Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

8-inch Jointer-Planer

Model JJP-8BT

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-707400

Ph.: 800-274-6848 Revision B 08/2014

www.jettools.com Copyright © 2014 JET

Page 2

1.0 Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of these ma chin es in the processi ng of metal, plastics, or o ther m aterials may void the warrant y. The exc eptions

are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide pr oof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa t io n

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety warnings .............................................................................................................................................. 4

4.0 Features ......................................................................................................................................................... 6

5.0 Specifications ................................................................................................................................................. 6

6.0 Setup and assembly ....................................................................................................................................... 7

6.1 Unpacking and cleanup .............................................................................................................................. 7

6.2 Contents of main carton ............................................................................................................................. 7

6.3 Contents of stand ....................................................................................................................................... 8

7.0 Assembly ........................................................................................................................................................ 9

7.1 Stand assembly (optional) .......................................................................................................................... 9

7.2 Mounting Jointer-Planer to Stand ............................................................................................................... 9

7.3 Jointer-Planer assembly ........................................................................................................................... 10

8.0 Jointer setup ................................................................................................................................................. 10

9.0 Planer setup ................................................................................................................................................. 11

10.0 Operating controls ...................................................................................................................................... 11

10.1 Power ..................................................................................................................................................... 11

10.2 Planer controls and adjustments

10.3 Jointer controls and adjustments

11.0 Adjustments ............................................................................................................................................... 13

11.1 Cutterhead Knife Adjustment ................................................................................................................. 13

11.2 Replacing Cutter Knives ......................................................................................................................... 14

11.3 Jointer Fence Adjustment ....................................................................................................................... 14

11.4 Belt replacement .................................................................................................................................... 14

12.0 Basic Operations ........................................................................................................................................ 15

12.1 Dust collection ........................................................................................................................................ 15

12.2 Initial startup ........................................................................................................................................... 15

12.3 Changing mode of operation .................................................................................................................. 15

12.4 Jointer operations ................................................................................................................................... 16

12.5 Planer operations ................................................................................................................................... 17

13.0 Maintenance ............................................................................................................................................... 19

13.1 Blade Care ............................................................................................................................................. 19

13.2 Sharpening the Knives ........................................................................................................................... 19

14.0 Lubrication .................................................................................................................................................. 19

15.0 Optional Accessories ................................................................................................................................. 19

16.0 Troubleshooting the JJP-8BT ..................................................................................................................... 20

16.1 Performance Troubleshooting – Jointer ................................................................................................. 20

16.2 Performance Troubleshooting – Planer .................................................................................................. 21

16.3 Mechanical Troubleshooting – Planer/Jointer ........................................................................................ 22

17.0 Replacement Parts ..................................................................................................................................... 22

17.1.1 Jointer/Planer – Parts List ................................................................................................................... 23

17.1.2 Assembly Drawing Index ..................................................................................................................... 27

17.1.3 Planer Table Assembly ....................................................................................................................... 28

17.1.4 Motor Assembly ................................................................................................................................... 29

17.1.5 Front Frame Assembly ........................................................................................................................ 29

17.1.6 Chain Drive Assembly ......................................................................................................................... 30

17.1.7 Front Cover Assembly ......................................................................................................................... 30

17.1.8 Cutterhead Guard Assembly ............................................................................................................... 31

17.1.9 Dust Cover Assembly .......................................................................................................................... 31

17.1.10 Jointer Infeed Table Assembly .......................................................................................................... 32

17.1.11 Jointer Outfeed Table Assembly ....................................................................................................... 32

17.1.12 Cutterhead/Feed Roller Assembly .................................................................................................... 33

17.1.13 Jointer Fence Assembly .................................................................................................................... 33

17.1.14 Rear Frame and Cover Assembly ..................................................................................................... 34

17.2.1 Jointer/Planer Stand – Parts List ......................................................................................................... 35

17.2.2 Jointer/Planer Stand – Exploded View ................................................................................................ 35

18.0 Electrical Connections – JJP-8BT .............................................................................................................. 36

............................................................................................................. 12

............................................................................................................. 12

3

Page 4

3.0 Safety warnings

1. Read and understand the entire owner's manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with all of

these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This Woodworking Jointer-planer is designed and intended for use by properly tra ined and experienced

personnel only. If you are not familiar with the proper and safe operation of a woodworking jointer or

planer, do not use until proper training and knowledge have been obtained.

5. Do not use this for other than its intended use. If used for other purposes, JET disclaims any real or implied

warranty and holds itself harmless from any injury that may result from that use.

6. Always wear approved safety glasses/face s hields while using this woodworking jointer-planer. Everyday

ey eglass es only h ave impact r esistant lenses; they are not safe ty glasses.

7. Before operating this woodworking jointer-planer, remove tie, rings, watches and other j ewelry, and roll

sleeves up past the elbows. Remove all loose clothing and confine long hair. Non-slip footwear or anti-skid

floor strips are recommended. Do not wear gloves.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities contain

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cemen t and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and work with approved safety equipment, such as face or

dust masks that are specifically designed to filter out microscopic particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make certain the switch is in the OFF position before connecting the machine to the power source.

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adj usting wrenches

are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance purposes,

use extreme caution and replace the guards immediately.

16. Make sure the woodworking jointer-planer is firmly secured to the floor or bench before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check for

alignment of moving parts, binding of m oving parts, breakage of parts, mounting and any ot her conditions

that may affect its operation. A guard or other part that is damaged should be properly repaired or

replaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap material, oil and grease.

20. Keep visitors a safe distance from the work area. Keep children away.

21. Make your workshop child proof with padlocks, master switches or by removing starter keys.

4

Page 5

22. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

23. Maintain a balanced stance at all times so that you do not fall or lean against t he cutterhead or other

moving parts. Do not overreach or use excessive force to perform any machine operation.

24. Use the right tool at the correct speed and feed rate. Do not force a tool or attachment to do a job for which

it was not designed. The right tool will do the job better and safer.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maintain tools with care. Keep knives sharp and clean for the best and safest performance. Follow

instructions for lubricating and changing accessories.

27. Turn off the machine before cleani ng. Use a brush or com pressed air to remove chips or debris — do not

use your hand s.

28. Do not stand on the machine. Serious injury could occur if the machine tips over.

29. Never leave the machine running unattended. Turn the power off and do not leave the machine until it

comes to a complete stop.

30. Before turning on machine, remove all extra equipment such as keys, wrenches, scrap, stock, and cleaning

rags away from the machine.

31. Always use a hold-down or push block when surfacing stock less than 12" inches long, or 3 inches wide, or

3 inches thick.

32. Do not perform jointing operations on material shorter than 8", n a rrower than 3/4" or less than 1/4" thick.

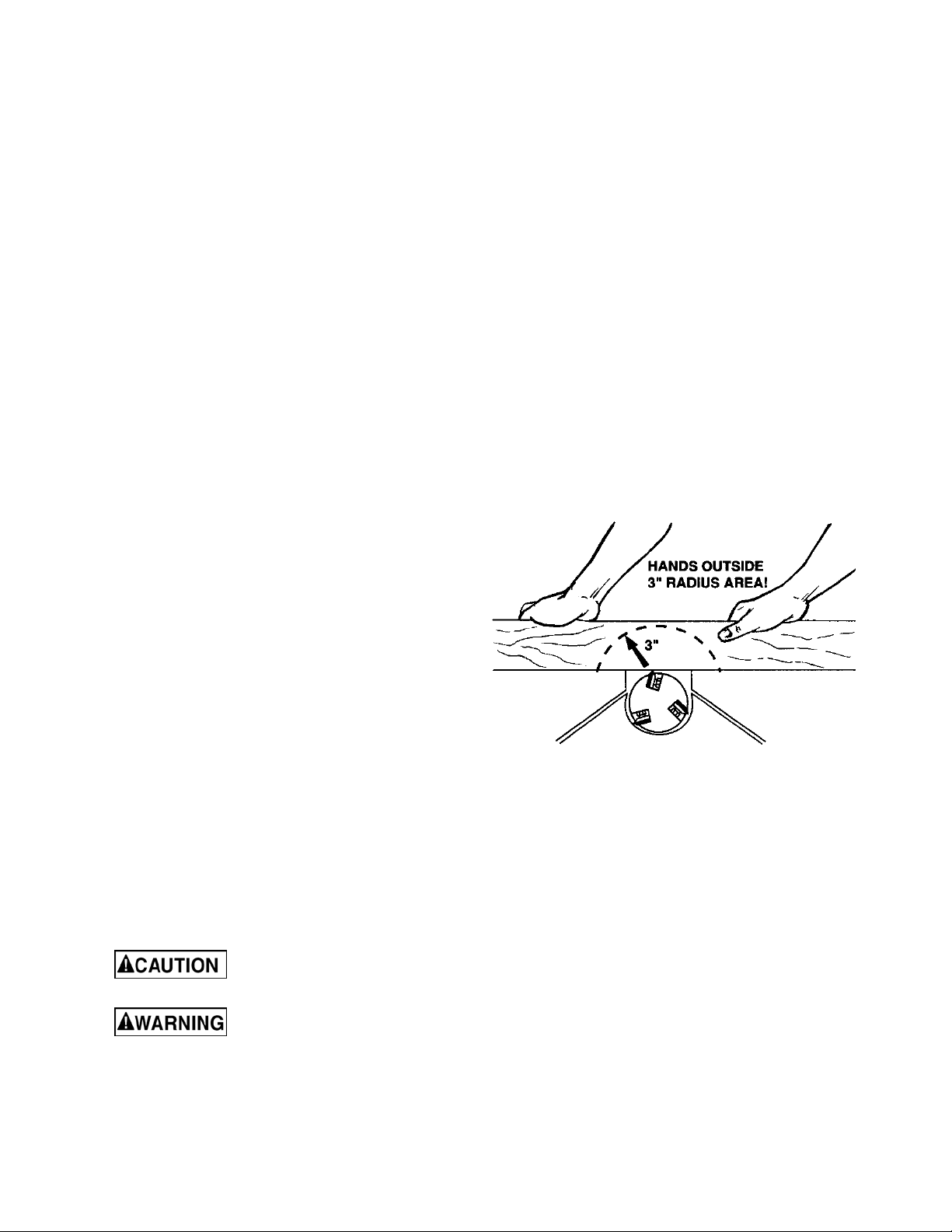

33. The hands must never be closer t han 3 inches to

the cutterhead (see Figure).

