Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

6-inch Woodworking Jointer

Models JJ- 6CS X , JJ- 6CS DX , JJ -6H H D X

WALTER M EIE R (Manufac turing) Inc.

427 New Sanford Road

LaVergne, Tennesseee 3708 6 Part No. M-708457DX

Ph.: 800-274-6848 Revision B1 07/2012

www.jettool s.c om Copyright © 2012 Walter Meier (Manufacturing) Inc .

Page 2

Warranty and Service

Walter Meier (Manufacturing), Inc., warrants every product it sells. If one of our tools needs service or repair, one of

our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any

of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or

®

perform routine maintenance and major repair on your JET

your area call 1-800-274-6848.

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with

your local W MH Tool Group distributor, or visit jettools.com.

WARRANTY

JET products carry a limited warranty which varies in duration based upon the product (MW = Metalworking, WW =

Woodworking).

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools,

abrasives and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general JET warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

Five Year Warranties do not cover woodworking (WW) products used for commercial, industrial or educational

purposes. Woodworking products with Five Year Warranties that are used for commercial, industrial or education

purposes revert to a One Year Warranty. This warranty does not cover defects due directly or indirectly to misuse,

abuse, negligence or accidents, normal wear-and-tear, improper repair or alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name

of the location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the

merchandise. If our inspection discloses a defect, we will repair or replace the product, or refund the purchase price,

at our option. We will return the repaired product or replacement at our expense unless it is determined by us that

there is no defect, or that the defect resulted from causes not within the scope of our warranty in which case we will,

at your direction, dispose of or return the product. In the event you choose to have the product returned, you will be

responsible for the shipping and handling costs of the return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR

EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND

FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATIO N MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECI AL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as general

information and are not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

®

whatsoever. JET

branded products are not sold in Canada by Walter Meier.

tools. For the name of an Authorized Service Center in

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Introduction ............................................................................................................................................. 6

Specifica tions .......................................................................................................................................... 7

Unpac king ............................................................................................................................................... 8

Assembly ................................................................................................................................................ 9

Electrical ............................................................................................................................................... 12

Adjustments .......................................................................................................................................... 1 3

Operating Controls ................................................................................................................................ 22

Operation .............................................................................................................................................. 2 2

Maintenance .......................................................................................................................................... 25

Lubrication............................................................................................................................................. 27

Troubleshooti ng Operating Problems ..................................................................................................... 28

Troubleshooti ng Mechanical and Electrical P r oblems ............................................................................. 29

Optional Accessories ............................................................................................................................. 29

Parts ......................................................................................................................... ............................ 3 0

Fence – Parts All Models ................................................................................................................... 30

Fence – Assembly All Models............................................................................................................. 31

Stand – Parts, JJ-6CSX and JJ-6CSDX ............................................................................................. 3 2

Stand – Parts, JJ-6HHDX only ........................................................................................................... 34

Stand – Assembly, JJ-6HHDX only .................................................................................................... 35

Bed – Parts All Model s ....................................................................................................................... 36

Cutterhead – Parts and Assembly JJ-6CSX ....................................................................................... 3 8

Cutterhead – Parts and Assembly JJ-6CSDX ..................................................................................... 39

Cutterhead – Parts and Assembly JJ-6HHDX ..................................................................................... 40

Wiring Diagram – All Models .............................................................................................................. 41

3

Page 4

Warnings

1. Read and understand the entire owner's manual befor e att empting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This Woodworking Jointer is designed and intended for use by properly trained and experienced

personnel only . If you are not famili ar wit h the proper and safe operat ion of a woodworki ng joint er, do

not use until proper t r aining and knowledge have been obtained.

5. Do not use this Jointer for other than its intended use. If used for other purposes, Walter Meier

(Manufactur ing), I nc., discl aim s any real or impli ed warranty and hol ds i tself harml ess fr om any inj ury

that may result from that use.

6. Always wear approved safety glasses/face shields while using this woodworking jointer. Everyday

eyeglasses only have impact resistant lenses; they ar e not safety glasses.

7. Before operating this woodworking jointer, remove tie, rings, watches and other jewelry, and roll

sleeves up past the el bows. Remove all loose cl othing and confine long hair. Non-slip footwear or

anti-skid floor strips are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended periods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , birt h defects or other repr oductiv e harm. Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalline sil ic a from bricks, cement and other masonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not oper ate this machine while tired or under t he influence of drugs, alcohol or any medic ation.

11. Mak e c er tain the switch is in the OFF position before connecting t he machine to the power source.

12. Mak e c er tain the machine is properly grounded.

13. Mak e all machine adjustment s or mai ntenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning i t on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use ext r eme caution and replace the guards immediately.

16. Mak e sure t he woodworking jointer i s firmly secured to the floor or bench before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, break age of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. Pr ov ide for adequate space surrounding work area and non-glare, ov er head lighting.

19. Keep the floor around the machine cl ean and free of scrap material, oil and grease.

4

Page 5

20. Keep v isitors a safe distance from the work area. Keep children away.

21. Mak e y our workshop chi ld proof with padlocks, m aster switc hes or by r em ov ing starter keys.

22. Giv e your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

23. Maint ain a bal anced stance at al l tim es so that you d o not f all or l ean agai nst the c utt erhead or ot her

moving part s. Do not over r eac h or use exc essive force to perform any machine operation.

24. Use the right tool at the correc t speed and f eed rat e. Do not force a t ool or attachm ent to do a j ob for

which it was not designed. T he ri ght tool will do the job better and saf er.

25. Use recommended accessories; improper accessories may be hazardous.

26. Mai ntain tools with care. K eep knives sharp and clean f or the best and saf est performance. Foll ow

instructions for lubricating and changi ng ac c essori es.

27. T ur n off the machi ne before cleaning. Use a brush or compressed air to r emove chips or debris — do

not use your hands.

28. Do not stand on the machine. Serious injury c ould oc c ur if the mac hine tips over.

29. Never leave the machine running unattended. Turn t he power off and do not leave the machine until it

comes to a complete stop.

30. Bef ore turning on machi ne, remove all ext ra equipment such as key s, wrenches, scrap, stock, and

cleaning rags away from the machine.

31. At all times hold the stock firmly . Always use a hold-down or push bl ock when surfacing stock less

than 12 inches long, or 3 inches wide, or 3 inc hes thick.

32. Do not perf orm jointing oper ations on material shorter than 8", narrower than 3/4" or l ess than 1/4"

thick.

33. T he hands must never be closer than 3 inches to

the cutterhead ( see Fi gur e) .

34. Never apply pressure to stock directly over the

cutterhead. T his may resul t in the stock t ipping

into the cutterhead along with the operator's

fingers. Position hands away from extreme ends

of stock, and push through with a smooth, even

motion. Never back workpi ec e toward the infeed

table.

35. Do not make cuts deeper than 1/2" when

rabbeting. On other cuts such as edging,

surfacing, etc., depth of cut shoul d not be over

1/8" to avoid overloading the machine and to

minimize chanc e of kic k bac k.

36. To avoid k ickback, the grain must run in t he same direction you are cut ting. B efore att empting t o

joint, or plane, each work piece must be carefully examined f or stock c ondition and grain orientati on.

37. W hen working wit h a s wirl grai n wood or burl s, m aki ng it nec essary to pl ane agai nst the grai n, us e a

lesser depth of cut and a sl ow rate of f eed.

38. Move the hands in an alternate m otion from back to front as the work continues through the cut.

Never pass the hands direct ly over the cutter knife. As one hand approaches the kniv es remove it

from the stock in an arc motion and place it back on the stock in a position beyond the cutt er k nife

5

Page 6

Familiariz e y our self with the following safety noti c es used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precauti ons are not heeded, it may result in seri ous injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

