Page 1

Assembly Instructions and Parts Manual

Taper Attachment Kit for GHW Lathes

Model TAK-GHW

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-321520

Ph.: 800-274-6848 Revision B 03/2014

www.jettools.com Copyright © 2014 JET

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide pro of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa t io n

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items; Light-Duty Air Tools

1 Year – Motors; Machine Accessories; Heavy-Duty Air Tools; Pro-Duty Air Tools

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

Assembly

Note: numbers in parentheses (#) refer to t he

exploded view and part s li st.

1. Remove the splash guard from the backside

of the lathe.

2. Remove the taper att ac hm ent f r om the box .

3. Remove the dust cover (29) held in place

with six screws (5).

4. Loosen and remove gib screws (16 & 24) .

Do not adjust or rem ov e gib screw (24A);

this will aid assembly when putting the taper

attachment together.

5. Remove the longitudinal slide assembly (6 &

11) from the slide base.

6. Thoroughly cl ean all par ts of the taper

attachment wi th cleaning solvent.

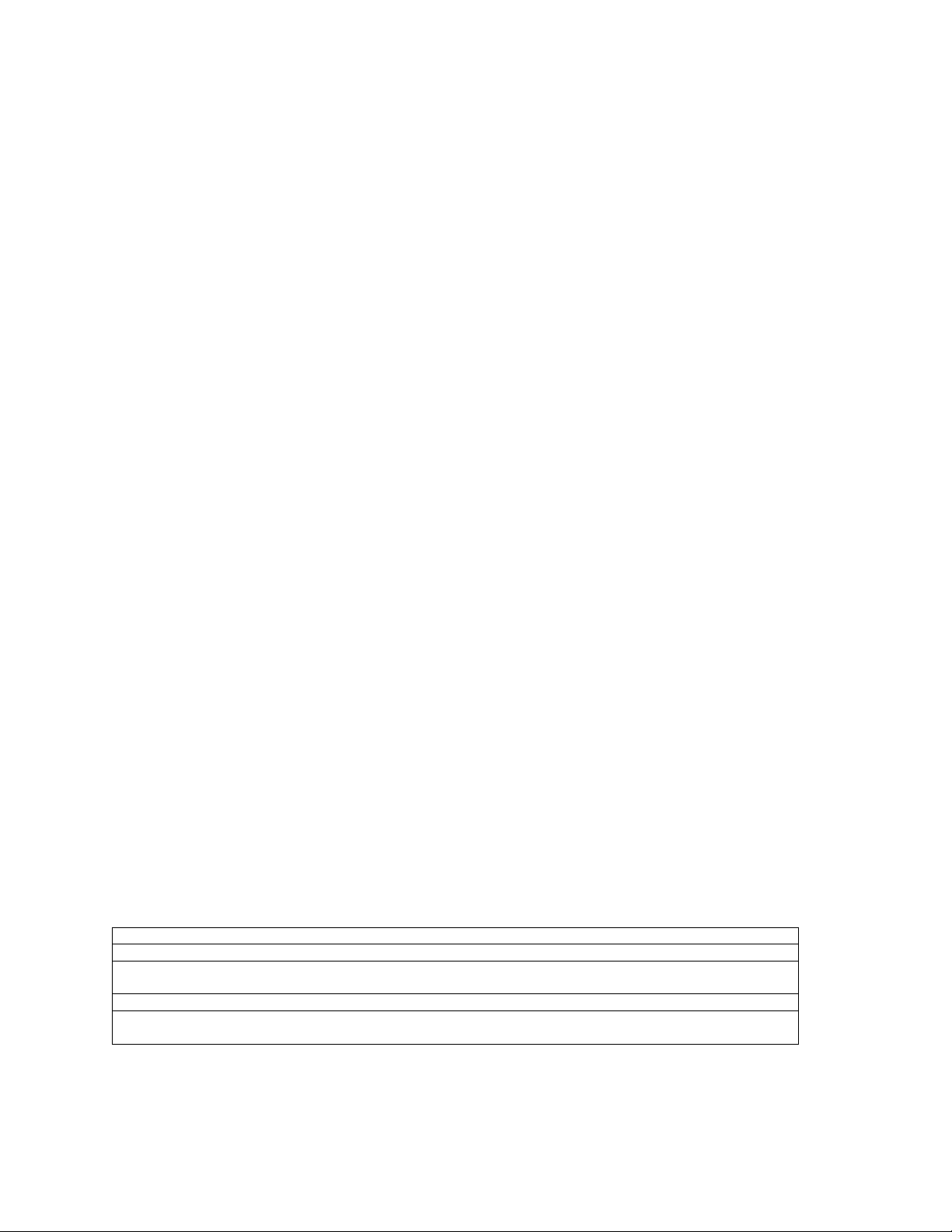

7. Remove two nuts (A, Figur e 1) and the

bearing cap (B, Fi gur e 1) fr om the end of the

cross slide screw (C, Figure 1)

