Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

10" Job Site Table Saw

Benchtop Series – Model No. JBTS-10MJS

For models with serial no. 12120886 and higher

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-707000

Ph.: 800-274-6848 Revision B

www.j

ettools.com Copyright © 2017 JET

2 01/2017

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please contact

Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official JET

branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Covered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty does not

cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair,

alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood. Use of these machines in

the processing of metal, plastics, or other materials outside recommended guidelines may void the warranty. The exceptions

are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a Two Year

Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof of initial

purchase when calling. If a product requires further inspection, the Technical Service representative will explain and assist

with any additional action needed. JET has Authorized Service Centers located throughout the United States. For the name of

an Authorized Service Center in your area call 1-800-274-6846 or use the Service Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor or visit

the JET website.

How State Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are given as

general information and are not binding. JET reserves the right to effect at any time, without prior notice, those alterations to

parts, fittings, and accessory equipment which they may deem necessary for any reason whatsoever. JET

are not sold in Canada by JPW Industries, Inc.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries, Inc., or any

of its successors in interest to the JET brand.

®

branded products

2

Page 3

Table of Contents

Warranty and Service .......................................................................................................................................... 2

Table of Contents ................................................................................................................................................ 3

Warnings .............................................................................................................................................................. 4

Table Saw Safety ................................................................................................................................................. 6

Specifications ....................................................................................................................................................... 7

Definitions and Terminology ................................................................................................................................ 7

Electrical .............................................................................................................................................................. 8

Grounding Instructions ..................................................................................................................................... 8

115 Volt Operation Only ................................................................................................................................... 8

Extension Cords ............................................................................................................................................... 8

Features ............................................................................................................................................................... 9

Shipping Contents ............................................................................................................................................. 10

Assembly ........................................................................................................................................................... 12

Stand .............................................................................................................................................................. 12

Attaching Saw to Stand .................................................................................................................................. 12

Mounting the Saw to Work Surface ............................................................................................................... 13

Rear Table Extension .................................................................................................................................... 13

Handwheel Handle ......................................................................................................................................... 14

Installing the Blade ......................................................................................................................................... 14

Removing the Blade ....................................................................................................................................... 14

Blade Guard Assembly .................................................................................................................................. 15

Installing the Push-stick Storage .................................................................................................................... 16

Storage ........................................................................................................................................................... 16

Adjustments ....................................................................................................................................................... 17

Setting up the Stand ...................................................................................................................................... 17

Folding the Stand ........................................................................................................................................... 17

Adjusting the Table Insert .............................................................................................................................. 17

Aligning the Blade Guard Splitter ................................................................................................................... 18

90° and 45° Positive Stop Adjustm ent ........................................................................................................... 19

Blade Tilt Pointer ............................................................................................................................................ 19

Blade Parallel to the Miter Slot ....................................................................................................................... 20

Adjusting the Miter Gauge ............................................................................................................................. 21

Rip Fence Adjustment .................................................................................................................................... 21

Rip Fence Indicator ........................................................................................................................................ 22

Table Extension Sc a le Poin ter ....................................................................................................................... 22

Rear Table Extension Adjustment ................................................................................................................. 22

Adjusting the Locking Lever ........................................................................................................................... 22

Additional Blade Adjustments ........................................................................................................................ 20

Operation ........................................................................................................................................................... 23

Basic Saw Operations .................................................................................................................................... 23

Cutting Operations ......................................................................................................................................... 24

Maintenance ...................................................................................................................................................... 28

Push Stick Construction .................................................................................................................................... 29

Troubleshooting ................................................................................................................................................. 30

Parts .................................................................................................................................................................. 31

Ordering Replacement Parts ......................................................................................................................... 31

JBTS-10MJS Table Saw – Parts List ............................................................................................................. 31

JBTS-10MJS Table Saw – Exploded View .................................................................................................... 36

JBTS-10MJS Mobile Stand – Parts List ......................................................................................................... 38

JBTS-10MJS Mobile Stand – Exploded View ................................................................................................ 40

Wiring Diagram .................................................................................................................................................. 41

The specifications in t his m anual ar e giv en as general infor m ation and ar e not bindin g. JET res erves th e righ t

to effect, at any time and without prior notice, changes or alterations to parts, fittings, and accessory

equipment deemed necessary for any reason whatsoever.

3

Page 4

Warnings

1. Read and understand the entire owners' manual before attempting assembly or operation.

2. Read and understand the war nings p osted on the m achine an d in t his m anua l. F ailure t o com pl y with

all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This saw is designed and intended f or us e by proper ly tr ained and exp erie nced p ersonne l onl y. If you

are not familiar with the pr o per an d safe op erat ion of a tab le sa w, do no t use until proper trainin g and

knowledge have been obtained.

5. Do not use this saw for oth er tha n i ts int en ded us e. If us ed f or oth er purposes, JET dis claims any real

or implied warranty and holds itself harmless from any injury that may result from that use.

6. Always wear approv ed safety glasses/f ace shields while us ing this table saw. Everyday eyeglasses

only have impact resistant lenses; they are not safety glasses.

7. Before op erating this sa w, remove tie, rings , watches and other j ewelry, and roll sleeves up past th e

elbows. Remove all loos e cloth ing and conf in e long hai r. Non-s lip foot wear or anti- sk id f loor str ips are

recommended. Do not wear gloves.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. WARNING: Drilling, sawing, sanding or machining wood products generates wood dust and other

substances known to the State of California to cause cancer. Avoid inhaling dust generated from

wood products or use a dust m ask or other safeguards to avoid inhaling d ust generated from wood

products.

10. Wood products emit chemicals known to the State of California to cause birth defects or other

reproductive harm. (California Health and Safety Code Section 25249.6)

11. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

12. Make certain the switch is in the OFF position before connecting the machine to the power supply.

13. Make certain the machine is properly grounded.

14. Make all machine adjustments or maintenance with the machine unplugged from the power source.

15. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

16. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

17. Make sure this machine is firmly secured to the floor or bench before use.

18. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check f or alignment of m oving parts, bindin g of moving parts , breakage of parts , mounting

and any other conditions that may affect its oper ation. A guard or other part th at is damaged shoul d

be properly repaired or replaced.

19. Provide for adequate space surrounding work area and non-glare, overhead lighting.

20. Keep the floor around the machine clean and free of scrap material, oil and grease.

21. Don't use in da ngero us env ironm ent. Don't use p ower t ools in dam p or wet locat ions, or ex pose them

to rain. Keep work area well lighted.

22. Keep visitors a safe distance from the work area. Keep children away.

23. Make your workshop child proof with padlocks, master switches or by removing starter keys.

24. Give your work undivided a ttention. Look ing around, c arrying o n a conversati on and “hors e-pla y” are

careless acts that can result in serious injury.

4

Page 5

25. Maintain a balanced stance at all times so that you do not fall or lean against the blade or other

moving parts. Do not overreach or use excessive force to perform any machine operation.

26. Use the right tool at th e correct s peed and feed rate. D o not force a tool or attac hm ent to do a job for

which it was not designed. The right tool will do the job better and safer.

27. Use recommended accessories; improper accessories may be hazardous.

28. Maintain tools with care. Keep saw blades sharp and clean for the best and safest performance.

Follow instructions for lubricating and changing accessories.

29. Disconnect tools before servicing and when changing accessories such as blades.

30. Make sure the work piece is securely attached or clamped to the table.

31. T urn off the mac hine befor e cleaning . Use a br ush or c ompres sed air to r emove chips or debris — do

not use your hands.

32. Do not stand on the machine. Serious injury could occur if the machine tips over.

33. Nev er lea ve th e m ac hine running unattended. T urn the power of f and do not le av e the m ac hine unt il i t

comes to a complete stop.

34. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if pr ecautions ar e not heeded, it may result i n serious injur y or poss ibly

even death.

5

Page 6

Table Saw Safety

1. Always use a s aw blade guard, splitt er and anti-kick back pawls for ev ery through–sawing oper ation.

Through–sawing operations are those in which the blade cuts completely through the workpiece

when ripping or crosscutting. Always be sure the blade guard is tightened securely.

2. Always hold work firmly against the miter gauge or rip fence.

3. Always use a push stick (provided with this saw), especiall y when ripping narrow stock . Refer to the

ripping instructions in this Operator’s Manu al where the push stick is covered in detail. A patter n for

making your own push stick is included on page 29.

4. Never perform any operation by freehand, which means using only your hands to support or guide the

workpiece. Always use either the fence or the miter gauge to position and guide the work.

Warning: Freehand cutting is the major cause of kickback and finger/hand amputations. Never

use the miter gauge and fence simultaneously.

5. Never stand or have any part of your bod y in lin e with the path of the saw blade. Keep your han ds out

of the saw blade path.

6. Never reach behind or over the cutting tool for any reason.

7. Remove the rip fence when crosscutting.

8. Do not use a molding head with this saw.

9. Feed work into the blade against the direction of rotation only.

10. Never use the rip fence as a cut-off gauge when crosscutting.

11. Never attempt to free a sta lled saw blade with out first turning the sa w OFF. Turn power switch O FF

immediately to prevent motor damage.

12. Provide adequate support to the rear and the sides of the saw table for long or wide workpieces.

13. Avoid kic kback s (work thr own back towar ds you) b y keeping t he blade shar p, the rip f ence para llel to

the saw blade and by keeping the splitter, anti-kickback pawls and guards in place, aligned and

functioning. Do not re lease work before passing it c ompletel y beyond the saw b lade. Do not rip work

that is twisted, warped or does not h ave a straig ht edg e to gu ide it alon g the f enc e. Do no t attem pt to

reverse out of a cut with the blade running.

14. Av oid awkward operat ions and hand posit ions where a sudd en slip could cause your hand to move

into the saw blade.