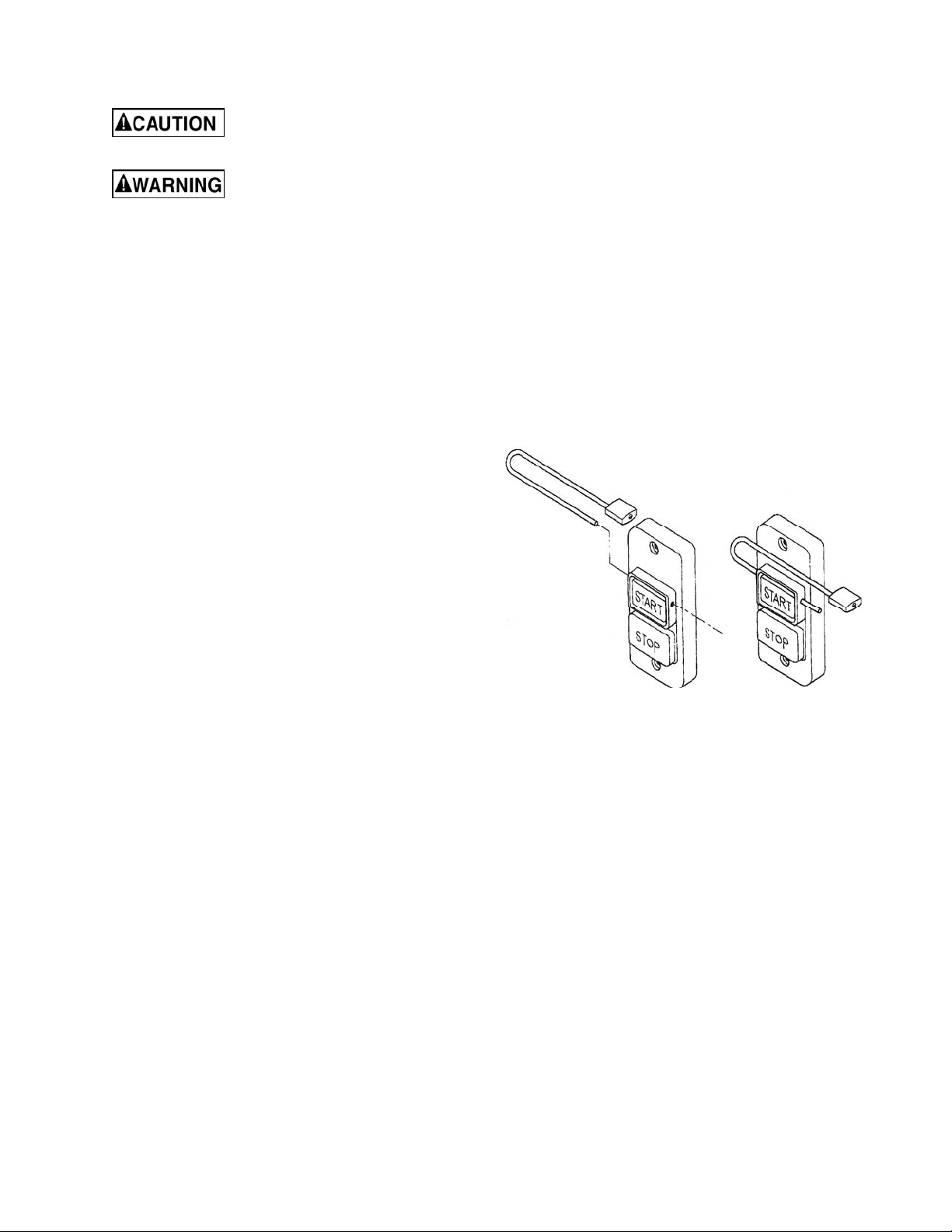

On-Off Switch Padlock

The jointer is equipped with a push-button

switch that will accept a safety padlock (see

figure – not included). To safeguard your

machine from unauthorized operation and

accidental starting by y oung chil dren, the u se of

a padlock is highly recommended. JET model

PD-LK-1 (Stock No. 709012) is available from

your local author iz ed J E T distributor or by calling

Walter Mei er (Manufacturi ng), Inc., at the phone

number on the cover of t his manual.

Introduction

Model PD-LK-1 On-Off Sw itch P adloc k

This manual is provided by W MH Tool Group cov ering the safe oper ation and mai ntenance procedure s

for Models JJ-6CSX, JJ-6CSDX and JJ-6HHDX Jointers. This manual contains instructions on

installation, safety precautions, general operating procedures, maintenance instructions and parts

breakdown. This machine has been designed and constr uc t ed to provide years of trouble free operat ion if

used in accordanc e with instructions set f orth in this manual. If there are any questions or com ments,

please contact your loc al supplier or Walter Meier, or visit our web site: www.jettools.com .

6

Page 7

Specifications

Model JJ-6CSX JJ-6CSDX

Stock Number – Bed and Stand Kit ................................ 708457K........................................... 708457DXK

Stock Number – Bed Assembly ..................................... 708457J............................................ 708457DXJ

Stock Number Stand...................................................... 708457S........................................... 708457DXS

Cutting Capacity ............................................... 6-1/16"W x 1/2"D................................... 6-1/1 6 "W x 1/2"D

Cutterhead Speed ...................................................... 4800 RPM.............................................. 6000 RPM

Number of Knives ...................................................................... 3............................................................ 3

Rabbeting Capaci ty .............................................................. 1/2"........................................................ 1/2"

Rabbet Ledge ........................................................ 3-1/8" x 8-3/4"........................................ 3-1/8" x 8-3/4"

Table Surface ............................... 7-3/8"W x 45-3/4"L x 31-1/4"H...................... 7-3/8"W x 56"L x 31-1/4"H

Fence ............................................................. 3-7/8"H x 29-1/8"L.................................. 3-7/8"H x 32-3/4"L

Knife Size ................................................... 6-1/16 " x 5/8" x 1/8 " T ........................... 6 - 1 /1 6 " x 3/4" x 5/64"T

Fence Tilt ................................................................... 45ºL, 45ºR ............................................ 45 ºL , 45ºR

Positive Stops...................................................... 45ºL, 90º, 45ºR...................................... 45ºL, 90º, 45ºR

Motor ................................................. 1HP, 1Ph, 60Hz, 115/230V.................... 1HP, 1Ph, 60Hz, 115/230V

pre-wired 115V pre-wired 115V

Net Weight (approx.)....................................................... 215 lbs.................................................... 237 lbs

Shipping Weigh t ............................................................ 230 lbs.................................................... 258 lbs

Model JJ-6HHDX

Stock Number – Bed and Stand Kit ............................... ......................................................... 708466DXK

Stock Number – Bed Assembly .................................... .......................................................... 708466DXJ

Stock Nu mbe r S ta n d..................................................... .............................................................. 708466S

Cutting Capacity ........................................................... ......................................................... 6"W x 1/2"D

Cutterhead Speed ........................................................ ............................................................ 6000 RPM

Number of Knives ......................................................... ............................................. 27 four-sided inserts

Number of Rows in Cutterhead ..................................... .......................................................................... 4

Table Surface ............................................................... .................................... 7-3 /8 "W x 56"L x 31-1/4"H

Fence ........................................................................... ................................................ 3-7/8"H x 32-3/4"L

Knife Ins e r t Size ........................................................... ....................................... 0.59”L x 0.59”W x 0.10T

Fence Tilt ..................................................................... ........................................................... 45 ºL , 45ºR

Positive Stops............................................................... .................................................... 45ºL, 90º, 45ºR

Motor ............................................................................ ........1HP, 1Ph, 60Hz, 115/230V (pre-wired 115V)

Net Weight (approx.)..................................................... ................................................................. 237 lbs

Shipping We ig h t .......................................................... ................................................................. 258 lbs

The above specifications were current at the time this manual was publi shed, but because of our policy of

continuous im provement, Walt er Meier (Manuf acturing), Inc. , reserves the ri ght to change speci fications

at any time and without pri or notice, without incurring obligations.

7

Page 8

Unpacking

This unit is shipped in two cartons. Open both

cartons and check for shipping damage. Report

any damage immediately to your distributor and

shipping agent. Do not discard any shipping

material unti l the Jointer i s assembled and running

properly.

Compare the contents of your cartons with the

following parts l ist to make sure all parts are intact.

Missing parts, if any, should be reported to your

distribut or. Read the instruction manual thoroughly

for assembly, maintenance and safety instructions.

Stand Carton

1 Stand with Mot or

1 Stand Cover with Mounting Hardware

1 Dust Chute with Mounting Hardware

1 Pedestal Switch wi t h Mount ing Hardware (JJ-

6HHDX only)

Main Unit Carton

1 Bed Assembly

1 Fence Assembly

1 Cutterhead Guard ( A )

1 Belt Guard (E)

1 V-Belt (D)

4 1/4-20 x 1/2 Pan Head Screws (L)

4 1/4 Flat Washers (M)

1 Lock Handle, Flat Washer, and Loc k Nut for

Fence (G)

1 Fence Handle (F)

3 Lock Bolts (B)

3 3/8" Lock Washers (C)

2 Handwheel Assembly (N)

2 Push Blocks (K)

1 Operating Instr uc ti ons and Par ts Manual

1 Warranty Card

Tools Included for JJ-6CSX

1 12/14mm Open End Wrench (O)

1 8/10mm Open End Wrench (P)

1 3mm Hex Wrench (Q)

Tools Included for JJ-6CSDX

1 12/14mm Open End Wrench (O)

1 8/10mm Open End Wrench (P)

1 3mm Hex Wrench (Q)

1 4mm T-Hex Wrench

1 8mm Hex Wrench

Tools included for JJ-6HHDX:

1 12/14mm Open End Wrench (O)

1 8/10mm Open End Wrench (P)

1 3mm Hex Wrench (Q)

1 6mm Hex Wrench

2 Star Point Screwdrivers (R)

5 Knife Inserts (S)

10 Knife Insert Screws (T)

Stand Carton

Main Unit Carton

Tools included for Model JJ-6HHDX only

8

Page 9

Assembly

Unpacking and Cleanup

1. Carefully fini sh rem oving all content s f rom bot h

shipping cartons. Compare contents of the

shipping cartons wi t h the list of contents above.

Place parts on a protected surface.

2. Set packing material and shipping cartons to

the side. Do not discard until machine has

been set up and is running properly.

3. Clean all rust protected surfaces (bed, fence,

etc.) with kerosene or diesel oil. Do not use

gasoline, paint thinner, mineral spirits, etc.

These may damage paint ed surf ac es.

Cutterhead knives are

dangerously sharp! Use

extreme cautio n when cl eani ng .

4. Apply a thin layer of paste wax to the bright

surfaces of the fence and tables to prevent

rust.