8. Remove the thrust bear ing assembly from

the cross feed screw.

9. Remove two hex socket c ap screws (D,

Figure 1) and the block (E, Figur e 1) .

10. Attach the main body (A, Figure 2) to the

carriage wit h two M8 x 30 hex socket cap

screws, and two M8 fl at washers (B, Figure

2). Tighten the hex cap screws to hol d the

main body in place but l oose enough to

allow adjustment with a dead blow hammer,

or rubber mallet.

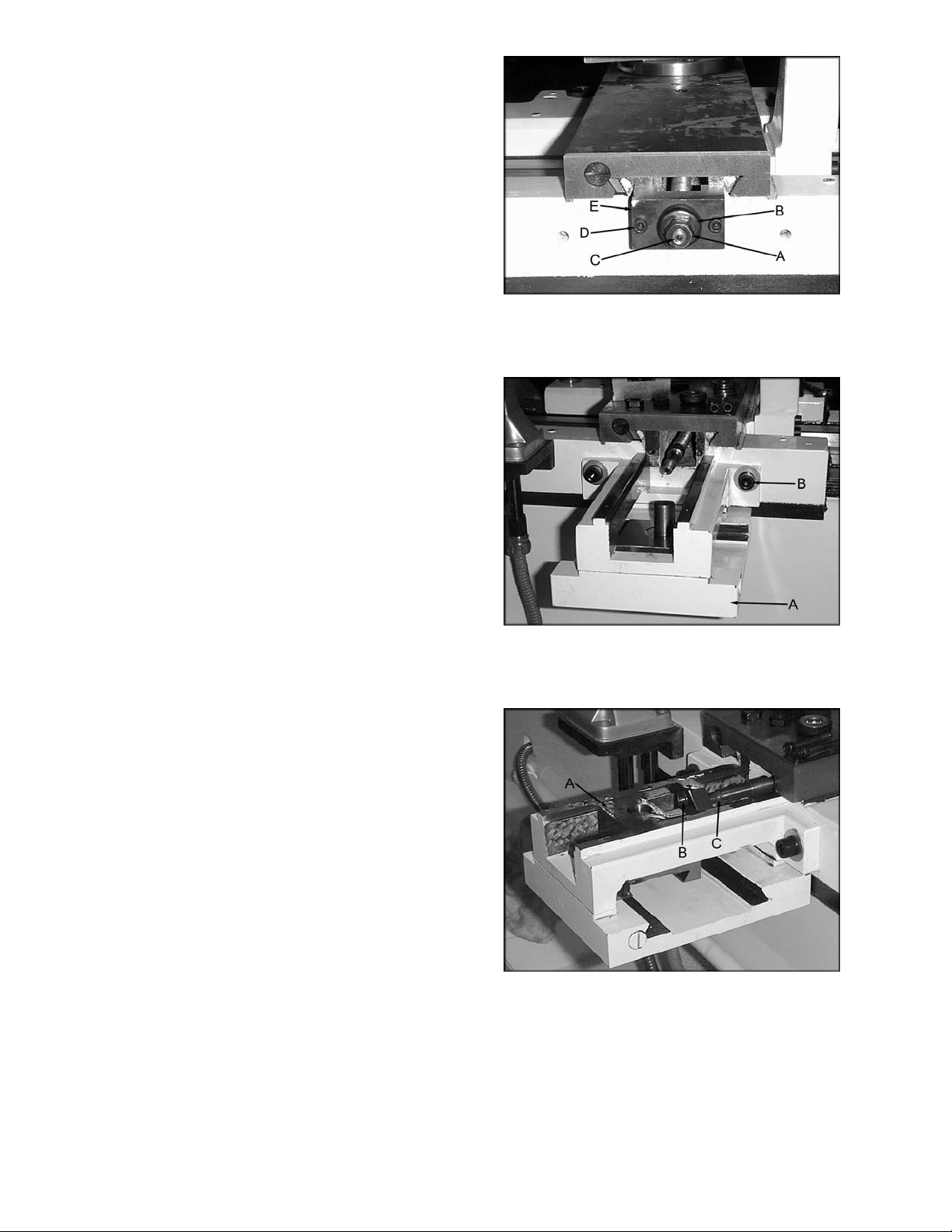

11. Pl ac e the cr oss sli de block (A, Figure 3)

onto the taper sli de r est ( 22) .

