Jesel INS-29425 User Manual

Pushrod Length Checker Instructions

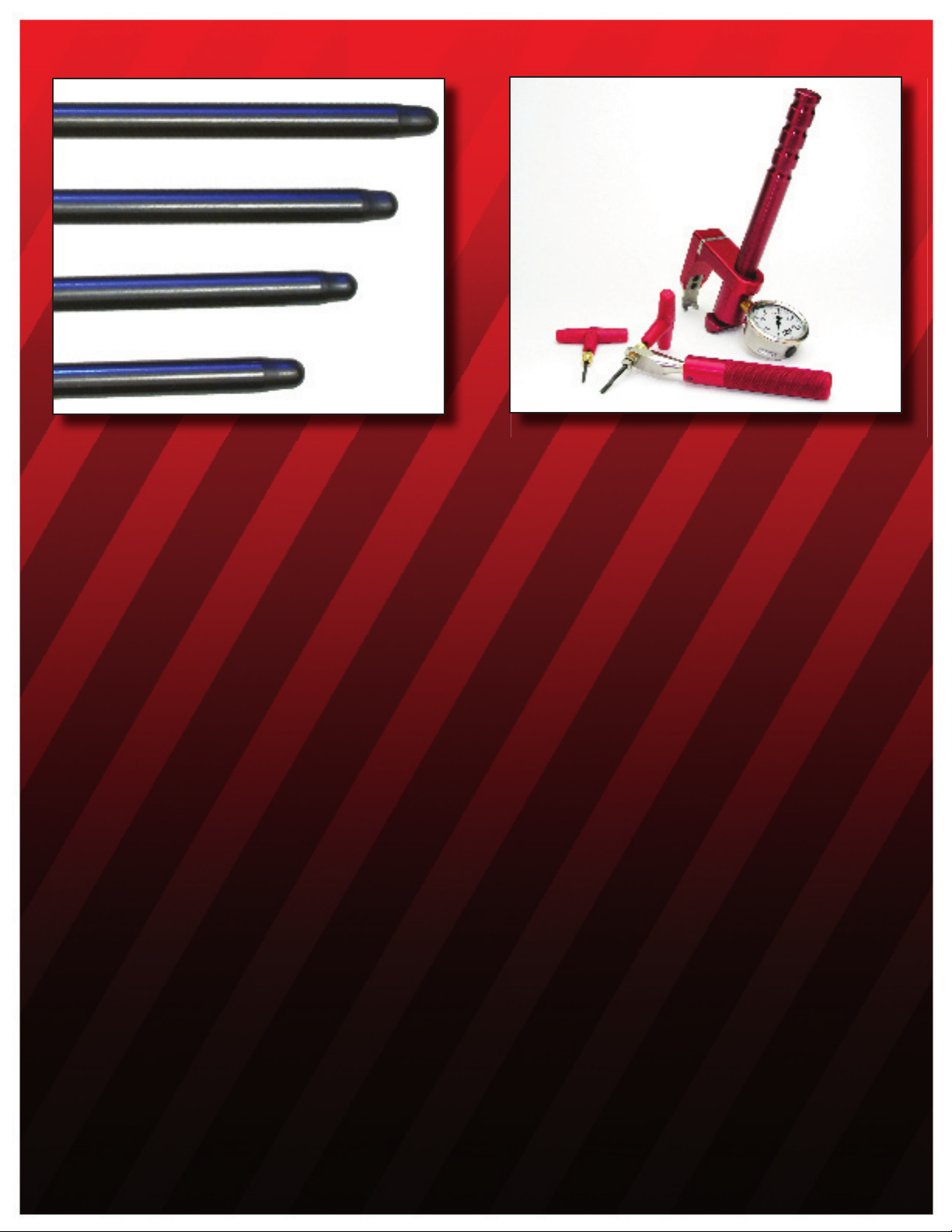

TOL-29400 6” - 12” Pushrod Checker / Cup Adj

TOL-29425 6” - 12” Pushrod Checker / Ball Adj

INS-29425

CUP ADJUSTER

SET THE LASH ADJUSTER TO THE PROPER

STARTING POSITION.

CUP STYLE ADJUSTER:

SET THE ADJUSTER ONE

FULL TURN DOWN FROM

SEATED POSITION.

BALL ADJUSTER

BALL STYLE ADJUSTER:

SET THE TO P OF TH E

ADJUSTER FLUSH WITH

THE TOP OF ADJUSTER

NUT.

TOL-29450 6” - 9” Pushrod Checker / Cup Adj

STEP 1: STARTING WITH CYLINDER NUMBER ONE,

ROTATE THE ENGINE UNTIL INTAKE LIFTER IS ON

THE CAMS BASE CIRCLE (OPPOSITE FROM FULL

LIFT). ASSEMBLE THE ADJUSTABLE PUSHROD TO

THE APPROXIM ATE LENGTH, PLACE ONTO TH E

INTAKE LIFTER AND BOLT THE ROCKER ARM TO

STAND. CHECK FOR PUSHROD TO CYLINDER HEAD

INTERFERENCE AND CORRECT IF ANY OBSTRUCTION

IS PRESENT.

