Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

12-inch Jointer-Plane r

Models JJP-12, JJP-12H H

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-708475

Ph.: 800-274-6848 Revision D 10/2014

www.jettools.com Copyright © 2014 JET

Page 2

1.0 Warranty and service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of these mac hines in the proces sing of metal, pla st ics, or ot her mat er ials may void the warranty. T he excep tio ns

are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa tion

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety warnings .............................................................................................................................................. 4

4.0 Specifications ................................................................................................................................................. 6

5.0 Features and terminology .............................................................................................................................. 7

6.0 Receiving ....................................................................................................................................................... 7

7.0 Unpacking ...................................................................................................................................................... 7

8.0 Electrical connection ...................................................................................................................................... 7

9.0 Operating controls .......................................................................................................................................... 8

9.1 Jointer to Planer setup ............................................................................................................................... 8

9.2 Planer to Jointer setup ............................................................................................................................... 8

9.3 Control switch ............................................................................................................................................. 9

9.4 Planer controls and adjustments ................................................................................................................ 9

9.5 Jointer controls and adjustments ................................................................................................................ 9

10.0 Adjustments ............................................................................................................................................... 11

10.1 Table and knife adjustments .................................................................................................................. 11

10.2 Coplanar alignment ................................................................................................................................ 11

10.3 Setting cutterhead knives (straight knives only) ..................................................................................... 13

10.4 Replacing cutterhead knives (straight knives only) ................................................................................ 14

10.5 Replacing or rotating knife inserts (helical cutterhead only) ................................................................... 14

10.6 Jointer table lock handle adjustment ...................................................................................................... 15

10.7 Belt replacement .................................................................................................................................... 15

10.8 Feed roller height adjustment ................................................................................................................. 16

10.9 Feed roller pressure adjustment ............................................................................................................. 17

10.10 Planer table adjustment ........................................................................................................................ 17

11.0 Basic operations ......................................................................................................................................... 18

11.1 Dust collection ........................................................................................................................................ 18

11.2 Initial startup ........................................................................................................................................... 18

11.3 Changing mode of operation .................................................................................................................. 18

11.4 Jointer operations ................................................................................................................................... 18

11.5 Planer operations ................................................................................................................................... 20

12.0 Maintenance ............................................................................................................................................... 22

12.1 Blade care .............................................................................................................................................. 22

12.2 Sharpening knives (straight knives only) ................................................................................................ 22

13.0 Lubrication .................................................................................................................................................. 22

14.0 Troubleshooting the JJP-12,JJP-12HH ...................................................................................................... 23

14.1 Performance troubleshooting – Jointer .................................................................................................. 23

14.2 Performance troubleshooting – Planer ................................................................................................... 24

14.3 Mechanical troubleshooting – Planer/Jointer ......................................................................................... 25

15.0 Replacement parts ..................................................................................................................................... 26

15.1 Parts List for JJP-12, JJP-12HH ............................................................................................................. 26

15.2 Infeed Table Assembly – Exploded View ............................................................................................... 31

15.3 Outfeed Table Assembly – Exploded View ............................................................................................ 32

15.4 Cutterblock Assembly – Exploded View ................................................................................................. 33

15.5 Base Assembly – Exploded View ........................................................................................................... 34

15.6 Motor Assembly – Exploded View .......................................................................................................... 35

15.7 Planer Table Assembly – Exploded View ............................................................................................... 36

15.8 Fence Assembly – Exploded View ......................................................................................................... 37

16.0 Electrical connection for JJP-12, JJP-12HH .............................................................................................. 38

17.0 Optional accessories .................................................................................................................................. 39

3

Page 4

3.0 Safety warnings

1. Read and understand the entire owner's manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with all of

these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This woodworking Jointer-Planer is designed and intended for use by properly trained and experienced

personnel only. If you are not familiar with the proper and safe operation of a woodworking jointer or

planer, do not use until proper training and knowledge have been obtained.

5. Do not use this machine for other than it s intended use. If used for ot her pu rposes, JET d isclaim s any rea l

or implied warranty and holds itself harmless from any injury that may result from that use.

6. Always wear approved safety glasses/face shield while using this woodworking jointer-planer. NOTE:

Everyday eyeglasses only have impact resistant lenses; they are not safety glasses.

7. Before operating this woodworking jointer-planer, remove tie, rings, watches and other jewelry, and roll

sleeves up past the elbows. D o not wear loose clothing. C onfine long hair. Non-slip footw ear or anti-skid

floor strips are recommended. Do not wear gloves.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities contain

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and oth er masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and work with approved safety equipment, such as face or

dust masks that are specifically designed to filter out microscopic particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make certain the switch is in the OFF position before connecting the machine to the power source.

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adj usting wrenches

are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance purposes,

use extreme caution and replace the guards immediately.

16. Make sure the jointer-planer is firmly secured to the floor or bench before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check for

alignment of moving parts, binding of m oving parts, breakage of parts, mounting a nd any other conditions

that may affect its operation. A guard or other part that is damaged should be properly repaired or

replaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap material, oil and grease.

20. Keep visitors a safe distance from the work area. Keep children away.

21. Make your workshop child proof with padlocks, master switches or by removing starter keys.

4

Page 5

22. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

23. Maintain a balanced stance at all times so that you do not fall or lean against the cutterhead or ot her

moving parts. Do not overreach or use excessive force to perform any machine operation.

24. Use the right tool at the correct speed and feed rate. Do not force a tool or attachment to do a job for which

it was not designed. The right tool will do the job better and more safely.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maintain tools with care. Keep cutters sharp and clean for the best and safest performance. Follow

instructions for lubricating, and changing accessories.

27. Make sure the workpiece is sec urely attached or clamped to the table. Never use your hand to hold t he

workpiece.

28. Turn off the machine before cleani ng. Use a brush or com pressed air to remove chips or debris — do not

use your hands.

29. Do not stand on the machine. Serious injury could occur if the machine tips over.

30. Never leave the machine running unattended. Turn the power off and do not leave the machine until the

cutterhead comes to a complete stop.

31. Before turning on machine, remove all extra equipment such as keys, wrenches, scrap, stock, and cleaning

rags away from the machine.

Jointer operation

32. Always use a hold-down or push block when surfacing stock less than 12" inches long, or 3 inches wide, or

3 inches thick.

33. Do not perform jointing operations on material shorter than 8", n a rrower than 3/4" or less than 1/4" thick.

34. The hands must never be closer than 3 i nches to the cutterhead (see

Fi gur e at right).

35. Never app ly pressure to stock directly over the cutterhead. Thi s may

result in the stock tipping into the cutterhead along with the operator's

fingers. Position hands away f rom extreme ends of stock, and p ush

through with a smooth, even motion. Never back workpiece toward

the infeed table.

36. To avoid kickback, the grain must run in the same direction you are cutting. Before attempting to joint or

plane, each workpiece must be carefully examined for stock condition and grain orientation.

37. When working with a swirl grain wood or burls, making it necessary to plane against the grain, use a lesser

depth of cut and a slow rate of feed.

38. Move the hands in an alternate motion from back to front as the work continues through the cut. Never

pass the hands directly over the cutter knife. As one hand approaches the knives, remove it from the stock

in an arc motion and place it back on the stock in a position beyond the cutter knife.

39. At all times hold the stock firmly against the table and fence.

Planer ope r a t i on

40. Keep hands outside the machine. NEVER reach under the guards to try to clear stock that stops

feeding. Do not cl ear chi ps and s awdust wit h hands; use a bru sh. Do not have any part of t he hands

under that part of the board t hat is over the table when starting a cut; the inf eed roll will engage the

board and forc e it down against t he table causing a pinching acti on.

41. Check stock conditi on. Do not pl ane boards with l oose knots or with nai ls or any f orei gn materi al on

its surfac e. Knife impact on t hese objects can cau se the kniv es to be pulled out and cause them t o

shatter against the chipbreaker or pressure bar. Twisted, warped, or in wind stock should first be

jointed on one surface before attempting to plane a parall el surf ac e on the planer. Serious stock flaws

cannot be removed by use of a planer alone.

42. T o avoid kickbac ks, use this machine f or single board surfaci ng only. Never make cuts deeper t han

1/8 inch (3mm).

5

Page 6

Familiariz e y our self with the following safety noti c es used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if prec autions are not heede d, i t may result i n serious i njur y or possi bly

even death.

