Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Oscillating Edge Sander

Model: OES-80CS

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-708447

Ph.: 800-274-6848 Revision C 03/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide pro of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa t io n

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tat e Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Introduction ............................................................................................................................................. 6

Specifica tions ................................................................................................................ .......................... 6

Unpac king ............................................................................................................................................... 7

Shipping Contents ................................................................................................................................ 7

Tools Needed for Assembly ................................................................................................................. 7

Assembly ................................................................................................................................................ 8

Stand Assembly ................................................................................................................................... 8

Installing Table and Motor Unit to Stand ............................................................................................... 8

Sanding Belt Installation ....................................................................................................................... 9

Drum Guard & Dust Port .................................................................................................................... 10

Extension Table ................................................................................................................................. 10

Electrical ............................................................................................................................................... 1 1

Grounding Inst r uc tions ....................................................................................................................... 11

115 Volt Operati on ............................................................................................................................. 11

230 Volt Operati on ............................................................................................................................. 11

Adjustments .......................................................................................................................................... 12

Sanding Platen Angle Adjustment ...................................................................................................... 12

Platen Lock Tension Adjustment ........................................................................................................ 12

Changing the Sandi ng B el t ................................................................................................................. 13

Belt Track in g Ad ju stment ...................................................................................................... ............. 1 3

Motor Mount Trac ki ng A djustm ent ...................................................................................................... 14

Table Adjustment ............................................................................................................................... 14

Basic Operations ................................................................................................................................... 15

Horizontal Sanding ............................................................................................................................. 15

Vertical Sandi ng ................................................................................................................................. 15

Contour Sanding ................................................................................................................................ 16

Troubleshooting Operating Pr oblem s ..................................................................................................... 17

Parts ..................................................................................................................................................... 17

Ordering Replacement Parts .............................................................................................................. 17

Table and Motor – Assembly .............................................................................................................. 18

Table and Motor – Parts ..................................................................................................................... 19

Idle Drum – Assembly ........................................................................................................................ 21

Idle Drum – Parts ............................................................................................................................... 22

Stand Assembly ................................................................................................................................. 23

Wiring Diagram ...................................................................................................................................... 24

The specifi cati ons in this m anual are giv en as general i nform ation and are not bi nding. J ET reserv es the

right to eff ect, at any tim e and wit hout pri or notic e, changes or alt erat ions to par ts, fi tti ngs, and accessory

equipment deemed nec essary for any reason whatsoever.

3

Page 4

Warnings

1. Read and understand the ent ire owner's manual before attempting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This Oscillati ng Edge Sander is designed and i ntended f or use by properly t rained and experi enced

personnel only . If you are not f amiliar with the proper and saf e operation of an edge sander, do not

use until proper training and knowledge have been obtained.

5. Do not use this mac hine for other than its intended use. If used for other purposes, JET disclaim s any

real or implied warranty and holds itself harmless f r om any injur y that m ay result from that use.

6. Always wear approved safety glasses/face shields while using this Oscillating Edge Sander.

Everyday eyeglasses only have impact resistant lenses; they are not safety glasses.

7. Bef ore operating t his edge sander, remov e tie, ri ngs, watches and ot her je welry, and r oll sl eeves up

past the elbows. Rem ove all loose cl othing and confi ne long hair. Non-sl ip foot wear or anti-ski d floor

strips are recommended. Do not wear glov es.

8. Wear ear protector s (plugs or muffs) during extended periods of operati on.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lum ber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any m edic ation.

11. Make certain t he switc h is i n the OFF position before connect ing the machine to the power source.

12. Make certain t he machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Form a habit of c hecking to see that all extra equipment such as adjusting keys, wrenche s, scrap,

stock, and cl eaning r ags are rem oved away from the machine before turning on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replac e the guards immediately when maintenance is complete.

16. Make sure the edge sander is fi rmly secured to the floor before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. Provide f or adequate space surrounding work area and non- glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap mater ial, oil and grease.

4

Page 5

20. Keep visit or s a safe di stanc e from the work area. Keep children away.

21. Make your workshop chil d pr oof with padlocks, master switc hes or by removing starter k ey s.

22. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

23. Maintain a balanced stance at all tim es so that y ou do not fall or lean against the sanding bel t or other

moving part s. Do not over r eac h or use excessive force to perform any m ac hine operation.

24. Use the ri ght t ool at the c orrect speed and f eed rate. Do not f orce a t ool or attachm ent to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maintain mac hiner y with care. Follow instructions for lubricating and changing accessories.

27. Tur n off the m achi ne bef ore cleani ng. Use a brush or c om pressed air t o rem ov e dust or debr is — do

not use your hands.

28. Do not stand on the machine. S eri ous i njur y c oul d oc c ur if the mac hine tips over.

29. Never leave t he m ac hine r unning unattended. Turn the power off and do not l eav e the machine until it

comes to a complete stop.

30. At all times hold the stock firmly.

31. Do not use t his sander f or other t han it int ended use. If used for ot her purposes, JE T discl aims any

real or implied warranty and holds itsel f harmless for any injury or damage which may r esul t from that

use.

Familiariz e y our self with the following saf ety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precauti ons are not heeded, it may result in serious injury or possibly

even death.

5

Page 6

Introduction

This manual is provided by JET covering the safe operation and maintenance procedures for a JET

Model OES-80CS Sander. This manual contains instructi ons on installation, safety precauti ons, general

operating proc edures, maintenance i nstructions and part s breakdown. This m achine has been designed

and constructed to pr ovi de years of troubl e free operation if used in accor dance wit h instructi ons set fort h

in this m anual. If there are any questi ons or com ments, please contact either y our local supplier or JET.

JET can also be reached at our web site: www.jettool s.com.

