Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Oscillating Drum Sander

Model 22-44OSC

JET

427 New Sanford Road Part No. M-659006K

LaVergne, Tennessee 37086 Revision D 03/2016

Ph.: 800-274-6848 ECR 16020409184

www.jettools.com Copyright © 2015 JET

Page 2

Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use o f these machin es in t he processing of metal , plasti cs, or other mat er ials out s ide recommend ed gui delines m ay

void the warranty. The exceptions are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Informa tion

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Appli es

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

Table of Contents

Warranty and Service ............................................................................................................................................ 2

Table of Contents .................................................................................................................................................. 3

Warning ................................................................................................................................................................. 4

Introduction ........................................................................................................................................................... 6

Specifications ........................................................................................................................................................ 6

Features and Terminology .................................................................................................................................... 7

Unpacking ............................................................................................................................................................. 8

Shipping Contents ................................................................................................................................................. 8

Assembly ............................................................................................................................................................... 9

Stand Assembly ................................................................................................................ ................................ 9

Drum Head Installation .................................................................................................................................... 10

Conveyor Table Installation ............................................................................................................................. 10

Installin g Accessories .......................................................................................................................................... 10

Infeed and Outfeed Tables .............................................................................................................................. 10

Dust Cover .................................................................................................................... .................................. 11

Dust Collection ................................................................................................................................................ 11

Installing Abrasives ......................................................................................................................................... 11

Grounding Instructions ........................................................................................................................................ 13

Extension Cords .............................................................................................................................................. 13

Operating Controls .............................................................................................................................................. 14

On/Off Switch (Sanding Drum) ........................................................................................................................ 14

Switch Lockout ................................................................................................................................................ 14

Conveyor ......................................................................................................................................................... 14

Drum Height Control ........................................................................................................................................ 14

Oscillator Switch .............................................................................................................................................. 14

Adjustments ........................................................................................................................................................ 15

Depth Gauge ................................................................................................................................................... 15

Conveyor Belt Tension and Tracking .............................................................................................................. 15

Trackers .......................................................................................................................................................... 15

Conveyor Belt Replacement ............................................................................................................................ 16

Checking Drum Alignment ............................................................................................................................... 16

Fine Tuning Drum Alignment ........................................................................................................................... 17

Tension Roller Alignment ................................................................................................................................ 17

Tension Roller Pressure Adjustment ............................................................................................................... 18

Drum Height Control Adjustment ..................................................................................................................... 18

Operation ............................................................................................................................................................ 19

Basic Operating Procedure ............................................................................................................................. 19

Setting Depth of Cut ........................................................................................................................................ 19

Establishing Proper Drum Height .................................................................................................................... 19

Selecting SandSmart™ Feed Rates ............................................................................................................... 19

Tips for Maximum Performance ...................................................................................................................... 20

Maintenance ........................................................................................................................................................ 21

Tracker Kit ........................................................................................................................................................... 22

Abrasives ............................................................................................................................................................ 23

Abrasive Selection Guide ...................................................................................................... .......................... 23

Optional Accessories .......................................................................................................................................... 24

Troubleshooting .................................................................................................................................................. 24

Troubleshooting – Motor and Electrical Problems ........................................................................................... 24

Troubleshooting – Mechanical Problems ........................................................................................................ 25

Troubleshooting – Operational Problems ........................................................................................................ 26

Replacement Parts .............................................................................................................................................. 26

Drum Head Assembly – Exploded View .......................................................................................................... 27

Drum Head Assembly – Parts List .................................................................................................................. 28

Conveyor and Motor Assembly – Exploded View ........................................................................................... 30

Conveyor and Motor Assembly – Parts List .................................................................................................... 31

Gearbox Assembly .......................................................................................................................................... 32

Closed Stand Assembly .................................................................................................................................. 33

Infeed and Outfeed Tables .............................................................................................................................. 34

Wiring Diagram ................................................................................................................................................... 35

3

Page 4

Warning

1. Read and understand this entire manual before attempting assembly or operati on.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This sander is designed and int ended for use by proper ly t rained and experi enced personnel onl y. If

you are not f amiliar wit h the proper and safe operati on of a sander, do not use unt il proper training

and knowledge have been obtained.

5. Do not use this sander for other than it s intended use. If used for other pur poses, JET disclaim s any

real or implied warranty and holds itself harmless fr om any injury that may result from that use.

6. Always wear appr oved safety glasses/face shields while u si ng this sander. Everyday eyeglasses only

have impact resistant lenses; they are not safety glasses.

7. Before operati ng this sander, rem ove tie, rings, watches and other j ewelry, and r oll sleeves up past

the elbows. Remove all loose clothing and c onfine l ong hair . Non-slip footwear or anti- skid floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint .

• Crystalline silica from bricks, cem ent and other masonry products.

• Arsenic and chrom ium from chemically treated lumber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, al c ohol or any m edic ation.

11. M ak e c er tain the switch is in the OFF position bef ore connecting the machine to the power supply.

12. M ak e c er tain the machine is properly grounded.

13. M ak e all machine adjustments or maintenance with the machine unplugged f r om the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machi ne is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. M ak e sure t he sander is firmly secured to the stand or work table before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. Provide for adequate space surroun ding work area and non-glar e, overhead lighting.

19. Keep the floor around the machi ne clean and free of scrap material, oil and grease.

20. Keep visitors a safe dist anc e from the work area. K eep children away.

4

Page 5

21. M ak e y our workshop chi ld proof with padlock s, m ast er switc hes or by r em oving starter keys.

22. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

23. M aintain a balanc ed stance at all t imes so that you d o not fall or lean against mov ing parts. Do not

overreach or use exc essive force to perform any machine operation.

24. S tand to one side of the conv eyor and m ake sure no one else is standing i n line with t he conv eyor

while feedi ng into the machine. Should a part sli p while being fed, it may exit t he machine at a high

rate of speed and can cause injuries to anyone standing di r ec tly in front of the infeed.

25. Use the ri ght t ool at the corr ect speed and f eed r ate. Do not forc e a tool or att achment to do a job for

which it was not designed. T he ri ght tool will do the job better and safer.

26. Use recom mended accessories; improper accessories m ay be hazardous.

27. Maintain tools with care. Keep abrasives clean for the best and safest performance. Follow

instructions for lubricating t he machine and changing accessories.

28. Always feed stock against the r otation of the drum.

29. Keep your hands clear when feeding parts onto the conveyor. The part will be forced down as it

begins to feed, causi ng a pinc hing ac tion bet ween the par t and t he conv eyor bed. Nev er reach i nto a

running mac hine. Turn off sander and disconn ect from power befor e att empting to r etriev e parts fr om

beneath the drum.

30. Turn of f the m achine and discon nect f rom power bef ore cleani ng. Use a bru sh or com pressed air to

remove chips or debris — do not use your hands.

31. Do not st and on the machine. Serious injur y c ould oc c ur if the machine tips over.

32. Never leave the machine r unning unattended. Turn the power off and do not leav e the mac hine until it

comes to a complete stop.

33. Remove loose items and unnecessary work pieces from the area bef or e starting the machine.

Familiariz e y our self with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result i n mi nor i njur y and/or

possible machine damage.

This means that if precautions are not heeded, it may result i n serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by JET covering the safe operation and maintenance procedures for a JET

Model 22-44OSC Oscillating Drum Sander. This manual contains instructions on installation, safety

precautions, gener al oper ati ng procedur es, mai ntenance i nstructi ons and parts breakdo wn. Thi s mac hine

has been designed and c onst ruct ed to prov ide c onsistent , l ong-t erm operati on if used i n accor dance with

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local suppli er or JET. JET can also be reached at our web site: www.jettools.com.