4.0 Specifications

Model number .......................................................................... JJP-12 ................................................... JJP-12HH

Stock number .......................................................................... 708475 ....................................................... 708476

Cutterhead speed (RPM) ............................................................ 5500 ........................................................... 5500

Cutterhead diameter (in.) ............................................................ 2-3/4 ........................................................... 2-3/4

Number of knives .............................................................................. 3 .................................. 56 four-sided inserts

Knife size (LxWxT)(in.) ............................................... 12 x 1-3/5 x 1/8 ...................................... 0.59 x 0.59 x 0.10

Dust port outside diameter (in.) ......................................................... 4 ................................................................. 4

Dust collection minimum CFM ...................................................... 400 ............................................................. 400

Jointer table size (LxW/in.) ...................................................... 55 x 12 ....................................................... 55 x 12

Table height from floor (in.) ....................................................... 33-1/2 ......................................................... 33-1/2

Maximum stock removal (in.) ......................................................... 1/8 .............................................................. 1/8

Fence size (L xH/in.) .................................................................. 43 x 6 ......................................................... 43 x 6

Fence tilt .......................................................................... 90° to 45° R ................................................ 90° to 45° R

Fence positive stop ....................................................... 90° and 45°R .............................................. 90° and 45°R

Planer table size (LxW/in.) ................................................ 21-1/4 x 12 ................................................. 21-1/4 x 12

Full width cutting depth (in.) ........................................................... 1/8 ..................................... See Table 1 below

Maximum workpiece thickness (in.) ........................................... 8 -3/4 ........................................................... 8-3/4

Maximum depth of cut (in.) ........................................................... 5/32 ..................................... See Table 1 below

Minimum length of workpiece (in.) .................................................... 6 ................................................................. 6

Feed rate .................................................................................. 20 fpm ........................................................ 12 fpm

Table movement per one handwheel revolution ......................... 5/32” ........................................................... 5/32”

Motor, TEFC ................................ 3HP, 1PH, 230V only, 60Hz, 12.5A ........... 3HP, 1PH, 230V only, 60Hz, 12.5A

Switch ...............................................magnetic switch with limit switch ................ magnetic switch with limit switch

Power cord (plug not included) ............................. 14AWG 300V, 8 ft. ..................................... 14AWG 300V, 8 ft.

Overall Dimensions (LxWxH/in.) ......................... 55 x 29-1/2 x 39-2/5 ................................... 55 x 29-1/2 x 39-2/5

Stand Footprint (LxW/in.) .................................................. 22 x 19-1/2 ................................................. 22 x 19-1/2

Net weight (lbs.) ............................................................................ 500 ............................................................. 500

Full Width Cutting Depths for Helical Cutterheads During Planing

Very dense and/or very tight grained lumber (e.g., Rock

Maple, Purpleheart, Ipe)

Dense and/or tight grained lumber (e.g., Oak, Ash, Walnut) No more than 3/32” per full width cut per pass

Soft woods (e.g., Douglas Fir or White Pine) No more than 1/8” per full width cut per pass

No more than 1/16” per full width cut per pass

Table 1

The specifications in this manual are given as general inf ormation and ar e not binding. JET reserves the right to

effect, at any time and without prior notice, changes or alterations to parts, fittings, and accessory equipment deemed

necessary for any r eason whatsoever.

Read and understand the entire contents of this manual before attempting

assembly or operat io n! Failure to comply may cause serious injury!

6

Page 7

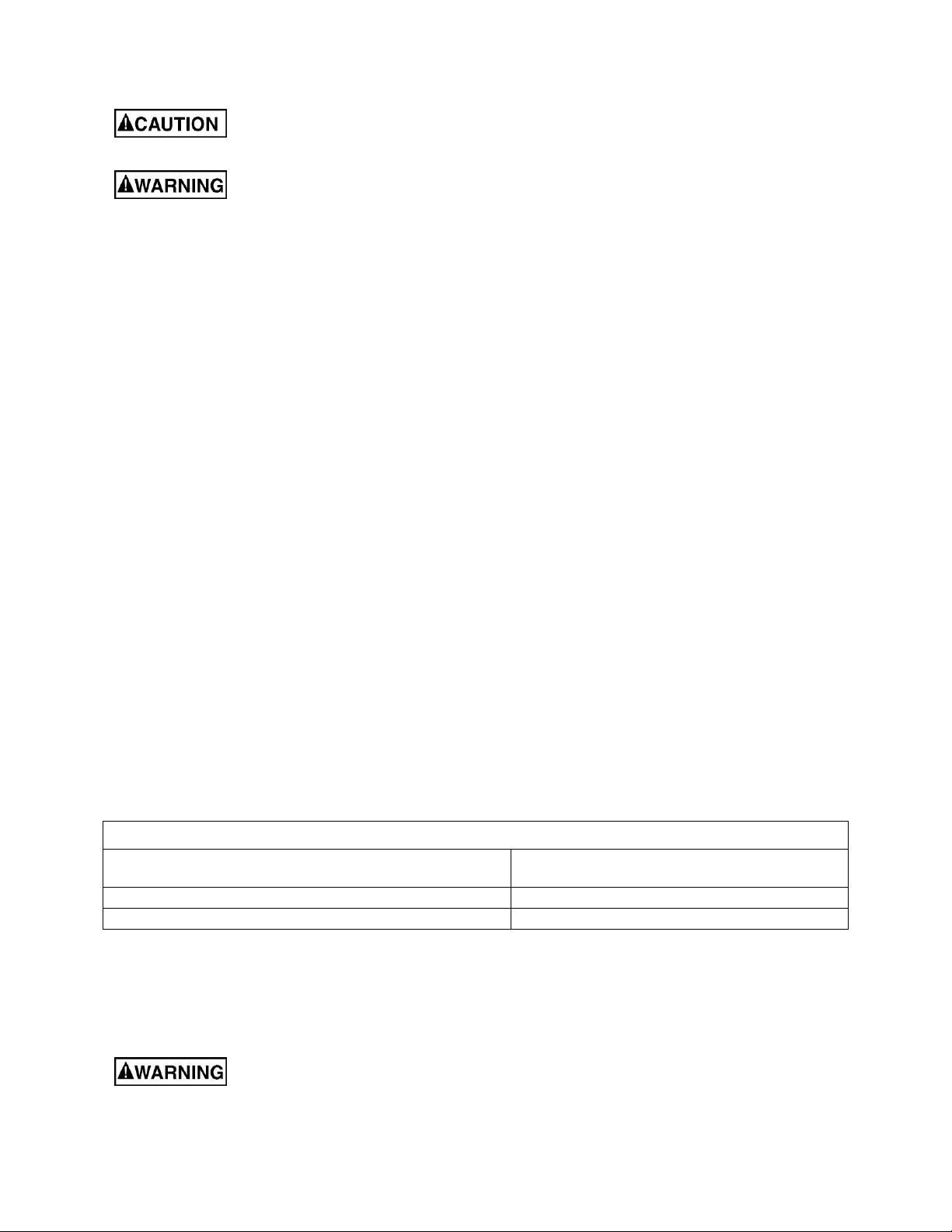

5.0 Features and terminology

Figure 1 – Featur es and Terminology

6.0 Receiving

Carefully unpack the machine and any loose

items from the wood crate and inspect for

damage. Any damage should be reported

immediately to your distributor and shipping

agent. Before proceeding further, read your

manual thoroughly to familiarize yourself with

proper assembly, maintenance and safety

procedures.

Remove the screws that hol d the machi ne to the

shipping skid. Remove the protective coating

from the table, bed rolls, feed rolls, cutterhead

and loose items packed wit h the machine. This

coating may be removed with a soft cloth

moistened with kerosene. Do not use acetone,

gasoline or l acquer thinner f or this purpose. Do

not use solvents on pl astic parts.

Use care when cleaning the

cutterhead ; th e kni ves are very sharp.

7.0 Unpacking

1. Remove all contents from the shipping

carton. Do not discard the car ton or packi ng

material until the machine is set up and

running satisfactorily.

2. Inspect the contents for shipping damage.

Report damage, if any, to your distributor.

Tools Required for Assembly

1 Accurate Straight Edge (approximately 2 ft)

1 Cross-point Screwdriver

1 4mm Hex Wrench (included)

1 5mm Hex Wrench

1 6mm Hex Wrench (included)

1 10mm Box Wrench

1 13mm Box Wrench

Note: Use of sockets and ratchets will speed

assembly time but are not required.

8.0 Electrical connection

All electrical connections

must be done by a qualified

electrician . All adjustments or repai rs must

be done with the machine di sconnect ed from

the power source, unplugged. Failure to

comply may result in serious injury!

The Model JJ P-12 and JJ P-12HH Joi nt er-Planer

is rated at 230V. This machine is not supplied

with a plug. Use a pl ug and outlet rated at least

30 amps. The circuit for the machine should also

be protected by at least a 30 amp cir c uit breaker

or fuse.

Make sure the cutterhead rotates in the

proper direction. If it does not, disconnect

machine fr om power supply and r ev erse two of

the phase wires on the supply input.

7

Page 8

9.0 Operating controls

Disconnect machine from

power source b efore making any adjust ments.

Failure to compl y may cause seri ou s injury.

Cutterhead knives are

dangerousl y sharp. Use extreme caution when

working around them. Failure to comply may

cause serious inj ury.

