Jesel INS-32000 User Manual

INS - 32000

CAM BOLT IS

LH THREAD

KBD-32000

BIG-BLOCK

KIT SHOWN

Belt Drive Instruction Sheet

KBD - 32000, Mark 4 BB Chevrolet

KBD - 32200, Mark 5 BB Chevrolet

KBD - 32300, Gen 6 BB Chevrolet

SEE STEP 11 FOR AFTERMARKET BLOCKS

JESEL’S BIG-BLOCK CHEVY BELT DRIVE IS THE

MOST ACCUR ATE AND DUR ABLE CAMSHAFT

DRIVE SYSTEM AVAILABLE AND IS USED BY THE

COUNTRY’S TOP RACE TEAMS. A PATENTED HIGH

TORQUE BELT OPERATES WITHOUT LUBRICATION

AND SPINS WITH LESS FRICTION THAN CHAINS

OR GEAR DRIVE SYSTEMS. THE RUB BER BELT

ABSORBS DESTRUCTI VE HA RMONICS, WHICH

CAN CAUSE SERIOUS PROBL EMS O N RACIN G

ENGINES. SO ME FEATURES INCLUDE A BILLET

ALUMINUM UPPER PULLEY WITH A HIGH TORQUE

DRIVE TOOTH CONFIGUR ATION, AN ALLOY STEEL

CRANK PULLEY AND GRADE 8 HARDWARE.