15. Never use solvents to cle an plastic parts. Sol vents could possib ly dissolve or otherwis e damage the

material. Only a soft damp cloth should be used to clean plastic parts.

16. Mount your table saw on a bench or stand before performing any cutting operations.

17. Never cut metals or materials that may make hazardous dust.

18. Alwa ys use in a well-venti lated ar ea. Rem ove sawdust f requentl y. Clean out sawd ust from the interior

of the saw to preve nt a potenti al fire ha zard. Attach a vacuum to t he dust port f or addit ional sawd ust

removal.

19. Never leave the saw runni ng unattended. Do not leav e the saw until the blade com es to a complete

stop.

20. For proper operation follow the instructions in this Operator’s Manual.

Note: On machines with no s tand or if a s tand is not b e in g use d , a ho le ap pr oxim ately 11 in. square must

be cut under the saw t o allow sawdust to f all through. Failure to cut this h ole will cause s awdust to build

up in the motor area, resulting in a fire hazard and potential motor damage.

6

Page 7

Specifications

Stock Number ..................................................................................................................................... 707000

Model Number ............................................................................................................................ JBTS-10MJS

Motor ...................................................................................................................... 120VAC, 1PH, 60Hz, 15A

Blade Speed - no load (RPM) ................................................................................................................. 4000

Saw Blade Diameter (in.) ............................................................................................................................ 10

Arbor Diameter (in.) .................................................................................................................................... 5/8

Blade Tilt (deg.) ..................................................................................................................................... 45 left

Rip Capacity (in.) ......................................................................................................................................... 25

Maximum Rip Left of Blade (in.) .................................................................................................................. 11

Maximum Cutting Depth at 90º (in.) ........................................................................................................ 3-1/8

Maximum Cutting Depth at 45° (in.) ........................................................................................................ 2-1/2

Dado Capacity (in.) .......................................................................................................................... 13/16 x 6

Table Height, with Stand (in.) ...................................................................................................................... 35

Main Table Size (in.) ................................................................................................................... 24 W x 21 D

Table Size with Side and Rear Extension Wings (in.) .......................................................... 30-1/4 W x 21 D

Table Size with Both Wings Fully Extended (in.) ............................................................ 42-3/8 W x 35-3/4 D

Dust Port Diameter (in.) .......................................................................................................................... 2-1/2

Gross Weight (lbs.) ................................................................................................................................... 105

Net Weight (lbs.) ......................................................................................................................................... 91

Definitions and Terminology

Arbor: Metal shaft that connects the drive

mechanism to the blade.

Bevel Edge Cut: Tilt of the saw arbor and blade

between 0° and 45° to perform an angled cutting

operation.

Blade Guard: Mechanism mounted over the saw

blade to prevent accidental contact with the cutting

edge.

Crosscut: Sawing operation in which the miter

gauge is used to cut across the grain of the

workpiece.

Dado Blade: Blade(s) used for cutting grooves and

rabbets.

Dado Cut: Flat bottomed groove in the face of the

workpiece made with a dado blade.

Featherboard: Device used to keep a board

against the rip fence or table that allows the

operator to keep hands away from the saw blade.

Kerf: The resulting cut or gap made by a saw

blade.

Kickback: An event in which the workpiece is lifted

up and thrown back toward an operator, caused

when a work piece binds on the saw blade or

between the saw blade and rip fence (or other fixed

object). To minimize or prevent injury from

kickbacks, see the Operating Instructions section.

Miter Gauge: A component that controls the

workpiece movement while performing a crosscut

of various angles.

Non-Through Cut: A sawing operation that

requires the lowering of the splitter and removal of

the blade guard and kick-back pawls, resulting in a

cut that does not protrude through the top of the

workpiece (includes Dado and rabbet cuts).

The blade guard and kick-back pawls must be reinstalled and splitter raised after performing a nonthrough cut to avoid accidental contact with the

saw blade during operation.

Parallel: Position of the rip fence equal in distance

at every point to the side face of the saw blade.

Perpendicular: 90° (right angle) intersection or

position of the vertical and horizontal planes such

as the position of the saw blade (vertical) to the

table surface (horizontal).

Push Board/Push Stick: An instrument used to

safely push the workpiece through the cutting

operation.

Rabbet: A cutting operation that creates an

L-shaped channel along the edge of the board.

Rip Cut: A cut made along the grain of the

workpiece.

Splitter: Metal plate to which the blade guard is

attached that maintains the kerf opening in the

workpiece when performing a cutting operation.

Standard Kerf: 1/8" gap made with a standard

blade.

Straightedge: A tool used to check that a surface

is flat or parallel.

Through Sawing: A sawing operation in which the

workpiece thickness is completely sawn through.

Proper blade height usually allows a 1/8" of the top

of the blade to extend above the wood stock.

7

Page 8

Electrical

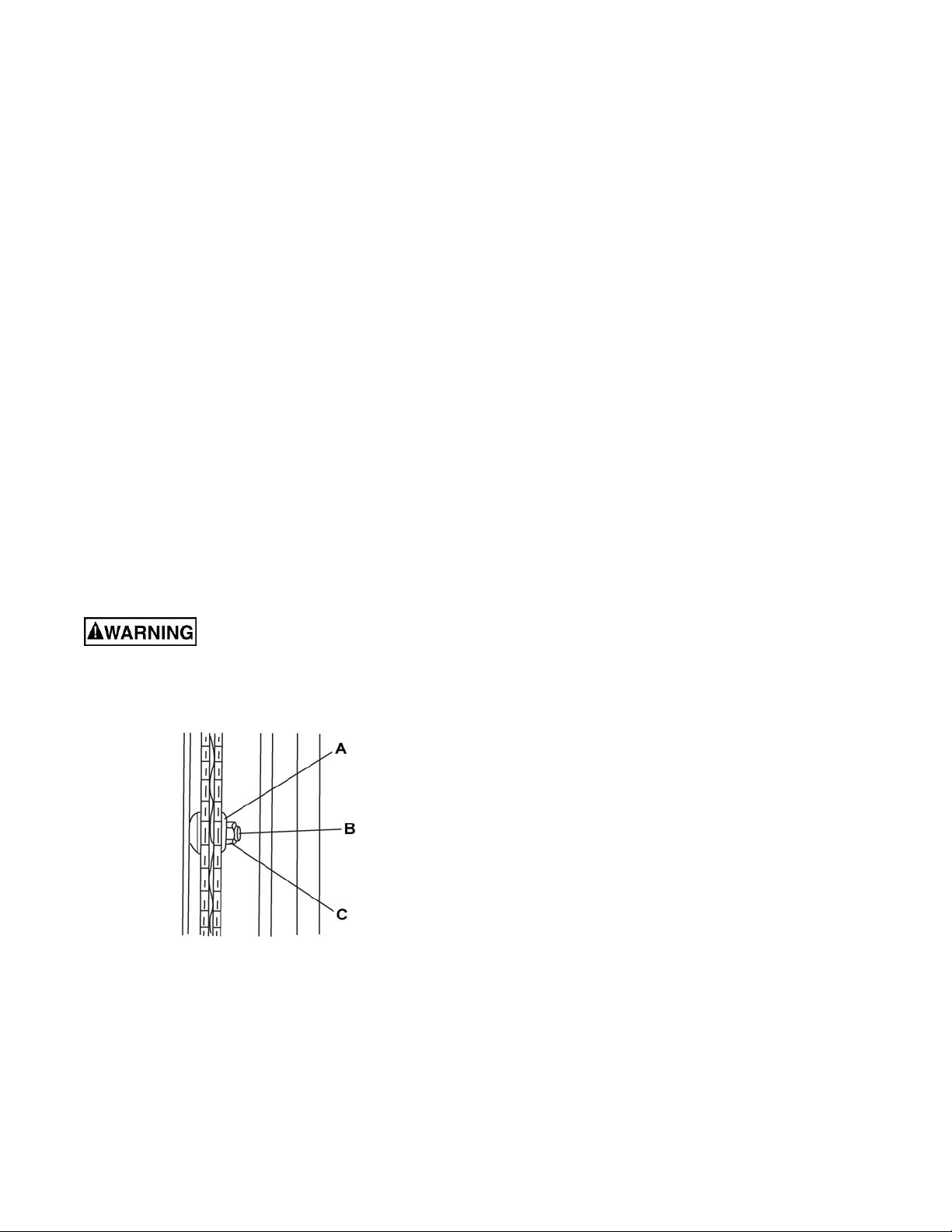

Grounding Instructions

In the event of a malfunction or breakdown,

grounding provides a path of least res istance f or

electric current to reduce the risk of electric

shock. This tool is equip pe d with an elec tric cor d

having an equipment-gr oun ding c onductor an d a

grounding plug.

The plug must be plugged into a m atching outle t

that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided – if it wil l not fit

the outlet, have t he proper outlet installed b y a

qualified electrician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes is the equipmentgrounding conductor. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-gr ounding c onductor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded.

Use only 3-wire extension cords that have 3prong grounding plugs and 3-pole receptacles

that accept the tool’s plug.

Repair or replace damaged or worn cord

immediately.

