This .pdf document is bookmarked

Assembly Instructions and Parts Manual

Fence and Rail Set for ProShop II™ Saw

Fits all JET ProShop, ProShop II, and JTAS-10 Table Saws

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-725005

Ph.: 800-274-6848 Edition 2 12/2018

www.jettools.com Copyright © 2017 JET

1.0 IMPORTANT SAFETY

INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING

THIS MACHINE.

WARNING – To reduce risk of injury:

1. Read and understand the entire owner’s

manual before attempting assembly or

operation.

2. Read and understand the warnings posted

on the machine and in this manual. Failure

to comply with all of these warnings may

cause serious injury.

3. Replace the warning labels if they become

obscured or removed.

4. This table saw is designed and intended for

use by properly trained and experienced

personnel only. If you are not familiar with

the proper and safe operation of a table

saw, do not use until proper training and

knowledge have been obtained.

5. Do not use this table saw for other than its

intended use. If used for other purposes,

JET disclaims any real or implied warranty

and holds itself harmless from any injury that

may result from that use.

6. Always wear approved safety glasses or

face shield while using this table saw.

Everyday eyeglasses only have impact

resistant lenses; they are not safety glasses.

7. Before operating this table saw, remove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Do not wear

loose clothing. Confine long hair. Non-slip

footwear or anti-skid floor strips are

recommended. Do not wear gloves.

8. Wear ear protectors (plugs or muffs) during

extended periods of operation.

9. Do not operate this machine while tired or

under the influence of drugs, alcohol or any

medication.

10. Make certain the machine is properly

grounded.

must not be used until maintenance is

complete.

12. Remove adjusting keys and wrenches. Form

a habit of checking to see that keys and

adjusting wrenches are removed from the

machine before turning it on.

13. Keep safety guards in place at all times

when the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately.

14. Check the alignment of the riving knife,

fence and miter slot to the blade. A caution

decal is installed on each guard to remind

the operator of the dangers of improper

machine operation.

15. Check damaged parts. Before further use of

the machine, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of

moving parts, breakage of parts, mounting

and any other conditions that may affect its

operation. A guard or other part that is

damaged should be properly repaired or

replaced.

16. Provide for adequate space surrounding

work area and non-glare, overhead lighting.

17. Keep the floor around the machine clean

and free of scrap material, oil and grease.

18. Keep visitors a safe distance from the work

area. Keep children away.

19. Make your workshop child proof with

padlocks, master switches or by removing

safety keys.

20. Give your work undivided attention. Looking

around, carrying on a conversation and

“horse-play” are careless acts that can result

in serious injury.

21. Maintain a balanced stance at all times so

that you do not fall or lean against the blade

or other moving parts. Do not overreach or

use excessive force to perform any machine

operation.

22. Use the right tool at the correct speed and

feed rate. Do not force a tool or attachment

to do a job for which it was not designed.

The right tool will do the job better and safer.

11. Make all machine adjustments or

maintenance with the machine unplugged

from the power source. A machine under

repair should be RED TAGGED to show it

23. Use recommended accessories; improper

accessories may be hazardous.

2

24. Maintain tools with care. Keep blade sharp

and clean for the best and safest

performance. Follow instructions for

lubricating and changing accessories.

25. Check the saw blade for cracks or missing

teeth. Do not use a cracked or dull blade or

one with missing teeth or improper set.

Make sure the blade is securely locked on

the arbor.

26. Keep hands clear of the blade area. Do not

reach past the blade to clear parts or scrap

with the saw blade running. Never saw

freehand. Avoid awkward operations and

hand positions where a sudden slip could

cause your hand to contact the blade.

27. Do not attempt to saw boards with loose

knots or with nails or other foreign material,

on its surface. Do not attempt to saw

twisted, warped or bowed stock unless one

edge has been jointed for guiding purposes

prior to sawing. Excessively warped stock

should not be used.

28. Do not attempt to saw long or wide boards

unsupported where spring or weight could

cause the board to shift position.

29. Always use the riving knife, blade guard,

push stick and other safety devices for all

operations where they can be used. On

operations such as dadoing or molding

where the blade guard cannot be used, use

feather boards, fixtures and other safety

devices and use extreme caution. Reinstall

the riving knife and blade guard immediately

after completing the operation that required

their removal.

30. Be sure the saw blade rotates clockwise

when viewed from the motor side (left side)

of the machine.

31. Turn off the machine before cleaning. Use a

brush or compressed air to remove chips or

debris — do not use bare hands.

32. Do not stand on the machine. Serious injury

could occur if the machine tips over.

33. Never leave the machine running

unattended. Turn the power off and do not

leave the machine until it comes to a

complete stop.

34. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

35. Blade should have minimum exposure

during cuts. Adjust blade to approximately

1/8” inch above surface of workpiece.

WARNING: This product can expose you

to chemicals including lead which is known to

the State of California to cause cancer and

birth defects or other reproductive harm. For

more information go to http://www.

p65warnings.ca.gov.

