Operating Instructions and Parts Manual

Benchtop Cold Saw

Model J-F225

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-414220

Ph.: 800-274-6848 Revision C 01/2016

www.jettools.com Copyright © 2016 JET

Warranty and Service

JET® warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Covered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of these machines in the processing of metal, plastics, or other materials outside recommended guidelines may

void the warranty. The exceptions are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initial purchase when calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Table of Contents

Warranty and Service .................................................................................................................................... 2

Table of Contents .......................................................................................................................................... 3

Warnings ....................................................................................................................................................... 4

Introduction.................................................................................................................................................... 6

Specifications ................................................................................................................................................ 6

Features ........................................................................................................................................................ 7

Unpacking ..................................................................................................................................................... 8

Assembly ....................................................................................................................................................... 8

Electrical ........................................................................................................................................................ 9

Adjustments ................................................................................................................................................ 10

Controls ....................................................................................................................................................... 12

Operation..................................................................................................................................................... 12

Maintenance ................................................................................................................................................ 13

Lubrication ................................................................................................................................................... 13

Blade Selection ........................................................................................................................................... 14

Troubleshooting Blade and Cutting Problems ............................................................................................ 15

Parts List – J-F225 Cold Saw...................................................................................................................... 16

Exploded View – J-F225 Cold Saw ............................................................................................................. 18

Wiring Diagram ........................................................................................................................................... 19

Ordering Replacement Parts....................................................................................................................... 20

3

Warnings

1. Read and understand the entire owner's manual before attempting assembly or operation.

2. Read and understand the war nings p osted on the m achine an d in t his m anua l. F ailure t o com pl y with

all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. The cold saw is des ign ed and intended for us e by properly trained a nd ex per ienc e d p er s onne l on l y. If

you are not familiar with the proper a nd safe operati on of a cold s aw, do not use until proper traini ng

and knowledge have been obtained.

5. Do not use this cold saw for other than its intended use. If used for other purposes, JET disclaims any

real or implied warranty and holds itself harmless from any injury that may result from that use.

6. Always wear approved s afety glasses/face shields while usin g this cold saw. Everyday eyeglass es

only have impact resistant lenses; they are not safety glasses.

7. Before operating the cold saw, rem ove tie, rings, watc hes and oth er je welry, a nd roll s leeves up past

the elbows. Remove al l loo se clothi ng and c onfin e lon g hair. N on-sl ip foot wear or anti-sk id f loor str ips

are recommended. Do not wear glo ves.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemicals k nown to cause cancer , birth defects or other reproductiv e harm. Some ex amples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make certain the switch is in the OFF position before connecting the machine to the power supply.

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If rem oved for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Make sure the cold saw is firmly placed on a secure foundation.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check f or alignment of m oving parts, bindin g of moving parts , breakage of parts, m ounting

and any other conditions that may affect its oper ation. A guard or other part th at is damaged shoul d

be properly repaired or replaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap material, oil and grease.

20. Keep visitors a safe distance from the work area. Keep children away.

4

21. Make your workshop child proof with padlocks, master switches or by removing starter keys.

22. Give your work undivided a ttention. Look ing around, c arrying o n a conversati on and “hors e-pla y” are

careless acts that can result in serious injury.

23. Mainta in a balanced stance at all times so that you do not fall into th e bl ade or oth er m oving par ts. Do

not overreach or use excessive force to perform any machine operation.

24. Use the r ight to ol at the c orr ect spee d and feed rate. Do n ot for ce a t ool or att achm ent to d o a j ob f or

which it was not designed. The right tool will do the job better and safer.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maintain tools with care. Keep saw blades sharp and clean for the best and safest performance.

Follow instructions for lubricating and changing accessories.

27. T ur n of f the machine before clea n ing. Us e a br ush or compres sed air to remove c hips or d ebr is — do

not use your hands.