34. Never apply pressure to stock directly over the

cutterhead. This may result in the stock tipping into

the cutterhead along with the operator's fingers.

Position hands away from extreme ends of stock,

and push through with a smooth, even motion.

Never back workpiece toward the infeed table.

35. To avoid kickback, the grain must run in the same

direction you are cutting. Before attempting to joint,

or plane, each work piece must be carefully

examined for stock condition and grain orientation.

36. When working with a swirl grain wood or burls,

making it necessary to plane against the grain, use a lesser depth of cut and a slow rate of feed.

37. Move the hands in an alternate motion from back to front as the work continues through the cut. Never

pass the hands directly over the cutter knife. As one hand approaches the knives remove it from the stock

in an arc motion and place it back on the stock in a position beyond the cutter knife (Fig. 2).

38. At a ll times h old the stock firmly.

39. Do not use this for other than it intended use. If used for other purposes, JE T d isclaims a ny real or im plied

warranty and holds itself harmless for any injury or damage which may result from that use.

Familiariz e you rself with the following safety no tices used in this manual:

This means that if preca utions are not heeded, it m ay result in minor injury a nd/or possible

machine damage.

injury.

This means that if precautions are not heeded, it may result in serious, or possibly even fatal,

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

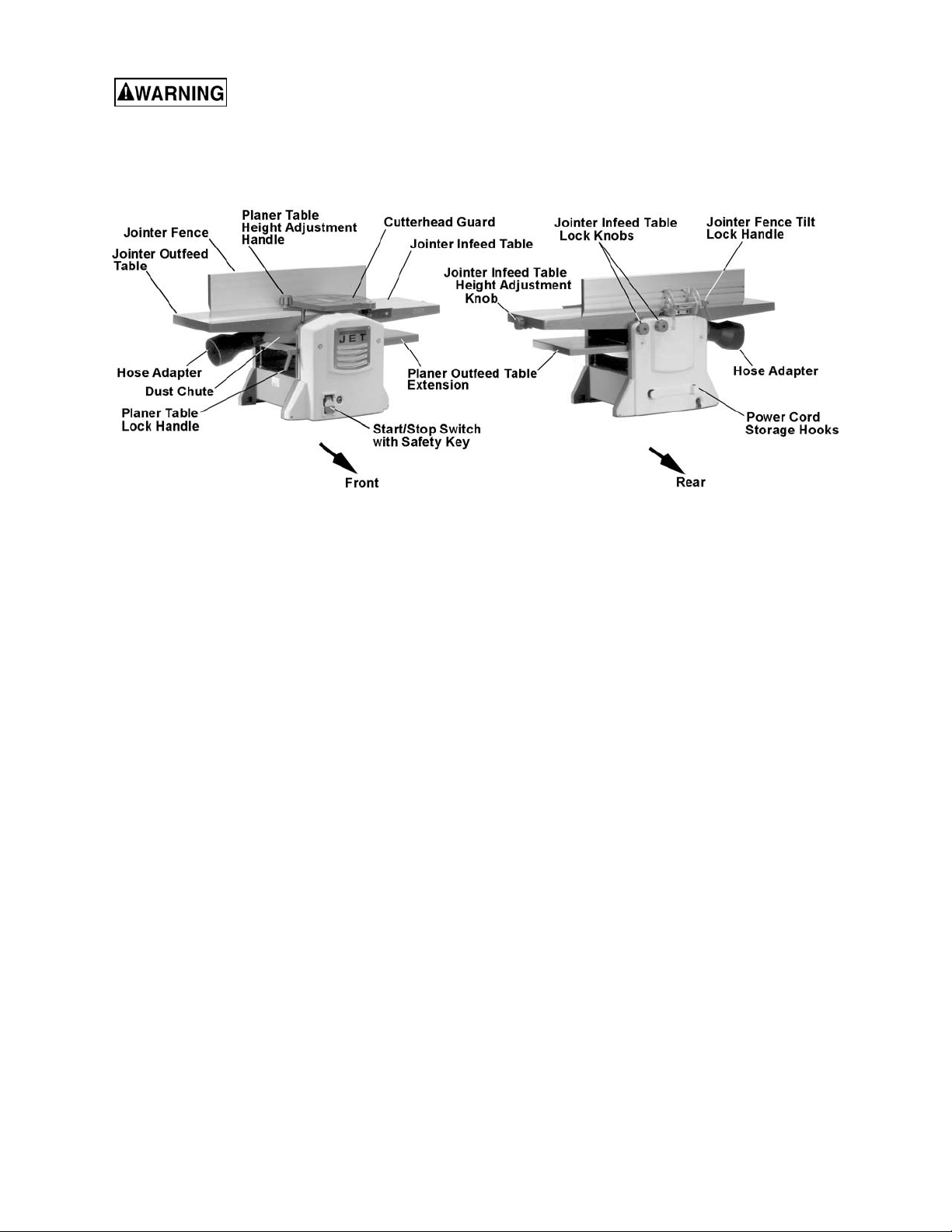

Read and understand the entire contents of this manual before attem pting assembly

or operation! Failure to comply may cause serious injury!

4.0 Features

Features

5.0 Specifications

Model number ........................................................................................................................................... JJP-8BT

Stock number .............................................................................................................................................. 707400

Cutterhead speed ...................................................................................................................................... 9000rpm

Number of knives .................................................................................................................................................. 2

Cutter knife length .......................................................................................................................................... 8-1/4"

Cutter knife thickness .................................................................................................................................... 0.060"

Dust port diameter ................................................................................................................................. 2-1/2" or 4”

Jointer table ............................................................................................................................................ 29"x 8-1/4”

Max stock removal ............................................................................................................................................ 1/8”

Max cutting width ................................................................................................................................................. 8"

Fence .................................................................................................................................................... 4-1/8" x 21”

Fence tilt ................................................................................................................................................. 90°- 45° R

Fence positive stop .................................................................................................................................. 90°, 45°R

Planer table .................................................................................................................................... 10-5/8" x 8-1/2"

Planer capacity

Maximum cutting thickness ......................................................................................................................... 4-1/2"

Max depth of cut .............................................................................................................................................. 5/64”

Min length of work piece ...................................................................................................................................... 6"

Feed rate ................................................................................................................................................... 19.5 fpm

Motor

Voltage ...................................................................................................................................... 120V, 60Hz, 13A

Switch ...................................................................................................... Toggle switch with overload protection

Overall Dimensions (LxWxH) .............................................................................................. 31" x 16-1/2" x 18-1/2"

Net weight ........................................................................................................................................ 58 lbs

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, JET reserves the right to change specifications at any time and without prior notice, without incurring

obligations.