WARNING: Drilling, sawing, sanding or

machining wood products generates wood

dust and other substances known to the

State of California to cause cancer. Avoid

inhaling dust generated from wood products

or use a dust mask or other safeguards for

personal protection.

Wood products emit chemicals known to the

State of California to cause birth defects or

other reproductive harm. For more

information go to http://www.p65warnings.ca.

gov/wood.

1.1 Kickback

The most common accidents among table saw

users, according to statistics, can be linked to

kickback, the high-speed expulsion of material

from the table that can strike the operator.

Kickback can also result in the operator’s hands

being pulled into the blade.

Kickback Prevention

Tips to avoid the most common causes of

kickback:

Make sure the riving knife is always aligned

with the blade. A workpiece can bind or stop

the flow of the cut if the riving knife is

misaligned, and result in kickback.

Use a riving knife during every cut. The

riving knife maintains the kerf in the

workpiece, which will reduce the chance of

kickback.

Never attempt freehand cuts. The workpiece

must be fed parallel to the blade, otherwise

kickback will likely occur. Always use the rip

fence or miter gauge to support the

workpiece.

Make sure that rip fence is parallel to blade.

If not, the chances of kickback are very high.

Take the time to check and adjust the rip

fence.

Feed cuts through to completion. Anytime

you stop feeding a workpiece that is in the

middle of a cut, the chance of binding,

resulting in kickback, is greatly increased.

3

Tips for Kickback Protection

Kickback can happen even if precautions are

taken to prevent it. Listed below are some tips to

protect you if kickback does occur:

Stand to the side of the blade when cutting.

An ejected workpiece usually travels directly

in front of the blade.

Wear safety glasses or a face shield. Your

eyes and face are the most vulnerable part

of your body.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious or possibly fatal

injury.

Never place your hand behind the blade. If

kickback occurs, your hand will be pulled

into the blade.

Use a push stick to keep your hands farther

away from the moving blade. If a kickback

occurs, the push stick will most likely take

the damage that your hand would have

received.

4

2.0 Table of contents

Section Page

1.0 IMPORTANT SAFETY INSTRUCTIONS ............................................................................................... 2

1.1 Kickback ............................................................................................................................................. 3

2.0 Table of contents .................................................................................................................................... 5

3.0 About this manual .................................................................................................................................. 5

4.0 Specifications for JET ProShop II™ Fence ............................................................................................. 6

5.0 Unpacking .............................................................................................................................................. 7

Contents of Shipping Container ................................................................................................................ 7

6.0 Assembly and Adjustments .................................................................................................................... 7

6.1 Tools required for assembly ............................................................................................................... 7

6.2 Installing Rails .................................................................................................................................... 7

6.3 Wood extension table (optional) ......................................................................................................... 8

6.4 Installing Fence ................................................................................................................................ 10

6.5 Attaching scale ................................................................................................................................. 11

7.0 Replacement Parts ............................................................................................................................... 13

7.1.1 52” and 30” ProShop Rail Set – Exploded View ........................................................................... 14

7.1.2 52” and 30” ProShop Rail Set – Parts List .................................................................................... 15

7.2.1 ProShop II Fence Assembly – Exploded View .............................................................................. 16

7.2.2 ProShop II Fence Assembly – Parts List ....................................................................................... 17

8.0 Warranty and Service ........................................................................................................................... 18

3.0 About this manual

This manual is provided by JET covering assembly instructions for the JET ProShop II™ Fence and Rail

System. This manual contains instructions on installation, maintenance instructions and parts breakdown.

The Fence has been designed and constructed to provide consistent, long-term operation if used in

accordance with the instructions set forth in this document.

If there are questions or comments, please contact your local supplier or JET. JET can also be reached at

our web site: www.jettools.com.

Retain this manual for future reference. If the fence transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attempting

assembly or operation. Failure to comply may cause serious injury.

Register your product using the mail-in card provided, or register online:

http://www.jettools.com/us/en/service-and-support/product-registration/

5

4.0 Specifications for JET ProShop II™ Fence

Fence

Stock number 725005

Side plate height 2-1/2 in. (64 mm)

Side plate length 33-1/4 in. (845 mm)

Fence width 3-1/8 in. (80 mm)

Body material steel

Side plate material Extruded aluminum

Head material Steel

Cross bar length 13-3/4 in. (350 mm)

Rails

Stock number 708483 708484

Material steel steel

Actual length, front & back rails 55 in. (140 cm) 77-1/4 in. (196 cm)

Actual length, guide rail 59-7/16 in. (151 cm) 81-3/4 in. (208 cm)

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

30 in. Rip 52-in. Rip

Table 1

6

5.0 Unpacking

Open shipping container and check for shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until Fence and

Rails are assembled and working properly.

