Operating Instruction

JessEm Tool Company, LTD

100 Caplan Ave., Unit 14 & 15

Barrie, ON L4N9J2 Canada

705-726-8233

705-726-7519 Fax

1-866-272-7492

www.jessem.com

jessem@jessem.com

Mast

-R-

Lift

s

and Parts Manual

Models: 02101A and 02102A

Revised: 6/25/09

Thankyou for choosingthis product from JessEmTool Company. Weappreciate your

supportandhopethatourproductservesyouwell. This product is designed to provide

manyyearsof reliableservice provided it is used as intended and takencare of.

This user manualwillassist you inassemblyand general operation of this product. It

is not our intent to teach you about woodworking. Itis assumedthat youare an

experienced woodworkerwith the basic skillsandexperience necessarytousethis

productsafely. If after reading the following instructions, if you are unsure or

uncomfortable about safely using this product we urge you to seek additional

information through widely available woodworkingbooks or classes.

As part of our Continuous Product ImprovementPolicy, JessEm products are

alwaysadvancing in design andfunction.Thereforetheremaybedifferencesbetween

what is shownin our catalogs, websiteor atretaildisplayand what is sold at time of

purchase. We reserve the rightto make positive changes to our products at our

discretion.

Model 02101A – Fits Table Opening 9-1/4” x 11-3/4”

Fits Porter Cable7518/7519RouterMotor

Model 02102A – Fit Table Opening 8-1/4” x 11-3/4”

This unit is for non-JessEm Router Tables

AdapterCollars forModel02101A

Model 02111 – Fits Porter Cable 690/890, Bosch 1617/1618, DeWalt

610/616/618

Model 02113 (3-1/4” diameter) – Fits Makita1101

Model 02115 – Fits Hitachi M12VC and KM12VC

Model 02118 – Fits Milwaukee 5615/5616/5619

Shim Kit Model 02116 – Fits Milwaukee 5625

Important!!

Read and understand the contents of this manual

before assembly or operation of this product.

IMPORTANT SAFETY PRECAUTIONS

Before operating any router, read and understand allsafety instructions inthe

owner’smanual that came with the router.

If you do not have a manual, contact the manufacturerandobtainonebeforeusing

any power tool.

Alwaysweareye protectionin compliancewith ANSIsafetystandards whenoperating

any power tool.

Always use proper guards and safety deviceswhenoperatingpowertoolsand

machinery.

Carefullycheckrouterbitsbeforeeachuse.Do not use if damage or defectis

suspected.

DonotexceedtherecommendedRPMforany router bit.

Donotwearlooseclothingorjewelrythatmay catchon toolsor equipment.

Unplugthetoolormachinewhenmounting or makinganyadjustments to mechanical

performance.

ROUTER SAFETY PRECAUTIONS

Neverforcethebitoroverloadtherouterbeyond theexpectations of the tool.

Be sure that at least3/4 of the shanklength is insertedsecurelyin therouter collet.

Never bottom out the bit in the collet. Allow 1/8” clearance between shank and bottom

of collet.

Alwaysmakesurethefenceonyourroutertable is locked into position before each

use.

Always rout in two or more passeswhen largeamountsofstockmust beremoved.

Usereduced RPM speedsforlargediameterbits.

DO NOT USE A CORDLESS DRILL T

O RAISE

AND LOWER THE LIFT CARRIAGE. THE

AMOUNT OF FRICTION WILL CAUSE

PREMATURE WEAR OF THE THREADS.

CALIFORNIA PROPOSITION 65 WARNING

This product contains lead known to the State of California to cause cancer or

reproductive harm. Components made of brass are known to contain lead. Wash hands

after using this product.

Suggested Router Bit Speeds

BitDiameter Max. Speed

1”(25mm) 24,000 RPM

1-1/4”-2”(30-50mm) 18,000 RPM

2-1/4”- 2-1/2” (55-65mm) 16,000RPM

3”-3-1/2”(75-90mm) 12,000 RPM

JessEm Tool Company Limited Warranty

AllJessEmproductsarewarrantedto be free fromdefectsinmaterial and

workmanship. JessEmwillrepairorreplaceanyproductwhichuponinspection

provestobe defective for a period of (1)yearfromdatedreceipt andproof of

purchase. All warranty claimsshouldbe madedirecttoJessEm ToolCompany.