Specifications

Model number ........................................................................................................................... 22-44OSC

Stock numbers:

Sander kit complete ................................................................................................................ 659006K

Sander only .............................................................................................................................. 659006

Con veyor ...................................................................................................................... ....... 649003-02

Stand ...................................................................................................................................... 659006S

Capacities:

Maximum board width (i n.) .................................................................................................44 (two passes)

Minimum board length (in.) ................................................................................................................ 2-1/4

Maximum board thic k ness (in.) ................................................................................................................ 4

Minimum board thick ness (in.) ............................................................................................................ 1/32

Motor and Elect ri c als:

Conveyor motor ............................................ 1/30HP, 0.45A, 40 RPM, 43 inch-lb. torque, direct drive D.C.

Drum motor .....................TEFC induction, capacitor start, 1-3/ 4HP (1.3kW), 1PH, 115V only, 15.5A, 60Hz

Motor speed (RPM) ........................................................................................................................... 17 20

Drum speed (RPM) ............................................................................................................................ 17 00

Conveyor variable feed rate (FPM) ................................................................................ 0-10 (SandSmart)

On/off switch ............................................................................................ paddle style with removable key

Recommended cir c uit * ........................................................................................................................ 20A

Main Materials:

Frame........................................................................................................................................... cast iron

Drum .......................................................................................................................... . aluminum extrusion

Cabinet............................................................................................................................................... steel

Dimensions:

Con veyor height from floor (in .) .............................................................................................................. 3 2

Drum size (in.) ............................................................................................................................... Ø5 x 23

Dust chute (in.) ........................................................................................................................................ 4

Cabinet height (in.) ................................................................................................................................ 2 9

Overall dimensions, assembled (in.) ............................................................................... 44L x 27W x 52H

Weights:

Net (lbs.) ............................................................................................................................................. 336

Shipping (lbs.) ..................................................................................................................................... 36 3

* subject to local/national electrical codes.

The above specifications were current at the tim e this manual was published, but because of our policy of

continuous impr ovement, JET reserves the right to change specific ations at any tim e and without prior

notice, without incurring obligati ons.

6

Page 7

Features and Terminology

The illust ration below shows the maj or components and featur es of the 22-44O SC Sander. These are

referenc ed throughout t he manual and will help to familiarize you with the operation and functions of the

machine.

Figure 1 – Featur es

7

Page 8

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until the Drum

Sander is assembled and running properly.

Compare the c ontent s of y our cont ainer wit h t he

following parts list to make sure all parts are

intact. Mi ssing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Note: The letter designat ors identifyi ng parts on

this page are used throughout the Assembly

section of this manual for reference convenience.

Shipping Contents

Main Container Contents

Contents show n in Figur e 1

1 Handwheel (A)

1 TufTool (B)

1 Drum Head (C)

1 Conveyor Table Assembly (D)

1 Bottom Plate (E)

2 Stand Side (F)

1 Rear Plate (G)

1 Front Plat e (H)

1 Hardware Bag (see below for c ontents)

1 Owner's Manual (not shown)

Hardware Bag Contents

Note: The letter designat ors identifyi ng parts on

this page are used throughout this manual for

reference convenience.

04 Hex Cap Screw, 3/8”x1” (J)

04 Socket Head Cap Scr ew, 5/ 16"x3/4” (K)

12 Hex Cap Screw, 5/16”x 1/2” (L)

04 Flat Washer, 3/8" ( M)

04 Lock Washer, 5/16” ( N)

16 Flat Washer, 5/16" ( P )

03 Hex Wrenches, 1/8" , 4mm and 6mm (not

shown

Figure 2 – Main Container Contents

Figure 3 – Hardwar e Bag Contents

8

Page 9

Assembly

Stand Assembly

1. Position two stand sides (F1, F2) on the

ground with the base down, about 3 feet

apart with the openings toward the center.

2. Mount the bottom plate (E) to the stand

sides with four each 5/16" hex cap screws

) and 5/16" flat washers (P1). Hand-

(L

1

tighten only at t his tim e.

3. Secure the left side of the rear plat e (G) to

the left stand side (F

hex cap screw s (L

). Hand-tight en only .

(P

2

F

1

) with t wo each 5/16"

1

) and 5/16" flat washers

2

PPPPP

4. Secure the r ight si de of the rear plate (G) t o

the right st and side (F

as above. Hand-tighten only.

5. Secure the front plate (H) to the left and right

stand sides (F

, F2) in the same manner as

1

above with f our each 5/16" hex c ap screws

(L) and 5/16" flat washers (P ). Hand-tight en

only.

2

P

L

2

G

) in the sam e m anner

2

Base

L

1

P

1

E

F

Base

2

H

Figure 4

9

Page 10

Drum Head Installation

Tools required for as s em bly :

001 Flat head screwdriver

001 Set of open-end wrenches

001 Set of Hex wrenches

001 Adjustable wrench

Referring to Fi gur e 5:

1. Place the sander (C) ont o the stand previously

assembled.

The sand er is very h eavy. Use a

hoist or assi st ance when moving to avoid inju ry

to self and equipmen t.

Align the f our threaded mounting holes of the

sander base (C

stand.

2. Secure the sander (C) to the stand from inside

the cabinet using four 3/8” x 1” hex cap

screws (J) and four 3/8” flat washers (M).

3. Attach the handwheel (A) to the height

adjustment sc rew (C

screws with the 4mm hex wrench supplied.

) with t he slotted holes on the

1

), and tighten the two set

2

After installing the drum head to the stand, finish

tightening all mounting hardware that was previously hand-ti ghtened during the stand assembly.

Conveyor Table Installation

1. Raise the drum as f ar as it will go by turning the

handwheel (A) clockwise.

2. Place the conveyor (D) onto the sander

base (C1).

Align the four holes in the conveyor (D) with the

four holes in the sander bas e.

3. Secure the conveyor i n place with four 5/16” x

3/4” socket head cap screws (K), four 5/16”

lock washers (N) and four 5/16” flat

washers (P ).

4. Plug the sander's motor cord into the

receptacl e of t he contr ol box (D

Important: The conveyor belt has been over-

tensioned for the purpose of shipping. Before

operation, adj ust the belt tension (see page 15).

).

1

Installing Accessories

Infeed and Outfeed Tables

Figure 5

Figure 6

2. Mount the table (A) to the base brack et (B) wit h

four 1/4" -20 x 3/4" carriage bol ts (E), four 1/ 4"

flat washers (F) and four 1/4" hex nuts (G).

Note: Leave the carriage bolts loose for now.

The infeed and outfeed table is an optional

accessory.

1. Bolt the base bracket (B, Fi g. 6) to the sander

base with two 3/8”-16 x 1” hex head cap

screws (C) and two 3/8” flat washers (D).

Tighten the screws.

3. Place a str aight edge on the conv eyor bed and

extending out over the extension table. Raise

or lower the ex tension t abl e until it is l evel wit h,

or slightly below, the surface of the conveyor

belt. Tight en the hex nuts (G).

4. Repeat for the other table.

10

Page 11

Dust Cover

To open the dust cover, push in on the knob

(A, Fig. 7) and lif t. The lat ch can be adj usted using

the screw behind it.

Dust Collection

Dust collection is mandatory for a safe work

environment and extended abrasive life. The

22-44OSC is equi pped with a 4” dust collection por t

at the top of the dust cover. It is designed to be

used with standard 4” dust collection hose

(B, Fig. 7) connected to a high volume dust

collector (minimum 500 CFM) as shown.

