This .pdf document is bookmarked

Operating Instructions and Parts Manual

Drum Sander

Model 22-44 Plus

JET

427 New Sanford Road Part No. M-649003K

LaVergne, Tennessee 37086 Revision D 03/2016

Ph.: 800-274-6848 ECR 16020409184

www.jettools.com Copyright © 2014 JET

shown with opt ional infeed-outfeed tables and open s tand

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use o f these machin es in the processing of metal , plastics, or other m aterials outs ide recommended gui delines m ay

void the warranty. The exceptions are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provid e pr o of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Appli es

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning ................................................................................................................................................... 4

Introduction ............................................................................................................................................. 6

Specifica tions ................................................................................................................ .......................... 6

Features and Terminology ....................................................................................................................... 7

Unpac king ............................................................................................................................................... 8

Contents of the Shipping Container ...................................................................................................... 8

Assembling the O pen Stand ( Optional Accessory) ................................................................................... 9

Casters (Optional Acces s or y ) ............................................................................................................... 9

Assembly .............................................................................................................................................. 10

Installing Dr um Head .......................................................................................................................... 10

Installing Conveyor Table ................................................................................................................... 10

Infeed and Outfeed Tables (Optional Accessor y ) ................................................................................ 10

Dust Cover ......................................................................................................................................... 1 1

Dust Collection ................................................................................................................................... 11

Installing Abrasives ............................................................................................................................ 11

Grounding Inst r uc tions ........................................................................................................................... 13

Extension Cords................................................................................................................................. 14

Adjustments .......................................................................................................................................... 14

Drum Height Control .......................................................................................................................... 14

Switch Lockout ................................................................................................................................... 14

Depth Gauge ..................................................................................................................................... 14

Conveyor Belt T ensi on and Trac k ing .................................................................................................. 15

Trackers............................................................................................................................................. 15

Conveyor Belt Replacement ............................................................................................................... 15

Checking Drum Alignment .................................................................................................................. 16

Fine Tuning Drum Alignment .............................................................................................................. 17

Tension Roller Alignment ................................................................................................................... 18

Tension Roller Pressure Adjustment .................................................................................................. 18

Drum Height Control Adjustment ........................................................................................................ 19

Operation .............................................................................................................................................. 1 9

Basic Operati ng P r oc edur e ................................................................................................................ 19

Setting Depth of Cut ........................................................................................................................... 19

Establishi ng P r oper Dr um Hei ght ....................................................................................................... 19

Selecting S andSmart™ Feed Rates ................................................................................................... 20

Tips for Maximum Performance .......................................................................................................... 20

Maintenance .......................................................................................................................................... 21

Tracker Kit (98- 0080) ............................................................................................................................. 22

Abras ives .............................................................................................................................................. 2 3

Troubleshooting: Motor and Electric al Problems .................................................................................... 2 4

Troubleshooting: Mechanical Problems.................................................................................................. 24

Troubleshooting: Operational Problems ................................................................................................. 2 6

Optional Accessories ............................................................................................................................. 27

Replacement Parts ................................................................................................................................ 27

Conveyor and Motor A ssembly........................................................................................................... 28

Parts List: Conv ey or and Motor A ssembly .......................................................................................... 29

Drum Head Assembly ........................................................................................................................ 30

Parts List: Dr um Head Assembly ........................................................................................................ 31

Parts List: Open Stand – #609004 (Optional Accessory)..................................................................... 33

Parts List: Closed St and – #609005 ( Optional Accessory) .................................................................. 34

Parts List: Inf eed and Outfeed Tables – #98-2202 (Optional A c c essory) ............................................. 35

Electri c al Connec tions ........................................................................................................................... 36

3

Warning

1. Read and understand this entire manual before att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This sander is designed and int ended for use by proper ly t rained and experi enced personnel onl y. If

you are not f amiliar wit h the proper and safe operati on of a sander, do not use unt il proper training

and knowledge have been obtained.