ContactJessEmfora warrantyclaimreturn authorizationandinstructions to

proceed.Theconsumer is responsiblefor shipping coststo return productto

JessEm Tool Company.We will repairor replace the product at our discretion

and JessEmTool willreturnshipmentto you at nocharge.

Warranty Limitations

This warrantydoes not cover:

Repairs or alterations made or attempted by anyone other than JessEm Tool

CompanyoranauthorizedJessEm serviceprofessional.

Normal wearandtear

Abuse, misuse or neglect.

Impropercare or maintenance.

Continueduse afterpartialfailure.

Products thathave beenmodifiedinanyway.

Productsusedwithimproperaccessories.

Premature thread weardueto adjusting height withelectricor cordlessdrill

CONTENTS:

(1)Mast-R-Lift,(1)Height AdjustmentHandle,(1)InsertRing,(1)InsertRingWrench, (1)Hex

Key,(1)StartPin

TOOLSREQUIREDFORASSEMBLY:

6mmand8mm HexKey

TOOLSREQUIREDFORADJUSTMENT:

10mm Wrench

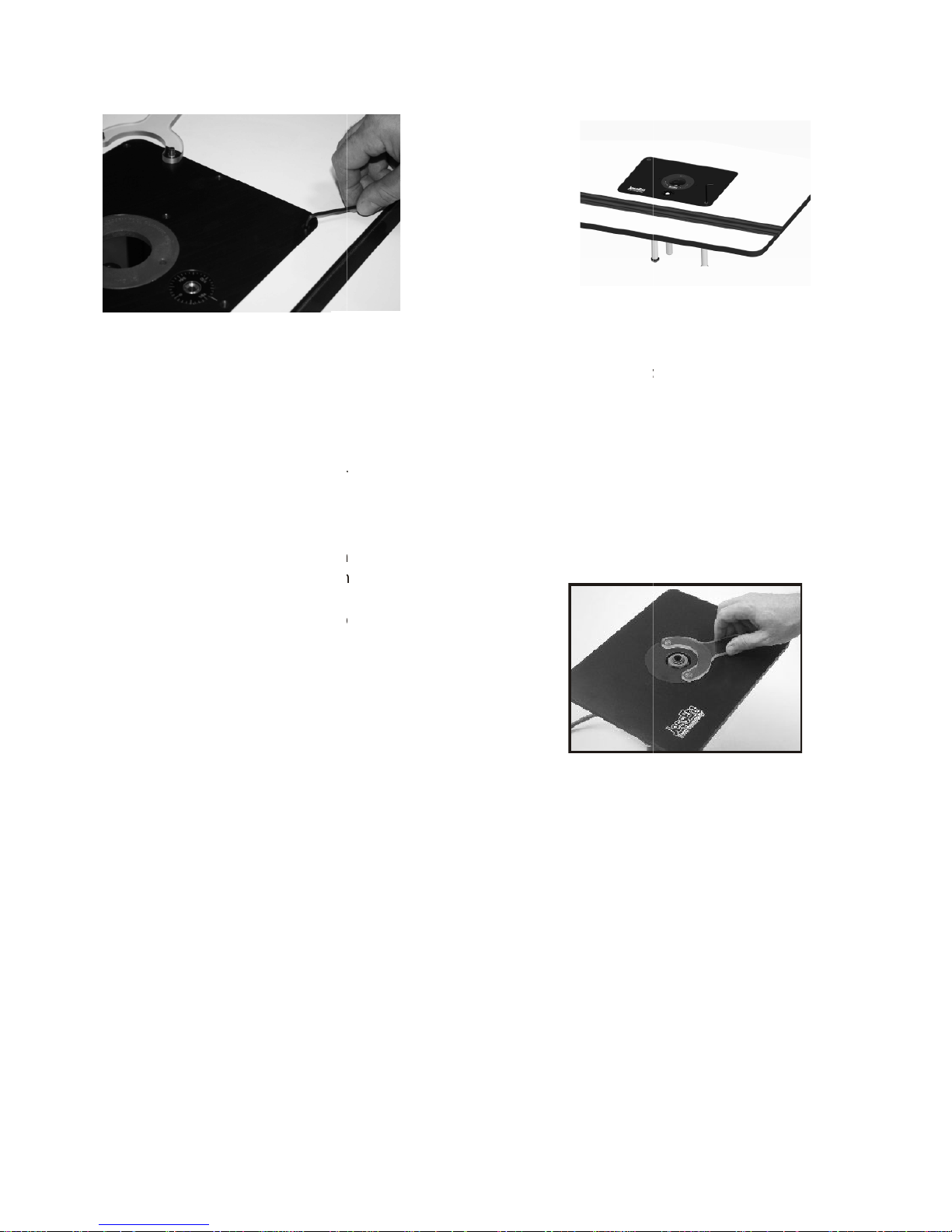

Figure 1

Placethecrankhandleintothehex holein the

lift’s dialon the top plate. Cranktheliftcarriage

upso thatitjust contacts theO-ringsatthe top of

the carriage shafts. The carriageshould be all

thewaytowardthetopplate. With a 5/16” hex

wrench, loosen the cap screw onthecarriage

clamptoallowthemotortoslideintothecarriage

assembly (Fig.1). The Mast-R-Lift willacceptthe

PorterCable7518out of the box. If you are

using a smaller diameter router motor insertthe

adaptercollar intothe opening.

Installing the Router

(cont’d)

Rotate the router so that when the final

installation is made all router controls will

be positionedforconvenient access.Then

backthe motor off approx. 1/16”from

contactingthe top plateand tighten the

cap screw on the carriage assembly.

InstallingaJessEmLift ina

CustomRouter TableApplication

A JessEmrouter lift is similartousinga

routermountingplate.Yourtabletopmust

haveaportmachined intothetop.JessEm

offerssolidphenolicroutertablestopswith

pre-machinedports for all JessEmrouter

lifts. If you are installingthisLiftina custom

tableapplicationyouwillhavetofabricate

thisopeningyourself.JessEmoffers a

separate templateforthis operation.See

your JessEmdistributorfortheproper

template for yourJessEmrouterlift.