Specifications

Model ....................................................................................................................................... OES-80CS

Stock Number................................................................................................................................ 708447

Fence (HxL)(in.) ............................................................................................................................... 4 x 24

Abrasive Belt Size (WxL)(in.) ............................................................................................................ 6 x 89

Dust Chute Diameter (in.) ........................................................................................................................ 4

Extension Table Size (in.) ..................................................................................................... 9-7/8 x 11-7/8

Table Size (LxW)(in.) ........................................................................................................................ 32 x 7

Table Tilt (deg.) ..................................................................................................................................... 9 0

Motor ....................................................... TEFC 1-1/2 HP, 1 PH, 115/230V (prewired 115V), 18/ 9 A, 60Hz

Belt Speed (SPFM) ........................................................................................................................... 3,900

Oscillation Stroke (in.) ........................................................................................................................... 1/2

Oscillations per Minute ........................................................................................................................ 108

Overall Dimensions (LxWxH)(in.) ......................................................................................... 51 x 26.5 x 44

Net Weight, approximate (lbs.) ............................................................................................................. 258

Shipping Weight , approximate (lbs.)..................................................................................................... 275

The above specifications were current at the time this manual was published, but bec ause of our policy of

continuous impr ovement, JET reserves the ri ght to change specifications at any tim e and without pri or

notice, without incurring obligations.

6

Page 7

Unpacking

Upon deliv ery, open shi pping c ontai ners and c heck

that all parts are in good condition. Any damage

should be reported to y our distribut or and shipping

agent immedi ately. Bef ore proceeding f urther, read

your manual and familiarize yourself thoroughly

with assembly, maintenance and safety

procedures.

Compare the contents of your container with the

following part s list to make sure all parts are intact.

Missing parts, if any, should be reported to your

distribut or. Read the instruction manual thoroughly

for assembly, maintenance and safety instructions.