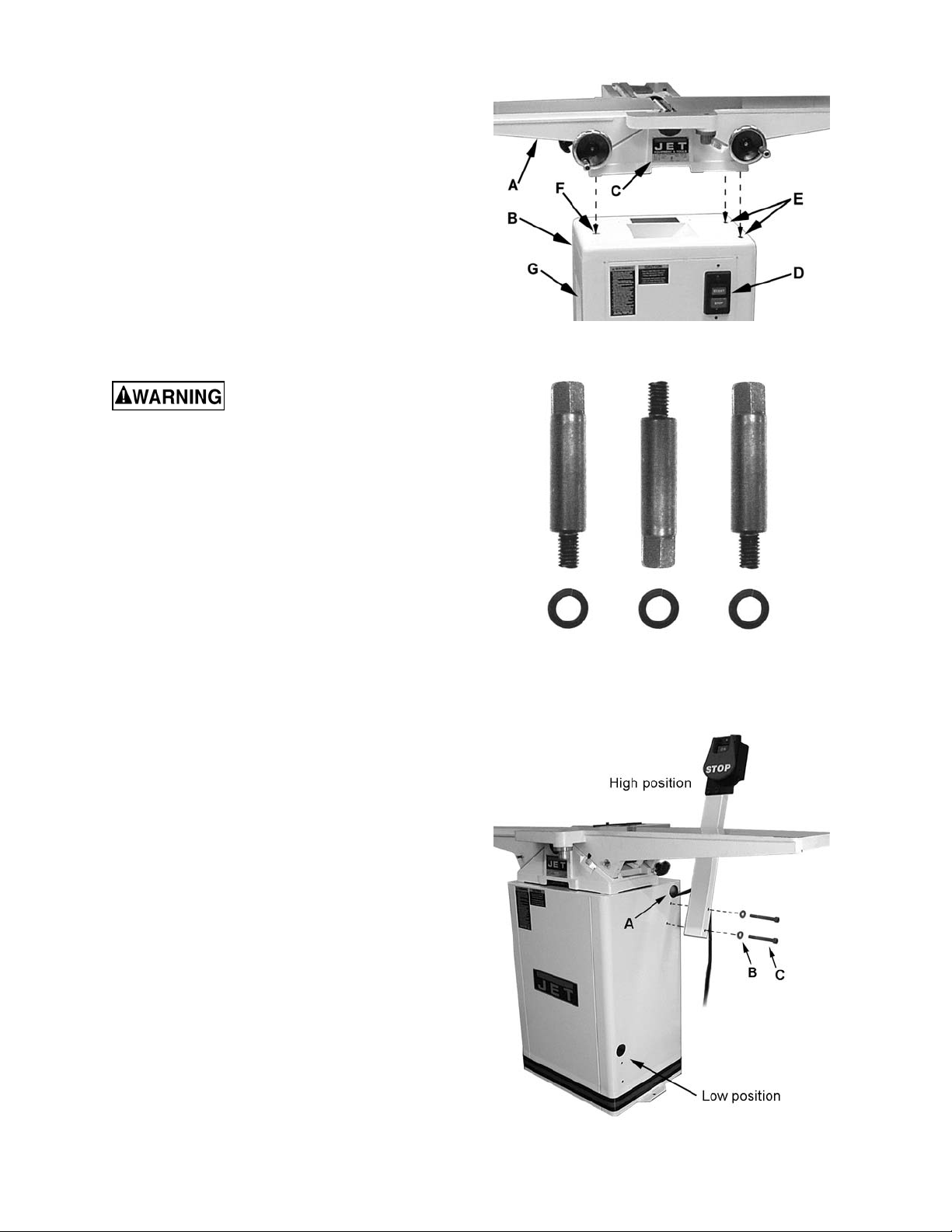

Installing Bed to Stand

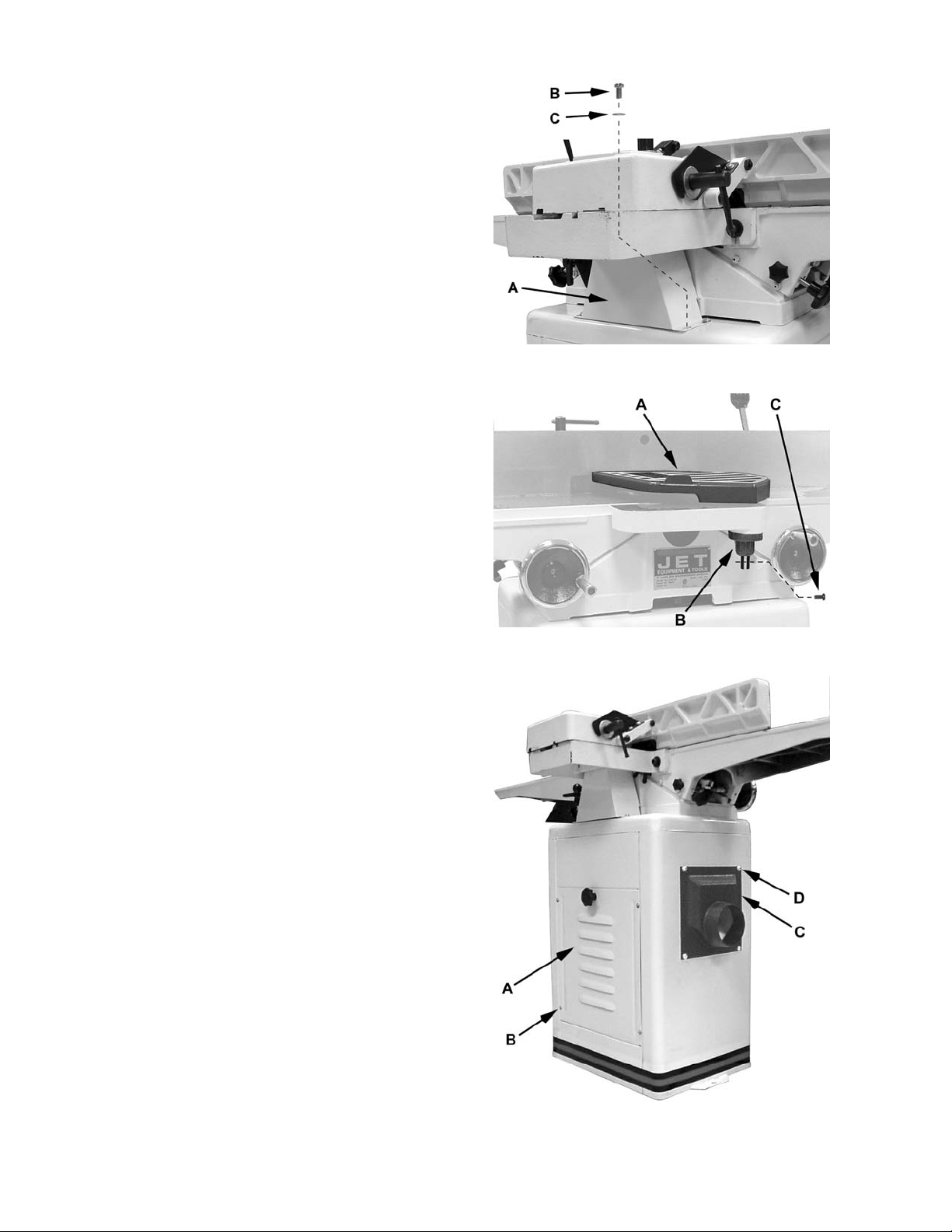

Referring to Figur e 1:

1. Place bed assembly (A) on top of stand (B). Be

sure the identification label (C) on the bed

faces the sam e direction as the switch (D) on

the stand.

2. Line up two holes in the stand top (E) with

holes in the bed assembl y by viewing thr ough

the access door in rear side of the stand.

3. Attach stand to bed assembly by using two 3/8"

lock bolts and lock washers (Figure 2). Hand

tighten only at t his tim e.

Figure 1

Figure 2

4. Line up the third hole in the stand (F ) with the

hole in the bed assembly by viewing through

the dust chute (G).

5. Install the thi rd 3/8" lock bolt and lock washer

through the dust chute ( G) to secure t he bed to

the stand.

6. Tighten all three lock bolts with a 14mm

wrench.

Installing Pedestal Switch (JJ-6HHDX)

Referring to Figur e 3:

1. The switch may be installed in either high

position or low position to suit the operator.

Slide the connect ion plug through the ope ning

(A) and secure the pedestal switch using two

5/16”x3” screws (C) and 5/16” flat washers (B).

2. Connect the plug of t he pedestal switch to the

motor plug insi de the cabinet.

Figure 3

9

Page 10

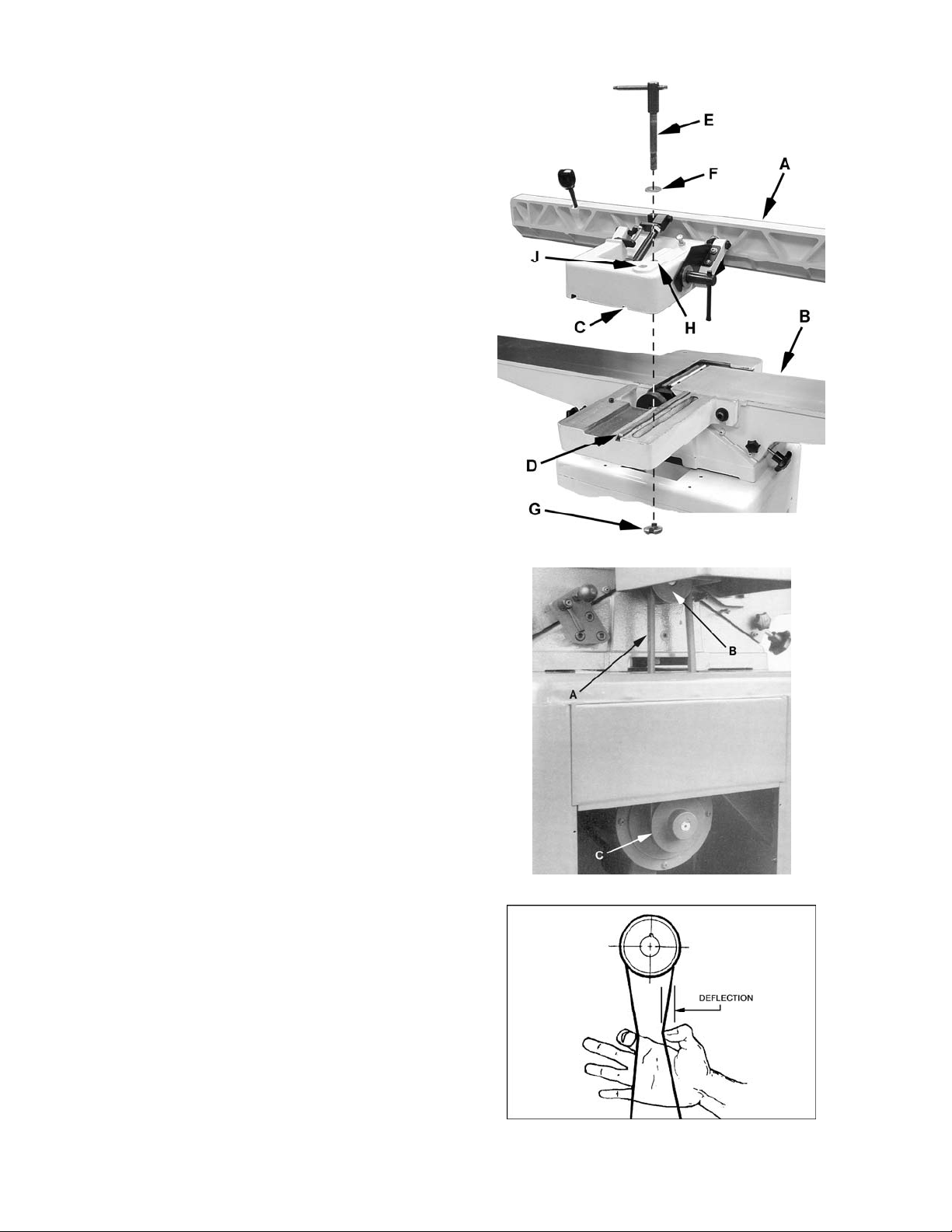

Installing Fence to Bed

Referring to Figur e 3a:

1. Take the lock handle ( E), flat washer (F), and

lock nut (G) from the carton.

