Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

ET-C Series Electric Trolley

JET

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-262605

Ph.: 800-274-6848 Revision E1 06/2017

www.jettools.com Copyright © 2017 JET

Page 2

1.0 Warranty and Service

JET warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please

contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

JET branded website.

• JET products carry a limited warranty which varies in duration based upon the product. (See chart below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Covered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. JET woodworking machinery is designed to be used with Wood.

Use of these machines in the processing of metal, plastics, or other materials outside recommended guidelines may

void the warranty. The exceptions are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initial purchase when calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. JET has Authorized Service Centers located throughout the

United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the JET website.

More Information

JET is constantly adding new products. For complete, up-to-date product information, check with your local distributor

or visit the JET website.

How State Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

JET LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH PRODUCT.

EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

JET SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

JET sells through distributors only. The specifications listed in JET printed materials and on official JET website are

given as general information and are not binding. JET reserves the right to effect at any time, without prior notice,

those alterations to parts, fittings, and accessory equipment which they may deem necessary for any reason

whatsoever. JET

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors; Machine Accessories

2 Year – Metalworking Machinery; Electric Hoists, Electric Hoist Accessories; Woodworking Machinery used

for industrial or commercial purposes

5 Year – Woodworking Machinery

Limited Lifetime – JET Parallel clamps; VOLT Series Electric Hoists; Manual Hoists; Manual Hoist

Accessories; Shop Tools; Warehouse & Dock products; Hand Tools; Air Tools

NOTE: JET is a division of JPW Industries, Inc. References in this document to JET also apply to JPW Industries,

Inc., or any of its successors in interest to the JET brand.

®

branded products are not sold in Canada by JPW Industries, Inc.

2

Page 3

2.0 Table of Contents

1.0 Warranty and Service ............................................................................................................................. 2

2.0 Table of Contents ................................................................................................................................... 3

3.0 Introduction ............................................................................................................................................ 3

4.0 IMPORTANT SAFETY INSTRUCTIONS ............................................................................................... 4

5.0 Specifications ......................................................................................................................................... 5

6.0 Unpacking .............................................................................................................................................. 6

6.1 Contents of Shipping Container ......................................................................................................... 6

7.0 Installation & Assembly .......................................................................................................................... 6

7.1 Mount Trolley to Beam ....................................................................................................................... 6

7.2 Power and Pendant Cords ................................................................................................................. 6

7.3 Mounting Your Hoist ........................................................................................................................... 7

7.4 Installing Lug Mount Access or y .......................................................................................................... 8

8.0 Electrical Instructions ............................................................................................................................. 8

8.1 Grounding ........................................................................................................................................... 8

8.2 Voltage Conversion ............................................................................................................................ 9

8.3 Inspecting Trolley Motion .................................................................................................................. 9

8.4 Extension Cords ................................................................................................................................. 9

9.0 Control Pendant Accessories ............................................................................................................... 10

10.0 Troubleshooting the ET-C Series Trolleys ......................................................................................... 10

11.0 Replacement Parts ............................................................................................................................. 10

11.1.1 ET-C Series Trolley – Exploded Vie w ......................................................................................... 11

11.1.2 ET-C Series Trolley – Parts List .................................................................................................. 12

11.2.1 Lug Mount Assembly (Optional) for SS-3C,SS-1C Hoists .......................................................... 15

11.3.1 ET-C Series Trolley Electrical Components – Exploded View .................................................... 16

11.3.2 ET-C Series Trolley Electr ical Components – Parts List ............................................................. 17

12.0 Electrical Connections – ET-C Series Trolleys .................................................................................. 18

12.1.1 ET-C Trolley SINGLE PHASE ONLY .......................................................................................... 18

12.1.2 ET-C Trolley – THREE PHASE ONLY ........................................................................................ 19

12.1.3 Electrical Connections – Control Pendants ................................................................................. 20

3.0 Introduction

This manual is pro vided b y JET covering th e saf e oper ation an d m aintenanc e proc edures f or a J ET ET -C

Series Electric Trolley. This manual contains instructions on installation, safety precautions, general

operating procedures , maintenance instruc tions and parts breakdown. T his machine has been d esigned

and constructed to provide consistent, long-term operation if used in accordance with instructions set

forth in this manual. If there are any questions or comments, please cont act either your loca l supplier or

JET. JET can also be reached at our web site: www.jettools.com.

The ET-C Series Electric Trolleys comply with OSHA regulations and ANSI/ASME B30.11 and

B30.17 standards.

Record your purchase information here for quick reference:

Model No.: Stock No.: Serial No.:

Purchased From: Date Purchased:

Date Installed: Installer:

3

Page 4

4.0 IMPORTANT SAFETY INSTRUCTIONS

• Read and understand this entire manual

before attempting assembly or operation.

You should also be th oroughly familiar with

all information in the owner’s manual that

accompanied your hoist.

• Read and understand the warnings posted

on the machine and in this manual. Failure

to comply with all of these warnings may

cause serious injury.

• Replace the warning labels if they become

obscured or removed.

• This trolley is des igned and intende d for use

by properly trained and experienced

personnel only. If you are not familiar with

the proper and saf e o per at ion of a trolley, do

not use until proper trainin g and knowledge

have been obtained.

• Do not use this trolley for other than its

intended use. If used for other purposes,

JET disclaims any real or implied warranty

and holds itself harmless from any injury that

may result from that use.

• Do not install this trolley where explosive

hazards may exist.

• Beam must be properly installed and rated

for anticipated loads . Do not ins tall trolley on

beams of unknown capacity.

• Do not install trolley on damaged or

deformed beams.

• Never subject trolley to a side pull or load.

Load must be centered directly under the

hoist/trolley assembly.

• Make sure load is stable and s ecure before

moving.

• Never lift load higher than is necessary to

safely move it.

• Do not use to lift people, or loads over

people. Warn others in the vicinity when

lifting or transpor ting a load. Avoid s winging

load and hook.

• Do not use in wet, damp or poorly lit

locations. This trolle y is not rated f or outdoor

use.

• Do not exceed the rated capacity of the

trolley.

• Maintain firm footing when operating the

trolley.

• Always inspect the trolley for damage prior

to use. If the troll ey is damaged, do n ot use

until it has been repaired or replaced.

• Leave all internal m aintenance to a qualified

JET service center.

• Do not operate this trolley while tired or

under the influence of dr ugs, alcohol or any

medication.

• JET trolleys are designed to be used with

hoists of the same r ated c a pacity. Never use

a hoist with a capacity greater than the

capacity of the trolley.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

4

Page 5

5.0 Specifications

Figure 1

Stock No. Model

262605 1/2ET-3C 3-5 9 1/8 10 10 2 6 1/2 3 1/2 9 11/16 4 1/2 2 3/4 3 11/16 1 5/8

262610 1ET-3C 3-5 9 1/8 10 10 2 6 1/2 3 1/2 9 11/16 4 1/2 2 3/4 3 11/16 1 5/8

262620 2ET-3C 4-6 9 3/4 10 5/8 11 1/2 2 43/64 7 43/64 4

262630 3ET-3C 4-6 10

262250 5ET-3C 5-7

272705 1/2ET-1C 3-5 9 1/8 10 10 2 6 1/2 3 1/2 9 11/16 4 1/2 2 3/4 3 11/16 1 5/8

272710 1ET-1C 3-5 9 1/8 10 10 2 6 1/2 3 1/2 9 11/16 4 1/2 2 3/4 3 11/16 1 5/8

272720 2ET-1C 4-6 9 3/4 10 5/8 11 1/2 2 43/64 7 43/64 4

272730 3ET-1C 4-6 10

272750 5ET-1C 5-7

A

(min.-max.)