Shipping Contents

01 Front Panel with Door (Stand)

01 Rear Panel (Stand)

02 Side Panel (Stand)

01 Shelf

02 M5x10 Screw

02 M5 Flat Washer

02 M5 Lock Washer

01 Extension Table Assembly

01 Drum Guard & Dust Port

01 Owner’s Manual

01 Warranty Card

01 Table and Motor Unit

01 Back Stop Bracket

01 Belt Tension Handle

01 Belt Tracking Tool

01 Miter Gauge Assembly

01 Sanding Belt

Cabinet Hardware

01 Lock Knob (20mm Length)

02 Lock Knob (12mm Length)

01 Lock Knob (35mm Length)

04 Cabinet Pads

04 5/16” x 5/8” Screws

22 5/16” Flat Washers

12 5/16” Hex Nuts

08 5/16” x 5/8” Hex Cap Bolts

02 5/16” x 1-1/4” Hex Cap Bolts

04 Larger O/D 5/16” Flat Washers

10 5/16” Lock Washers

Extension Table Hardware

05 1/4" x 5/8” Hex Cap Bolts

05 1/4" Flat Washers

05 1/4” Lock Washers

01 Bracket

02 10-24x3/4 Socket Head Cap Screws

Dust Chute Hardware

03 Pan Head Screws

Tools Needed for Assembly

2 12mm Wrench or sockets

1 10mm Wrench or sockets

1 Flat Head Screw Driver

1 Cross Point Screw Driver

7

Page 8

Assembly

Stand Assembly

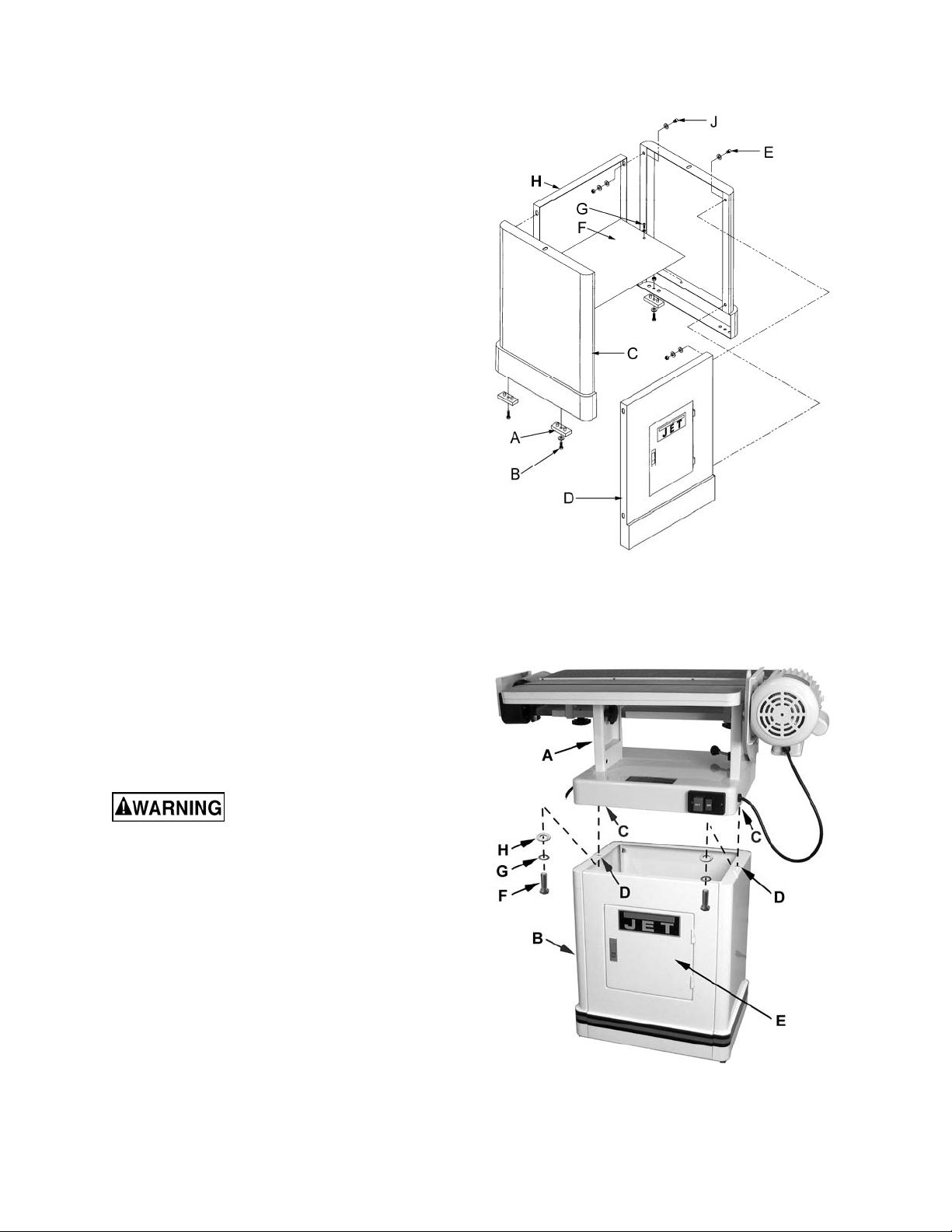

Referring to Fi gur e 1:

1. Remove all contents from the shipping

container.

2. Clean all rust protected surfaces with a mild

solvent. Do not use paint or lacquer thinner,

gasoline, or mineral spirits; these will damage

painted surfaces.

3. Attach the four rubber pads (A) to the bottoms

of the side panels (C) with four each

5/16” x 5/8” screws, 5/16” flat washers and

5/16” hex nut s (B). The hardware can be found

in the bag with the rubber pads.

4. Attach the side panels (C) to the front panel (D)

with four 5/16” x 5/8” hex cap screws, eight

5/16” flat washers, four 5/16” lock washers, and

four 5/16” hex nuts (E). Hand tighten the

hardware at this point.

Note: Assemble the stand upside down to

make sure that the tops of t he panels are flush.

5. Mount the shelf (F) to the inside of the stand

with two M5x10 pan head screws, two M5 flat

washers and two M5 lock washers (G).

Figure 1

6. Finish the stand a s sembly by attac hing the rear

panel (H) to side panels (C) with four

5/16” x 5/8” hex cap screws, eight 5/16” flat

washers, four 5/16” lock washers, and four

5/16” hex nut s (J).

7. Make sure stand is sitting evenly on a level

surface befor e tightening hardware.

Installing Table and Motor Unit to Stand

The Table and Motor Unit is

heavy! Use great care and adequ ate resources

when lifting the unit up onto the stand! Failure

to comply may cause serious injury and/or

damage to the sander and/or property!

Referring to Fi gur e 2:

1. With t he aid of another person, caref ully lif t the

table and motor unit (A) out of the shipping

box, and up onto the stand (B).

2. Li ne up threaded hol es i n the base (C) with the

holes in the stand (D).

3. Open the cabinet door (E) and through the

opening attach main unit to stand with two

5/16” x 1-1/4” hex cap screws (F), two 5/16”

lock washers (G) and two 5/16” flat

washers (H). Tight en with a 12mm wrench.

Figure 2

8

Page 9

Referring to Fi gur e 3:

4. The sanding platen (A) is presently in the

horizontal positi on. Pull lock handle (B) forward

to unlock the plat en assembly.

5. Tilt sanding platen to the vertical position (C),

which will look like D in Fig. 4; then push the

lock handle (B) to loc k the platen assembly in

place.

Note: Do not turn the l ock handle. Turning or

rotating the lock handl e will change the tension

of the locking assembly. This may cause the

locking assembly not to work, making it

necessary for adjustment before using the

machine.

Figure 3

Sanding Belt Installation

Referring to Fi gur e 5:

1. From the rear of the sander, remove the belt

guard (A) by unscrewing two lock knobs (B).

Take out the sanding belt and r emovable f ence

from behind the belt guar d.

2. Place the handle (C) on belt tensioning

lever (D). Remove the tension from the

mechanism by moving the handle (C) to the

Loose position.

3. Place belt on both roll ers so that the edge of

the belt is even wit h the edge of the rollers.

Note: Make sure that direction arrow on belt

matches the direction indicator on the top of

the platten.

4. Tighten the belt by moving the tension arm

handle (C) to the Tight po sit ion. Rot ate the bel t

by hand in the di rection indicated by t he arrow

on top of t he platten. If the bel t tracking needs

adjustment, see Belt Tracking Adjustment on

page 13.

Figure 4

Figure 5

9

Page 10

Drum Guard & Dust Port

Referring to Fi gur e 6:

Mounting the Drum G uard & Dust Port (referred to

below as drum guard)

1. Insert f our M4x20 f lat head screws (A) t hrough

the two hinges (B) of the drum guard (C). T hen

place two rectangular spacers (D) on the

threaded ends of t he screws.

Note: Orient the spacers so the slightly

rounded side sits against the hinge and the

edge farther f rom the screws lines up with the

edge of the hinge.

2. Secure the drum guard (A) to the belt guard on

the rear side of the sander by threading the

screws through the mounting holes (E) in the

belt guard. Tighten the screws.

Mounting the Connect ion P late

3. Place the drum guard (C) in the cl osed positi on

– this will cover t he dr iv e drum (J).

Note: You may have to slightly lift the cover

when closing i n order to clear the motor case.

This is normal.

4. Place washers (G) on two smal l lock knobs (H)

and then insert the threaded end of one lock

knob through the slot of the connection

plate (F) and the other lock knob through the

hole of the connect ion plate.

Figure 6

5. Secure the slotted side of the extension plate

to the drum guard (C) and the side with the

hole to the belt guard (E).