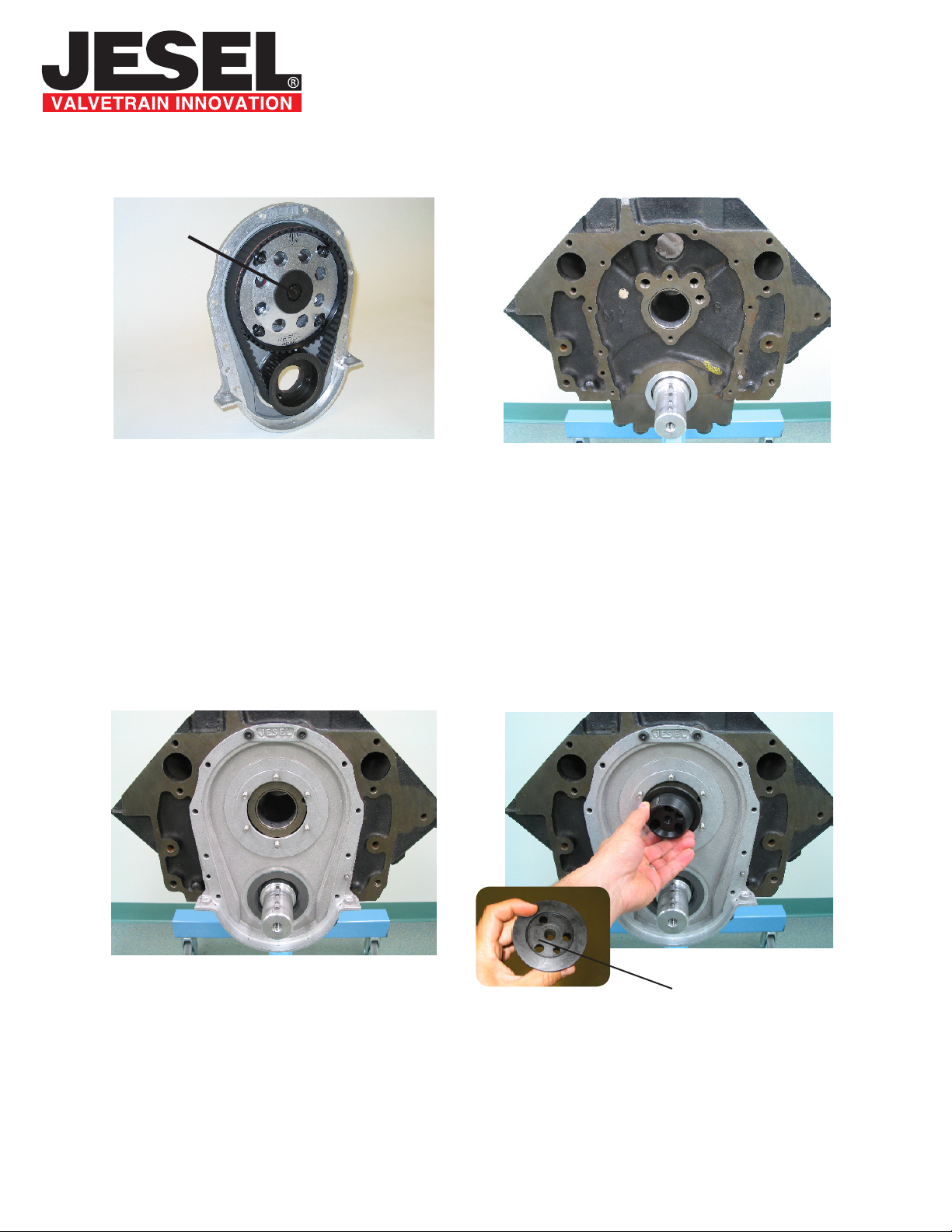

STEP 1

CHECK FOR COVER TO BLOCK INTERFERENCE AND

CORRECT IF PRESENT BY MODIFYING THE BLOCK.

IF YOUR BLOCK HAS BEEN LINE BORED, YOU

MAY ENCOUNTER A MISALIGNMENT BET WEEN

THE CRANK SEAL AND CRANK SNOUT. WE

RECOMMEND ENLARGING THE DOWEL PIN HOLES

IN THE COVER AND LOOSELY INSTALLING THE

COVER BOLTS BEFORE DRIVING ON THE LOWER

PULLEY. THIS PROCEDURE WILL INSURE THAT THE

CRANK SEAL IS CENTERED AROUND THE CRANK

SNOUT.

STEP 2

SECURE THE BELT DRIVE COVER TO THE BLOCK

USING AN OEM TYPE GASKET AND A THIN LAYER OF

RTV SEALER. TORQUE THE COVER BOLT 96 IN / LBS

(8 FT / LBS).

LUBRICATE AND SLIDE CAMSHAFT INTO BLOCK.

LOCATE THE REAR THRUST WASHER (WSH-39610

2.950” OD X 1.960” ID X .031”), CAM ADAPTOR

(ADP-30080) AND THREE 5/16-18 X 3/4” CAM

ADAPTOR BOLTS (BLT-31400).

STEP 3

APPLY A VERY THIN LAYER OF RTV SEALER TO THE

RECESSED AREA ON THE CAM ADAPTOR.

LUBRICATE AND INSTALL THE REAR THRUST WASHER

ON THE CAM SNOUT. APPLY RTV SEAL ANT TO THE

THREADS OF THE CAM ADAPTOR BOLTS AND BOLT

THE ADAPTOR TO THE CAMSHAFT.

TORQUE CAM ADAPTOR BOLTS TO 26-28 FT/LBS. A

SPANNER WRENCH (TOL-39260) IS AVAILABLE TO

ASSIST IN TIGHTENING THE BOLTS.