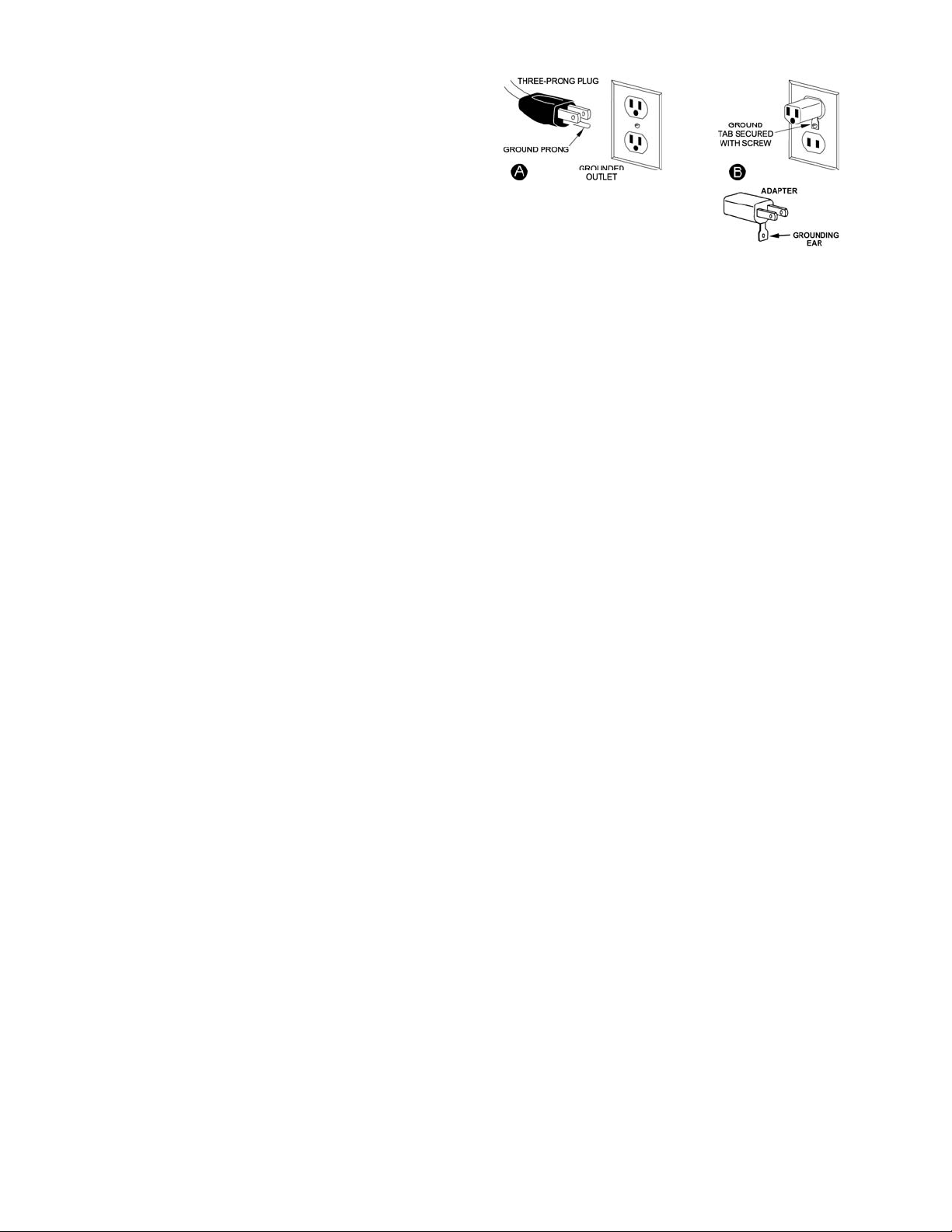

Figure A

Extension Cords

Make sure your extension cord is in good

condition. When using an extension cord, be

sure to use one heavy enough to carry the

current your machine wil l draw. An undersized

cord will cause a drop in the line voltage

resulting in power loss and overheating. The

table below shows the correct size to use

depending on the cord length and nameplate

ampere rating. If in d oubt, use the next heavier

gauge. Remember, the smaller the gauge

number, the heavier the cord.

Cord Length AWG

00 – 25ft 016

225 – 50ft 014

Important: Make certain the receptacle in

question is properly grounded. If you are not

sure, have a registered electrician check the

receptacle.

115 Volt Operation Only

Referring to Figure A:

As received from the factory, your table saw is

ready to run at 115-volt operation. This table

saw, when wired for 115 vo lt, is intende d for use

on a circuit that has an outlet and a plug that

looks like the one il lustrated in (A). A tem porary

adapter, which looks like the adapter shown in

(B), may be used t o connect this plug to a twopole receptacle if a properly grounded outlet is

not available. The temporary adapter should

only be used until a properly grounded outlet

can be installed by a qualified electrician. This

adapter is not applicab le in Canada. The green

colored rigid ear, lug, or tab, extend ing from the

adapter, must be connected to a permanent

ground such as a properly grounded outlet box.

8

Page 9

Features

Figure 1 – Features

9

Page 10

Shipping Contents

Unpacking

1. Remove the contents from the shipping

container.

2. Compare the contents of the shipping

container and hardware bags with the lists

found below. Mak e certain that all item s are

accounted for befor e discar ding an y packing

material. Report any shortages or damage

to your JET distributor.

Contents of the Shipping Container

(These items shown in Figure 3)

A Blade Guard (1)

B Kickback Pawl (1)

C Riving Knife (1)

D Table Saw (1)

E Pedal (1)

F Miter Gauge (1)

G Stand Assembly (1)

H Rear Table Extension (1)

J Rear Table Extension Tube (2)

K Push Stick (1)

L Rip Fence (1)

M Roller Wheel (2)

-- Hardware Bags

see contents on next page

-- Owner’s Manual (1)

-- Warranty Registration Card

Tools Supplied for Assembly

(These items shown in Figure 2)

N Blade Wrench

O 4mm Hex Wrench

P 5mm Hex Wrench

Figure 2 – Supplied Tools

Tools not included

00Adjustable Wrench

006mm Hex Wrench

00Crosspoint Screwdriver

00Combination Wrench

Figure 3 – Contents of Shipping Container

10

Page 11

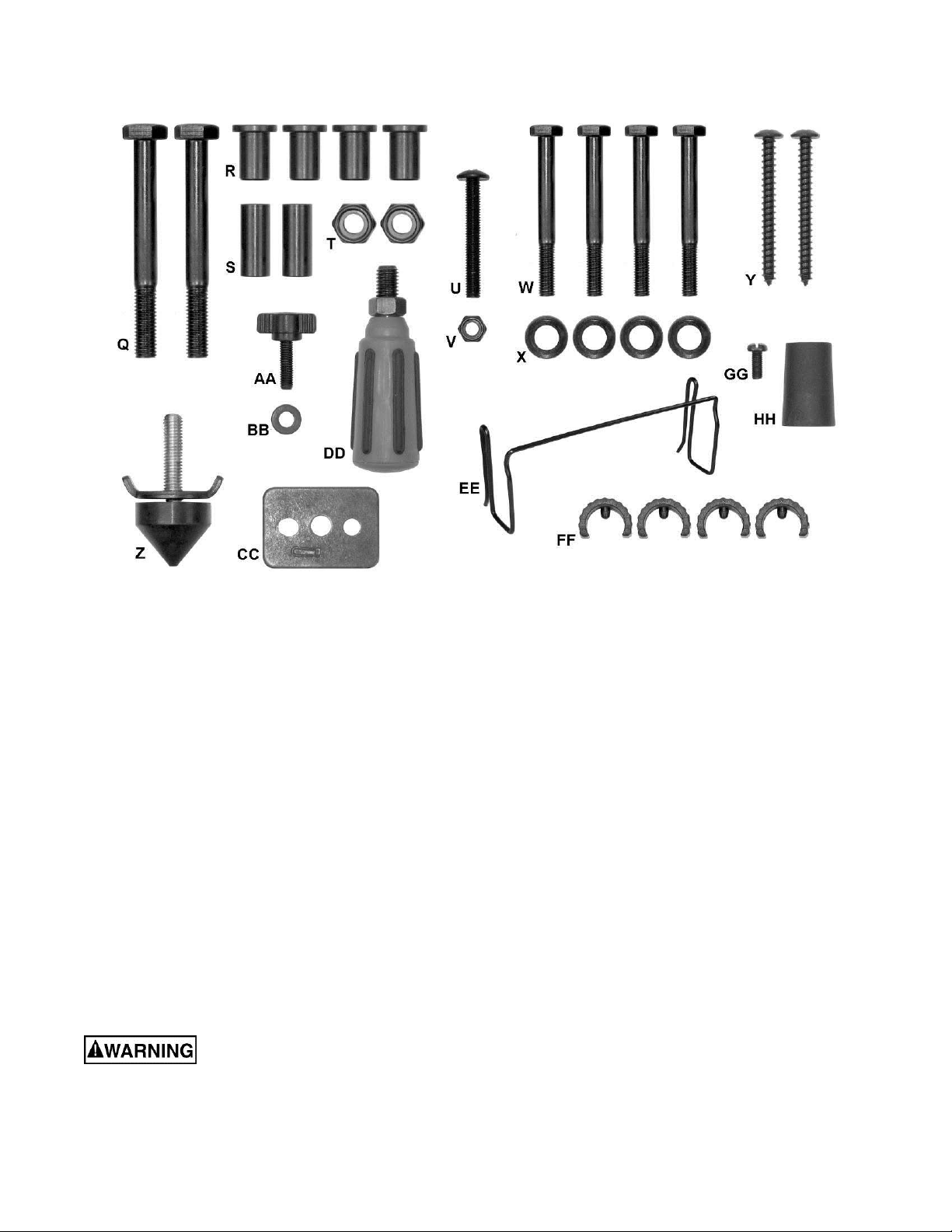

Hardware

The following items are shown in Figure 4.

Q Screw (2)

R Collar (4)

S Shaft Sleeve (2)

T Nut (2)

U Screw (1)

V Nut (1)

W Screw (4)

X Plastic Flat Washer (4)

Y Screw (2)

Figure 4 – Hardware

aZ oStand Pad (1)

AA oSplitter/Riving Knife Lock Knob (1)

BB oFlat Washer (1)

CC oSplitter/Riving Knife Plate (1)

DD oHandwheel Handle (1)

EE oPush Stick Storage Clip (1)

FF oPlastic Stop (4)

GG oScrew (1 )

HH oRear Extension Pad (1)

Read and understand all assembly instructions before attempting assembly! Failure to

comply may cause serious injury!