B C

10 11/16

10 11/16

D E F G H I J K L

12 43/64

12 27/32

12 27/32

14 5/32 3 9 5/32 5 12 7/16 4 1/4 4 6 1 9/16

13 5/8 16 1/2 4 10 1/2 6 13 1/4 4 7/16 4 6 1/4 2 1/8

12 43/64

14 5/32 3 9 5/32 5 12 7/ 16 4 1/4 4 6 1 9/16

13 5/8 16 1/2 4 10 1/2 6 13 1/4 4 7/16 4 6 1/4 2 1/8

5 1/4 3 1/4 4 3/4 1 19/32

5 1/4 3 1/4 4 3/4 1 19/32

Stock No. Model

262605 1/2ET-3C 1/2 3-5 43.3 39.36

262610 1ET-3C 1 3-5 43.3 39.36

262620 2ET-3C 2 4-6 59 39.36

262630 3ET-3C 3 4-6 59 39.36

262250 5ET-3C 5 5-7 78.75 39.36

272705 1/2ET-1C 1/2 3-5 43.3 39.36

272710 1ET-1C 1 3-5 43.3 39.36

272720 2ET-1C 2 4-6 59 39.36

272730 3ET-1C 3 4-6 59 39.36

272750 5ET-1C 5 5-7 78.75 39.36

Capacity

(ton)

Beam Flange

Width

(in.)

Minimum

Radius Curve

(in.)

Travel Speed

(FPM)

Motor

3 Phase,

230/460V

(prewired

460V)

1 Phase,

115/230V

(prewired

230V)

Duty

Cycle

Rating

25% 82

25%

25%

25%

25%

25%

25%

25%

25%

25%

Net Weight

Approx.

(lbs.)

82

112

148

185

84

84

114

150

187

The above specif ic atio ns wer e cur r ent at t he t ime this manual was p ub lis he d, but bec ause of our policy of

continuous improvem ent, JET reserves the right to change specif ications at any time and without prior

notice, without incurring obligations.

5

Page 6

6.0 Unpacking

Open shipping container and check for shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any ship ping material unt il the Trolley is

assembled and running properly.

Compare the contents of your container with t he

following parts list to make sure all parts are

intact. Missing part s, if any, should be reported

to your distributor. Read the instruction m anual

thoroughly for assembly, maintenance and

safety instructions.

6.1 Contents of Shipping Container

1 Electric Trolley

1 Cord holder with cable tie

12 Phillips Pan Head Sc re ws, M5x 12

12 Lock Washers, 5mm

1 Owner's Manual

1 Warranty Card

7.0 Installation & Assembly

Figure 2

6. Re-install th e p late ( C) and two h ex n uts ( B),

and tighten the hex nuts.

7. Reinstall the adjusting screw and hex nuts

(A) and adjust to the proper width.

8. Double-check the wheel clearance on the

beam, and make further adjustments if

necessary.

The ET-C Series trolley is designed to run on

standard “I” beams, wide-f langed “H” beams, or

curved track with a minim um r adius shown in the

chart on page 5.

7.1 Mount Trolley to Beam

The trolley is heavy; use an

assistant or a lifting device to help st abiliz e it

while you assemble it to the beam.

1. Loosen the hex nuts (A, Figure 2) on the

adjusting screw, and remove the adjusting

screw.

2. Remove the two hex nuts (B, Figure 2) with

the plate (C, Figure 2).

3. Slide out the suspension shaft with the

spacers (D, Figure 2).

4. Assemble the trolley to the beam. The trolley

must be installed on a be a m with a minimum

clearance (wheels to flange) of 1/16” to a

maximum of 1/8” on eac h side of the beam

(see Figure 1, page 5). Position the side

plates (E, Figure 2) to achieve this

measurement on your beam.

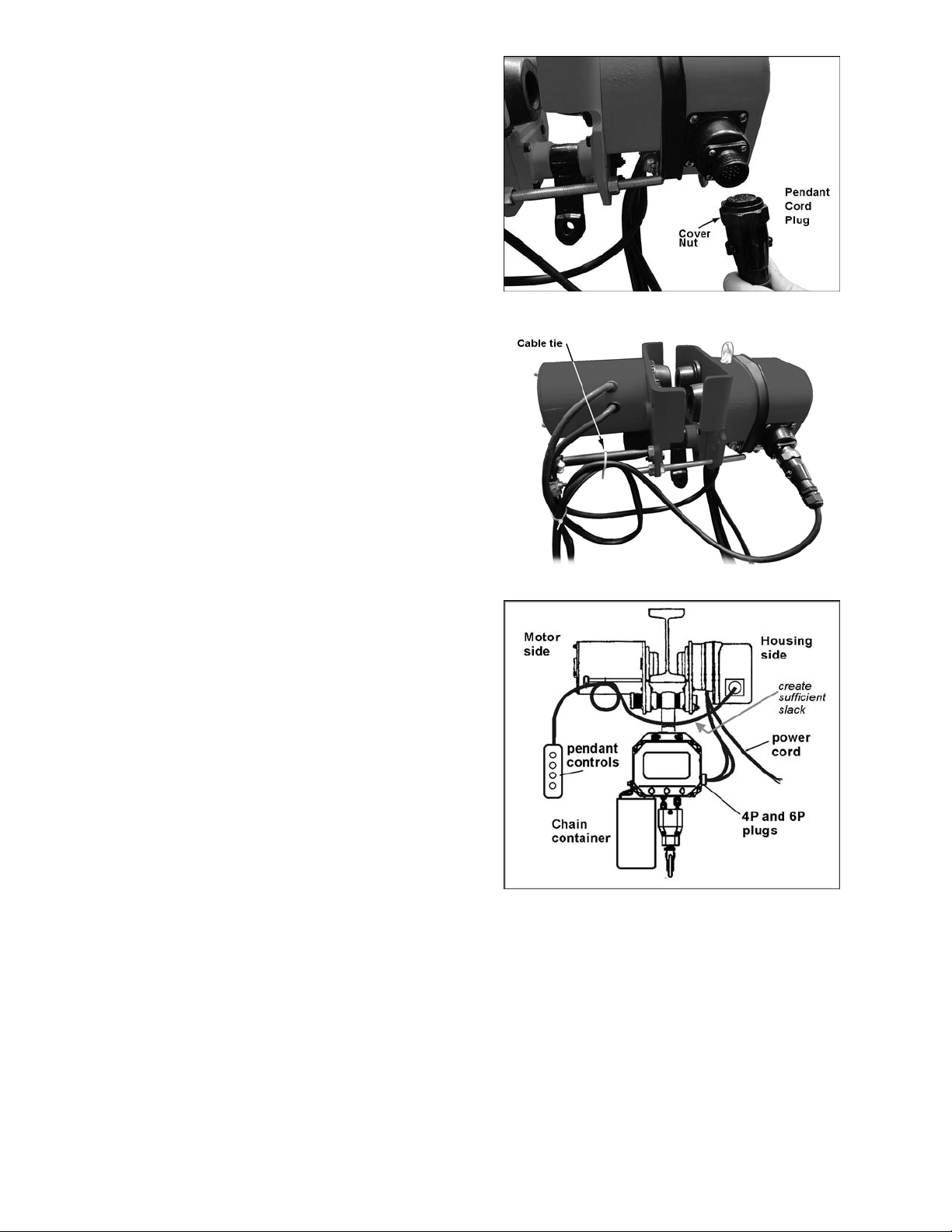

7.2 Power and Pendant Cords

NOTE: A pendant c ord is not supplied with the

trolley, and must be purc hased s epar ate l y. If you

need to change th e voltage requirem ents on the

trolley, it is more convenient to do that before

installing a pendant cord. See “Voltage

Conversion” on page 9.