6

Page 7

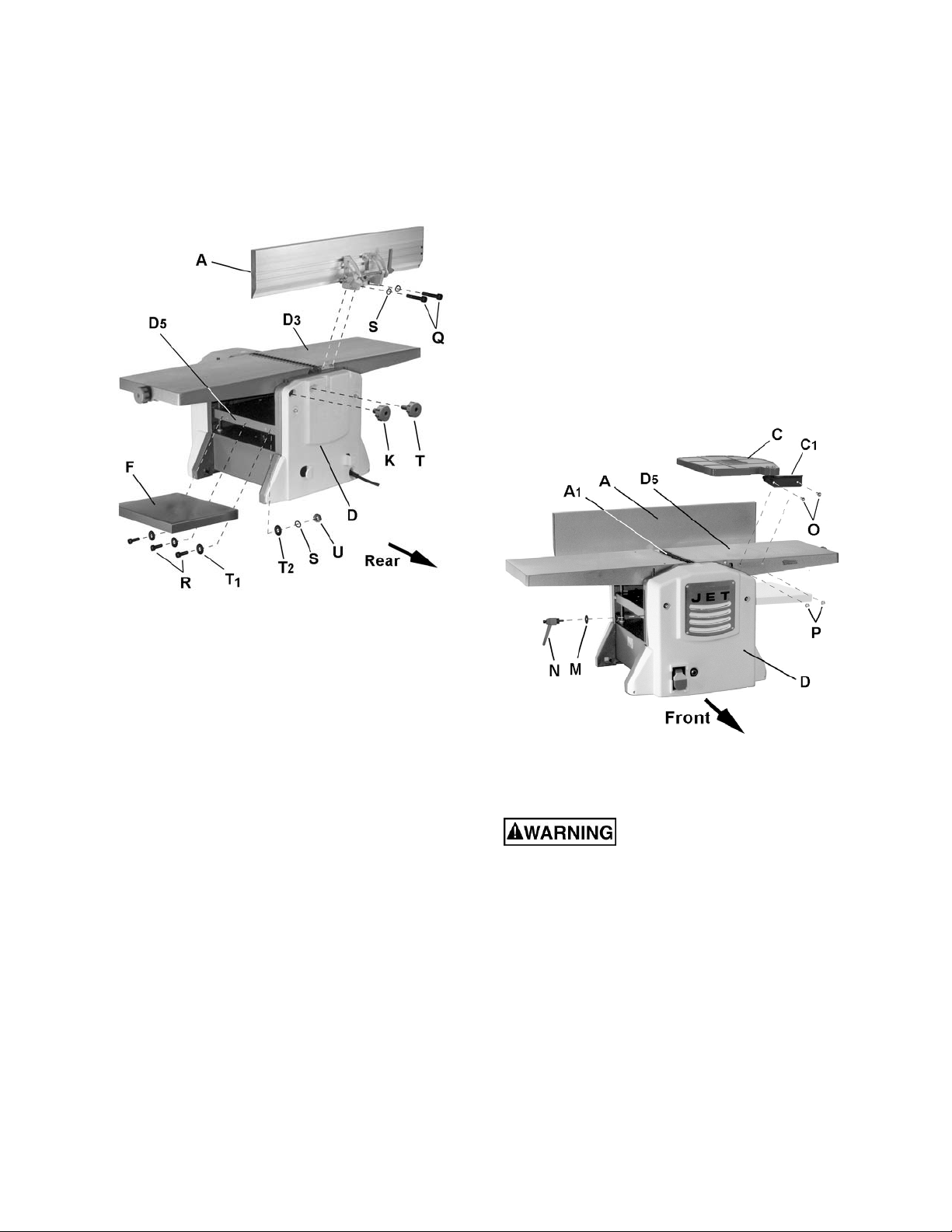

6.0 Setup and assembly

6.1 Unpacking and cleanup

Remove all contents from the shipping carton. Do

not discard the carton or packing material until your

Model JJP-8BT Jointer-Planer is assembled a nd is

running satisfactorily.

Compare the contents of the carton against the list

of parts in Contents of Shipping Container (below).

The letter identification in the list corresponds to

the items shown at right. This is your key for

identifying the parts used throughout the Assembly

section for easy reference.

Remove the protective coating that is applied to the

table with a household grease and spot remover.

6.2 Contents of main carton

01 Jointer Fence – A

01 Dust Chute – B

01 Cutterhead Guard – C

01 Jointer-Planer – D

01 2-1/2" to 4" Hose Adapter – E

01 Planer Outfeed Table Extension – F

01 Owner's Manual – G

02 Push Blocks – H

01 Warranty Card (not shown)

Knobs and Handles

01 Lock Knob (p/n JJP8BT-90L) – J

01 Lock Knob (p/n JJP8BT-90S) – K

01 Elevating Handle (p/n JJP8BT-19A) – L

01 Flat Washer, 6mm – M

01 Lock Handle (p/n JJP8BT-25A) – N

Figure 2 – Knobs and Handles

Hardware

02 Pan Head Machine Screw – O

02 Hex Nut – P

02 Socket Head Cap Screw, M6x25 – Q

03 Socket Head Cap Screw, M6x10 – R

05 Lock Washer, 6mm – S

06 Flat Washer, 6mm – T

03 Hex Nut, M6 – U

Figure 1 – Contents of the Main Carton

Figure 3 – Hardware

(included in JJP10BT-HP Hardware Package)

Tools Included

01 Knife Setting Gauge – V

01 3, 5, 6mm hex wrenches (set of 3) – W

01 8/10mm Open-end Wrench – X

Figure 4 – Tools Included

7

Page 8

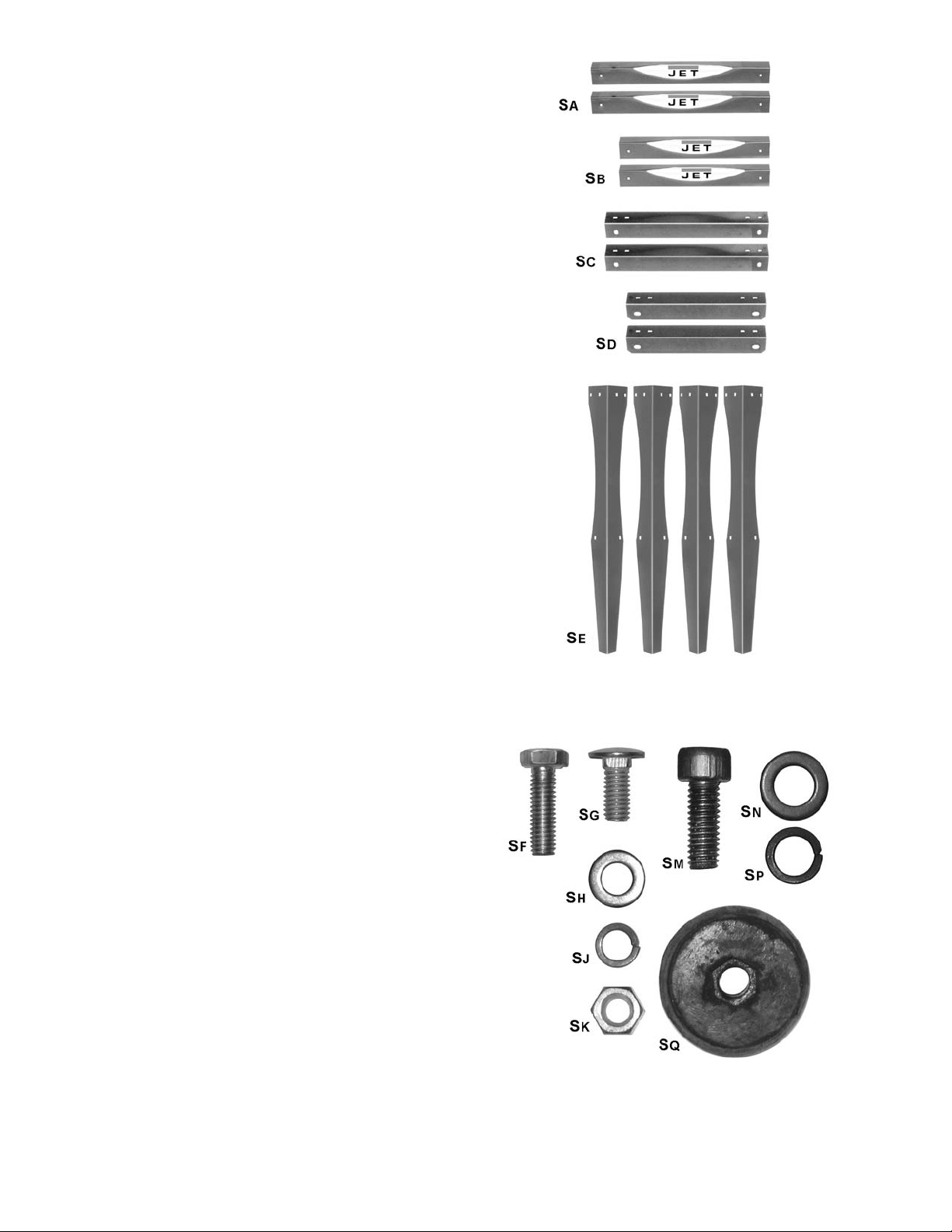

6.3 Contents of stand

The stand is not included but is an optional item

available for purchase. To purc hase, call Custom er

Service at the phone number on the cover of this

manual. The following instructions are included if

you have purchased the stand or will purchase one

at a later date.

Compare the contents of the carton against the list

of parts below.

Contents of Stand Carton

02 Long Support Plate – SA

02 Short Support Plate – SB

02 Long Stand Top Support – SC

02 Short Stand Top Support – SD

04 Stand Leg – SE

Stand Hardware

(included in Hardware Package, p/n JJP10BT-HP)

Note: The index number in parentheses refers to

the same item as shown in the parts breakdowns.