When repositi oning the dr um guard, sli ghtly l oosen

both lock knobs, open or close the cover, then

secure the lock k nobs.

Extension Table

Referring to Fi gur e 7:

1. Attach the bracket (E) for the extension t able to

the side of the motor housing (D) and secure

with two socket head cap screws (F).

2. Slide the shaft of the extension table (C) into

the bracket (E), positioning the table so the

opening (B) wraps around the drive dr um (A).

3. Insert lock knob (G) into the threaded hol e on

the side of t he bracket (E) v isibl e from t he rear

of the sander.

Figure 7

10

Page 11

Electrical

Grounding Instructions

This sander must be

grounded while in use to

protect the operat or from electric shock.

The temporary adapter should only be u sed until

a properly grounded outl et can be instal led by a

qualified electrician. This adapter is not

applicable in Canada. The green colored rigi d

ear, lug, or tab, extending from the adapter,

must be connect ed to a permanent ground such

as a properly grounded outlet box.

In the event of a malfunction or breakdown,

grounding prov i des a path of least resistanc e f or

electric current to reduce the risk of electric

shock. This tool is equipped with an electric

cord having an equipment-grounding conductor

and a grounding plug. The plug must be

plugged into a matching outlet that is properly

installed and grounded in accordance with all

local codes and ordinanc es.

Do not modify the plug provided. If it will not fi t

the outlet , have the proper outlet i nstalled by a

qualified el ectrician. Improper connecti on of the

equipment-grounding conductor can result in a

risk of electric shock. The conductor, with

insulati on having an outer surf ace that is green

with or without y ellow stripes, is the equipment grounding conduct or. If repai r or replac ement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool i s proper ly grounded. U se onl y

three wire ex tension cords that have thr ee- pr ong

grounding plugs and t hree-pole recept acles that

accept the tool ’s pl ug.

Repair or replace a damaged or worn cord

immediately.

230 Volt Operation

Referring to Fi gur e 9:

If 230V, single-phase operation is desired, the

following inst r uc tions must be followed:

1. Disconnect the machine from the power

source.

2. The JET O sci llati ng Edge Sander m ot or has

four numbered leads that are factory

connected f or 115V operation, as sho wn in

(A). For 230V operation reconnec t the l eads

as shown in (B).

3. The 115V att achment pl ug (C) supplied wit h

the Oscillating Edge Sander must be

replaced with a UL/ CSA listed plug sui table

for 230V operation (D). Contact your local

Authorized JET Service Center or qualified

electrician for proper procedures to install

the plug. T he Oscill ating E dge Sander must

comply wit h all loc al and national codes after

the 230-volt plug is installed.

4. The Oscil lating E dge Sander with a 230-v olt

plug should only be connected to an outlet

having the same configuration as shown in

(D). No adapter is available nor should be

used with the 230-volt plug.

115 Volt Operation

Referring to Fi gur e 8:

As received from the factory, your Oscillating

Edge Sander is ready to run at 115-volt

operation. This Oscillating Edge Sander, when

wired for 115 volt, is i ntended for use on a circuit

that has an outlet and a pl ug that looks like the

one illustrated in (A). A temporary adapter,

which looks li ke the adapter shown in (B), may

be used to connect this plug to a two-pole

receptacle if a properly grounded outlet is not

available.

Figure 8

Figure 9

11

Page 12

Extension Cords

Make sure your extension cord is in good

condition. When using an ex tension cord, be sure

to use one heav y enough to car ry the curr ent your

machine will draw. An undersized cord will cause

a drop in the line voltage resulting in power loss

and overheati ng. Table 1 sho ws the cor rect si ze t o

use depending on t he cord length and namepl ate

ampere rating. If in doubt, use the next heavier

gauge. Remember, the sm aller the gauge number,

the heavier the cor d.

Recommended Extension Cord Gauges

Extension Cord Length in Feet *

Amps

25 50 75 100 150 200

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

Adjustments

Sanding Platen Angle Adjustment

Referring to Fi gur e 10:

1. Disconnect the machine from the power

source.

2. Pull the lock handle (B) forward (unlock) to

release tension.

Move the sanding platen (A) to the desired

position. Use a combination square between

the table and sanding platen to get precise

angles.

3. Hold the platen (A) while locking the handle.

Platen Lock Tension Adjustment

*based on li miting th e lin e voltag e drop to 5V at 150% of th e

rated amp eres.

NR: Not Recommended.

Table 1

Figure 10

1. Disconnect the machine from the power

source.

2. Loosen (unlock) the handle (B, Fig. 10) and

place the platen in the horizontal position as

shown in (A, Fig. 10). Do not loc k.

3. Tensi on eccent ric bl ock by tighteni ng the nyl on

nut (B, Fi g. 11) with a 14mm wrench. Turn t he

nut in by 1/4 t urn increments and test locki ng

handle for proper tension.

The lock handle is properl y tensioned when it

requires positive force to move the eccentric

block (at tached to the locki ng handle) from one

side to the other. The platen and motor

assembly must stay in a locked position

without sliding once the handle has been

moved to the locked position. Re-adjust as

necessary.

Figure 11

12

Page 13

Changing the Sanding Belt

Referring to Fi gur e 12:

1. Disconnect the machine from the power

source.

2. Lock the sandi ng platen i n the v ertical posit ion

(see the Sanding Platen Angle Adjustment

section on page 12).

3. Release tension on the belt by loosening the

handle (C).

4. Loosen or remove the lock knobs (B) and

remove the belt guar d (A).

5. Remove the old belt and install the new belt

matching the direction of the arrows on the belt

with the arrow label on t he top of the platen.

6. Line up edge of belt with edge of r oller s.

7. Place tension on the belt by moving the

tension arm handle (C) to the Tight position.