1. Thread the cord holder (Figure 3) into the

hole on the motor side plate and tighten th e

jam nut and lock washer. The ring on the

cord holder should be positioned vertically.

5. Re-install the suspensio n shaft, while using

the spacers (D) to achieve the required

width. Spacers must be moved in sets of

two, placing equal number s on both sides of

the hoist hanger to m aintai n the c en terl ine of

the trolley. Place any extra spacers on the

outside of the shaft, as shown in Figure 2.

Figure 3

6

Page 7

2. Insert the male plug of the pend ant cord into

the socket on the trolley. See Figure 4.

Secure the connection by tightening the

cover nut with your fingers.

3. Attach the pendant cord t o the cord holder.

The cord must be sec ur ed t o th e c ord holder

in a way that relieves strain on the

connections. One method of doing this is to

form a loop in the pendant cord and place

the cable tie as shown in Figure 5. Do not

tighten the cable tie yet.

4. Create sufficient slack in the pendant cord

where it passes under the I- beam (Figur e 6)

so that the cord will not rub against the

beam.

5. Tighten the cable tie to secure the pendant

cord to the cord holder.

7.3 Mounting Your Hoist

This trolley has been des igned to work with the

JET C-Series Hoist. The y can be connected so

that one pendant cord and power cord will

operate both trolley and hoist. Make sure the

hoist has been set to the same voltage

specifications as the trolley.

Make connections fr om the trolley to your hoist

as follows:

1. Hang the hoist on the trolley hanger, using

hook or lug mount. (See page 8 for

instructions on installing the optional lug

mount.) The hoist should be positioned so

that the electrical so cket on the trolle y is on

the same side as the sockets on the hoist,

as shown in Figure 6.

Figure 4

Figure 5

2. Remove the power cord and pendant cord

from the hoist.

3. Connect the two 4P and 7P plugs of the

trolley cords into their appropriate sockets

on the hoist.

Figure 6

7

Page 8

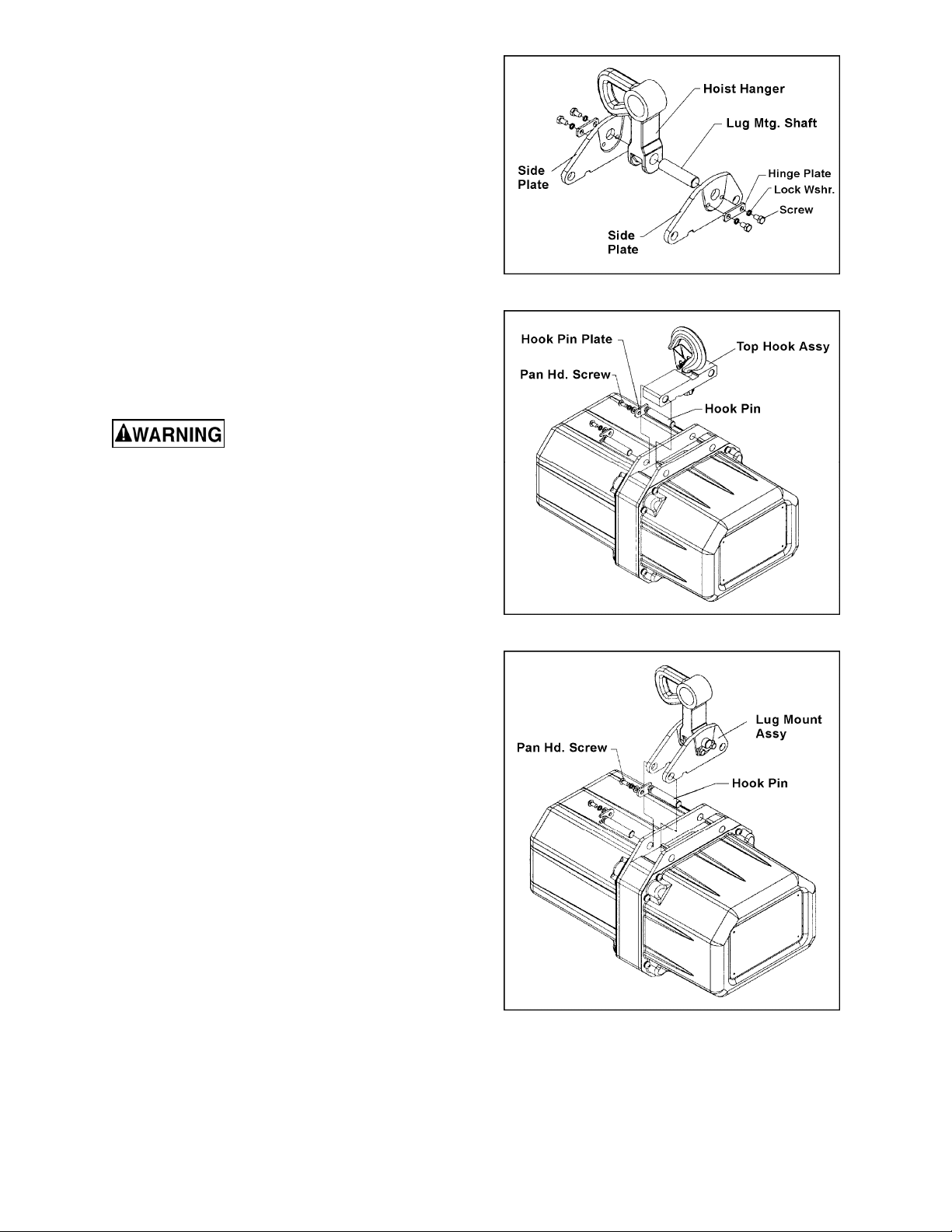

7.4 Installing Lug Mount Accessory

1. Assemble the side plates, hoist ha nger and

lug mounting shaft, as shown in Figure 7.

2. Install the hinge plates, lock washers and

hex cap screw to secure the assembly.

3. On the electric hoist, remove the two

screws, hook pin plate, hook pin, etc.

(Figure 8)

4. Remove the top hook assembly from the

hoist, and replace it with the lug mount

accessory as shown in Figure 9. Re-install

the hook pins, hook pin plates, screws and

washers. Firmly tighten the screws.

8.0 Electrical Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

8.1 Grounding

In the event of a malfunction or breakdown,

grounding provides a path of least res istance f or

electric current to reduce the risk of electric

shock.

This machine’s power cord must be fitted with

an appropriate UL/CS A listed plug, or it can be

“hard-wired” directly to a control panel. If hardwired, make sure a disconnect is available for

the operator.