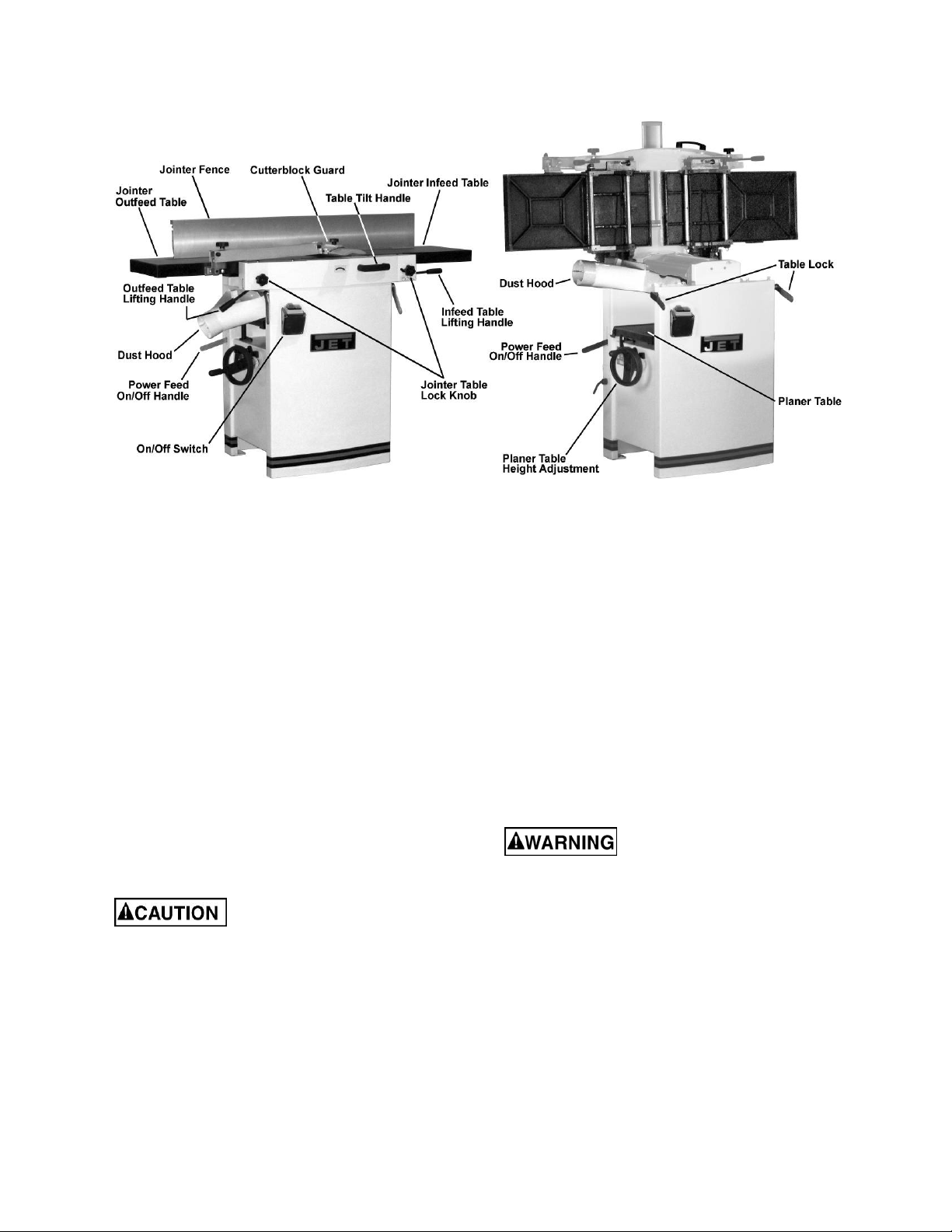

9.1 Jointer to Planer setup

To change the machine c onf iguration from jointer

to planer (refer to Fi gur e 2):

1. Release both cabinet table locks (A) by rotat-

ing the handles toward the operator, then

pulling away from the machine.

2. Raise the table (C) using the handle (B).

Table is heavy. Use care when

raising. F ailure to compl y may

cause serious inj ury.

When raised, the table should be in the

vertical position as shown in C, Fig. 3. The

latch (E, Fig. 3) should be engaged,

preventing the table from an accidental

forward fall.

3. Position the dust chute (D,H Fig. 3) to the

right. Use ex treme care t o av oid contact with

cutterhead knives.

Figure 2

Note: The planer table may need to be

lowered to all ow clearance needed to position

the dust chute.

9.2 Planer to Jointer setup

Refer to Figure 3:

To change the m achine configurati on from planer

to jointer:

1. Pull the release knob (F) and reposition the

dust chute (D, G) to the left. It should be

positioned as shown i n D, Fi g. 2.

Table is heavy. Use care when

lowering. Failure to comply

may cause serious injury.

2. Release the latch (E) and bring the table

forward using the tilt handle (B). It should be

positioned as shown i n C, Fi g. 2.

3. Lock the table (C) by pushing the lock

handles (A) in toward the machine and

rotating down (away from the operator).

Figure 3

8

Page 9

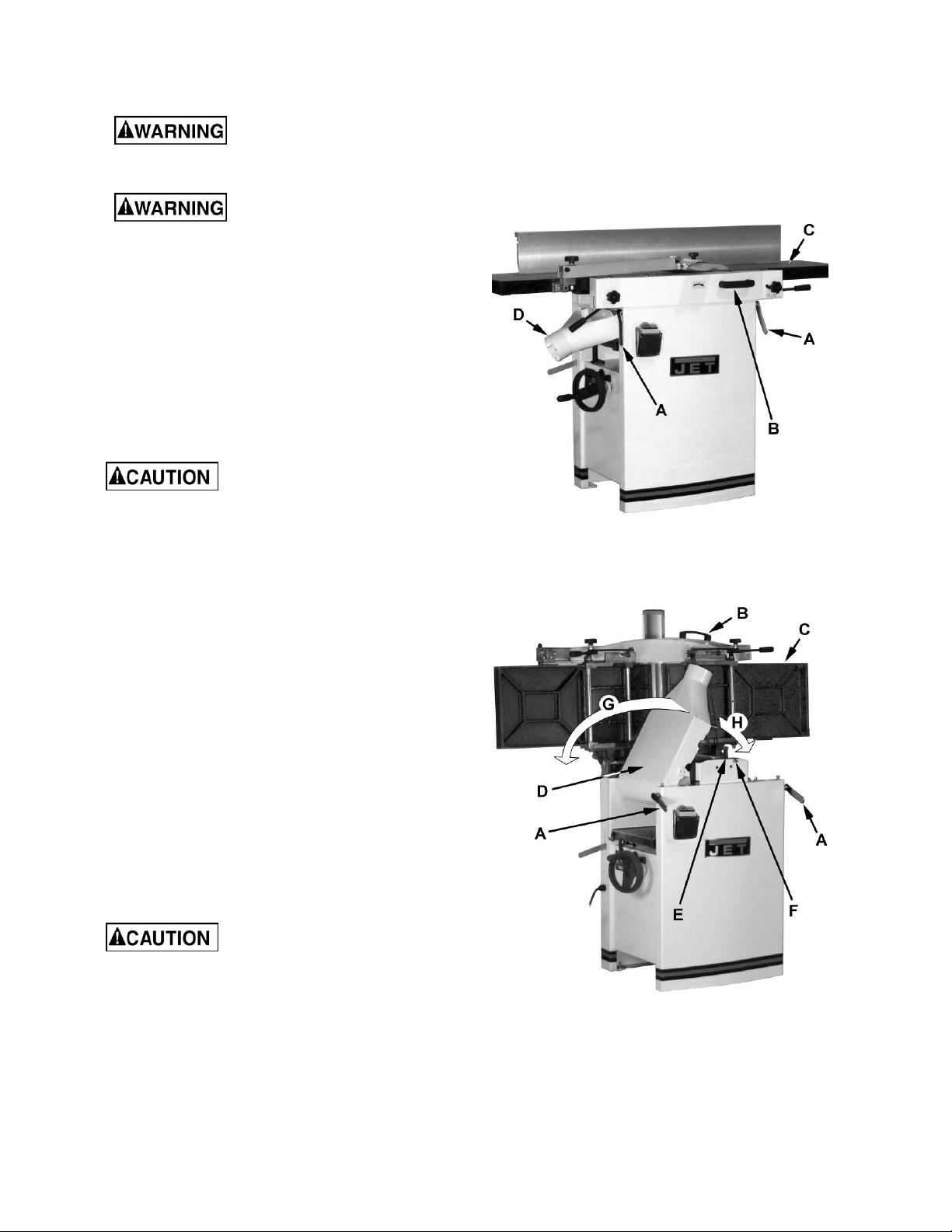

9.3 Control switch

Once a properly rated plug is connected, plug

power cord int o outlet. Press the green on but ton

(A, Fig. 4) to start. Press the red off button

(B, Fig. 4) to stop.

9.4 Planer controls and adjustments

Refer to Figure 5:

Power Feed

Placing the planer power feed handle (D) in the up

position turns the planer power feed on (see

arrow). Placing the handle in the down position

turns the power feed off.

Table Lock

Turn the table lock (E ) clock wise to l ock the height

adjustment handwheel (F) and secure the planer

table (C) in its selected position. Turn the table

lock (E) counterclockwise to release and permit

table adjustment.

Table Height Adjustment

The planer tabl e height is set as follows:

Figure 4

1. Unlock the table lock (E).

2. Rotate the height adjustment handwheel (F)

clockwise to raise the planer table (C),

countercl oc k wise to lower.

3. Lock the table lock (E).

Each revoluti on of the handwheel (F) results in a

5/32" up or down movement of the table (C). A

scale on the handwheel column indicates the

amount of handwheel rotation. A pointer (B)

indicates the table position relative to the

cutterhead on t he scale (A) located on the side of

the cabinet.