JET offers a variety of Dust Collectors and Air

Filtration Units. Contact your local distributor for

more informati on.

Figure 7

Installing Abrasives

An 80-grit, 3-1/8” wide abrasive strip is already

installed on the drum of your sander.

Proper attac hm ent of the abr asiv e stri p t o the drum

is critical to achieving top performance from your

drum sander. Abr asive strips do not have to be premeasured. The end of the roll is first tapered and

attached to the left (outboard) side of the drum.

Then the stri p is wrapped around t he dr um, and the

second taper is made for attachment to the right

(inboard) side of the drum.

Note: You can use the original abrasive strip

mounted to the dr um as a templat e for cutting y our

own strips.

1. Mark and cut a taper at one end of the roll as

shown in Figure 8. Because the tapered end

should use all of the left (outboard) slot width,

its end must be trimmed back as shown.

2. Raise the fastener lever (D, Fig. 9) on the

outboard end of drum, and insert the tapered

end of the abrasive (E, Fig. 9) so that it uses

most of the width of the slot. Release the

fastener l ever to securely hold the str ip end to

the fastener.

Figure 8

Figure 9

3. Begin wrappi ng the strip around t he drum. The

tapered edge of the str ip end should follow the

edge of the drum.

4. Continue to wrap the abrasive in a spiral

fashion by r otati ng the drum with one hand and

guiding the strip with the other (Figure 10).

Successive windings of the strip should be

flush with previous windings without any

overlap.

Figure 10

11

Page 12

5. Mark the trailing end of the strip where it

crosses the right (inboard) end of the drum

(Figure 11).

6. Remove the abrasiv e strip from the drum, and

cut a taper as was done with t he starting edge

(see Figure 8). Note: The taper on the

remaini ng roll can be used as the taper for the

starting edge of the next strip to be cut.

7. Rewrap the drum beginning at the left, as

described in steps 2 through 4.

8. You can use your fingers to work the infeed

take-up f astener, but it will be more c onvenient

to use the TUF Tool suppli ed with your sander.

Hold the TUFTool with the red end pointing

away from you (Fi gure 12) and insert its hook

into the out side hole of the fastener lever (see

Figure 14).

9. Lif t the lev er with the TUFTool, pulli ng the lever

up until it touches the inside of the drum.

10. Turn the T UFTool counterclock wise and lower

it onto the abrasive strip, making sure it is

holding the paper ti ght (Figure 13).

11. Insert t he tapered end of t he abrasive stri p into

the slot and fastener. It may be necessary to

trim the tapered end of the abrasive strip so

that it does not “bot tom out” against the inside

of the drum.

IMPORTANT: Leave a gap – at least 1/8” –

between the tapered strip and the cl osed end

of the slot (Fi gure 13) to allow stri p to be pull ed

into the f astener as needed. If necessary, trim

the outside edge of t he abrasive strip.

Figure 11

Figure 12

12. Hold t he abrasive in pl ace with your left hand,

lift up the T UFTool and tur n it clockwise whil e

maintaini ng upward pressure. Slowly move the

TUFTool away from you slightly, then down,

while easing it out of the hole. This releases the

lever in its proper posi tion (Figure 14).

All abrasive strips will stretch in use and may

stretch enough to al low the take-up lever to reach

its lowest position so that it cannot maintain tension

on the strip. If this occurs, follow the above

procedures to re-set the take-up lever.

Always remove TUFTool from machine before

operating.

Figure 13

Figure 14

12

Page 13

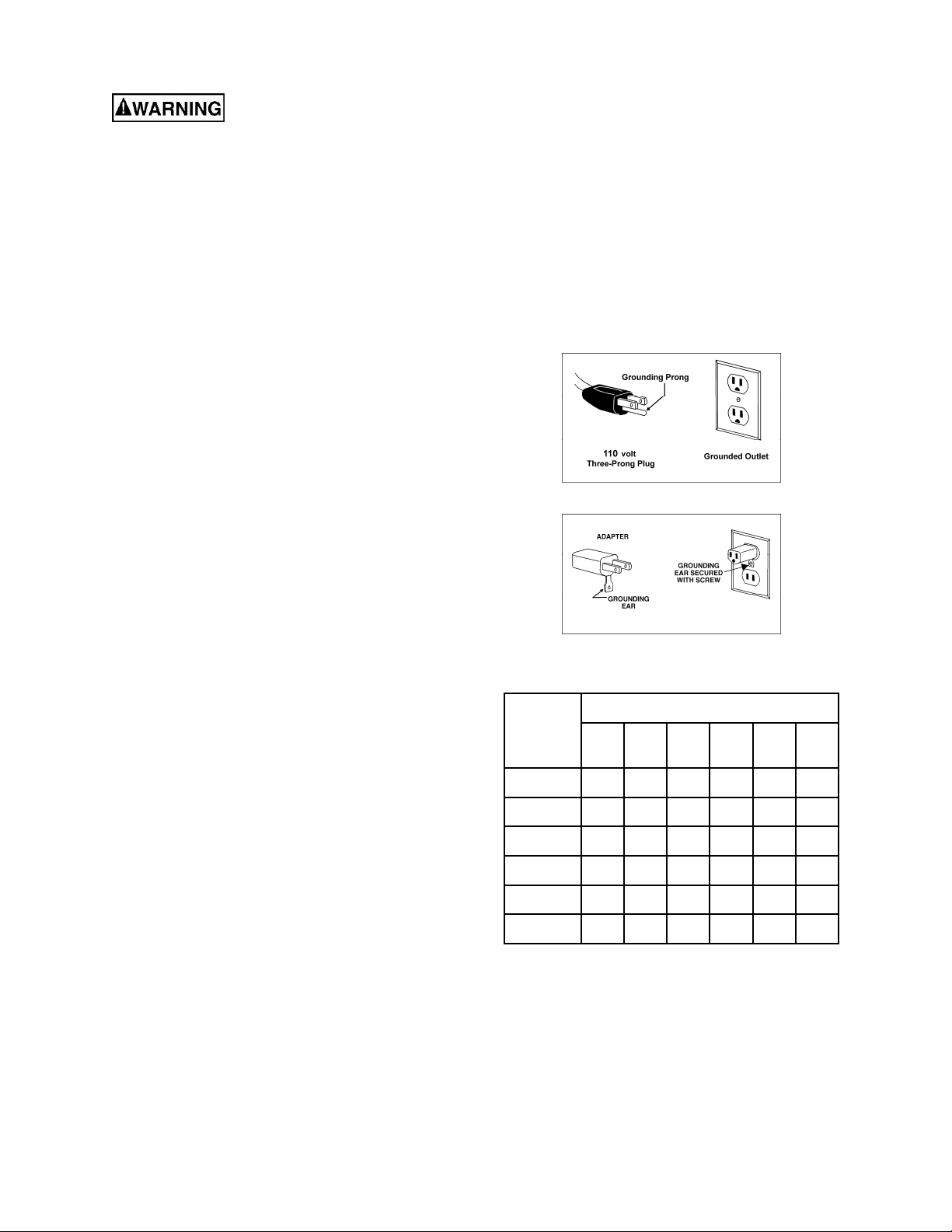

Grounding Instructions

permanent gr ound such as a properly grounded

outlet box, as shown in Fi gur e 16.

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly ground ed to help

prevent electrical shock and possible fatal

injury.

In the event of a malfunction or breakdown,

grounding prov i des a path of least resistanc e f or

electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-groundi ng c onduc tor and a

grounding plug. The plug m ust be inserted into a

matching outlet that is properly installed and

grounded in accord ance wit h all l ocal codes and

ordinances.