Figure 7

Figure 8

If a plug is installed, it m ust have an equipm entgrounding conductor and a grounding prong.

The plug must be plugged into a m atching outle t

that is properly installed and grounded in

accordance with all local codes and ord inances.

Do not modify the plug.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes is the equipmentgrounding connector. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-gr ounding c onductor to a

live terminal.

Figure 9

8

Page 9

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded.

Repair or replace damaged or worn cord

immediately.

8.2 Voltage Conversion

The single phase models (ET-1C) are

designed for 115 volt or 23 0 volt oper atio n. T hey

are pre-wired for 230 volt. The three phase

models (ET-3C) are designed for 230 volt or

460 volt operation. They are pre-wired for 460V.

To switch voltage :

1. Disconnect trolley from power supply, and

disconnect the pendant cord from the trolley.

2. Remove the two screws and lock washers

on the underside of the housing (s ee Figure

10) and slide the protect ive band out of the

way. Remove the housing.

3. Carefully pull the plug out of the current

socket and insert it into the new sock et (see

Figure 10). Make sur e the notch on the plug

fully engages the socket.

4. Re-install the housing, re-position the

protective band, and insert the screws and

lock washers. Tighten the screws securely.

Test the motion of the hoist also:

2. With no load o n the load h ook, pr ess the U P

button very briefly and observe ho ist action.

The hook should m ove upward. (Two speed

models have a two-position UP button.

Press the button onl y part wa y to operate l ift

motor at slow speed, press fully to operate

at high speed.)

3. If no motion occurs when the UP button is

pressed and the hoist is connected to a

three phase power supply, the po wer supply

wires are incorrectly positioned.

4. Switch any two of the three suppl y wires at

the power source. Do not attempt to rewire

the hoist/trolley circuit or pendant

controls for this problem. Use the same

safety precautions when reversing two of the

supply wires as was used when the wires

were originally connected.

5. Re-connect power and test hoist and trolley

movement again without load. Run hoist to

the complete lifting height to ensure limit

switches are operating properly.

Refer to your hoist manual for more detailed

instructions on operation and testing of the hoist.

8.4 Extension Cords

If an extension cord is nece ssar y, make s ure the

cord rating is suitable f or the am perage lis ted on

the trolley’s motor plate. An undersize cord will

cause a drop in line voltag e resulting in loss of

power and overheating.

Figure 10

8.3 Inspecting Trolley Motion

1. Before closing the circuit break er and tes t ing

the trolley, check that wiring has been

complete. If the trolley cannot be observed

when the circuit breaker is closed, s tation a n

observer within sight of the trolley to report

any movement when powe r is applied to the

trolley. Be prepared to disconnect power if

trolley motor starts when the power is

applied. The trolle y must remain motionless

when power is applied. F ind and cor rect a ny

problems before continuing.

The chart in Figure 11 shows the correct size

cord to use based on cord length and motor

plate amp rating. If in doubt, use the next

heavier gauge. T he smaller the gauge number,

the heavier the cord.

Recommended Gauges (AWG) of Extension Cords

Extension Cord Length *

25

50

75

100

150

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on limiting the line voltage drop to 5V at 150% of the

rated amperes.

NR: Not Recommended.

feet

feet

feet

feet

feet

200

feet

Figure 11

9

Page 10

9.0 Control Pendant Accessories

Pendants with 4 buttons are for Lifting and Lowering, and 2-direction Trolley travel.

152411 Single Speed, 4 Button Control Pendant with 10’ Lift.

152416 Single Speed, 4 Button Control Pendant with 15’ Lift.

152421 Single Speed, 4 Button Control Pendant with 20’ Lift.

153431 Single Speed, 4 Button Control Pendant with 30’ Lift.

10.0 Troubleshooting the ET-C Series Trolleys

Trouble Probable Cause Remedy

Trolley will not

operate, or operates

intermittently.

Trolley drifts

excessively after

stopping.

Hoist moves in wrong

direction.

Check trolley connections to power

source. Make sure power source

No incoming power, or low voltage.

Fuse blown or circuit breaker tripped. Replace fuse/reset circuit breaker.

Thermal overload protector has

tripped; motor overheated.

Conductors in pendant cord

damaged.

Motor damaged.

Grease or oil on the brake lining.

Brake pad is worn or damaged. Replace brake pad.

Two of the three power supply wires

are switched.

matches specifications on trolley

name plate. If low voltage, have

certified electrician check incoming

power.

See “Motor overheats” below.

Check for continuity in each

conductor. If faulty, replace entire

pendant cord.

Have motor inspected and repaired/

replaced by a qualified service

technician.

Open the trolley, disassemble the

brake and clean the lining.

Switch any two of the three supply

wires.

Excessive load or too frequent use.

Motor overheats.

Brake is dragging.

Operate within rated load and

according to duty cycle rating.

Have brake repaired or replaced by a

qualified service technician.

11.0 Replacement Parts

Replacement parts are lis ted on the fol lowing pag es. To order parts or reach our service de partm ent, call

1-800-274-6848 Monday through Friday, 8:00 a.m. to 5:00 p.m. CST. Having the Model Number and

Serial Number of your machine available when you call will allow us to serve you quickly and accurately.

Non-proprietary parts , such as fas teners, can be foun d at local hard ware stores, or may be ordered f rom

JET. Some parts are shown for reference only, and may not be available individually.