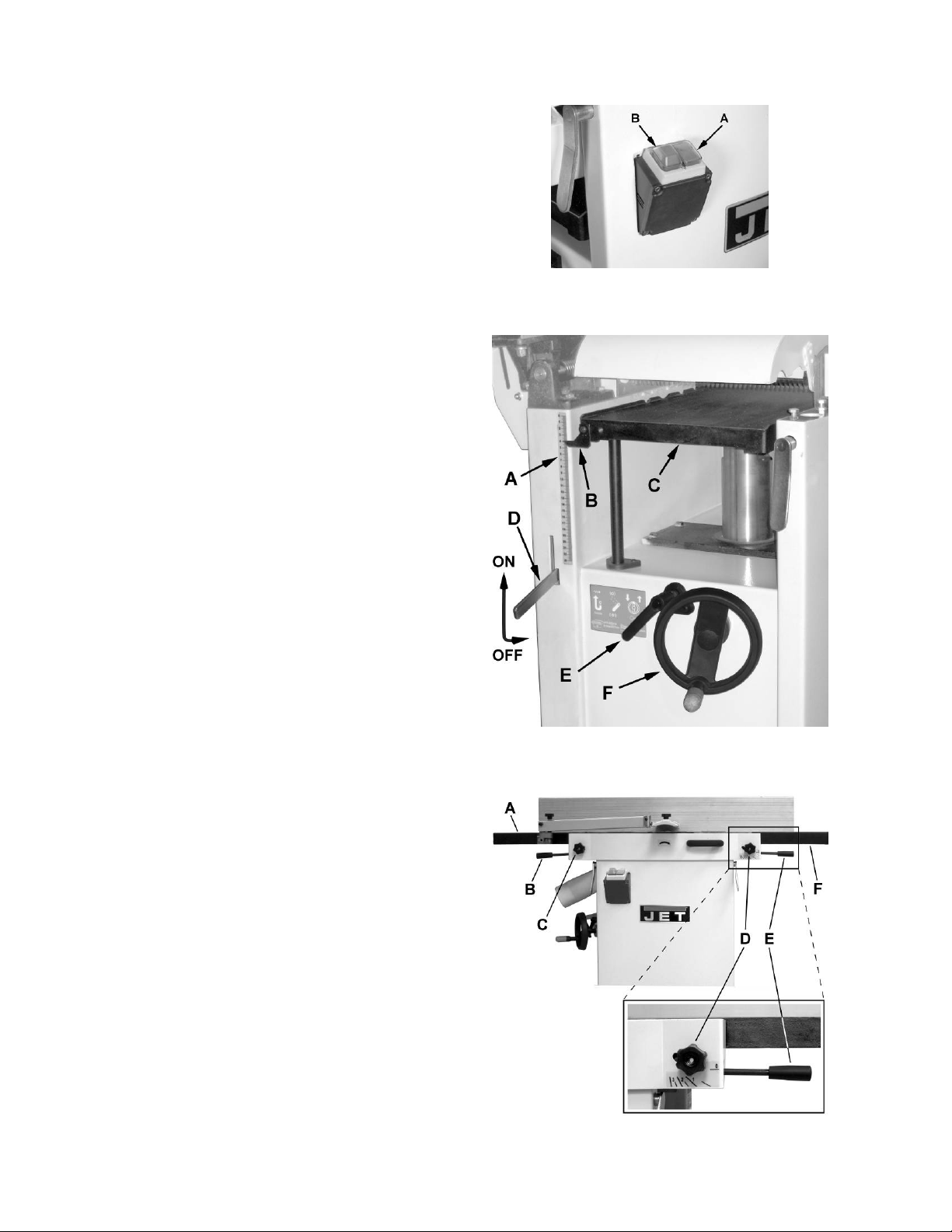

9.5 Jointer controls and adjustments

Refer to Figure 6:

Outfeed Table Height Adjustment

Lock knob (C) and lifting handle (B) control the

height adjustment of the outfeed table (A).The

outfeed tabl e i s ini tiall y adj usted at t he f actor y and

should not be repositioned except during certain

adjustments. These are described in sect. 10.1,

Table and Knife Adjust ments.

Figure 5

Infeed Table Height Adjustment

Lock knob (D) and lifting handle (E) control the

height adjustment of the infeed table (F).

To adjust:

1. Loosen lock knob (D).

Figure 6

9

Page 10

2. Raise the lif ting handle (E) to raise the inf eed

table for a shallow depth of cut. Lower the

handle for a deeper c ut.

3. Tighten the lock knob (D).

The infeed t able lifting handle in t he fully lowered

position resul ts in a depth of cut of 5/32".

Note: A depth of cut of 1/16" or less is recom-

mended.

Cutterhead Guard

Properly posi tioned, the cutterhead guard (H, Fig.

7) should rest against t he fence (A, Fig. 7).

Fence Movement

Refer to Figure 7:

The fence (A) can be moved forward (B) or

backward (C) acro ss the width (W ) of the tabl e. It

also tilt s up to 45 degrees backwards (D).

Loosen the lock knob (J), slide the guard into

position, then ti ghten the lock knob.

When edge jointing, the fence assembly should

periodically be moved to different positions to

distribute wear on the cutterhead knives.

To slide fence f or ward or back ward:

1. If necessary, loosen the c utterhead guard (H)

to permit the fence assembly to move freely

without being c onstr ained by the guard.

2. Loosen two fence assembly locking

handles (E).

3. M ov e the enti re fence assembl y t o the desired

position; then re- tighten the handles (E).

4. Readjust and secure the cutterhead guard.

To tilt fence back ward:

The fence (A) can be tilted backward (D) up to 45°

(that is, for a total included angle of 135° from

table surface) as follows:

1. Loosen locking handles (F).

2. Tilt the fence back (A , C) to t he desired a ngle

up to 135 degrees. Or you can place your

beveled reference piece on the table and

against the f ence, adj usting t he f ence unt i l t he

angle of the f ence matches the bev el of your

gauge piece.

3. Tighten the locking handles (F).

4. Readjust and secure the cutterhead guard.

Figure 7

10

Page 11

10.0 Adjustments

10.1 Table and knife adjustments

For accurat e jointi ng, at least thr ee thi ngs m ust be

true:

1. Infeed and outfeed tables must be coplanar.

2. Knives or knife inserts must be set in the

cutterhead so that the highest point of their ar c

is level with the outfeed table.

3. On the standard cutterhead, knives must be

parallel with the outfeed table across the

entire length of the knives.

These alignments are explained below.

Disconnect machine from

power source b efore making any adjust ments.

Failure to compl y may cause seri ou s injury.

10.2 Coplanar alignment

Definit io n of c op la na r

When the infeed tabl e is set to the same level as

the outfeed tabl e and all points on the t ables lie in

the same plane, thus forming a "perfect" flat

surface, the t ables are said to be coplanar.

Figure 8

For optim um perform ance of the j ointer , the i nfeed

and outfeed tables must be coplanar. If they are

not, the fi nished workpiec e may have a slight taper

or twist across its jointed width or length.

Determining if t abl es are coplanar

The tables hav e been set coplanar at the factory,

but they should be double-checked by the

operator. Also, as the machine undergoes use, the

tables should be checked occasionally and

adjusted if necessary.

The procedure described below uses a steel

straight edge to set the tables, which should be

accurate enough for most purposes.

Important: The t ables must be locked i n position

when performing the following test.

Refer to Figures 8 and 9:

1. Disconnect jointer from power source.

2. Loosen the lock knob (A) and slide the

cutterhead guard ( B , C) to clear the table.

3. Slide the fence assembly back (H, E) as far as

it will go, or remove it from the machine

entirely.

4. Rotate the cutterhead to avoid knife

interference.

Figure 9

5. Place a st raight edge (D) ac ross the back of the

outfeed table (F ) and ext ending over t he infeed

table (G). Note the position of the infeed table

(G). Note the position of the straight edge in

Figure 8 with respect to the fence (H).

6. Raise the infeed table (G) until it contacts the

straight edge (D).

The straight edge should lie level across both

tables. Move the straight edge to the front of the

outfeed tabl e as shown i n Fi gure 9 and perf orm t he

same test .

If the straight edge does not lie level, the front or

back of one of the tabl es must be adjusted t o make

the tables coplanar. Proceed as described in

Performing t he c oplanar alignm ent (following page).

11

Page 12

Performing the coplanar alignment

If alignment is required as determined in the

previous section, proceed as follows:

Disconnect machine from

power source before making

any adjustmen ts. Failure to comply may cause

serious injury.