Compare the contents of your container with the

following parts list to make sure all parts are

intact. Missing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of Shipping Container

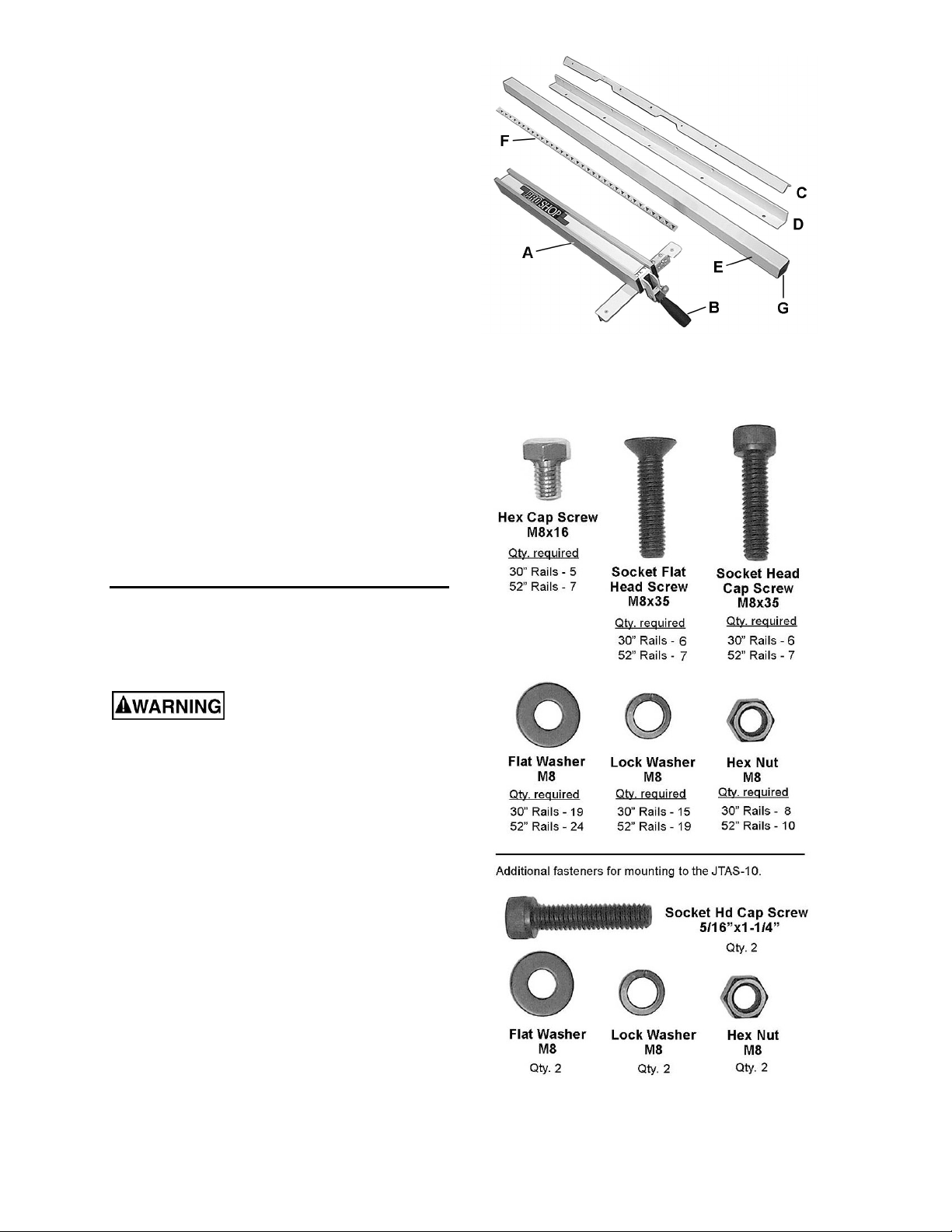

Figure 1

(shown in Figures 1 and 2)

1 ProShop Fence – A

1 Handle – B

1 Rear Rail – C

1 Front Rail – D

1 Guide Tube – E

1 Scale – F*

2 End Covers – G

1 Hardware Package (JPSR-RHP) – Figure 2

1 Owner's Manual

1 Product Registration Card

* located inside Guide Tube (E)

6.0 Assembly and

Adjustments

Disconnect table saw from

power source before attempting any

assembly or adjustment.

6.1 Tools required for assembly

Hex wrenches, 4mm and 6mm

Open End Wrench, 13mm

Electric Drill with 3/16” and 5/16” drill bits (for

optional wood extension table only)

(4) C-Clamps, 4” to 6” (for optional wood

extension table only)

6.2 Installing Rails

Refer to exploded view in sect. 7.0 for any

clarification of part positions.