10

Page 11

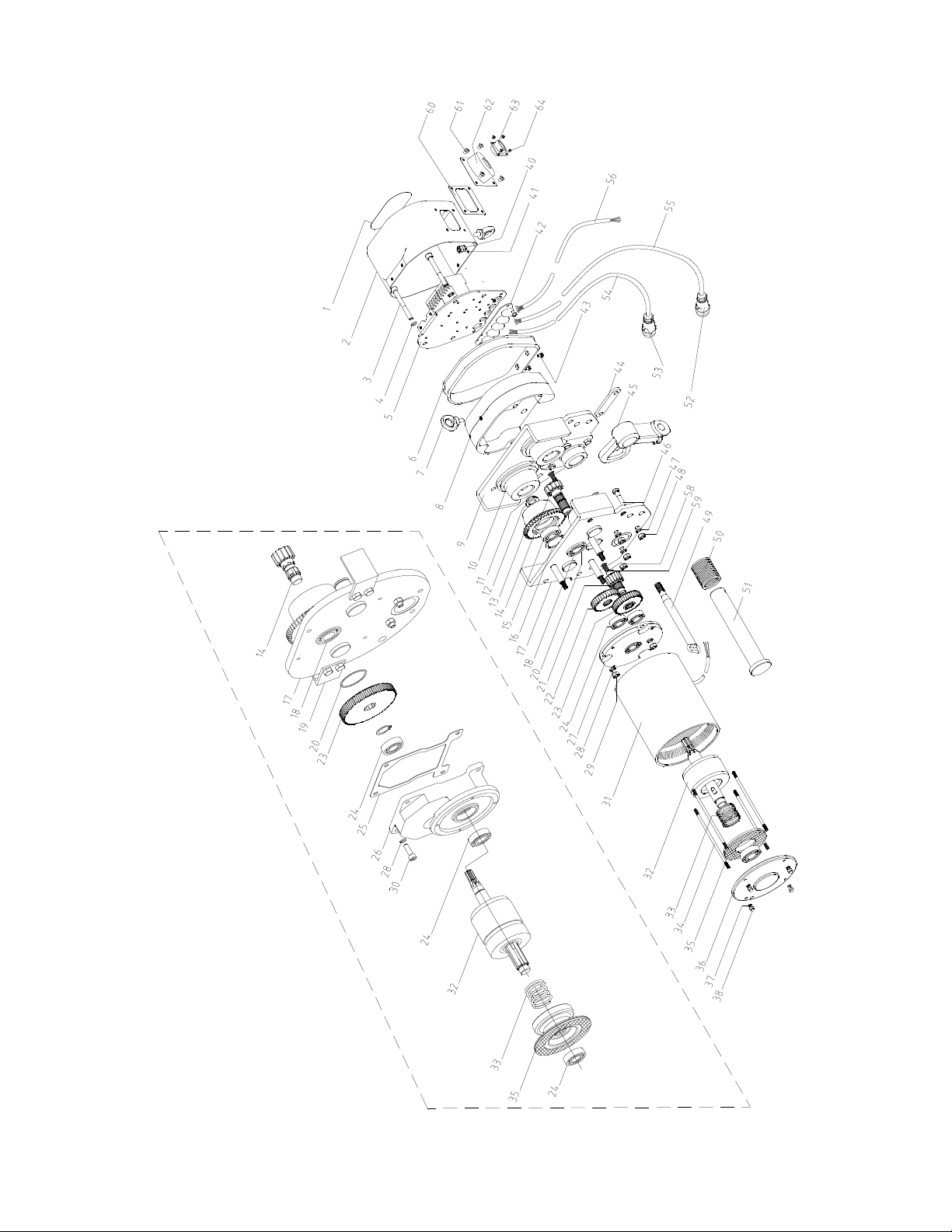

11.1.1 ET-C Series Trolley – Exploded View

Y

L

N

O

E

S

A

H

P

E

E

R

H

T

D

N

A

E

L

G

N

I

S

N

I

T

E

5

&

3

R

O

F

11

Page 12

11.1.2 ET-C Series Trolley – Parts List

Index No. Part No. Description Size Qty

1 ................ LM000123 ........ Name Plate (1/2T, three phase) .............................. ....................................... 1

.................. LM000124 ........ Name Plate (1T, three phase) ................................. ....................................... 1

.................. LM000125 ........ Name Plate (2T, three phase) ................................. ....................................... 1

.................. LM000126 ........ Name Plate (3T, three phase) ................................. ....................................... 1

.................. LM000127 ........ Name Plate (5T, three phase) ................................. ....................................... 1

.................. LM000128 ........ Name Plate (1/2T, single phase) ............................. ....................................... 1

.................. LM000129 ........ Name Plate (1T, single phase) ................................ ....................................... 1

.................. LM000130 ........ Name Plate (2T, single phase) ................................ ....................................... 1

.................. LM000131 ........ Name Plate (3T, single phase) ................................ ....................................... 1

.................. LM000132 ........ Name Plate (5T, single phase) ................................ ....................................... 1

2 ................ 1ET-3C-2G ...... Housing (1/2T,1T,2T,3T,5T) .................................... ....................................... 1

3 ................ 1ET-3C-3 ......... Socket Head Cap Screw (1/2T,1T,2T,3T,5T) .......... M8x70 ............................ 2

4 ................ 1ET-3C-4 ......... Lock Washer (1/2T,1T,2T,3T,5T) ............................ 8mm ............................... 7

5 ................ 1ET-3C-5 ......... Electrical Board (1/2T,1T,2T, three phase) ............. ....................................... 1

.................. 3ET-3C-5 ......... Electrical Board (3T, 5T, three phase) .................... ....................................... 1

.................. 1ET-1C-5 ......... Electrical Board (1/2T,1T,2T, single phase) ............ ....................................... 1

.................. 3ET-1C-5 ......... Electrical Board (3T,5T, single phase) .................... ....................................... 1

6 ................ 1ET-3C-6 ......... Protective Band (1/2T,1T,2T,3T,5T) ........................ ....................................... 1

7 ................ 1ET-3C-7 ......... Eye Bolt (1/2T,1T,2T,3T,5T) .................................... M8x16 ............................ 2

8 ................ 1ET-3C-8G ...... Balance Spacer (1/2T,1T,2T) .................................. ....................................... 1

.................. 3ET-3C-8G ...... Balance Spacer (3T,5T) .......................................... ....................... ................ 1

9 ................ 1ET-3C-9G ...... Plain Side Plate Ass embly (1/2T,1T) ....................... ....................................... 1

.................. 2ET-3C-9G ...... Plain Side Plate Assembly (2T) ............................... ....................................... 1

.................. 3ET-3C-9G ...... Plain Side Plate Assembly (3T) ............................... ....................................... 1

.................. 5ET-3C-9G ...... Plain Side Plate Assembly (5T) ............................... ....................................... 1

10 .............. 1ET-3C-10 ....... Plain Wheel (1/2T,1T).............................................. ....................................... 2

.................. 2ET-3C-10 ....... Plain Wheel (2T) ...................................................... ....................................... 2

.................. 3ET-3C-10 ....... Plain Wheel (3T) ...................................................... ....................................... 2

.................. 5ET-3C-10 ....... Plain Wheel (5T) ...................................................... ....................................... 2

11 .............. 1ET-3C-11 ....... Circlip for shaft (1/2T,1T) ......................................... Ø17mm .......................... 4

.................. 2ET-3C-11 ....... Circlip for shaft (2T) ................................................. Ø 25mm ......................... 4

.................. 3ET-3C-11 ....... Circlip for shaft (3T) ................................................. Ø 30mm ......................... 4

.................. 5ET-3C-11 ....... Circlip for shaft (5T) ................................................. Ø 35mm ......................... 4

12 .............. 1ET-3C-12 ....... Washer (1/2T,1T) .................................................... ....................................... 4

.................. 2ET-3C-12 ....... Washer (2T) ............................................................. ....................................... 4

13 .............. 1ET-3C-13 ....... Geared Wheel (1/2T,1T).......................................... ....................................... 2

.................. 2ET-3C-13 ....... Geared Wheel (2T) .................................................. ....................................... 2

.................. 3ET-3C-13 ....... Geared Wheel (3T) .................................................. ....................................... 2

.................. 5ET-3C-13 ....... Geared Wheel (5T) .................................................. ....................................... 2

14 .............. 1ET-3C-14 ....... Fifth Gear (1/2T,1T,2T)............................................ ....................................... 1

.................. 3ET-3C-14 ....... Fifth Gear (3T,5T) .................................................... ....................................... 1

15 .............. 1ET-3C-15 ....... Roller Bearing (1/2T,1T) .......................................... 6203-2Z .......................... 4

.................. 2ET-3C-15 ....... Roller Bearing (2T) .................................................. 6205-2Z .......................... 4

.................. 3ET-3C-15 ....... Roller Bearing (3T) .................................................. 6206-2Z .......................... 4

.................. 5ET-3C-15 ....... Roller Bearing (5T) .................................................. 6207-2Z .......................... 4

16 .............. 1ET-3C-16 ....... Circlip for hole (1/2T,1T) .......................................... 40mm ............................. 4

.................. 2ET-3C-16 ....... Circlip for hole (2T) .................................................. 52mm ............................. 4

.................. 3ET-3C-16 ....... Circlip for hole (3T) .................................................. 62mm ............................. 4

.................. 5ET-3C-16 ....... Circlip for hole (5T) .................................................. 72mm ............................. 4

17 .............. 1ET-3C-17G .... Gear Side Plate Assembly (1/2T,1T) ....................... ....................................... 1

.................. 2ET-3C-17G .... Gear Side Plate Assem bl y (2T) ............................... ....................................... 1

.................. 3ET-3C-17G .... Gear Side Plate Assem bl y (3T) ............................... ............................