04 Hex Cap Screw, M6x20 (#13, Stand Assbly) –

SF

24 Carriage Bolt, M6x12 (#9, Stand Assbly) – SG

28 Flat Washer, 6mm (#8, Stand Assbly) – SH

24 Lock Washer, 6mm (#7, Stand Assbly) – SJ

28 Hex Nut, M6 (#6, Stand Assbly) – SK

04 Socket Head Cap Screw, M8x20 (#16, Stand

Assbly)

04 Flat Washer, M8 (#14, Stand Assbly) – SN

04 Lock Washer, M8 ( #15, Stand Assbly) – SP

04 Rubber Foot (#12, Stand Assbly) – SQ

– SM

Figure 5 – Contents of Stand Carton

Figure 6 – Stand Hardware

(included in JJP10BT-HP Hardware Package)

8

Page 9

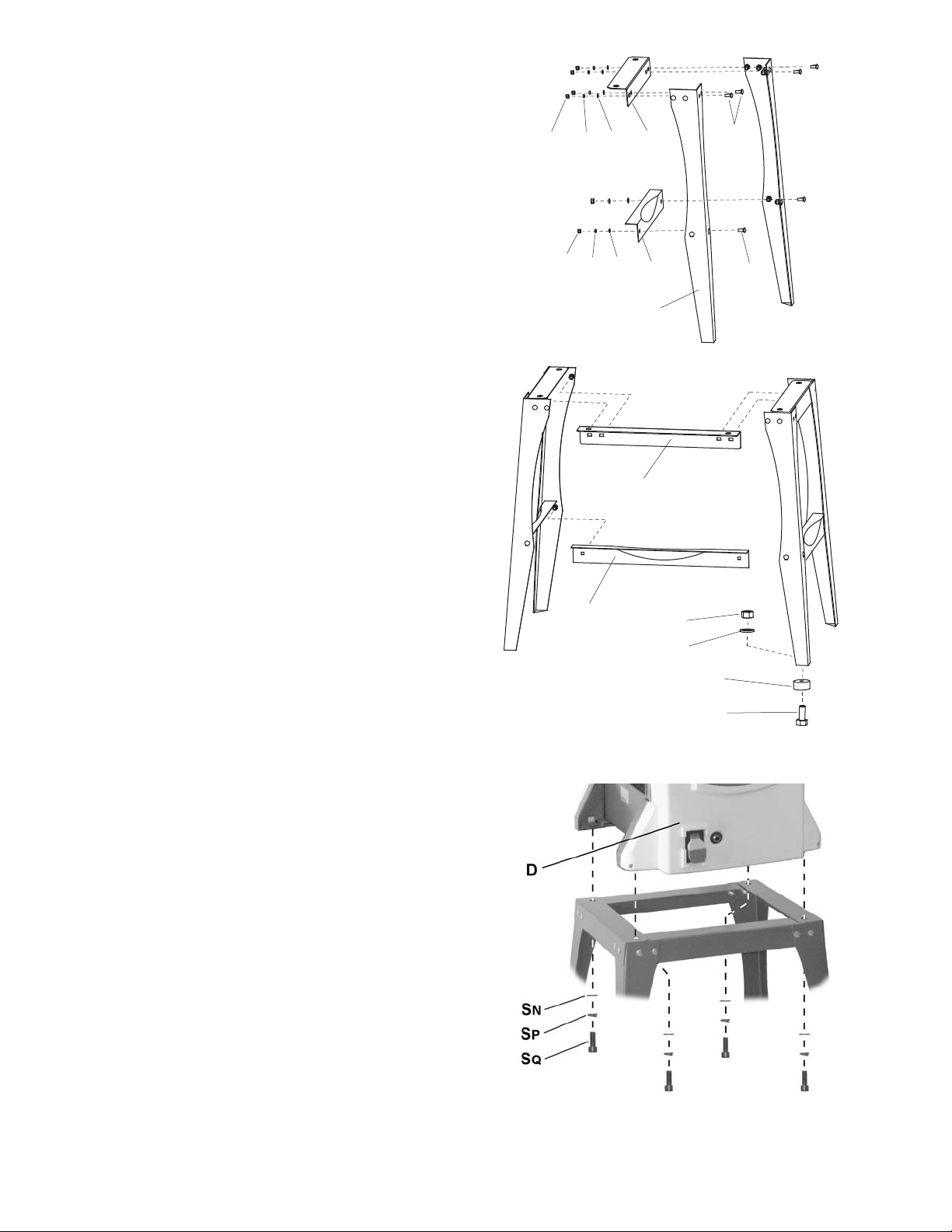

7.0 Assembly

For assembly convenience, the item letter

designators used thr oug ho ut t he Assembly sectio n

are the same as those used to identify shipping

content and hardware components in sect. 6.0.

7.1 Stand assembly (optional)

Note: If you do not plan to use a stand at this time,

skip this page and proceed to sect. 7.3, Jointer-

Planer Assembly.

Refer to Figure 7:

1. Select two legs (SE), one short stand top

support (SD) and one short support plate (SB).

2. Attach one end of the stand top support (SD)

to the top of the first leg with two carriage bolts

(SG ), f la t w a she rs (SH ) , lo c k w a she r s ( SJ) a nd

hex nuts (SK). Attach the other end of the

stand top support (SD) to the second leg in the

same manner. Hand-tighten only at this time.

3. Attach a support plate (SB) to each leg (SE ) in

the same manner with two carriage bolts (SG),

flat washers (SH), lock washers (SJ) and hex

nuts (SK). Hand-tighten only at this time.

4. Repeat steps 1–3 using the remaining legs,

short stand top support and support plate.

SK

SK

SJ

SJ

SH

SH

SE

SC

SD

SB

SG

SG

5. Complete the stand construction by attaching

long stand top supports (SE) and long support

plates (SA) to the leg assemblies constructed

in steps 1–4. Hand-tighten all hardware onl y at

this time.

6. Place a rubber foot (SQ) on a hex cap screw

(SF), then insert the threaded end of the screw

through the opening on the bottom of the leg.

7. Secure with flat washer (SH) and hex nut (SK).

8. Attach rubber feet to remaining legs in the

same manne r.

9. Place stand upright. Ensure that the stand is

on a level surface and all four legs are

contacting the surface.

10. Tighten all hex nuts with the 10mm

wrench (X, Figure 4) provided.

7.2 Mounting Jointer-Planer to Stand

Refer to Figure 8:

1. Place the Jointer-Planer (D) onto the

assembled stand and secure with 4 socket

head cap screws (SM), lock washers (SP), and

flat washers (SN).

2. Tighten all socket head cap screws (SM) with

the 5mm hex wrench (W, Figure 4) provided.

SA

SK

SH

Figure 7

Figure 8

SQ

SF

9

Page 10

7.3 Jointer-Planer assembly

Refer to Figure 9:

Fence

1. Attach jointer fence (A) to back of jointer

outfeed table (D3) with two each socket head

cap screws (Q) and lock washers (S). Tighten

screws with 5mm hex wrench (provided).

5. Using a 4mm hex wrench (provided), turn

setscrews slightly clockwise to raise the table

or counterclockwise to lower the table.

Lock Handle

Refer to Figure 10:

6. Attach planer table lock handle (N) and flat

washer (M).

Cutterhead Guard

7. Install cutterhead guard (C) by securing the

bracket (C1) to the side of the jointer infeed

table (D5) with two each pan head machine

screws (O) and hex nuts (P).

Important: It is extremely important that spring

action causes the cutterguard (C) to retract

against the fence (A), concealing the cutterhead

1). If spring ret ur n tension is not enough,

(A

adjust the spring located on the cutterhead pivot

shaft accor dingly

Figure 9

Lock Knobs

The JJP-8BT Jointer-Planer comes equipped with

two lock knobs to secure the position of the jointer

infeed table.

2. Install jointer infeed table lock knobs (K, T).

Note: The shaft length of the two lock knobs

(refer to Figure 2) is different. Be sure to install

each in the correct location.

Extension Table

3. Attach the planer outfeed extension table (F)

to the planer table (D5) with three socket head

cap screws (R), six flat washers (T), three lock

washers (S) and three hex nuts (U).

Screws (R) and flat washers T1 are inserted

through the extension table (F) and planer

table (D5), then fastened from inside the planer

table (D5) with flat washers (T2), lock washers

(S) and hex nuts (U).

4. Tighten screws with 5mm hex wrench and

10mm open end wrench.

Extension Table Adjustment

Two setscrews located underneath the extension

table (F) are used to adjust the height position of

the outer (protruding) edge, which must be slightly

higher than the main table (D5) in order to minimize

snipe (see sect.12.5, Avoiding Snipe).