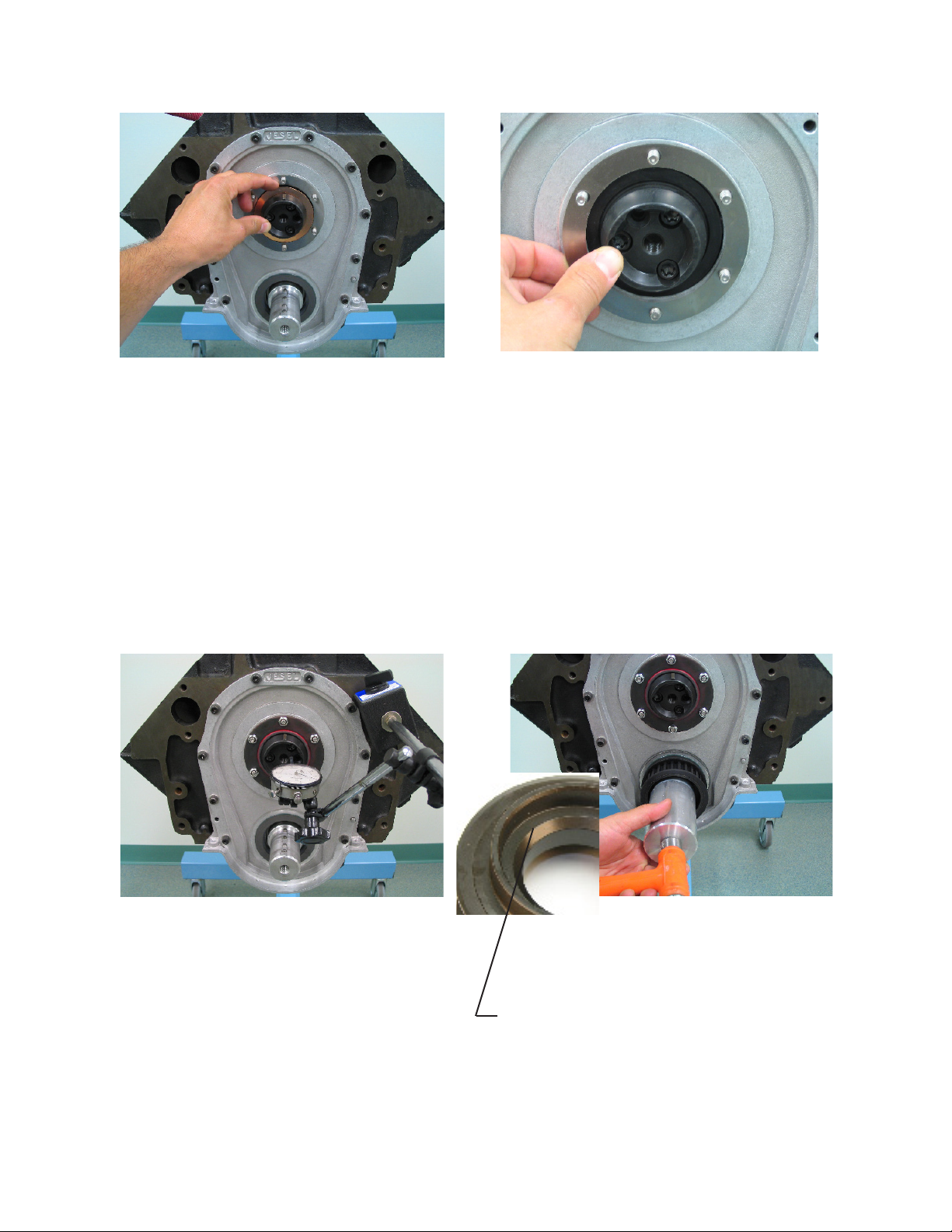

STEP 4

STEP 5

APPLY A THIN FILM OF OIL TO THE OUTER BRONZE

THRUST WASHER (WSH-39660 2.950” OD X 2.260” ID

X .031”) AND INSTALL OVER THE NOSE OF THE CAM

ADAPTOR.

LOCATE THE 3 THRUST SHIMS (.010”, .015” .020:), CAM

THRUST PLATE WITH CAM SEAL (PLT-35260) AND 6

THRUST PLATE NUTS (NUT-34750).

CHECK FOR CAMSHAFT END PLAY BY INSTALLING ALL 3

THRUST SHIMS. JESEL INCLUDES (1) .010”, (1) .015” AND

(1) .020” THICK THRUST SHIM WITH THIS KIT.

KEEP SHIMS DRY. DO NOT OIL OR USE ANY TYPE OF

SEAL ANT ON SHIMS

CAREFULLY INSTALL THRUST PLATE MAKING SURE NOT

TO DAMAGE CAMSHAFT SEAL ON ADAPTOR KEYWAY.

KEEP ALL SEAL AREAS DRY.

STEP 6

INSTALL THRUST PL ATE AND TORQUE NUTS TO 96

IN/ LBS (8 F T/LBS).CHECK CAMSHAFT END PLAY BY

SETTING A DIAL INDICATOR ON THE FACE OF THE

CAM ADAPTOR AND MOVE CAM FRONT TO BACK.

ADJUST THE SHIMS UNTIL THE CAMSHAFT ENDPLAY

IS BETWEEN .008” AND .012”.

REMOVE THRUST PLATE AND SHIMS. APPLY A THIN

FILM OF RTV SEALANT BET WEEN SHIMS TO

PRE V E N T POS SIBLE OIL LEAKAGE. REINSTALL

SHIMS AND THRUST PL ATE AND RETORQUE NUTS.

I KEEP OIL OFF SEAL AREA. BE CAREFUL NOT TO

DAMAGE SE AL ON ADAPTOR KEY WAY.

STEP 7

LUBRICATE THE CR ANK SNOUT WITH A HIGH

QUALITY ANTI-SEIZE COMPOUND.

WE RECOMMEND APPLYING A THIN LAYER OF RTV

SEAL ANT TO THE INNER CHAMFER OF THE LOWER

PULLEY TO PREVENT OIL SEEPAGE.

INSTALL THE PULLEY (PLY-35530) ONTO THE CR ANK

SNOUT AND DRIVE IT ON UNTIL THE PULLEY STOPS

AGAINST THE CRANKSHAFT. A LOWER PULLEY

DRIVER (TOL-39310) IS AVAILABLE TO ASSIST IN THIS

ST E P.

TO REMOVE LOWER PULLEY: ATTACH A PULLER TO

THE THREE THREADED 5/16-18 HOLES. DO NOT PULL

ON THE RINGS OF THE PULLEY

Loading...

Loading...