.................. 5ET-3C-17G .... Gear Side Plate Assem bl y (5T) ............................... ....................................... 1

18 .............. 1ET-3C-18 ....... Roller Bearing (1/2T,1T,2T) ..................................... 6004-2ZN ....................... 1

.................. 3ET-3C-18 ....... Roller Bearing (3T,5T) ............................................. 6205-2ZN ....................... 1

19 .............. 3ET-3C-19 ....... Safety Block (3T) ..................................................... ....................................... 4

.................. 5ET-3C-19 ....... Safety Block (5T) ..................................................... ....................................... 4

........... 1

12

Page 13

Index No. Part No. Description Size Qty

20 .............. 1ET-3C-20 ....... Roller Bear ing w/S nap Rin g (1/2T ,1T ,2T) ............... 42m m ............................. 1

.................. 3ET-3C-20 ....... Roller Bearing w/S nap Rin g (3T ,5T ) ....................... 52mm ............................. 1

21 .............. 1ET-3C-21 ....... Third Gear (1/2T,1T,2T) .......................................... ....................................... 1

22 .............. 1ET-3C-22 ....... Fourth Gear (1/2T,1T,2T) ........................................ ....................................... 1

23 .............. 1ET-3C-23 ....... Second Gear (1/2T,1T,2T) ...................................... ....................................... 1

.................. 3ET-3C-23 ....... Second Gear (3T,5T) ............................................... ....................................... 1

24 .............. 1ET-3C-24 ....... Roller Bearing (1/2T,1T,2T) ..................................... 6003-2Z .......................... 4

.................. 3ET-3C-24 ....... Roller Bearing (3T,5T) ............................................. 6004-2Z .......................... 4

25 .............. 3ET-3C-25 ....... Gear Case Gasket (3T,5T) ...................................... ....................................... 1

26 .............. 3ET-3C-26G .... Gear Case (3T,5T) .................................................. ....................................... 1

27 .............. 1ET-3C-27 ....... Flange (1/2T,1T,2T) ................................................. ....................................... 1

28 .............. 1ET-3C-28 ....... Lock Washer (1/2T,1T,2T,3T,5T) ............................ 8mm ............................... 4

29 .............. 1ET-3C-29 ....... Hex Nut (1/2T,1T,2T) ............................................... M8 .................................. 3

30 .............. TS-1504051 ..... Socket Head Cap Screw (3T,5T) ............................ M8x25 ............................ 4

31 .............. 1ET-3C-31G .... Motor Case Assembly (1/2T,1T,2T, three phase) ... ....................................... 1

.................. 3ET-3C-31G .... Motor Case Assembly (3T,5T, three phrase) .......... ....................................... 1

.................. 1ET-1C-31G .... Motor Case Assembly (1/2T,1T,2T,single phase) ... ....................................... 1

.................. 3ET-1C-31G .... Motor Case Assembly (3T,5T, single phase) .......... ....................................... 1

32 .............. 1ET-3C-32 ....... Rotor Assembly (1/2T,1T,2T three phrase) ............. ....................................... 1

.................. 3ET-3C-32 ....... Rotor Assembly (3T,5T, three phrase) .................... ....................................... 1

.................. 1ET-1C-32 ....... Rotor Assembly (1/2T,1T, 2T single phase) ............ ....................................... 1

.................. 3ET-1C-32 ....... Rotor Assembly (3T,5T, single phase) .................... ....................................... 1

33 .............. 3ET-3C-33 ....... Brake Spring (1/2T,1T,2T,3T,5T) ............................ ....................................... 1

34 .............. 1ET-3C-34 ....... Motor Stay Bolt (1/2T,1T,2T) ................................... ....................................... 4

.................. 3ET-3C-34 ....... Motor Stay Bolt (3T,5T) ........................................... ....................................... 4

35 .............. 3ET-3C-35 ....... Friction Pad Assembly (1/2T,1T,2T,3T,5T) ............. ....................................... 1

36 .............. 1ET-3C-36G .... Motor End Plate (1/2T,1T,2T,3T,5T) ....................... ....................................... 1

37 .............. 1ET-3C-37 ....... Lock Washer (1/2T,1T,2T,3T,5T) ............................ 5mm ............................... 4

38 .............. 1ET-3C-38 ....... Acorn Nut (1/2T,1T,2T,3T,5T) ................................. M5 .................................. 4

40 .............. 1ET-3C-40 ....... Lock Washer (1/2T,1T,2T,3T,5T) ............................ 8mm ............................... 1

41 .............. 1ET-3C-41 ....... Hex Nut (1/2T,1T,2T,3T,5T) .................................... M8 .................................. 1

42 .............. 1ET-3C-42 ....... Cable Press Plate (1/2T,1T,2T,3T,5T) .................... ....................................... 1

43 .............. 1ET-3C-43 ....... Phillips Pan Head Screw (1/2T,1T,2T,3T,5T) ......... M5x 10 ............................ 2

44 .............. 1ET-3C-44 ....... Plate Key (1/2T,1T) ................................................. ....................................... 1

.................. 2ET-3C-44 ....... Plate Key (2T) .......................................................... ....................................... 1

.................. 3ET-3C-44 ....... Plate Key (3T) .......................................................... ....................................... 1

.................. 5ET-3C-44 ....... Plate Key (5T) .......................................................... ....................................... 1

45 .............. 1ET-3C-45 ....... Hoist Hanger (1/2T,1T) ............................................ ....................................... 1

.................. 2ET-3C-45 ....... Hoist Hanger (2T) .................................................... ....................................... 1

.................. 3ET-3C-45 ....... Hoist Hanger (3T) .................................................... ....................................... 1

.................. 5ET-3C-45 ....... Hoist Hanger (5T) .................................................... ....................................... 1

46 .............. 1ET-3C-46 ....... Hex Cap Screw (1/2T,1T) ........................................ M8x40 ............................ 8

.................. 2ET-3C-46 ....... Hex Cap Screw (2T) ................................................ M10x45 .......................... 8

.................. 3ET-3C-46 ....... Hex Cap Screw (3T) ................................................ M10x50 .......................... 8

.................. 5ET-3C-46 ....... Hex Cap Screw (5T) ................................................ M14x65 .......................... 8

47 .............. 1ET-3C-47 ....... Lock Washer (1/2T,1T) ............................................ 8mm ............................... 8

.................. 2ET-3C-47 ....... Lock Washer (2T) .................................................... 10mm .............. ............... 8

.................. 3ET-3C-47 ....... Lock Washer (3T) .................................................... 10mm .............. ............... 8

.................. 5ET-3C-47 ....... Lock Washer (5T) .................................................... 14mm .............. ............... 8

48 .............. 1ET-3C-48 ....... Hex Nut (1/2T,1T) .................................................... M8 .................................. 8

.................. 2ET-3C-48 ....... Hex Nut (2T) ............................................................ M10 ................................ 8

.................. 3ET-3C-48 ....... Hex Nut (3T) ............................................................ M10 ...........