Figure 10

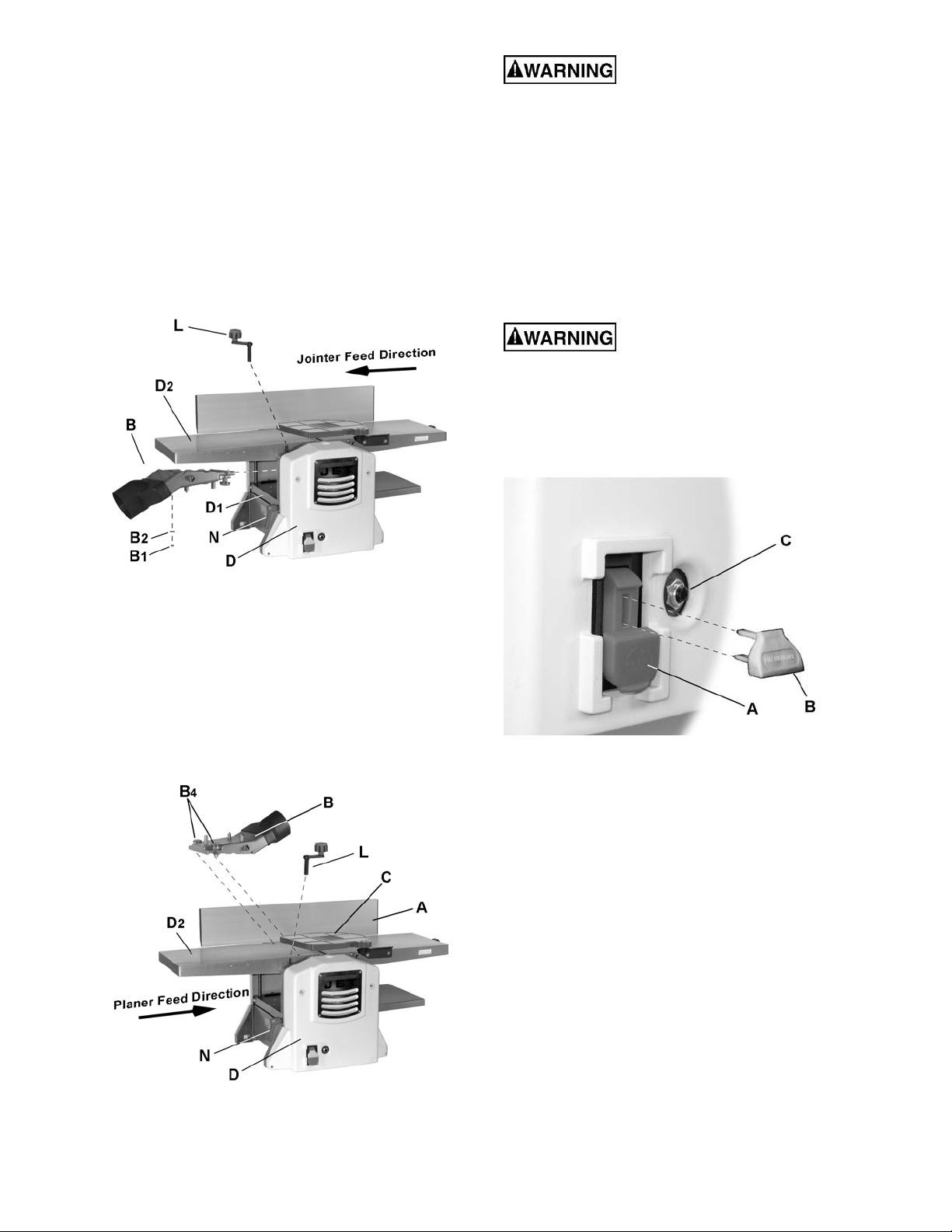

8.0 Jointer setup

Disconnect machine from

power source before making any adj ustments.

Failure to comply may cause serious injury.

Refer to Figure 11:

1. Loosen lock handle (N).

2. Install planer table height adjustment handle

(L).

3. Turn handle (L) counterclockwise and lower

planer table (D

4. Remove hex nut (B1) and flat washer (B2) from

dust chute (B).

5. Orient the dust chute (B) as shown and install

into the infeed opening.

Position the chute (B) such that the two

positioning keys and one threaded positioning

1) all the way.

10

Page 11

screw underneath the chute meshes with three

positioning holes on the table (D1).

6. Raise the table (turn handle L clockwise) until

the dust chute (B) is held firmly in place

between the planer infeed table (D

jointer outfeet table (D

7. Tighten lock handle (N).

Step 8 is optional.

8. Further secure the dust chute by reinstalling

the hex nut (B1) and flat washer (B2) from

underneath the planer infeed table (D1).

2). Do not overtighten.

1) and

Cutterhead knives are

dangerously sharp. Use extreme caution when

working around them. Failure to comply may

cause serious injury.

2. Orient the dust chute (B) as shown. Install onto

the jointer outfeed table (D2) and secure by

tightening lock knobs (B4).

Important: Dust chute (B) must be properly

installed in both Jointer setup and Pla ner setup. If

improper installation fails to activate a microswitch, the machine will not star t .

9. Remove handle (L).

Figure 11

9.0 Planer setup

If the machine is currently set up for jointer

operation, remove the dust chute (B, Figure 11).

Refer to the Jointer Setup section above.

Refer to Figure 12:

1. Swing cutter guard (C) away from fence (A),

which will expose the cutterhead.

10.0 Operating controls

Disconnect machine from

power source before making any adj ustments.

Failure to comply may cause serious injury.

10.1 Power

Plug power cord into outlet.

Refer to Figure 13:

Figure 13

Start/Stop

Figure 12

Pull the red switch (A) out to start. Push in to stop.

Safety Key

Removing the safety key (B) will render the

start/stop switch inoperable. The machine can

continue to operate without the key, but upon

stopping cannot be restarted until it is reinstalled.

Reset Switch

If the machine should come to an unexpected stop

during operation due to overload or jammed w orkpiece, etc.:

1. Set the start/stop switch (A) set to stop

(pushed in).

2. Momentarily press, then release the reset

switch (C).

3. Restart machine.

11

Page 12

10.2

Planer controls and adjustments

Refer to Figure 14:

Table Lock

Turn the lock handle (A) counterclockwise to

release and permit table adjustment. Turn the lock

handle (A) clockwise to secure the planer table (D)

in its se le c t e d position.

Table Height Adjustment

The pl aner table height is set as follows:

1. Unlock the table lock (A).

2. Install the removeable adjustment handle (C)

onto the shaft (B).

3. Rotate the adjustment handl e (C) clockwise to

raise the planer table (D), counterclockwise to

lower.

Each revolution of the adjustment handle (C) results

in a 3/32" up or down movement of the tab le (D). A

scale indicates the amount of table travel. The

pointer (E) indicates the table position on the scale

relative to th e cu tter h ead .

Note: A depth of cut of 1/16" or less is recommended.

Figure 14

10.3

Jointer cont ro ls and adjustments

Refer to Figure 15.

Infeed Table Height Adjustment

Two lock knobs (F) a nd a height adjustment knob

(E) control the height adjustment of the infeed table

(D).

To adjust:

1. Loosen lock knobs (F).

2. Turn the height adjustment knob (E ) clockwise

to raise the infeed table (D) or counterclockwise to lower the table.

The amount of table adjustment can be read

on the scale (C).

3. Tighten the lock knobs (F).

Figure 15

Cutterhead Guard

Refer to Figure 15.

Properly positioned, the cutterhead guard (A)

should rest against the fence (B

1).

Fence Bevel Adjustment

The fence (B2) can be tilted backward (G) up to

45° (that is, for a total included angle of 135° from

table surface) as follows:

12

Page 13

1. Loosen lock handle (J).

2. Tilt the fence (B2) back to the desired angle up

to 135 degrees (G). Or you can place your

beveled reference piece on the table and

against the fence, adjusting the fence until the

angle of the fence matches the bevel of your

gauge piece.

3. Tighten the lock handle (J).

11.0 Adjustments

11.1 Cutterhead Knife Adjustment

Cutterhead knives are

dangerously sharp! Use extreme ca ution when

inspecting, removing, sharpening or replacing

knives into the cutterhead. Failure to comply

may cause serious injury!

Determining if adjustment is necessary:

1. Disconnect machine from the power source.

2. Remove the cutterhead guard.

Refer to Figures 16 and 17:

7. When the blade is at the proper height,

alternately tighten the six gib lock screws (A).

Repeat steps 3 – 7 to adjust the remaining blade.

Note: The most common cause for unsatisfactory

cutting performance is improperly set knives. Many

aftermarket devices are avaialable to further assist

in the accurate setting of knives.

Note: To rotate the cutterhead the cutterhead

pulley must be turned. This require s removing the

panel on the front of the cabinet for access.

3. Rotate the cutterhead (E ) until one knife is i n

the 12 o'clock position. The 12 o'clock position

is the highest point a blade will reach in the

cutting arc (C, Figure 17).

4. Place the knife setting gauge (J) on the

outfeed table (F). One end of the gauge should

be positioned over the cutting knife (C)

towards the near the end of the blade (G).

Use care when handling the

knife setting gauge near the blades to pr event

damage.

Note the position of the knife blade with respect to

the gauge, then move the gauge to the other side

of the table towards the fence (H) and again note

the position of the knife blade with respect to the

gauge.

The blade must be at the same height at each end

and must also be at the same height as the

outfeed table (bottom of gauge). If this is not the

case, adjustment is required as follows:

Adjustment procedure

Figure 16

B

C

D

E

A

5. Slightly loosen six gib lock screws (A) by

turning into the lock bar (B), clockwise as

viewed from the infeed table (K).

6. Adj ust the blade height by turning jack screws

(D) upon which the blade rests. To lower t he

blade, turn the screw clockwise. To rai se, turn

the screw counter-clockwise.

Figure 17

13

Page 14

11.2 Replacing Cutter Knives

Disconnect machine from

power source before making any adj ustments.

Failure to comply may cause serious injury.

1. Disconnect machine from the power source.

2. Remove the cutterhead guard.

If setting to maximum positions do not stop the

fence at 0º or 90º, make adjustments as follows:

Fence 90º Adjustment

1. Loosen lock handle (H) and bring fence fully

forward. Using a square, determine if the fence

is 90º to the table.