8. Reinstall the belt guard (A) and tighten t he lock

handles (B)

Note: Belts stretch with wear. When a belt is

replaced, y ou m ay have to adj ust trac king.

Belt Tracking Adjustment

The B elt Tracking Adjustment is a f ine adj ustment

procedure. The M otor Mount Tracking Adjustment

(following section) is a course adjustm ent.

Figure 12

To adjust the belt t r acking:

1. Disconnect the machine from the power

source.

2. Push the belt by hand from left to right (the

direction indicated top of the platen) and

observe the bel t’s position on the rol lers. The

oscillating movement of the belt is by design.

Observe the belt 's range of m ovement from it s

highest to lowest position. The edges of the

belt should not have a tendency to move

above or below the edges of the rollers.

If adjustm ent is still nec essary :

3. Insert t he round shaft of t he belt tracking tool

(provided) into the micro adjust lock nut (A)

and turn away from you to loosen.

4. Turn the micr o adjusting screw (B) i n 1/4 turn

increments until the belt tracks evenly on the

roller s when rotated by hand.

Tip: Moving the belt tracking tool away from

you raises the belt on the drum and towards

you lowers the belt on the drum.

5. Tighten the mic r o adjusting nut (A).

Figure 13

6. Connect the machine to power.

7. Turn on the po wer to the m achine and ob serv e

the belt’s up and down range of m ov em ent.

Adjustment is correct when the edges of the

belt do not m ove above or below the edge s of

the rollers.

8. W hen adjustm ent is com plete, ti ghten t he micro

adjust lock nut (A).

If the tracki ng cannot be corrected go to the Motor

Mount Track ing Adjust m ent section (next page).

13

Page 14

Motor Mount Tracking Adjustment

Referring to Fi gur e 14:

The OES-80CS comes with tracking adjustment

bolts (A) on t he motor pl ate. These are set at t he

factory and should not require any further

adjustment. If, howev er, you are not abl e to track

the belt with the Belt Tracking Adjustment

described in t he prev i ous section, the m ot or mount

bolts will have to be adjusted.

Note: The Motor Mount Tracking Adjustment is a

course adjustment. Use the Belt Tracking

Adjustment first for fine adjustment. If it cannot be

adjusted, then use the procedure described below.

To adjust:

1. Disconnect the machine from the power

source.

2. Slightly loosen the four motor mount nuts (B)

just enough so the tracking screws (A) can be

turned to make an adjustm ent.

3. Loosen the two locking hex nuts (C) that

secure the tracking screws (A).

4. Turn one screw (A) a 1/4 turn and rotate the

sanding belt by hand to observe which

direction t he adjustment i s causing the belt t o

move. If it is trav eling i n the direction needed

to correctl y tr ac k the belt go t o st ep 6.

5. If the bel t starts to tr avel in t he wrong di r ec tion,

back off a quarter turn and tighten the other

screw a quar ter tur n. Thi s should start t he belt

moving in the proper direction.

6. Tighten both loc king nut s (C) and m otor m ount

nuts (B). Then return to the Belt Tracking

Adjustment sect ion (previous page) and again

attempt to fine tune the tracking.

Figure 14

Table Adjustment

Do not position table below

sanding belt! Keep an overlap of at least 1/16”

between table and sanding belt to avoid

material and/or fingers getting caught! Failure

to comply may cause seriou s injury!

1. Loosen two lock knobs (A, Fig. 15).

2. Raise or lower work table to desired level.

3. Tighten two lock knobs.

Figure 15

14

Page 15

Basic Operations

Removing the belt guard

exposes more o f the sandi ng bel t! Repl ace th e

belt guards immediately after completing any

sanding that requires its removal! Failure to

comply may cause seriou s injury!

Horizontal Sanding

For hor izontal sanding, the platen is locked in the

horizontal posi tion as shown (F) and the removable

fence (D) is secured to the table (E) as follows.

Referring to Fi gur e 16:

1. Place 5/16 flat was hers ( not shown) and guide

blocks (B) on two 12mm lock knobs (A) – Note:

the 12mm refers to the threaded shaft length.

2. Insert the guide blocks (B) into the miter slot

(C) and position the lock knobs (G) on the

table (E) as shown.

3. Place the removable fence (D) on the table

and secure by tightening the lock knobs

(G, Fig. 16 and Figure 17).

Figure 16

The backstop (H, Fig. 17) can also be used by

swiveling the drum guard & dust port (J, Fig. 17)

out of the way and plac ing the backstop pi n in the

positioni ng hol e and securing in plac e with t he lock

knob (K, Fig. 17) and 5/16" flat washer . Note: This

is better shown in Figure 18. The drum guard &

dust port (J, Fig. 17) can then be returned to the

position shown.

Vertical Sanding

Referring to Fi gur e 18:

For vertical sanding, the platen (G) is locked in the

vertical position as shown and the backstop (H)

and/or the mit er gauge (B) m ay be used.

Miter Gauge

1. Slide the guide bar ( D) of the miter gauge (A)

into the miter slot (C) on the table.

Figure 17

2. Set the miter angle; then secure the mi ter by

tightening the lock handle (B).

Backstop

Place the back stop pin in the po sitioni ng hole and

secure in place with the lock knob (E) and 5/16"

flat washer (F).

Figure 18

15

Page 16

Contour Sanding

Referring to Fi gur e 19:

Contour sanding is done f rom the extension table

mounted on the motor where the sanding belt

wraps around the drive drum (D). To set up the

sander for cont our sandi ng:

1. Loosen the t wo lock knobs (C) that secure the

drum guard & dust port (E).

2. Swing the end guard (E) back, bringing the

drive drum (D) into view.

3. Tighten the loc k k nobs (C).

4. Mount the extens ion t able (A) to the sander by

inserting the post (B) into the bracket (F).