5. Do not use this sander f or other than it s intended use. If used for other pur poses, JET disclaim s any

real or implied warranty and holds itself harmless fr om any injury that m ay resul t from that use.

6. Always wear appr oved safety glasses/face shields while usi ng this sander. Everyday ey eglasses only

have impact resistant lenses; they are not safety glasses.

7. Before operati ng this sander, rem ove tie, rings, watches and other j ewelry, and r oll sleeves up past

the elbows. Remove all loose clothing and confine l ong hair . Non-slip footwear or anti-skid floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended peri ods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not oper ate this machine while tir ed or under t he i nfluence of drugs, alcohol or any medi c ation.

11. Mak e c ertain the switch is in the OFF position before connecting the machine to the power supply.

12. Mak e c ertain the machine is properl y grounded.

13. Mak e all machine adjustments or maintenance with the machine unplugged f r om the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Make sure the sander is firmly secured to the stand or work tabl e before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. Pr ov ide for adequate space surroundi ng work area and non-glare, ov er head lighting.

19. Keep the floor around the machi ne cl ean and free of scrap material, oil and grease.

20. Keep v isitors a safe distance from the work area. Keep children away.

4

21. Mak e y our workshop child proof wit h padlocks, master switches or by removing starter keys.

22. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

23. M aintain a balanc ed stance at all t imes so that you d o not fall or lean against mov ing parts. Do not

overreach or use exc essive force to perform any machine operation.

24. S tand to one side of the conv eyor and m ake sure no one else is standing i n line with t he conv eyor

while feedi ng into the machine. Should a part sli p while being fed, it may exit t he machine at a high

rate of speed and can cause injuries to anyone standing directly in front of the infeed.

25. Use the right t ool at the corr ect speed and f eed rat e. Do not forc e a tool or att achment to do a job for

which it was not designed. T he ri ght tool will do the job better and safer.

26. Use recom mended accessories; improper accessories may be hazardous.

27. Maintain tools with care. Keep abrasives clean for the best and safest performance. Follow

instructions for lubricating the machine and changing accessories.

28. Always feed stock against the rotation of the drum.

29. Keep your hands clear when feeding parts onto the conveyor. The part will be forced down as it

begins to feed, causi ng a pinc hing ac tion bet ween the par t and t he conv eyor bed. Nev er reach i nto a

running mac hine. Turn off sander and disconn ect from power befor e att empting to r etriev e parts fr om

beneath the drum.

30. Turn of f the m achine and discon nect f rom power bef ore cleani ng. Use a bru sh or com pressed air to

remove chips or debris — do not use your hands.

31. Do not stand on the machine. Serious injur y c ould occur if the machine tips over.

32. Never leave the machine r unning unattended. Turn t he power off and do not leave the machine until it

comes to a complete stop.

33. Remove loose items and unnecessary work pi eces from the area before starting the machine.

Familiariz e y our self with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result i n mi nor i njur y and/or

possible machine damage.

This means that if precautions are not heeded, it may result i n serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Introduction

This manual is provided by JET, covering the safe operation and maintenance procedures for a JET

Model 22-44 Plus Drum Sander. This manual contains instructions on installation, safety precautions,

general operating procedures, maintenance instructions and parts breakdown. This machine has been

designed and constructed to provide years of trouble free operation if used in accordance with

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local suppli er or JET. JET can also be reached at our web site: www.jettools.com.

Specifications

Model Number .......................................................................................................................... 22-44 Plus

Stock Num ber.............................................................................................................................. 649003K

Maximu m Width (in.) ..........................................................................................................44 (two passes)

Minimum Lengt h (i n.) ......................................................................................................................... 2-1/4

Maximum Thickness (in.) ......................................................................................................................... 4

Minimu m Thicknes s (in.) ..................................................................................................................... 1/32

Drum Size (in.) ................................................................................................ 5 x 22 Extrusion, A luminum

Drum Speed (RPM) ........................................................................................................................... 1700

Dust Chute (in.) ....................................................................................................................................... 4

Conveyor Motor ............................................ 90DCV, 40 RPM, 0.45 A, 43 inch-lb. torque, direct drive D.C.