If adjustment is required:

Cutterhead knives are

dangerously sharp. Use extreme caution when

inspecting, removing, s harpening, or repl acing

knives into the cutterhead. Failure to comply

may cause serious injury.

Refer to Figures 16 and 17 on previous pages:

3. Turn all six gib lock screws (A) into the lock bar

(B) by turning in a clockwise direction as

viewed from the infeed table (K).

4. Carefully remove t he cutter knife (C) and lock

bar (B).

5. Repeat for the remaining knife.

6. Thoroughly clean all surfaces of the

cutterhead, knife slots and lock bars of any

dust or debris.

7. Insert the first replacement knife (C) into the

knife slot, making sure it faces the proper

direction.

8. Insert lock bar (B) and tighten just enough to

hold in place.

9. Repeat for other the remaining blade.

Following installation, the knives must be adjusted

as described in sect. 11.1, Cutterhead Knive

Adjustment.

11.3 Jointer Fence Adjustment

2. Loosen jam nut (E) and adjust stop screw (D)

in or out until a fence postion of 90º with

respect to the table is achieved.

3. Secure the jam nut (E).

Check the scale indication. If the indicator (C) does

not point to zero:

4. Loosen screw (B), adjust accordingly, then

retighten screw.

Fence 45º Adjustment

Verify that the fence and scale indication is

accurate at 90º as outlined in Fence 90º

Adjustment above.

1. Loosen lock handle (H) and set the fence all

the way back. Using a square, determine if the

fence is 135º to the table.

If adjustment is required:

2. Loosen jam nut (G) and adjust stop screw (F)

in or out until a fence postion of 135º with

respect to the table is achieved. Note: The

screw head stops against the fence mounting

bracket.

Secure the jam nut (G).

11.4 Belt replacement

Refer to Figure 19 when installing or replacing the

the feed-roller (A) or cutterhead drive (D) belts.

Refer to Figure 18:

The jointer fence (A) can be adjusted from a full

forward position (90º to table, corresponding to a

scale reading of 0º) to a f ull back-tilted position of

135 º (scale reading of 45 º).

Figure 18

Disconnect machine from

power source before making any adj ustments.

Failure to comply may cause serious injury.

11.4.1 Feed-roller belt replacement

Cutterhead knives are

dangerously sharp. Use extreme caution when

replacing any belt. Contact with cutterhead

knives will cause serious injury.

1. Remove the front panel. This is the panel

where the Start/Stop switc h is loc a t e d .

2. Remove feed-roller belt (A) from pulley (B)

while man ually rota ting pulley (C).

When this is accomplished, belt will fall away

from pulley (C).

3. Loop the new belt around pulley (C), then

around pulley (B) while manually rotating

pulley (C).

14

Page 15

4. When installed, continue to manually rotate

pulley (C) and verify that belt is properly

seated on both pulleys.

5. Replace front cover.

6. Loop belt around pulley (E) while manually

rotating pulley (F).

Use extreme caution to avoid

contact with cutterhead knives while

performing this step. Contact with cutterhead

knives will cause serious injury.

7. Manually rotate pulley (F) to verify that the

grooves in the belt are properly meshed with

the grooves on both pulleys.

This completes the cutterhead drive belt

installation.

8. Replace the feed-roller belt (Feed-roller Belt

Replacement section steps 3–5).

12.0 Basic Operations

12.1 Dust collection

Before initial operation, the machine must be

connected to a dust collector.

Important: If a dust collection system is not used,

the quality of your cut will suffer severely.

Figure 19

11.4.2 Cutterhead drive belt replacement

Cutterhead knives are

dangerously sharp. Use extreme caution when

replacing any belt. Contact with cutterhead

knives will cause serious injury.

The cutterhead drive belt should seldom if ever,

require replacement. Follow the procedure below if,

however, the belt should require replacement.

1. Remove the feed-roller belt as described in

Feed-roller Belt Replacement above.

2. Remove the bottom portion of the cutterhead

drive belt (D) from pulley (E) while manually

rotating pulley (F).

Use extreme caution to avoid

contact with cutterhead knives while

performing this step. Contact with cutterhead

knives will cause serious injury.

3. Remove top portion of belt (D ) from pulley F,

then work it under the chain and past pulley B

to remove completely.

12.2 Initial startup

After the assembly and adjustments are complete

the planer is ready to be tested. Plug in and start

the machine. Keep your finger on the Stop button

in case of a problem. The machine should run

smoothly with little or no vibration or rubbing

noises. Investigate and correct the source of any

problems before further operation.

DO NOT attempt to investigate

or adjust the planer while it is running. Wait

until the mac hine is turned off, unplugged and

all working parts have come to a complete

standstill.

Always wear ANSI-approved

safety glasses or goggles when operating

equipment.

12.3 Changing mode of operation

When changing the operating mode (planer to

jointer and back) the machine must be turned off,

unplugged, and come to a complete stand-still. To

change the mode of operation, see sect. 8.0, Jointer

Setup, and sect 9.0, Plan er Setu p on page 12.

4. Install new belt by first feeding the lower loop

downward behind the gear (H) a nd pulley (C).

This will properly position the lower loop of the

belt in close proximity to pulley (E).

5. Slide the top loop of the belt aro und and past

pulley (B), sliding it underneath and past chain

(G); then loop around pulley (F).

15

Page 16

12.4 Jointer operations

Correct operating position

The operator must be positioned offset to the

infeed table (Figure 20).

Figure 20

Hand placement

Never pass hands directly over

the cutterhead.

Referring to Figure 21:

At the start of the cut, the left hand holds the

workpiece firmly against the infeed table and fence

while the right hand pushes the workpiece in a

smooth, even motion toward the cutterhead. After

the cut is under way, the new surface rests firmly

on the outfeed table. The left hand is transferred to

the outfeed side (Figure 21) and presses down on

this part of the workpiece, at the same time

maintaining flat contact with the fence. The right

hand presses the workpiece forward and before

the right hand reaches the cutterhead it should be

moved to the work on the outfeed table.

Figure 21

Direct ion of Grain

Avoid feeding work into the jointer against the grain

(Figure 22). This may result in chipped and

splintered edges.

Figure 22

Feed with the gra in to obtai n a smooth surfac e, as

shown in Figure 23.

Surfacing

The purpose of surfacing on a jointer is to produce

one flat surface (Figure 21). The other side can

then be milled to precise, final dimensions on a

thickness planer resulting in a board that is smooth

and flat on both sides and each side parallel to the

other.

If the wood to be jointed is cupped or bowed,

place the concave side down, and take light

cuts until the surface is flat.

Never surface pieces shorter than 12 inches or

thinner than 3/8 inch without the use of a

special work holding fixture.

Never surface pieces thinner than 3 inches

without the use of a push block.

Cuts of appro ximately 1/16" or less at a time

are recommended, which provides for better

control over the material being surfaced. More

passes can then be made to reach t he des ired

depth.

Figure 23

Edge Jointing

Jointing (or edging) is the process of creating a

finished, flat edge surface that is suitable for joinery

or finishing (Figure 24). It is also a necessary step

prior to ripping stock to width on a table saw.

Never edge a board t hat is less t han 3 inches

wide, less than 1/4 inch thick, or 12 inches

long, without using a push block.

W hen edging wood wider than 3 inches lap the

fingers over the top of the wood, extending

them back over the fence such that they will

act as a stop for the hands in the event of a

kickback.

When workpiece is twice the

length of the jointer infeed or o utfeed table use

an infeed or outfeed support.

16

Page 17

To edge:

1. Make sure the fence is set to 90°. Double

check it with a square.

2. Inspect stock for soundness and grain

direction (refer to Direction of Grain on

previous page).

Several passes may be required to achieve full

bevel.

Figure 25

12.5 Planer operations

Figure 24

3. If the board is bowed (curved), place the

concave edge down on the infeed table.

4. Set the infeed table for a cut of approximately

1/16 inch.

5. Hold the stock firmly against the fence and

table, feed the stock slowly and evenly over

the cutterhead.

Beveling

Beveling an edge is the same operation as edge

jointing, except that the fence is tilted to a specified

angle.

Make certain material being beveled is over 12

inches long, more than 1/4 inch thick and 1

inch wi de.

To bevel:

1. Use a bevel gauge to determine the desired

angle. Then set the fence to the same angle.

2. Inspect stock for soundness and grain

direction (refer to Direction of Grain on

previous page).

3. Set the infeed table for a cut of approximately

1/16.

4. If the board is bowed (curved), place the

concave edge down on the infeed table.

5. Feed the stock through the cutterhead, making

sure the face of the stock is completely flat

against the fence and the edge is m ak ing solid

contact on the infeed and outfeed tables

(Figure 25).

For wood wider than 3 inches – hold with

fingers close together near the top of the

stock, lappi ng over the board and ex tending

over the fence.

For wood less than 3 inches wide – use

beveled push blocks and apply pressure

toward the fence. Keep fingers near top of

push block.