5. Set the table to the desir ed height, then secure

into positi on by tightening the lock knob (G).

Important: When the extension t able (B) is not in

use, the drum guard & dust port (E) should always

be in the closed posi tion so the drive drum (D) is

not in view.

Figure 19

16

Page 17

Troubleshooting Operating Problems

Trouble Possible Cause Solution

Sander will not star t

Sanding belt does

not come up to speed

Machine vibrates

excessively

Abrasive belt keeps

tearing

Sanded edge not

square

1. Sander unplugged from

wall or motor

2. Fuse blown or circuit

breaker tripped

3. Cord damaged

1. Extension cord too light

or too long

2. Motor not wired for

proper voltage

3. Low current

1. Stand on uneven floor

2. Motor mounts are loose

3. Tension spring i s worn

or broken

1. Belt is runni ng in the

wrong directi on

1. Table not square to

sanding platen

1. Check all plug connections

2. Replace fuse or reset circuit breaker

3. Replace cord

1. Replace with adequat e si z e and length

cord (see Recommended Extension

Cord Gauges on page 12)

2. Refer to motor junction cover for proper

wiring

3. Contact a qualified electrician

1. Adjust stand so that it r ests evenly on the

floor

2. Tighten motor mount bolts

3. Replace spring

1. Arrow on the sanding belt and m ac hine

should be pointing in the same direction.

1. Use a square to adjust table to sanding

platen

Sanding marks on

wood

1. Wrong grit sanding belt

2. Feed pressure too great

3. Sanding against the

grain

1. Use coarser grit for stoc k removal and

fine grit for finish sanding.

2. Never force work i nto sanding platen

3. Sand with the grain

Parts

Ordering Replacement Parts

To order parts or reach our service department, call 1-800-274-6848 Monday through Friday (see our

website for business hours, www.jettools.com). Having the Model Number and Serial Number of your

machine available when you call will allow us to serve you quickly and accurately.

17

Page 18

Table and Motor – Assembly

18

Page 19

Table and Motor – Parts

Index No. P art No. Descri ption Size Qty.

1 ............... EHVS80 CS-01 .........Ba se ...................................................................................................... 1

2 ............... EHVS80-02N ...........Push Button Switch ............................................................................... 1

3 ............... EHVS80 -03N ...........Switch Panel ......................................................................................... 1

4 ............... TS-081C082 ............Pan Head Screw ................................................#10-24×1-1/2” ............. 3

5 ............... EH VS8 0-0 2B ...........Sw itch Box .............................................................................. .............. 1

6 ............... TS-0560071 .............Hex Nut ..............................................................#10-24 ........................ 5

7 ............... EHVS80 -07 ..............Strain Relie f ........................................................................................... 2

8 ............... EHVS80-08 ..............Work Tab le Ba r ..................................................................................... 1

9 ............... EHVS80-09A ...........Nylon Insert Lock Nut .........................................3/8”-24........................ 1

10 ............. EHVS80-10 ..............Locking Block ........................................................................................ 1

11 ............. EHVS80-11 ..............Spring Pin...........................................................∅4 .............................. 1

12 ............. EHVS80-12 ..............Lock Handle .......................................................... ................................ 1

13 ............. 10102023A ..............Knob ..................................................................................................... 1

................. EHVS80 -12A ...........Lock Handle Assembly

14 ............. S0430525 ................Key.....................................................................5×5×25 ....................... 1

15 ............. TS-0050031 .............Hex Cap Screw ..................................................1 /4 ” -2 0 ×3 /4 ”................ 1

16 ............. TS-0680021 .............Flat Washe r ........................................................1/4”............................. 5

17 ............. EHVS80-17 ..............Table ..................................................................................................... 1

18 ............. EHVS80 -18 .............Screw .................................................................M10 ............................ 2

19 ............. TS-1540071 .............Hex Nut ..............................................................M10 ............................ 2

20 ............. EHVS80-20 ..............Guide Block ........................................................................................... 2

21 ............. EHVS80-21 ..............Fence .................................................................................................... 1

22 ............. EHVS80-22A ...........JET Knob ...........................................................M8×12 mm .................. 3

23 ............. OES80CS-23 ...........D rive Drum (

serial no. 05110394 and higher) .............................................. 1

24 ............. EHVS80-24 ..............Guide Bar .............................................................................................. 1

25 ............. S0310306 ................Pin......................................................................∅3 .............................. 1

26 ............. TS-0267021 .............Set Screw ...........................................................1/4”-20×1/4”................ 1

27 ............. EHVS80-27 ..............Location Plate........................................................................................ 1

28 ............. EHVS80-28 ..............Pointer................................................................................................... 1

29 ............. ................................Sanding Belt (local purc hase) .............................6”W x 89”L.................. 1

30 ............. 10104046 .................Miter Gauge Body.................................................................................. 1

................. EHVS80 -MG ............Miter Gauge Assembly

31 ............. TS-081B042.............Pan Head Screw ................................................#8-32×5/8” .................. 3

32 ............. TS-0560061 .............Hex Nut ..............................................................#8-32 .......................... 3

33 ............. EHVS80-33 ..............Knob ..................................................................................................... 1

34 ............. 20101048 .................Platen .................................................................................................... 1

35 ............. OES80CS-135 .........Side Plate .............................................................................................. 1

................. TS-0051061 .............Hex Cap Screw (m otor plate-not shown) ..........5/16”-18×1-1/4”........... 2

................. TS-0561021 .............Hex Nut (motor plate-not shown) ......................5/16”-18 ...................... 2

36 ............. EHVS80-36A ...........JET Knob ...........................................................M8×35 mm .................. 1

37 ............. EHVS80-37A ...........Pin......................................................................∅6×40mm .................. 1