11

Page 12

Assembly

Note: The letter designators used in the assembly

section are the sam e as those used in the ship ping

contents and hardware s ection ( pag e 10-11) for the

purpose of simplif ying part identif ic atio n.

Stand

Stand may pop up unexpectedly

without weight of saw on stand. In order to

avoid injury, verify that the lock hook (G

7) located at the front of the stand is locked

onto the stop screw before mounting the table

saw.

Stand Pad and Pedal

Referring to figure 5:

1. Thread the stand p ad (Z) through the wing nut

(Z

1) to the bottom of the left rear leg.

Adjustment is desc r ibe d i n Sett ing up the St and

on page 17.

2. Attach the pedal (E) to the left f ront leg using

the screw (U) and hex nut (V). Secure with

10mm socket and crosspoint screwdriver.

Wheel

Referring to Figure 6:

3. Attach two collars (R

(M).

1, R2) to each roller wheel

1, Fig.

Figure 5

Figure 6

4. Attach one roller wheel assembly to the right

front leg using the bolt (Q), the shaft sleeve (S),

and the hex nut (T) as shown.

Note: Verify that the side of the wheel that h as

more ribs is facing toward the inside of the

stand.

5. Attach the other roller wheel to the right rear

leg using the same manner.

6. Tighten screw (Q) and hex nut (T) with two

17mm wrenches.

Note: Do not overtighten, because doing so will

not allow the wheels to turn.

Attaching Saw to Stand

Referring to Figure 7:

Do not cut the bands and

release the stand hook (G

is properly attached to the stand.

1. Place table saw (D) on the top of stand (G)

aligning the holes in the bas e with the holes in

the stand.

1) until the table saw

Figure 7

2. Insert four hex bolts (W) through t he plastic f lat

washers (X) and holes in base and stand.

3. Tighten all f our bolts (W ) with a 13 mm sock et,

but do not overtighten.

Note: To set up the stan d or fold down the stand,

see Setting Up The Stand and Folding The Stand

on page 17.

12

Page 13

Mounting the Saw to Work Surface

A hole to allow sawdust to fall

through must be provided when the saw is

mounted to a work surface (stand not used).

Failure to do so will cause sawdust to build up

in the motor area, which can result in fire or

damage to the motor.

Referring to Figure 8:

A

A

If the stand is not us ed, the saw must be proper ly

secured to a sturdy workbench through the four

mounting holes that are l ocated at the base of the

saw.

The surface of the table where the saw is to be

mounted must have a hole (B) that is large enough

to facilitate sawdust fall-through and removal.

1. Squ are the saw on the mounting surface, and

mark the location of the four 3/8 in. mounting

holes (A).

2. Drill pilot holes in t w o d ia go nal c orners (mark ed

(A) in the mounting surface.

3. Mark an 11x11 in. square (B), centered bet-

ween the four mounting holes (A).

4. Cut out and remove the square.

5. This opening will allo w sawdust to fall through

the saw base.

6. Place the saw on the work surface, and align

the mounting holes of the saw with the two

holes drilled in step 2.

7. Fasten the saw to the work surface using

screws (Y, Fig. 4) provided.

B

A

A

Figure 8

Do not operate this saw on the

floor. Doing so is very dangerous. Failure to

comply may cause serious injury!

Rear Table Extension

Referring to Figure 9:

1. Attach the rubber pa d (HH) to the inside of the

rear table extensi on (H). T hread t he screw (GG)

thru the rubber pad with the screwdriver. Tighten

the screw (GG).

2. Insert the two rear table ex tension tubes (J) into

the rear table extension (H). Fol low arro ws J

Note: The tubes (J) must be inserted into the

back of the extension with the ben t end last so

that the bar will hold the extension in place.

(J

4).

3. Snap plastic stops (FF

1) over the extension

tubes (J). This will ‘lock’ the tube (J) into the

extension (H). Make sure the pin in the stops fit

1, J2.

Figure 9

into the matching holes in the extension tubes.

4. Following arrows J1, J3, insert the rear table

extension into the t wo extension tube brack ets

(J

3) under the table.

5. Snap two black plastic stops (FF

2) over the end

of the rear table extension t ubes (J). Make sure

the pin in the stops fit into the matching holes in

the extension tubes.

13

Page 14

Handwheel Handle

Thread the handwhee l ha n dle (DD, Fig. 10) into the

handwheel hole (A. Fig. 10), and then tighten the

nut against the handwheel with a 10 mm wrench.

Installing the Blade

To avoid injury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected from

the power source outlet.

Referring to Figure 11:

1. Remove the table insert (A).

2. Place the blade onto the arbor with the blade

teeth pointing forward to the front of the saw.

3. Mak e sure the bla de fits f lush against the inner

flange.

4. Clean the outer blade flange (H) and install it

onto the arbor and against the blade.

5. Thread the arbor nut onto the arbor, making

sure the flat side of the nut is against the b lad e,

then hand-tighten.

Figure 10

6. Pull the ar bor locking lever (G) toward the front

of the machine while spinning the blade by

hand until the latch locks into place and the

blade will no longer turn.

7. Place the wrench (E) on the arbor nut and tur n

clockwise (toward the rear of the saw table).

8. Lower the blade to the down position. Replace

the table insert (A) and the blade guard.

Important: Do no t operate this saw until t he blade

and blade guard spl itter are aligned and in work ing

order.

Removing the Blade

To avoid injury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected from

the power source outlet.

Referring To Figure 11:

1. Remove the table insert (A) and raise the blade

to the maximum height by turning the blade

elevation handwheel clockwise.

2. Remove blade guard.

3. Adjust the blade to the 90° vertical position by

unlocking the blade t ilt in g lo ck knob and turning

the bevel tilting handwheel counterclockwise,

and then lock into position.

4. Pull the arbor locking lever (G) toward the front

Figure 11

of the tool while spinning the blade by hand

until the latch lock s into pl a c e and th e b lad e will

no longer turn.

5. Place the blade wrench (E) on the arbor nut (J).

6. Loosen and remove the arbor nut and the

flange by pulling the wrench towards the front

of the machine.

7. Then remove the blade (F). Clean but do not

remove the inner blade flange before

reassembling the blade.

14

Page 15

Blade Guard Assembly

To avoid injury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected from

the power source outlet.

● When installing the blade guard, cover the

blade teeth with a piece of folded cardboard to

protect yourself from possible injury.