Conveyor Vari able Feed Rate (FPM) ............................................................................. 0-10 (SandSmart)

Motor ........................................................................................ TEFC, Induction, 1-3/4HP, 1Ph, 115V only

Overall Dimensions, assembled (in.) ............................................................................... 28L x 40W x 52H

Stand Footpri nt (in.) .................................................................................................................. 15L x 40W

Net Weigh t (lb s.) .................................................................................................................................. 23 1

Shipping Weigh t (lbs.) .......................................................................................................................... 25 4

The above specifications were current at the time this manual was publi shed, but because of our policy of

continuous impr ovement, JET reserves the ri ght to change specifications at any tim e and without prior

notice, without incurring obligations.

6

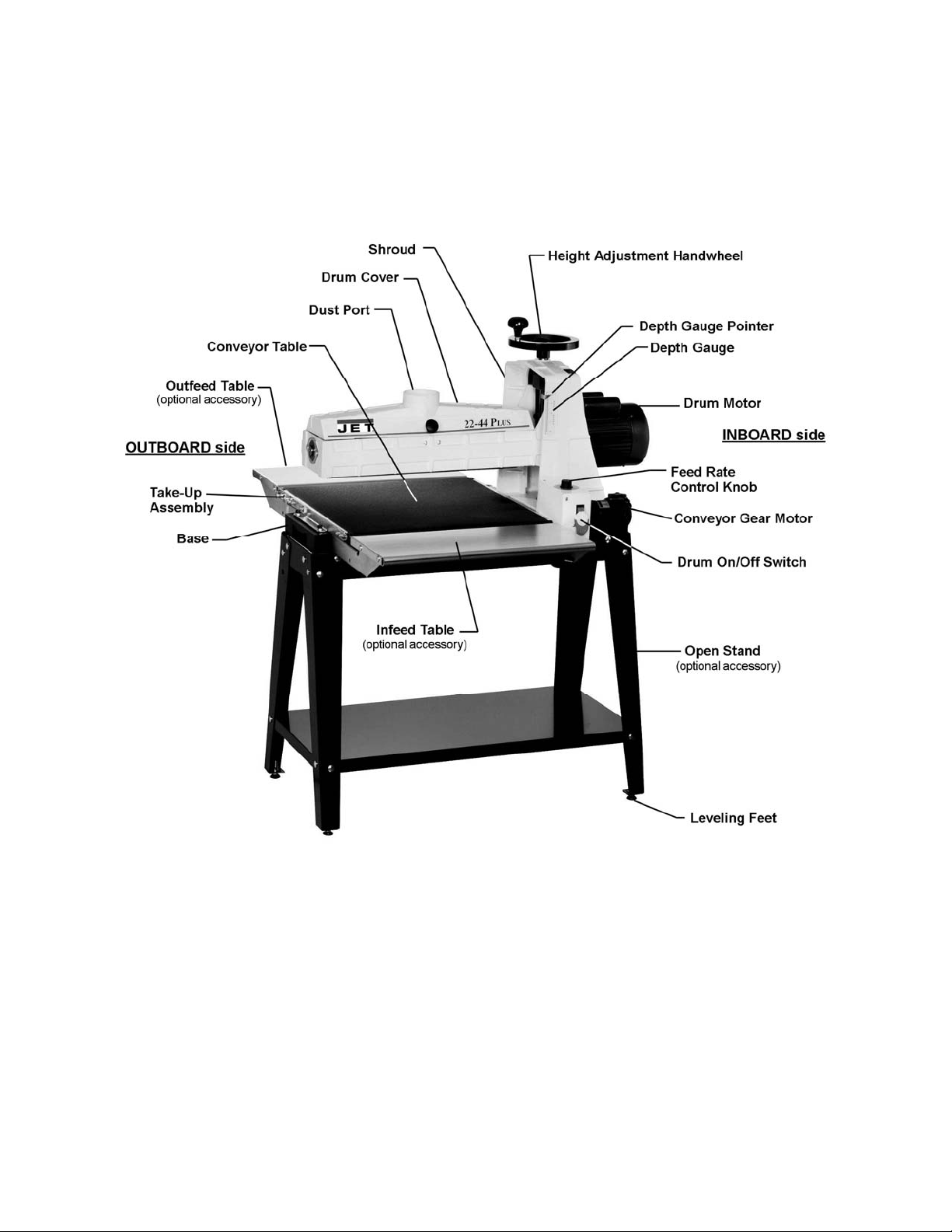

Features and Terminology

The illustrat ion below shows the major components and f eatures of the 22-44 Plus Sander. These are

referenc ed throughout t he manual and will help to familiarize you with the operation and f unctions of the

machine.

Figure 1

7

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until the Drum

Sander is assembled and running properly.

Compare the c ontent s of y our cont ainer wit h t he

following parts list to make sure all parts are

intact. Mi ssing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Container

Refer to Figure 2

Box 1:

1 Drum Sander

1 Handwheel

1 TUF Tool

1 Abrasive Strip (already i nstalled on drum)

1 Owner’s Manual (not shown)

1 Warranty Car d (not shown)

1 Hardware Bag containing:

4 Socket Head Cap Screws, 5/16”-18x3/4”

4 Lock Washers, 5/16”

4 Flat Washers, 5/16”

4 Hex Cap Screws, 3/8”-16x3/4”

4 Flat Washers, 3/8”

3 Hex Wrenches, 1/8”, 4mm and 6mm (not

shown)