Figure 2

Before installing the router motor, prop the

unit up on blocks of wood (Fig. 2) so the

router’scollet can extend through the center

hole in the top plate. The motor housing

must slide all the way through and contact

the inside back of the center hole on the

plate.

Now slide the router motor into the carriage

so the top of the motor housing just makes

contact with the inside surface of the center

holein the top plate.

Installing the Router

Levelingthe Lift to theTableTop

The Mast-R-

Lift features 8 drilled and tapped

holes around the perimeter of the insert plate

with adjustable set screws (Fig. 4

). Using the

hexwrenchincluded withyour

lift,turntheset

screwsintheclockwise direction to raisethe

insertplate or turnthe setscrewsin the counter

clockwisedirectionto lower the insertplateuntil

theinsertplate is level(flush) withthe routertable

surface. Start at one cornero

f the insert plate

andwork yourwayaroundtheperimeterof the

insertplate untilall set screwshavebeen

adjusted properlysothattheinsertplatedoesnot

rest aboveorbelow the tablesurface. Oncethe

insertplate has beenleveled properly, please

figure4 for adjustingthe insert plateto thetable.

Figure 4

Securingthe Mast-R-

Liftto the Table

After adjusting the levelingscrews and

gettingtheliftplatelevel and flushwiththe

table top,theMast-R-Lift

canbe secured

byinserting a bolt

through the top of the

then screwingtheboltinto the

correspondingcornerhole in thetable

openingusinga hex key (Fig.5

). Thiswill

securetheliftorplatefrom moving during

operation. Refer to the router lift or plate

manualformoredetail

s on levelingthelift

or platetothetable.

see

Tab-Loc InsertRings

The Rout-R-

Lift FX comes with one insert

ring

with a pre

center hole.

Additional ring sets are

available with different diameter pre

holes and/or no pre

creating your own custom center hole

diameters. See your JessEm distributor for

these

and other accessories.

1.

Placethe insertring into the center

holeof

the Lift’s top plate (Fig. 6).

2.

Withtheinsert wrenchprovided,insert

the

prongs of the wrench into the

corresponding

holes in theinsert ring and

turntheinsert ring

tighten.