STEP 2: BE SURE THAT THE ADJUSTER STARTING

POSITION IS SET AS DESCRIBED ABOVE. SCREW OUT

THE ENDS OF THE ADJUSTABLE PUSHROD UNTIL THEY

CONTACT THE ADJUSTER.

STEP 3: ADJUST PUSHROD ENDS UNTIL DESIRED

LASH IS OBTAINED. REMOVE ROCKER AND MEASURE

PUSHROD. REPEAT PROCEDURE FOR THE EXHAUST

ROCKER.

NEVER ROTATE THE VALVETRAIN USING THE PUSHROD CHECKING TOOL.

BEFORE ORDERING PUSHRODS: DUE TO VARIANCES IN ENGINE MACHINING PROCESSES AND CAMSHAFT

GRINDS, IT IS NOT UNCOMMON FOR PUSHROD LENGTHS TO VARY IN LENGTH FROM ONE BANK OR EVEN FROM ONE

CYLINDER TO ANOTHER. BEFORE ORDERING NEW PUSHRODS, CHECK THE PUSHROD LENGTH ON SEVERAL DIFFERENT

CYLINDERS AND ON BOTH SIDES OF THE ENGINE.

JESEL OFFERS 5/16”, 3/8” AND CUSTOM MODULAR

TAPERED PUSHRODS TO TAILOR TO ALL RACING

APPLICATIONS.

VALVE ADJUSTMENT:

1. ROTATE ENGINE UNTIL EXHAUST ROCKER BEGINS

TO OPEN EXHAUST VALVE. SET INTAKE LASH TO

DESIRED SPEC.

2. ROTATE ENGINE UNTIL INTAKE ROCKER BEGINS TO

RETURN FROM ITS FULL LIFT POSITION. SET EXHAUST

LASH TO SPEC.

3. RE P E AT F O R THE REMA I N I N G C Y L I N D ER S

FOLLOWING THE CORRECT FIRING ORDER OF YOUR

ENGINE.

Maintain your valvetrain

properly with Logan-Smith’s

Spring Pressure Tester and

Torque Wrench Valve Lash

tool.

TOL-PC100

TOL-TQ100

TORQUE SPECS:

ADJUSTER NUT - 1/8” HEX 25 LBS-FT

ADJUSTER NUT - 5/32” HEX 30 LBS-FT

5/16-18 T45 SHAFT BOLT 26-28 LBS-FT

5/16-18 ARP 12pt SHAFT BOLT 35 LBS-FT

3/8-16 STAND BOLT 45-50 LBS-FT

7/16-14 STAND BOLT 60-65 LBS-FT

Torque specs listed above are the recommended torque specs

when using 30wt engine oil as a lubricant. Torque specs will be

lower if using a Moly based lubricant. To convert to Newton/meters,

multiply lbs-ft by 1.356. The torque values listed are intended to be

for general information. Actual torque values may vary depending

upon your application.

WARNING - DO NOT:

NOTES:

1. NEVER ROTATE THE VALVET RAIN USING THE

CHECKER PUSHROD.

2. MAKE SURE PUSHRODS ARE CLEAN AND PROPERLY

LUBRICATED BEFORE FINAL INSTALLATION.

3. MAKE SURE THERE IS NO INTERFERENCE BETWEEN

PUSHROD AND ENGINE BLOCK OR CYLINDER HEAD.

4. NEVER MODIFY THE COUNTERBORE FOR THE LASH

ADJUSTER TO TRY TO FIT A LONGER PUSHROD.

- MODIFY THE ADJUSTER CUP COUNTERBORE

- LOOSEN SHAFT BOLTS UNDER SPRING LOADS

- RUN PUSHROD ADJUSTER MORE THAN TWO TURN

OUT FROM FULLY SEATED POSITION

- RUN WITH ROUGH OR DAMAGED PUSHROD TIPS

- ALLOW PUSHRODS TO INTERFERE WITH BLOCK OR

CYLINDER HEADS

- DEGREASE ROCKER AND RUN WITHOUT LUBE

- OVERTIGHTEN ADJUSTER NUTS

www.jesel.com

1985 Cedarbridge Ave · Lakewood, NJ 08701 · Phone: 732-901-1800 · Fax: 732-901-6777

THESE INSTRUCTION SHEETS ARE INTENDED AS REPRESENTATIONS ONLY. JESEL IS IN NO EVENT LIABLE FOR CONSEQUENTIAL DAMAGE,

INSTALLATION COST OR OTHER COST OF ANY NATURE. NO REPRESENTATIVE IS AUTHORIZED TO ASSUME FOR JESEL ANY OTHER LIABILITY

IN CONNECTION WITH ANY JESEL PRODUCT. NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

revised 06-07

Loading...

Loading...