1. Disconnect power from machine.

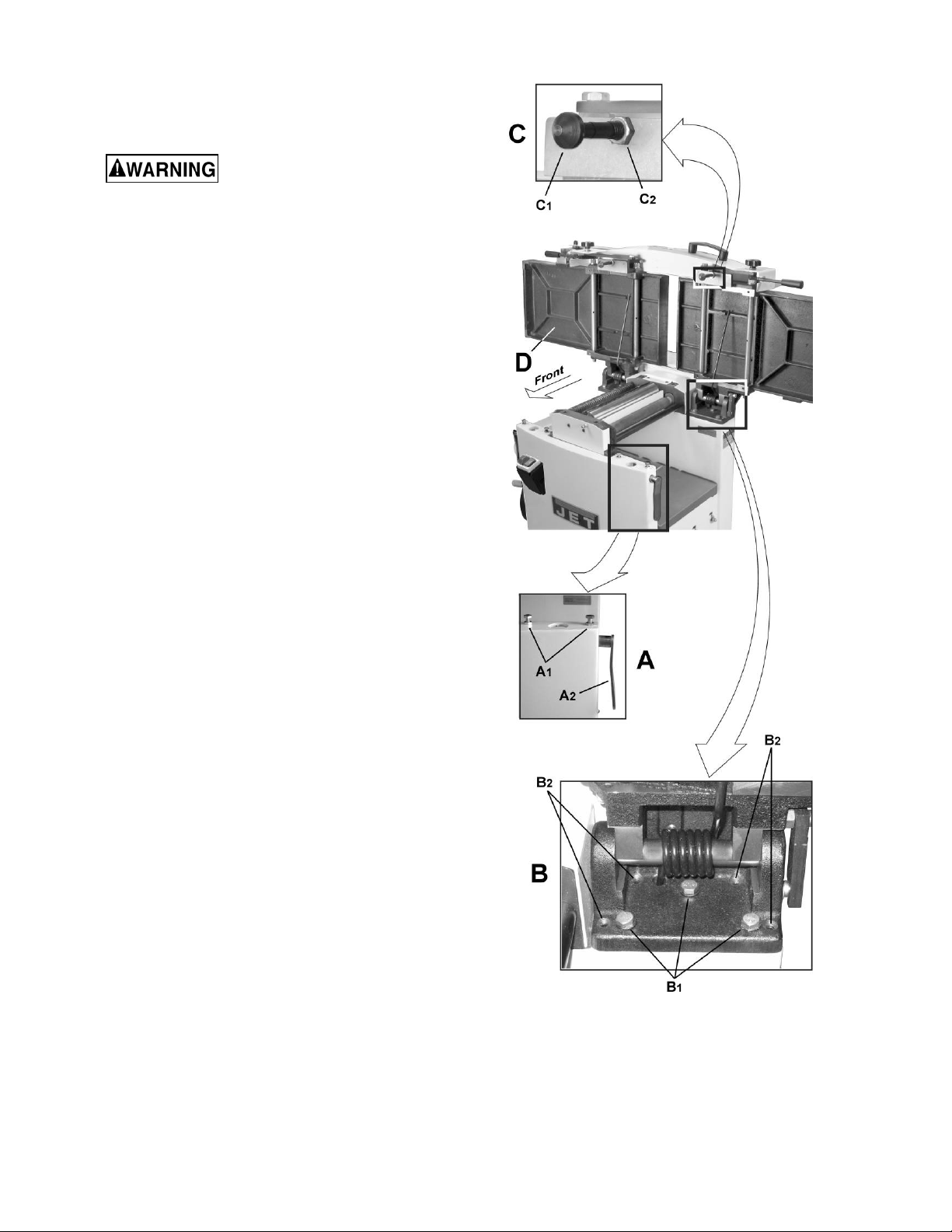

2. Unlock both cabinet lock handles (A2,Fig. 10).

3. Raise the table (D) fully upright.

Adjustment is performed by means of four

setscrews (B

) that adjust the t abl e pitch and ti lt at

2

the back (towards the fence) and two hex cap

screws (A

) that adjust the table toward the fr ont.

1

Adjustment c an consist of a front adjust ment, rear

adjustment or (more probable) a combination of

both.

Rear adjustment

Tools requir ed – 13mm wrench, 4mm hex wrench

1. With a 13mm wrench, loosen three hex cap

screws (B

).

1

2. Using a 4mm hex wrench, make very slight

adjustments of 1/8 to 1/4 turns to four

setscrews (B2) as required.

A clockwise turn will raise the table; a

counterclockwise turn will lower the table.

Adjusting the two right setscrews will have

greatest adjustm ent impact t o the table's ri ght

side; adjusting the two left setscrews will have

greatest adjustment impact to the table's left

side.

3. When adjustm ent is complete, tighten t he hex

cap screws (B

).

1

Front adjustment

Tools requir ed – two 13mm wrenches

1. Hold the hex cap screws (A

) in place with one

1

wrench while using the other to loosen the

locking hex nut s.

2. Adjust the screws (A

) slightly from 1/8 to 1/4

1

turn.

A countercl ockwise turn will raise the table; a

clockwise turn will lower the table. Adjusting

the right screw will have greatest adjustment

impact to the table's right side; adjusting the

left screws will have greatest adjustment

impact to the table' s l eft si de.

3. When adjustment is complete, secure by

tightening the hex nut while maintaining the

position of the screw with t he second wr enc h.

It may be necessary to repeat the exercise in this

Figure 10

section more than once to achieve co-planar

alignment.

Note: If the tables do not lock properly after the

adjustment, see sect. 10.6, Jointer Table Lock

Handle Adjustment.

12

Page 13

10.3 Setting cutterhead knives

(straight knives only)

Important: Before perf orming any adj ustment s in

this section, the inf eed and outfeed tabl es must be

coplanar (see sect . 10.2, Coplanar alignment).

Cutterhead knives are

dangerously sharp! Use extreme caution when

inspecting, removing, sharpening o r replacing

knives into the cutterhead. Failure to comply

may cause serious injury!

1. Disconnect machine from the power source.

2. Remove the cutterhead guard (B, Fig. 8).

Refer to Figures 11 and 12:

3. Car efully number each knife blade (C) with a

magic marker to differentiate each.

Note: Rotate the cutterhead via the cutterhead

pulley. Rem ove the back panel of the cabinet for

access.

4. Rotate the cutterhead (E) and determine the

12 o'clock position of knife number one. The

12 o'clock posi ti on i s the highe st poi nt a bl ade

will reach in the c utti ng ar c (C, Fig. 12).

5. Set a straightedge (J) on t he outfeed table (F)

near the fence (H). One end of the straightedge should be positioned over the cutting

knife (C) near the end of the blade as shown

in Fig. 11.

Figure 11

B

C

D

E

A

Use care when handling the

straightedge near blades to prevent damage.

6. Note the position of the knife blade with

respect to the straightedge, then move the

straightedge t o the other side of the t able and

again note the posi tion of the k nife blade with

respect to the straight-edge.

Blade number one must be at the same height

at each end and must also be at the same

height as the outfeed table (bottom of

straightedge). If this is not the case,

adjustment is required as follows:

7. Slightly loosen five gib lock screws (A) by

turning into the lock bar (B), clockwise as

viewed from the infeed table (G).

8. Adj ust the blade hei ght by turning jack screws

(D) upon which t he blades rest. To lower the

blade, turn t he screw clockwise. T o raise, t urn

the screw counter-cl oc k wise.

9. When the blade is at the proper height,

alternately tighten the five gib lock screws (A).

Repeat steps 4-9 for blades two and three.

Figure 12

13

Page 14

10.4 Replacing cutterhead knives

(straight knives only)

Disconnect machine from

power source b efore making any adjust ments.

Failure to compl y may cause seri ou s injury.

1. Disconnect machine from the power source.

2. Remove the cutterhead guard (B, Fig. 8).

Cutterhead knives are

dangerousl y sharp. Use extreme caution when

inspecting, remo ving, sharpenin g, or replacing

knives into the cutterhead. Failure to comply

may cause serious injury.

Refer to Figures 11 and 12:

3. Turn all five screws (A) into the lock bar (B) by

turning i n a clockwise directi on as viewed from

the infeed table (G).

4. Carefully remove the cutter knife (C) and lock

bar (B).

5. Repeat for remaining two knives.

6. Thoroughly clean all surfaces of the

cutterhead, knife slots and lock bars of any

dust or debris.

7. Insert replacement knife (C) into t he knif e sl ot,

making sure it f aces the proper direction.

8. Insert lock bar (B) and tight en j ust enough to

hold in place.

9. Repeat for other two blades.

The knives must now be adju sted as described in

sect. 10.3, Setting c utt er head k niv es .

10.5 Replacing or rotating knife

inserts (helical cutterhead only)

The knife inserts on the model J JP-12HH ar e foursided. When dull, simply remove each insert,

rotate it 90° for a fresh edge, and re- install it.

Use the provided st ar point screwdriv er t o remove

the knife insert screw. See Figure 13. It is

advisable to r otate all inserts at t he same time t o

maintain consistent cutting. However, if one or

more knife inserts develops a nick, rotate only

those inserts affected.

Each knife insert has an etched referenc e mark to

keep track of the rotations.

An extra set of 5 knife inserts and knife insert

screws are included wit h y our J JP-12HH.

Figure 13

(Model JJP-12HH only)

IMPORTANT: When removing or rotating inserts,

clean saw dust f rom the screw, the inser t, and the

cutterhead platform. Dust accumulation between

these element s can prevent the i nsert from seating

properly, and m ay affect the quality of the cut.