Box 2:

1 Conveyor Assembly

Read and understand the

entire contents of this manual before

attempting set-up or operation. Failure to

comply may cause seriou s injury.

Figure 2

8

Assembling the Open Stand (Optional Accessory)

(Refer to Figure 3. If fur ther clarification is needed, c onsult the parts breakdown on page 35.)

Tools requi red for St and assembly: Ratchet wrench with 1/2” socket

1. Assembl e legs (H) to outside of Short Rails (L) using carr iage bolts (N) and flanged lock nuts (O).

Finger tighten only .

2. Assem ble Long Rail (K) on inside of legs and on top of Short Rails (L). Finger t ighten only. NOT E:

Flange of Long Rail ( K) overl aps flange of Short Rail (L). See Det ail 1 below.

3. Turn stand upside down. I nstall shelf (J) into legs (H) using carriage bolts and lock nuts.

4. Fully tighten all flanged lock nuts in shelf and legs.

5. If you ar e using the provi ded leveling f oot (M), pl ace it in bot tom hole of leg by placing a hex nut (P)

and flat washer (R) ab ove and bel ow the leg fl ange. If you are mounting the opti onal casters, see

“Casters” below.

6. Tur n stand ri ght- side up, and lev el it using the lev eling f eet. Tighten t he leveli ng feet hex nuts agai nst

the leg flange.

Casters (Optional Accessory)

1. If you are installing the optional casters, pr ess down on the tab to lock the caster, then remove the

hex nut and washer with a 19m m wrench. Install the caster through the hole i n the stand leg and

secure it with the washer and hex nut. See Detail 2 below.

2. Press down with your foot on the large tab to lock a caster; press down on the small tab to unlock it.

Figure 3

9

Assembly

Tools requi red for assemb ly:

1 Flat head screwdriver

1 Set of open-end wrenches

1 Set of Hex wrenches

1 Adjustable wrench

Installing Drum Head

The drum sander must be bolted down to a

workbench or stand. If you pur c hased o ne of the

JET stands, plac e the sander b ase on t he stand

and align the holes. Secure the sander to the

stand using f our 3/8” x 3/ 4” hex cap screws and

four 3/8” fl at washers. See F igure 4.