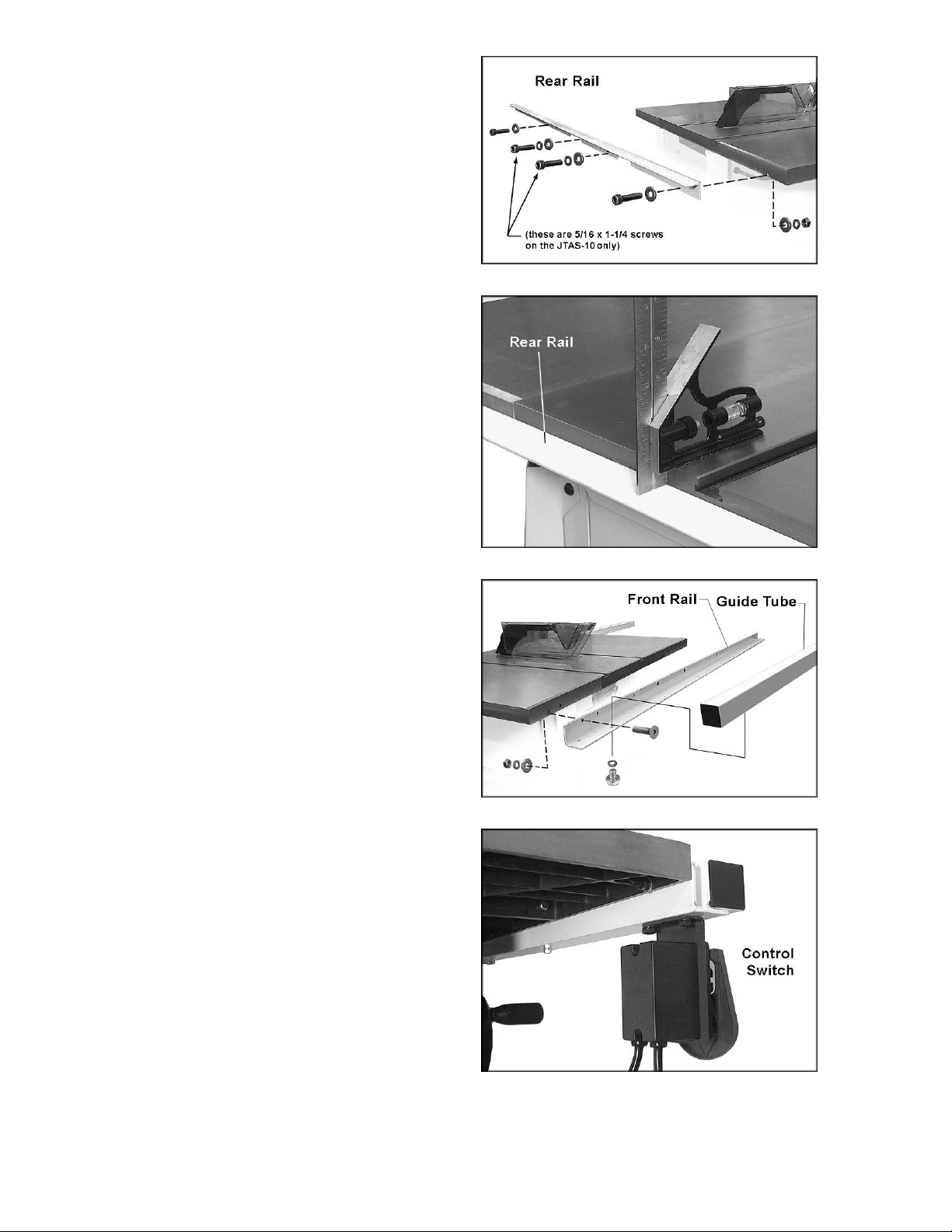

1. Place rear rail against back edge of table,

making sure the notches in rail are properly

oriented. See Figure 3.

2. On the JPS-10TS table saw, insert four

M8x35 socket head cap screws with M8 flat

washers (plus M8 lock washers on the two

7

Figure 2

(NOTE: These are not to scale)

inner screws).

NOTE: On the JTAS-10 table saw, use 5/16

x 1-1/4 socket head cap screws for the two

inner screws.

3. Secure the two outer screws with a flat

washer, lock washer and hex nut behind the

lip of the saw table. Only finger tighten all

nuts and screws.

4. The rear rail must be parallel to table top to

ensure proper fence operation. Measure

distance from rail to table surface at several

points along table. A sliding combination

square is handy for this, as shown in Figure

4. All measurements should be the same.

There is slight adjustment in the rail holes to

allow for achieving parallelism with the table

surface.

5. When rear rail is parallel with table surface,

securely tighten all screws and nuts along

the length of rail.

6. Place front rail against front edge of table,

and insert four M8x35 socket flat head

screws through the countersunk holes in

rail. Secure the two outer screws with a flat

washer, lock washer and hex nut behind the

lip of the table extensions. See Figure 5.

NOTE: On the JPS-10TS table saw, the two

inner screws will thread into the table top

without further need of fasteners. On the

JTAS-10 table saw, the two inner screws will

need flat washer, lock washer and hex nut

inside table lip.

Figure 3

Figure 4

7. Mount table saw control switch to threaded

holes in bottom of front rail using the

fasteners that came with the saw. See

Figure 6.