2. Place the fence assembly (A) onto the table

(B). Be sure the key stock (D) on the bed lines

up with the channel (C) in the fence casting.

3. Place the flat washer (F) on hole (H)*; insert

the lock handle (E) through the fence casting

and the table casting.

4. Thread the lock nut (G) onto the lock handle

(E). Make sure the tab on the nut faces up and

engages the slot i n the tabl e c asting.

*Note: For rabbeting operations use hole (J).

Installing the Drive Belt

Referring to Figur e 4:

1. Place V-belt (A) onto cutterhead pull ey (B) and

through opening i n stand.

2. Pull V-belt down and place onto motor

pulley (C).

Note: If the belt i s difficult to roll on the pull ey,

loosen the motor m ounting screws.

3. Check to make sure that motor pulley and

cutterhead pul ley are v ertic ally aligned and the

V-belt does not contact the sides of the

opening in the base. If the pulleys are not

aligned, remove belt and adjust the motor

pulley in or out on t he motor shaft and then r eattach the belt.

4. The V-belt is properly tensioned when finger

pressure on the bel t half way bet ween the two

pulleys causes 1/2" def l ecti on (Figure 5). If the

belt is too loose, l oosen the four motor mount

bolts, push down on the motor to tension t he V belt, and tighten the mounting bolts.

Figure 3a

Figure 4

5. A new belt may have a tendency to stretch

slightly until broken in. After two hours of

operation, check belt tension again. Readjust

the tension if necessary.

Figure 5

10

Page 11

Installing Belt Guard

Referring to Figur e 6:

1. Place the belt guard (A) over the opening in the

stand.

2. Li ne up the holes in the stand wit h the holes in

the guard.

3. Attach the guard to the stand using four

1/4-20 x 1/2” pan head machine screws (B)

and four 1/4” flat washers (C).

Installing Cutterhead Guard

1. Remove the screw from the guard post.

Referring to Figur e 7:

2. Turn spring knob (B) approximately one and

one half revolutions counter-clockwise (as

viewed from the top) and hold.

3. Insert the guard post into hole i n table. Make

sure that the spring inside t he spring knob (B)

engages the slot i n guard post.

4. Thread the screw (C) back into the guard post.

5. Check for proper operation. The cutterhead

guard (A) must return fully to the fence when

released. If guard does not return fully, pull

guard, apply more tension to the spring knob

(B) by turning it another half turn counterclockwise, and re- insert guard. If guard cl oses

too quickly and stri kes fence too hard, release

some tension on the spring.

6. Insert screw (C) back into the guard post.

Figure 6

Figure 7

Installing Access Cover

Referring to Figur e 8:

Install access cover (A) by placing bott om of panel

in the stand and fastening with four #5-40 x 3/8"

pan head screws and four flat washer s (B).

Installing Dust Chute

Referring to Figur e 8:

Attach the dust chute ( C) to the base with four 1/4"

x 1/2" machine screws and four 1/4" washers (D).

Figure 8

11

Page 12

Electrical

Grounding Instructions

This jointer must be

grounded while in use to

protect the operat or from electric shock.

The temporary adapter should onl y be used unti l

a properly grounded outlet can be instal led by a

qualified electrician. This adapter is not

applicable in Canada. The green colored rigid

ear, lug, or tab, extending from the adapter,

must be connect ed to a permanent ground such

as a properly grounded outlet box.

In the event of a malfunction or breakdown,

grounding prov ides a path of least resistance f or

electric current to reduce the risk of electric

shock. This tool is equipped with an electric

cord having an equipment-grounding conductor

and a grounding plug. The plug must be

plugged into a matching outlet that is properly

installed and grounded in accordance with all

local codes and ordinanc es.

Do not modify the plug provided. If it will not fi t

the outlet , have the proper outlet i nstalled by a

qualified el ectrician. Improper connecti on of t he

equipment-grounding conductor can result in a

risk of electric shock. The conductor, with

insulati on having an outer surface t hat is green

with or without y ellow stripes, is the equipment grounding conductor . If r epair or r eplac ement of

the electric cord or plug is necessary, do not

connect the equi pment-groundi ng c onduc tor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool i s properl y gr ounded. U se onl y

three wire ex t ensi on c or ds t hat have three- pr ong

grounding plugs and t hree-pole recept acles that

accept the tool’s pl ug.

Repair or replace a damaged or worn cord

immediately.

230 Volt Operation

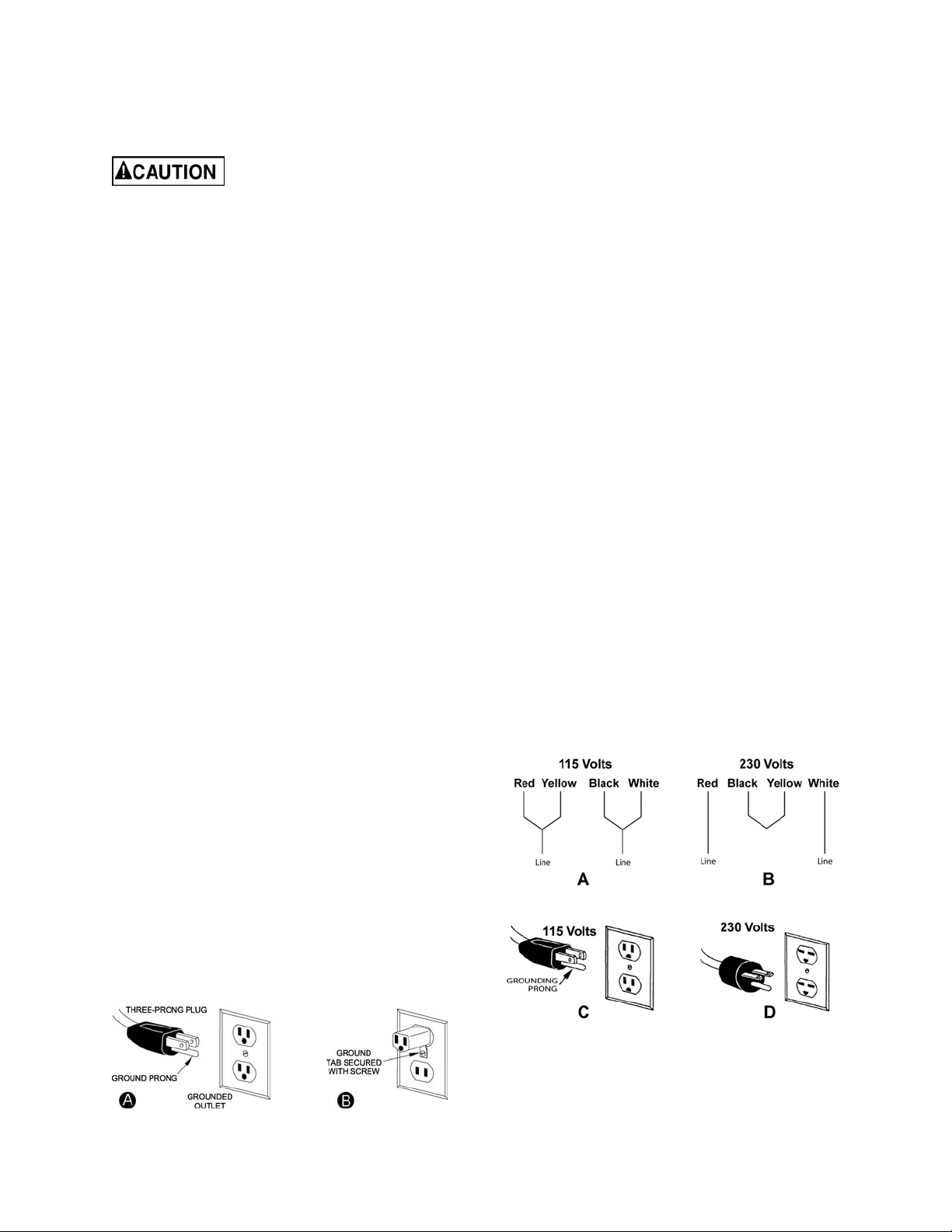

Referring to Figur e 10:

If 230V, single-phase operation is desired, the

following instr uc tions must be followed:

1. Disconnect the machine from the power

source.

2. The Jointer motor has four numbered leads

that are factory connected for 115V

operation, as shown in (A). For 230V

operation reconnect the leads as shown in

(B).

3. The 115V attachm ent plug (C) supplied with

the Woodworking Jointer must be replaced

with a UL/CSA li sted plug suitable for 230V

operation (D) . Contact your local Author ized

JET Service Center or qualified electrician

for proper procedures to install the plug.

The Woodworking Joi nter must comply with

all local and nati onal c odes after the 230-volt

plug is installed.

4. The Woodworking Jointer with a 230-volt

plug should only be connected to an outlet

having the same configuration as shown in

(D). No adapter is available nor should be

used with the 230-volt plug.

115 Volt Operation

Referring to Figur e 9:

As receiv ed f rom t he f actory , your W oodworking

Jointer is ready to run at 115-volt operation. This

Woodworking J ointer, when wired for 115 volt, is

intended for use on a circuit that has an outl et

and a plug that look like the ones illustrated in

(A). A temporary adapter, which looks like the

adapter shown in (B), may be used to connect

this plug to a two-pole receptacle if a properly

grounded outlet is not av ailable.