38 ............. TS-0561011 .............Hex Nut ..............................................................1/4”-20........................ 2

39 ............. EHVS80-39A ...........Spacer................................................................................................... 1

40 ............. TS-0733031 .............External Tooth Lock Washer ...............................#10 ........................... 11

41 ............. EHVS80-28A ...........Location Block ....................................................................................... 1

42 ............. TS-0561031 .............Hex Nut ..............................................................3/8”-16........................ 1

43 ............. TS-0051021 .............Hex Cap Screw ..................................................5 /1 6 ” -1 8 ×5 /8 ” .............. 4

44 ............. TS-0720091 .............Lock Washer ......................................................3/8”............................. 2

45 ............. EHVS80-49 ..............Washer Head Scr ew ...........................................#10-24 x 3/8” .............. 3

46 ............. EHVS80-57 ..............Tilt Scale ............................................................................................... 1

47 ............. TS-081C052 ............Pan Head Screw ................................................#10-24x3/4” ................ 1

48 ............. EHVS80-59 ..............Pointer................................................................................................... 1

49 ............. TS-081C022 ............Pan Head Screw ................................................#10-24x3/8” ................ 2

50 ............. OES80CS-150 .........Motor ..................................................................1 -1/2HP, 1PH ............. 1

51 ............. TS-0051061 .............Hex Cap Screw ..................................................5 /1 6 ” -1 8 x1- 1 /4 ” ........... 5

(index #12,13) ..................................................... 1

(index #20,24-28,30-33,41) .................................... 1

19

Page 20

Table and Motor – Parts

Index No. P art No. Descri ption Size Qty.

52 ............. TS-0680031 .............Flat Washe r ........................................................5/16” ......................... 10

53 ............. OES80CS-153 .........Pin......................................................................................................... 2

54 ............. EHVS80-67 ..............Motor Cord ............................................................................................ 1

55 ............. OES80CS-155 .........Dust Port ............................................................................................... 1

56 ............. OES80CS-156 .........Sanding Belt Cover ................................................................................ 1

57 ............. EHVS80-70A ...........Up-Down Table Mount Plate .................................................................. 2

58 ............. EHVS80-71A ...........JET Knob ...........................................................M8X20mm .................. 4

59 ............. EHVS80-72 ..............Back Stop Bracket ................................................................................. 1

60 ............. TS-0720081 .............Lock Washer ......................................................5/16” ......................... 14

61 ............. TS-0561021 .............Hex Nut ..............................................................5/16”-18 ...................... 6

62 ............. TS-0051061 .............Hex Cap Screw ..................................................5 /1 6 ” -1 8 x1- 1 /4 ” ........... 2

63 ............. TS-2285121 .............Flat Head Screw .................................................M5x12 ........................ 8

64 ............. TS-2284201 .............Flat Head Screw .................................................M4x20 ........................ 8

65 ............. EHVS80-94 ..............Extension Table ..................................................................................... 1

66 ............. EHVS80-96 ..............Supporting Rod ..................................................................................... 1

67 ............. EHVS80-57A ...........Tilt Angle Scale Label ............................................................................ 1

68 ............. EHVS80-108 ............Direction Label ...................................................................................... 1

69 ............. EHVS80-107 ............Warning Label ...................................................................................... 1

70 ............. EHVS80-68 ..............Power Cord ........................................................................................... 1

71 ............. OES80CS-171 .........Hinge .................................................................................................... 2

72 ............. OES80CS-172 .........Knob ..................................................................M6 .............................. 2

73 ............. OES80CS-173 .........Supporting Seat ..................................................................................... 1

74 ............. TS-0206041 .............Socket Head Cap Screw .....................................#10-24x3/4” ................ 2

75 ............. OES80CS-175 .........Spacer................................................................................................... 2

76 ............. EHVS80-34G ...........Graphite Pad ......................................................................................... 1

77 ............. EHVS80-51 ..............Belt Tension Arm ................................................................................... 1

78 ............. EHVS80-54 ..............Tension Arm Handle .............................................................................. 1

79 ............. OES80CS-

80 ............. EHVS80-111 ............Drum Guard .......................................................................................... 1

81 ............. OES80CS-181 .........ID Label ................................................................................................. 1

82 ............. OES80CS-182 .........Hinge Bracket ........................................................................................ 2

179 .........Connecti on Pl ate ................................................................................... 1

20

Page 21

Idle Drum – Assembly

21

Page 22

Idle Drum – Parts

Index No. P art No. Descri ption Size Qty.

................. OES80CS-IDRA.......Idle Drum Complete Assembly

1 ............... OES80CS -201 .........Tension Bar ........................................................................................... 1

2 ............... OES80CS -203 .........S pring.................................................................................................... 1

3 ............... TS-0561021 .............Hex Nut ..............................................................5/16” ........................... 1

13 ............. TS-1523011 .............Socket Set Screw ...............................................M6x6 .......................... 2

15 ............. S0400545 ................K ey.....................................................................5x5x45m m.................. 1

16 ............. OES80CS-216 .........Worm .................................................................................................... 1

17 ............. OES80CS-217 .........Spacer................................................................................................... 1

18 ............. S0400425 ................K ey.....................................................................4 x4x25 ....................... 1

19 ............. TS-0640081 .............Nylon Insert Lock Nut .........................................5/16” ........................... 6

20 ............. TS-0680031 .............Flat Washe r ........................................................5/16” ........................... 4

22 ............. TS-0720081 .............Lock Washer ......................................................5/16” ........................... 6

23 ............. TS-2342141 .............Nylon Insert Lock Nut .........................................M14 ............................ 2

24 ............. OES80CS-224 .........Bracket .................................................................................................. 1

25 ............. TS-0050031 .............Hex Cap Screw ..................................................1 /4 ” -2 0 x3/4 ” ................ 2