NOTE: If you are installing an optional wood

extension table, install it before mounting the

guide tube. See sect. 6.3.

8. Remove scale from inside guide tube, and

press black end cap onto guide tube.

9. Align the holes in the guide tube with those

in the front rail. The edge of the guide tube

near which the holes are positioned should

face toward the table saw. Insert seven

M8x16 hex cap screws, lock washers and

flat washers. See Figure 5. Finger tighten

only until all screws are inserted, then

tighten all screws. Be careful not to strip the

holes while tightening.

6.3 Wood extension table (optional)

The optional wood extension table (including the

optional router table) sits flush against saw table

and along the inside of rails.

Figure 5

Figure 6

8

The extension table is not bolted to the saw

table; it is bolted only to the rails. The extension

table and saw table must be aligned properly so

the fence will slide smoothly from one to the

other.

The wood extension table may be provided with

fasteners – do not use those with this JPSF

Fence and Rail system. Instead, use the

fasteners that are provided with the JPSF Fence

and Rails.

1. Place wood extension table upside down on

top of table saw.

IMPORTANT: If you are using a mobile

base under your saw, you may need to shift

the placement of the legs from that shown in

the following procedure, so that the legs rest

properly upon the mobile base. Check this

before proceeding.

2. Position leg brackets at one end of wood

table, as shown in Figure 7. Hold leg firmly

in place while driving in screws using a

Phillips bit in a power drill.

Figure 7

NOTE: You may wish to first mark and predrill the holes. Pre-drill holes with a 3/16”

drill bit approximately 1/2” deep. Do not drill

through table top or table frame!

3. Attach other leg to wood table in the same

manner.

4. Place wood extension table between rails

and up against saw table, leaving the

extension table raised just slightly above

saw table. Clamp extension table to front

and back rails, as shown in Figure 8.

Clamping pressure should be enough to

secure table yet allow minor adjustments.

5. Use rubber mallet to tap extension table up

flush against saw table. Then tap down the

extension table at various points along its

edge where it meets the saw table, until it is

level with saw table. As one part of the edge

becomes level with table, tighten the clamp

on that side. Then move to the other side

and repeat, until the full length of the edge is

level with saw table. Lay a straight edge

across both extension table and saw table

to ensure proper leveling.

6. When the wood extension table is properly

aligned, drill holes into wood table using the

holes in the rails as guide. See Figure 8.

(You may wish to drill 3/32" pilot holes first.)

Drill 8mm (5/16”) holes into front edge of

table using the holes in the front rail as a

guide. Drill 8mm (5/16") holes into back

edge of table using the holes in the rear rail

as guide.