Do not modify the pl ug provided. If it will not fit

the outlet , have the proper outlet i nstalled by a

qualified elec trician.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor, with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conduct or. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor t o a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properl y grounded. Use onl y

three wire ex tension cords that have three-prong

grounding plugs and t hree-pole recept acles that

accept the tool ’s pl ug.

Repair or replace a damaged or worn cord

immediately.

As received f rom the factory, your drum sander

is intended f or use on a 20 amp, 110V dedic ated

circuit, whic h has an outlet and a plug that look

like the ones ill ustrat ed i n Figure 15. The sander

cannot be rewired to voltages other than f act ory

settings.

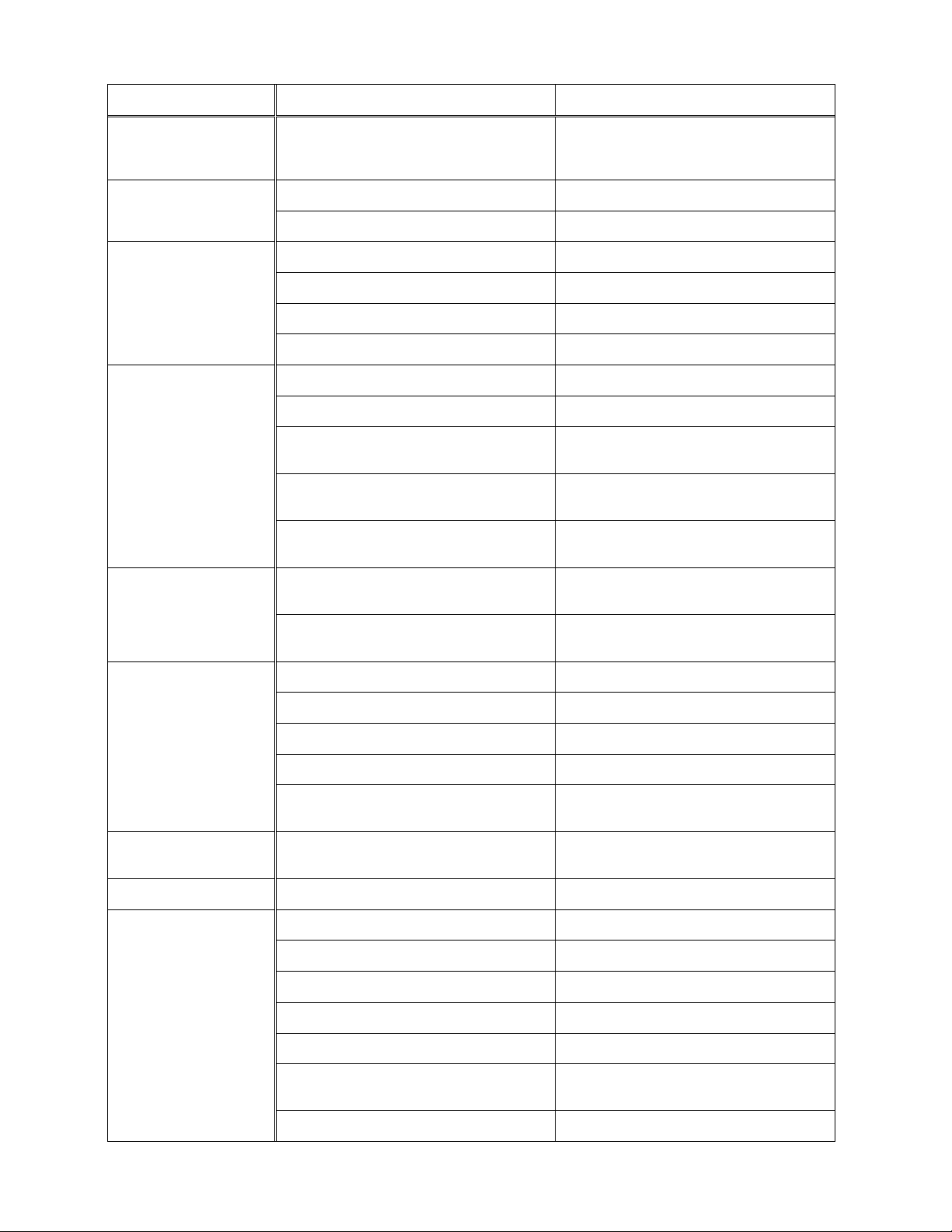

A temporary adapter, which looks like the

adapter ill ustrated in Figur e 16, may be used to

connect this plug to a two-pole receptacle, as

shown in Figure 16, if a pr oper ly grounded outl et

is not available. The temporary adapter should

only be used until a properly grounded outlet

can be installed by a qualified electrician. This

adapter is not applicable in Canada. The

green colored rigid ear, lug, or tab, extending

from the adapter, must be connected to a

Extens ion Cords

If an extension cord is nece s sary, make sure the

cord rati ng is suitabl e for t he amper age listed on

the machine's motor plate. An undersized cord

will cause a drop in line voltage resulting in loss

of power and overheating.

Table 1 shows the correct size cord to use

based on cord length and motor plate amp

rating. If in doubt, use the next heavier gauge.

The smaller the gauge number, t he heavier the

cord.

Figure 15

Figure 16

Recommended Gauges (AWG) of Extension Cords

Extension Cord Length *

25

50

75

100

150

200

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on limit in g the li ne vol tag e drop t o 5V at 150 % of t he

rated amp eres.

NR: Not Recommended.

feet

feet

Table 1

feet

feet

feet

feet

13

Page 14

Operating Controls

On/Off Switch (Sanding Drum)

To start the sander, pul l switch (A, Fig. 17) out. T o

stop the sander, push switch in. This switch

operates the sanding drum only. The conveyor is

controlled separat ely.

Switch Lockout

For safet y and to prevent unauthorized use of the

sander, pull out the key (B, Fig. 17). Press switch

(A, Fig. 17) to OFF position before removing the

key. When t he key i s removed, the drum cannot be

started.

Note: The conv eyor bel t can stil l run when the k ey

is removed).

To replace the key, slide it back into the switch until

it snaps.

Conveyor

The conveyor speed is contolled by the conveyor

speed rate contr ol knob (E, Fig. 18) which sets the

conveyor speed from stopped (knob fully

counterclockwise) to 10fpm (knob fully clockwise).

Drum Height Control

Drum height is cont rolled by the height adjustment

handwheel. Rotating the handwheel counter-

clockwise lowers the drum; clockwise raises it.

One revolution of the handwheel moves the drum

approxim ately 1/16”.

Oscillator Switch

Referring to Fi gur e 18:

The 22-44OSC sander can be operated as a

simple sander or as an oscillating sander.

When operating as a linear sander, the sander

drum rotates as the convey or slides the workpiece

through. W hen in the oscill ating mode, in addition

to the operati on described, the sander drum head

oscillates from left to right as shown in Figure 18.

For linea r sanding mode :

1. Sander must be turned off.

2. Pull the oscillator switch (A) OUT.

Note: Before pulling the oscillator switch out for

linear sanding mode, turn the oscillator switch to

manually position the sanding drum to center or

where otherwise desired.

3. Turn machine on.

Figure 17

Figure 18

For oscillatin g san di ng mode:

1. Sander must be turned off.

2. Press oscillator switch (A) IN and at the same

time rotat e the switch (either direction) until the

pins (B) protruding from the oscillator switch

shaft engage in the detent (C) of the pulley

base.

3. Turn the feed rate control knob (E) fully

clockwise.

Note: The feed rate must be set to maximum

when in the oscillation mode.