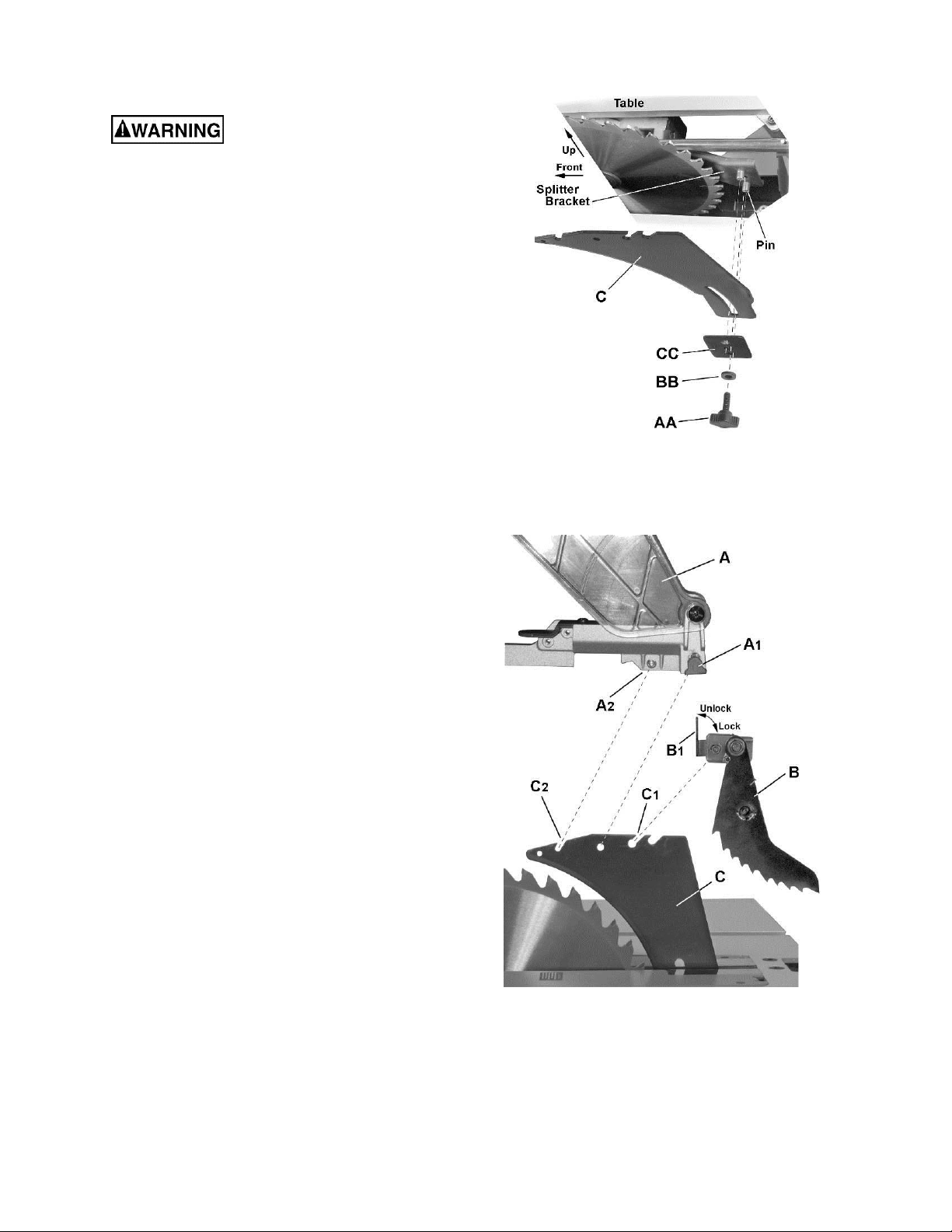

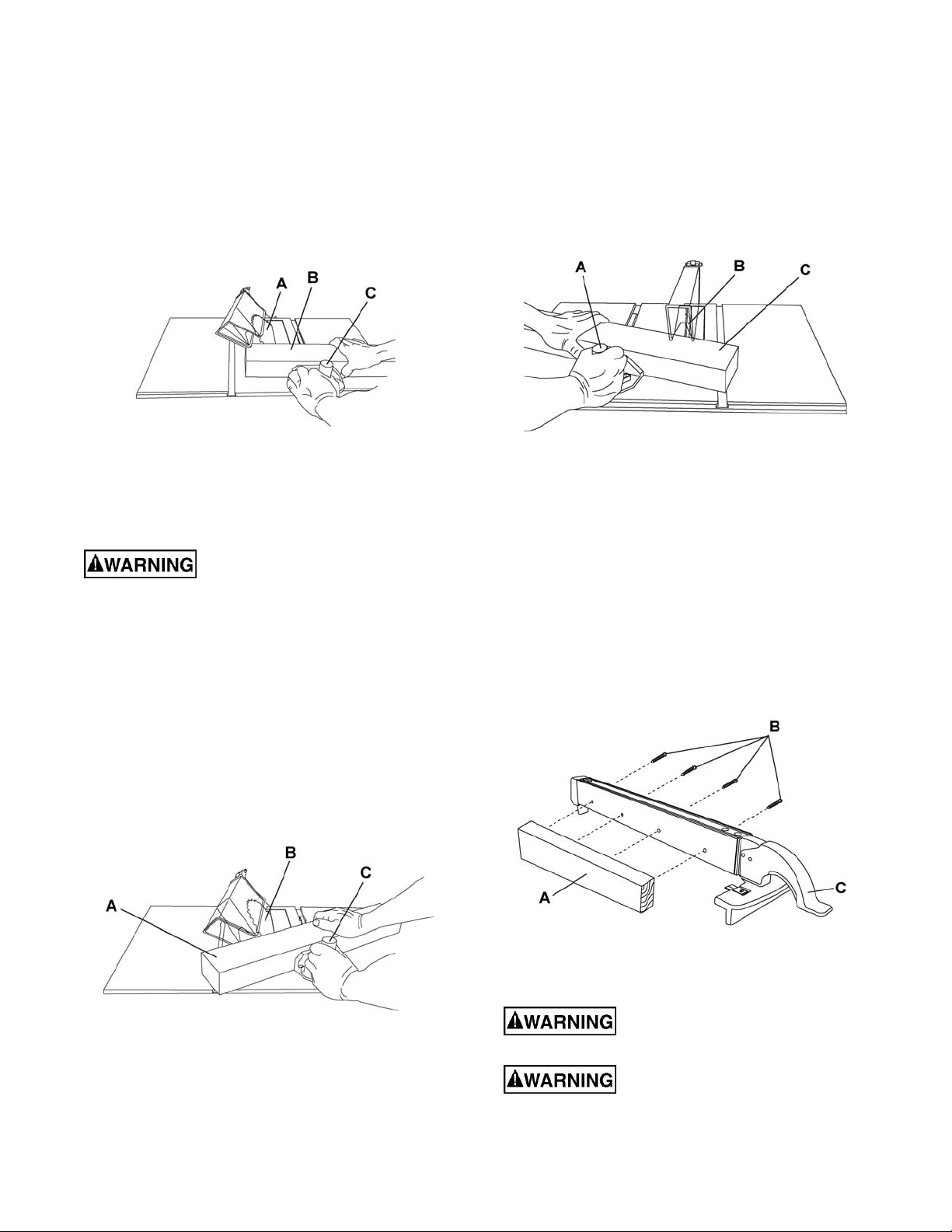

Splitter (riving knife) installation (Figure 12)

1. Remove the table insert.

2. Raise the blade arbor to the maximum height

and set the bevel angle to 0°.

3. Install the splitter (C) onto the splitter bracket,

fitting the curved slot on the splitter over the

bracket pins.

4. Install the splitter plate (CC), followed by the

flat washer (BB) and lock knob (AA). Tighten

the lock knob, leaving enough slack to

manually adjust the splitter (C).

5. Raise the splitter (C) as hi gh as it will go, then

tighten the lock knob (AA) to secure the splitter

in this position.

Figure 12

Kickback pawl installation (Figure 12a)

6. Place the lock lever (B

1) on the kickback pawl

assembly (B) in the unlock position.

7. Install the kickback pawl (B) onto the splitter.

The flat sides of the mounting pin on the

kickback pawls should pass though the

mounting slot (C1) on the splitter (C).

Note: Make sure the “anti-kickback pawls do

not get caught between the insert and the

guard, but rest on top of the insert.

8. Press firmly down on the kickback pawl to

ensure that it is prop erly seated on th e splitter,

then place the lock lever (B1) in the lock

position.

Blade guard installation (Figure 12a)

9. Slide the lock lever (A1) on the blade guard (A) up

and hold..

10. Place the blade guard (A) on the splitte r (C),

meshing t he pin (A

slot (C

2) on the splitter.

2) on the blade guard with the

11. Push the blade guard assembly down firmly on the

splitter; then release the lock lever (A

1).

12. Lift up on the blade guard assembly (A) to confirm

that it is firmly secure d to the splitte r (C).

15

Figure 12a

Page 16

Installing the Push-stick Storage

Attach the metal push-stick storage bracket (Figure 13)

into the provided slot (D, Fig. 14) on the right side of the

body shell. The bracket will snap into place.

Storage

Rip fence and miter gauge

Storage brackets f or the rip fence (B, Fig. 14) and

miter gauge (C, Fig. 14) are located on the right

side of the saw housing.

Note: Adjust the miter gauge to 45º-60º

putting away in storage.

Blade wrench

Insert the handle of th e blade wrench (A, Fig. 14)

into the slot located to the right side of the saw

housing.

before

Figure 13

D

Figure 14

Blade

1. Loosen and remove the knob (A, Fig. 15) on

the left side of the saw housing.

2. Place extra blades (B, Fig. 15) onto the

bushing. Replace the knob and tighten.

Figure 15

16

Page 17

Adjustments

Setting up the Stand

Referring to Figure 16:

1. Release the stand lock hook (D) by sliding it

away from the stop screw.

2. Raise the handle cover (A) first, then pull the

locking handle (B) out and hold.

3. Step on the pedal (C) and pull the stand

upward until it is fully unfolded.

4. Release the locking handle (B) to lock the

stand into position. Lower the cover (A).

Note: Make sure the stand is locked securely.

5. Place the stand on a level surface and adjust

the left stand pad (Z, F ig. 5) s o that all legs ar e

contacting the floor and are at a similar angle to

the floor.

Note: Make sure the table saw is locked

securely in position. Adjust the stand pad to

make sure the table saw is totally stable.

Folding the Stand

1. Raise the handle cover (A, Fig. 16) first and

pull the locking handle (B, Fig. 16) out.

Figure 16

2. Push slowly downward on the stand (A, B, Fig. 17).

3. Release the locking handle (B, Fig. 16).

4. Rotate the stand hook (D, Fig. 16) onto the

stop screw to secure the stand legs into the

collapsed positio n.

5. Secure the side exte nsion table (H, Fig. 16) b y

pushing the cam locking lever (F, Fig. 16)

downward.

Note: For convenient storage, there are two

stand up supports (G, F ig. 16) on the right s ide

of the table saw for supporting the table saw

when not in use (C, Fig. 17).

Adjusting the Table Insert

The table insert (A, Fig. 18) is already installed on

your table s a w. Verify that t h e t ab l e i ns er t is f l us h with

the table top surface on all four corne rs of the insert .

To avoid serious injury, the

table insert must be level with the table.

If the table insert is not f lush with the table, adjust

the four hex screws (B, Fi g. 18) with a 4 mm hex

wrench until it is flush with the table.

To raise the insert, turn the hex screws (B) counter-

Figure 17

Figure 18

clockwise. To lo wer the insert, tur n the hex scr ews

clockwise.

17

Page 18

Aligning the Blade Guard Splitter

To avoid injury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected.

● When installing the blade guard, cover the

blade teeth with a piece of folded cardboard to

protect yourself from possible injury.

● Never operate this tool without the safety

guard in place for all through sawing operations.

Important: The splitter must always be correctly

aligned with the blade so the cut workpiece will

pass on either side without binding or twisting.

The splitter/riving knife is adjusted at the factory

and should not require adju s tm ent. In the e vent t hat

adjustment becomes necessary, follow the

procedure below.

Referring to Figure 19:

1. Remove the table inser t and raise the blade to

the maximum height by turning the blade

elevation handwheel clockwise.

2. Remove the blade guard and pawl assembly

(see Blade Guard Assembly on page 15)

3. Adjust the blade to the 90° vertical position by

unlocking the blade t ilt in g lo ck knob and turning

the bevel tilting handwheel counterclockwise,

and then lock into position.

4. To see if the blade (A) and splitter (B) are

correctly aligned, lay a straightedge along the

side of the blade and against the splitter

(making sure the square is between the teeth

of the blade).