Depth of Cut

Thickness planing refers to the sizing of lumber to a

desired thickness while creating a level surface

parallel to the opposite side of the board. Board

thickness t ha t t he p lane r will pr o d uce is indic a t e d by

the scale (see Table Height Adjustment on page

13). Preset the planer to the desired thickness of the

finished workpiece using the gauge. The depth-ofcut is adjusted by raising or lowering the planer table

(D, Figure 14) using the adjustable handle (C,

Figure 14).

The quality of thickness planing depends on

the operator's judgment about the depth of cut.

The depth of cut depends on the width,

hardness, dampness, grain direction and grai n

structure of the wood.

The maximum thickness of wood that can be

removed in one pass is 5/64" for planing

operations on workpieces up to 5-1/2” wide.

The workpiece must be positioned away f rom

the center tab on the rollercase to cut 1/8”.

The maximum thickness of wood that can be

removed in one pass is 1/16” for planing

operations on workpieces from 5-1/2” up to 8"

wide.

For optimum planing performance, the depth

of cut shoul d be less than 1/16”.

The board s hould be planed with shallow cuts

until the work has a level side. Once a level

surface has been created, flip t he lumber and

create parallel sides.

Plane alternate sides until the desired thick-

ness is obtained. When half of the total cut has

been taken from each side, the board will have

a uniform, moisture content and additional

drying will not cause it to warp.

The depth of cut should be shallower when the

workpiece is wider.

When planing hardwood, take light cuts or

plane the wood in thin widths.

Make a test cut with a test piece and verify the

thickness produced.

17

Page 18

Check the accuracy of the test cut before

working on the finished product.

Precautions

A thickness planer is a precision wood-working

machine and should be used on quality lumber

only.

Do not plane dirty boards; dirt and small

stones are abrasive and will wear out the

blade.

Remove nails and staples. Use the planer to

cut wood only.

Avoid knots. Heavily cross-grained wood

makes knots hard. Knots can come lose and

jam the blade. Any article that encounters

planer blades may be forcibly ejec ted from the

planer creating a risk of injury.

Preparing the Work

A thickness planer works best when the

lumber has at least one flat surface. Use a

jointer to create a flat surface.

Twisted or severely warped boards can jam

the planer. Rip the lumber in half to red uce the

magnitude of the warp.

The work should be fed into the planer in the

same direction as the grain of the wood.

Sometimes the wood will change directions in

the middle of the board. In such cases, if

possible, cut the board in the middle so the

grain direction is correct.

Do not plane a board that is

less than 6" long. It is recommended that when

planing short boards you butt them end to e nd

to avoid kickback and reduce snipe.

Planing

1. Position the workpiece with the face to be

planed on top.

Note: Feed direction is left to right (see

Figure 12).

2. Turn the planer on.

3. Rest the board end on the infeed side of the

table and direct the board into the planer.

4. Slide the workpiece into the infeed side of the

planer until the infeed roller begi ns to advance

the workpiece.

5. Let go of the workpiece and allow the

automatic feed to advance the workpiece.

6. Do not push or pull on the workpiece. Move to

the rear and receive the planed lumber by

graspi ng it in the same manner that it wa s fed.

To avoid the risk of injury due

to kickbacks, do not sta nd directly in line wit h

the front or rear of the planer.

7. Do not grasp any portion of the board that has

not gone past the infeed roller.

8. Repeat this operation on all of the boards that

need to be the same thickness.

Avoiding Snip e

Snipe refers to a depression at either end of the

board caused by an uneven force on the

cutterhead when the work is entering or leaving the

planer.

Snipe will occur when the boards are not supported

properly or when only one feed roller i s in contact

with the work at the beginning or end of the cut.

Feeding the Work

The planer is supplied with planer blades mounted

in the cutterhead. Feed direction is left to right (see

Figure 12). The planer feed is automatic; it will vary

slightly depending on the type of wood.

Preparation:

Feed rate refers to the rate at which the

lumber travels through the planer.

The operator is responsible for aligning the

work so it will feed properly.

Raise or lower the table to get the depth of cut

desired.

The surface that the planer produces will be

smoother if a shallower depth of cut is used.

Stand on the front side of the machine.

Boards longer than 24” should have additio nal

support from free standing material stands.

These can be purchased f rom JET – Stock #

709209. See sect. 15.0, Optional Accessories.

Precauti ons for av oiding snipe:

Push the board up while feeding the work until

the outfeed roller starts advancing it.

Move to the rear and receive the planed board

by pushing it up when the infeed roller loses

contact with the board.

When planing more than one board of the

same thickness, butt the boards together to

avoid snipe.

Make shallow cuts. Snipe is more apparent

when deeper cuts are taken.

Feed the work in the direction of the grain.

Work fed against the grain will have chipped,

splintered edges.

18

Page 19

13.0 Maintenance

13.1 Blade Care

Blades are extremely sharp!

Use caution when cleaning or

changing. Failure to comply may cause serious

injury!

The condition of the blades will affect the

precision of the cut. Observe the q uality of the

cut that the machine produces to check the

condition of the blades.

Dull blades will tear, rat her than cut the wood

fibers and produce a fuzzy appearance.

Raised grain will occur when dull blades pound

on wood that has varying density. A raised

edge will also be produced where the blades

have been nicked.

When gum and pitch collect on the blades,

carefully remove with a strong solvent. Failure to

remove gum and pitch build up may result in

excessive friction, blade wear and overheating.

When blades become dull, they should be

replaced, or touched up – see sect. 13.2,

Sharpening the Knives.

4. Lay the stone on the infeed table.

5. Lower the infeed table and turn the cutterhead

by turning the cutterhead pulley. The infeed

table height is set properly when the stone's

surface is flush with the knife bevel.

6. Keep the c utterhead from rotating by grasping

the cutterhead pulley while sliding the stone

back and forth across the table.

7. Take the same amount of passes for all two

blades.

When the blades have been sharpened and still

are not cutting efficiently, trying to touch up the

blades further will only cause the formation of a

second beveled edge. When this starts to happen,

it is time to replace blades with another set. It is

recommended to keep a second set of blades o n

hand so that they may be installed while the first

set is being professionally sharpened.

13.2 Sharpening the Knives

Blades are extremely sharp!

Use caution when handling.

Failure to comply may cause serious injury!

1. Disconnect the machine from the power

source.

2. Remove the blade guard and belt cover.

3. To protect the infeed table from scratches,

partially cover the sharpening stone wit h paper

(Figure 26).

15.0 Optional Accessories

Stock No. Description

707401 8" Jointer/Pl aner Bl ades

707402 8" Jointer Planer S tand

709209 Adjustable Roller Stand, 12.5” wide

Figure 26

14.0 Lubrication

Use a good grade of light grease on the steel

adjusting screws located in the raising and

lowering mechanisms of the work tables.

The cutterhead ball bearings are lifetime lubricated

and need no further care.

19

Page 20

16.0 Troubleshooting the JJP-8BT

16.1 Performance Troubleshooting – Jointer

Trouble Probable Cause Remedy

Finished stock is

concave on back end. Knife is higher than outfeed table.

Finished stock is

concave on front end. Outfeed table is higher than knife.

Chip out. Cutting against the grain. Cut with the grain whenever possible.

Dull knives. Sharpen or replace knives.

Feeding workpiece too fast. Use slower rate of feed.

Cutting too deeply. Make shallower cuts.

Knots, imperfections in wood.

Fuzzy grain. Wood has high moisture content. Allow wood to dry or use different stock.

Dull knives. Sharpen or replace knives.

Cutterhead slows

while operating.

“Chatter” marks on

workpiece.

Feeding workpiece too quickly, or

applying too much pressure to

workpiece.

Knives incorrectly set.

Align cutterhead knives with outfeed

table. See sect. 11.1, Cutterhead Knife

Adjustment.

Align cutterhead knives with outfeed

table. See sect. 11.1, Cutterhead Knife

Adjustment.

Inspect wood closely for imperfections;

use different stock if necessary.

Feed more slowly, or apply less

pressure to workpiece.

Set knives properly as described in

sect. 11.1, Cutterhead Knife

Adjustment. Check that knife slots are

clean and free of dust or debris.

Uneven knife marks on

workpiece.

Feeding workpiece too fast. Feed workpiece slowly and consistently.

Cutting too deeply. Make shallower cuts.

Knives are nicked, or out of alignment.

Align knives per sect. 11.1, Cutterhead

Knife Adjustment. Replace nicked

knives.

20

Page 21

16.2 Performance Troubleshooting – Planer

Trouble Probable Cause Remedy

Snipe

Note: Snipe can be

minimized but not

eliminated

Fuzzy Grain

Torn Grain

Rough/Raised Grain

Rounded, glossy

surface

Inadequate support of long boards. Support long boards with extension

rollers.

Dull kniv es. Sharpen knives.

Lumber not butted properly. Butt end to end each piece of stock as

they pass through.

Planing wood with high moisture

content.

Dull knives. Sharpen or replace.

Too heavy a cut. Adjust proper depth of cut

Knives cutting against grain. Cut along the grain.

Dull kniv es. Sharpen knives.

Dull kniv es. Sharpen knives.

Too heavy a cut. Adjust proper depth.

Moisture content too high. Remove high moisture content from

Dull knives. Sharpen or replace knives.

Feed speed too slow. Increase speed.

Remove high moisture content from

wood by drying.

wood by drying.

Uneven depth of cut

side to side.