4. Turn the machine on.

14

Page 15

Adjustments

Depth Gauge

The depth gauge indicates the distance between

the bottom of the sanding drum and the top of

the conveyor surface. Adjustment is performed

by “zeroing” the gauge.

1. Loosen screw (A, Figure 19) sufficiently to

allow the pointer (B) to be turned to depth

gauge scale.

2. With an abrasive strip on the drum, lower

sanding drum to where it touches top of

conveyor belt.

3. At this drum position, the depth gauge

pointer (B) should align with the zero mark

of the scale. If it does not, loosen screw (A)

and raise or l ower pointer t o align with z ero

on the scale.

4. Re-tighten scr ew (A).

Note: Depending on t he desired accurac y, you

may need to repeat t his process when installing

different abr asive grits.

slippage of conveyor belt on the drive roller

during sanding operation; the conveyor belt is

too loose if it can be stopped by hand pres sure

applied directly to the top of the conveyor belt.

Excessive belt tension can result in bent rollers,

bent brackets, and/ or premature wearing of the

bushings or belt .

Tracking. Belt tracking adjustments are made

while the conveyor belt is running. After the

proper belt t ension is obtained (see abov e), t urn

the conveyor on and set it at t he fastest speed

setting. Watch for a tendency of the conveyor

belt to drift to one side of the conveyor. To

adjust tracki ng, tighten t he take-up screw nut on

the side toward which the belt is drifting, and

loosen the take-up screw nut on the opposite

side an equal amount.

Adjusting t he take-up screw nuts on eit her side

of the conv eyor allows belt t racki ng adjustment s

to be made without aff ecting belt tension.

Note: Adjust tak e-up screw nuts only 1/ 4 turn at

a time. Then allow time for the belt to react to

the adjustments before proceeding further. Try

to avoid over adj ustm ents.

Figure 19

Conveyor Belt Tension and Tracking

Conveyor belt tension adjustment may be

necessary during the break-in period to

compensate for belt stretching.

IMPORTANT: The conv eyor belt has been over-

tensioned for the purpose of shipping. Before

operating the sander, adjust the belt tension

according to the following instructions!

Tension. To adjust the tension of the conveyor

belt, fi rst adj ust the t ake-up scre w nut (A, Fi gure

20) using the attached wrench (B, Figure 20).

Do this on both sides of the c onveyor to obtai n

approxim ately equal tension on bot h sides of the

belt when taut. Insufficient belt t ensi on will cause

Figure 20

Trackers

The sander comes equipped with “Trackers”,

ceramic guides that reduce the amount of

adjustments needed to keep the conveyor belt

tracked (cent ered) on the conveyor bed. These

guides have a magneti c backing to keep t hem in

place. If a Tracker wears through, it can be

reversed by turning it over. The Tracker Kit

section on Page 22 contains more information

about re-setting trackers.

15

Page 16

Conveyor Belt Replacement

1. Unplug the machine from the wall

receptacl e, and unplug the mot or cord from

the control box r ec eptacle.

2. Raise drum to its hi ghest position using the

handwheel.

3. Loosen the conveyor take-up screw nuts

(A, Fig. 20) to relieve belt tension, and slide

the driven roller fully inward.

4. Remove the four bolts that attach the

conveyor table to the base. Lift up the

conveyor t able and remov e it from machine.

Avoid tearing the belt on any edges

underneath the conveyor bed.

5. Install new belt, and re-install conveyor

table. Take care not to damage the

Trackers. T ensi on and trac k the new belt.

Note: If the conveyor belt continually tracks to

one side of the machine, reversing the belt on

the conveyor bed may remedy the problem . To

make sure the conveyor bed is not twisted,

place a level on the conveyor bed. Level the

machine if needed. If there is still a problem,

proceed with the steps below:

Step 1: Check the conveyor drive roller and t he

driven roll er to make sure they are parallel to the

surface of the conveyor bed. To do this, first

center the conv eyor belt on the bed. Then l ay a

straight-edge on the exposed edge of the

conveyor bed on the left (outboard) side,

extending it over the roller. Note the distance

between the roll er and the straightedge.

Step 2: Now repeat S tep 1 on the ri ght (inboard)

side of conveyor. Compare the measurements

from side to side. If they are not equal, loosen

one of the brac kets that hold t he roller i n place.

Tip this bracket until the distance between the

roller and the straight-edge are equal from side

to side, then tight en the bracket.

3. Insert gauge between the drum and conveyor bed at the outer end of the drum

(Figure 21).

Figure 21

With the dust cover open, lower sanding

drum while slowly rotating drum by hand

until the drum lightly contacts the thic kness

gauge.

4. Remove thickness gauge and place under

drum at the other end.

5. If the drum does not contact the thickness

gauge to the same degree as the opposite

end of the drum, ali gnm ent is necessary.

To align the drum:

6. Loosen t he four 3/8” hex cap screws – two

front, two rear (A, Fig. 22). This allows the

entire drum carriage and shroud to be

pivoted on two scr ews – one screw in f ront,

one in back.

7. Lay the thickness gauge under the drum

lengthwise. See Figure 23. Rotate the fine

tune adjustment knob (B, Fig. 22) until the

drum contacts the gauge equally along its

entire surfac e. Rotate the knob clockwi se to

raise the outboard end of the drum,

countercl ockwise to lower the outboard end

of the drum. Use the height adjustment

handwheel to raise or lower the entire drum.

Checking Drum Alignment

The sanding drum must be aligned parallel to

the conveyor bed for proper m achine operati on.

The sanding drum comes preset from the

factory. If a problem with the drum alignment

occurs, foll ow the instructions below.

First inspect the ali gnm ent with a gauge of some

kind. The following procedure uses a steel

straight edge as a gauge.

1. Unplug sander fr om power source.

2. Open the dust cover and remove the

abrasive strip from the drum.

8. When drum is parallel to conveyor, tighten

the four screws (A, Fig. 22).

Conveyor table removed for clarity

Figure 22

16

Page 17

Fine Tuning Drum Alignment

Tension Roller Alignment

Note: This is an operational test. Perform this

alignment after you have become familiar with

sander operati on.

When sanding boards wider than the drum,

drum alignm ent is critical and must be adj usted

exactly level to slightly higher on the outboard

end. This will prevent any ridges from

developing in t he stock. Always check t his on a

piece of scrap wood, as follows, bef ore sanding

the work piece.

1. Run a pi ece of scrap wood a pprox im atel y 6”

wide by 30” to 40” l ong through the sander

sideways so that the end of the board

extends past the end of the drum .

2. Without changing drum height, rotate the

board 180° and sand the same side.

3. If a ri dge is vi sibl e where the drum ov erlaps,

loosen the four screws (A, Fig. 22) and raise

the outboard end of the drum by turning the

fine tune adjustment knob (B, Figure 22)

slightly cl oc k wise.

Important: Only turn fine tune adjustment knob

when all four screws (A, Fig. 22) are loose.

4. Repeat this process until the ridge is

eliminat ed and the entire board is sanded.

5. Tighten the four screws (A, Fig. 23).

The infeed and outf eed rollers are tensioned to

provide downward pre ssure on the workpiece t o

prevent sl ippage on the f eed conveyor. Tension

rollers are set at the factory, but should be

inspected and may require adjustment as the

sander receives use.

Improperly adjusted tension

rollers (i.e. those set too high, rendering

them non-functional) could allow kick-back

of pieces being sanded.

1. Unplug sander from power source and

remove abrasive (D, Figure 24) from drum.

2. Loosen all f our hex nuts on the bearing bolts

(E, Figure 24). This will allow both tension

rollers to drop to their lowest position.