12. Posit ion the main body so that the hole in

the cross slide bloc k (B, Figure 3) lines up

with the cross slide screw (C, Figure 3).

13. Push the cros s slide block to engage the

cross slide screw through the hole in the

slide. It is important to get the slide to pass

over the cross slide screw sm oothly. Use a

rubber mallet , or a dead blow hammer to

position t he m ain body so that the slide

passes smoothly ov er the c r oss sli de screw

without lifting it.

Figure 1

Figure 2

Figure 3

3

Page 4

14. Make sure the inner bearing assembly is in

place before r e- assembly, no spacer. The

smaller, i nner diam eter bearing goes on first.

15. Pl ac e the longitudinal slide (A, Figure 4) int o

the main body.

16. Using a di al indicator with a magnetic base

(B, Figure 4) attached to the lathe bed, level

the longitudinal slide to the bed. The slide

assembly is level when it is less than .005”

from end to end. Keep the cross slide block

centered on the lead screw. Use a rubber

mallet, or a dead blow hamm er to position

the main body so that the cross slide block

passes smoothly ov er the lead screw and

that the longitudinal slide is level.

Note: repeat steps 13 & 16 until the longitudinal

slide is level and t he cross slide block passes

smoothly over the cr oss slide scr ew.

17. Tighten two M10 x 30 hex socket cap

screws that hol d the main body in plac e.

18. Re-check the longitudinal slide for level.

19. Clean and lightly oil all gib surfaces that

were previously r em ov ed.

20. Replac e the taper slide, gibs and gib

screws.

21. Check t o m ak e sure the slide moves easily

and without excessive play.

22. Replac e the outer bearing assembly (A,

Figure 5). The smaller inner diam eter

bearing goes on fir st.

23. Install two hex nuts (B, Figure 5). Tighten

the inner nut fir st to snug up the bearing

assembly. Turn the cross slide handle and

check for smooth r otati on. Tighten the jam

nut to hold the adjustment.

Figure 4

Figure 5

Note: It is not necessary, but a good idea to drill

and pin the taper i n plac e through the slide

bracket (3N).

24. Replac e the dust cover.

25. Thread the lock down linkage (A, Figure 6)

into the end of the slide assembly (B, Figure

6).

26. Pl ac e the clam p ( C , Fi gur e 6) onto the lathe

bed and tighten two hex socket cap screws

(D, Figure 6).

27. Line up the hole in clamp with the lock down

linkage (E, Figur e 6) and insert . Tighten the

hex socket cap screw (F, Fi gur e 6).

Figure 6

4

Page 5

28. Using a di al indicator mounted to the

carriage indicate along the tool post, while

moving the carriage, (Figure 7). You are

checking t o see that t he taper sli de is

parallel to t he m ov ement of t he carriage.

Note: You will need to loosen hex socket c ap

screws (12 & 13). This will allow you to turn the

adjusting screw (18).

29. When the taper slide is parallel make sure

the screws (12 & 13) are tight , and mar k the

zero point with a chisel .

• These taper attac hm ents are designed and

intended for use by pr oper ly trained and

experienced personnel only. If you are not

familiar with the proper and safe operation of

a taper attac hm ent, do not use until proper

training and knowledge have been obtained.

• Tighten the clam p br ac k et (59N) only when

using the taper at tachment. You may want

to remove the clamp brac k et when not using

the taper attachm ent.

Figure 7

Replacement Parts

To order parts or reach our ser vice department, call 1-80 0-274-6848 Mo nday through Frida y, 8:00 a.m. to 5:00

p.m. CST. Having the Model Number and Serial Number of your machine available when you call will allow us

to serve you quickly and accurately.