.................. 5ET-3C-48 ....... Hex Nut (5T) ............................................................ M14 ................................ 8

49 .............. 1ET-3C-49 ....... Cord Holder (1/2T,1T,2T,3T,5T) .............................. ....................................... 1

50 .............. 1ET-3C-50 ....... Spacer (1/2T,1T) ..................................................... ..................................... 16

.................. 2ET-3C-50 ....... Spacer (2T) .............................................................. ..................................... 16

.................. 3ET-3C-50 ....... Spacer (3T) .............................................................. ..................................... 16

.................. 5ET-3C-50 ....... Spacer (5T) .............................................................. ..................................... 16

..................... 8

13

Page 14

Index No. Part No. Description Size Qty

51 .............. 1ET-3C-51 ....... Suspension Shaft (1/2T,1T) .................................... ....................................... 1

.................. 2ET-3C-51 ....... Suspension Shaft (2T) ............................................. ....................................... 1

.................. 3ET-3C-51 ....... Suspension Shaft (3T) ............................................. ....................................... 1

.................. 5ET-3C-51 ....... Suspension Shaft (5T) ............................................. ....................................... 1

52 .............. 1ET-3C-52A ..... Male Plug for 7-Pin (1/2T,1T,2T,3T,5T) .................. YD28K7TQPGB.5 .......... 1

53 .............. 1ET-3C-53A ..... Male Plug for 4-Pin (1/2T,1T,2T,3T,5T) .................. YD24K4TQPGB.5 .......... 1

54 .............. 1ET-3C-54 ....... Coupling Cable P (1/2T,1T,2T,3T,5T) ..................... 1M .................................. 1

55 .............. 1ET-3C-55 ....... Coupling Cable C (1/2T,1T,2T,3T,5T) ..................... 1M .................................. 1

56 .............. 1ET-3C-56 ....... Power Cord (1/2T,1T,2T,3T,5T) .............................. 2M .................................. 1

58 .............. 1ET-3C-58 ....... Hex Nut (1/2T,1T,2T) ............................................... M12 ................................ 3

.................. 3ET-3C-58 ....... Hex Nut (3T,5T) ....................................................... M16 ................................ 3

59 .............. 1ET-3C-59 ....... Threaded Shaft (1/2T,1T) ........................................ ....................................... 1

.................. 2ET-3C-59 ....... Threaded Shaft (2T) ................................................ ....................................... 1

.................. 3ET-3C-59 ....... Threaded Shaft (3T) ................................................ ....................................... 1

.................. 5ET-3C-59 ....... Threaded Shaft (5T) ................................................ ....................................... 1

60 .............. 1ET-3C-60 ....... Seal Gasket (1/2T,1T,2T,3T,5T) ............................ ....................................... 1

61 .............. TS-1533042 ..... Phillips Pan Head Machine Screw (1/2T,1T,2T,3T,5T)…M5X12 .................... 4

62 .............. 1ET-3C-52 ....... Connector Case (1/2T,1T,2T,3T,5T) ....................... ....................................... 1

63 .............. 1ET-3C-63 ....... Female Plug (1/2T,1T,2T,3T,5T) ............................. YD28J15Z ...................... 1

64 .............. 1ET-3C-64 ....... Phillips Pan Head Machine Screw (1/2T,1T,2T,3T,5T)…M3X14 .................... 4

14

Page 15

11.2.1 Lug Mount Assembly (Optional) for SS-3C,SS-1C Hoists

For Electric Hoists in 1/2T, 1T and 2T

Index No. Part No. Description Size Qty

................. 1/2SS-3C-LMA ......... Lug Mount Assembly (1/2T) (includes #1 and 3-7) .....................................

................. 1SS-3C-LMA ............ Lug Mount Assembly (1T) (includes #1 and 3-7) ........................................

................. 2SS-3C-LMA ............ Lug Mount Assembly (2T) (includes #1 and 3-7) ........................................

1 ............... 1/2SS-3C-116 .......... Side Plate L.H. (1/2T) ....................................... ....................................... 1

................. 1SS-3C-116 ............. Side Plate L.H. (1T) .......................................... ....................................... 1

................. 2SS-3C-116 ............. Side Plate L.H. (2T) .......................................... ....................................... 1

2 ............... 1ET-3C-45 ............... Hoist Hanger (1/2T,1T)* .................................... ....................................... 1

................. 2ET-3C-45 ............... Hoist Hanger (2T)* ............................................ ....................................... 1

3 ............... 1/2SS-3C-118 .......... Lug Mounting Shaft (1/2T,1T) ........................... ....................................... 1

................. 2SS-3C-118 ............. Lug Mounting Shaft (2T) ................................... ....................................... 1

4 ............... 1/2SS-3C-119 .......... Side Plate R.H. (1/2T) ....................................... ....................................... 1

................. 1SS-3C-119 ............. Side Plate R.H. (1T) .......................................... ....................................... 1

................. 2SS-3C-119 ............. Side Plate R.H. (2T) .......................................... ....................................... 1

5 ............... 3SS-3C-061 ............. Hinge Plate........................................................ ....................................... 2

6 ............... 1/2SS-3C-012 .......... Lock Washer ..................................................... 6mm ............................... 4

7 ............... 1/2SS-3C-120 .......... Hex Head Cap Screw ....................................... M6x10 ............................ 4

For Electric Hoists in 3T and 5T

Index No. Part No. Description Size Qty

................. 3SS-3C-LMA ............ Lug Mount Assembly (3T) (includes #1 and 3-7) ........................................

................. 5SS-3C-LMA ............ Lug Mount Assembly (5T) (includes #1 and 3-7) ........................................

1 ............... 3SS-3C-116 ............. Side Plate (3T) .................................................. ....................................... 2

................. 5SS-3C-116 ............. Side Plate (5T) .................................................. ....................................... 2

2 ............... 3ET-3C-45 ............... Hoist Hanger (3T)* ............................................ ....................................... 1

................. 5ET-3C-45 ............... Hoist Hanger (5T)* ............................................ ....................................... 1

3 ............... 2SS-3C-118 ............. Lug Mounting Shaft (3T) ................................... ....................................... 1

................. 5SS-3C-118 ............. Lug Mounting Shaft (5T) ................................... ....................................... 1

5 ............... 3SS-3C-061 ............. Hinge Plate........................................................ ....................................... 2

6 ............... 1/2SS-3C-012 .......... Lock Washer ..................................................... 6mm ............................... 4

7 ............... 3SS-3C-120 ............. Hex Head Cap Screw ....................................... M6x12 ............................ 4

* Hoist Hanger comes pre-assembled to the electric trolley.