(NOTE: Figur e 24 only shows outboard end

of drum. Adjustments must be made on both

ends of drum.)

3. Lower sanding drum to where it just contacts

the conveyor bed. Then raise the sanding

drum by making 3/4 turn of the height

adjustment handle.

4. Tighten the four hex nuts (E, Figure 24).

Both tension rollers are now positioned

about 1/16” belo w the bot tom of the sanding

drum.

Note: Keep trac k of how many revolutions of the

fine tune knob are needed to change drum

alignment for wider (over 22”) sanding. When

sanding narrow stock (less than 22”) l oosen the

four screws (Figure 22) and turn fine tune

adjustment knob counterclockwise the same

amount as the initi al wide sanding so that drum

is again parall el.

Figure 23

Figure 24

17

Page 18

Tension Roller Pressure Adjustment

Drum Height Control Adjustment

You can increase or decrease tension roller

pressure by turning the screws on the tension

roller brack ets (Figure 25).

Figure 25

Too much tension r oller pressure can result in a

“snipe” mar k, which is identified as a visi ble line

running across the width of the board and

located approx im ately 2- 1/4” f rom t he end of t he

board.

If the snipe occurs on the leading end of the

board, adjust the outfeed tension roller. If the

snipe occurs on the trailing end of the board,

adjust the infeed tension roller.

Tension roll er pressure can also be adj usted by

raising the height of the rollers, as follows:

1. Repeat “Tension Roller Alignment” except

raise the sandi ng drum only 1/4 turn of the

height adjustment handle.

If the height control mechanism does not

operate easily or smoothly or there is ex cessive

vertical movement or deflection of the drum

carriage, perform the following adjustments.

1. Tighten all four lock nuts (A, Fig. 26) and

then loosen them 1/8 to 1/ 4 turn. If the lock

nuts are set too t ight, height contr ol will not

operate easily . If the l ock nuts are too l oose,

excessiv e deflection of the outboard end of

the drum carriage will r esul t.

2. Thor oughly lubricate the mating surfac es of

the motor mount slide (B , Fig. 26), and the

height adjustment screw (C, Fig. 26).

Figure 26

2. If both tensi on roll ers are causing snipe t hen

tighten all four hex nuts (E, Fig. 24) at this

position.

3. If only outfeed tension roller causes snipe,

only ti ghten rear (outf eed) hex nuts on each

end of drum at this position, then raise

sanding drum anot her 3/4 turn of the handle.

4. Press inf eed tension roller down to rest on

conveyor bed and ti ghten front (infeed) hex

nuts at this positi on.

This process sets the t ension roller assembl y at

an angle provi ding less ten sion pressure on t he

outfeed roller.

18

Page 19

Operation

Before using your drum sander, review the

previous pages in this manual on initial set-up

and adjustment. In this section, you will learn

how to operate the machine. Make sure an

abrasive strip is mounted and a proper dust

collection system is connected.

Basic Operating Procedure

1. Set depth of cut.

2. Start dust collec tion system.

3. Select linear or osci llating sanding mode.

4. Start drum.

5. Start conveyor and select feed rate. If

oscillator is engaged, set feed rate to

maximum speed.

6. Feed stock through m ac hine.

To feed stock through t he sander, rest and hold

the board to be sanded on the conveyor belt,

allowing t he c onveyor belt to carr y the board into

the drum. Once the stock is halfway through,

reposition yourself to the outfeed side of the

machine to receive and control the board as it

exits.

Setting Depth of Cut

Adjusting the drum sander f or the proper cont ac t

between the abrasiv e and the stock determ ines

the depth of cut. The depth of cut is controlled

by the height adj ustm ent handwheel.

It may take som e experimentati on to determine

the proper depth of cut, given the variables of

abrasive grit, type of wood, and feed rate. For

best results, use scrap wood t o pract i ce sanding

and to develop skill and familiarity with the

machine befor e doing finish work.

A combination of several variables will

determine the proper depth of cut to use,

including t he following:

Do not start drum while in

contact with stock!

For sanding with gri ts coarser than 80, you can

lower the drum slight ly .

Always maintain control of stock. Through

practice you will learn the proper depth of cut

considering t he v ari ables above.

Selecting SandSmart™ Feed Rates

A faster feed rate allows faster sanding but

fewer revolutions of the drum per inch of

sanding. A slower feed rate provides more

revolutions of the drum per inch of sanding to

allow a greater depth of cut and smooth

sanding.

Note: If sanding wit h the oscill ator engaged, the

feed rate must be set t o maximum speed.

Begin experimenting with the feed rate set at

about 40% to 50% of maximum. The best f eed

rate will depend on a number of factors,

including type of stock, grit and depth of cut

used, and whether t he stoc k is fed direc tly in line

with the conveyor bed or at an angle. If the drum

motor is lugging down, if the conveyor belt is

slipping, or if you observe a ripple eff ect on the

stock, slow down the feed rate. If the finish is

smooth and the machine is not overworki ng, you

can experiment using a faster feed rate.

The SandSmart control continuously monitors

the load on the drum motor, and automatically

regulates the speed of the conveyor motor to

maintain t he highest feed rate without overload.

If the load on the drum motor increases, the

SandSmart control will decrease the conveyor

feed rate and will stop the conveyor under

extreme conditions. If the load on the drum

decreases, SandSmart will increase the feed

rate but will not increase it faster than the

manual setting on the speed adjustment label.

1. Abrasive type and gri t size.

2. Width of the piece being processed.

3. Hardness of the piec e.

4. Feed rate of the conv ey or belt.

Establishing Proper D rum Height

A good rule of thumb when sanding with grits

finer than 80 i s to place the stock to be sanded

under the drum and lower drum until it contacts

the stock. Drum should still rotate by hand.

Without changing drum height, finish f eeding

the stock under the sander.

Start sanding drum and sand the stock at that

same positi on.

Figure 27

19

Page 20

The best and most consistent finish will be

achieved if the convey or does not c hange speed

during operation. When the red indicator light

(B, Fig. 27) comes on, the SandSmart control

has detected t oo great a depth of cut and/ or too

fast a feed rate.

This change in conveyor speed may affect the

finish surface. If the finish is affected, make

another sanding pass without changing any

settings. If the finish is still affected, make

adjustments by slowing the conveyor and/or

decreasing the depth of cut and run the stock

through again.

Also try a f aster feed rate or less depth of cut if

the stock you are work ing begins to show burn

marks. With cherry, hard maple or other

hardwoods, usi ng a shallower depth of cut and a

faster feed rate will help minimize burn marks.

Slightly angling the stock as it is fed into the

machine will al so hel p pr ev ent burning the stock.

Because of the wide range of variables, it is

important to experiment with your specific

conditions and m ak e adjustm ent s to achi ev e t he

optimum f eed rat e. If pr oblems occur, fi rst c heck

and adjust the feed rate, referring to the

“Troubleshooting” sections in this m anual.

Tips for Maximum Performance

The versatility designed into the 22-44OSC

drum sander allows it to be used for a wide

variety of tasks that will boost the return on your

investment. For example, its capabilities range

from taking the place of a planer to thickness

rough stock, to speeding up fine sanding work

often done with slower, dust-generating hand

sanders.

Learning how to use its adjustments and

controls will allow you to fine-tune the machine

for maximum results. The best results come

from experimenting with different abrasive grits

and machine adj ustments to fit the job at hand.

Following i s a list of useful tips which can hel p

you improve performance of your sander.

Dust Collection

When connecti ng dust coll ect ors, remem ber that

straight pi pe will not restrict airflow as much as

flexible tubing. Y’s and elbows will restrict airflow

less than T’s. Also, a hose smaller than 2-1/2”

diameter shoul d not be used.