Figure 8

9

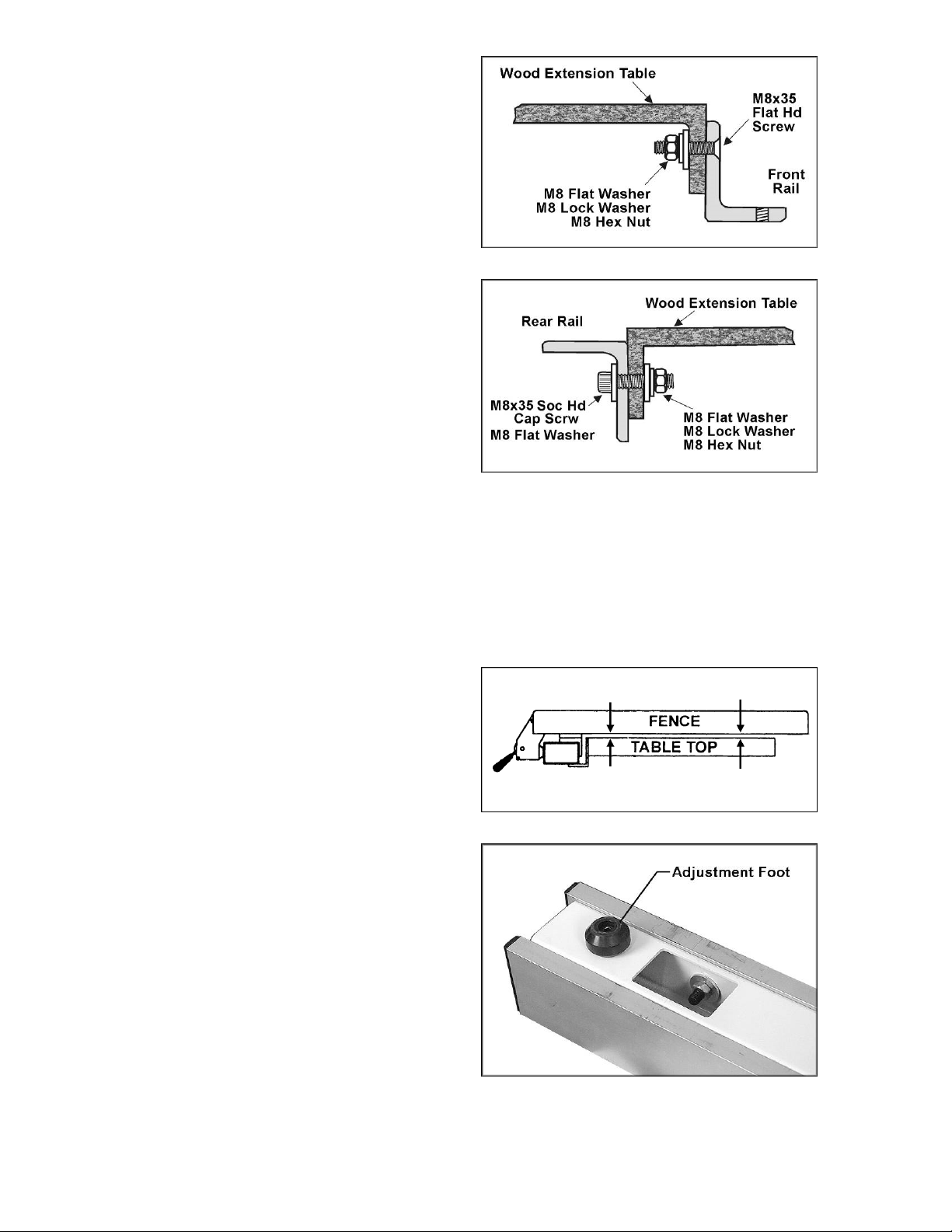

7. Install M8 x 35 socket flat head screws

through front rail and secure each with flat

washer, lock washer, and hex nut behind lip

of wood table (Figure 9). Finger tighten only.

8. Install M8 x 35 socket head cap screws and

flat washers in rear rail, and secure with flat

washer, lock washer and hex nut behind lip

of wood table (Figure 10). Finger tighten

only.

9. Re-check table for alignment, make further

adjustments if necessary, then tighten all

screws and nuts.

10. Rotate the footpads on the legs until they

reach the floor, then tighten the hex nuts up

against the legs.

11. Refer back to sect. 6.2, step #8 to assemble

the guide rail.

6.4 Installing Fence

Figure 9

1. Thread handle into hole on fence.

2. Lift handle all the way up and place fence

onto rails. Slide fence into position and push

handle down firmly to lock in place.

Note: Magnets in handle base allow handle

to be kept in raised position.

Several adjustments are necessary before using

the fence for ripping wood; follow these steps in

the order in which they are presented.

6.4.1 Level with Saw Table

3. Lock fence on guide rail.

4. View the fence from the left or right side of

the saw. There should be a small space

between the table surface and the fence

bottom, to prevent the fence from dragging

on the saw table. This space should be

equal along the entire length of the fence,

as shown in Figure 11.

5. If this space is not equal, unlock the fence

and turn it over. Loosen the hex nut under

the adjustment foot (Figure 12) and rotate

the adjustment foot as needed to raise or

lower the rear of the fence. Tighten the hex

nut and re-position the fence to check the

spacing.

Figure 10

Figure 11

6. If the front of the fence needs adjusting,

rotate the two nylon adjustment screws an

equal amount (see Figure 13).

7. Continue these two adjustment methods

until the fence-to-table spacing is correct.

10

Figure 12

6.4.2 Square to Table

8. Place a square on table and against side of

fence, as shown in Figure 13. Lock fence

down with handle. The fence should be 90°

to table.

9. If fence is not 90° to table, unlock the fence

and rotate one of two nylon adjustment

screws (clockwise will raise that side of the

fence assembly, counterclockwise will

lower). See Figure 13. Lock fence and

check adjustment again. Continue to adjust

as needed.

6.4.3 Parallel to Miter Slot

10. Check parallelism of fence by aligning side

of fence with edge of miter slot in table.

Lock fence down with handle.

11. If fence side is not parallel with miter slot,

unlock fence and lift it off guide rail. Adjust

one of two set screws (Figure 14) until fence

is parallel to miter slot along its entire length

when in locked position.

NOTE: You may need to re-adjust clamping

pressure after aligning fence.

Figure 13

6.4.4 Clamping Pressure

The fence has been adjusted by the

manufacturer to lock securely when the handle

is pushed down. If adjustment is needed, unlock

fence and lift it off guide rail. Adjust equally two

set screws (Figure 14) until fence is held

securely when lock handle is pushed down.

6.5 Attaching scale

Disconnect saw from power

source (unplug).

Important: The fence must be square to the

table and parallel to the miter slot before

attaching the scale to the guide tube. Follow all

preceding instructions before continuing.

1. Install a blade on the saw, and raise the

blade above the table surface. Lift the blade

guard and the anti-kickback pawl out of the

way.

2. Slide the fence until it just contacts the

cutting tips of the blade (Figure 15) and lock

it down with the handle. Do not force the

fence into the blade.

Figure 14

3. Center the cursor on the screws to allow

future adjustment on both sides of the

cursor line. See Figure 16. Draw a line on

the guide tube even with the cursor line.