15

Page 16

11.3.1 ET-C Series Trolley Electrical Components – Exploded View

16

Page 17

11.3.2 ET-C Series Trolley Electrical Components – Parts List

Index No. Part No. Description Size Qty

501 ........... 1ET-3C-501 ............. Electrical Component Board (3Ph) ...................... .................................... 1

................. 1ET-1C-501 ............. Electrical Component Board (1/2T,1T, 2T: 1Ph) .. .................................... 1

................. 3ET-1C-501 ............. Electrical Component Board (3T,5T: 1Ph) ........... .................................... 1

502 ........... 1ET-3C-502 ............. Transformer (3Ph) ................................................ (460/230)/24V ............. 1

................. 1ET-1C-502 ............. Transformer (1Ph) ................................................ (230/115)/24V ............. 1

503 ........... 1ET-1C-503 ............. Capacitor (1/2T,1T,2T: 1Ph) ................................ 65µF ............................ 1

................. 3ET-1C-503 ............. Capacitor (3T,5T: 1Ph) ........................................ 120µF .......................... 1

504 ........... 1ET-1C-504 ............. Capacitor (1/2T,1T,2T: 1Ph) ................................ 16µF ............................ 1

................. 3ET-1C-504 ............. Capacitor (3T,5T: 1Ph) ........................................ 30µF ............................ 1

505 ........... TS-1541001 ............. Lock Nut (1Ph) ..................................................... M4 ............................... 2

506 ........... 1ET-1C-506 ............. Retainer Pin (1Ph) ............................................... .................................... 2

507 ........... 1ET-1C-507 ............. Capacitor Holder (1/2T,1T,2T: 1Ph) .................... .................................... 1

508 ........... TS-1501061 ............. Socket Head Cap Screw (1Ph) ........................... M4x20 ......................... 2

509 ........... 1ET-1C-509 ............. Capacitor Holder (1/2T,1T,2T: 1Ph) .................... .................................... 1

................. 3ET-1C-509 ............. Capacitor Holder (3T,5T: 1Ph) ............................. .................................... 2

510 ........... TS-1541001 ............. Lock Nut (1Ph) ..................................................... M4 ............................... 2

513 ........... TS-1532032 ............. Pan Head Screw (3Ph) ........................................ M4x10 ......................... 5

................. TS-1532032 ............. Pan Head Screw (1Ph) ........................................ M4x10 ......................... 7

514 ........... TS-2361041 ............. Lock Washer (3Ph) .............................................. M4 ............................... 7

................. TS-2361041 ............. Lock Washer (1Ph) .............................................. M4 ............................... 9

515 ........... TS-1550021 ............. Flat Washer (3Ph) ................................................ M4 ............................... 5

................. TS-1550021 ............. Flat Washer (1Ph) ................................................ M4 ............................... 7

516 ........... 1ET-3C-516A ........... Contactor .............................................................. VB6-30-01 ................... 1

517 ........... 1ET-1C-517 ............. Contactor Holder (1Ph) ........................................ .................................... 1

518 ........... TS-1532032 ............. Pan Head Screw .................................................. M4x10 .............. ........... 2

519 ........... 1ET-3C-519 ............. Terminal Board .................................................... .................................... 1

17

Page 18

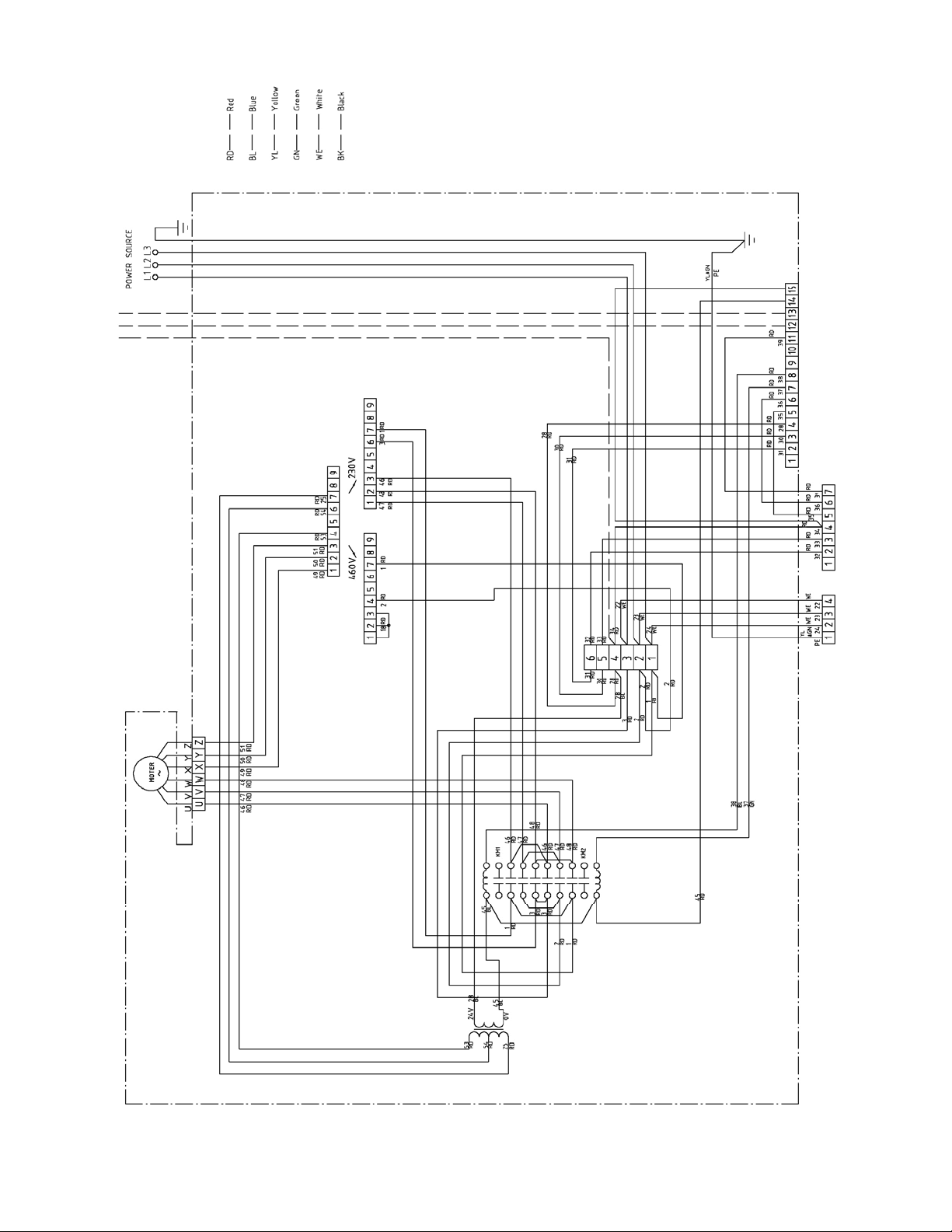

12.0 Electrical Connections – ET-C Series Trolleys

12.1.1 ET-C Trolley SINGLE PHASE ONLY

18

Page 19

12.1.2 ET-C Trolley – THREE PHASE ONLY

19

Page 20

12.1.3 Electrical Connections – Control Pendants

4-PUSHBUTTON WIRING DIAGRAM

FOR SINGLE SPEED HOISTS

4-PUSHBUTTON WIRING DIAGR AM

FOR DUAL SPEED HOISTS

6-PUSHBUTTON WIRING DIAGRAM

FOR SINGLE SPEED HOISTS

6-PUSHBUTTON WIRING DIAGRAM

FOR DUAL SPEED HOISTS

4-PUSHBUTTON WIRING DIAGRAM

FOR VFD HOISTS

20

Loading...

Loading...