The blade and spli tter should be per fectly in-line. If

the blade and splitter are not correctly aligned:

5. Loosen two screws (C) just enough to permit

adjustment of the splitter mounting bracket (D).

6. Adjust the splitter (B) until i t is aligned with the

saw blade (A), using the straightedge as

reference.

7. Tighten screws (C) and recheck alignment.

8. Replace table insert, pa wl assembly and blade

guard assembly.

18

Figure 19

Page 19

90° and 45° Positive Stop Adjustment

Adjusting the Positive Stop

Your saw has positive stops that will quickly

position the saw blade at 90° and 45° to the table.

Make adjustments only if necessary.

90° Stop

1. Disconnect the saw from the power source.

2. Raise the blade to the maximum elevation.

3. Loosen the blade bevel loc k handle. Adjust the

blade (A) to th e maximum vertical position and

retighten the bevel lock handle.

4. Place a co mbinatio n squar e (C) on the table (B)

and against the blade (A) to determine if the

blade is 90° to the table.

5. If the blade is not 90° to the table, loosen or

tighten the hex screw (G) with a 5 mm hex

wrench until 90° is achieved.

6. Loosen the bevel lock handle and reset the

blade at the maximum vertical position, then

tighten the bevel lock handle.

7. Check again to see if the blade is 90° to the

table. If not, repeat step 5.

8. Check the bevel angle scale. If the pointer does

not read 0°, loosen the scr ew that secures the

pointer, adjust to read 0°, retighten the pointer

screw.

45° Stop

1. Disconnect the saw from the power source.

2. Raise the blade to the maximum elevation.

Figure 20

3. Loosen the blade bevel loc k handle. Adjust the

blade (D) to the m aximum bevel position (45°)

and retighten the bevel lock handle.

4. Place a combination square (F ) on the table (E)

and against the blade (D) to determine if the

blade is 45° to the table.

5. If the blade is not 45° to the table, loosen or

tighten the hex screw (H) with a 5 mm hex

wrench until 45° is achieved.

6. Loosen the bevel lock handle and reset the

blade at the maximum bevel position (45°),

then tighten the bevel lock handle.

7. Check again to see if the blade is 45° to the

table. If not, repeat step 5.

Blade Tilt Pointer

When the blade is positioned at 90°, loosen the

holding screw, adjust the blade tilt pointer to read

0° on the scale, then retighten the screw.

19

Figure 21

Page 20

Blade Parallel to the Miter Slot

Additional Blade Adjustments

To avoid injury from an

accidental start, make sure the switch is in the

OFF position and the plug is disconnected from

the power source outlet.

This adjustment was made at the factory, but it

should be rechecked and adjusted if necessary.

This adjustment m us t be correc t to assur e accur ate

cuts and to prevent the possibility of kickback,

which can result in serious injury.

Referring to Figure 22:

1. Re move the yellow switch key and unplug the saw.

2. Remove the blade guard.

3. Raise the blade to the m axim um height and set

the bevel angle at 0°

4. Select and mark with a felt tip marker, one

blade tooth with a “right set ” angle and pos ition

this tooth at the front of the saw approximately

1/2 in. above the table (D) .

Refer to Figure 23.

If the front and rear measurements are not the

same:

1. Remove the combination square (C) and

loosen the four adjusti ng screws (A) on th e top

of the table about a half turn.

2. Cover the blade with a folded piece of

cardboard to protect your hands. Move the

blade and motor mounting rod carefully to the

left or right as much as needed to align the

blade correctly.

3. Tighten the four screws (A) and rem easure, as

described in steps 4 to 9 in the previous section.

Figure 22

5. Place the combinatio n squar e bas e (G) into the

right side miter gauge slot (F ) flush against the

inside of the miter gauge slot.

6. Adjust the ruler (E) so it touches the front

marked tooth (D) and lock ruler so it holds its

position in the square assembly.

7. Nex t rotate the b lade, m oving the m arked tooth

(D) to its new position (A) at the rear of the

saw.

8. Carefully move the combination square from

position (G) to (C).

9. If the ruler touches the marked tooth at the

front and rear position (E at D, B at A), no

adjustment is needed. If not, perform the

adjustment procedure described in the next

section.

Figure 23

4. If sufficient adjus tment cannot be made b y the

four adjusting scr ews (A), then also loos en the

two adjusting screws (B) and repeat all

previous steps. Loos en these screws (B) only if

necessary as the y are set for ac curate 90° a nd

45° settings.

5. Recheck the bla de clearance mak ing sure that

the blade does not hit t he table insert or other

parts when at the 90° and 45° settings.

6. Retighten all four adjusting screws (A) and

reset the 90° and 45° setting as described in

the 90° and 45° Positive Stop Adjustment

section (page 19).

20

Page 21

Adjusting the Miter Gauge

Referring to Figure 24:

1. Loosen the lock handle (B) to allow the miter

body (C) to rotate freely. Position the miter

body at 90° so the positive detent secures its

position. Tighten th e loc k hand le (B) to hold the

miter body in position.

2. If the pointer (A) requires adjustment, loosen

the screw under the poi nter with a screwdr iver.

Adjust the pointer to 90° on the scale, then

firmly tighten the adjustment screw.

To change angles on the miter gauge:

3. Loosen the loc k handle ( B) and rotat e the miter

body to the desired angle as indicated by the

scale. Secure in pos ition by tightening the lock

handle.

Rip Fence Adjustment

Referring to Figure 25:

1. For adjustm ents, position the f ence to the right

of the blade, parallel with the miter gauge slot.

2. Place the rear clamp (A) of the fence on the

back rail of the table, and lower the front end

over the front rail (E). Push the handle (F)

down to lock.

3. T o change the position of the fence, lift up on

the handle to unlock , and slide the f ence to the

desired position, th en push the hand le down to

lock.

4. To check the rip fence adjustment, place the

fence along one edge of the miter gauge

groove, and lock the handle. It should be

parallel to the miter groove to provide accura te

cuts.

If an adjustment is needed to make it parallel:

1. Loosen the two hex bolts (C) on the top of the

rip fence, and lift up on the handle (F).

2. Adjust the fence ( B) so it is parallel to t he miter

gauge slot and lock the handle (F) into position.

3. Make sure the fence (B) is parallel to the slot

and tighten the two hex bolts (C) securely.

4. Unlock the fence handle (F) and slide th e fenc e

left and right, then reposition it against the miter

gauge slot again and lock into position to

double check its alignment.

Failure to properly align the fence can cause

“kickback” and serious injury could occur.

Figure 24

Figure 25

If the fence is loose when the handle is in the

locked position:

1. Move the handle upward to the unlocked

position.

2. Turn the adjusting scr ew (D) clock wise until th e

rear clamp is snug.

3. Do not turn the adjusti ng screw more than 1/4

turn at a time.

4. Over-tightening the screw will cause the rip

fence to come out of alignment.

21

Page 22

Rip Fence Indicator

The rip fence indicator points to the scale on the

front of the table saw. The m easurement shown b y

the indicator wil l provide the user with accurac y up

to 1/16 of an inch. The m easurement shown is the

distance from the blade to the side of the fence

closest to the blade.

To check the accuracy:

1. Measure the actual distance to the side of the

rip fence.

If there is a difference between the measurement

and the indicator, adjust the indicator as follows:

2. Loosen the indicator screw (A, Fig. 26).

3. Slide the indicator to th e correct measurement

position on the scale, then retighten the screw.

Table Extension Scale Pointer

The table extension scale pointer (A, Fig. 27)

should be at 13 inches on the scale when the

extension is in the closed position. If adjustment is

required, loosen the holding screw (B, Fig. 27),

position the pointer over the 13 inch m ark er and r etighten the screw.

Rear Table Extension Adjustment

The rear table extension (A, Fig. 28) should be

positioned as close as possible to the rear of the

table when ripping short material.

Figure 26

Figure 27

The rear table extension should be fully extended

when ripping longer materials that require extra

support.

Adjusting the Locking Lever

If the extension table moves when it is open and

locked in place, the cam locking lever (A, Fig. 29)

may be loose and require adjustment.

To adjust the locking lever tension:

1. Hold the stud (B) stationar y, and loos en the nut

(C) with a 10 mm wrench.

2. Rotate the rod using a wrench on one of the

flats (D). Do not overtension!

3. Re-tighten the nut (C).

22

Figure 28

Figure 29

Page 23

Operation

Basic Saw Operations

Raising the Blade

To raise or lower the blade , turn the blade elevat ion

handwheel (A, Fig. 30) to the desire d blade height,

and then tighten the bev el lock handle ( B, Fig. 30) to

maintain the desired blade angle.

Figure 30

Tilting the Blade

Two methods are available for tilting the saw blade.

Rapid blade tilting:

Loosen the bevel loc k handle (B, F ig. 30), move the

handwheel (A, Fig. 30) to the desired angle, then

tighten the bevel lock handle.

Fine adjustment blade tilting:

Loosen the bevel lock handle (B, Fig. 30), push in

the handwheel (A, Fig. 30) and at th e s ame time turn

the handwheel (A, Fig. 30) to tilt the saw blade.

When the saw blade is at t he desired angle, tighten

the bevel lock handle (B, Fig. 30).

5. If the removab le safet y key is r emoved wh ile the

saw is running, it c an be turned OFF but cannot

be restarted without inserting the removable

safety key (A).

Figure 31

Overload Protection

This saw has an overload reset button (C, Fig. 31)

that resets the motor after it shuts off due to

overloading or low vo ltage. If the m otor stops during

operation, turn the ON / OFF switch to the OFF

position. Wait about five minutes for the motor to

cool, the push the res et button (C, Fig. 31) a nd turn

the switch to the ON position.

Dust Chute

To prevent fire hazard, clean and remove

sawdust from under the saw frequently.