Figure 9

Figure 10

Page 13

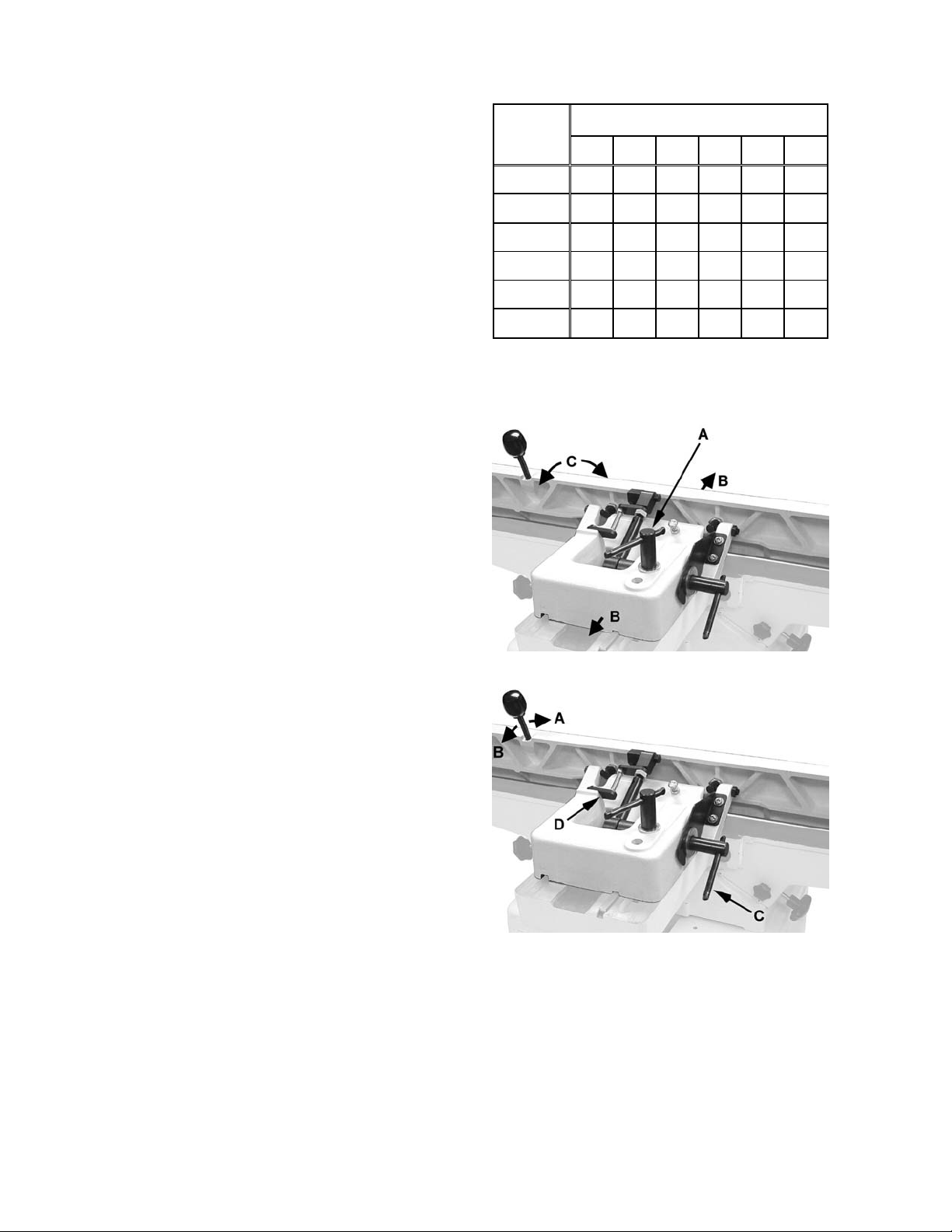

Extension Cords

Make sure your extension cord is in good

condition. W hen using an ex tension cord, be sure

to use one heav y enough to carry the current your

machine will draw. An undersized cord will cause

a drop in the line voltage resulting in power loss

and overheati ng. T able 1 sho ws the cor rect si ze to

use depending on t he cord length and namepl ate

ampere rating. If in doubt, use the next heavier

gauge. Remember, the sm aller the gauge number,

the heavier the cord.

Adjustments

Recommended Extension Cord Gauges (AWG)

Extension Cord Length in Feet *

Amps

25 50 75 100 150 200

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

Drive Belt Tension

See step 4 of Installing the Driv e B elt.

Fence Movement

The fence can be moved forward or backward

across the width of the table (B, Fig. 11). It also tilts

up to 45 degre es forward and has a positiv e stop

at 90 degrees.

To slid e fence forward or backward

When edge jointing, the fence assembly should

periodically be moved to different positions to

distribut e wear on the c utt er head k nives.

1. Loosen the locking handle (A, Fig. 11).

2. Push the enti re fence assembly (B, Fig. 11) t o

the desired position, and tighten the locking

handle.

To tilt fence forward

The fence c an be tilted for ward to any angl e down

to 45 degrees.

1. Loosen locki ng handle ( C, Figure 12).

2. Move the lever forward (A, Figure 12) to the

desired angle do wn t o 45 degr ees. O r y ou c an

place your reference piece on the table and

against the fence, and adjust the fence until

the angle of the fence matches the bevel of

your gauge piece.

*based on li mi ti ng th e lin e voltage drop t o 5V at 15 0% of th e

rated amp eres.

NR: Not Recommended.

Table 1

Figure 11

3. Tighten locki ng handle (C, Figure 12).

To tilt fence backward

1. The fence can be tilted backward up to 45°

(that is, for a tot al included angle of 135° from

table surface).

2. Loosen locki ng handle ( C, Fig. 12).

3. Flip the 90° stop bl ock (D, Fig. 12) out of the

way.

4. Move the lev er (B, Fi g. 12) bac k to t he desired

angle up to 135 degrees. Or you c an plac e

Figure 12

your bevel ed reference pi ece on the table and

against the f ence, adjusting the fence until t he

angle of the fence matches the bevel of your

gauge piece.

5. Tighten locki ng handle (C, Fig 12).

Important: When the tilted operation is finished and

the fence is returned t o 90°, do not forget to flip the

90° stop block (D, Fig. 12) back to its original

position.

13

Page 14

Fence Stop Adjustments

Periodically check the 90° and 45° backward

(135°) tilt accuracy of the fence with an angle

measuring device, such as an adju st able square or

machinist’s protractor.

90º Fence Adjustment

Referring to Figur e 13:

The 90º stop is control led by the st op bolt (E) and

the stop plat e (C).

1. Set the infeed t able to approx im ately t he sam e

height as the outf eed table.

2. Move the fence by releasing lock handle (D)

and pushing the fence assembly until it

overlaps the tables (B).

3. Tighten lock handle (D).

4. Adjust the fence to a 90º angle by releasing

lock handle (J), pulli ng up on the fence handle

(A), and tightening the lock handle (J).

Note: The stop bolt (E) should be resting

against the stop plate (C).

Figure 13

5. Place an angl e measuring dev ice on the t able

and against the f ence to confirm a 90º setti ng

(A, Fig. 14).

6. If the fence is not square to t he table, release

the lock handle (J), loosen the hex nut (F), and

turn the stop bolt (E) unt il the fence is square

to the table.

7. Tighten the lock nut (F) to retain the setting.

Tighten the lock handle (J).

45º Fence Backward Stop Adju stment

Referring to Figur e 15:

The 45º fence backward stop (fence positioned

away from the operator) is controlled by the stop

bolt (E).

1. Loosen the lock handle (A). Move the stop

plate (D) out of t he way and position t he fence

at the 135º angle. Make sure the fence sits

against the stop bolt. ( E ).

2. Tighten the lock handle (A)

3. Place an angl e measuring dev ice on the t able

and against the f ence t o confirm a 135º sett ing

(A. Fig. 16).

Figure 14

Figure 15

4. To adjust, loosen the lock nut (F), tur n the stop

bolt (E) until a 135º angle is obtained.

5. Tighten the lock nut (F).

Figure 16

14

Page 15

Infeed Table Depth Stop

Referring to Figur e 17:

The infeed tabl e depth stop (A) l imits the depth of

a cut (set by adjusti ng the infeed table handwheel)

to a maximum depth of 1/8”. For normal

operations, the depth of cut should never exceed

1/8", except f or rabbet ting operations.

If a rabbeting operation is desired:

1. Lower the infeed table to 1/8", which will cause

the depth stop limiter to engage.

2. Loosen t he lock handl e (B) and pull out on t he

stop handle (C).

3. Continue lowering the table to the desired

depth of cut.

Important: Never override the depth stop limiter

unless performing rabbeting operations.

Gib Adjustment

After a peri od of use, the gibs may become l oose

and need adjusting.

To adjust (ref er t o Figure 18) :

Figure 17

1. Loosen setscrew locknuts (A) and gib lock

screws (B).

Note: The infeed table has three gib

adjustment screws A (Infeed). The outfeed

table has two gib adjustment screws

A (Outfeed) and two gib lock wing screws (B).

2. Tighten each setscrew 1/4 turn star ting at the

bottom and working up. If a 1/4 turn does not

remove all play, take anot her 1/ 4 turn. Repeat

a 1/4 turn at a time for all three (or two) set

screws until pl ay is rem ov ed.

3. Tighten wing screws (B) and lock nuts (A).

Important: If gibs are adjusted, also perform the

Outfeed Table Adjustment to ensure the proper

knife height in r elation to the outfeed table.

Figure 18

15

Page 16

Setting Cutterhead Knives (JJ-6CSX)

Cutterhead knives are

dangerousl y sharp! Use extreme caution when

inspecting, removing, sharpening or replacing

knives into the cutterhead. Failure to comply

may cause seriou s injury!

1. Carefully number each blade with a magic

marker to make them easier to differentiate.

2. Rotate the cutterhead by turning the

cutterhead pul ley and determ ine t he 12 o'cl ock

position of knife number one. The 12 o'clock

position i s the highest point a blade will r each

in the cutting arc.

3. Loosen table lock screw (A, Fig. 19) and gib

lock screw (B, Fig. 19) and rai se the outfeed

table to the height of blade number one by

turning hand wheel (A, Fig. 20). Counterclockwise will cause the outfeed table t o raise.