11

Figure 15

4. Remove the fence, and clean the guide tube

surface with alcohol. Peel off some of the

scale backing, and align the zero point of

the scale with your mark on the guide tube.

See Figure 17. Position the scale far

enough from the edge so that it can be read

easily through the cursor lens. Continue to

peel the backing and apply the scale, while

keeping the scale as straight as possible

along the guide tube.

5. Connect the saw to power and make a test

cut. Carefully measure the width of the cut

board and adjust the fence cursor to match

this measurement.

NOTE: Cursor position should be inspected

after each blade change. Always make test cuts

to verify settings.

Figure 16

Figure 17

12

7.0 Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call

1-800-274-6848 Monday through Friday (see our website for business hours, www.jettools.com). Having

the Model Number and Serial Number of your machine available when you call will allow us to serve you

quickly and accurately.

Non-proprietary parts, such as fasteners, can be found at local hardware stores, or may be ordered from

JET.

Some parts are shown for reference only, and may not be available individually.

13

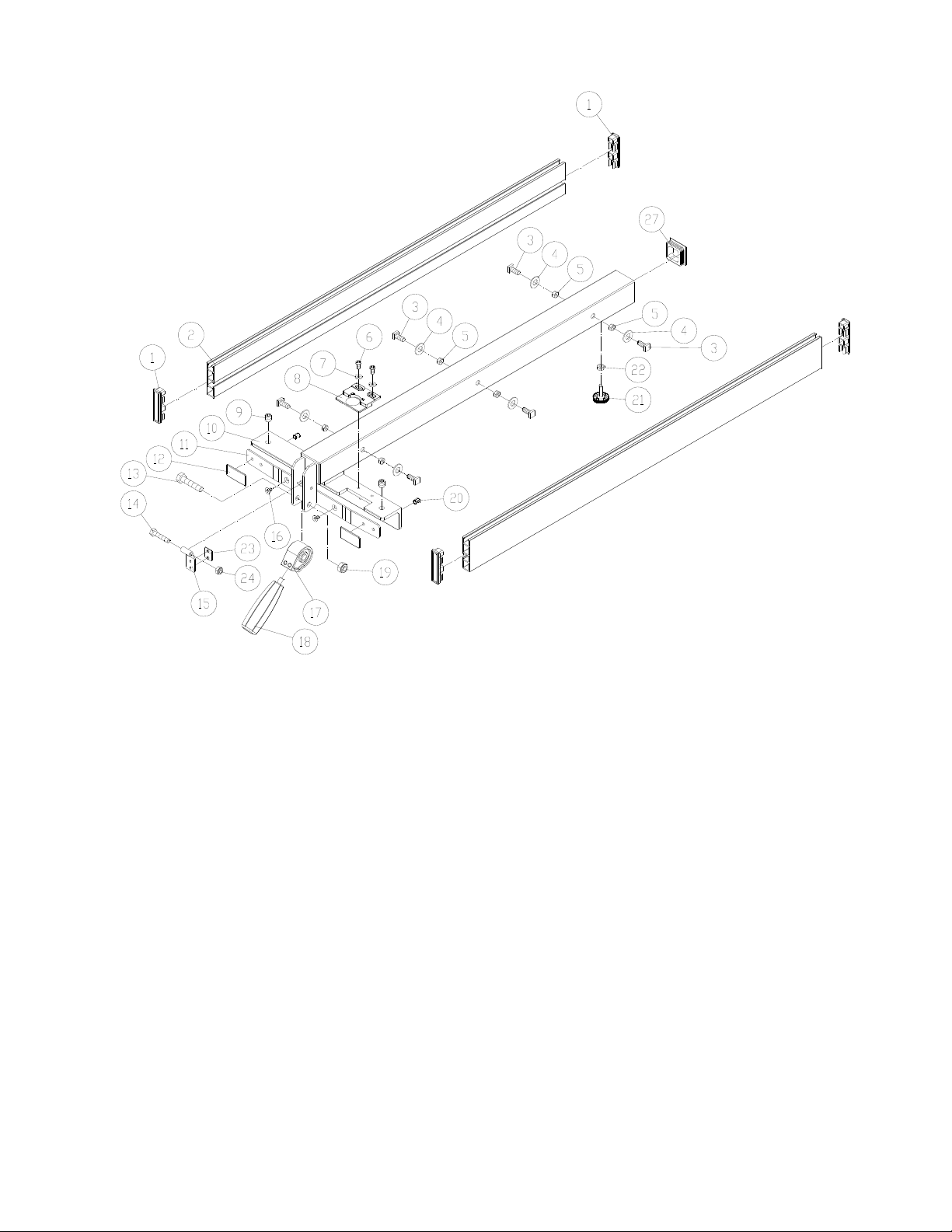

7.1.1 52” and 30” ProShop Rail Set – Exploded View

14

7.1.2 52” and 30” ProShop Rail Set – Parts List

Index No. Part No. Description Size Qty

................. 708484 ..................... JPSR-52: 52” Pro Shop Rail Set .......................... ......................................