3.

Turntheinsert wrench clockwise to

loosen

and remove the ring. If the insert

ring becomes

too tight to loosen with hand

pressure, a tap

clockwiseon the insert

wrenchwitha block of

lift

-drilled 1-1/2” diameter

-drilled

-drilled holes for

Figure 6

counter clockwise to

wood will loosen it.

Figure 5

Using the Mast

-R-

Lift

Toraiseyourrouter,turn the heightadjustment

handle clockwise. To lower,turn the handle

counter-clockwise. Keep in mind that one

complete revolutionequals 1/16” of change.

Whenyouradjustmentiscomplete,removethe

handle and place somewhere offthe work

surfacefor safety. Refer to the chart below for

fractional and decimal adjustmentsbased on

amount of revolutions made.

Fraction

Decimal

Number of

Revolutions

1/64”

0.016”

1/4

1/32”

0.031”

1/2

1/16”

0.062”

1 Revolution

1/8”

0.125”

2

1/4”

0.250”

4

1/2” 0.500” 8

Re-Adjustingthe Thread Tensioning

All JessEm Lifts feature ourpatentedthread

tensioning design. This feature is why it is not

necessary to lock therouter into position after

setting the cutting height. The design keeps

tension on the position wherever you set the

height. Thread tension isset at the factory and

depending on the amountof useyoumayhaveto

resetthisadjustment periodically.If the bit height

ever begins to change (or drop) during use,the

threadtensioning likely needs to be reset.

1.

TurntheLiftupsidedownona tablewiththe

threaded height adjustmentrod facingyou.

2.

With an open end wrench, (Fig. 7) loosen

the hex nut that is located on the right side of

the brass post next to the threaded rod. Then

usea hexwrench to backout the set screw that

threadsthrough the nut untilthe brass

tensioning collar can be turned.

Figure 7

Figure 8

3. Then route the brass tensioning

collar (Fig. 8) with vertical grooves, so

it tightens against the rubber washer.

Note: A drop of oil on the rubber

washer eases the rotation of the

brass collar.

4. Make certain the set screw seats

in one of the vertical grooves when

tightening the brass collar.

5. Tighten the nylon lock nut with the

open end wrench again and the

adjustment is complete.