To prevent sawdust bui ldup inside the sa w housing,

attach a vacuum hose (A, Fig. 32) to the dust chute

(B, Fig. 32) at the rear of the table saw. DO NOT

operate the saw with the hose in place unless the

vacuum is turned on.

On/Off Switch

The ON / OFF switch has a removable safety key.

With the key removed fr om the switch, unauthori zed

and hazardous use by children and others is

minimized.

Referring to Figure 31:

1. To tur n the saw ON, ins ert the saf ety switch k ey

(A) into the slot in the switch (B). Move the

switch upward to the ON position.

2. To turn the saw OFF, move the switch

downward.

3. To lock the switch in the O FF pos ition, grasp th e

end (or yellow par t) of the safet y switch key (A),

and pull it out.

4. With the removable safety key removed, the

switch will not operate.

Figure 32

Using the Table Extension

Use the scale on the front rail for rip cuts up to 13 in.

For rip cuts greater than 1 3 in., set and the lock the

fence on the 13 in. m ark. Unlock the extension tab le ,

and slide the table with the fence to the desired

dimension using the scale on the rear rail.

Referring to Figure 33:

1. Release the cam locking lever (A).

2. Slide the table extension to the desired

measurement and the n tighten the cam locking

lever.

23

Page 24

Figure 33

Cutting Operations

1. Remove the miter gauge and store it in the

“storage” compartment in the base of the saw.

2. Secure the rip fence to the table.

3. Raise t he blade so it is about 1/8 i n. higher than

the top of the workpiece.

4. Place the workpiece flat o n the ta bl e an d a gai ns t

the fence. Keep the workpiece away from the

blade.

5. T urn the sa w ON and wait for the blade to com e

to full speed.

6. Slowly feed the workpiece into the blade by

pushing forward only on the workpiece section

(A, Fig. 34) that will pass between the blad e and

the fence.

There are two basic types of cuts: ripping and

crosscutting. Ripping is cutting along the length and

the grain of the workpiece. Crosscutting is cutting

either across the width or across the grain of the

workpiece. (It is not safe to rip or crosscut by

freehand). Ripping re quires the use of the rip f ence,

and crosscutting requires the miter gauge. NEVER

USE THE TWO AT THE SAME TIME.

Before using the saw each time,

check the following:

• The blade is tightened to the arbor.

• The bevel angle lock knob is tightened.

• If ripping, make sure the fence is locked into

position and is parallel to the miter gauge

slot.

• The blade guard is in place and working

properly.

• Safety glasses are worn.

• The failure to adhere to these common safety

rules, and those printed in the front of this

manual, can greatly increase the likelihood

of injury.

Ripping

AVOID KICKBACK by pushing

forward on the section of the workpiece that

passes between the blade and the fence. Never

perform any freehand operations.

Figure 34

Referring to Figure 35:

7. Keep your thum bs of f the t a ble t op. W hen bot h of

your thumbs touch t he f ront edg e of the t abl e (C),

finish the cut with a push stick. To make an

additional push stick, use the pattern on page 29.

8. The push stick (D) should always be used for

any ripping operation.

To prevent serious injury:

• Never use a miter gauge when ripping.

• Never use more than one rip fence during a

single cut.

• Do not allow familiarity or frequent use of

your table saw to cause careless mistakes.

Remember that even a careless fraction of a

second is enough to cause a severe injury.

• Keep both hands away from the blade and

clear from the path of the blade.

• The workpiece must have a straight edge

against the fence and must not be warped,

twisted, or bowed when ripping.

9. Continue pushing the workpiece with the push

stick (D) until it passes through th e blade guard

and clears the rear of the table.

10. Never pull the piece back when the blade is

turning. Turn the switch OFF. When the blade

completely stops, you can then remove the

workpiece.

Never attempt to pull the

workpiece backwards during a cutting operation.

This will cause kickback and serious injury to

the user can occur. When the blade completely

24

Page 25

stops, raise the anti-kickback pawls (A) on each

side of the splitter and slide the workpiece out.

Figure 35

4. Start the s aw and wait for the bl ade (C) to com e

up to full speed. Never stand directly in line of

the saw blade path, a lways stand to the side of

the blade that you are cutting on.

5. Kee p the workpiece (B) against the f ace of the

miter gauge (A) and flat against the table . Then

slowly push the workpiece through the blade.

6. Do not try to pull the workpiece back with the

blade turning. Turn the switch OFF, and

carefully slide the work piece out when the blade

has completely stopped.

Always position the larger surface

of the work-piece on the table when crosscutting

and/or bevel crosscutting to avoid instability.

Bevel Ripping

This cut is the same as ripping except the blade

bevel angle is set to an angle other than “0º.

Ripping Small Pieces

To avoid injur y from blade c ontact, never m ake cuts

narrower than 1/2 in. wide.

1. It is unsafe to rip small pieces. Instead, rip a

larger piece to obtain the size of the desired

piece.

2. When a small width is to be ripped and your

hand cannot safel y pass between the blad e and

the rip fence, use one or more push sticks to

move the workpiece. Always use a push stick

during ripping operations.

Crosscutting

Do not allow familiarity or

frequent use of your table saw to cause careless

mistakes. Remember that even a careless fraction

of a second is enough to cause a severe injury.

Keep both hands away from the

blade and the path of the blade.

Figure 36

Using Wood Facing on the Miter Gauge

Slots are provided in the miter gauge for attaching

an aux iliary facing (A) to make it easier to cut very

long or short pieces. Select a suitable piece of

straight wood, drill two holes through it and attach it

to the miter gauge with scre ws. Make sure the facing

does not interfere with the proper operation of the

sawblade guard. When cutting long work pieces, you

can make a simple outfeed support by clamping a

piece of plywood to a sawhorse.

Never attempt to pull the

workpiece backwards during a cutting operation.

This will cause kickback and serious injury to the

user can occur.

Referring to Figure 36:

1. Rem ove the rip fenc e and plac e the m iter gauge

in the miter gauge slot on the table.

2. Adj ust the blade he ight so that it is 1/8 in. hig her

than the top of the workpiece.

3. Hold the workpiece firmly against the miter

gauge with the blade path in line with the

desired cut location.

Figure 37

Bevel Crosscutting 0°~45° Blade Level & 90° Miter

Angle

This cutting operation is the same as crosscutting

except the blade is at a bevel angle other than 0°.

Always work to the right side of

the blade during this type of cut. The miter

gauge must be in the right side slot because the

bevel angle may cause the blade guard to

25

Page 26

interfere with the cut if used on the left side

groove.

1. Set th e blade (B) to 0° bevel angle and tighten

the blade bevel lock knob.

Referring to Figure 38:

1. Adjust the blade (A) to the desired angle, and

tighten the blade bevel lock k nob.

2. Tighten the miter lock handle (C) at 90°.

3. Hold workpiece (B) firmly against the f ace of the

miter gauge throughout the cutting operation.

Figure 38

Compound Miter Crosscutting 0°~45° Blade Bevel

& 0°~45 Miter Angle

This sawing operation c ombin es a m iter angle with a

bevel angle.

Always work to the right side of

the blade during this type of cut. The miter

gauge must be in the right side groove because

the bevel angle may cause the blade guard to

interfere with the cut if used on the left side

groove.

1. Set the miter gauge (C) to the desired angle.

2. Place t he miter gauge in the r ight side groove of

the table.

2. Set the miter gauge (A) at the desired miter

angle and lock in posit ion by tig htening th e miter

gauge locking handle.

3. Hold the work piece (C ) firml y against th e face of

the miter gauge throughout the cutting

operation.

Figure 40

Using the Wood Facing on the Rip Fence

When performing some special cutting operations,

you can add a wood f acing to either side of the rip

fence (C, Fig. 41).

1. Use a sm ooth straight 3/4 in. thick wood board

(A, Fig. 41) that is as long as the rip fence.

2. Attach the wood facing to the fence with wood

screws (B, Fig. 41) (not included) through the

holes in the fence. A woo d f enc e s hould be us e d

when ripping material such as thin paneling to

prevent the material f rom catching between the

bottom of the fence and the table.

3. Set the blade (B) bevel to the desired bevel

angle and tighten the blade bevel lock knob.

4. Hold workpiece (A) firmly against the f ace of the

miter gauge throughout the cutting operation.

Figure 39

Mitering 0°~45° Miter Angle

This sawing operation is the same as crosscutting

except the miter gauge is locked at an angle other

than 90°.

Figure 41

Dado Cuts

The maximum dado cut width is 13/16 in.

Only Stackable dado blades can

be used on this saw.

DO NOT use Adjustable or Wobble

type dadoes.

Referring to Figure 42:

26

Page 27

1. Remove the saw blade and the blade g uard for

dado cuts ONLY. Reinstall and realign blade

guard for all thr ough- sawing operations. Instal l

a dado not exceeding 6 in. diameter and 13/16

in. width.

2. Install a dado table insert m aking sure that the

rear of the insert is flush with the table.

Note: A dado table insert i s not inc luded b ut can

be ordered (SN 707001) by calling th e number

on the cover of this manual.

3. Instructions for operating the dado is packed

with the separately purchased dado set.

4. T he arbor (B) on this saw res tricts the m axim um

width of the cut to 13/16 in.

5. It is not necessar y to install the outs ide flange (A)

before threading on the arbor nut (C) for the

maximum 13/16 in. dado cuts. Make sure that the

arbor nut (C) is ti ght, and th at at least on e thread

of the arbor sticks out past the nut.

6. Use only the correct number of round outside

blades and inside chippers as shown in the dado

set’s instruction manual. Blade/chippers must

not exceed 13/16 in. total in width.

7. Check the saw to ensure that the dado will not

strike the housing, insert, or motor when in

operation.

For your own safety, always

replace the blade, blade guard assembly, and

table insert when you are finished with the dado

operation.