Board thickness does

not match depth of cut

scale.

“Chatter” marks on

workpiece.

Cutting depth too shallow. Increase depth.

Planer bed rough or dirty. Clean pitch and residue, and wax

planer table.

Surface of feed rollers clogged. Clear chips off of rollers.

Knife incorrectly set. Adjust knives.

Depth of cut scale incorrect.

Knives incorrectly set.

Cutting too deeply. Make shallower cuts.

Adjust depth of cut scale.

Set knives properly as described in

sect. 11.1, Cutterhead Knife

Adjustment. Check that knife slots are

clean and free of dust or debris.

21

Page 22

16.3 Mechanical Troubleshooting – Planer/Jointer

Trouble Probable Cause Remedy

Machine will

not start/

restart or

repeatedly

trips circuit

breaker or

blows fuses.

No incoming

power.

Planer frequently

trips.

Building circuit

breaker trips or

fuse blows.

Motor failure. If electric motor is suspect, have a qualified electrician test the motor

Dust chute not

seated properly on

either Jointer

Infeed or Planer

Table

1. Verify unit is connected to power and Start/Stop switch is in the

Start pos ition (see sect. 10.1, Power).

2. Verify unit is connected to power. Set the Start/Stop switch to the

Stop position, depress and release the reset switch, then reset the

Start/Stop switch to the Start position (see sect. 10.1, Power).

One cause of overloading trips, which are not electrical in nature, is

too heavy a cut. The solution is to take a lighter cut.

Verify that planer is on a circuit of correct size. If circuit size is

correct, there is probably a loose electrical lead.

for function or take the machine to a service center and have it

tested.

Adjust the dust chute, making sure th a t the key on the dust chute

depresses the micro-switch on machine.

17.0 Replacement Parts

Replacement parts are listed on the followi ng pages. To order parts or reach our service departm ent, call 1800-274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Having the Model Number and Serial

Number of your machine available when you call will allow us to serve you quickly and accurately.

22

Page 23

17.1.1 Jointer/Planer – Parts List

Note: Parts without part numbers are for reference only and cannot be purchased individually.

Index No. Part No. Description Size Qty

1 ................ JJP8BT-1 .................. Chain Support Bracket............................................. ...................................... 1

2 ................ JJP8BT-2 .................. Sprocket................................................................... ...................................... 1

3 ................ JJP8BT-3 .................. E-Clip ....................................................................... Ø6 ................................. 1

4 ................ TS-2361051 .............. Lock Washer ............................................................ M5 ............................... 40

5 ................ TS-1540031 .............. Hex Nut .................................................................... M5 ................................. 9

6 ................ TS-1550031 .............. Flat Washer ............................................................. M5 ............................... 22

7 ................ JJP8BT-7 .................. Corn er Sprocket....................................................... ...................................... 4

8 ................ JJP8BT-8 .................. Chain ....................................................................... ...................................... 1

9 ................ JJP8BT-9 .................. Base......................................................................... ...................................... 1

10 .............. JJP8BT-10 ................ Infeed Pointer Label................................................. ...................................... 1

11 .............. TS-1502031 .............. Socket Head Cap Screw.......................................... M5x12 ........................... 3

12 .............. JJP8BT-12 ................ Driv en Lead Screw .................................................. ...................................... 3

13 .............. JJP8BT-13 ................ Driv e Lead Screw .................................................... ...................................... 1

14 .............. JJP8BT-14 ................ Extension Table ....................................................... ...................................... 1

15 .............. TS-1503021 .............. Socket Head Cap Screw * ....................................... M6x10 ........................... 3

16 .............. JJP8BT-16 ................ Crank Arm Bushin g.................................................. ...................................... 1

18 .............. JJP8BT-18 ................ Main Table ............................................................... ...................................... 1

.................. JJP8BT-19A .............. Elevating Handle Assembly (includes #19,23,24) ... ...................................... 1

19 .............. JJP8BT-19 ................ Crank Arm................................................................ ...................................... 1

20 .............. JJP8BT-20 ................ Guide Rail ................................................................ ...................................... 2

21 .............. TS-1503041 .............. Socket Head Cap Screw.......................................... M6x16 ........................... 4

23 .............. JJP8BT-23 ................ Knob Screw ............................................................. ...................................... 1

24 .............. JJP8BT-24 ................ Knob ........................................................................ ...................................... 1

.................. JJP8BT-25A .............. Locking Handle Assembly (includes #25,44,45,75) . ...................................... 1

25 .............. JJP8BT-25 ................ Locking Handle ........................................................ ...................................... 2

27 .............. TS-1532032 .............. Pan Head Machine Screw ....................................... M4x10 ........................... 3

28 .............. TS-2361041 .............. Lock Washer ............................................................ M4 ................................. 3

29 .............. JJP8BT-29 ................ Poin ter ..................................................................... ...................................... 1

31 .............. TS-1540021 .............. Hex Nut .................................................................... M4 ................................. 2

32 .............. JJP8BT-32 ................ Cord Clamp.............................................................. ...................................... 1

33 .............. TS-1532052 .............. Pan Head Machine Screw ....................................... M4x16 ........................... 2

34 .............. JJP8BT-34 ................ Cover ....................................................................... ...................................... 2

35 .............. JJP8BT-35 ................ Rear Support ........................................................... ...................................... 1

36 .............. JJP8BT-36 ................ Self-Tappin g Screw ................................................. ST4.2x10..................... 10

37 .............. JJP8BT-37 ................ Scale ........................................................................ ...................................... 1

38 .............. TS-1502011 .............. Socket Head Cap Screw.......................................... M5x8 ........................... 13

39 .............. JJP8BT-39 ................ Power Cord Protector .............................................. ...................................... 1

40 .............. JJP8BT-40 ................ Rear Support Cover ................................................. ...................................... 1

41 .............. JJP8BT-41 ................ Pin............................................................................ ...................................... 2

42 .............. JJP8BT-42 ................ Self-Tappin g Screw ................................................. ST4.2x20....................... 4

43 .............. JJP8BT-43 ................ Power Cord .............................................................. ...................................... 1

44 .............. JJP8BT-44 ................ Screw ....................................................................... ...................................... 2

45 .............. JJP8BT-45 ................ Sprin g ...................................................................... ...................................... 2

46 .............. TS-1550031 .............. Flat Washer ............................................................. M5 ................................. 4

47 .............. TS-2331051 .............. Cap Nut.................................................................... M5 ................................. 4

48 .............. JJP8BT-48 ................ Th read Lock Bushing ............................................... ...................................... 4

49 .............. TS-1540031 .............. Hex Nut .................................................................... M5 ................................. 2

50 .............. JJP8BT-50 ................ Outfeed Table Spacer.............................................. ...................................... 4

51 .............. JJP8BT-51 ................ Infeed Table Spacer ................................................ ...................................... 4

52 .............. JJP8BT-52 ................ Bearin g .................................................................... ...................................... 1

53 .............. JJP8BT-53 ................ Sprin g ...................................................................... ...................................... 2

54 .............. JJP8BT-54 ................ Bushing Block .......................................................... ...................................... 5

55 .............. JJP8BT-55 ................ Sprin g ...................................................................... ...................................... 1

56 .............. JJP8BT-56 ................ Roll er ....................................................................... ...................................... 2

57 .............. 707401 ...................... Knife......................................................................... ...................................... 2

58 .............. JJP8BT-58 ................ Hose Adapter ........................................................... ........ .............................. 1

59 .............. JJP8BT-59 ................ Pin............................................................................ ...................................... 4

60 .............. JJP8BT-60 ................ Knife Gib .................................................................. ...................................... 2

23

Page 24

Index No. Part No. Description Size Qty

61 .............. JJP8BT-61 ................ Screw ....................................................................... .................................... 12

62 .............. JJP8BT-62 ................ Cutterhead ............................................................... ...................................... 1

63 .............. TS-1540041 .............. Hex Nut * ................................................................. M6 ................................. 9

64 .............. JJP8BT-64 ................ Outfeed Table .......................................................... ...................................... 1

65 .............. TS-1550021 .............. Flat Washer ............................................................. M4 ................................. 3

66 .............. TS-1501041 .............. Socket Head Cap Screw.......................................... M4x12 ........................... 2

67 .............. JJP8BT-67 ................ Fen ce Support ......................................................... ...................................... 1

68 .............. TS-1550041 .............. Flat Washer * ........................................................... M6 ................................. 8

69 .............. TS-2361061 .............. Lock Washer * ......................................................... M6 ................................. 9

70 .............. TS-1482021 .............. Hex Cap Screw ........................................................ M6x12 ........................... 2

71 .............. JJP8BT-71 ................ Fen ce Bracket.......................................................... ......... ............................. 1

72 .............. JJP8BT-72 ................ Screw ....................................................................... ...................................... 2

73 .............. TS-1503061 .............. Socket Head Cap Screw * ....................................... M6x25 ........................... 2

74 .............. JJP8BT-74 ................ Washer .................................................................... Ø6 ................................. 6

75 .............. JJP8BT-75 ................ Lockin g Nut .............................................................. ...................................... 2

76 .............. JJP8BT-76 ................ Angl e Pointer ........................................................... ....... ............................... 1