28. Do not stand on the machine. Serious injury could occur if the machine tips over.

29. Never leave the machine running unattended. Turn the power off and do not leave the machine until it

comes to a complete stop.

30. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not he eded, it m ay result in serious inj ury or p ossibly

even death.

5

Introduction

The JET Model J-F225 Cold Saw is a pendulum bench saw designed for cutting metals. Operation is

manual: after turning on the electrical power supply to the machine and clamping the workpiece in the

vice, the operator starts the blade by pressing the micro switch located on the control lever; he then

moves the head downwards in order to cut the material; after completing the cut, the cutting head returns

to position ready for a new cutting cycle. The Model J-F225 can perform miter cuts up to 45° to the left.

Specifications

Model Number ...................................................................................................................................... J-F225

Stock Number ..................................................................................................................................... 414220

Disc Blade

Disc diameter ......................................................................................................................... 225mm (9 in.)

Hole diameter (in) .................................................................................................................................... 1.3

Blade thickness (in) ............................................................................................................................... 0.08

Cutting Speed

Blade Speed (RPM) ................................................................................................................................. 50

Vise Opening (Max) ...................................................................................................................................... 6

Motor ..................................................................................................................... 1HP, 1PH, 115VAC, 60Hz

Other

Coolant Capacity .......................................................................................................................... 2.7 quarts

Dimensions ...................................................................................................................25"L x 15"W x 28"H

Weight .................................................................................................................................................84 lbs

Cutting Capacity

Degree Round Square (vise slot clamp) Rectangle

90°

45°

The specificatio ns in this m anual ar e given as general inform ation and are not binding. JET res erves the

right to effect, at an y tim e and without pr ior not ice, c ha nges or altera tions to parts, f ittings, and ac cess ory

equipment deemed necessary for any reason whatsoever.

Ø 2-1/2”

Ø 2”

2-1/4”(W) x 2-1/4”(H) 2-1/2”(W) x 2-15/16”(H)

1-5/8”(W) x 1-5/8”(H) 1-3/4”(W) x 1-1/4”(H)

6

Features

In this section, refer to Figure 1 except where

otherwise specified.

Miter Cutting Head

The miter cutting head (F igure 1) is t he unit that

cuts the material and consists of a cast iron

base, blade support unit and guard,

transmission unit, and m otor. T he depth of cut is

set by adjusting the depth cut stop. The miter

cutting head swivels and can be adjusted from

0–45º.

Miter Positioning

The cutting angle (miter position) is manually

adjusted and described in Performing Angle

Cuts on page 10.

Self-centering Vise

The self-centering vise holds the work piece in

place during cuttin g. The work piece is secured

in the vise by turning the vise handle.

Trigger Handle

The trigger handle is located on the operating

lever used to raise and lower the saw. It

contains a micro-switch (Figure 9), which starts

the saw when pressed.

Figure 1

Flood Coolant System

Coolant is dispensed directed onto the saw

blade from a coolant fitting on the upper blade

guard. Coolant is provided through tubing from

the coolant pump mounted on the back of the

motor casing.

The coolant flow control valve (Figure 2) is

located on the back of the saw. Adjust the valve

to achieve desired flow. Flow starts when the

switch on the machine is turned on and the

micro-switch in the trigger handle is depressed .

Releasing the micro-switch stops coolant flow.

This coolant system can operate with either a

soluble oil base coolant or water-soluble

synthetic coolant. Coolant should be changed

regularly. Some r ecomm ended brands are DoAll

and Lenox. These coolants are ava ilable at your

local industrial distributor.

Figure 2

7

Unpacking

Remove packing and two wrapped parcels

containing the handle and workstop, requiring

simple assem bly, from shipping cont ainer. T hen lift

machine from c ontainer and place on sturdy work

surface.