5

Page 6

TAK-GHW Taper Attachment Kit – Exploded View

6

Page 7

TAK-GHW Taper Attachment Kit – Parts List

Index No Part No Description Size Qty

1 ................ TAK1340A-1.............. Slide Base................................................................ ...................................... 1

2 ................ TS-1504081 .............. Hex Socket Cap Screw ............................................ M8 x 40 ......................... 4

3N .............. TAK1340W-3N .......... Slide Bracket............................................................ ...................................... 1

4 ................ TS-1504061 .............. Hex Socket Cap Screw ............................................ M8x 30 .......................... 2

5 ................ TAK1340A-5.............. Screw ....................................................................... M5x 8 ............................ 6

6 ................ TAK1340A-6.............. Longitudinal Slide .................................................... ...................................... 1

7 ................ 84-0004-00 ................ Taper Indicator Plate ............................................... ...................................... 1

8 ................ TAK1340A-8.............. Rivet......................................................................... ...................................... 2

9 ................ TAK1340A-9.............. Angle Indicator Plate................................................ ...................................... 1

10 .............. TAK1340A-10............ Rivet......................................................................... ...................................... 2

11 .............. TAK1340A-11............ Taper Slide .............................................................. ...................................... 1

12 .............. TS-1503031 .............. Hex Socket Cap Screw ............................................ M6 x 12 ......................... 1

13 .............. TS-1503051 .............. Hex Socket Cap Screw ............................................ M6 x 20 ......................... 1

14 .............. TAK1340A-14............ Axle .......................................................................... ...................................... 1

15 .............. TAK1340A-15............ Gib Strip ................................................................... ...................................... 1

16 .............. TAK1340A-16............ Adjusting Screw ....................................................... ...................................... 2

17 .............. TAK1340A-17............ Adjusting Nut ........................................................... ...................................... 1

18 .............. TAK1340A-18............ Adjusting Screw ....................................................... ...................................... 1

19 .............. TAK1340A-19............ Adjusting Knob......................................................... ...................................... 1

20 .............. TAK1340A-20............ Spring Pin ................................................................ 3 x 14 ............................ 1

21 .............. 84-0013-00 ................ Clamping Plate ........................................................ ...................................... 1

22 .............. TAK1340A-22............ Taper Slide Rest ...................................................... ...................................... 1

23 .............. TAK1340A-23............ Gib Strip ................................................................... ...................................... 1

24 .............. TAK1340A-24............ Adjusting Screw ....................................................... ...................................... 1

24A ............ TAK1340A-24............ Adjusting Screw ....................................................... ...................................... 1

25 .............. TAK1340A-25............ Cross Slide Block..................................................... ...................................... 1

26 .............. TS-1503051 .............. Hex Socket Cap Screw ............................................ M6 x 20 ......................... 2

27 .............. TAK1340A-27............ Feed Block ............................................................... ...................................... 1

29 .............. TAK1340A-29............ Dust Cover ............................................................... ...................................... 1

50 .............. TAK1340A-50............ Universal Joint (includes #52,54)............................. ...................................... 1

51 .............. TAK1340A-51............ Spring Pin ................................................................ 4 x 19 ............................ 2

52 .............. TAK1340A-52............ Universal Joint (re: TAK1340A-50) .......................... ...................................... 1

53 .............. TAK1340A-53............ Hex Nut .................................................................... ...................................... 1

54 .............. TAK1340A-54............ Adjusting Shaft (re: TAK1340A-50) ......................... ...................................... 1

55 .............. TAK1340A-55............ Lock Block ............................................................... ...................................... 1

56 .............. TS-1524011 .............. Set Screw ................................................................ M8 x 8 ........................... 1

57 .............. TS-1504041 .............. Hex Socket Cap Screw ............................................ M8 x 20 ......................... 1

58 .............. TAK1340A-58............ Eccentric Shaft......................................................... ...................................... 1

59N ............ TAK1340W-59N ........ Clamp Bracket ......................................................... ...................................... 1

60 .............. TS-1524011 .............. Set Screw ................................................................ M8 x 8 ........................... 1

61N ............ TAK1340W-61N ........ Clamp Block............................................................. ...................................... 1

62 .............. TS-1504081 .............. Hex Socket Cap Screw ............................................ M8 x 40 ......................... 2

63 .............. TS-1550061 .............. Flat Washer ............................................................. M8 ................................. 2

7

Page 8

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.jettools.com

8

Loading...

Loading...