Attach the handwhe el ( A, Fi gure 6) t o the hei ght

adjustment screw, and tighten the two set

screws with the 4mm hex wrench suppli ed.

Installing Conveyor Table

1. Rai se the drum as f ar as it will go by t urni ng

the handwheel (A, Fi gur e 5) cl oc k wise.

Figure 4

2. Align t he four holes in the convey or with the

four holes in the base of t he dr um assembl y .

3. Secure the conveyor in place with four

5/16”-18 x 3/4” socket head cap screws (B,

Figure 5), f our 5/16” lock washers and four

5/16” flat washers.

4. Plug the motor cord into the control box

receptacle.

IMPORTANT: The conveyor belt has been over-

tensioned for the purpose of shipping. Before

operating the sander, adjust the belt tension

according t o instr uc tions on page 15.

Infeed and Outfeed Tables (Optional Accessory)

1. Bolt the base bracket (B, Figure 6) to the

sander base with two 3/ 8”-16 x 1” hex head

cap screws (C) and two 3/8” flat washers

(D). Tighten the screws.

2. Mount the table (A) to the base bracket (B)

with four 1/4"-20 x 3/4" carriage bolts (E),

four 1/4" fl at washers (F) and four 1/4" hex

nuts (G). Note: Leave the carriage bolts

loose for now.

Figure 5

3. Plac e a straight edge on the conv eyor bed

and extendi ng out over the extension table.

Raise or lower the ext ension table until it is

level with, or slightly below, the surface of

the conveyor belt . Ti ghten the hex nuts (G).

4. Repeat for the other table.

Figure 6

10

Dust Cover

To open the dust c ov er, push i n on t he knob (C,

Figure 5) and lift. The latch can be adjusted

using the screw behind it.

Dust Collection

Dust collection is mandatory for a safe work

environment and extended abrasive life. The 2244 Plus is equipped with a 4” du st c ollection port

at the top of the dust cov er . It is designed t o be

used with standard 4” dust collection hose

connected to a high volume dust collector

(minimum 500 CFM), as shown in Fi gur e 7.

JET offers a variety of Dust Col lectors and Air

Filtration Uni ts. Contact your local distribut or or

visit our website for more information.

Installing Abrasives

An 80-grit abrasive strip is already installed on

the drum of your sander. Page 23 offers

information on other abrasives available and

their recommended uses.

Figure 7

Proper attachment of the abrasive strip to the

drum is critical to achieving top performance

from your drum sander. Abrasive strips do not

have to be pre-m easured. The end of t he roll is

first t apered and attached to the left (out board)

side of the drum. Then the strip is wrapped

around the drum , and the second taper i s made

for attac hment to the right (inboard) si de of the

drum.

NOTE: When using Ready To Wrap

abrasives, not all of the steps below are

necessary. You can use the original abrasive

strip mounted to the drum as a template for

cutting your own stri ps.

1. Mar k and cut a taper at one end of t he roll

as shown in Figur e 8. Because the tapered

end should use al l of the l eft (outboar d) slot

width, its end must be trimmed back as

shown.

2. Rai se the fastener lev er (D, Figur e 9) on t he

outboard end of drum, and insert the

tapered end of the abr asive (E, Figure 9) so

that it uses most of the width of the slot.

Release the fast ener lever to securely hold

the strip end to the fastener.

TM

Figure 8

(not applicable to “Ready - To-Wrap” strips)

Figure 9

3. Begin wrapping the strip around the drum.

The tapered edge of the strip end should

follow the edge of the drum.

4. Continue to wrap the abrasive in a spiral

fashion by rotati ng the drum with one hand

and guiding the strip with the other (Figure

10).

Figure 10

11

Loading...

Loading...