Assembly

Handgrip

Tools requ ired

23mm wrench

Crosspoint screwdriver

Referring to Figure 3:

1. Screw the threaded end (D) of the operating

handle into the threaded opening (E) of the

crank case. Back off slightly, aligning the

position of the trigger handle (A) for a

comfortable grip when operator stands before

the machine.

2. Secure the operating handle (B) by tightening

the lock nut (C) with a 23mm wrench.

3. Attach the connector (F) of the cable to the

socket (G) on the side of the switchbox.

4. Attach the cable cover (H) to the crankcase (K). Secure the cover with four M4x6 pan

head screws (J).

Tighten with a crosspoint screwdriver. Make

sure the cable can move freely inside the

cover and is not pinched between the cover

base and crankcase.

Figure 3

Work Stop

Tools requ ired

adjustable wrench

Referring to Figure 4, assemble the workstop as

follows:

1. Loosen the lock knob (A) on the stock stop (B)

and slide it onto the stop bar (C).

2. Thread the assembly (D) into the mounting

bracket (E). Place an adj ustable wrenc h at the

indents (F) and tighten the rod.

8

Figure 4

Electrical

Electrical Requirements

When connecting the cold saw to the power

source outlet, the outlet must be properly

grounded to protec t the operator from electr ical

shock.

In the event of a malfunction or breakdown,

grounding provides a path of least res istance f or

electrical current to reduce the risk of electrical

shock. This m achine is eq uipp ed wit h an elec tric

cord having an equipment-groundin g conductoroutlet that is properly insta lled and grounded in

accordance with all local codes and ordinances.

This saw is equipped with a power cord.

Improper connection of the equipment groundin g

conductor can result in a risk of electric shock.

The conductor with insulation having an outer

surface that is green (with or without yellow

stripes) is the equipm ent -grounding conductor.

If repair or replacement of the electric cord or

plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

Plug power cord into a 110-120V properly

grounded outlet protected by a 14-am p fuse or

circuit breaker.

Do not touch the prongs of

the power cord plug when plugging or

unplugging to or from an outlet.

If improperly grounded, this

power tool can cause serious injury from

electrical shock, particularly when used in

damp locations or near plumbing. If an

electrical shock occur s, there is t he potenti al

of a secondary hazard such as your hands

coming in contact involuntarily with the

rotating blade.