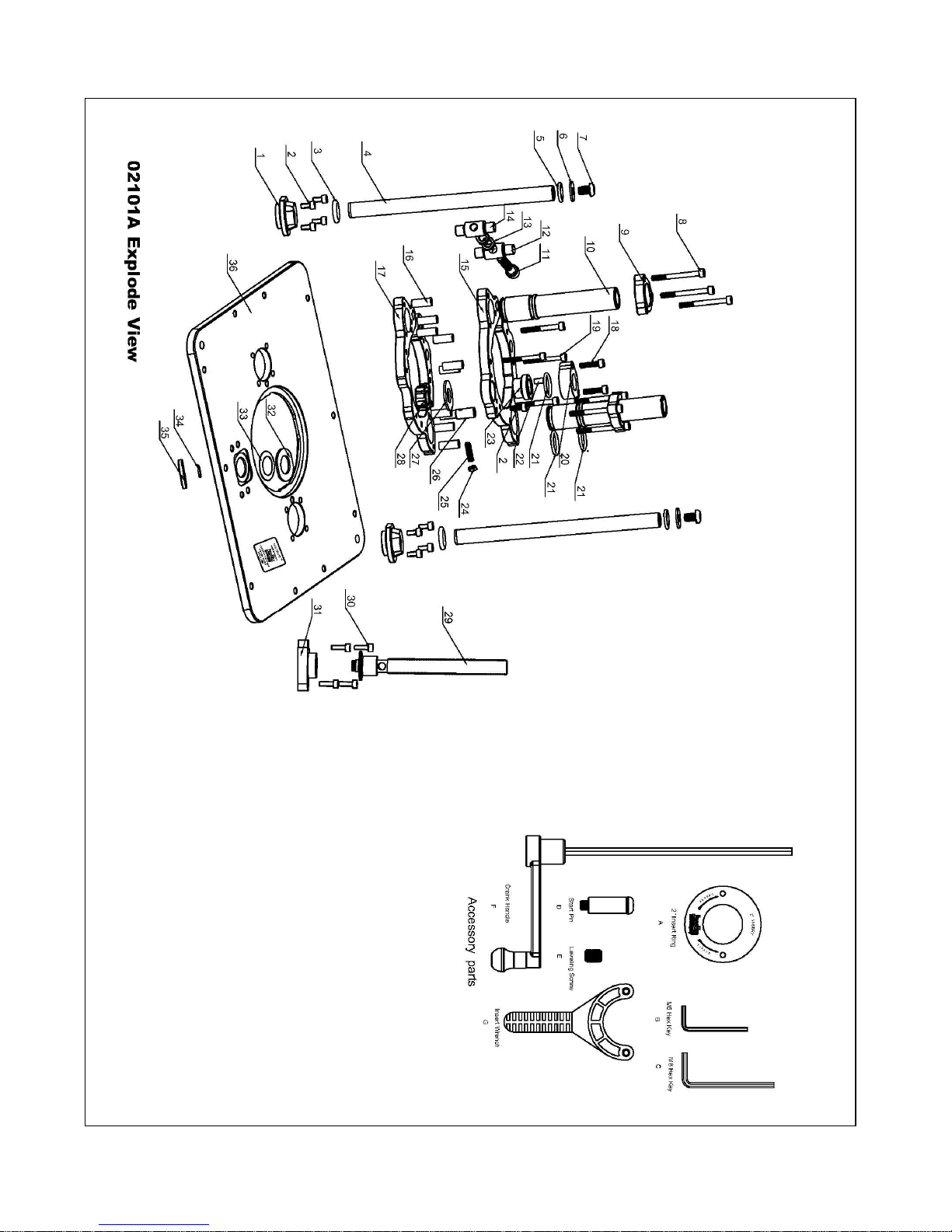

02101A Mast-R-Lift Parts List

Item No. Part No. Description Qty Specification

1 02101A-001 Guide Tube Base 2

2 02101A-002 Shaft Mtg Block Bolt 9 M6X12

3 02101A-003 Rubber O-ring 2 M29.4X18.6X5.4

4 02101A-004 Bearing Tube 2

5 02101A-005 Rubber O-ring 2 M25.4X18.6X3.4

6 02101A-006 washer 2 M8.5X25X2.5

7 02101A-007 Screw 2 M8X16

8 02101A-008 Carriage Bolt long 6 M6X63

9 02101A-009 Carriage Tube Retainer 2

10 02101A-010 Guide Tube 2

11 02101A-011 Carriage Lock bolt 1 M10X60

12 02101A-012 Clamp pin 1

13 02101A-013 Carriage Adjusting Lock Nut 2 M10

14 02101A-014 Clamp pin 1

15 02101A-015 Down carriage plate 1

16 02101A-016 Carriage Spacer 10

17 02101A-017 Upper Carriage Plate 1

18 02101A-018 Retainer Bolt 2 M6X25

19 02101A-019 Carriage bolt short 4 M6X50

20 02101A-020 Retainer 1

21 02101A-021 Rubber O-ring 3 M32X25.2X3.4

22 02101A-022 Pin 1

23 02101A-023 Shaft Bushing 1

24 02101A-024 Backlash Lock Nut 1 M6

25 02101A-025 Backlash set screw 1 M6X25

26 02101A-026 Backlash Pin 1

27 02101A-027 Rubber Washer 1

28 02101A-028 Brass Backlash Nut 1

29 02101A-029 Lead Screw w/spring pin 1

30 02101A-030 Mtg Block Bolt 4 M6X18

31 02101A-031 Spindle Mounting Block 1

32 02101A-032 Brass Washer 1

33 02101A-033 Spring Washer 1

34 02101A-034 Rubber Washer 1

35 02101A-035 Height Dial 1

36 02101A-036 Top Plate 1

A 02101A-A 2" Insert Ring 1

B 02101A-B Hex Key 1 M6

C 02101A-C Hex Key 1 M8

D 02101A-D Starter Pin 1

E 02101A-E Leveling Screw 11 M6X8

F 02101A-F Crank Handle 1

G 02101A-G Wrench 1

Loading...

Loading...