Multi pl e- Piece Sandi ng Run s

When abrasiv e planing (or t hickness sanding) a

run of sim ilar pieces that you want to h ave the

same thickness, it is best to determine the

thickness of the thinnest piece and process all

pieces to that same thickness in one session. Be

aware that the sander will remove cups and

crowns in the workpiece; consider this when

measuring and processing stock to the same

thickness.

Sanding Multiple Pieces At Once

When sanding multiple pieces simultaneously,

make sure to stagger (step) the pieces across

the width of the conveyor belt. This provides

better contact with the tension rollers. Try to

process only multi ple pieces of similar thickness.

If there is a signif icant thickness difference, t he

thinner pieces can slip on the conveyor belt if

they do not cont act the t ension roll ers. Al so note

that pieces thicker than 3/4” should be longer

than the minimum normally recommended to

prevent tipping of the stock.

Edge Sanding

When edge sanding, the sander will mimic the

opposite edge of t he stock which is lyi ng on the

conveyor belt . B ecause of this, i t is im port ant f or

the stock edge to have been ripped at the proper

angle to the face before the sanding process.

When edge sanding stock that is less than 3/4”

wide or more t han 2” high, it is good procedure

to stack and clamp several pieces together to

prevent them from slipping or tipping on the

conveyor belt.

Sanding Imperfect Stock

When sanding stock with a c up or crown, place

the crown up. This will stabilize the stock to help

prevent tipping or rocking during sanding. After

the crown has been rem oved and t he top is fl at,

turn the stock ov er and sand the opposit e side.

To avoid personal inj ury, t ake speci al care when

sanding stock that is twisted, bowed, or

otherwise v aries in thi ckness from end t o end. If

possible, support such stock as it is being

sanded to keep it from slipping or tipping. Use

extra rol ler stands, hel p from another person, or

hand pressure on the stock, to minimize

potentially hazardous situations.

Face Frames and Raised Panel Doors

It is v ery important t o have the proper abrasive

contact when doing this type of sanding. If the

machine is set t o take an excessive depth of cut,

the result can be a gouge or dip as the drum

goes from sanding the rails at full width to

sanding just a f ew inches of width on the sti les.

To prevent this make sure, when using

abrasives finer than 80 grit, that the drum is in

contact with the wood but can still be spun by

hand. If there is room, angli ng the stock on the

conveyor belt can also help. Slowing the

conveyor f eed when coming t o a rail in t he stock

can help prevent a dip or gouge. T hi s all ows the

abrasive to work t he wider width with l ess effort,

and to achiev e bet ter c onsistency of the fi ni shed

surface.

20

Page 21

Stock Feeding Angle

Some pieces, because of their dimensions, will

need to be f ed into the machi ne at a 90° angle

(perpendicular to the drum). However, even a

slight offset angle of the stock will provide for

more effective stock removal. The optimum

feeding angle for stock removal is about 60°.

Angling the workpiece for stock removal

provides other advantages, such a s les s l oadi ng

of certain areas of the drums due to glue lines or

mineral streaks in the stock, m ore even wear of

abrasive stri ps, potenti ally faster feed rates, and

lighter l oads on the m otor. Note that to get the

best final finish, however, the stock should be

fed through t he machine so it will be sanded in

line wit h the grain of the wood on the fi nal one or

two passes.

Leave the dust col lector on when c leaning dust

from the drums. Also brush the conveyor belt

after cleaning operations. If not cleaned, the

conveyor belt could allow stock to slip during

sanding operations.

For best results, perform the following

recommended pr oc edur es on a monthly basis:

• Lubricate conveyor bushings and check for

wear.

• Lubricate all movi ng parts, such as thr eaded

rods, washers, and bu shings. (Bearings are

pre-sealed and requir e no lubrication.)

• Clean sawdust from the abrasive strip and

brush dust fr om the conveyor belt.

• Keep oscill ation roller and gib areas cl ean.

Maintenance

Before doing maintenance on

the machine, disco nnect it f rom the electri cal

supply by pulling out the plug or switching

off the main switch! Failure to co mply may

cause serious inj ury.

Keeping the Machine Clean

For best results, make cleaning the sander a

regular shop procedure. Allowing excess buildup of dust and debris can adversely affect

performance through the loading of the

abrasives, slippage on the conveyor table,

and/or the accumulation of material inside the

drums which can thr ow off the c enter of balance.

• Blow dust from motors and switches. Blow

dust from insi de of sanding dr um , which may

cause vibration or offset the center of

balance.

• Check all set screws for tightness on parts

such as bearings, the conveyor, and

couplings.

21

Page 22

Tracker Kit

Stock No.: 98-0080A

Trackers dramatically reduce tracking adjust-

ments of conveyor belts. They are already

installed on your sander. The following

information is for re-setting or replacing your

trackers, should that become necessary. Refer

to Figure 28.

1. Di sconnect power to sand er, and di sconnect

motor cord from contr ol box r ec eptacle.

2. Lower conveyor table as far as it will go.

3. Loosen t he conveyor take-up screw nuts to

relieve conveyor belt tension and slide

driven roll er fully inward. Slide c onveyor belt

to one side of bed.

4. Remove the f our bolts holding t he conveyor

table to the sander base.

5. Lift conveyor table and slide it out of the

sander. Turn conveyor table upside down.

Be careful not to damage the conveyor belt.

6. On t he undersi de of the c onveyor bed, there

are U-channels welded to the bed. The

Tracker is positioned on the inside of the

first U-c hannel on the infeed side of sander

(the U-channel c losest to the rubber covered

drive roll er and gear m ot or). T he back of the

Tracker is magnetized and will stick to the

side wall of the convey or bed. Do not install

Tracker if the edge of the conveyor belt is

damaged or torn.

7. With the first Tracker installed, slide the

conveyor belt into the bottom slot of the

Tracker. Note: When install ed properl y, onl y

the bottom lip of t he Tracker will be visible.

The top slot is to be used if the bottom slot

wears out.

8. Install second Tracker opposite t he first. Use

both Trackers unless the second one does

not fit in conveyor or if conveyor belt is

damaged.

9. Turn conveyor table right-side up and reposition it onto the sander. Re-attach the

four mounting bolts and tighten. Caution:

Be careful not to knock Tracker(s) out of

conveyor bed when turning conveyor over.

10. Make sure all switches are off. Connect

power to sander and plug i n m otor.

11. Tension the conveyor belt using take-up

screw nuts. If both Trackers are i nstalled, it

is very important to have equal tension on

both sides of the conveyor belt. Tighten bot h

sides of take-up screw nuts until equal

tension is obtained.

12. To check tension, turn on conveyor full

speed and place both hand s on conv eyor. If

conveyor belt can be stopped, continue

tensioning until conveyor belt cannot be

stopped by both ha nds on the belt whil e the

conveyor is operat ing at full speed.

13. Make sure conveyor belt runs smoothly

inside Tracker slot and that the magnet is

holding the Tr ac k er in positi on.

14. Conti nue to watch tracking of conv eyor and

adjust only if necessary, making sure to

keep equal tension on conveyor belt at all

times and not allowing conveyor belt to

buckle under conv ey or bed.

Figure 28 – Underside of c onv ey or s hown

22

Page 23

Abrasives

The abrasive material you choose will have a

substantial effect on the performance of your

sander. Vari ations i n paper type, weight, coat i ng

and durability all contribute to achieving your

desired finish.