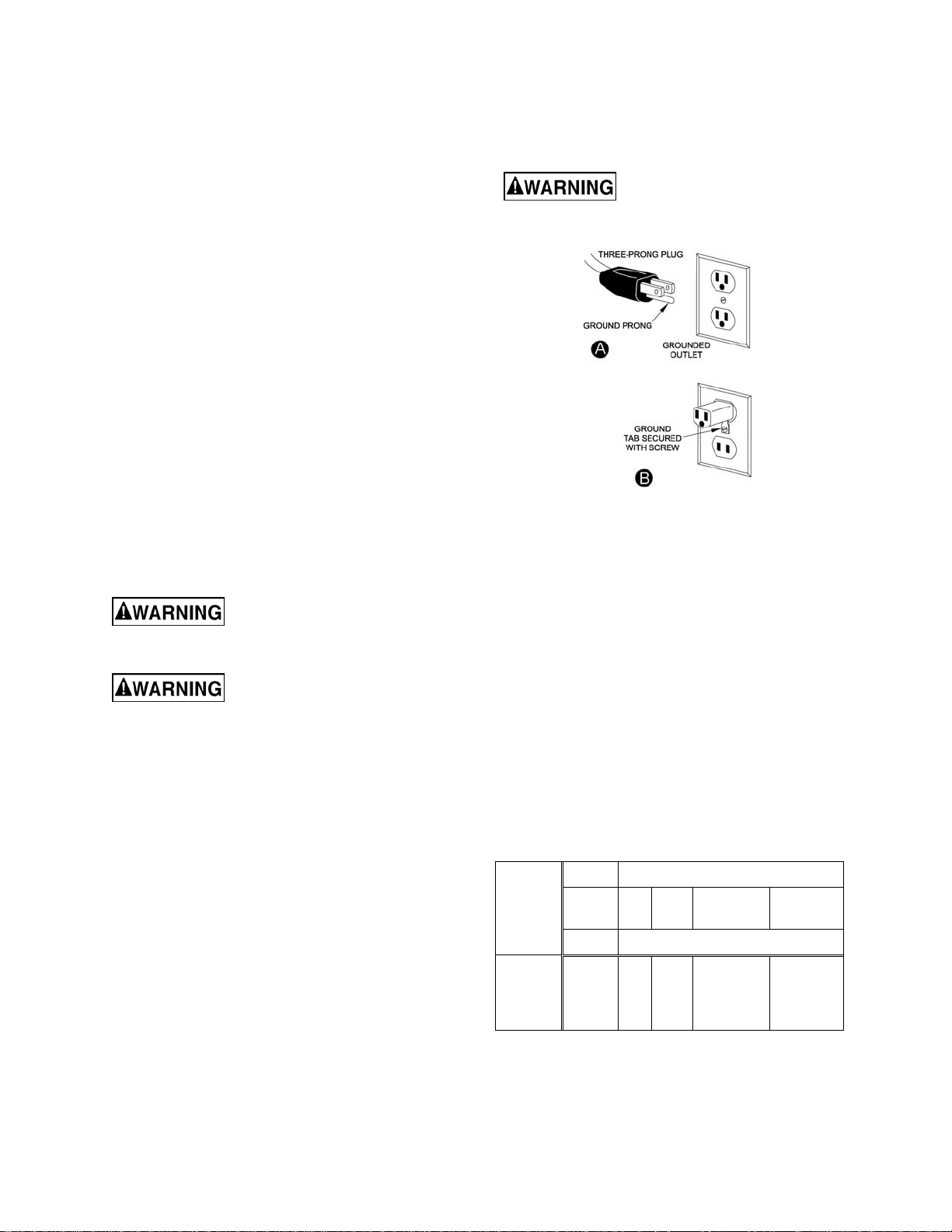

Electrical Connections

The J-F225 Cold S aw is rated at 115V, 1Phase

and is designed for use on a circuit with an

outlet that looks the one shown in Fig. A. and

have a grounding pro ng, also s hown in Fig. A . A

temporary adapter (Fig. B) may be used to

connect the plug to a two-prong receptacle

(Fig. B) if a properly grounded outlet is not

available. A temporary adapter should only be

used until a properly grounded outlet can be

installed by a q ualified elec trician. This ad apter

is not applicable in Canada. The green colored

lug must be fastened to the cover plate screw.

Important: The adapter illus trated i n F i g. B is f or

use only if you already have a properly

grounded two-prong receptacle. Do not modify

the plug provided-if it wil l not fit the outlet, have

the proper outlet installed by a qualified

electrician. Check with a qualified electrician or

service personnel if the grounding instructions

are not completel y understood, or if in doubt as

to whether the tool is properly grounded.

Before plugging into the

power source, be sure that power switch is

in the OFF position.

Extension Cords

Use only three-wire extension cords that have

three-prong grounding type plugs and threeprong receptacles that accept the tool's plug.

Replace or repair damaged or worn core

immediately.

USE PROPER EXTENSIO N CORD. Make sure

your extension cord is good condition. When

using an extension cord, be sure to use one

heavy enough to carr y the current your produc t

will draw. An unders ized cord will cause a dr op

in line voltage resulting in loss of power and

overheating. Table 1 shows the correct size to

use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier

gage, The smaller the gage num ber, the he avier

the cord.

Volts Total length of cord in feet

Amp

Rating

0 – 06

6 – 10

10 – 12

12 – 16

9

120V

240V

25

50

50

100

AWG

18

16

18

16

14

16

16

12

100

200

16

14

14

not rcmd

Table 1

150

300

14

12

12

not rcmd

Adjustments

Remove power when making

any adjustments. Failure to

comply may result in serious injury!

