150-21 ............... Disc Hub .................................................................. ...................................... 1

22 .............. S90-150-22 ............... Brake Disc ............................................................... ...................................... 2

23 .............. S90-150-23 ............... Ratchet Disc ............................................................ ...................................... 1

24 .............. S90-150-24 ............... Pawl Spring.............................................................. ...................................... 2

25 .............. S90-150-25 ............... Pawl ......................................................................... ...................................... 2

26 .............. S90-150-26 ............... Snap Ring ................................................................ 8mm .............................. 2

27 .............. S90-200-27G ............. Brake Cover ............................................................. ...................................... 1

28 .............. S90-050-28 ............... Hand Chain – specify length .................................... 5x25mm ........................ 1

29 .............. S90-200-29 ............... Hand Chain Wheel .................................................. ...................................... 1

30 .............. S90-150-30 ............... Pinion Nut ................................................................ M12 ............................... 1

31 .............. S90-150-31 ............... Split Pin.................................................................... 3x25 mm ........................ 1

22

Page 23

Index No Part No Description Size Qty

32 .............. S90-200-32G ............. Hand Wheel Cover .................................................. ...................................... 1

33 .............. S90-150-33 ............... Chain Anchor Plate .................................................. ...................................... 1

34 .............. S90-150-34 ............... Split Pin.................................................................... 2.5x23mm ..................... 1

35 .............. S90-150-35 ............... Chain Anchor Pin ..................................................... ...................................... 1

.................. L100-WT ................... Warning Tag (not shown) ........................................ ...................................... 1

Note: When ordering replacement chains (index #6 and 28), specify length.

23

Page 24

12.1.6 S90-300 Chain Hoist (3 Ton) – Parts List

Index No Part No Description Size Qty

1 ................ S90-300-1G ............... Top Hook Assembly................................................. ...................................... 1

.................. .................................. Top Hook ................................................................. ...................................... 1

.................. .................................. Safety Latch ............................................................. ...................................... 1

.................. .................................. Double Spring .......................................................... ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M5x30 ........................... 1

.................. .................................. Lock Nut................................................................... M5 ................................. 1

.................. .................................. Top Hook Holder...................................................... ...................................... 1

.................. .................................. Rivet......................................................................... 10x32mm ...................... 2

2 ................ JLP300A-63 .............. Safety Latch Assembly ............................................ ...................................... 2

.................. .................................. Safety Latch ............................................................. ...................................... 2

.................. .................................. Double Spring .......................................................... ...................................... 2

.................. .................................. Socket Head Cap Screw ......................................... M5x30 ........................... 2

.................. .................................. Lock Nut................................................................... M5 ................................. 2

3 ................ S90-150-3 ................. Top Hook Shaft ........................................................ ...................................... 1

4 ................ S90-300-4G ............... Bottom Hook Assembly ........................................... ...................................... 1

.................. .................................. Bottom Hook ............................................................ ...................................... 1

.................. .................................. Safety Latch ............................................................. ...................................... 1

.................. .................................. Double Spring .......................................................... ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M5x30 ........................... 1

.................. .................................. Lock Nut................................................................... M5 ................................. 1

.................. .................................. Bottom Hook Holder ................................................ ...................................... 1

.................. .................................. Socket Head Cap Screw ......................................... M8x25 ........................... 1

.................. .................................. Lock Nut................................................................... M8 ................................. 1

.................. .................................. Socket Head Cap Screw ......................................... M10x25 ......................... 2

.................. .................................. Lock Nut................................................................... M10 ............................... 2

.................. .................................. Bottom Idle Shaft ..................................................... ...................................... 1

.................. .................................. Bottom Idle Sheave ................................................. ...................................... 1

.................. .................................. Roller Pin ................................................................. 3x30mm ...................... 24