26 ............. OES80CS-226N.......Lead Screw ........................................................................................... 1

27 ............. OES80CS-227 .........Spring.................................................................................................... 1

28 ............. OES80CS-228 .........Ball Bearing ........................................................698 ............................. 3

29 ............. OES80CS-229 .........Retaining Ring ....................................................STW-8 ........................ 1

30 ............. TS-1502051 .............Socket Head Cap Screw .....................................M5x20 ........................ 2

31 ............. TS-0208061 .............Socket Head Cap Screw .....................................5/16”x1” ...................... 1

32 ............. TS-2284121 .............Flat Head Screw ................................................M4x12 ....................... 3

34 ............. BB-6202VV ..............Ball Bearing ........................................................6202LLU .................... 2

35 ............. OES80CS-235 .........Bearing Housing .................................................................................... 1

36 ............. BB6003ZZ ...............Ball Bearing ........................................................6003ZZ....................... 1

37 ............. S0400430 ................K ey.....................................................................4 x4x30 ....................... 1

38 ............. OES80CS-238 .........Gear Housing ........................................................................................ 1

39 ............. TS-1502021 .............Socket H

40 ............. OES80CS-240 .........Bushing ................................................................................................. 2

41 ............. OES80CS-241 .........Cam ...................................................................................................... 1

42 ............. OES80CS-242 .........Worm Gear ............................................................................................ 1

43 ............. OES80CS-243 .........Worm Gear Shaft................................................................................... 1

44 ............. OES80CS-244 .........Column.................................................................................................. 2

48 ............. TS-0051081 .............Hex Cap Screw ..................................................5 /1 6 ” -1 8 x1- 3 /4 ” ........... 1

49 ............. TS-1551031 .............Lock Washer ......................................................M5 .............................. 6

50 ............. OES80CS-250 .........Rod ....................................................................................................... 1

52 ............. EHVS80-81 ..............Belt Tracking Tool.................................................................................. 1

53 ............. TS-0810012 .............Round Head Sl otted Machine Screw...................#10-24x1/4” ................ 4

54 ............. OES80CS-254 .........Self Tapping Screw ............................................M3 x6 .......................... 1

55 ............. OES80CS-255 .........Dust Hood (Left) .................................................................................... 1

56 ............. OES80CS-256 .........Dust Hood (Right) .................................................................................. 1

57 ............. OES80CS-257 .........Ring ...................................................................................................... 2

58 ............. OES80CS-258 .........Wave Washer ........................................................................................ 2

59 ............. OES80CS-259 .........Idle Drum .............................................................................................. 1

60 ............. OES80CS-260 .........Track Adjustin g Block ............................................................................ 1

61 ............. OES80CS-261 .........Drive Shaft ............................................................................................ 1

62 ............. OES80CS-262 .........Button Head Socket Screw .................................5/16 ”X 1-3 /4 ................ 2

63 ............. OES80CS-263 .........Guard .................................................................................................... 1

65 ............. OES80CS-265 .........Foam Sheet for Drive Shaft ................................................................... 1

66 ............. OES80CS-266 .........Idle Drum Bracket .................................................................................. 1

67 ............. OES80CS-267 .........Track Adjusting Screw ........................................................................... 1

68 ............. OES80CS-268 .........Track Adjusting Nut ............................................................................... 1

69 ............. OES80CS-269 .........Retaining Ring ....................................................S10 ............................ 1

70 ............. OES80CS-270 .........Bearing Housing .................................................................................... 1

71 ............. OES80CS-271 .........Foam Sheet for Lead Screw .................................................................. 1

72 ............. OES80CS-272

.........Cone Disc Spring................................................................................... 2

ead Cap Screw .....................................M5x10 ........................ 5

(index # 1-72) .......................................... 1

22

Page 23

Stand Assembly

Index No. P art No. Descri ption Size Qty.

1 ............... TS-0680031 .............Flat Washe r ........................................................5/16” ......................... 22

2 ............... TS-0720081 .............Lock Was h e r ......................................................5/16” ......................... 10

3 ............... TS-0561021 .............Hex Nut ..............................................................5/16”-18 ...................... 8

4 ............... EHVS80 CS-S04.......Side Panel ............................................................................................. 2

5 ............... EHVS80 CS-S05.......Pad ....................................................................................................... 4

6 ............... EHVS80 CS-S06.......Screw .................................................................................................... 4

7 ............... EHVS80 CS-S07.......Rear Panel ............................................................................................ 1

8 ............... TS-0561021 .............Hex Nut ..............................................................5/16”-18 ...................... 4

9 ............... TS-0051061 .............Hex Cap Scr e w ..................................................5/16” -1 8 x1- 1 /4 ” ........... 2

10 ............. TS-1533032 .............Pan Head Screw ................................................M5x10 ........................ 2

11 ............. EHVS80CS-S11.......D oor ...................................................................................................... 1

12 ............. EHVS80CS-S12.......Shelf ...................................................................................................... 1

13 ............. EHVS80CS-S13.......L atch Assembly ..................................................................................... 1

14 ............. TS-1551031 .............Lock Washer ......................................................M5 .............................. 2

15 ............. EHVS80CS-S15.......Front Panel (W/Door)............................................................................. 1

16 ............. EHVS80CS-S16.......Screw .................................................................................................... 2

17 ............. EHVS80CS-S17.......JET Label .............................................................................................. 1

18 ............. TS-1550031 .............Flat Washe r ........................................................M5 .............................. 2

19 ............. TS-0081031 .............Hex Cap Screw ..................................................5 /1 6 ” -1 8 x3/4 ” .............. 8

................. STRIPE-1-3 /4 ..........JET Str ipe (no t show n ) .......................................1-3/4”w ................ per ft.

23

Page 24

Wiring Diagram

24

Loading...

Loading...