Performing Angle Cuts

The JET J-F225 c an perform cuts at angles up to

45º to the left. Adjust the angle of a cut as follo ws

while referring to Figure 5:

1. Loosen two hex cap screws (A) with a 6mm

hex wrench to free the turntable.

2. Turn the machine body to any positi on be t ween

0–45º, reading position on the angle scale on

the base.

3. Tighten the hex cap screws (A).

Blade Travel Adjustment

Tools requ ired

12mm wrench

13mm wrench

The height of retract and depth of c ut stop adjustments lim it the upper and lower tra vel limits of the

saw blade.

To make adjustments (refer to Figure 5):

Height of retract – this is the upper travel limit of the

saw blade when the trigger handle is raised.

Adjustment is made by setting the position of

screw B.

Depth of cut stop – this is the lower travel limit of

the saw blade when the trigger handle is brought

down. Adjustment is made by setting the position of

screw C (not visible in photo).

Figure 5

Blade Guard Adjustment

Remove power when making

any adjustments. Failure to

comply may result in serious injury!

Referring to Figure 5:

When the saw head is lowered all the way, the

blade should not be visible (G). If the blade is

visible, the blade guar d (F) needs to be adjusted as

follows:

1. Loosen two socket head cap screws (D) just

enough to permit the bracket (E) movement for

adjustment.

2. Manually adjust the blade guard (H) until blade

is not visible at G.

Note: Durint step 2, the saw must be in the

lowered postion.