Clockwise will cause the outfeed table to

lower. Set a straight edge on the outfeed

table. Posi tion of the table and straight edge

should look like Figure 21. Use care when

handling the str aight edge near the blades so

as not to damage them.

4. When the outfeed tabl e and bl ade num ber one

are the same hei ght, tighten gib and tabl e lock

screws.

Important: Do not change the setting for the

outfeed tabl e again. This will only change if the

blades are replaced.

5. Bring the straight edge toward the left of the

jointer and conf irm t hat blade num ber one is at

the same height at the lef t of the t able as it is

at the right side of the table. (Fig. 22)

Figure 19

Figure 20

6. If blade is higher or lower at the right of the

table than it is at the left, slightly loosen four

screws (A, Fig. 21) by turning clockwise as

viewed from the infeed table. Blades are

adjusted with jac ki ng screws To lower, tur n the

screw clockwise. To raise, turn the screw

counter-clockwise.

Blades are set at the proper height when the

top of the blades are 1/16" above the

cutterhead.

7. Alternately tighten four screws to hold each

blade in place.

8. Repeat this process wit h blades two and three.

The outfeed table and cutterhead knives are

correctly adjusted when all three blades are

parallel to the outfeed table and all three

blades are set at the same height in the

cutterhead.

Figure 21

Figure 22

16

Page 17

Replacing Knives (JJ-6CSX)

Planer knives are dangerously

sharp. Use extreme caution when inspecting,

removing, sh arpening, or repl acing knives i nto

the cutterhead. Failure to comply may cause

serious injury.

1. Disconnect machine from the power source.

2. Remove blade guard by turning the knob

(A, Fig. 23) clockwise while lift ing up on blade

guard.

Blades are sharp! Use great

care when hands are around

blade area!

3. Loosen four screws (A, Fig. 24).

Note: Loosen screws by t urni ng in a c loc kwise

direction as viewed from the infeed table.

Carefully remove the knife (C, Fig. 24) and the

lock bar with screws (B, Fig. 24).

Repeat for the other t wo blades.

4. Before assembly, clean all parts thoroughly

and clear cutt erhead knife sl ots of any dust or

debris.

Figure 23

5. Insert knife into the cutt erhead channel maki ng

sure it faces the pr oper dir ec ti on.

6. Insert lock bar and screws and ti ghten to hold

in place. Blades are set at the proper height

when the top of the blade is 1/16" abov e the

cutterhead. Do not ti ghten firmly at this time.

7. Repeat for other two blades.

8. To set the knives to the outfeed table and to

the same height in the cut terhead, s ee Setting

Cutterhead Knives (JJ-6CSX) on page 16.

Figure 24

17

Page 18

Outfeed Table Adjustmen t

When you receive the jointer, the knives have

been pre-set at the factory. However, the height

and paralleli sm of t he kniv es with t he outf eed tabl e

should be checked, and any needed adjustments

made, before putting the jointer into operation.

Adjust the height of t he outf eed table as follows:

1. Disconnect jointer from power source.

2. Carefully num ber each blade with a marker to

make them easier to differentiate.

3. Place a straightedge upon the outfeed table

and extend i t over the cutterhead (Figures 25

and 26).

Jointer kni ves are dangerously

sharp. Do not grab the

cutterhead itself to ro tate it! Failure to comply

may cause seriou s injury.

4. Rotate the cutterhead, using the drive belt or

pulley, until k nife number one is at it s highest

point. The apex of the knife shoul d just barely

come in contact with the straightedge.

If the apex of t he knif e number one j ust makes

contact with the str aightedge, no adjustment is

required f or the outfeed table. P roceed to the

Setting Cutt er head K niv es section.

If the apex of the knife number one comes

below the straightedge (a gap exists) or

pushes the straightedge up, proceed with the

following steps:

5. Loosen both gib lock screws (B, Fig. 18) and

the lock knob (Figure 25).

Figure 25

6. Raise or lower the outfeed table until the

straight edge cont acts the knife tip, as shown

in Figure 26. Using the drive belt or pulley,

rock the cutterhead slightly to make sure the

apex of the knife i s just barely contacting the

straight edge.

When adjustment is complete:

7. Lock the outfeed table at that setting by

tightening the lock knob (Figure 25) and gib

lock screws (B, Fig. 18). The outfeed table

adjustment i s com plete.

The outfeed table adjustm ent is only made against

one knife (blade number one was arbitrarily

selected here). After the outfeed table has been

set at the correct height, do not change it except

for special operations or after replacing k niv es.

After this adj ustment is compl eted, it is necessary

to proceed to the Setting Cutterhead Knives

section to verify that all three knives are at the

correct height and par allel to the outfeed table.

Figure 26

18

Page 19

Setting Cutterhead Knives (JJ-6CSDX)

Note: Before setting knives for model JJ-6CSDX

Jointer, the Outfeed Table Adjustment should be

done to ensure the proper k nife height in r elation to

the outfeed table.

Knives for the JJ-6CSDX cutterhead are adjusted

by means of a cam. It is important to note t hat the

entire adjustment is accomplished within one

complete r otation (360 degrees) of the cam. A full

rotation of the cam will cause the knife blade to

move a total of .015” from one extreme to the

other. Turni ng the cam more t han one full rotation

will not further adjust the knife setting, but will

simply begin the adjustment all over again. The

knife adjustment pr oc edure is outlined below.

Cutterhead knives are

dangerousl y sharp! Use extreme caution when

inspecting, removing, sharpening or replacing

knives into the cutterhead. Failure to comply

may cause seriou s injury!

Figure 27

To adjust (ref er t o Figures 27 & 28):

1. Disconnect jointer from power source.

2. Carefully num ber each blade with a marker to

make them easier to differentiate.

3. Place a straightedge ac ross the outfeed tabl e

extending it over the cutterhead towards one

end of the knife.

Cutterhead knives are

dangerousl y sharp. Do no t grab the cu tterhead

itself to rotate it! Failure to comply may cause

serious injury.

4. Rotate the cutter head back a nd for th using the

drive belt or pull ey, until knif e number one is at

its highest poi nt. The apex of the knife should

just barely come in contact with the

straightedge.

5. Move the straightedge towards the other end

of the knife and repeat step 4.

The apex of t he knife at bot h ends of the k nife

must just make contact with the straight edge. If

the apex of the knife comes below the

straightedge (a gap exists) or pushes the

straightedge up, pr oc eed to the next step.

6. Using a 4mm hex wrench, slightly loosen the

four gib screws.

7. Using a 3mm hex wrench, loosen the cam

locking scre ws to per mit adjustment of the cam

(described in t he next st ep) .

Important: Always keep the cam locking

screws snug enough so that t he c am can’t

Figure 28

rotate freely. This is especially important for

when the cam is rotated counterc lockwise since

this acti on will cause the cam l ocking screw to

loosen furt her.

8. Using an 8mm hex wrench, adjust the cam.

This is a very sensitive adjustment. Start by

rotating t he cam in a clockwise direc tion just a

few degrees.

9. Next, keep the cutterhead steady by firmly

holding on to t he pulley, place a piece of wood

pressed against the knife’s edge and press to

properly seat the blade.

10. Check your progress by repeati ng steps 4 and

5. If the knife becomes m ore out of adjustment,

turn the cam in the other direc tion.

11. The adjustment is almost complete when the

requirements described in Steps 4 and 5 are

met.

12. Next, while pressing the k nife firml y against the

cam, snug the t wo inside gib screws that hold

the gib and knife in place. Verify that t he k nife is

still in adjustment (steps 4 and 5).

13. Tighten the two outside gib screws, then the

two inside gib screws. Verify that the knife is

still in adjustment (steps 4 and 5).

14. Tighten the gib lock screws.

15. Repeat thi s entir e procedure for the rem aining

two knives.

19

Page 20

Replacing Knives (JJ-6CSDX)

Join ter knives are dangerously

sharp. Use extreme caution when inspecting,

removing, or replacing knives.

To remove/r eplac e a knife (Refer to Figure 29):

1. Remove four gib screws (A) with a 4mm hex

wrench.

2. Remove the gib ( B ) and knife (C).

If the knif e is being reused (kniv es are double-

edged), clean t he knife, gib and cut terhead of

all pitch and debris.

3. Lay the new knife or unused edge of the old

knife back onto the cutterhead (D).

4. Replace the gib (B) and screws (A). Finger

tighten only at t his tim e.

5. Press against the cutting edge of the knif e at

the center of the blade with a piece of wood.

DO NOT USE FINGERS! This is to ensure t hat

the cam is making proper contact with the

knife.

6. Snug the inside two screws, then the outside

two screws.

7. Release the piece of wood pressing against

the knife and tight en the gib screws.

8. Replace the rem aining two blades by repeating

steps 1 – 7.

9. Determine if kniv es need to be set.

Follow the Outfeed Table Adjustment section

steps 3 and 4 only t o determi ne if knives need

to be set. Do not complete the entire

outfeed table adjustment. If knives need to

be set, proceed to the Setting Cutterhead

Knives section.

Figure 29

Setting Knives for Rabbeting and Nicks

(NOTE: Rabbeting is not applicable to the JJ6HHDX helical head jointer)

To position t he kniv es for rabbet cuts, take a shop

scale with 1/32” graduations and place it against

the end of t he c utterhead. Sli de the knife out until it

is at the 1/32” m ark on the scale; t hat is, the knife

will now be 1/32” beyond the edge of the

cutterhead. The gib should remain in normal

position, even with the edge of the cutterhead.

(Figure 30). This adjustment will ensure that the

knife clears the end of t he gib and cutterhead, and

has good contact with the workpiece. (See the

Rabbeting section for further information.)

Note: This will also corr ect for small nicks without

requiring r eplac ement of knives.

Figure 30

20

Page 21

Rotating and Replacing Knife Inserts (JJ-6HHDX)

Knife inserts are dangerously

sharp. Use extreme caution when inspecting,

removing, or replacing knife inserts.

The knife inserts on the model JJ-6HHDX Jointer

are four-sided. When dull, simply remove each

insert, rot ate it 90° for a fresh edge, and r e-install

it. No further adjustment is necessary.