Selecting Drum Abrasi ves

It is important to select the proper grit of

abrasive for the type of sanding being performed

to achieve maximum results. As with any

sanding operation, first begin sanding with a

coarser grit, depending upon the roughness of

the stock or the am ount of stock to be rem oved.

Then progressiv ely work toward finer grit s. The

chart below shows the general uses for the

various grits.

The amount of stock to be removed i s a major

considerati on when choosing the grit grade with

which to begin. Grits 24, 36, 50 and 60 are

primarily designed for stock removal. Grits 24

and 36 will remove the most material in one

pass, whether you are doing abrasive planing,

cleaning up glued panels, or flattening stock.

Grits from 100 through 220 are primarily

finishing grits designed to remove the scratch

pattern from the previous grit used. For best

results, never skip more than one grit grade

when progressing through a sandi ng s equenc e.

For fine work, such as furniture, try not to skip

any grit grades during the sanding process.

In general, premium quality abrasives will

produce a better finish with a less noticeable

scratch pattern.

Note: Grits that are too fine can sometimes

burnish the wood and leave a glossy surface

which will not accept stains evenly. This will vary

by type of wood. Oak, for example, is

susceptible to burnishing because of its open

pores.

Cleaning Abrasive Strips

Regularly cl ean the abr asive stri ps on the drum s

with commercially available cleaning sticks,

following the manufacturer’s directions. When

cleaning, also brush the stick crumbs from the

drum while it is still rotating.

In some cases, build-ups resulting from burns

can also be removed with Plexiglas held on

edge over the rotating drum.

Always wear eye protection

while performing sandpaper cleaning, and

take all precautions to avoid any contact of

hands or clothing with the rotating drum.

Cloth-backed abrasives can be cleaned by

soaking in pai nt thinner or mineral spirits for 20

minutes to one hour, then using a brush to

remove any build-up. Dry the abrasive strips

completely before using. Any used solvents

should be discarded in compliance with

environment al r egulations.

Increasing Abrasive Life

Abrasive life can be increased not only by

cleaning, but by r em ov ing the abrasive strip from

the drum and reversing it. To do this, remove the

strip and use what was the trailing end as the

starting end on the left (outboard) side of the

drum. Rever sing the stri p will provi de a fresh set

of cutting edges on the abr asive.

Abrasive Selection Guide

Grit Common Application

024 ...... Abrasive planing, surfacing rough-sawn boards, maximum stock removal, glue rem ov al.

036 ...... Abrasive planing, surfacing rough-sawn boards, maximum stock removal, glue rem ov al.

050 ...... Surfacing and dimensioning boards, tr ui ng warped boa r ds

060 ...... Surfacing and dimensioning boards, tr ui ng warped boa r ds.

080 ...... Light dimensioning, removal of planer ripples.

100 ...... Light surfacing, removal of planer ripples.

120 ...... Light surfacing, minimal stock removal.

150 ...... Finish sanding, minimal stock r em oval.

180 ...... Finish sanding only, not for stock rem ov al.

220 ..... Finis h sanding only, not f or stock r emoval.

23

Page 24

Optional Accessories

98-2202 Infeed/Outfeed Tables

Troubleshooting

Troubleshooting – Motor and Electrical Problems

Trouble Probable Cause Remedy

Check plug connections. Connect main

Sander will not start.

Drum motor overloads.

No incoming p ower.

Circuit fuse blown or breaker tripped. Replace fuse or re-set breaker.

Switch is malfunctioning. Replace switch.

Inadequate circuit. Check electrical requirements.

Feed rate too fast or depth of cut too

large.

cord to power source, and motor cord into

control box receptacle.

Reduce feed rate and/or depth of cut.

Conveyor motor

oscillates.

Drum motor or conveyor

motor sta lls.

Motor overload

protector trips or shop

wiring breaker trips.

Motor not properly aligned.

Transfer rod collar is worn. Replace transfer rod collar.

Drive roller bent. Replace drive roller.

Excessive depth of cut.

Improper conveyor belt tension. Adjust tension (see page 15).

Excessive load on sanding drum and

motor.

Too many tools on circuit.

Excessive length or inadequate size

extension cord.

Loosen housing bolts, run motor, retighten

bolts.

Reduce depth of cut; use coarser grit;

reduce f eed rate.

Allow motor to cool and re-set overload

button.

Connect sander to a dedicated circuit.

Have a certified electrician correct any

shop wiring problem.

Use a shorter or heavier gauge extension

cord (s ee Table 1).

24

Page 25

Troubleshooting – Mechanical Problems

Trouble Probable Cause Remedy

Conveyor belt does not

move, o r runs

`intermittently.

Conveyor belt slips on

drive roller.

Board slips on conveyor

belt.

Conveyor belt tracks to

one side, or oscillates

from side to side.

Abrasive strip is loose.

Shaft coupling (#20, page 30) is loose or

unattached.

Improper conveyor belt tension. Adjust belt tension.

Excessive depth of cut or feed rate. Reduce depth of cut; reduce feed rate.

Tension rollers too high. Lower tension rollers (see page 17).

Excessive feed rate. Reduce feed rate.

Dirty or worn conveyor belt. Replace conveyor belt.

Abrasive improperly wrapped. See Installing Abrasives.

Conveyor belt out of adjustment. Readjust conveyor belt; see page 16.

Drive or driven roller needs adjusting. Readjust; see page 16.

Conveyor belt worn or defective.

Drive roller worn, b ent, or varies in

diameter sid e to side.

Roller bushings elongated due to excessive

wear.

Strip caught on inside edge of slot, or on

inboard side of drum.

Strip not cut properly.

Align the shaft flats of the gear motor and

the drive roller and tighten the s haftcoupling setscrews.

Replace conveyor belt; see Conveyor Belt

Replacement.

Replace drive roller.

Replace bushings.

Re-adjust the strip end in the slot and/or

trim the abrasive edge.

Re-cut and re-install abrasive strip. See

Installing Abrasives.

Excessive depth of cut. Reduce depth of cut.

Excessive feed rate. Reduce feed rate.

Abrasive loads up

prematurely.

Tab le height adjus t ment

works improperly .

Drum drive v-belt slips. Improper v-belt tension. Increase tension.

Knocking sound while

running.

Inadequate dust collection. Increase airflow at dust port.

Inadequate abrasive. Use an open-coat abrasive.

Stock fed at 90° angle to drum.

Improper adjustment of height control.

Bearing(s) out of alignment. Re-align bearings.

V-belt worn. Replace v-belt.

Dust in drum. Remove material inside drum.

Pulley wobbling or out of round. Replace pulley.

Set-screws loose in pulley or bearing. Re-tighten set-screws.

Abrasive fastener on drum loose (without

abrasi ve strip in place).

Drum bearing(s) worn. Replace drum bearing(s).

Angle stock 60° if possible to avoid resin

line bui ldu p.

Readjust height control. See Drum Height

Control.

Insert abrasive strip, or replace fastener.

25

Page 26

Troubleshooting – Operational Problems

Trouble Probable Cause Remedy

Ripples in sanded

surface.

(No n-unifor mly spaced

ripples).

Ripples in sanded

surface.

(Un ifor mly s paced

ripples).

Sniping of wood

(gouging near end of

board).

Burning of wood.

Gougin g of wood.

Line or groove in stock. Inconsistent feed rate.

Lines or groove in stock

while in oscillation mode

Unsanded ridge along

length of piece

(sandpaper appears

clean).

Uneven feed rate. Check for these conditions and refer to

Excessive feed rate. Reduce depth of cut and/or feed rate.

Excessive depth of cut. Reduce depth of cut and/or feed rate.

Sander vibration.

Tension rollers set too low.