3. Tighten the two socket head cap screws (D).

10

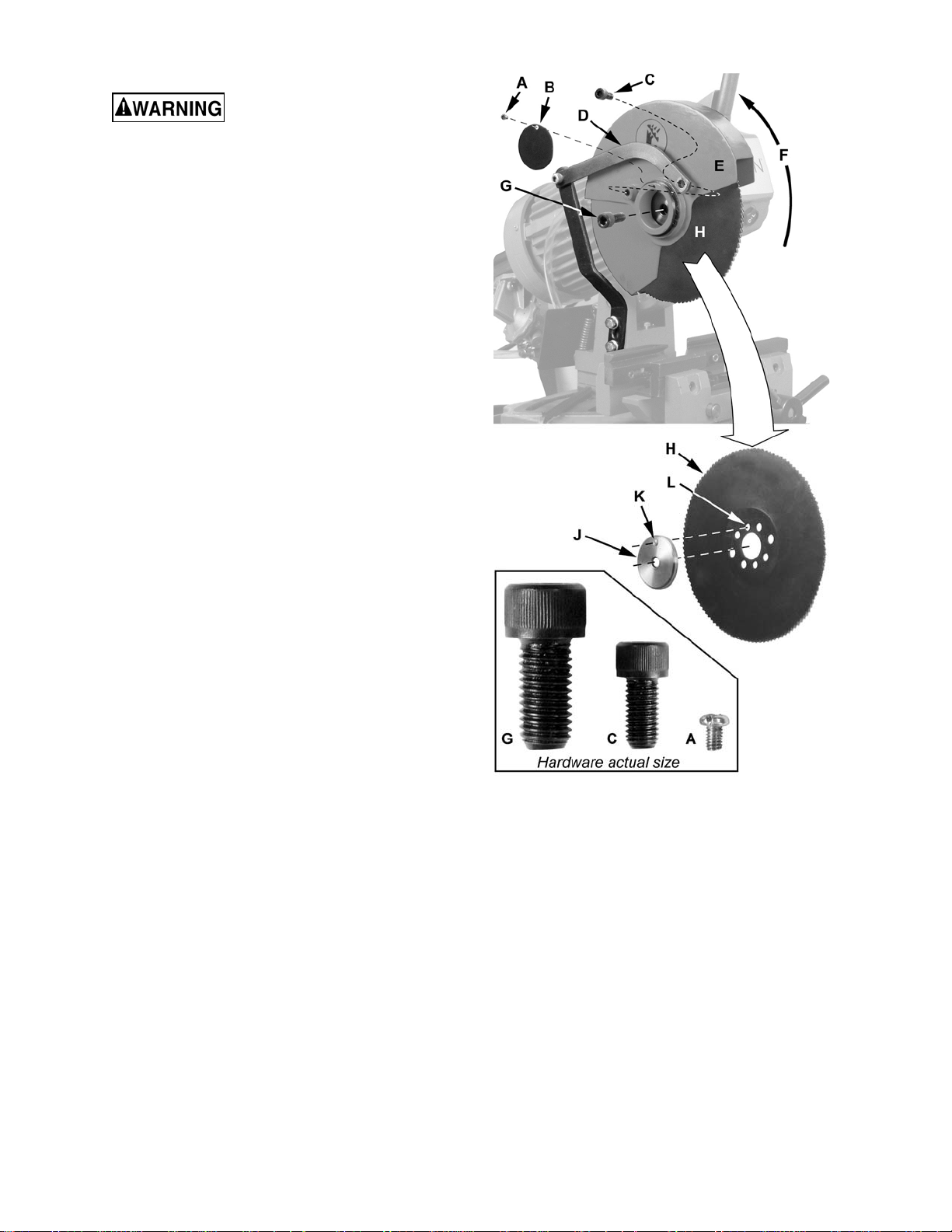

Changing the Saw Blade

The cold saw must not be

connected to the p ower source wh en changing

saw blades. Failure to comply may result in

serious injury!

Remove the saw blade as foll ows while ref erring to

Figure 6:

1. Remove the scr ew (A) and cover plate ( B), or

loosen the screw just enough to sl ide the co ver

plate away to reveal the hub.

2. Remove the socket head cap screw C that

secures the bracket (D) to the lower blade

guard (E).

3. Raise the lower blade guard (E) upwards (F).

4. Remove socket head cap screw (G) that

secures the blade (H).

Note: This screw has a left thread requiring a

clockwise turn to loosen and a counterclockwise turn to tighten.

5. Remove the blade (H) and outer flange (J).

Discard the old blade (or have it resharpened)

and replace with a new one.

6. Install the new blade in the reverse order

described above. Not e that the f lange (J) has a

pin (K) that needs to match up with the correct

keyhole (L), if the blade has more than one

keyhole, make the selection such that the

mounting holes of the flange and blade are

centered.

Figure 6

11

Controls

Power Switch – The power switch has two

positions, off and on. To operate the m achine, the

Power switch must be set to on. Then depress

micro-switch (Figure 8) in the trigger handle to

start.

Locking Key – When the saw is not in use, the

switch should b e locked in the off position. T o lock

the switch in the off position, pull out the safety key

(Figure 7). The saw will not start with the key

removed. However, if the ke y is remove d while the

switch is in the on position, it can be turned off

once. The saw will not restart until the key has

been reinserted into the switch.

Trigger Handle – To operate, the On/Off switch

must be set to on and the microswitch on the

trigger handle (Figure 8) depressed.

Figure 7

Figure 8

Operation

Before using the machine:

1. Check that safety devices (ex., blade guards)

are in position and work perfectly and that

personal safety requirements are complied

with.

2. Check the sharpness of the blade and verify

coolant flow.

To operate:

3. Mak e sure the work piece is securely clam ped

in the vise.

4. Turn the power on (Figure 7).

5. Grip the trigger handle ( Fig ure 8) on th e contro l

lever.

6. Start the blade by pressing the micro-switch on

the handgrip.

The down stroke speed of the head is controlled

manually by the operator.

When the cut is complete:

7. Raise the head.

8. Remove the work piece from the vise usin g the

vise hand wheels.

12

Loading...

Loading...