................. 708483 ..................... JPSR-30: 30” Pro Shop Rail Set .......................... ......................................

1 ............... JPSR52-101 ............. 52” Guide Tube .................................................... .................................... 1

................. JPSR30-101 ............. 30” Guide Tube .................................................... .................................... 1

2 ............... JPSR52-102 ............. 52” Front Rail ....................................................... .................................... 1

................. JPSR30-102 ............. 30” Front Rail ....................................................... .................................... 1

3 ............... JPSR52-103 ............. 52” Rear Rail ........................................................ .................................... 1

................. JPSR30-103 ............. 30” Rear Rail ........................................................ .................................... 1

4 ............... JPSR30-104 ............. End Cover ............................................................ .................................... 2

5 ............... TS-1490021 ............. Hex Cap Screw .................................................... M8-1.25x16 ................. 7

6 ............... TS-2361081 ............. Lock Washer ........................................................ M8 ............................. 21

7 ............... JPSR30-107 ............. Flat Head Socket Screw ...................................... M8-1.25x35 ................. 7

8 ............... TS-1540061 ............. Hex Nut ................................................................ M8 ............................. 12

9 ............... TS-1504071 ............. Socket Head Cap Screw ...................................... M8-1.25x35 ................. 7

10 ............. JPSR52-110 ............. 52” Scale .............................................................. .................................... 1

................. JPSR30-110 ............. 30” Scale .............................................................. .................................... 1

11 ............. TS-1550061 ............. Flat Washer .......................................................... M8 ............................. 26

12 ............. TS-0208071 ............. Socket Head Cap Screw (for JTAS-10 only) ....... 5/16”-18x1-1/4” ........... 2

................. JPSR-RHP ............... Rail Hardware Package (not shown) ..........................................................

15

7.2.1 ProShop II Fence Assembly – Exploded View

16

7.2.2 ProShop II Fence Assembly – Parts List

Index No. Part No. Description Size Qty

................. 725005 ..................... ProShop II Fence Assembly ................................ ......................................

1 ............... JPSF1-101A ............. Side Plate End Cover ........................................... .................................... 4

2 ............... JPSF1-102A ............. Side Plate ............................................................. .................................... 2

3 ............... JPSF1-103 ............... Square Bolt .......................................................... M8-1.25x20 ................. 6

4 ............... TS-1550061 ............. Flat Washer .......................................................... M8 ............................... 6

5 ............... TS-1540061 ............. Hex Nut ................................................................ M8-1.25 ....................... 6

6 ............... TS-1534032 ............. Phillips Pan HD Mach Screw ............................... M6-1.0x10 ................... 2

7 ............... TS-1550041 ............. Flat Washer .......................................................... M6 ............................... 2

8 ............... JPSF1-108 ............... Cursor .................................................................. .................................... 1

9 ............... JPSF1-109 ............... Adjustment Screw ................................................ .................................... 2

10 ............. JPSF1-110 ............... Fence Body .......................................................... .................................... 1

11 ............. JPSF1-111 ............... Slide Hold Plate ................................................... .................................... 1

12 ............. JPSF1-112 ............... Pad ....................................................................... .................................... 2

13 ............. TS-1491081 ............. Hex Cap Screw .................................................... M10-1.5x50 ................. 1

14 ............. TS-1482101 ............. Hex Cap Screw .................................................... M6-1.0x50 ................... 1

15 ............. JPSF1-115 ............... Lock Plate ............................................................ .................................... 1

16 ............. TS-2246101 ............. Flat Head Screw .................................................. M6-1.0x10 ................... 2

17 ............. JPSF1-117 ............... Lock Cam ............................................................. .................................... 1

18 ............. JPSF1-118 ............... Handle .................................................................. .................................... 1

19 ............. TS-1541041 ............. Nylon Insert Lock Nut ........................................... M10-1.5 ....................... 1

20 ............. TS-1524011 ............. Set Screw ............................................................. M8-1.25x8 ................... 2

21 ............. JPSF1-121 ............... Adjustment Foot ................................................... .................................... 1

22 ............. TS-1540041 ............. Hex Nut ................................................................ M6-1.0 ......................... 1

23 ............. JPSF1-123 ............... Stop Pad .............................................................. .................................... 1

24 ............. TS-1541021 ............. Nylon Insert Lock Nut ........................................... M6-1.0 ......................... 1

25 ............. JPSF1-25 ................. JET Logo (not shown) .......................................... .................................... 1

26 ............. JPSF1-26A ............... ProShop II Label (not shown) .............................. .................................... 1

27 ............. JPSR30-104 ............. End Cover ............................................................ .................................... 1

17

8.0 Warranty and Service

JET® warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

Accessories carry a limited warranty of one year from the date of receipt.

Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Covered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initial purchase when calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET® branded products are not sold in Canada by JPW Industries, Inc.

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

18

19

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

20

Loading...

Loading...