Before instal ling each screw, lightl y coat the screw

threads with mac hine oil and wipe off any excess.

Securely tighten each screw which holds the knife

inserts before operating the planer. Knife inserts

should be torqued to approximately 50 to 55 inchpounds.

Make sure all knife insert screws

are tightened securely. Loose inserts can be

propelled at high speed from a rotating

cutterhead , cau sin g inju ry.

14

Page 15

10.6 Jointer table lock handle

adjustment

Refer to Figure 10 on page 12:

For best performance, the jointer table lock

handles (A

down position when in the locked position. If

adjustment is required:

1. Disconnect machine from power source.

) should be approximately in the fully

2

2. Unlock the lock handles (A

) and raise the

2

table to the upright position.

3. Loosen locking nut (C

4. Adjust the table locking shaft (C

) with an 18mm wrench.

2

) in

1

increment s of 1/4 turns or less. Tur n c lockwise

to tighten the lock handle performance and

countercl oc k wise to loosen.

5. Tighten the locking nut (C

).

2

6. Test the lock ing function and repeat if necessary.

10.7 Belt replacement

Disconnect machine from

power source b efore making any adjust ments.

Failure to compl y may cause seri ou s injury.

Refer to Figure 14.

Preparation

To replace the cutterhead drive belt and/or the

planer feed-roller belt, the joi nter fence assembly

and two back panels must first be removed as

described below. A 4mm hex wrench and two

13mm wrenches are requir ed.

1. Remove the jointer fenc e assembly (A , Fi gure

14) by first loosening and removing two lock

handle assemblies (B).

2. Remove two button head socket screws (C)

and upper back panel (D).

3. Remove four button head socket screws (O)

and lower back panel (P).

Cutterhead Drive Belt Replacement

4. Loosen four motor mount screws (L). Lift the

motor and re st it in the hori zontal slot side of

the motor mount opening. This will create a

slack in the cutter head dr iv e belt (F).

5. Remove the cutterhead drive belt (F) from

around the cutterhead pulley (E) and motor

pulley (M).

6. If the feed-roller belt (K) is to be replaced,

continue. Otherwise proceed to step 10.

Figure 14

15

Page 16

-

roller Belt Replacement

Feed

Note: If the feed-roller belt is to be repl ac ed, steps

1–5 must be perf ormed to remove the cutterhead

drive belt before the feed-roller belt can be

replaced.

7. Place the power feed handle (J) in the down

(off/disengaged) position, which provides belt

slack for the next step.

8. Remove the feed-roller belt (G) from around

the feed-roller pulley (K) and motor pulley (M).

9. Loop the new belt around the smaller (inner)

motor pulley (M) and feed-roller pulley (K).

Note: The lower stretch of the feed-roller

pulley must be positioned between the belt-

brake plates (N).

Concluding Steps

10. Replace the cutterhead drive belt (F) by

looping it around the cutterhead pulley (E),

then the larger (outside) motor pulley (M)

11. Slide the motor so that the mounting screws

(L) rest back i n the v ertical sl ot openings, t hen

tighten the mounting screws.

12. Replace the lower back panel (P) and secure

with four button head socket screws (O).

13. Replace the upper back p anel (D) and secure

with two butt on head s oc k et screws (C).

14. Replace the jointer fence assembly (A) and

secure with two lock handle as s em blies (B).

10.8 Feed roller height adjustment

Refer to Figure 15.

The height of the infeed and outfeed rollers has

been set by the manufacturer for planing

operations. If this setting should ever need

adjustment, it is done using the screw and nut

, Figure 15) at each end of the rollers.

(A

1,A2

1. Disconnect machine from power source.

2. Rem ove the covers from front and back of the

machine.

3. A t the back, remove the chai n and sprockets

from their s h afts.

4. Loosen the hex nut (A

) as needed to raise or lower that end of

(A

2

) and rotate the scr ew

1

the roller. NOTE: Feed rollers must remain

parallel to the table, and about 1/ 32” below the

cutting arc of t he knives or knife inserts.

5. Adjust any of the four screw/nut assemblies as

Figure 15

6. Use a gauge on the planer table to verify the

height of the roller s i n r elation to the cutterhead.

7. When settings are corr ect, tight en the hex nuts

) up against the casting.

(A

1

8. Make test cuts to verify the setting.

needed.

16

Page 17

10.9 Feed roller pressure adjustment

Refer to Figure 15.

The pressure of the feed rollers against the

workpiece during pl aning operat ions is m aintained

by spring tension. To adjust this tension, turn the

socket head screw (B, Figure 15), clockwise to

increase pressure, counterclockwise to decrease

pressure.

10.10 Planer table adjustment

Disconnect machine from

power source b efore making any adjust ments.

Failure to compl y may cause seri ou s injury.

Checking Planer Tab le Parallel to Cutterhead

The planer tabl e is set parallel to the cutterhead by

the manufact ur er and no further adjustment should

be needed. If your m achine is plani ng a taper , fi rst

check to see if the kniv es are properl y adjusted i n

the cutter head (see sect. 10.3, Setting cutterhead

knives) and make adjustments if necessary.

After t he knives are confirmed t o be properly set,

check to see if the work tabl e is set paral lel to the

cutterhead as follows.

1. Disconnect machine from power source.

2. Rotate the cutterhead such that one of the

knives (A, Fig. 16) is at the 6 o'clock position.

Refer to Figure 17:

3. Place a gauge block (B) or an other m easuri ng

device on the w ork table (C) at one edge (D)

directly under the cutt er head.

4. Unlock the table loc k handle (F).

5. With the handwheel (G), gently raise the

table (C) until the gauge block (B) makes

slight contact with the tip of the knife blade,

then lock the tabl e.

A

Figure 16

BC

E

D

J

H

K

F

6. Move the gauge block ( B) to opposite end of

table (E).

If the di stance f r om the t abl e to ti p of t he knif e

blade is the same at both ends, the table is

parallel to t he c utt er head.

Adjusting Work Table Parallel to Cutterhead

If the work tabl e is not parallel to the cut terhead,

perform the adjustm ent procedure as follows:

7. With a 13mm wrench, loosen four hex cap

screws (H) located at each corner of the

column support (J).

G

Figure 17

8. Bring the table parallel to the cutterhead by

adjusting four setscrews (K) located at each

corner of the column support (J) next to the hex

cap screws (H).

9. Repeat steps 3 – 6, and i f further adjustment is

necessary, repeat steps 8, 9.

When the table is determined to be parallel to the

cutterhead, tighten the hex cap screws (H).

17

Page 18

11.0 Basic operations

11.1 Dust collection

Before initial operation, the machine must be

connected to a dust collector.

11.2 Initial startup

After the assembly and adjustments are

complete, the planer is ready to be tested. Turn

on the power supply at the main panel. Press

the Start button. Keep your finger on the Stop

button in case of a pr oblem. The planer should

run smoot hly with l i ttle or no v i br ati on or rubbi ng

noises. Investigate and correct the source of any

problems bef or e further operation.

DO NOT attempt to inves-

tigate or adjust the planer while i t is run ning.

Wait until the planer is turned off, unplugged

and all working parts have come to a

complete standstill.

in a smooth, even m otion t oward the cutt erhead.

After the cut is under way, the new surf ace r ests

firmly on the outfeed table. The left hand is

transferred to the outfeed side (Figure 18) and

presses down on this part of the workpiece, at

the same time maintaining flat contact with the

fence. The right hand presses the workpiece

forward and before the right hand reaches the

cutterhead it should be moved to the work on

the outfeed tabl e.

Surfacing

The purpose of planing on a jointer is to produce

one flat surf ace (Figure 19). The other side can

then be milled to pr ecise, final dimensions on a

thickness planer resulting in a board that is

smooth and flat on both sides and each side

parallel to t he other.

If the wood to be jointed is cupped or

bowed, place the concave side down, and

take light cuts unti l the surface is flat.

Never surf ace pi eces shorter t han 12 inc hes

or thinner t han 3/8 inc h without the use of a

special work holding fixture.

Always wear ANSI-approved

safety glasses or goggles when operating

the jointer-pl aner.

11.3 Changing mode of operation

When changing the operating mode (planer to

jointer and back ) the machine must be turned off

and at a complete standstill. To change the

mode of operation, see sect. 9.1, Jointer to

planer setup and sect. 9.2, Planer to jointer

setup.

11.4 Jointer operations

Correct operating position

The operator must be positioned offset to the

infeed table (Figure 18).

Figure 18

Hand placement

Never surf ace pieces thinner than 3 inc hes

without the use of a push bloc k .

Cuts of approximately 1/16" at a time are

recommended, which provides for better

control over the material being surfaced.

More passes can then be m ade to r each the

desired depth.

Figure 19

Never pass hands directly

over the cutterh ead.

At the start of the cut, the left hand holds the

workpiece firmly against the infeed table and

fence whil e the ri ght hand pushes the work piec e

18

Page 19

Direct ion of Grain

Avoid feeding work into the jointer against the

grain (Figur e 20) . This may result in c hipped and

splintered edges.

Figure 20

Feed with the grain to obtain a smooth surface,

as shown in Figure 21.

To edge:

1. Make sure the fence is set to 90°. Double

check it with a square.