Use the two provided star point screwdrivers to

remove the knife insert screw. Use one of the

screwdrivers to help hold the cutterhead in

position, and the other to remove the screw. See

Figure 30a. It is advisable to rotate all insert s at the

same time to maintain consistent cutting. However,

if one or m ore knif e inserts dev elops a nick , rotat e

only those inserts t hat ar e aff ec ted.

Each knife insert has an etched r eferenc e mark so

you can keep track of the rotations.

IMPORTANT: When removing or rotating inserts,

clean saw dust fr om the screw, the insert, and the

cutterhead platform. Dust accumulation between

these element s can prev ent the i nsert f rom seati ng

properly, and may affect the quality of the cut.

Before installi ng each screw, l ightly coat the screw

threads with mac hine oil and wipe off any excess.

Figure 30a – HH models only

Figure 31

Securely ti ghten each screw which hol ds the knif e

inserts before oper ating the planer!

Make sure all knife insert

screws are tightened securely. Loose inserts

can be propell ed at high speed from a rotating

cutterhead , cau sin g inju ry.

Determining Correct Table Height

When you receive the jointer, the knives have

been pre-set at the factory. However, the height

and paralleli sm of t he kniv es with t he outf eed tabl e

should be checked, and any needed adjustments

made, before putting the jointer into operation.

The outfeed table and cutterhead knives are

correctly adjusted when all three blades are

parallel to the outfeed table and all three blades

are set at the same height in the cutterhead.

Outfeed table t oo high – If the outfeed tabl e is too

high, a curved finished surface results (Figure 31).

Outfeed table t oo low – If t he outfeed table i s too

low, the work will have a gouge, or snipe, at the

end of the cut (Figur e 32).

Outfeed table at correct setting – Figure 33

illustrat es the correct setting of outf eed table level

with the knives. T he workpiece will rest firmly on

Figure 32

Figure 33

both tables with no open space under the finished

cut

21

Page 22

Operating Controls

1. Hand Wheel for Outfeed Table

2. Outfeed Table

3. Fence

4. Fence Adjustment Handle

5. Cutter Guard

6. Infeed Table

7. Hand Wheel for Infeed Table

8. On/Off Switch

Operation

Important: Before operating the jointer, make

sure all kni ves or knife inserts are seated and

secure in the cutterhead.

If you are inexperienced at jointing, use scrap

pieces of lum ber to check settings and get t he feel

of operations befor e att em pting regular work.

Stabilize l ong workpieces by using an a ssistant, or

roller stands set level with the outfeed or infeed

table surface.

The fence should be adjusted to create minimum

exposure to the cutterhead during the jointing

operation.

9. Table Lock Knob

10. Fence Tilt Lock Handle

11. Belt Guard

12. Fence Travel Loc k Handl e

13. Depth Limiter

Check the following before operating the joint er:

Outfeed table must be set level with the high

point of the knives or k nif e inserts.

Fence adjusted for minimum exposure of

cutterhead, and loc k ed at desir ed angle.

The cutterhead guard must be in place and

operating properly (except when rabbeting) .

Infeed tabl e set for desi r ed depth of cut.

Stand away from the cutterhead and turn the

machine on f or a f ew moments. Listen f or any

odd noises, rubbings, vibrations, etc. Correct

such problem s before at tempting oper ations on

the jointer.

Carefully check your workpiece for knots, holes,

staples or any foreign material that might

damage kniv es or pose a risk of kic kback. Also

check the workpiec e for grain orientation.

22

Page 23

Hand Placement

Never pass hands d irectly over

the cutterhead .

At the start of the cut, the left hand holds the

workpiece fi rmly agai nst t he infeed t able and f ence

while the right hand pushes the workpiece in a

smooth, even motion toward the cutterhead

(Figure 34). After the cut is under way, the new

surface rests firmly on the outf eed table. The left

hand is transferred to the outfeed side and presses

down on this part of the workpiece, at the same

time maintaining flat contact with the fence. The

right hand presses the workpiece forward and

before the right hand reaches the cutterhead it

should be moved to the work on t he outf eed table.

Surfacing

Figure 34

Always use a hold down or

push block when surfaci ng stock.

Surfacing, or j ointing the f ace of stock, is shown i n

Figure 35. A djust the inf eed table for depth of cut.

Cuts of approximately 1/16” at a time are

recommended, as this allows better control over

the materi al being surf aced. More passes can then

be made to reach the desired dept h.

Edge Jointing

Edge Jointing (Figure 36) is the most common

operation f or the j ointer. S et fence square with the

table. Depth of cut shoul d be the minimum required

to obtain a straight edge. Do not make cut s deeper

than 1/8" in a single pass. Hold the best face of the

workpiece firmly against the fence throughout the

feed.

Figure 35

Figure 36

23

Page 24

Rabbeting

A rabbet is a groove cut al ong the edge of a board.

See Figure 37. The width and thickness of the

wood to be rabbeted depends upon t he width and

length of the rabbet. However, never rabbet a

piece of wood less than 12” l ong.

Note: The knives must be extended beyond the

cutterhead by 1/32”. See the Setting Knives for

Rabbeting and Nicks section on page 20 for this

procedure.

A rabbet cut requires removal

of the guard. Use extreme

caution and keep hands clear of cutterhead.

Always re-install guard immediately after

rabbeting operation is completed.

Use push blocks to rabbet cut whenev er possible.

The rabbeting capacity is 1/2”.

1. Disconnect jointer from power source.

2. Set fence for desir ed width of rabbet.

3. Check width of the rabbet by measuring the

distance from the end of a knife in the

cutterhead to the fence.

Figure 37

4. Re-connect power. It is easier and safer to

take a series of shal low cuts. Lower the i nfeed

table 1/32” at a time and make successive cuts

until the desired depth of rabbet has been

obtained. See Figure 37.

Jointing Short or Thin Work

When jointing short or thin work pieces, use a push

block to eliminate all danger to the hands. Two

push blocks are shipped wit h your joint er. You can

also make your own easily from scrap material.

Examples are shown in Fi gur e 38.

Jointing Warped Surfaces

If the wood to be jointed i s cupped or bowed, place

the concave si de down, and take li ght cuts until the

surface is flat.

Avoid forci ng such materi al down against the tabl e

– excessive pressure will spring it while passing

the knives, and it will spring back and remain

curved after the c ut is completed.

Figure 38

24

Page 25

Beveling

To cut a bevel, lock the fence at the required angle

and run the work piece across the knives while

keeping it firmly against the fence and tables.

Several passes m ay be necessary to achiev e the

desired result.

Although the fence may be

tilted in or out for a bevel cut, it is

recommended for safety reaso ns that the f ence

be tilted in toward the operator, making a

cradled cut.

Direction of Grain

Avoid feeding work into the jointer against the

grain. This may result in chipped and splintered

edges. See Figure 39. Feed with the grain to

obtain a smooth surfac e, as shown in Figure 40.

Maintenance

Blade Care

Figure 39

Blades are extremely sharp!

Use caution when cleaning or

changing. Failure to co mply may cau se serious

injury!

When gum and pitch collect on the blades,

carefully r emove with a strong solv ent. Failure t o

remove gum and pitch build up may result in

excessiv e fric ti on, blade wear and overheating.

When blades becom e dull, t ouch up blades. See

Sharpening the Knives. NOTE: This does not appl y

to the JJ-6CSDX or JJ-6HHDX models – knives or

inserts must be rotated or replaced on these.

Sharpening the Knives (JJ-6CSX only)

Blades are extremely sharp!

Use caution when handling.

Failure to compl y may cause seri ou s in ju ry!

1. Disconnect the machine from the power

source.

2. Remove the blade guar d and belt cover.

3. To protect the infeed table from scratches,

partiall y cover the sharpeni ng stone with paper

(Figure 41).

4. Lay the stone on the infeed t able.

5. Lower t he inf eed table and turn t he cutter head

by turning the cutterhead pulley. The infeed

table height is set properly when the stone's

surface is flush with the knife bevel.

Figure 40

Figure 41

6. Keep the cutterhead from rotating by grasping

the cutterhead pulley while sliding the stone

back and forth across the table.

7. Take the same amount of passes for all three

blades.

When the blades have been sharpened and still are

not cutting ef ficiently, trying t o touch up the blades

further will only cause the formation of a second

beveled edge. When t his start s to hap pen, i t i s tim e

to replace blades with another set. It is

recommended to keep a second set of blades on

hand so that they may be install ed while the fir st set

is being professional ly sharpened.

25

Page 26

Cutterhead Removal

The entire cutterhead assembly may be removed

for cleaning or f or bearing and bl ade replacement.

Some woodworkers keep a spare cutterhead with

replacement blades should the origi nal cutterhead

have to be repaired.

Blades in the cutterhead are

sharp! Use extreme caution

when handling the removal of the cutterhead.

Failure to compl y may cause seri ou s in ju ry!

To remove the cutterhead (including bearings,

studs, and housing) from the base casting:

Referring to Figur e 42:

1. Disconnect the machine from the power

source.

2. Remove the front blade guard (A) and

screw (H).

3. Remove the lock handle (B), washer (C) and

lock nut (D) securing the fence assembly (E) to

the table (F).

4. Lift the fenc e as s em bly (E) from the table.

5. From the left side of the stand, remove the

dust chute (G ). Fr om th e bac k of t he ma chi ne

remove the cabinet ac c es s cover (not shown).

Referring to Figur e 43:

6. Using an 8mm hex wrench, loosen two hex

cap screws underneath fenc e base casting (E)

that secure the casting to the table (F).

Remove the fence base casting and set aside.

7. Remove four screws and washers (A) securing

the belt guard (B). Remove the belt guard.

8. Remove the V-belt (C) from the cutterhead

pulley (D). If necessary, loosen the motor

mounting screws with a 12mm wrench to

provide slack on the V- belt.

9. Using a 3mm hex wrench, loosen two set

screws that secure the cutterhead pulley (D) to

the cutterhead shaf t. Set the pulley and shaft

key aside.