Figure 42

27

Page 28

Maintenance

General Maintenance

For your own safety, turn the

switch OFF and remove the switch key. Remove

the plug from the power source outlet before

maintaining or lubricating your saw.

1. Clean out all sawdust that has accumulated

inside the saw cabinet and the motor.

2. Polish the saw table with an autom otive wax to

keep it clean and to m ake it easier to slide the

workpiece.

3. Clean cutting blades with pitch and gum

remover.

4. A worn, cut, or damaged power cord should be

replaced immediately.

All electrical or mechanical

repairs should be attempted only by a trained

repair technician. Contact customer service for

assistance. Use only identical replacement parts.

Any other parts may create a hazard.

5. Use liquid dishwashing detergent and water to

clean all plastic parts.

Note: Certain cleaning chemicals can damage

plastic parts.

6. Avoid use of cleaning chemicals or solvents,

ammonia and household detergents containing

ammonia.

Figure 43

If excessive loosen ess is obs erved in an y part of the

blade raising m echanism or tilting mechanis m, take

the complete unit to a Service Center.

Lubrication

All motor bearin gs are perm anently lubricat ed at the

factory and require no additional lubrication.

On all mechanical parts of your table saw where a

pivot or threaded rod is present, lubricate using

graphite or silicone. These dry lubricants will not

hold sawdust as would oil or grease.

Replacing the Carbon Brushes

Blade Raising and Tilting Mechanism

After ever y five hours of operation , the blade raising

mechanism and t ilting m echan ism s hould be chec k ed

for looseness, binding, or any other abnormalities.

Referring Figure 43:

1. With the saw disconnected from the power

source, turn the saw upside down and pull up

and push down on the motor unit.

2. Observe any movement of the motor mounting

mechanism. Looseness or play in the blade raising

screw rod (A) should be limited to 1/8 ” or less.

3. If excessive loose ness is observed in any other

parts of the blade raising mechanism or tilting

mechanism, tak e the complete unit to a Ser vice

Center.

Place a small am ount of dry lubricant on the bevel

gear (B). The screw rod (A ) must be kept clean and

free of sawdust, gum , pitch, and o ther contaminants

for smooth operations.

Always disconnect the plug from

the power source before inspecting the brushes.

The carbon brushes included with the unit will last

approxim atel y 50 hours of r unning t ime, or 1 0,000 O N/

OFF cycles. Re place bo th carbo n brush es when e ither

has less th an 1/4 in. lengt h of carbon rem aining, or if

the spring or wire is damaged or burned.

1. Remove the blad e guard, blade, rip fenc e, miter

gauge and stand assembly from the table saw.

2. Place cardboard or an old blank et on the f loor to

protect the saw table surface.

3. Place the saw upside down on the protective

material.

4. Tilt the blade elevation/tilting handwheel (A, Fig. 44)

to the 45° position.

28

Page 29

Figure 44

5. Referring to Figure 45:

6. Remove the black plastic cap ( B) from the side

of the motor (C).

7. Carefully remove the spring-loaded cap, and

then pull out the brush and replace.

8. Replace the other side.

9. The ears on the metal end of the as sembl y go in

the same hole the carbon part fits into. Do not

overtighten the plastic cap.

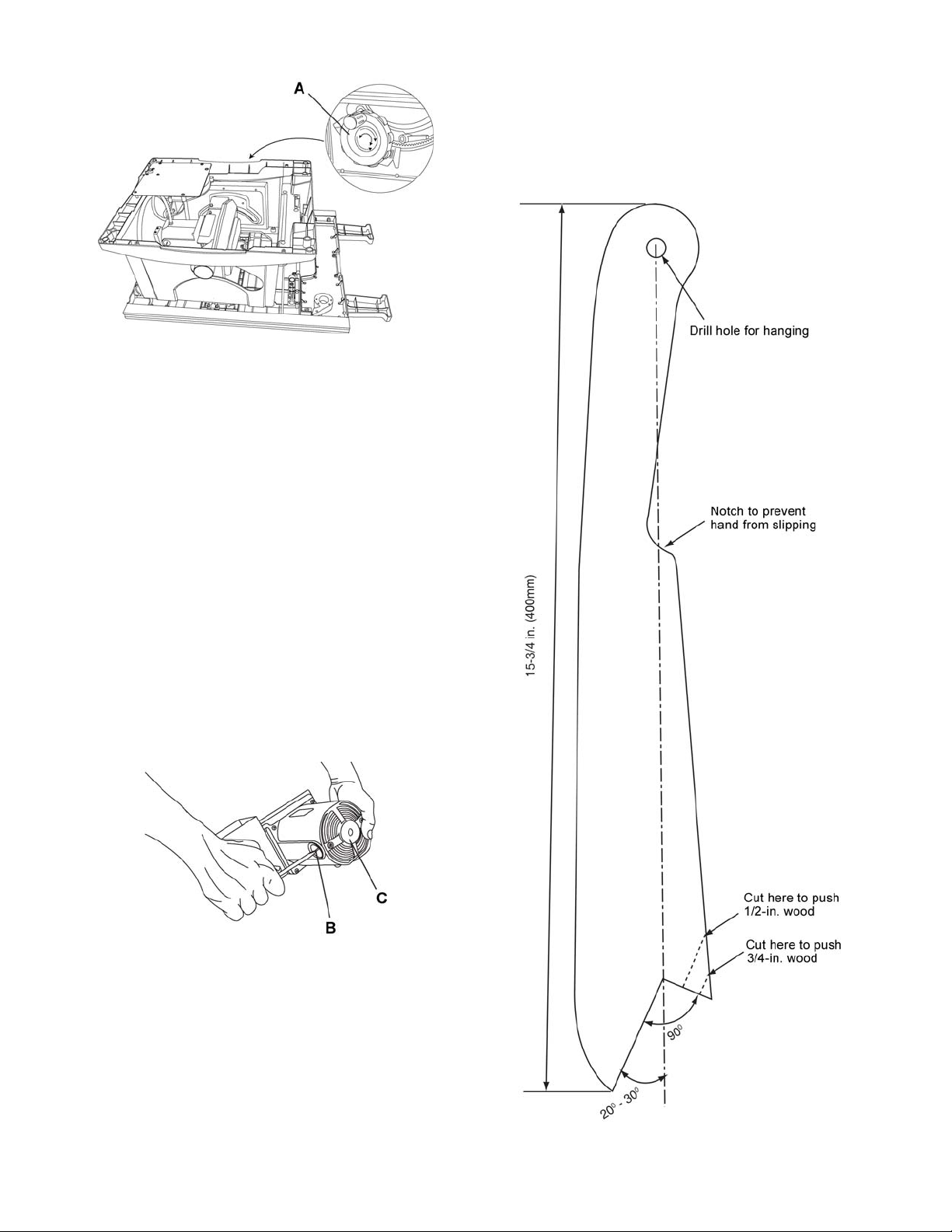

Push Stick Construction

Use solid wood or good quality plywood to construc t

a push stick using the template below. The push

stick must be thinner than the width of the m aterial

being cut.

10. Carefully set the saw in an upright position on a

clean level surface.

11. Replace the blade g uard, blade, r ip fence, miter

gauge and stand assembly to the table saw.

Note: To reinstall the same brushes, first make sure

the brushes go bac k in the way they came out. This

will avoid a break-in period that reduces motor

performance and increases wear.

Figure 45

Lubrication

All motor bearin gs are perm anently lubricat ed at the

factory and require no additional lubrication.

On all mechanical parts of your table saw where a

pivot or threaded rod is present, lubricate using

graphite or silico ne. These dr y lubricants will not hold

sawdust as would oil or grease.

29

Figure 46

Page 30

Troubleshooting

Trouble Probable Cause Remedy

Saw will not start.

Does not make

accurate 45° and

90° rip cuts.

Material pinched

blade when ripping.

Material binds on

splitter.

Saw makes

unsatisfactory cuts.

Material kicked

back from blade.

Blade does not

raise or tilt freely.

Blade does not

come up to speed.

Reset trips too

easily.

Machine vibrates

excessively.

Does not make

accurate 45° and

90° crosscuts.

Anti-kickback pawls

catch on the table

insert opening.

1. Saw is not plugged in.

2. Fuse blown or circuit breaker

tripped.

3. Cord is damaged.

4. Debris in on/off switch

1. Positive stop not adjusted

correctly.

2. Tilt angle pointer not set

accurately.

1. Rip fence not aligned with blade.

2. Warped wood, edge against fence

is not straight.

1. Splitter not aligned correctly with

blade.

1. Dull blade.

2. Blade mounted backwards.

3. Gum or pitch on blade.

4. Incorrect blade for work being

done.

5. Gum or pitch on blade causing

erratic feed.

1. Rip fence out of adjustment.

2. Splitter not aligned with blade.

3. Feeding stock without rip fence.

4. Splitter not in place.

5. Dull blade.

6. The operator letting go of material

before it is past saw blade.

7. Miter angle lock knob is not tight.

1. Sawdust and dirt in elevation/tilting

mechanisms.

1. Extension cord too light or too

long.

2. Low house voltage.

1. Saw not mounted securely to

workbench.

2. Bench on uneven floor.

3. Damaged saw blade.

1. Miter gauge out of adjustment. 1. Adjust miter gauge.

1. Splitter/riving knife not set in full

raised position.

1. Plug in saw.

2. Replace fuse or reset circuit breaker.

3. Replace power cord.

4. Remove switch from saw and

separate in half. Clean any debris

accumulated within.

1. Check blade with square and adjust

positive stop.

2. Check blade with square and adjust

to zero.

1. Check and adjust rip fence.

2. Select another piece of wood.

1. Check and align splitter with blade.

1. Replace blade.

2. Turn the blade around.