2. Inspect stock for soundness and grain

direction ( r efer to Direction of grain).

Figure 22 – Surfac ing

3. If the board is bowed (curved), place the

concave edge down on t he infeed table.

4. Set the infeed table for a cut of approximately 1/16 inch.

5. Hol d the stock firmly agai nst the fence and

table, feed t he stock slowly and evenly over

the cutter head.

Figure 21

Jointing

Jointing (or edging) is the process of creati ng a

finished, flat edge surface that is suitable for

joinery or finishing (Figure 22). It is also a

necessary step pri or to ri pping stock to width on

a table saw.

Never edge a board that is less than 3

inches wide, l ess than 1/4 i nch thick, or 12

inches long, without using a push block.

When edgi ng wood wider than 3 i nches, lap

the fingers over the top of the wood,

extending them back over the fence such

that they will act as a stop for the hands in

the event of a kickbac k.

Position the fence (move it forward) to

expose only the amount of cutterhead

required.

When workpiece is twice the

length of the jointe r inf e e d or out fe ed table

use an infeed or outfeed support.

Beveling

Beveling an edge is t he same operati on as edge

jointing, except that the fence is tilted to a

specified angle.

Make certai n material being bev eled is over

12 inches long, m ore than 1/ 4 inch thi ck and

1 inch wide.

To bevel:

1. Use a bev el gauge t o determine the desi red

angle. Then set the f enc e to t he same angle.

2. Inspect stock for soundness and grain

direction ( r efer to Direction of Grain).

3. Set the infeed table for a cut of

approxim ately 1/16.

4. If the board is bowed (curved), place the

concave edge down on the i nfeed table.

5. Feed the stock through the cutterhead,

making sure the face of the stock is

completely flat against the fence and the

edge is making solid contact on the infeed

and outfeed tabl es (Figure 23).

For wood wider than 3 inches – hold with

fingers close together near the top of the

stock, lappi ng over the board and ex tending

over the fence.

19

Page 20

For wood less than 3 inches wide – use

e

beveled push blocks and apply pressure

toward the fence. Keep fingers near top of

push block.

Several passes may be required to achiev e the

full bevel.

Stock

Fence

Infeed Tabl

Outfeed Table

Plane alternat e sides until the desir ed thick-

ness is obtained. W hen half of the total cut

has been taken from each side, the board

will have a uniform, moisture content and

additional dr ying will not cause it to warp.

The depth of cut should be shallower when

the workpiece i s wider.

When planing hardwood, take light cuts or

plane the wood in thin widths.

Make a test cut wit h a test piece and verif y

the thickness produced.

Check the accuracy of the test cut before

working on the finished product.

Figure 23 – Beveling

11.5 Planer operations

Depth of Cut

Thickness plani ng refers to the sizing of lum ber

to a desired thickness while creating a level

surface parallel to the opposite side of the

board. Board thickness that the planer will

produce is i ndi cated by the scale and the depth-

of-cut gauge (see sect. 9.4, Table height

adjustment). Preset the planer to the desired

thickness of the finished workpiece using the

gauge. The dept h-of-cut is adj usted by raising or

lowering the planer table (C, Fig. 5) using the

handwheel (F, Fig. 5).

The quality of thickness planing depends

upon the operator's judgment about the

depth of cut.

The depth of cut depends upon the width,

hardness, dampness, grain direction and

grain struct ur e of t he wood.

The maximum thickness of wood that can be

removed in one pass is 1/8” for planning

operations on workpi eces up to 5-1/2” wide.

The workpiece must be positioned away

from the cent er tab on the roll ercase to cut

1/8”.

A thickness planer is a precision

woodworking machine and should be used

on good-qualit y lumber only.

Precautions

Do not plane dirty boards; dirt and small

stones are abrasive and will wear out the

blade.

Remove nail s and staples. Use the pl aner to

cut wood only.

Avoid knots. Heavily cross-grained wood

makes knots hard. K nots can come l ose and

jam the blade. Any article that encounters

planer blades may be forcibly ejected from

the planer cr eating a risk of injury.

Preparing the Work

A thickness planer works best when the

lumber has at l east one fl at surface. Use a

jointer t o creat e a flat surf ac e.

Twisted or sev erely warped boards ca n jam

the planer. Ri p the lumber i n half to reduce

the magnitude of the warp.

The work should be fed into the planer in the

same direction as the grain of the wood.

Sometimes t he wood will change direct ions

in the mi ddle of the board. I n such cases, if

possible, c ut the board in the middle so the

grain dir ection is correct.

The maximum thickness of wood that can be

removed in one pass is 1/16” for planing

operations on workpi eces from 5-1/2” up t o

12" wide.

For optimum planing performance, the depth

of cut should be less than 1/16”.

The board should be planed with shallow

cuts until the work has a l evel si de. Once a

level surface has been created, flip the

lumber and create parallel sides.

Do not plane a board that is

less than 6" long. It is recommended that

when planing short boards you butt them

end to end to avoid kickback and reduce

snipe.

Feeding the Work

The planer is supplied with planer blades

mounted in the cutterhead and infeed and

outfeed rollers adjusted to the correct height.

The planer feed is autom atic; it will vary sli ghtly

depending on the type of wood.

20

Page 21

Preparation:

Feed rate refers to the rate at which the

lumber travels through the planer.

The operator i s responsible for al igning the

work so it will feed pr operl y .

Raise or lower the rollercase to get the

depth of cut desired.

The surface t hat the planer pr oduces will be

smoother if a shall ower depth of cut is used.

Stand on the side that the handle is

attached.

Avoiding Snipe

Snipe refer s to a depression at eit her end of the

board caused by an uneven force on the

cutterhead when t he work is ent ering or leav ing

the planer.

Snipe will occur when the boards are not

supported properl y or when only one feed rol ler

is in contact with the work at the beginning or

end of the cut.

Precauti ons for av oiding snipe:

Push the board up while feeding the work

until the outfeed roller starts advancing it.

Boards longer than 24” should have

additional support from free standing

material stands. These can be purchased

from JET – St ock # 709209. See sec t. 17.0,

Optional access or ies .

Planing

1. Position the workpiece with the face to be

planed on top.

2. Turn the planer on.

3. Turn the power feed on.

4. Rest t he board e nd on t he infeed roller pl ate

and direct the board into the planer.

5. Slide the workpiece into the infeed side of

the planer until the infeed roller begins to

advance the workpiece.

6. Let go of the workpiece and allow the

automatic f eed to advance the workpiece.

7. Do not push or pull on the workpiec e. Move

to the rear and receive the planed lum ber by

grasping it in the same manner that it was

fed.

Move to the rear and receive the planed

board by pushing it up when the i nfeed roller

loses contact with the board.

When planing more than one board of the

same thickness, butt the boards together to

avoid snipe.

Make shallow cuts. Sni pe is more apparent

when deeper cuts are taken.

Feed the work i n the direction of the grain.

Work fed against the grain will have

chipped, splintered edges.

To avoid the risk of injury

due to kickbacks, do not stand directly in

line with the front or rear o f the planer.

8. Do not gra sp any portion of the board that

has not gone past the outfeed roller.

9. Repeat this operation on all of the boards

that need to be the same thick ness.

21

Page 22

12.0 Maintenance

12.1 Blade care

Blades are extremely sh arp!

Use caution when cleaning

or changing. Failure to comply may cause

serious injury!

The condition of the blades will affect the

precision of the cut. Observe the quality of

the cut that the planer produces to check the

condition of the blades.

Dull blades will tear, rather than cut the

wood fibers and produce a fuzzy

appearance.

Raised grain will occur when dull blades

pound on wood that has varying density . A

raised edge will also be produced where the

blades have been nic k ed.

When gum and pitch collect on the blades,

carefully r emove with a strong solvent. Failur e to

remove gum and pitch build up may result in

excessiv e fric tion, blade wear and overheating.

6. Keep the cutterhead from rotating by

grasping the cutterhead pulley while sliding

the stone back and fort h across the table.

7. Take the same amount of passes for all

three blades.

If the blades have been sharpene d and still are

not cutting efficiently, trying to touch up the

blades furt her will only c ause the formation of a

second beveled edge. When this starts to

happen, it is tim e to replace bl ades with another

set. It i s recommended to keep a second set of

blades on hand so that they may be installed

while the first set is being professionally

sharpened.

Figure 24

When blades become dull, touc h up blades. See

sect. 12.2, Shar pening the Knives.

12.2 Sharpening knives (straight

knives only)

Blades are extremely sh arp!

Use caution when handling.

Failure to compl y may cause seri ou s in ju ry!

1. Disconnect the machine from the power

source.

2. Remove the blade guard and belt cover.

3. To protect the infeed table from scratches,

partially cover the sharpening stone with

paper (Figur e 24).

4. Lay the stone on the infeed table.

5. Lower the infeed table and turn the

cutterhead by t urning the cutter head pulley.

The infeed t able height is set properl y when

the stone's surface is flush with the knife

bevel.

Do NOT attempt to sharpen

helical knife inserts! Only rotate the knife

once it i s dull. If all sides have b een rotated

properl y, dispose of the knife and repl ace it

with a replacement insert. Refer to sect. 10. 5,

Replacing or rotatin g knife inserts.