Figure 42

Figure 43

10. Using a 14mm wrench, remove two screws

(A, Fig. 44) and lock washers that secure the

cutterhead bearing housings to the base.

Note: These screws and lock washers are

more easily accessibl e through the dust chute.

11. Carefully remove the cutter head ( A , Fi g. 45).

12. Before placing the new cutterhead back into

the casting, t horoughly clean the "saddle" and

the bearing hou sings of saw dust and grease

so that they seat properly.

Figure 44

26

Page 27

13. T o re-install the cutt erhead, reverse the above

steps.

Note: Make sure that the fence base cast ing is

level with the Outf eed t able when securi ng.

Lubrication

Use a good grade of li ght grease on the steel

adjusting screws located in the raising and

lowering mechanisms of the work tables.

Occasionally, apply a few drops of light

machine oil to the infeed/outfeed gibs. This

permits the tabl es t o sli de freely.

The cutterhead bal l beari ngs are lif etim e lubri cat ed

and need no further care.

Figure 45

27

Page 28

Troubleshooting Operating Problems

Trouble Probable Cause Remedy

Finished stock i s

concave on back

end.

Finished stock i s

concave on front end.

Chip out.

Fuzzy grain.

Raise outfeed table until it aligns with

Knife is higher than outfeed table.

Outfeed table is higher than knife.

Cutting against t he gr ain. Cut with the grain whenever possible.

Dull knives or knife inserts.

Feeding workpiec e t oo fast. Use slower rate of feed.

Cutting too deepl y. Make shallower cuts.

Knots, imperfections in wood.

Wood has high moistur e c ontent.

Dull knives or knife inserts.

tip of knife. See Outfeed Table

Adjustment ( page 18) .

Lower outfeed table until it aligns with

tip of knife. See Outfeed Table

Adjustment ( page 18) .

Sharpen or replac e k niv es.

Rotate or replace knife inserts.

Inspect wood closely for imperfections;

use different stoc k if necessary.

Allow wood to dry or use diff er ent

stock.

Sharpen or replac e k niv es.

Rotate or replace knife inserts.

Cutterhead slows

while operati ng.

“Chatter” marks on

workpiece.

Uneven knife marks

on workpiece.

Feeding workpiec e too quickly, or

applying too much pressure to

workpiece.

Knives incor r ectly set.

Feeding workpiec e too fast.

Knives are nicked, or out of

alignm ent.

Feed more slowly, or appl y l ess

pressure to workpiece.

Set knives properl y as descri bed in the

Setting Cutt er head K niv es section.

Check that knif e slots are cl ean and

free of dust or debris.

Feed workpiece slowly and

consistently.

Align knives per the S ett ing Cutterhead

Knives secti on. Replace nicked knives

or correct for small nicks – see Setting

Knives for Rabbeting and Nic k s on

page 20.

28

Page 29

Troubleshooting Mechanical and Electrical Problems

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly t ri ps

circuit breaker or

blo ws fu se s.

No incoming power.

Building cir c uit break er trips or fuse

blows.

Switch or motor f ailur e ( how to

distinguish).

Motor overheat ed.

Verify unit is connected to power, onbutton is pushed in com plet ely , and

stop-button is di sengaged.

Verify that joi nter is on a circuit of

correct size. If circuit size is correct,

there is probably a loose el ectrical

lead. Check amp setting on motor

starter.

If you have access to a voltmeter, you

can separate a switch f ailure from a

motor failure by first, verifying

incoming volt age at 110/220+/-10%

and second, checking t he v oltage

between switch and motor at

110/220+/-10%. If incoming voltage is

incorrect, y ou hav e a power supply

problem. If voltage between switch

and motor is incorr ec t, y ou hav e a

switch probl em. If v oltage between

switch and motor i s corr ect, you have

a motor problem.

Clean motor of dust or debris t o allow

proper air circulation. Allow motor to

cool down before r estar ting.

Motor failure.

Unit incorrectly wired.

On/off switch failure.

Optional Accessories

708801 .............Knives for Model JJ-6CSX Jointer (set of 3)

708801DX ........Knives for Model JJ-6CSDX Jointer (set of 3)

708815 .............Push Block

1791212 ...........Knife Inserts for Model JJ-6HHDX (set of 10)

If electric motor is suspect, you have

two options: Have a qualified

electrician test the motor for function

or remove the motor and take it t o a

qualified elec tric motor repair shop

and have it tested.

Double check to confirm all electrical

connections are corr ec t. Refer to the

Wiring Diagram section to make any

needed correcti ons.

If the on/off switch is suspect, you

have two options: Hav e a qualified

electrician test the switch for function,

or purchase a new on/off switc h and

establish if that was the pr oblem on

change out.

29

Page 30

Parts

Ordering Replacement Parts

To order parts or reac h our service department, call 1-800-274-6848, Monday through F riday (see our

website for business hours: www.jetttols.com). Having the Model Number and Serial Number of your

machine avail able when you call will allow us to serve you quickly and ac c ur ately.

Fence – Parts All Models

Index No. Part No. Description Size Qty.

................. JEJ-FW ....................Fence Assembly Complete (JJ-6CSX) ................................................... 1

................. JJ6CSDX -FAC .........Fence Assembly Complete (JJ-6C SDX)................................................. 1

1 ............... JEJ-F01W ................Fence Body (JJ-6CSX) .......................................................................... 1

1A ............ JJ6CSDX-2 01 ..........Fence Body (JJ -6CSDX)........................................................................ 1

2 ............... JEJ-F14 ...................Fence Link............................................................................................. 2

3 ............... JEJ-F02W ................Tilt Plate (JJ-6CSX) ............................................................................... 1

................. JJ6CSDX -203 ..........Tilt Plate (JJ-6CSDX)............................................................................. 1

4 ............... JED-F16 ..................Threaded Stud....................................................................................... 4

5 ............... TS-0561031 .............Hex Nut ..............................................................3/8”-16........................ 4

6 ............... JEB-F09...................Handle................................................................................................... 1

7 ............... 5DF-I09 ....................Knob ..................................................................................................... 1

8 ............... 5CH-F1 3A ................Flat Head Socket Screw (JJ-6CSX) ....................5/16”x1-5/8” ................ 2

8A ............ TS-0207041 .............Socket Head Cap Screw (JJ-6CSDX) .................1/4”-20x3/4” ................ 2

9 ............... JED-F02 ..................Block (JJ-6CSX) .................................................................................... 1

9A ........... PJ882-142 ...............Fixed Block (JJ-6CSDX) ........................................................................ 1

10 ............. JEJ-F03 ...................Block ..................................................................................................... 1

11 ............. JEJ-F04 ...................Bolt........................................................................................................ 1

12 ............. TS-0561041 .............Hex Nut ..............................................................7/16”-14 ...................... 1

13 ............. JEJ-F05 ...................Stud ...................................................................................................... 1

14 ............. JEJ-F06 ...................Swivel Block .......................................................................................... 1

15 ............. JEJ-F07 ...................Plate ...................................................................................................... 1

16 ............. 5FF-J12 ...................Spring Pin...........................................................Ø4x12 ........................ 1

17 ............. JEJ-F08 ...................Hex Cap Bolt ......................................................................

18 ............. JEJ-F09 ...................Plate ...................................................................................................... 1

19 ............. TS-0561072 .............Hex Nut ..............................................................5/8”-18UNF ................ 2

20 ............. JEJ-F10 ...................Bushing ................................................................................................. 1

21 ............. JEJ-F11W ................Fence Bracket (JJ-6CSX ) ...................................................................... 1

................ JJ6CSDX-221 ..........Fen ce Bracket (JJ-6CSDX) .................................................................... 1

22 ............. TS-0680061 .............Flat Wash er ........................................................1/2”............................. 3

23 ............. JEJ-F12 ...................Lock Handle .......................................................................................... 2

24 ............. JED-F17 .................Lock Nut ................................................................................................ 1

25 ............. TS-0051051 .............Hex Cap Screw ..................................................5/16”-18x1” ................. 1

26 ............. TS-0561021 .............Hex Nut ..............................................................5/16”-18 ...................... 2

27 ............. TS-0051081 .............Hex Cap Screw ..................................................5/16”-18x1-3/4” ........... 1

28 ............. JED-F03 ..................Plate ...................................................................................................... 1

29 ............. TS-0813032 .............Screw .................................................................1/4”-20x1/2” ................ 2

30 ............. TS-0680021 .............Flat Washer (JJ-6CSX) .......................................1/4”............................. 2

................. TS-0680021 .............Flat Washe r (JJ-6CSDX) ....................................1/4”............................. 4

31 ............. TS-0561052 .............Hex Nut ..............................................................1/2”-20UNF ................ 2

32 ............. PJ882-144 ...............Pad Block (JJ-6CSDX) .......................................................................... 1

33 ............. TS-069204 ...............Flat Washer (JJ-6CSDX) ....................................#10 ............................. 2

34 ............. TS-0206021 .............Socket Head Cap Screw (JJ-6CSDX) .................#10-24x1/2” ................ 2

................... 1

30

Page 31

Fence – Assembly All Models

31

Page 32

Stand – Parts, JJ-6CSX and JJ-6CSDX

Index No. Part No. Description Size Qty.

1 ............... JI-Y01 W ...................Stand Body ............................................................................................ 1

2 ............... JI-Y01AW ................Access Cover ........................................................................................ 1

7 ............... TS-0267041 .............Set Screw ...........................................................1/4”-20x3/8” ................ 2

8 ............... JH-M10 ....................Motor Pulley (JJ-6CSX) ............................................................. ............ 1

................. 6296125...................Motor Pulley (JJ-6CSDX) ....................................................................... 1

9 ............... VB-A36 ....................V-Belt (JJ-6CSX) ................................................A-36 ........................... 1

................. VB-A37 ....................V-Belt (JJ-6CSDX) ..............................................A-37 ........................... 1

10 ............. JC-M07 ....................Lock Bolt* ...........................................................3/8”-16........................ 3

11 ............. TS-0720091 .............Lock Washer* .....................................................3/8”............................. 3

12 ............. TS-0680031 .............Flat Wash er ........................................................5/16” ........................... 4