13.0 Lubrication

Use a good grade of light grease on the

steel adjusti ng screws located i n the raising

and lowering mechanisms of the work

tables.

The cutterhead ball bearings are lifetime

lubricated and need no f ur ther care.

22

Page 23

14.0 Troubleshooting the JJP-12,JJP-12HH

A

14.1 Performance tro ubleshooting – Jointer

Trouble Probable Cause Remedy

Finished stock i s

concave on back

end.

Finished stock i s

concave on front end.

Chip out. Cutting against the grain. Cut with the grain whenever possible.

Fuzzy grain.

Cutterhead slows

while operating.

Knife is higher than outfeed table.

Outfeed table is higher than knife.

Dull knives.

Feeding workpiec e too fast. Use slower rate of feed.

Cutting too deeply. Make shallower cuts.

Knots, imperfections in wood.

Wood has high moistur e c ontent.

Dull knives. Sharpen or replac e k niv es/inserts.

Feeding workpiec e too quickly, or

applying too much pressure to

workpiece.

Align cutterhead k nives with outfeed

table. See sect. 10.3, Setting

cutterhead kniv es .

Align cutterhead k nives with outfeed

table. See sect. 10.3, Setting

cutterhead kniv es .

Sharpen or replac e k niv es/Rotate

knife inserts or replace inserts.

Inspect wood closely for

imperfections; use different stock if

necessary.

Allow wood to dry or use diff er ent

stock.

Feed more slowly, or appl y l ess

pressure to workpiece.

“Chatter” marks on

workpiece.

Uneven knife marks

on workpiece.

Knives incorr ectly set.

Feeding workpiec e too fast.

Knives are nicked, or out of

alignment.

Table 2

Set knives properl y as descri bed in

sect. 10.3, Setting cutterhead knives.

Check that knif e slot s are clean and

free of dust or debris.

Feed workpiece slowly and

consistently.

lign knives per sect . 10. 3, Setting

cutterhead kniv es . Replace nicked

knives/Rotat e knife inserts.

23

Page 24

14.2 Performance troubleshooting – Planer

Trouble Probable Cause Remedy

Snipe

Note: Snipe cannot be

eliminated, but can be

so minimized as to

become negligible.

Fuzzy Grain

Torn G rain

Rough/Raised Grain

Table rollers not set pr oper ly. Adjust rollers to proper height

Inadequate support of long boards. Support long boar ds with ex tension

rollers.

Uneven feed roller pr essure front to

Adjust feed roller tension.

back.

Dull knives. Sharpen knives/Rotate knife inserts.

Lumber not butt ed pr operl y . Butt end to end each piece of stock

as they pass through.

Planing wood with high moisture

content.

Remove high moisture c ontent from

wood by drying.

Dull knives. Sharpen or replac e/Rotate knife

inserts.

Too heavy a cut. Adjust proper dept h of cut.

Knives cutti ng against grain. Cut along the grain.

Dull knives. Sharpen knives/Rotate knife inserts.

Dull knives. Sharpen knives/Rotate knife inserts.

Too heavy a cut. Adjust proper dept h.

Rounded, glossy

surface

Poor feeding of

lumber.

Uneven depth of cut

side to side.

Board thickness does

not match dept h of

cut scale.

Moisture cont ent too high. Remove high moisture c ontent from

wood by drying.

Dull knives. Sharpen or replac e k niv es/Rotate

knife inserts or replace.

Feed speed too slow. Increase speed.

Cutting dept h too shal low. Increase depth.

Inadequate f eed r oll er pr essure. Adjust feed roller tension. If proper

tension cannot be achieve, replace

feed rollers

Planer bed rough or dir ty. Clean pitch and resi due, and wax

planer tabl e.

Transmission v-belt slipping. Tighten transmission v-belt.

Surface of feed rollers clogged. Clear pitch and r esi due out of teet h.

Knife projection. Adjust knife pr ojec tion.

Cutterhead not level with bed. Level bed.

Depth of cut scale incor r ec t.

Adjust depth of cut scale.

Table 3

24

Page 25

14.3 Mechanical troubleshooting – Planer/Jointer

Trouble Probable Cause Remedy

Chain

jumping.

Machine will

not start/

restart or

repeatedly

trips circuit

breaker or

blo ws fuses.

Inadequate

tension.

Sprockets

misaligned.

Sprockets worn. Replace sprockets.

No incoming

power.

Overload

automatic reset

has not reset

Planer frequently

trips.

Building cir c ui t

breaker trips or

fuse blows.

Loose electri c al

connections.

Adjust chai n tension.

Align sprockets.

Verify unit is connected to power, on-button is pushed in

completely , and stop-button is disengaged.

When planer overl oads on the ci r c uit breaker built into the motor

starter, it takes tim e for the machine to cool down before restart.

Allow unit to adequately cool before attempting restar t.

One cause of overl oading trips, which are not electri c al in nature,

is too heavy a cut. The solution is to take a lighter cut. If too deep

a cut is not the problem, t hen c hec k the am p setting on the

overload relay. Match the full load amps on the motor as noted on

the motor plat e. If the amp setting is correct then there is probably

a loose electri c al lead. Check amp setting on motor starter.

Verify that planer is on a circuit of correct size. If circ uit size is

correct, ther e is probably a loose electrical lead. Chec k amp

setting on mot or start er .

Go through all the elec trical on the planer includi ng motor

connections, v er ifying the tightness of each. Look for any signs of

electric al ar ci ng whic h is a sure i ndicator of loose connections or

circuit overload.

Motor starter

failure.

Switch or Motor

failure – how to

distinguish.

Motor failure. If electric motor is suspect, you hav e two opti ons: Have a

Miswiring of the

unit.

Examine motor starter for burned or failed components. If

damage is found, replace motor starter. If motor starter looks

okay but is still suspect, you have two options: have a qualifi ed

electrici an test the motor starter for functi on, or pur chase a new

starter and establish if that was the problem on changeout

If you have access to a voltmeter, you can separate a starter

failure from a motor failure by first, verifying incoming voltage at

220+/-20 and second, chec k ing the voltage between starter and

motor at 220+/-20. If incoming voltage is incorrect, you have a

power supply problem . If voltage between starter and motor is

incorrect, y ou hav e a starter pr oblem. If voltage between starter

and motor is correct , you hav e a m otor pr oblem .

qualified electrician test the motor for func tion or remove the

motor and take it to a quali ty elec tric motor repair shop and have

it tested.

Double check t o confirm all electrical connecti ons are correct and

properly ti ght. The electrical connections other t han the motor are

pre-assembl ed and tested at the factory. Theref or e, t he motor

connections should be double checked as the highest probabi lity

for error. If problems persist, double-c hec k the factory wiring.

Table 4

25

Page 26

15.0 Replacement parts

To order parts or reach our service department, call 1-800-274-6848 Monday through Friday (see our

website for business hours, www.waltermeier.com). Having the Model Number and S er ial Number of y our

machine available when you call will allow us to serve you quickly and ac c ur ately.

15.1 Parts List for JJP-12, JJP-12HH

Index No. Part No. Descripti on Size Qty

1 ............... TS-1541031 .............Lock Nut .............................................................M8 .............................. 4

2 ............... JJP1 2-002 ...............Washer.................................................................................................. 4

3 ............... JJP1 2-003 ...............Outfeed Table Bracket Shaft .................................................................. 1

4 ............... JJP1 2-004 ...............Outfeed Table Bracket, Right ................................................................. 1

5 ............... TS-1504121 .............Socket Head Cap Screw .....................................M8x60 ........................ 4

6 ............... JJP1 2-006 ...............Eccentric Shaft ...................................................................................... 4

7 ............... JJP1 2-007 ...............Table ..................................................................................................... 2

8 ............... JJP1 2-008 ...............Cutterhead Guard Assembly (includes #401-426, 9, 10,33) .................... 1

9 ............... JJP1 2-009 ...............Bracket .................................................................................................. 1

10 ............. TS-1503071 .............Socket Head Cap Screw .....................................M6x30 ........................ 2

11 ............. JJP12-011 ...............Washe r...............................................................H12 ............................ 4

12 ............. TS-2342121 .............Lock Nut .............................................................M12 ............................ 4

13 ............. TS-1503051 .............Socket Head Cap Screw .....................................M6x20 ........................ 4

14 ............. JJP12-014 ...............Adjusting Handle ................................................................................... 2

15 ............. JJP12-015 ...............Knob ..................................................................................................... 2

16 ............. JJP12-016 ...............Bracke t S crew ....................................................................................... 2

17 ............. JJP12-017 ...............Bracke t S crew ....................................................................................... 2

18 ............. JJP12-018 ...............Eccentric Shaft Bracket ......................................................................... 2

19 ............. JJP12-019 ...............Eccentric Shaft Clamp ........................................................................... 2

20 ............. JJP12-020 ...............Table Locking Shaft ............................................................................... 2

21 ............. TS-1540081 .............Hex Nut ..............................................................M12 ............................ 2

22 ............. JJP12-022 ...............Outfeed Table Bracket, Left ................................................................... 1